check engine NISSAN ALMERA N15 1995 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 1117 of 1701

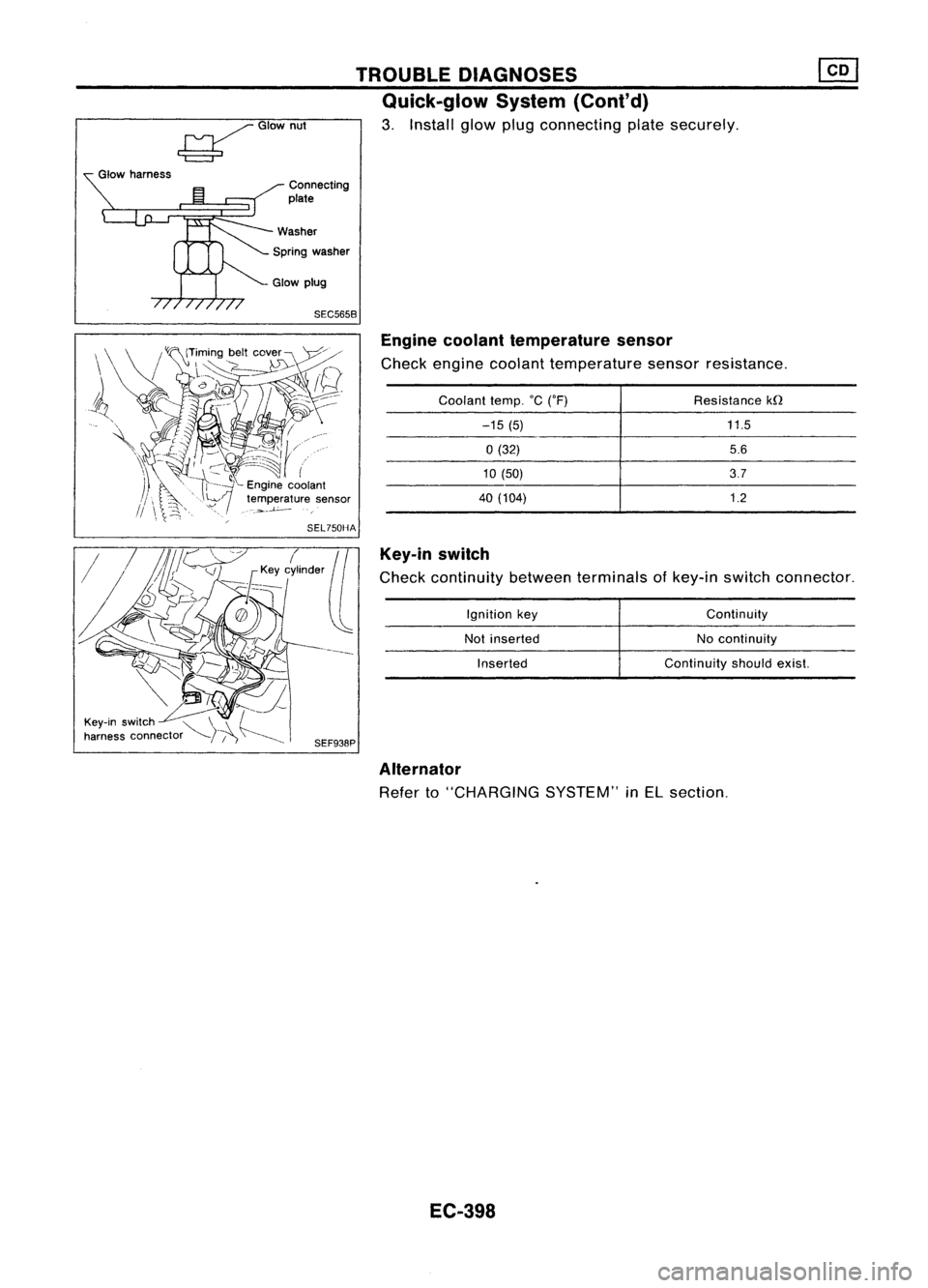

SEC5658Enginecoolant temperature sensor

Check engine coolant temperature sensorresistance.

Key-in switch

Check continuity betweenterminals ofkey-in switch connector.

11.5

5.6

3.7

1.2

Resistance

kfl

Continuity

No continuity

Continuity shouldexist.

Ignition

key

Not inserted

Inserted

Coolant

temp.°C('F)

-15 (5)

0(32)

10 (50)

40 (104)

TROUBLE

DIAGNOSES

Quick-glow System(Cont'd)

3. Install glowplugconnecting platesecurely.

Connecting

plate

Spring washer

~GIOwnut

Glow harness

Alternator

Refer to"CHARGING SYSTEM"inEL section.

