check engine NISSAN ALMERA N15 1995 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 1206 of 1701

![NISSAN ALMERA N15 1995 Service Manual

•:Mating mark(different color) 16

rollers

SEM129F TIMING

CHAIN

@K]

Installation

(Cont'd)

19. Assemble camshaftsprocketwithchain.

• Set timing chainbyaligning matingmarkswiththose of

cam NISSAN ALMERA N15 1995 Service Manual

•:Mating mark(different color) 16

rollers

SEM129F TIMING

CHAIN

@K]

Installation

(Cont'd)

19. Assemble camshaftsprocketwithchain.

• Set timing chainbyaligning matingmarkswiththose of

cam](/img/5/57349/w960_57349-1205.png)

•:Mating mark(different color) 16

rollers

SEM129F TIMING

CHAIN

@K]

Installation

(Cont'd)

19. Assemble camshaftsprocketwithchain.

• Set timing chainbyaligning matingmarkswiththose of

camshaft sprockets.

• Make suresprocket's matingmarksfaceengine front.

20. Install camshaft sprocketbolts.

• Apply newengine oiltobolt threads andseat surface .

•

SEM657D

2.0.3.0

mm

(0.079 -0.118 In)

21.

Install upperchaintensioner.

• Before installing chaintensioner, insertasuitable pininto

pin hole ofchain tensioner.

• After installing chaintensioner, removethepin.

22. Install lowerchaintensioner.

CAUTION:

• Check noproblems occurwhenengine isrotated.

• Make surethatNo.1piston isset atTOC onitscompres-

sion stroke.

• Make sureofthe direction ofthe gasket beforeinstalling

lower chaintensioner.

23. Apply liquidgasket tothermostat housing.

• Use Genuine LiquidGasket orequivalent.

24. Install thermostat housing.

25. Install waterpump pulley.

EM-27

Page 1208 of 1701

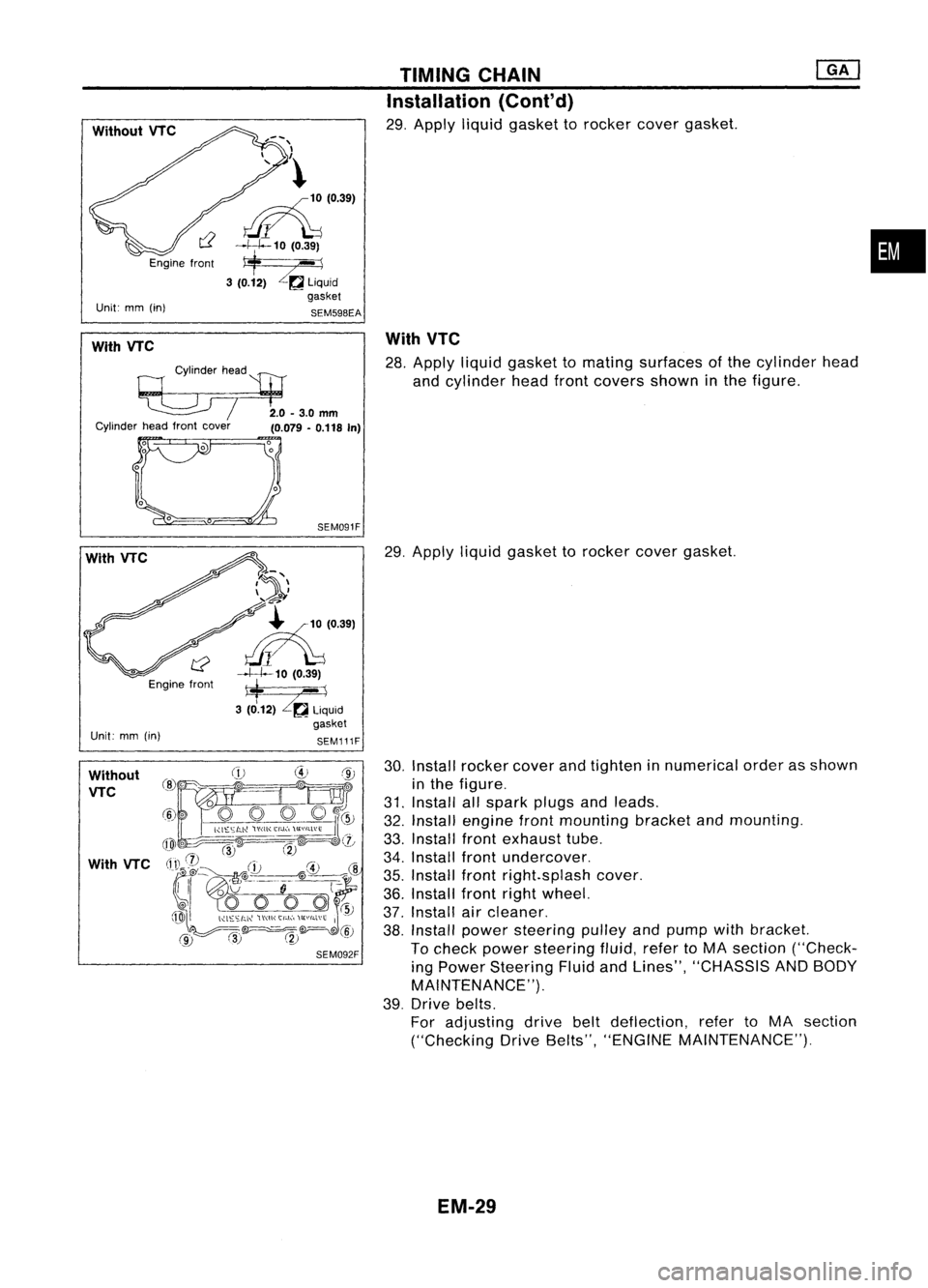

WithoutVTC

Engine front

Unit: mm(in)

~(0.39)

~1-J--10 (0.39)

* -\

3 (0.12)

Z~

Liquid

gasket

SEM59BEA TIMING

CHAIN

Installation (Cont'd)

29. Apply liquidgasket torocker covergasket.

•

With VTC

Cylinderhead

'l:tJ

~ /2.0-3.0mm

Cylinder headfront cover

(0.079-0.118 In)

With

VTC

28. Apply liquidgasket tomating surfaces ofthe cylinder head

and cylinder headfrontcovers showninthe figure.

