check engine NISSAN ALMERA N15 1995 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 1373 of 1701

HOWTOPERFORM EFFICIENT DIAGNOSIS FORANELECTRICAL INCIDENT

Incident Simulation Tests

INTRODUCTION

Sometimes thesymptom isnot present whenthevehicle isbrought infor service.

If

possible, re-create

the conditions presentatthe time ofthe incident. Doingsomay help avoid aNo Trouble FoundDiag-

nosis. Thefollowing sectionillustrates waystosimulate theconditionslenvironment underwhich the

owner experiences anelectrical incident.

The section isbroken intothesixfollowing topics:

• Vehicle vibration

• Heat sensitive

• Freezing

• Water intrusion

• Electrical load

• Cold orhot start up

Get athorough description ofthe incident fromthecustomer. Itis important forsimulating thecondi-

tions ofthe problem.

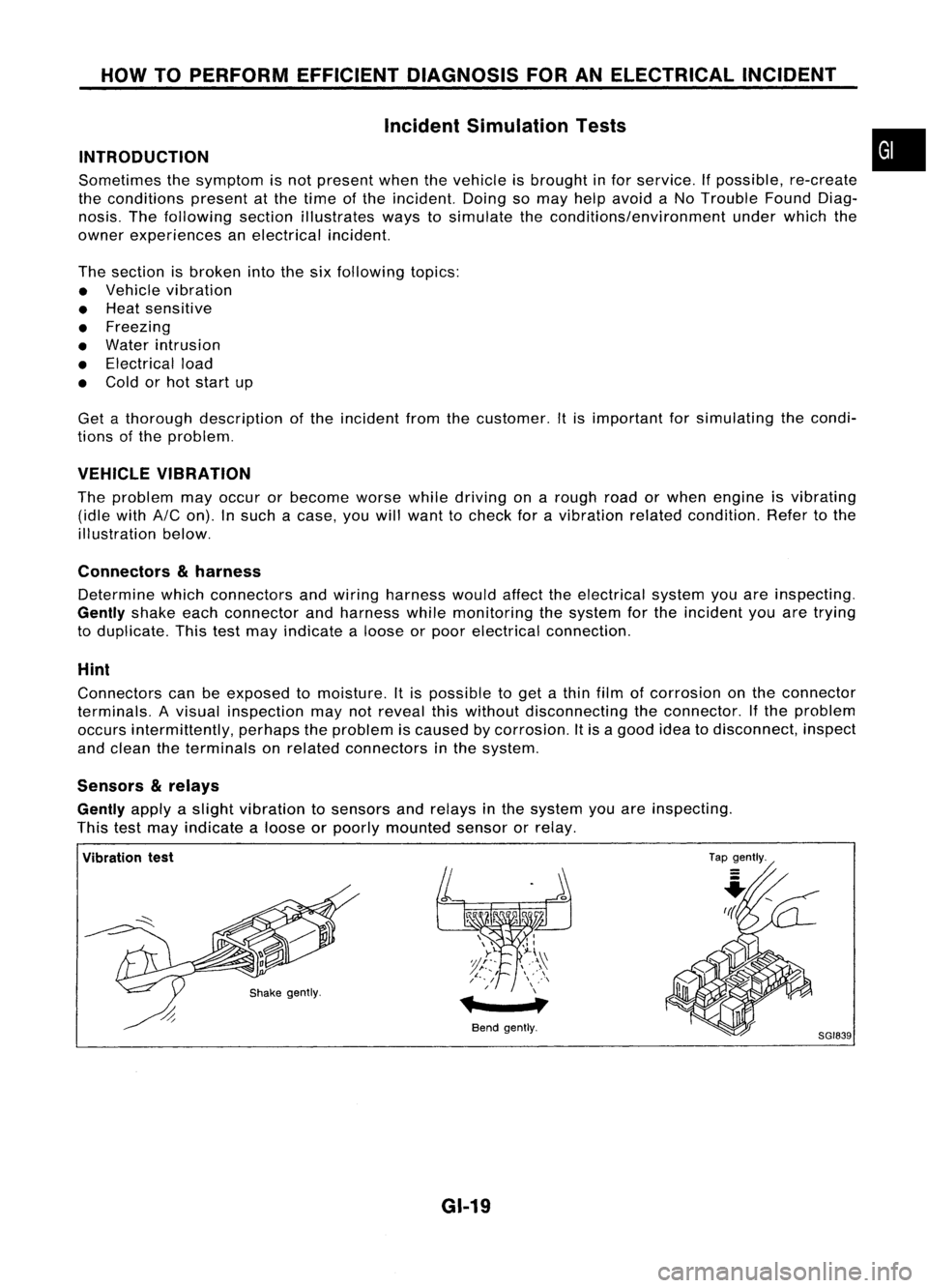

VEHICLE VIBRATION

The problem mayoccur orbecome worsewhiledriving onarough roadorwhen engine isvibrating

(idle with

AIC

on). Insuch acase, youwillwant tocheck foravibration relatedcondition. Refertothe

illustration below.

Connectors

&

harness

Determine whichconnectors andwiring harness wouldaffecttheelectrical systemyouareinspecting.

Gently

shakeeachconnector andharness whilemonitoring thesystem forthe incident youaretrying

to duplicate. Thistestmay indicate aloose orpoor electrical connection.

Hint

Connectors canbeexposed tomoisture. Itis possible toget athin film ofcorrosion onthe connector

terminals. Avisual inspection maynotreveal thiswithout disconnecting theconnector. Ifthe problem

occurs intermittently, perhapstheproblem iscaused bycorrosion. Itis agood ideatodisconnect, inspect

and clean theterminals onrelated connectors inthe system.

Sensors

&

relays

Gently

applyaslight vibration tosensors andrelays inthe system youareinspecting.

This testmay indicate aloose orpoorly mounted sensororrelay.

•

Vibration test

Bendgently.

GI-19

Tap

gently.

8GI839

Page 1375 of 1701

HOWTOPERFORM EFFICIENT DIAGNOSIS FORANELECTRICAL INCIDENT

Incident Simulation Tests(Cont'd)

Engine compartment

There areseveral reasons avehicle orengine vibration could•

cause anelectrical complaint. Someofthe things tocheck for

are:

• Connectors notfully seated.

• Wiring harness notlong enough andisbeing stressed due

to engine vibrations orrocking.

• Wires laying across brackets ormoving components.

• Loose, dirtyorcorroded groundwires.

• Wires routed tooclose tohot components.

To inspect components underthehood, startbyverifying the

integrity ofground connections. (RefertoGROUND INSPEC-

TION described later.)Firstcheck thatthesystem isproperly

grounded. Thencheck forloose connection by

gently shaking

the wiring orcomponents aspreviously explained. Usingthe

wiring diagrams inspectthewiring forcontinuity.