EC-398

Page 1121 of 1701

TROUBLEDIAGNOSES ~

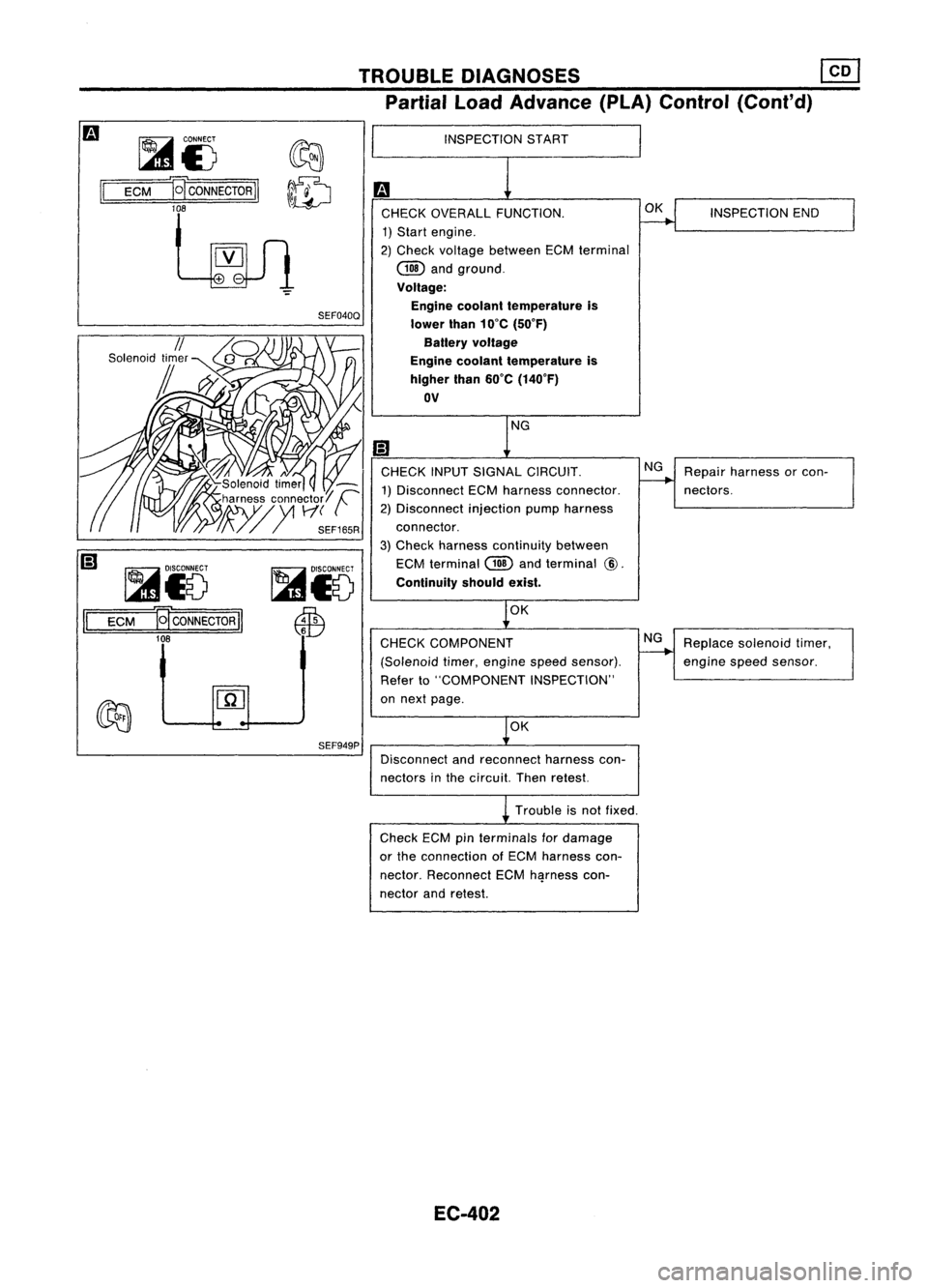

Partial LoadAdvance (PLA)Control (Cont'd)

II

~i5

D~CONNECTORII

lOB

~i5

ECM

M

CONNECTOR

II

10B

SEF040Q

SEF949P

INSPECTION

START

CHECK OVERALL FUNCTION.

1) Start engine.

2) Check voltage between ECMterminal

COO

andground.

Voltage: Engine coolant temperature is

lower than10'C (50'F)

Battery voltage

Engine coolant temperature is

higher than60'C (140'F)

OV

CHECK INPUTSIGNAL CIRCUIT.

1) Disconnect ECMharness connector.

2) Disconnect injectionpumpharness

connector.

3) Check harness continuity between

ECM terminal

COO

andterminal

@.

Continuity shouldexist.

OK

CHECK COMPONENT

(Solenoid timer,engine speedsensor).

Refer to"COMPONENT INSPECTION"

on next page.

OK

Disconnect andreconnect harnesscon-

nectors inthe circuit. Thenretest.

Trouble isnot fixed.

Check ECMpin

terminals

fordamage

or the connection ofECM harness con-

nector. Reconnect ECMh~rness con-

nector andretest.

EC-402 OK

NG

NG

INSPECTION

END

Repair harness orcon-

nectors.

Replace solenoid timer,

engine

speedsensor.