With VTC

Engine front

Unit: mm(in)

SEM091F

7~'\

\ ..... -4'

~-'?

~'0391

~10 (0.39)

*

--1

3 (0.12)

Zr.a

liquid

gasket

SEM111F

29.

Apply liquidgasket torocker covergasket.

Without VTC

With VTC

30.

Install rocker coverandtighten innumerical orderasshown

in the figure.

31. Install allspark plugsandleads.

32. Install engine frontmounting bracketandmounting.

33. Install frontexhaust tube.

34. Install frontundercover.

35. Install frontright.splash cover.

36. Install frontrightwheel.

37. Install aircleaner.

38. Install power steering pulleyandpump withbracket.

To check power steering fluid,refertoMA section ("Check-

ing Power Steering FluidandLines", "CHASSIS ANDBODY

MAINTENANCE").

39. Drive belts.

For adjusting drivebeltdeflection, refertoMA section

("Checking DriveBelts", "ENGINE MAINTENANCE").

EM-29

Page 1213 of 1701

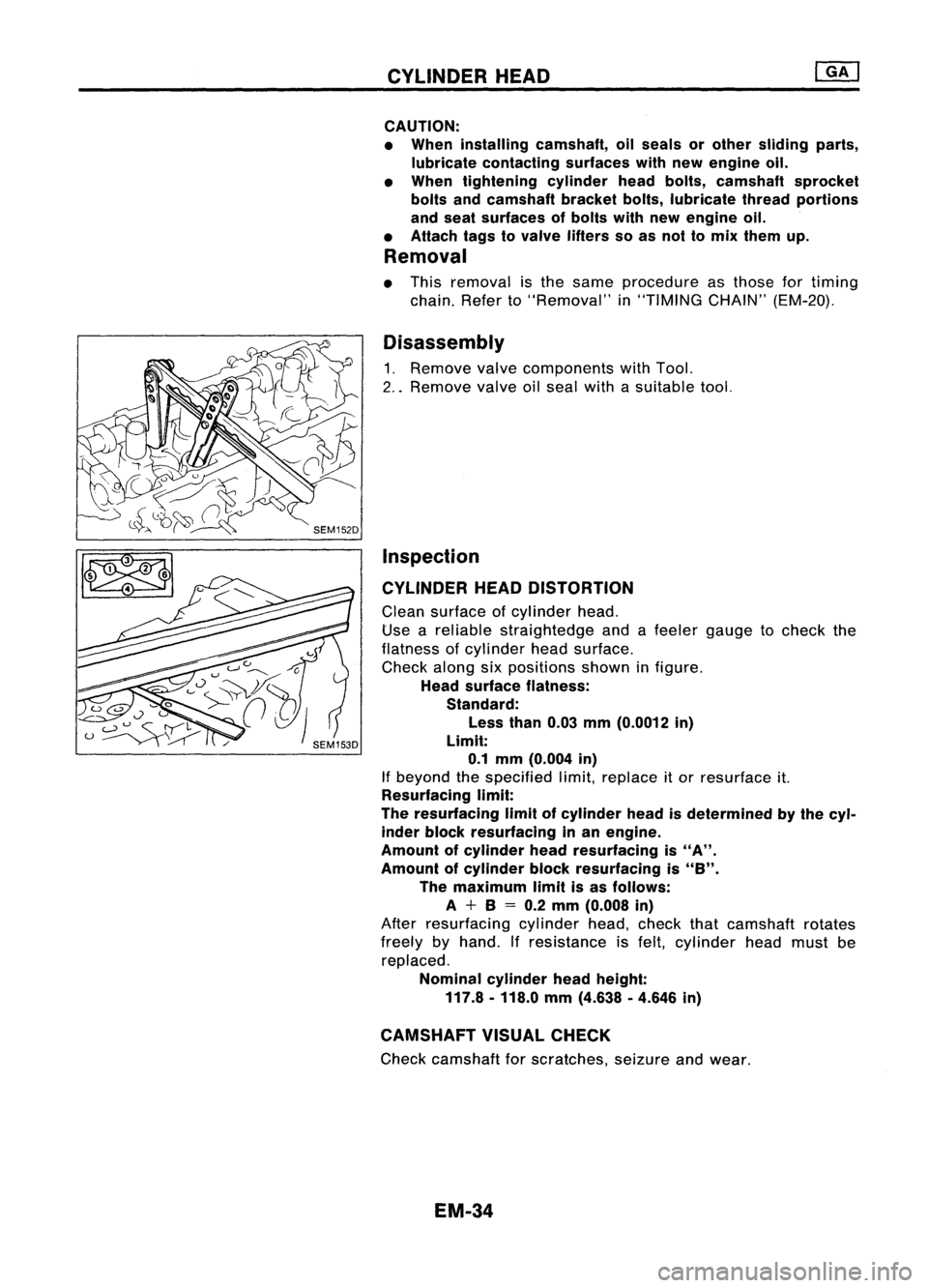

CYLINDERHEAD

CAUTION:

• When installing camshaft, oilseals orother sliding parts,

lubricate contacting surfaceswithnewengine oil.

• When tightening cylinderheadbolts, camshaft sprocket

bolts andcamshaft bracketbolts,lubricate threadportions

and seat surfaces ofbolts withnewengine oil.

• Attach tagstovalve lifters soas not tomix them up.

Removal

• This removal isthe same procedure asthose fortiming

chain. Referto"Removal" in"TIMING CHAIN"(EM-20).

Disassembly

1. Remove valvecomponents withTool.

2 .. Remove valveoilseal withasuitable tool.

Inspection

CYLINDER HEADDISTORTION

Clean surface ofcylinder head.