Behind theinstrument panel

An improperly routedorimproperly clampedharnesscan

become pinchedduringaccessory installation. Vehiclevibra-

tion canaggravate aharness whichisrouted alongabracket

or near ascrew.

Under seating areas

An unclamped orloose harness cancause wiring tobe pinched

by seat components (suchasslide guides) duringvehicle vibra-

tion. Ifthe wiring runsunder seating areas,inspect wirerout-

ing forpossible damageorpinching.

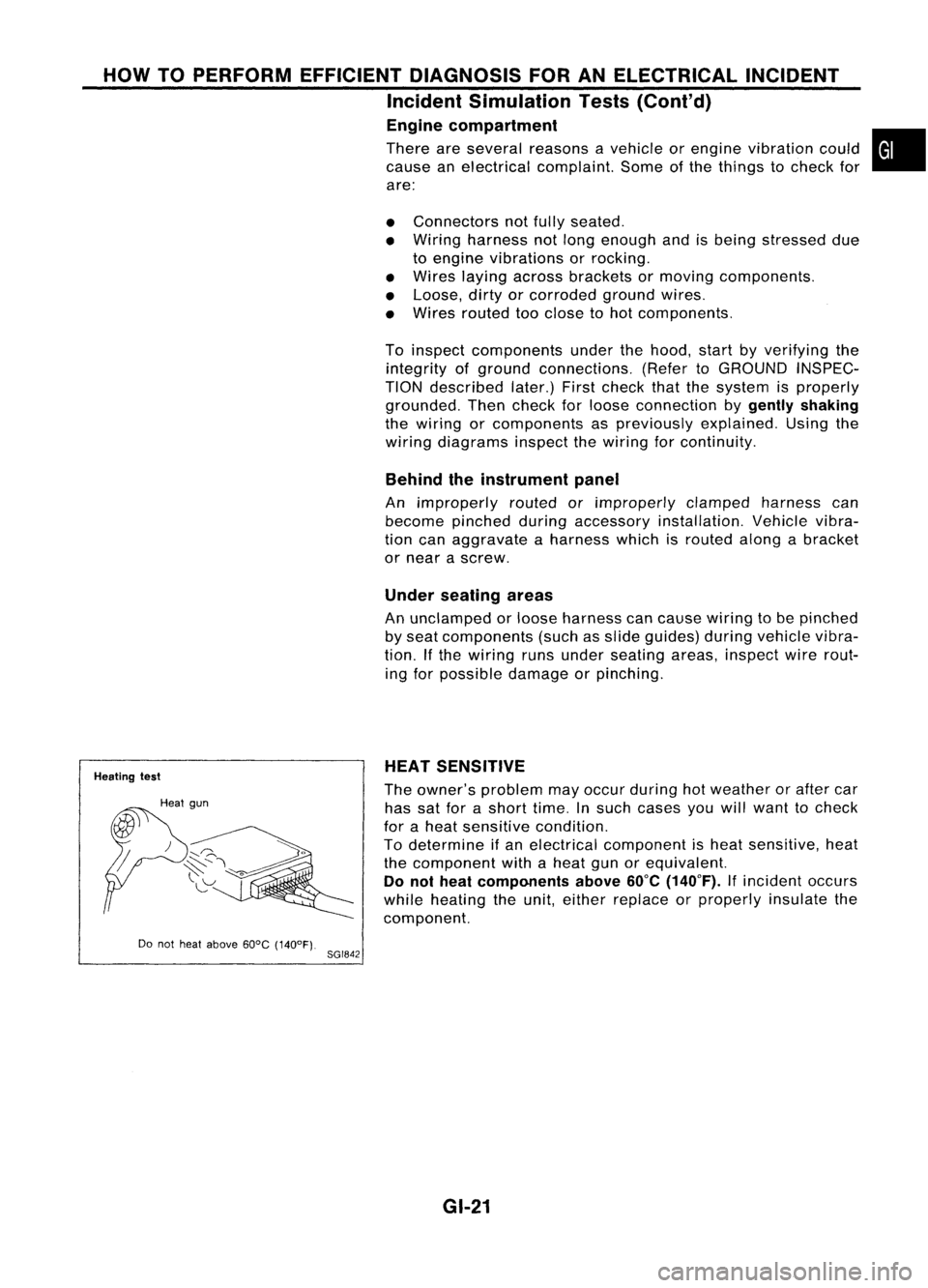

Heating test

Do not heat above 60°C(140°F).

8GI842 HEAT

SENSITIVE

The owner's problem mayoccur during hotweather orafter car

has satforashort time.Insuch cases youwillwant tocheck

for aheat sensitive condition.

To determine ifan electrical component isheat sensitive, heat

the component withaheat gunorequivalent.

Do not heat components above

60°C

(140°F).

Ifincident occurs

while heating theunit, either replace orproperly insulatethe

component.

