check engine NISSAN ALMERA N15 1995 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 1301 of 1701

TIMINGBELT

Camshaft TimingBelt(Cont'd)

INSPECTION

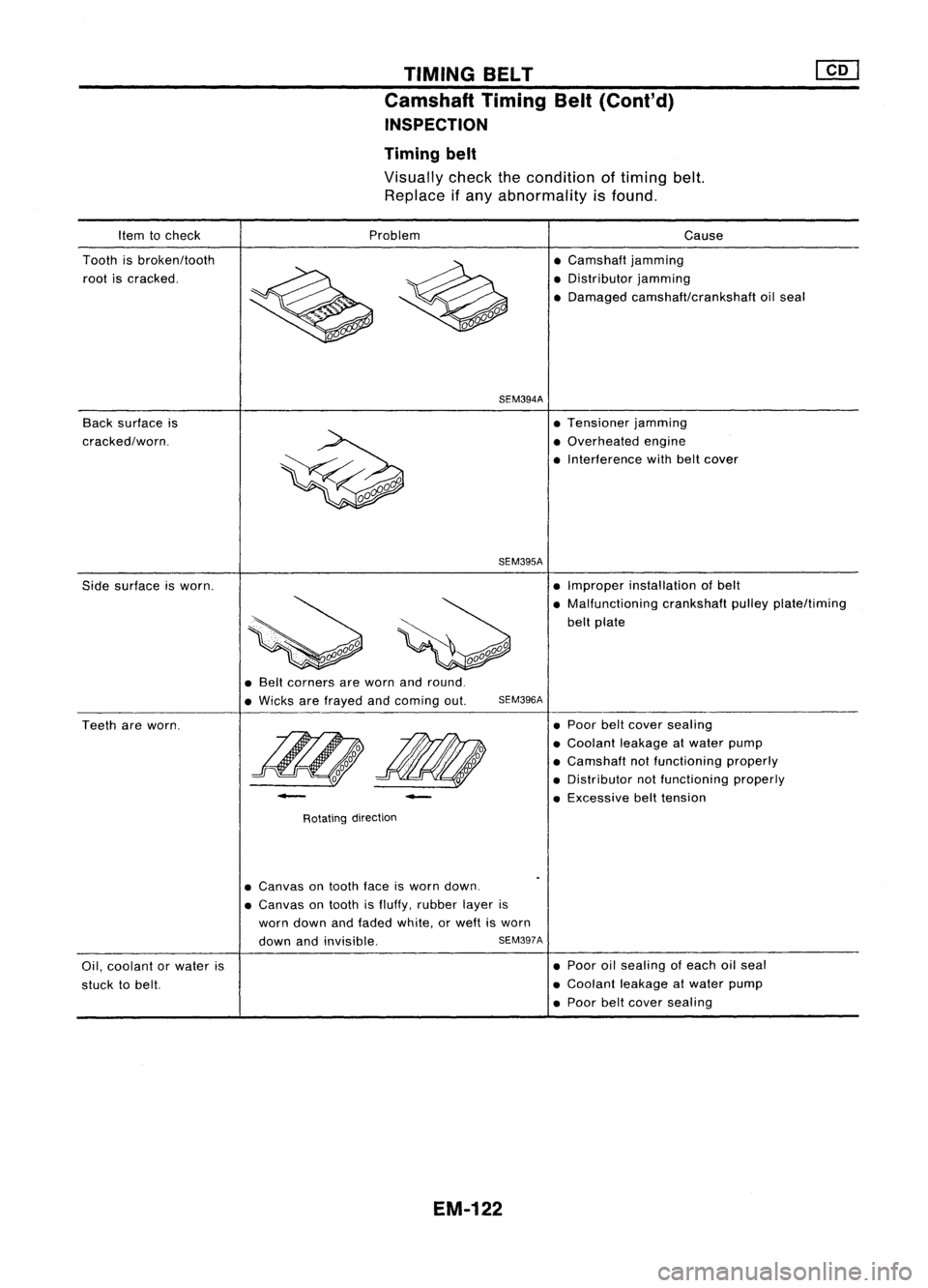

Timing belt

Visually checkthecondition oftiming belt.

Replace ifany abnormality isfound.

Item tocheck

Tooth isbroken/tooth

root iscracked.