Use areliable straightedge andafeeler gauge tocheck the

flatness ofcylinder headsurface.

Check alongsixpositions showninfigure.

Head surface flatness:

Standard:

Less than0.03mm(0.0012 in)

Limit: 0.1 mm (0.004 in)

If beyond thespecified limit,replace itor resurface it.

Resurfacing limit:

The resurfacing limitofcylinder headisdetermined bythe cyl-

inder block resurfacing inan engine.

Amount ofcylinder headresurfacing is

"A".

Amount ofcylinder blockresurfacing is

"8".

The maximum limitisas follows:

A +8

=

0.2 mm (0.008 in)

After resurfacing cylinderhead,check thatcamshaft rotates

freely byhand. Ifresistance isfelt, cylinder headmust be

replaced.

Nominal cylinderheadheight:

117.8 -118.0 mm(4.638 .4.646 in)

CAMSHAFT VISUALCHECK

Check camshaft forscratches, seizureandwear.

EM-34

Page 1217 of 1701

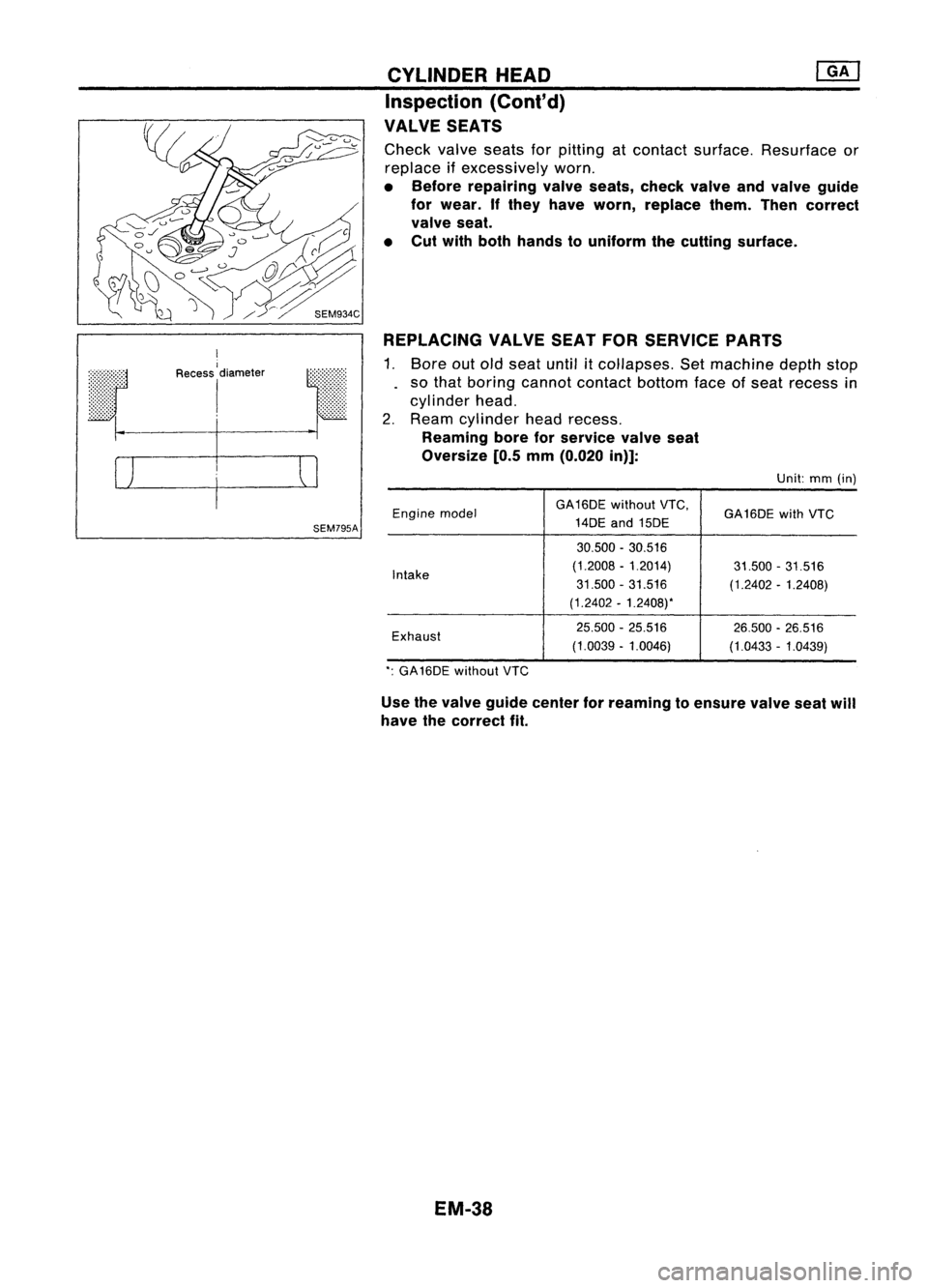

I

Recess

1

diameter

I

SEM795A CYLINDER

HEAD

Inspection (Cont'd)

VALVE SEATS

Check valveseats forpitting atcontact surface. Resurface or

replace ifexcessively worn.

• Before repairing valveseats, checkvalveandvalve guide

for wear. Ifthey have worn, replace them.Thencorrect

valve seat.

• Cut with both hands touniform thecutting surface.

REPLACING VALVESEATFORSERVICE PARTS

1. Bore outold seat until

it

collapses. Setmachine depthstop

so that boring cannot contact bottomfaceofseat recess in

cylinder head.

2. Ream cylinder headrecess.

Reaming boreforservice valveseat

Oversize [0.5mm(0.020 in)]:

Unit:mm(in)

Engine model GA16DE

withoutVTC,

GA16DE withVTC

14DE and15DE

30.500 -30.516

Intake (1.2008

-1.2014)

31.500-31.516

31.500 -31.516

(1.2402-1.2408)

(1.2402 -1.2408).