GI-21

Page 1385 of 1701

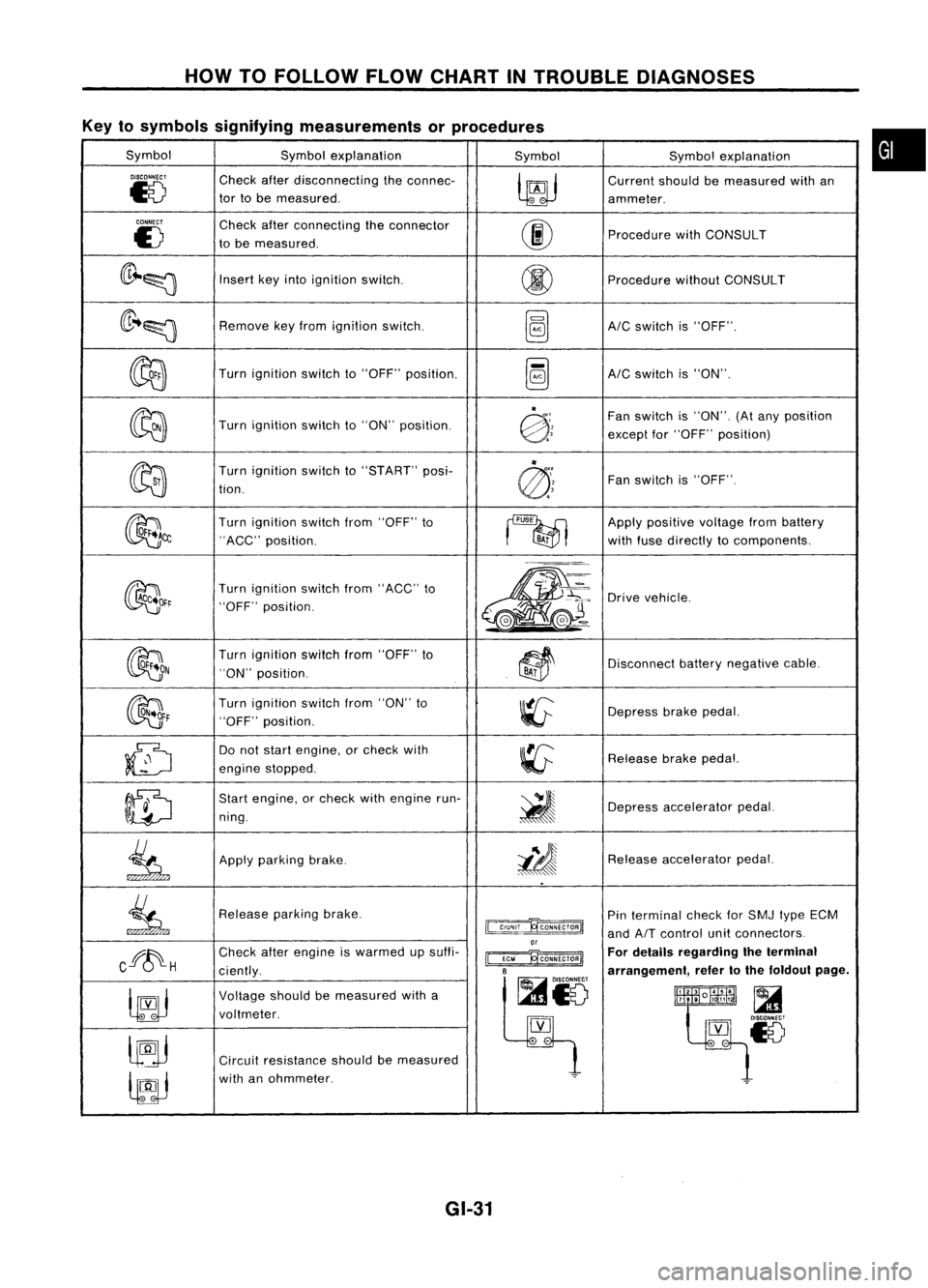

HOWTOFOLLOW FLOWCHART INTROUBLE DIAGNOSES

Key tosymbols signifying measurements orprocedures

Symbol Symbolexplanation

SymbolSymbolexplanation

DISCONNECT

Checkafterdisconnecting theconnec-

~

Current

shouldbemeasured withan

~8

tor

tobe measured.

ammeter.

CONNECT

Checkafterconnecting theconnector

00

E)

tobe measured. Procedure

withCONSULT

(lr~~

Insert

keyinto ignition switCh.

@

Procedure

withoutCONSULT

(lr ..~

Remove

keyfrom ignition switch.

~AIC

switch is"OFF".

~

Turn

ignition switchto"OFF" position.

~AIC

switch is"ON".

~

"

Fanswitch is"ON". (Atany position

Turn ignition switchto"ON" position.

@:;

exceptfor"OFF" position)

~ "

Turn ignition switchto"START" posi-

@'~

Fan

switch is"OFF".

tion.

~~

Turn

ignition switchfrom"OFF" to

~

Apply

positive voltagefrombattery

"ACC" position.

BA;

withfuse directly tocomponents.

~~r

Turn

ignition switchfrom"ACC" to

m-

~'~:

Drive

vehicle.

"OFF" position.

,.-=.

L

@J~ ..

~(e.-

OON

Turn

ignition switchfrom"OFF" to

~~

Disconnect

batterynegative cable.

"ON" position.

BAi

~F

Turn

ignition switchfrom"ON" to

~

Depress

brakepedal.

"OFF" position.

~

Do

not start engine, orcheck with

~

Release

brakepedal.

engine stopped.

ID

Start

engine, orcheck withengine run-

~

ning. Depress

accelerator pedal.

.

.

~

Apply

parking brake.

i!J

Release

accelerator pedal.

..

~

Release

parkingbrake.

~

Pin

terminal checkforSMJ typeECM

and

AIT

control unitconnectors

or

Cff~H

Check

afterengine iswarmed upsuffi-

~ For

details regarding theterminal

ciently.

B

arrangement,refertothe foldout page.

~io

~

Voltage

shouldbemeasured witha

lltlllliR~

t~~~18

voltmeter.

[YJ

lJ9j

.

-

Circuit resistance shouldbemeasured

lfJJ

with

anohmmeter.