Back surface is

cracked/worn. Problem

SEM394A

SEM395A

Cause

• Camshaft jamming

• Distributor jamming

• Damaged camshaft/crankshaft oilseal

• Tensioner jamming

• Overhe

ed

engine

• Interference withbeltcover

Side surface isworn. •

Improper installation ofbelt

• Malfunctioning crankshaftpulleyplate/timing

belt plate

• Belt corners areworn andround.

• Wicks arefrayed andcoming out.

SEM396A

Teeth areworn.

-

Rotating direction

-

•

Poor belt

cover

sealing

• Coolant leakageatwater pump

• Camshaft notfunctioning properly

• Distributor notfunctioning properly

• Excessive belttension

Oil, coolant orwater is

stuck tobelt.

•

Canvas

ontooth faceisworn down.

• Canvas

ontooth isfluffy, rubber layeris

worn down andfaded white, orweft isworn

down andinvisible.

SEM397A

EM-122

•

Poor oilsealing ofeach oilseal

• Coolant leakageatwater pump

• Poor belt

cover

sealing

Page 1315 of 1701

![NISSAN ALMERA N15 1995 Service Manual SEM202

SEM731BA

Grade number

Tightening sequence

r

1

@@

~.~.~

o

,..0

W

@

@ @

Facing frontofengine

(position 2)

SEM528DCYLINDER

HEAD

[£Q]

Inspection {Cont'd)

4. Remove cambracket capsan NISSAN ALMERA N15 1995 Service Manual SEM202

SEM731BA

Grade number

Tightening sequence

r

1

@@

~.~.~

o

,..0

W

@

@ @

Facing frontofengine

(position 2)

SEM528DCYLINDER

HEAD

[£Q]

Inspection {Cont'd)

4. Remove cambracket capsan](/img/5/57349/w960_57349-1314.png)

SEM202

SEM731BA

Grade number

Tightening sequence

r

1

@@

~.~.~

o

,..0

W

@

@ @

Facing frontofengine

(position 2)

SEM528DCYLINDER

HEAD

[£Q]

Inspection {Cont'd)

4. Remove cambracket capsandmeasure maximum widthof

plastigage. Camshaft bearingclearance:

Limit

0.1 mm (0.004 in)

5. Ifclearance appearstoexceed thelimit, replace camshaft

or cylinder head.

• Which partstobe replaced shouldbedecided uponafter

measuring thediameters ofthe parts concerned.

Assembly

1. Install valvecomponent parts.

Install valvespring withitsnarrow pitchsidetoward cylinder

head side.

• Always installnewvalve oilseals.

Refer tooil seal replacement.

• Before installing oilseal, install valve-spring seat.

• When installing valve,applyengine oilonthe valve stem

and lipofvalve oilseal.

• Check whether thevalve faceisfree from foreign matter.

• Install valvespring retainers onthe intake sideandvalve

rotators onthe exhaust side.

• Valve rotators cannotbedisassembled.

2. Install camshaft andbrackets andtighten bracket nutstothe

specified torqueintwo orthree stages.

Camshaft-bracket nuts:

~: 18-22 N'm (1.8-2.2 kg-m, 13-16 ft-Ib)

• Tighten bracketfromcenter tooutside.

• Apply sealant tobrackets No.1and No.5.

• When installing "brackets, setcamshaft sothat thepinof

camshaft fronthead isuppermost.

• Install newcamshaft oilseals.

Refer tooil seal replacement.

17.5 (0.689)

o

o

13.0

(0.512)

NO.1 journal bracket No.5journal bracket

Unit: mm(in)