Page 1122 of 1701

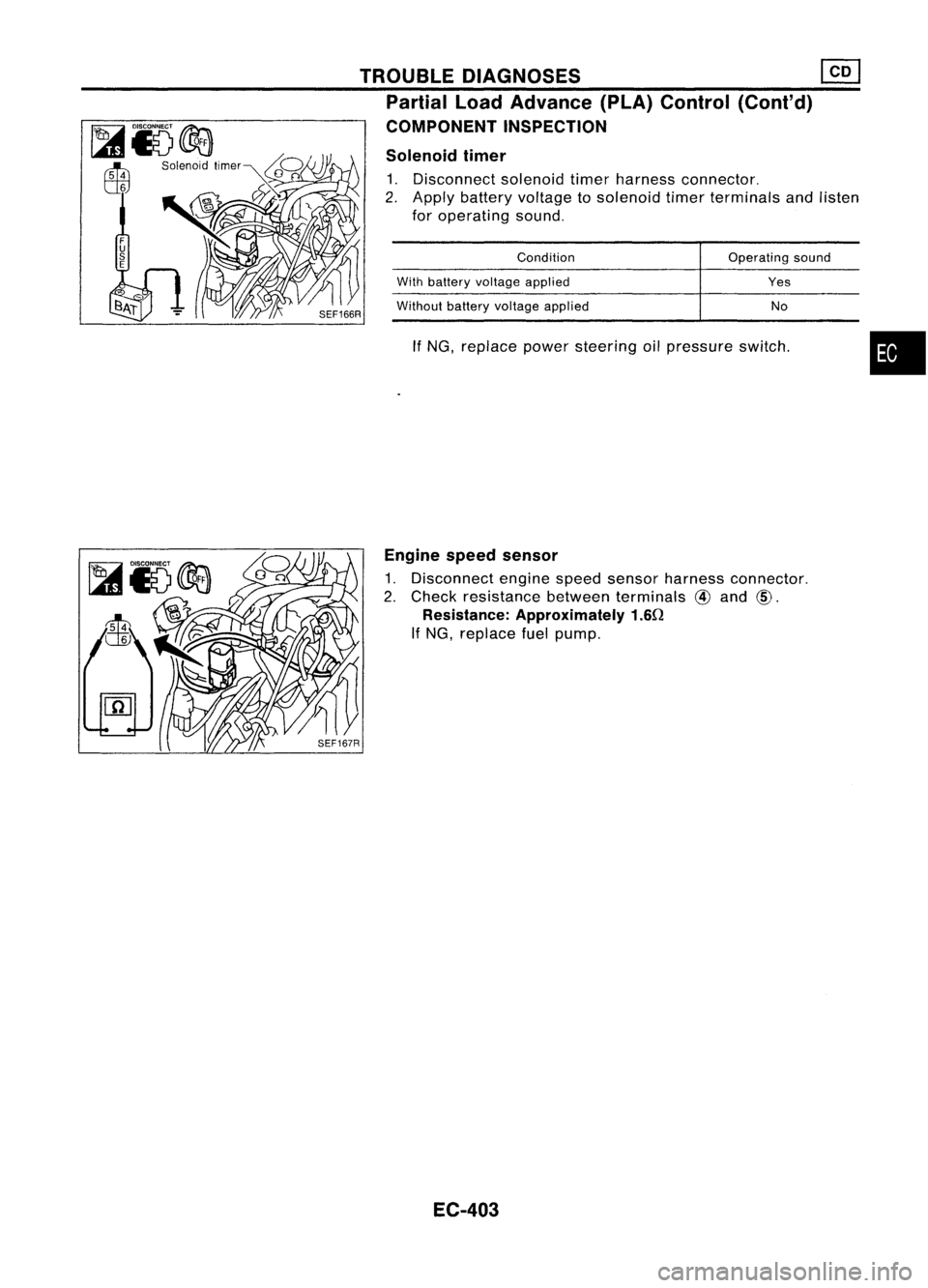

If

NG, replace powersteering oilpressure switch.

Solenoid

timer

1. Disconnect solenoidtimerharness connector.

2. Apply battery voltage tosolenoid timerterminals andlisten

for operating sound.

•

No

Operating

sound

Yes

Condition

With battery voltage applied

Without batteryvoltage applied

TROUBLE

DIAGNOSES ~

Partial LoadAdvance (PLA)Control (Cont'd)

COMPONENT INSPECTION

Engine speedsensor

1. Disconnect enginespeedsensor harness connector.

2. Check resistance betweenterminals

@

and

CID.

Resistance: Approximately 1.6Q

If

NG, replace fuelpump.