~

GI-31

•

Page 1400 of 1701

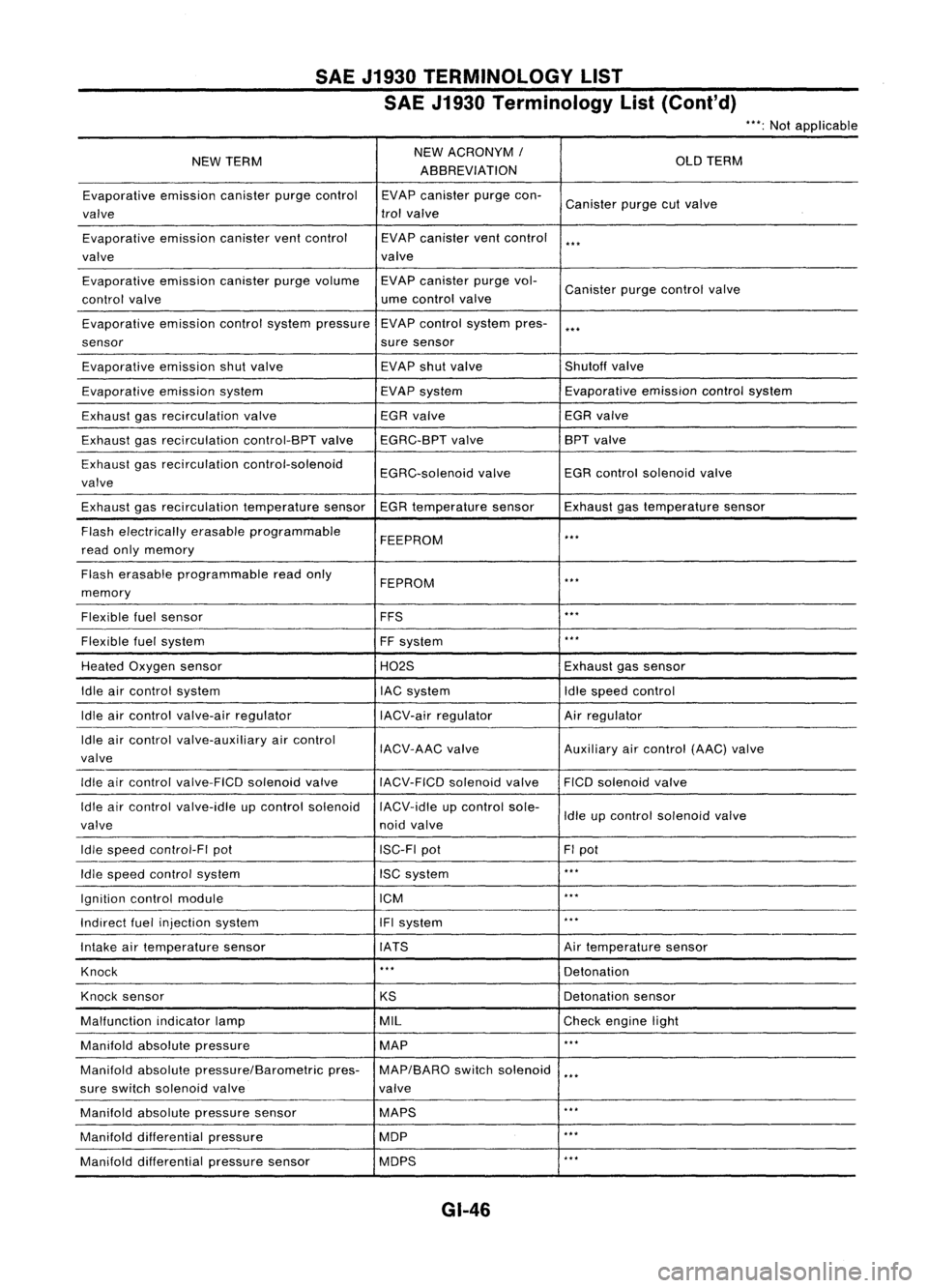

SAEJ1930 TERMINOLOGY LIST

SAE J1930 Terminology List(Cont'd)

***:

Not applicable

NEW TERM NEW

ACRONYM /

OLDTERM

ABBREVIATION

Evaporative emissioncanisterpurgecontrol EVAPcanister purgecon-

Canister purgecutvalve

valve trol

valve

Evaporative emissioncanisterventcontrol EVAPcanister ventcontrol

***

valve valve

Evaporative emissioncanisterpurgevolume EVAPcanister purgevol-

Canister purgecontrol valve

control valve ume

control valve

Evaporative emissioncontrolsystem pressure EVAP

control system pres-

***

sensor suresensor

Evaporative emissionshutvalve EVAP

shutvalve Shutoffvalve

Evaporative emissionsystem EVAPsystem Evaporative

emissioncontrolsystem

Exhaust gasrecirculation valve EGR

valve EGRvalve

Exhaust gasrecirculation control-BPTvalveEGRC-BPT valve BPT

valve

Exhaust gasrecirculation control-solenoid

EGRC-solenoidvalveEGR

control solenoid valve

valve

Exhaust gasrecirculation temperaturesensorEGRtemperature sensorExhaustgastemperature sensor

Flash electrically erasableprogrammable

FEEPROM

***

read onlymemory

Flash erasable programmable readonly

FEPROM

**.

memory

Flexible fuelsensor FFS

***

Flexible fuelsystem

FFsystem

***

Heated Oxygen sensor H02SExhaustgassensor

Idle aircontrol system lACsystem Idlespeed control

Idle aircontrol valve-air regulator IACV-airregulator Airregulator

Idle aircontrol valve-auxiliary aircontrol

IACV-AACvalve Auxiliaryaircontrol (AAC)valve

valve

Idle aircontrol valve-FICO solenoidvalve

IACV-FICDsolenoidvalve FICOsolenoid valve

Idle aircontrol valve-idle upcontrol solenoid IACV-idleupcontrol sole-

Idleupcontrol solenoid valve

valve noidvalve

Idle speed control-FI pot ISC-FIpot FIpot

Idle speed control system ISCsystem

***

Ignition controlmodule ICM

***

Indirect fuelinjection system IFIsystem

***

Intake airtemperature sensor IATS Airtemperature sensor

Knock

***

Detonation

Knock sensor

KSDetonation

sensor

Malfunction indicatorlamp MIL

Checkengine light

Manifold absolutepressure MAP

***

Manifold absolutepressure/Barometric pres-MAP/BARO switchsolenoid

***

sure switch solenoid valve valve

Manifold absolutepressure sensor MAPS

**.

Manifold differential pressure MOP

***

Manifold differential pressuresensor MOPS

***

GI-46

Page 1407 of 1701

PRECAUTIONSANDPREPARATION

Precautions forServicing Compressor

• Plug allopenings toprevent moisture andforeign matterfromentering.

• When thecompressor isremoved, storeitin the same position asitis when mounted onthe car.

• When replacing orrepairing compressor, follow"Maintenance ofLubricant QuantityinCompressor"

exactly. RefertoHA-68.

• Keep friction surfaces betweenclutchandpulley clean.

If

the surface iscontaminated, withlubricant,

wipe itoff byusing aclean waste clothmoistened withthinner.

• After compressor serviceoperation, turnthecompressor shaftbyhand more thanfiveturns inboth

directions. Thiswillequally distribute lubricantinsidethecompressor. Afterthecompressor is

installed, letthe engine idleandoperate thecompressor forone hour.

• After replacing thecompressor magnetclutch,applyvoltage tothe new oneandcheck fornormal

operation.