SEM676D

EM-136

Page 1316 of 1701

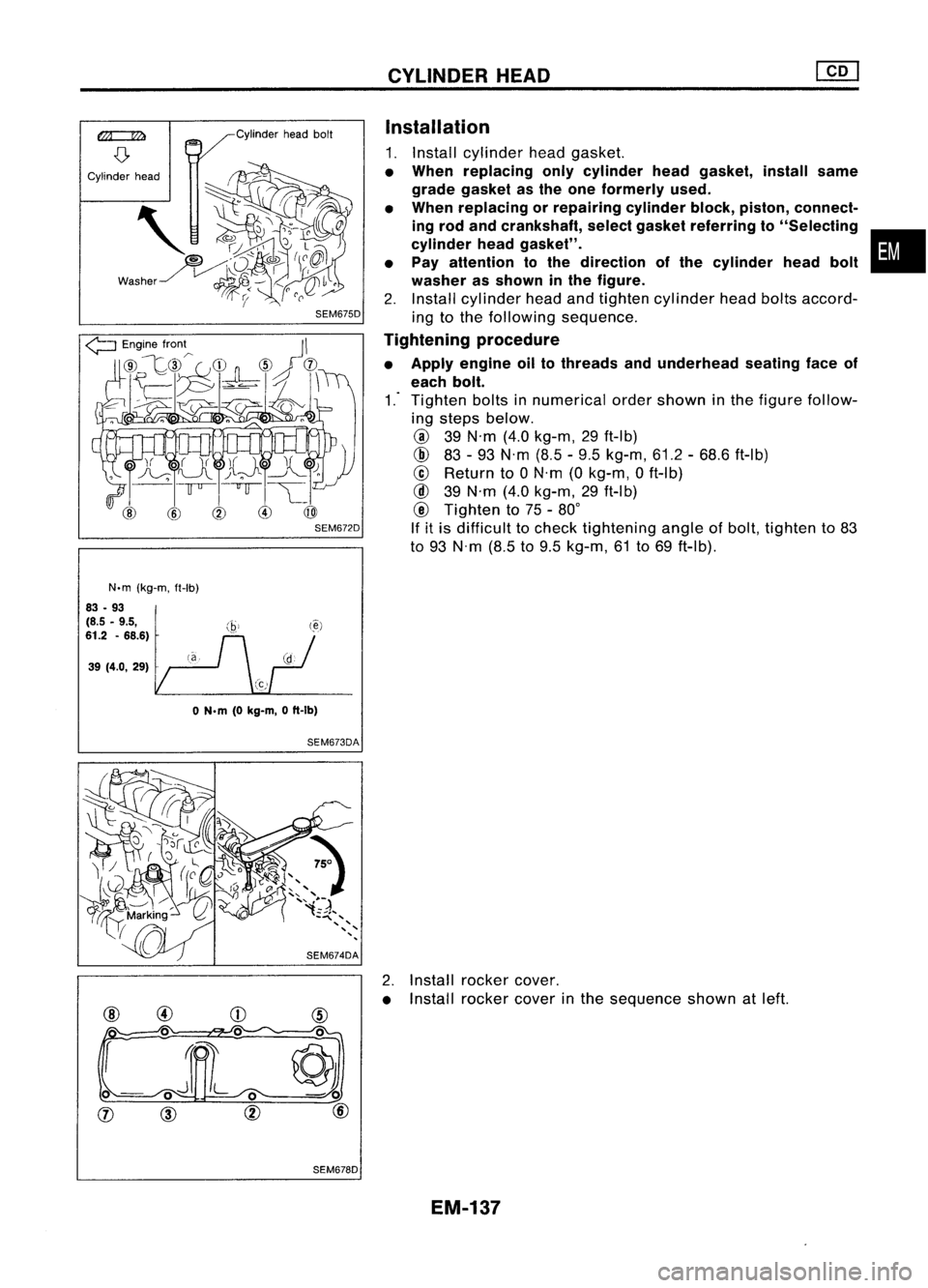

Cylinderheadbolt

N.m (kg-m, ft-Ib)

83 -93

(8.5 -9.5,

(Iii(~)

61.2 -68.6)

39 (4.0, 29)

o

N.m (0kg-m, 0ft-Ib)

SEM673DA

SEM678D CYLINDER

HEAD

Installation

1. Install cylinder headgasket.

• When replacing onlycylinder headgasket, installsame

grade gasket asthe one formerly used.

• When replacing orrepairing cylinderblock,piston, connect-

ing rod and crankshaft, selectgasket referring to"Selecting •

cylinder headgasket".

• Pay attention tothe direction ofthe cylinder headbolt

washer asshown inthe figure.

2. Install cylinder headandtighten cylinder headboltsaccord-

ing tothe following sequence.

Tightening procedure

• Apply engine oiltothreads andunderhead seatingfaceof

each bolt.

1.-

Tighten boltsinnumerical ordershown inthe figure follow-

ing steps below.

@

39N'm (4.0kg-m, 29ft-Ib)

@

83-93 N'm (8.5-9.5 kg-m, 61.2-68.6 ft-Ib)

@

Return to0N'm (0kg-m, 0ft-Ib)

@

39N'm (4.0kg-m, 29ft-Ib)

@

Tighten to75 -80°

If itis difficult tocheck tightening angleofbolt, tighten to83

to 93 N'm (8.5to9.5 kg-m, 61to69 ft-Ib).