EC-403

Page 1127 of 1701

TROUBLEDIAGNOSES

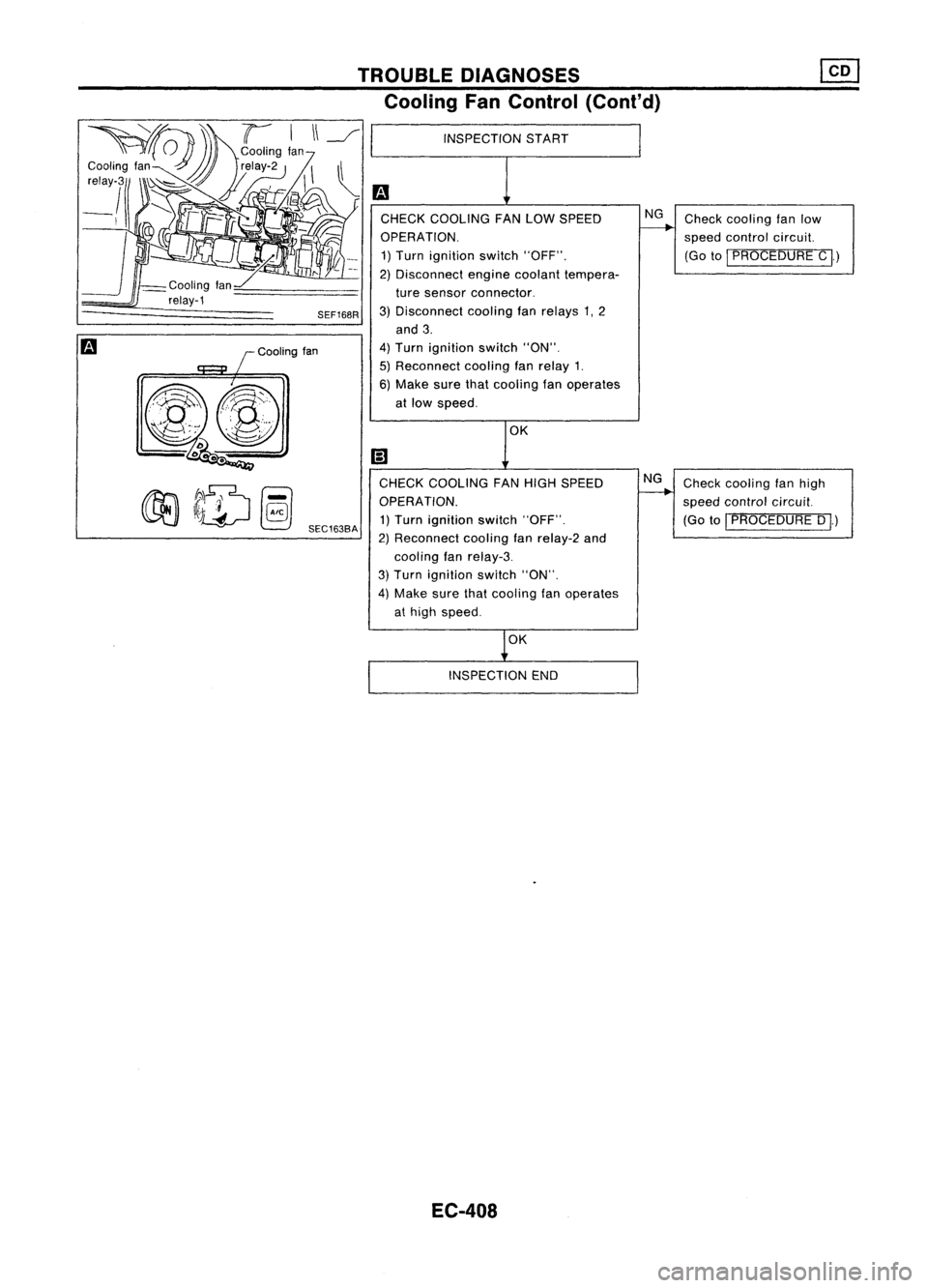

Cooling FanControl (Cont'd)

Checkcooling fanlow

speed control circuit.

(Go to

I

PROCEDURE C

P

Check cooling fanhigh

speed control circuit.

(Go to

I

PROCEDURE D

I.)

NG

NG

INSPECTION

START

OK

CHECK COOLING FANHIGH SPEED

OPERATION. 1) Turn ignition switch"OFF".

2) Reconnect coolingfanrelay-2 and

cooling fanrelay-3.

3) Turn ignition switch"ON".

4) Make surethatcooling fanoperates

at high speed.

CHECK

COOLING FANLOW SPEED

OPERATION. 1) Turn ignition switch"OFF".

2) Disconnect enginecoolant tempera-

ture sensor connector.

SEF168R

3)Disconnect coolingfanrelays 1,2

and 3.

4) Turn ignition switch"ON".

5) Reconnect coolingfanrelay 1.

6) Make surethatcooling fanoperates

at low speed.