SpecialService Tools

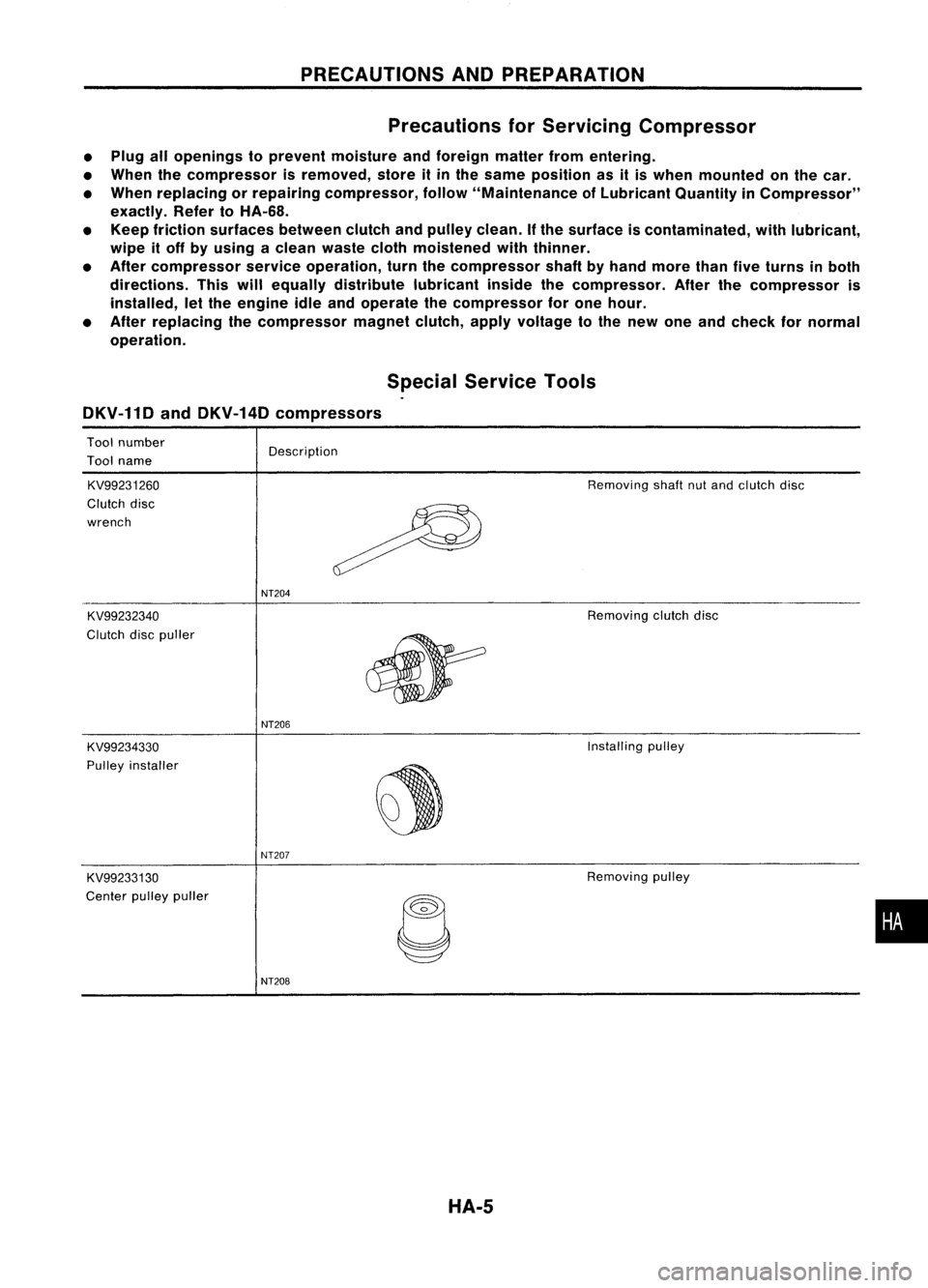

DKV-11D andDKV-14D compressors

Tool number

Tool name

KV99231260

Clutch disc

wrench

KV99232340

Clutch discpuller Description

NT204

Removing

shaftnutand clutch disc

Removing clutchdisc

NT206

KV99234330

Installing

pulley

PUlley installer

~

NT207

KV99233130

Removing

pulley

Center pulleypuller

C

•

NT208

HA-5

Page 1416 of 1701

TROUBLEDIAGNOSES

Contents

How toPerform TroubleDiagnoses forQuick andAccurate Repair HA-15

Operational Check HA-16

Symptom Chart HA-18

Preliminary Check HA-20

PRELIMINARY CHECK1

(A/C

does notblow coldair.) HA-20

PRELIMINARY CHECK2

(Air outlet doesnotchange.) HA-21

PRELIMINARY CHECK3

(Noise) HA-22

PRELIMINARY CHECK4

(I nsufficient heating) HA-23

Performance TestDiagnoses HA-24

INSUFFICIENT COOLING HA-24

Performance Chart HA-26

TEST CONDITION HA-26

TEST READING HA-26

Trouble Diagnoses forAbnormal Pressure HA-27

Harness Layout. HA-31

Circuit Diagram -Air Conditioner HA-34

Wiring Diagram -HEATER - HA-36

Wiring Diagram -AIC - HA-38

Main Power Supply andGround CircuitCheck HA-49

Diagnostic Procedure1

(SYMPTOM: Blowermotordoesnotrotate.) HA-50

Diagnostic Procedure2

(SYMPTOM: Intake doordoes notchange.) HA-52

Diagnostic Procedure3

(SYMPTOM: Magnetclutchdoesnotoperate when

A/C

switch andfanswitch areON.)