2. Install rocker cover.

• Install rocker coverinthe sequence shownatleft.

EM-137

Page 1329 of 1701

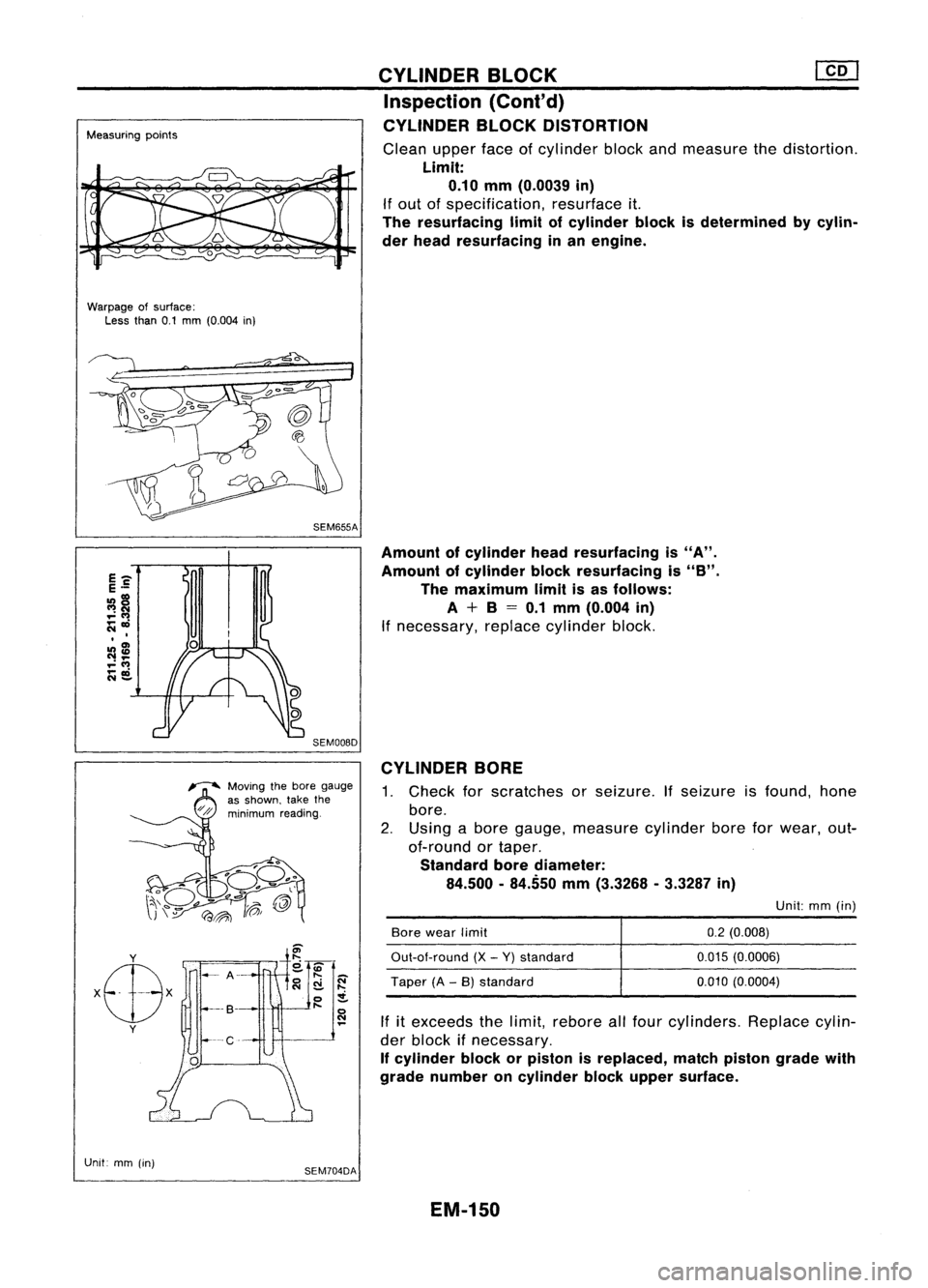

Measuringpoints

Warpage ofsurface:

Less than0.1mm (0.004 in)

SEM655ACYLINDER

BLOCK

Inspection (Cont'd)

CYLINDER BLOCKDISTORTION

Clean upperfaceofcylinder blockandmeasure thedistortion.