SEC163BA OK

INSPECTION END

EC-408

Page 1139 of 1701

ENGINELUBRICATION

&

COOLING SYSTEMS

SECTION

LC

CONTENTS

•

PRECAUTION

2

PREPARATION

3

GA

ENGINE LUBRICATION SYSTEM

5

Lubrication Circuit.. 5

Oil Pressure Check 6

Oil Pump 7

ENGINE COOLING SySTEM 9

Cooling Circuit 9

Water HoseDrawing 10

System Check 12

Water Pump 13

Thermostat 14

Water Outlet 15

Radiator 16

SR

ENGINE LUBRICATION SYSTEM 17

Lubrication Circuit. 17

Oil Pressure Check 17

Oil Pump 18

Oil FiIter 20

ENGINE COOLING SYSTEM 21

Cooling Circuit 21

System Check 21

Cooling SystemInspection 21

Water Pump 22

Thermostat 23

Water Outlet 24

Radiator 25CO

ENGINE LUBRICATION SYSTEM 26

Lubrication Circuit... 26

Oil Pressure Check 27

Oil Pump ,27

Oil Cooler 30

ENGINE COOLING SYSTEM 31

Cooling Circuit 31

System Check 32

Water Pump ,33

Thermostat 34

Radiator 35

GA,SR,CO

ENGINE COOLING SYSTEM 37

Radiator (Aluminum type) 37

GA,SR

SERVICE DATAANDSPECIFICATIONS (SOS)40

Engine Lubrication System(GA) 40

Engine Cooling System(GA) 40

Engine Lubrication System(SR) 40

Engine Cooling System(SR) 40

CO

SERVICE DATAANDSPECIFICATIONS (SOS)41

Engine Lubrication System .41

Engine Cooling System 41

Page 1144 of 1701

ENGINELUBRICATION SYSTEM

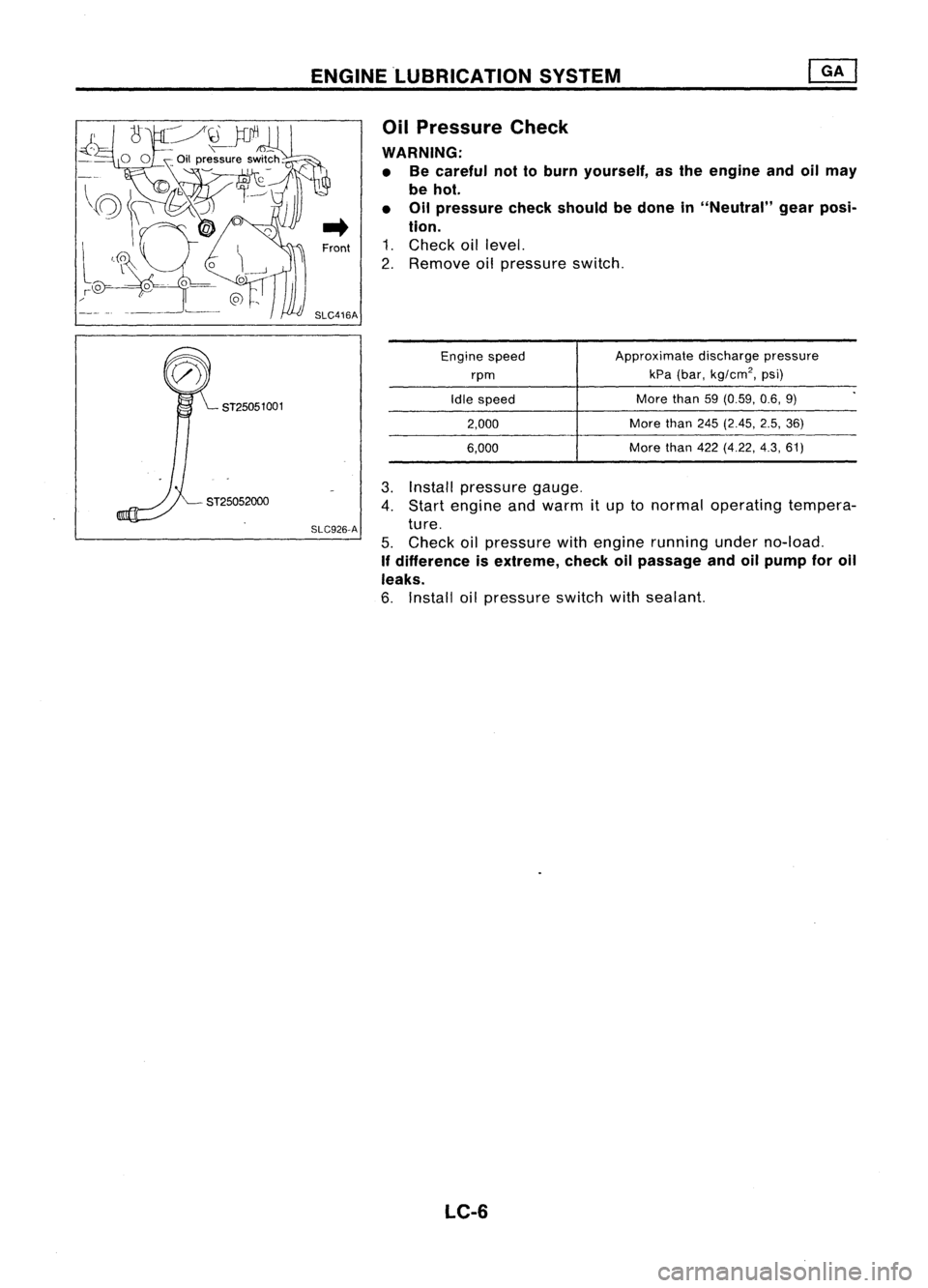

3. Install pressure gauge.

4. Start engine andwarm itup tonormal operating tempera-

ture.

5. Check oilpressure withengine running underno-load.

If difference isextreme, checkoilpassage andoilpump foroil

leaks.

6. Install oilpressure switchwithsealant.

Oil

Pressure Check

WARNING: • Becareful nottoburn yourself, asthe engine andoilmay

be hot.

• Oilpressure checkshould bedone in"Neutral" gearposi-

tion.

1. Check oillevel.

2. Remove oilpressure switch.

ST25051001 SLC926-A

Engine

speed

rpm

Idle speed

2,000

6,000 Approximate

dischargepressure

kPa (bar,

kg/cm

2,

psi)

More than59(0.59, 0.6,9)

More than245(2.45, 2.5,36)

More than422(4.22, 4.3,61)