- For GAand SRengines HA-54

- For CDengine HA-59

Electrical Components Inspection HA-62

Control Linkage Adjustment HA-64

System Description HA-65

HA-14

Page 1418 of 1701

TROUBLEDIAGNOSES

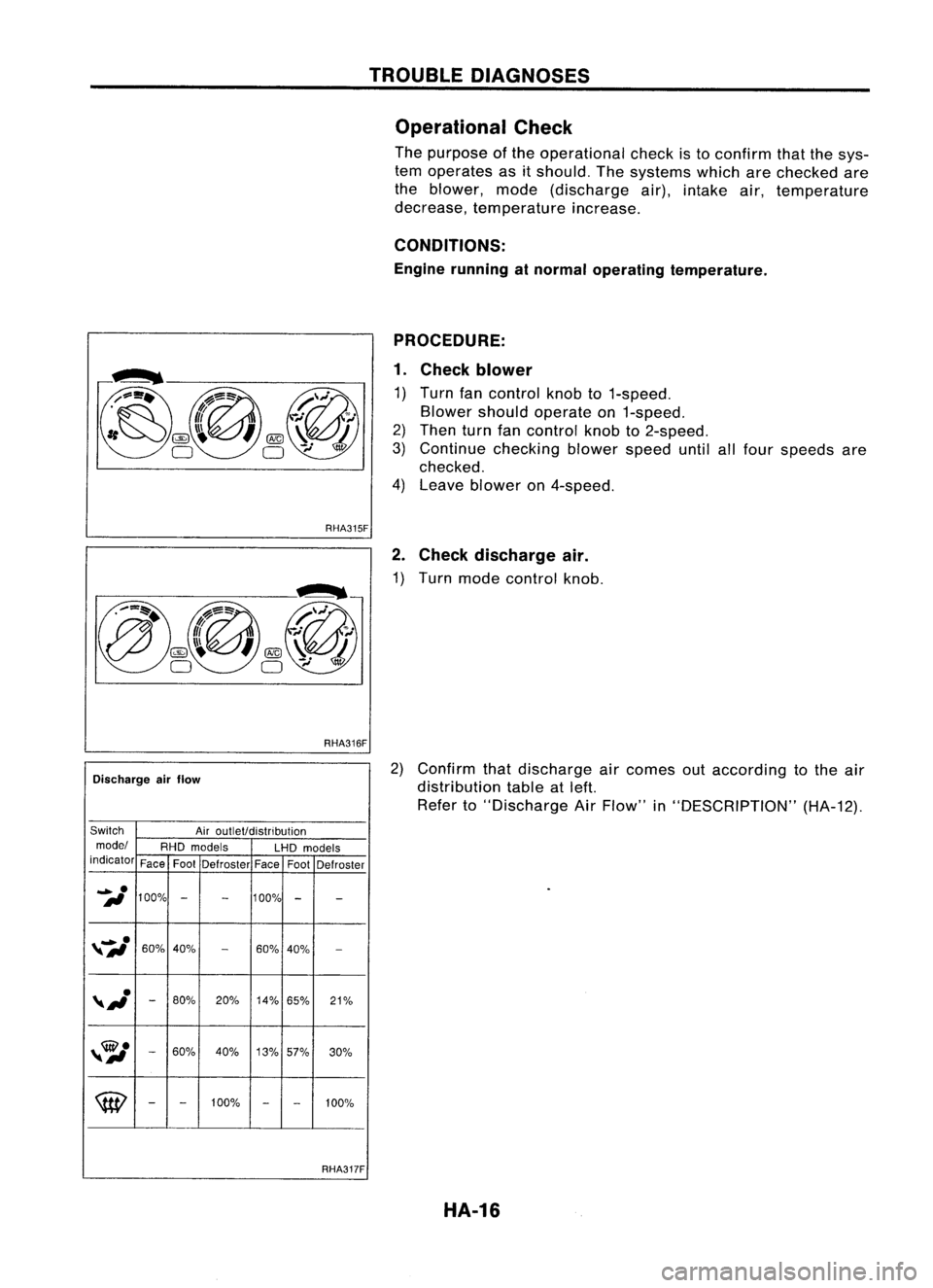

Operational Check

The purpose ofthe operational checkisto confirm thatthesys-

tem operates asitshould. Thesystems whicharechecked are

the blower, mode(discharge air),intake air,temperature

decrease, temperature increase.

CONDITIONS:

Engine running atnormal operating temperature.

RHA315F

RHA316F

Discharge airflow

Switch Airoutlet/distribution

model RHDmodels

LHDmodels

indicator FaceFootDefroster FaceFoot

Defroster

_e

100% 100%

II

-

- -

-

"#Ie

60%

40%

-

60%

40%

-

"J

-

80%

20%14%

65% 21%

,,

60% 40%

13%57%

30%

W

-

-

100%

-

-

100%

RHA317F PROCEDURE:

1. Check blower

1) Turn fancontrol knobto1-speed.

Blower shouldoperate on1-speed.

2) Then turnfancontrol knobto2-speed.

3) Continue checking blowerspeeduntilallfour speeds are

checked.

4) Leave blower on4-speed.

2. Check discharge air.

1) Turn mode control knob.

2) Confirm thatdischarge aircomes outaccording tothe air

distribution tableatleft.

Refer to"Discharge AirFlow" in"DESCRIPTION" (HA-12).

HA-16

Page 1422 of 1701

TROUBLEDIAGNOSES

Preliminary Check

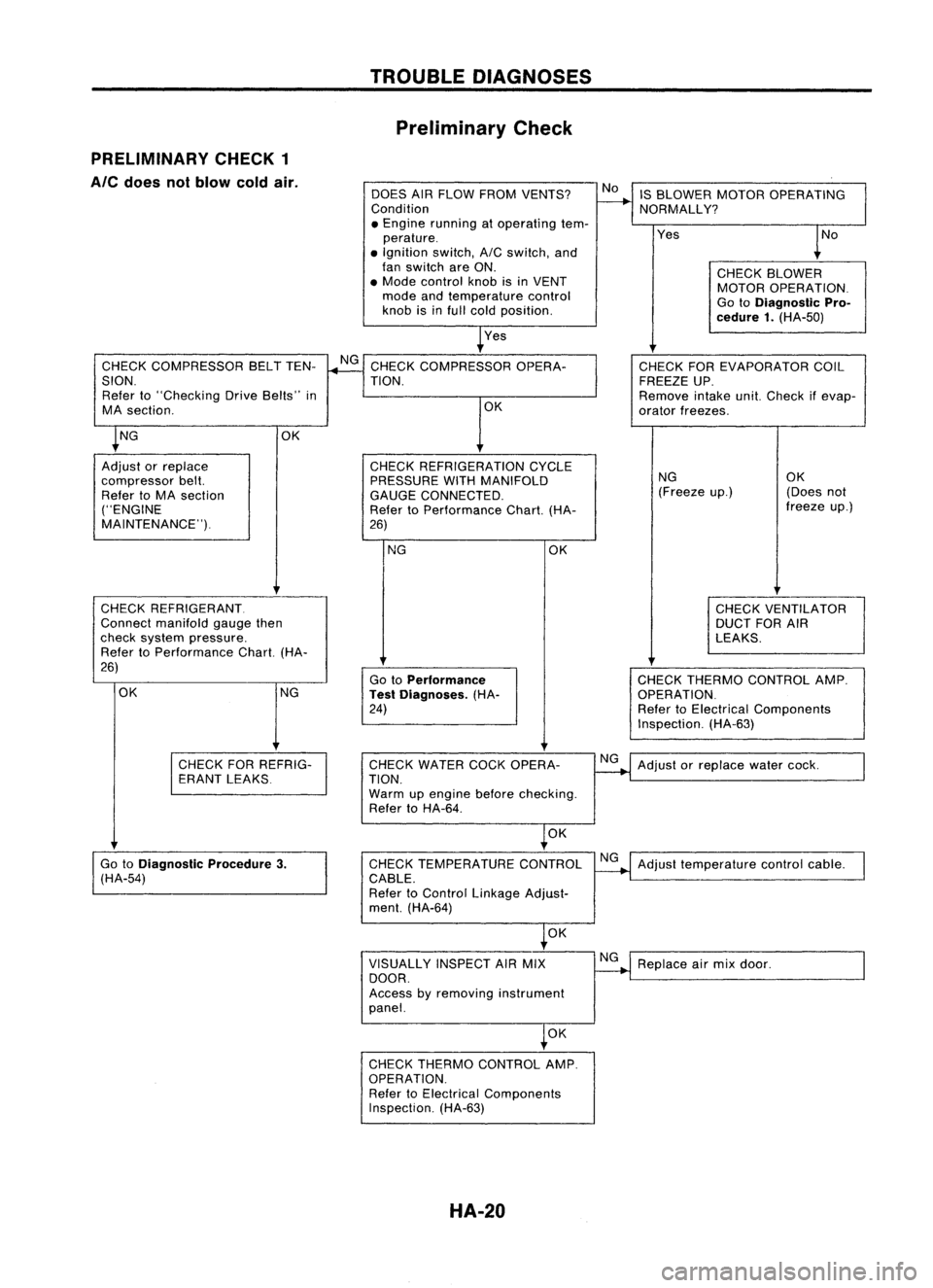

PRELIMINARY CHECK1

Ale

does notblow coldair.