Exhaust 25.500

-25.516

26.500-26.516

(1.0039 -1.0046)

(1.0433-1.0439)

.: GA 16DE without VTC

Use thevalve guide center forreaming toensure valveseatwill

have thecorrect fit.

EM-38

Page 1220 of 1701

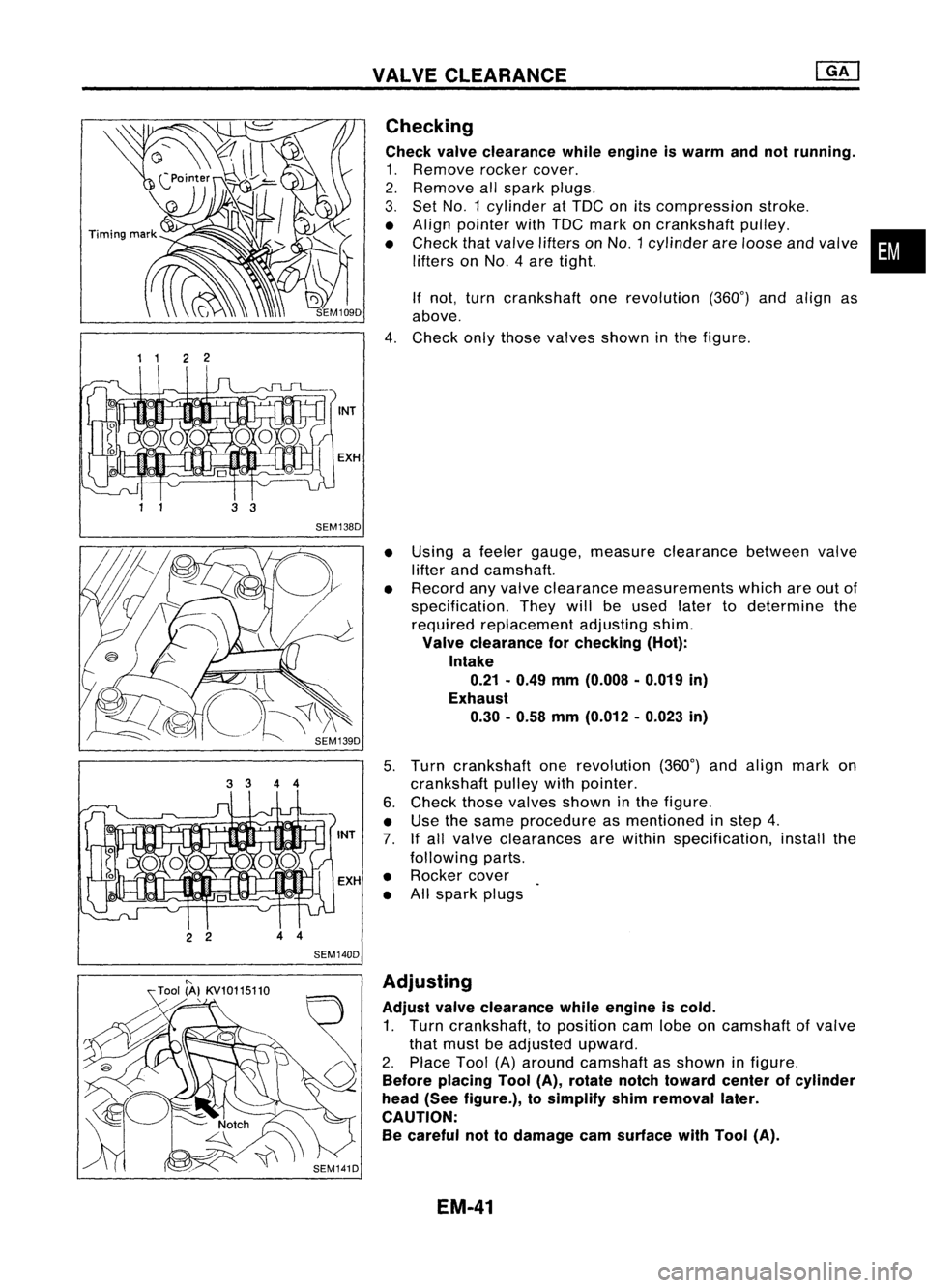

VALVECLEARANCE

1 1 22

2 2 44

SEM140D Checking

Check valveclearance whileengine iswarm andnotrunning.

1. Remove rockercover.

2. Remove allspark plugs.

3. Set

NO.1

cylinder atTOC onitscompression stroke.

• Align pointer withTOC mark oncrankshaft pulley.

• Check thatvalve lifters on

NO.1

cylinder areloose andvalve

lifters on

NO.4

aretight.

If not, turn crankshaft onerevolution (360°)andalign as

above.

4. Check onlythose valves showninthe figure.

• Using afeeler gauge, measure clearance betweenvalve

lifter andcamshaft.

• Record anyvalve clearance measurements whichareoutof

specification. Theywillbeused latertodetermine the

required replacement adjustingshim.

Valve clearance forchecking (Hot):

Intake 0.21 -0.49 mm(0.008 .0.019 in)

Exhaust 0.30. 0.58mm(0.012 -0.023 in)

5. Turn crankshaft onerevolution (360°)andalign markon

crankshaft pulleywithpointer.

6. Check thosevalves shown inthe figure.

• Use thesame procedure asmentioned instep 4.

7. Ifall valve clearances arewithin specification, installthe

following parts.

• Rocker cover

• Allspark plugs

•

"-

Tool (A}KV10115110

,

SEM141DAdjusting

Adjust valveclearance whileengine iscold.

1. Turn crankshaft, toposition camlobeoncamshaft ofvalve

that must beadjusted upward.

2. Place Tool(A)around camshaft asshown infigure.

Before placing Tool(A),rotate notchtoward centerofcylinder

head (Seefigure.), tosimplify shimremoval later.

CAUTION: Be careful nottodamage camsurface withTool (A).