LC-6

Page 1145 of 1701

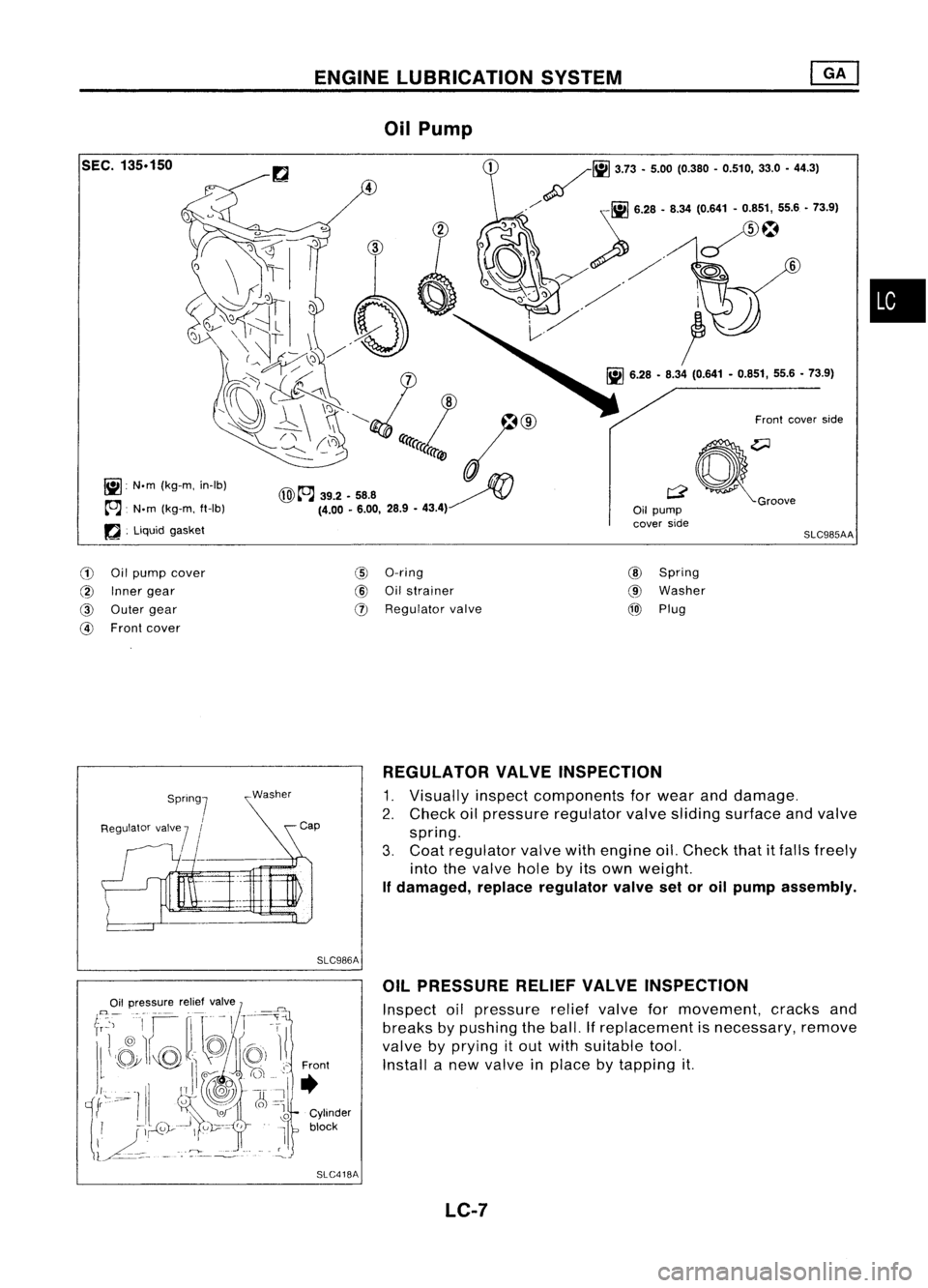

ENGINELUBRICATION SYSTEM

SEC.

135.150

lil

N.m(kg-m, in-Ib)

~. N.m(kg-m, ft-Ib)

rJ .

Liquid gasket

Oil

Pump

Frontcover side

a~:oo"

Oil pump

cover side

SLC985AA

•

CD

Oilpump cover

@

Inner gear

@

Outer gear

@

Front cover

I])

O-ring

@J

Oilstrainer

(J)

Regulator valve

@

Spring

@

Washer

@)

Plug

Spring]

I

Regulator valve

7

I

REGULATOR

VALVEINSPECTION

1. Visually inspectcomponents forwear anddamage.

2. Check oilpressure regulator valvesliding surface andvalve

spring.

3. Coat regulator valvewithengine oil.Check thatitfalls freely

into thevalve holebyitsown weight.

If damaged, replaceregulator valvesetoroil pump assembly.

SLC986A OILPRESSURE RELIEFVALVEINSPECTION

Inspect oilpressure reliefvalve formovement, cracksand

breaks bypushing theball. Ifreplacement isnecessary, remove

valve byprying itout with suitable tool.

Front Installanew valve inplace bytapping it.

•

Cylinder

block

SLC418A

LC-7

Page 1146 of 1701

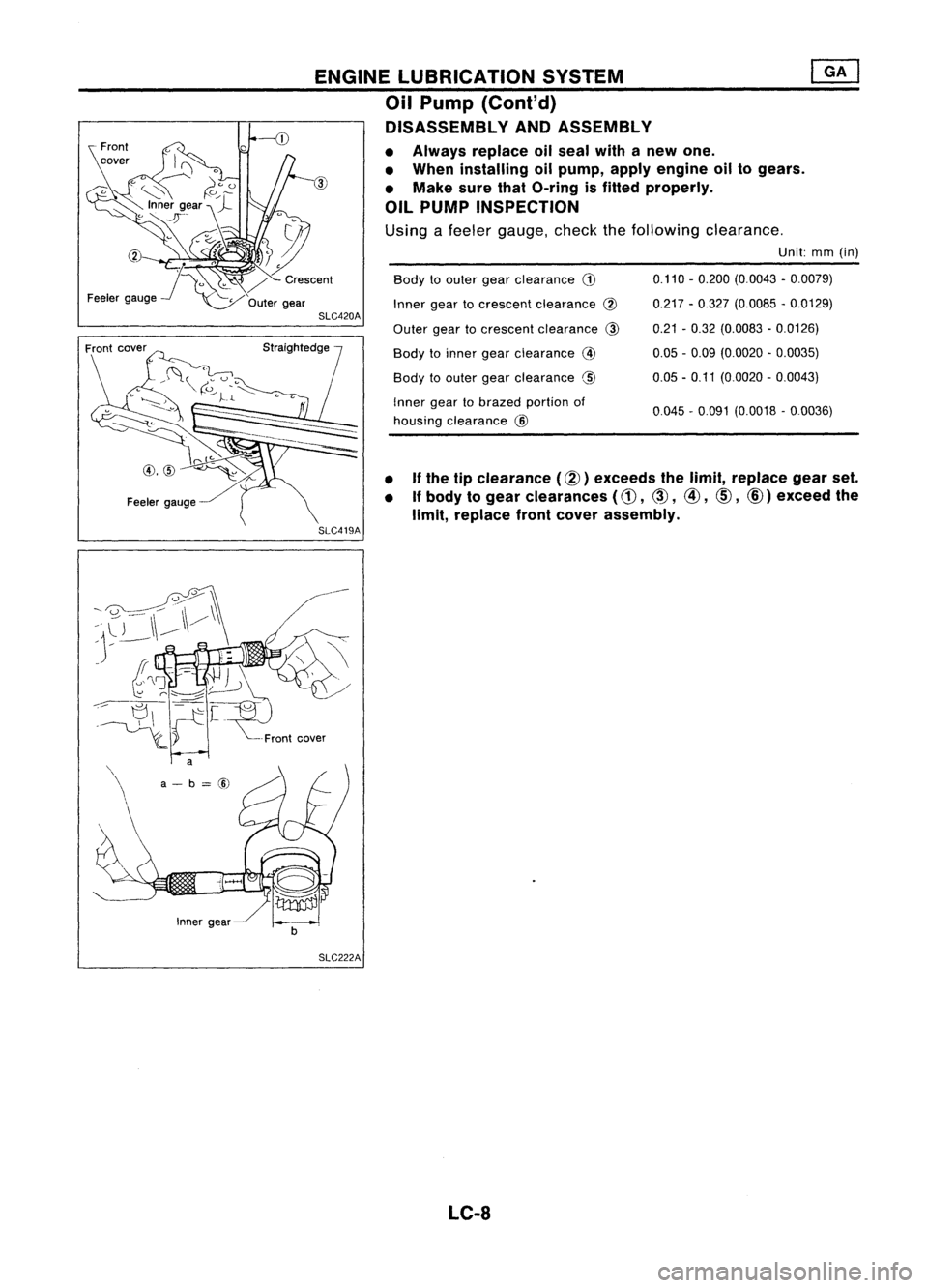

0.045-0.091 (0.0018 -0.0036)