Limit:

0.10

mm

(0.0039

in)

If out ofspecification, resurfaceit.

The resurfacing limitofcylinder blockisdetermined bycylin-

der head resurfacing inan engine.

SEM008D

Amount

ofcylinder headresurfacing is"A".

Amount ofcylinder blockresurfacing is"B".

The maximum limitisas follows:

A + B=0.1

mm

(0.004

in)

If necessary, replacecylinder block.

~ Moving thebore gauge

as shown, takethe

//p'

minimum reading.

CYLINDER

BORE

1. Check forscratches orseizure. Ifseizure isfound, hone

bore.

2. Using abore gauge, measure cylinderboreforwear, out-

of-round ortaper.

Standard borediameter:

84.500 -84.550

mm

(3.3268 -3.3287

in)

Unit:mm(in)

If itexceeds thelimit, rebore allfour cylinders. Replacecylin-

der block ifnecessary.

If cylinder blockorpiston isreplaced, matchpiston gradewith

grade number oncylinder blockupper surface.

y

Unit mm(in)

SEM704DA

Bore

wear limit

Out-aI-round (X-Y) standard

Taper (A-B) standard

0.2

(0.008)

0.015 (0.0006)

0.010 (0.0004)

EM-150

Page 1335 of 1701

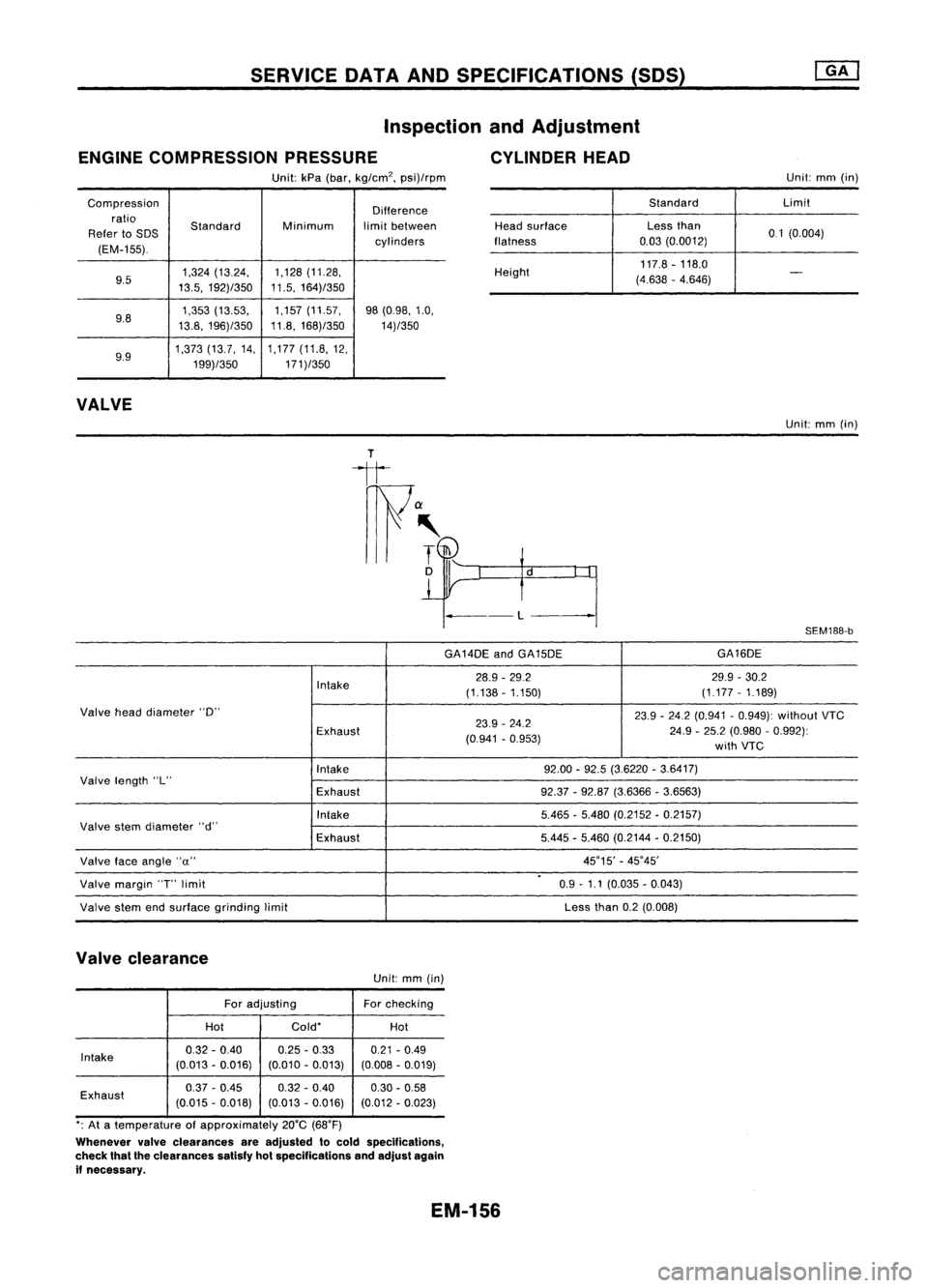

SERVICEDATAANDSPECIFICATIONS (50S)

Inspection andAdjustment

ENGINE COMPRESSION PRESSURE CYLINDERHEAD

Unit: kPa(bar, kg/cm

2,

psi)/rpm Unit:

mm(in)

Compression Difference

ratio Standard Minimumlimitbetween

Refer toSDS

cylinders

(EM-155).

9.5 1,324

(13.24, 1,128