EM-41

Page 1241 of 1701

COMPRESSIONPRESSURE

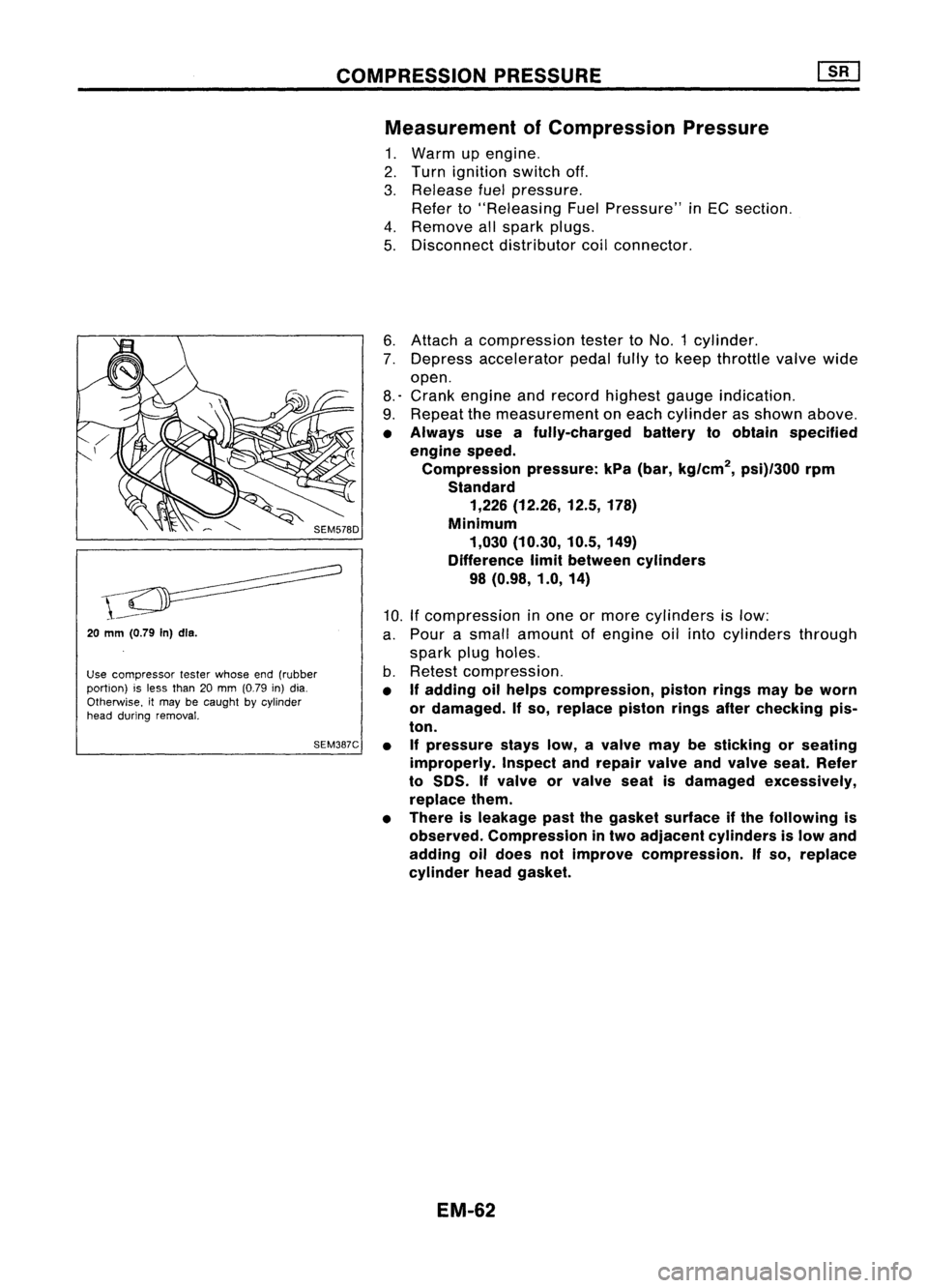

Measurement ofCompression Pressure

1. Warm upengine.

2. Turn ignition switchoff.

3. Release fuelpressure.

Refer to"Releasing FuelPressure" inEC section.

4. Remove allspark plugs.

5. Disconnect distributorcoilconnector.

20

mm (0.79

In)dls.

Use compressor testerwhose end(rubber

portion) isless than 20mm (0.79 in)dia.

Otherwise. itmay becaught bycylinder

head during removal.

SEM387C6.

Attach acompression testertoNO.1 cylinder.

7. Depress accelerator pedalfullytokeep throttle valvewide

open.

8.' Crank engine andrecord highest gaugeindication.

9. Repeat themeasurement oneach cylinder asshown above.

• Always useafully-charged batterytoobtain specified

engine speed.

Compression pressure:kPa(bar, kg/cm

2,

psi)/300 rpm

Standard 1,226 (12.26, 12.5,178)

Minimum 1,030 (10.30, 10.5,149)

Difference limitbetween cylinders

98 (0.98, 1.0,14)

10. Ifcompression inone ormore cylinders islow:

a. Pour asmall amount ofengine oilinto cylinders through

spark plugholes.

b. Retest compression.

• If

adding oilhelps compression, pistonringsmaybeworn

or damaged.

If

so, replace pistonringsafterchecking pis-

ton.

• Ifpressure stayslow,avalve maybesticking orseating

improperly. Inspectandrepair valveandvalve seat.Refer

to

50S.

If

valve orvalve seatisdamaged excessively,

replace them.

• There isleakage pastthegasket surface ifthe following is

observed. Compression intwo adjacent cylinders islow and

adding oildoes notimprove compression.

If

so, replace

cylinder headgasket.