0.110

-0.200 (0.0043 -0.0079)

0.217 -0.327 (0.0085 -0.0129)

0.21 -0.32 (0.0083 -0.0126)

0.05 -0.09 (0.0020 -0.0035)

0.05 -0.11 (0.0020 -0.0043)

Body

toouter gearclearance

CD

Inner geartocrescent clearance @

Outer geartocrescent clearance

@

Body toinner gearclearance @

Body toouter gearclearance @

Inner geartobrazed portionof

housing clearance

@

• Ifthe tipclearance (@)exceeds thelimit, replace gearset.

• Ifbody togear clearances (

(1), ~,

@,

@,

@)

exceed the

limit, replace frontcover assembly.

Using

afeeler gauge, checkthefollowing clearance.

Unit:mm(in)

SLC420A

ENGINE

LUBRICATION SYSTEM

Oil Pump (ConI'd)

DISASSEMBLY ANDASSEMBLY

• Always replace oilseal withanew one.

• When installing oilpump, applyengine oiltogears.

• Make surethatO-ring isfitted properly.

OIL PUMP INSPECTION

Feeler gauge

SLC419A

b SLC222A

LC-8

Page 1150 of 1701

ENGINECOOLING SYSTEM

System Check

WARNING: Never remove theradiator capwhen theengine ishot; serious

burns couldbecaused byhigh pressure fluidescaping fromthe

radiator.

Wrap athick cloth around capandcarefUlly loosenita quarter

turn torelease built-uppressure. Thenremove thecap com-

pletely.

CHECKING COOLINGSYSTEMHOSES

Check hosesforimproper attachment, leaks,cracks, damage,

loose connections, chafinganddeterioration.

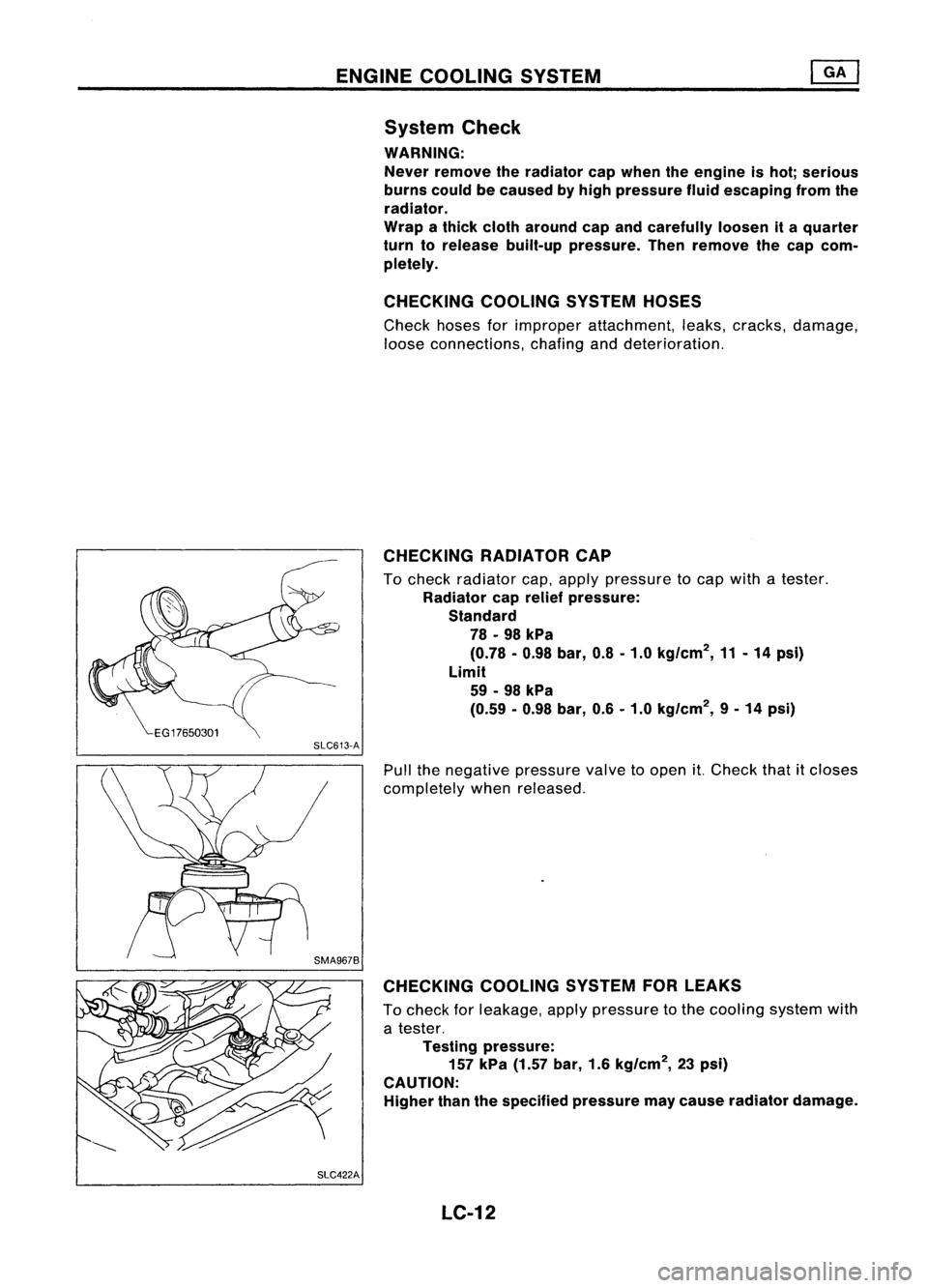

CHECKING RADIATORCAP

To check radiator cap,apply pressure tocap with atester.