(11.28,

13.5, 192)/350 11.5,

164)/350

9.8 1,353

(13.53, 1,157

(11.57,

98(0.98, 1.0,

13.8, 196)/350 11.8,

168)/350

14)/350

9.9 1,373

(13.7,14, 1,177

(11.8,12,

199)/350 171)/350

VALVE

Standard

Limit

Head surface Lessthan

0.1(0.004)

flatness 0.03

(0.0012)

Height 117.8

-118.0

(4.638 -4.646)

-

Unit: mm(in)

---L

SEM188-b

GA14DE andGA15DE GA16DE

Intake 28.9

-29.2 29.9-30.2

(1.138 -1.150) (1.177

-1.189)

Valve headdiameter "0"

23.9-24.2 (0.941 -0.949): without VTC

Exhaust 23.9

-24.2

24.9-25.2 (0.980 -0.992):

(0.941 -0.953)

withVTC

Intake 92.00

-92.5 (3.6220 -3.6417)

Valve length "L"

Exhaust 92.37-92.87 (3.6366 -3.6563)

Intake 5.465-5.480 (0.2152 -0.2157)

Valve stemdiameter "d"

Exhaust 5.445

-5.460 (0.2144 -0.2150)

Valve faceangle "u" 45°15'

-45°45'

.

Valve margin

'T'

limit 0.9-1.1 (0.035 -0.043)

Valve stemendsurface grinding limit Less

than0.2(0.008)

Valve clearance

Unit:mm(in)

For adjusting Forchecking

Hot Cold*

Hot

Intake 0.32

-0.40 0.25

-0.33

0.21-0.49

(0.013 -0.016) (0.010-0.013) (0.008-0.019)

Exhaust 0.37

-0.45 0.32-0.40

0.30-0.58

(0.015 -0.018) (0.013-0.016) (0.012-0.023)

*: At atemperature ofapproximately 20°C(68°F)

Whenever valveclearances areadjusted tocold specifications,

check thattheclearances satisfyhotspecifications andadjust again

if necessary.