EM-62

Page 1252 of 1701

Engine~

front

Y--J

SEM721E

SEM984C

~ Crankshaft

!..--..V

side

Crankshaft sprocket

SEM470E TIMING

CHAIN

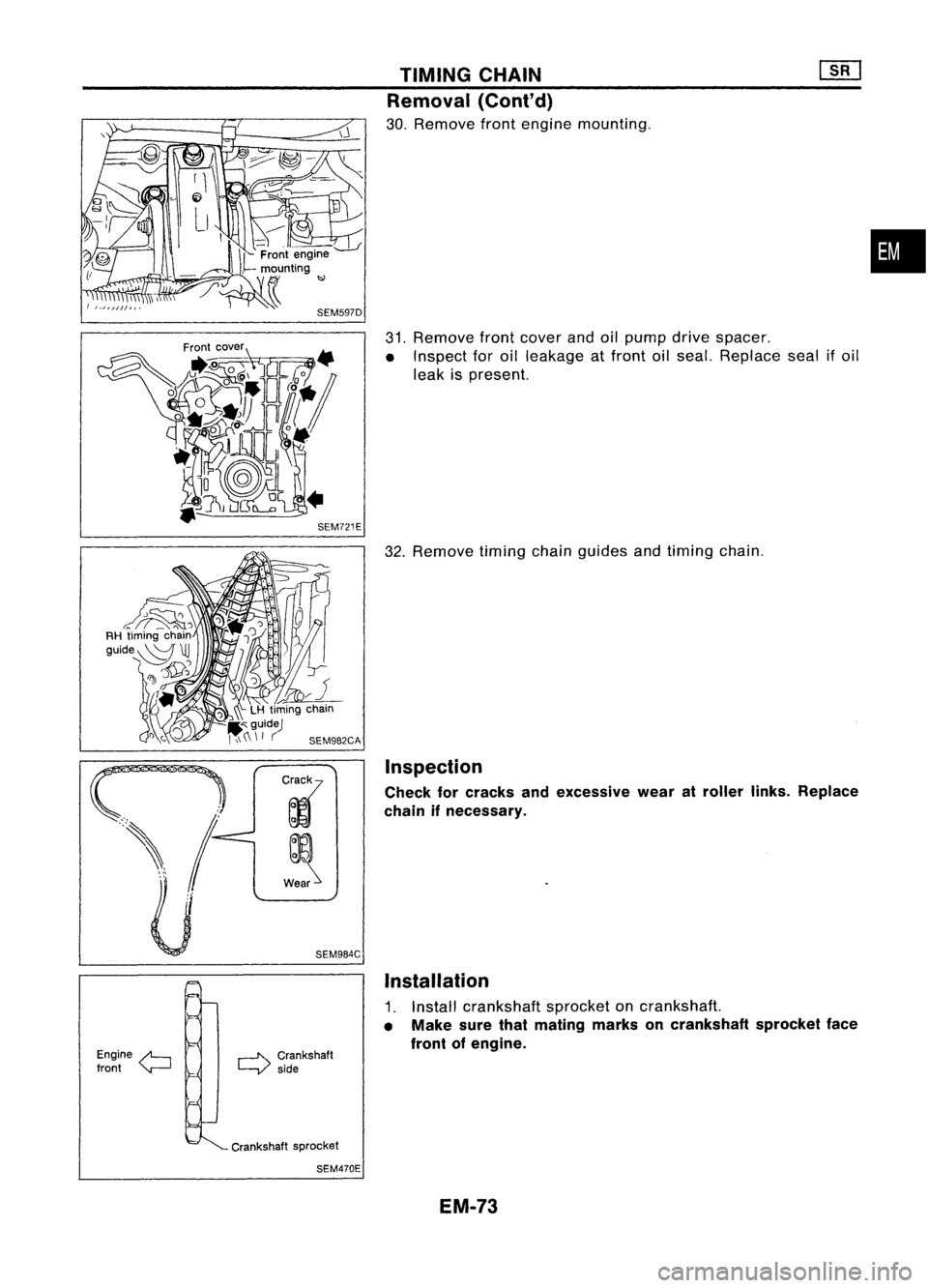

Removal (Cont'd)

30. Remove frontengine mounting.

31. Remove frontcover andoilpump drivespacer.

• Inspect foroilleakage atfront oilseal. Replace sealifoil

leak ispresent.

32. Remove timingchainguides andtiming chain.

Inspection

Check forcracks andexcessive wearatroller links.Replace

chain ifnecessary.

Installation

1. Install crankshaft sprocketoncrankshaft.

• Make surethatmating marksoncrankshaft sprocketface

front ofengine.