DOESAIRFLOW FROM VENTS?

Condition

• Engine running atoperating tem-

perature .

• Ignition switch,AICswitch, and

fan switch areON.

• Mode control knobisin VENT

mode andtemperature control

knob isinfull cold position.

Yes IS

BLOWER MOTOROPERATING

NORMALLY?

Yes

CHECKBLOWER

MOTOR OPERATION.

Go toDiagnostic Pro-

cedure 1.(HA-50)

CHECK COMPRESSOR BELTTEN-

SION. Refer to"Checking DriveBelts" in

MA section.

CHECK REFRIGERANT.

Connect manifold gaugethen

check system pressure.

Refer toPerformance Chart.(HA-

26)

NG CHECK

THERMO CONTROL AMP.

OPERATION.

Refer toElectrical Components

Inspection. (HA-63)

CHECK

FOREVAPORATOR COIL

FREEZE UP.

Remove intakeunit.Check ifevap-

orator freezes.

NG OK

(Freeze up.) (Doesnot

freeze up.)

CHECK VENTILATOR

DUCT FORAIR

LEAKS.

OK

Go toPerformance

Test Diagnoses. (HA-

24)

NG

CHECK

REFRIGERATION CYCLE

PRESSURE WITHMANIFOLD

GAUGE CONNECTED.

Refer toPerformance Chart.(HA-

26) OK

CHECK

COMPRESSOR OPERA-

TION.

OK

OK NG

Adjust orreplace

compressor belt.

Refer toMA section

("ENGINE

MAINTENANCE").

CHECKFORREFRIG-

ERANT LEAKS CHECK

WATER COCKOPERA-

TION.

Warm upengine beforechecking.

Refer toHA-64.

NG

Adjust orreplace watercock.

OK

Go toDiagnostic Procedure3.

(HA-54) CHECK

TEMPERATURE CONTROL

CABLE.

Refer toControl Linkage Adjust-

ment. (HA-64) NG

Adjust temperature controlcable.

OK

VISUALLY INSPECTAIRMIX

DOOR.

Access byremoving instrument

panel. NG

Replace airmix door.

OK

CHECK THERMO CONTROL AMP.

OPERATION. Refer toElectrical Components

Inspection. (HA-63)

HA-20

Page 1424 of 1701

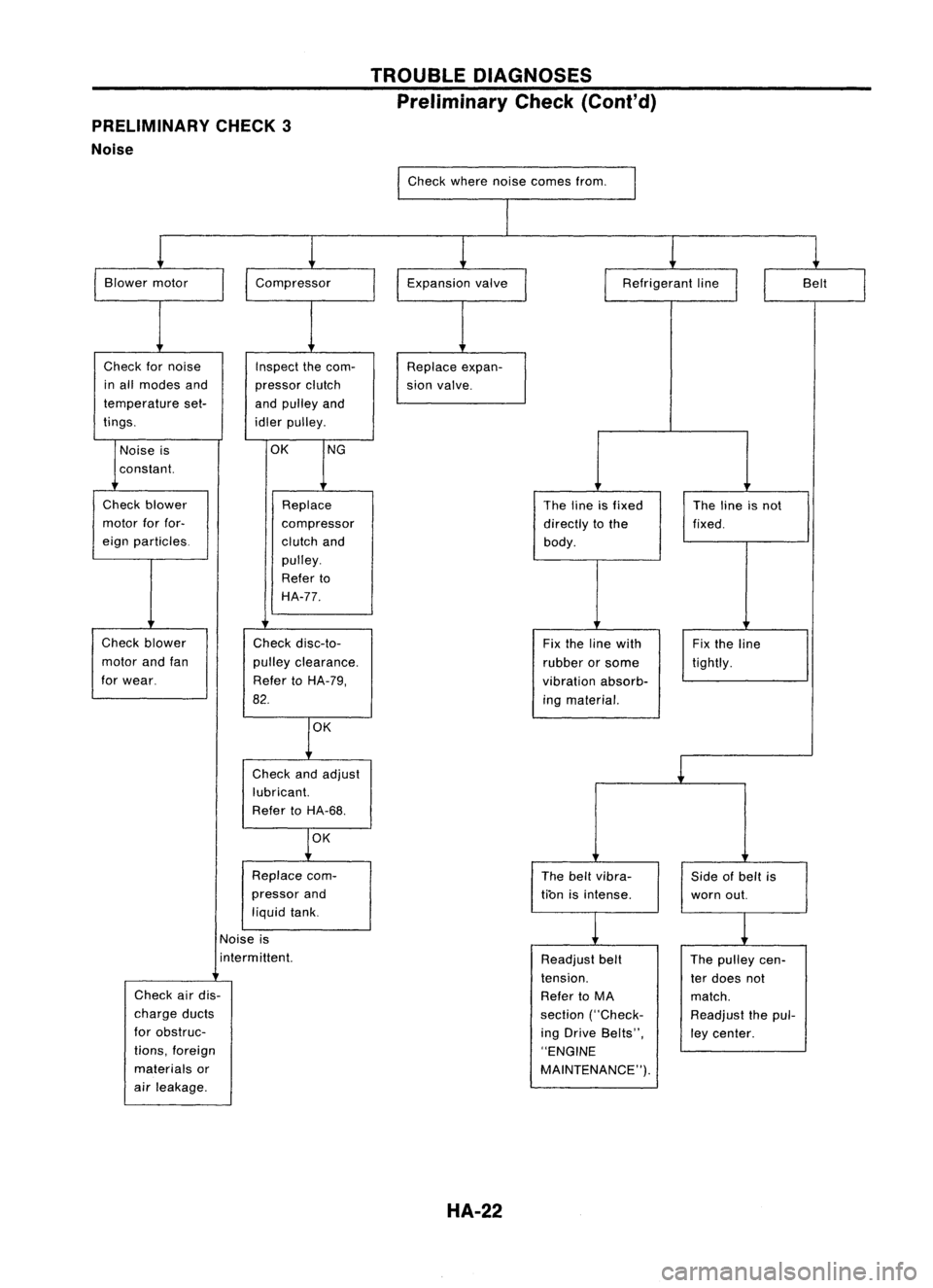

PRELIMINARY CHECK3

Noise TROUBLE

DIAGNOSES

Preliminary Check(Coni'd)

Check wherenoisecomes from.

I

I

Blower motor

Check fornoise

in all modes and

temperature set-

tings.