Radiator caprelief pressure:

Standard

78 -98 kPa

(0.78 -0.98 bar,0.8-1.0 kg/cm

2,

11-14 psi)

Limit

59 -98 kPa

(0.59 -0.98 bar,0.6-1.0 kg/cm

2,

9-14 psi)

SLC613-A

Pullthenegative pressure valvetoopen it.Check thatitcloses

completely whenreleased.

CHECKING COOLINGSYSTEMFORLEAKS

To check forleakage, applypressure tothe cooling systemwith

a tester.

Testing pressure:

157 kPa (1.57 bar,1.6kg/cm

2,

23psi)

CAUTION: Higher thanthespecified pressure maycause radiator damage.

SLC422A LC-12

Page 1151 of 1701

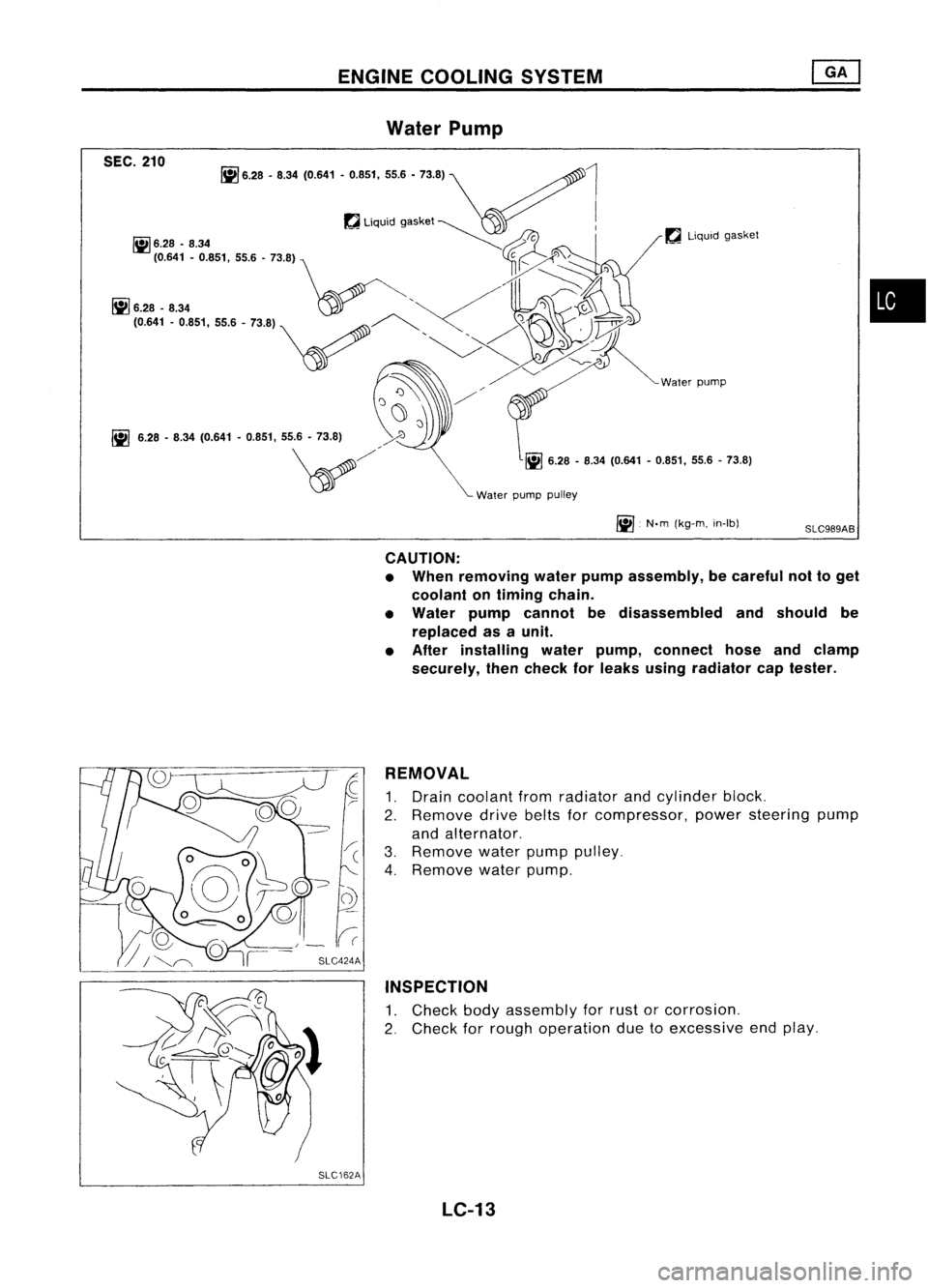

ENGINECOOLING SYSTEM

IiJ

6.28 -8.34 (0.641 -0.851, 55.6-73.8)

SEC.

210 Water

Pump

~ 6.28 -8.34 (0.641 -0.851, 55.6-73.8)

WaterpumppUlley

l

~Liquid gasket

~ N.m(kg-m, in-Ib)

SLC989AB

•

CAUTION:

• When removing waterpumpassembly, becareful nottoget

coolant ontiming chain.

• Water pumpcannot bedisassembled andshould be

replaced asaunit.

• After installing waterpump, connect hoseandclamp

securely, thencheck forleaks using radiator captester.

REMOVAL

1. Drain coolant fromradiator andcylinder block.

2. Remove drivebeltsforcompressor, powersteering pump

and alternator.

3. Remove waterpumppulley.

4. Remove waterpump.

INSPECTION

1. Check bodyassembly forrust orcorrosion.

2. Check forrough operation duetoexcessive endplay.

SLC162A LC-13