EM-73

•

Page 1267 of 1701

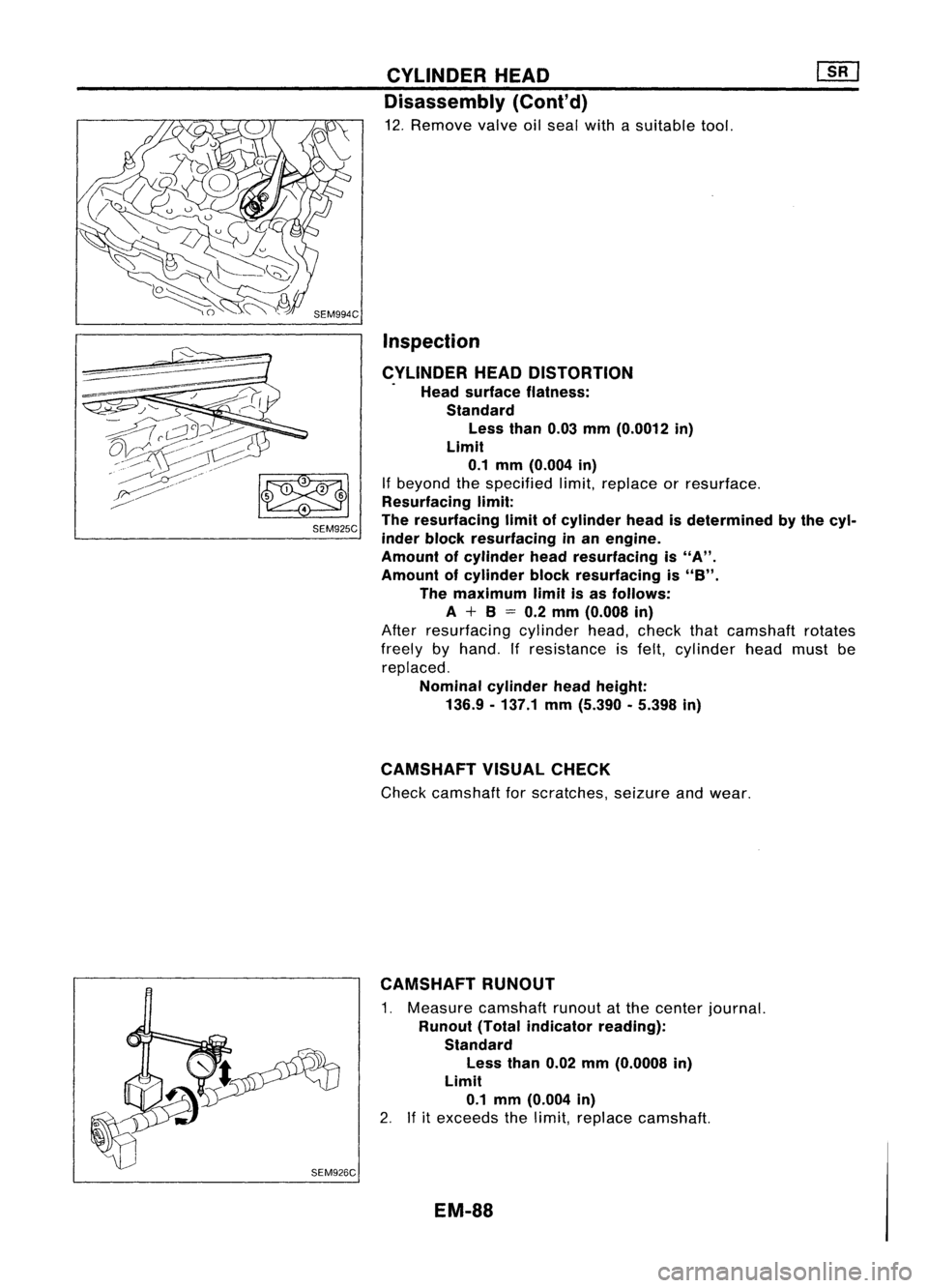

SEM925CCYLINDER

HEAD

Disassembly (Cont'd)

12. Remove valveoilseal with asuitable tool.

Inspection

CYLINDER HEADDISTORTION

. Head surface flatness:

Standard Less than0.03mm(0.0012 in)

Limit

0.1 mm (0.004 in)

If beyond thespecified limit,replace orresurface.

Resurfacing limit:

The resurfacing limitofcylinder headisdetermined bythe cyl-

inder block resurfacing inan engine.

Amount ofcylinder headresurfacing is

"A".

Amount ofcylinder blockresurfacing is

"B".

The maximum limitisas follows:

A

+

B

=

0.2 mm (0.008 in)

After resurfacing cylinderhead,check thatcamshaft rotates

freely byhand. Ifresistance isfelt, cylinder headmustbe

replaced.

Nominal cylinderheadheight:

136.9 -137.1 mm(5.390 -5.398 in)

CAMSHAFT VISUALCHECK

Check camshaft forscratches, seizureandwear.

CAMSHAFT RUNOUT

1. Measure camshaft runoutatthe center journal.

Runout (Totalindicator reading):

Standard Less than0.02mm(0.0008 in)

Limit

0.1 mm (0.004 in)

2. Ifitexceeds thelimit, replace camshaft.

EM-88

Page 1274 of 1701

![NISSAN ALMERA N15 1995 Service Manual CYLINDERHEAD

ill]

Assembly (Cont'd)

10. Install valvecomponent parts.

• Install valves withlarger diameter headonthe intake side.

•

Wide pitch

Narrow pitch

Paint mark

Cylinder headside

S NISSAN ALMERA N15 1995 Service Manual CYLINDERHEAD

ill]

Assembly (Cont'd)

10. Install valvecomponent parts.

• Install valves withlarger diameter headonthe intake side.

•

Wide pitch

Narrow pitch

Paint mark

Cylinder headside

S](/img/5/57349/w960_57349-1273.png)

CYLINDERHEAD

ill]

Assembly (Cont'd)

10. Install valvecomponent parts.

• Install valves withlarger diameter headonthe intake side.

•

Wide pitch

Narrow pitch

Paint mark

Cylinder headside

SEM085D•

Always usenew valve oilseal.

Refer toOIL SEAL REPLACEMENT.

• Before installing valveoilseal, install valvespring seat.

.' Install valvespring (uneven pitchtype) withitsnarrow

pitched sidetoward cylinder headside(paint mark).

• After installing valvecomponent parts,tapvalve stemtip

with plastic hammer toassure aproper fit.

11. Check hydraulic lashadjusters.

a. Push rocker armathydraulic lashadjuster location, andsee

if rocker armmoves. Ifitmoves atleast 1mm (0.04 in),it

indicates thatthere isair inthe high pressure chamber.

Noise willbeemitted fromhydraulic lashadjuster ifengine

is started without bleeding air.

b. Remove hydraulic lashadjuster anddipinacontainer filled

with engine oil.While pushing plungerasshown infigure,

lightly pushcheck ballusing athin rod. Airiscompletely

bled when plunger nolonger moves.

Air cannot bebled from thistype oflash adjuster byrunning the

engine.

SEM093D

• rEngine oil

- - , t-=1=i

Proper

rod

SEM772C

Rocker arm9UVide

Rock~rarm

Shim

Hydraulic

I

.,h

.dj"'"

i\\ j

12.

Install rocker arms,shims, rockerarmguides andhydrau-

lic lash adjusters.

CAUTION: Install allparts intheir original positions.