I

Compressor

Inspect thecom-

pressor clutch

and pulley and

idler pulley. Expansion

valve

Replace expan-

sion valve.

I

Refrigerant line

II

Belt

I

Noise is

constant.

OK

NG

Check blower

motor forfor-

eign particles.

Check blower

motor andfan

for wear. Replace

compressor

clutch and

pulley.

Refer to

HA-77.

Check disc-to-

pulley clearance.

Refer toHA-79,

82.

OK

Check andadjust

lubricant.

Refer toHA-68.

OK

Replace com-

pressor and

liquid tank. The

lineisfixed

directly tothe

body.

Fix the line with

rubber orsome

vibration absorb-

ing material.

The beltvibra-

tion isintense. The

lineisnot

fixed.

Fix the line

tightly.

Side ofbelt is

worn out.

Noise is

i nterm ittent.

Check airdis-

charge ducts

for obstruc-

tions, foreign

materials or

air leakage.

HA-22

Readjust

belt

tension.

Refer toMA

section ("Check-

ing Drive Belts",

"ENGINE

MAINTENANCE"). The

pulley cen-

ter does not

match.

Readjust thepul-

ley center.

Page 1425 of 1701

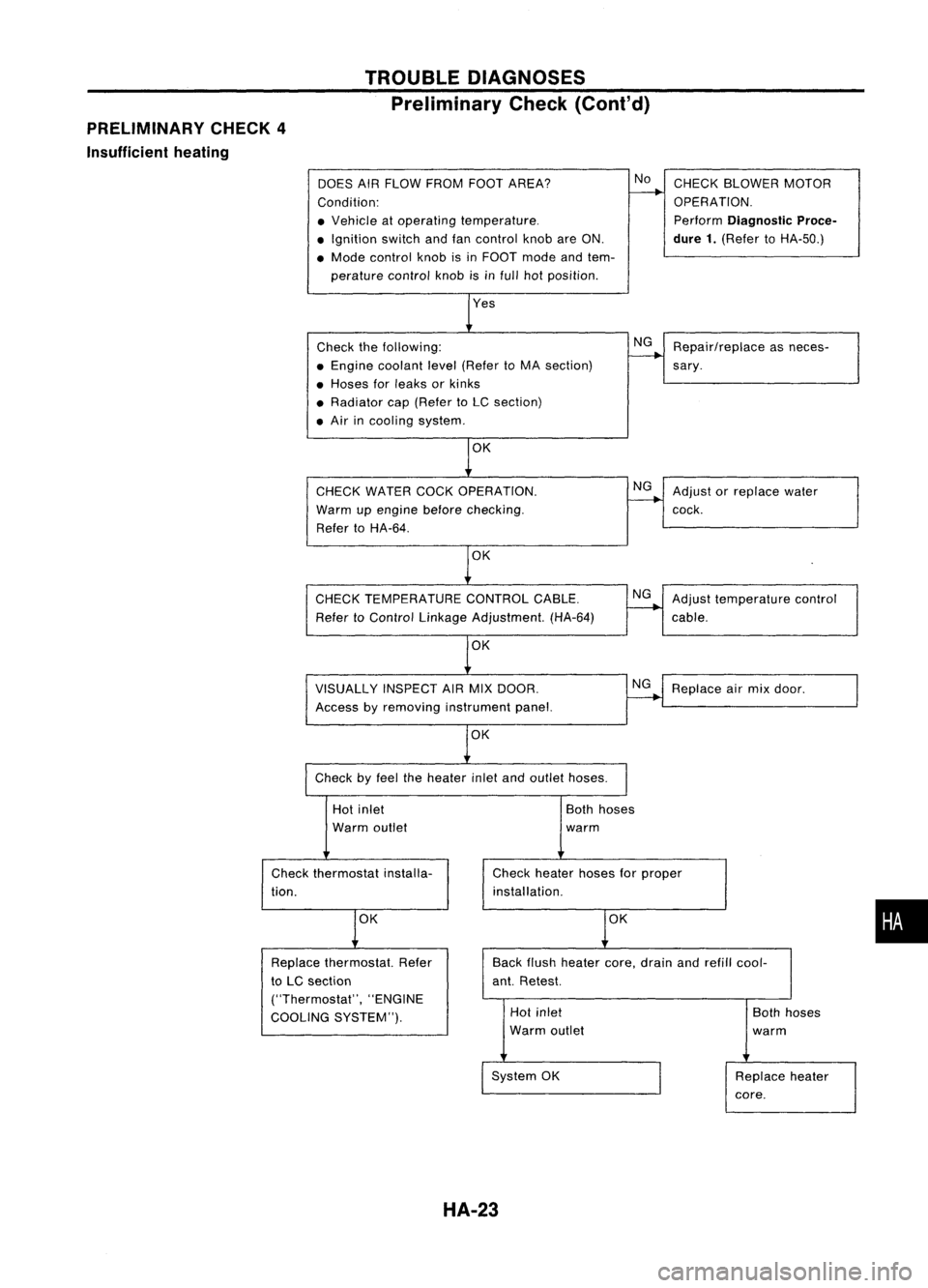

PRELIMINARY CHECK4

Insufficient heating TROUBLE

DIAGNOSES

Preliminary Check(Cont'd)

DOES AIRFLOW FROM FOOTAREA?

Condition:

• Vehicle atoperating temperature .

• Ignition switchandfancontrol knobareON.

• Mode control knobisin FOOT modeandtem-

perature controlknobisinfull hotposition.

Check thefollowing:

• Engine coolant level(Refer toMA section)

• Hoses forleaks orkinks

• Radiator cap(Refer toLC section)

• Air incooling system.

CHECK WATER COCKOPERATION.

Warm upengine before

checking.

Refer toHA-64.

OK

CHECK TEMPERATURE CONTROLCABLE.

Refer toControl Linkage Adjustment. (HA-64)

VISUALLY INSPECTAIRMIX DOOR.

Access byremoving instrument panel.

OK

Check byfeel theheater inletandoutlet hoses.

No

NG

NG

NG

NG

CHECK

BLOWER MOTOR

OPERATION.

Perform

Diagnostic Proce-

dure 1.

(Refer toHA-50.)

Repair/replace asneces-

sary .

Adjust orreplace water

cock.

Adjust temperature control

cable.

Replace airmix door.

Hot inlet

Warm outlet

Check thermostat installa-

tion.

OK

Both

hoses

warm

Check heater hosesforproper

installation.

OK

•

Back

flush heater core,drain andrefill cool-

ant. Retest.

Replace

thermostat. Refer

to LC section

("Thermostat", "ENGINE

COOLING SYSTEM"). Hot

inlet

Warm outlet

System OK

HA-23

Both

hoses

warm

Replace heater

core.