SEM202D EM-95

Page 1283 of 1701

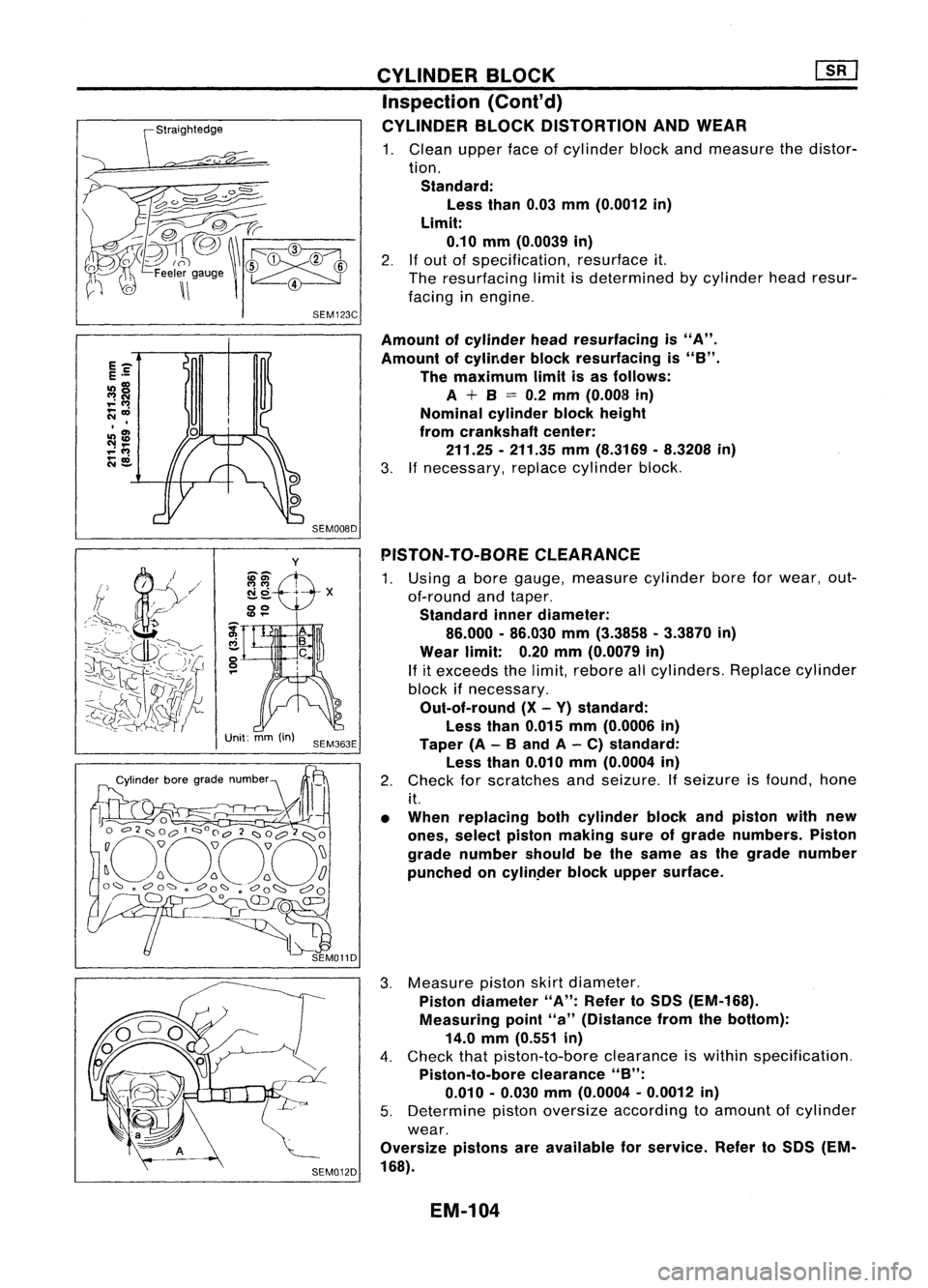

SEM123CCYLINDER

BLOCK ~

Inspection (Cont'd)

CYLINDER BLOCKDISTORTION ANDWEAR

1. Clean upperfaceofcylinder blockandmeasure thedistor-

tion. Standard: Less than0.03mm(0.0012 in)

Limit: 0.10 mm(0.0039 in)

2.

If

out ofspecification, resurfaceit.

The resurfacing limitisdetermined bycylinder headresur-

facing inengine.

SEM008D

Amount

ofcylinder headresurfacing is"A".

Amount ofcylinder blockresurfacing is

"8".

The maximum limitisas follows:

A

+

8

=

0.2 mm (0.008 in)

Nominal cylinderblockheight

from crankshaft center:

211.25 -211.35 mm(8.3169 -8.3208 in)

3. Ifnecessary, replacecylinder block.

y

ii-El)'

N 0+ -X

--

00

Unit: mm(in)

SEM363E PISTON-

TO-BORE CLEARANCE

1. Using abore gauge, measure cylinderboreforwear, out-

of-round andtaper.

Standard innerdiameter:

86.000 -86.030 mm(3.3858 -3.3870 in)

Wear limit: 0.20mm(0.0079 in)

If

itexceeds thelimit, rebore allcylinders. Replacecylinder

block ifnecessary.

Out-of-round (X-Y) standard:

Less than0.015 mm(0.0006 in)

Taper (A-

8

and A-C) standard:

Less than0.010 mm(0.0004 in)

2. Check forscratches andseizure. Ifseizure isfound. hone

it.

• When replacing bothcylinder blockandpiston withnew

ones, select piston making sureofgrade numbers. Piston

grade number shouldbethe same asthe grade number

punched oncylinper blockupper surface.

3. Measure pistonskirtdiameter.

Piston diameter "A":Refer toSDS (EM-168).

Measuring point"a"(Distance fromthebottom):

14.0 mm(0.551 in)

4. Check thatpiston-to-bore clearanceiswithin specification.

Piston-to-bore clearance"B":

0.010 -0.030 mm(0.0004 -0.0012 in)

5. Determine pistonoversize according toamount ofcylinder

wear.

Oversize pistonsareavailable forservice. RefertoSDS (EM-

168).

EM-104