EM-156

Page 1355 of 1701

GENERALINFORMATION •

SECTION

G

I

CONTENTS

PRECAUTIONS 2

Supplemental RestraintSystem(SRS)"AIR

BAG" (DualAirBag System) 2

Supplemental RestraintSystem(SRS)"AIR

BAG" (Single AirBag System) 2

Precautions forNATS V2.0(ForGasoline

Engine Model) 3

General Precautions 3

Precautions forMultiport FuelInjection

System orECCS Engine 5

Precautions forThree WayCatalyst 5

Engine Oils 5

Precautions forFuel 6

HOW TOUSE THIS

MANUAL 7

HOW TOREAD WIRING DIAGRAMS 9

Sample/Wiring Diagram-EXAMPL - 9

Description 11

Wiring Diagram Codes(CellCodes) 17

HOW TOPERFORM EFFICIENT DIAGNOSIS FOR

AN ELECTRICAL INCIDENT 18

Work Flow 18

Incident Simulation Tests 19

Circuit Inspection 23

HOW

TOFOLLOW FLOWCHART INTROUBLE

DIAGNOSES 29

CONSULT CHECKING SYSTEM

32

Function andSystem Application 32

Lithium BatteryReplacement.. 32

Checking Equipment 32

IDENTIFICATION INFORMATION 33

Model Variation 33

Identification Number 36

Di mens ions 39

Wheels andTires 39

LIFTING POINTSANDTOW TRUCK TOWING ..40

Preparation 40

Board-on

Lift

40

Garage JackandSafety Stand 41

2-pole Lift 42

Tow Truck Towing 43

TIGHTENING TORQUEOFSTANDARD BOLTS

44

SAE J1930 TERMINOLOGY LIST 45

SAE J1930 Terminology List.. 45

Page 1359 of 1701

PRECAUTIONS

General Precautions (Cont'd)

• After disconnecting vacuumorair hoses, attachatag to

indicate theproper connection.

• Use only thefluids andlubricants specifiedinthis manual.

• Use approved bondingagent,sealants ortheir equivalents

when required.

• Use tools andrecommended specialtoolswhere specified

for safe andefficient servicerepairs.

• When repairing thefuel, oil,water, vacuum orexhaust

systems, checkallaffected linesforleaks.

• Dispose ofdrained oilorthe solvent usedforcleaning parts

in an appropriate manner.

Precautions forMultiport FuelInjection System

or ECCS Engine

• Before connecting ordisconnecting anyharness connector

for the multiport fuelinjection systemorEGM (EGGS control

module):

Turn ignition switchto"OFF" position.

Disconnect negativebatteryterminal.

Otherwise, theremaybedamage toEGM.

• Before disconnecting pressurizedfuellinefrom fuelpump to

injectors, besure torelease fuelpressure.

• Becareful nottojar components suchasEGM andmass air

flow sensor.

Precautions forThree WayCatalyst

If a large amount ofunburned fuelflows intothecatalyst, the

catalyst temperature willbeexcessively high.Toprevent this,

follow theinstructions below:

• Use unleaded gasolineonly.Leaded gasoline willseriously

damage thethree waycatalyst.

• When checking forignition sparkormeasuring engine

compression, maketestsquickly andonly when necessary.

• Donot run engine whenthefuel tank level islow, otherwise

the engine maymisfire causing damage tothe catalyst.

Do not place thevehicle onflammable material.Keepflamma-

ble material offthe exhaust pipeandthethree waycatalyst.

Engine Oils

Prolonged andrepeated contactwithused engine oilmay

cause skincancer. Trytoavoid direct skincontact withused oil.

If skin contact is.made, washthoroughly withsoap orhand

cleaner assoon aspossible.

HEALTH PROTECTION PRECAUTIONS

• Avoid prolonged andrepeated contactwithoils, particularly

used engine oils.

• Wear protective clothing,including impervious gloves

where practicable.

• Donot putoily rags inpockets.

• Avoid contaminating clothes,particularly underpants, with

oil.

• Heavily soiledclothing andoil-impregnated footwearshould

not beworn. Overalls mustbecleaned regularly.

• First Aidtreatment shouldbeobtained immediately foropen

cuts andwounds.

• Use barrier creams, applying thembefore eachwork

period, tohelp theremoval ofoil from theskin.

GI-5

•

Page 1360 of 1701

PRECAUTIONS

Engine Oils(ConI' d)

• Wash withsoap andwater toensure alloil isremoved (skin

cleansers andnailbrushes willhelp). Preparations contain-

ing lanolin replace thenatural skinoilswhich havebeen

removed.

• Donot use gasoline, kerosine, dieselfuel,gasoil,thinners

or solvents forcleaning skin.

• If

skin disorders develop,obtainmedical advicewithout

delay.

• Where practicable, degreasecomponents priortohandling.

• Where thereisarisk ofeye contact, eyeprotection should

be worn, forexample, chemicalgogglesorface shields; in

addition aneye wash facility should beprovided.

ENVIRONMENTAL PROTECTIONPRECAUTIONS

Burning usedengine oilinsmall space heaters orboilers can

be recommended onlyforunits ofapproved design.Theheat-

ing system mustmeettherequirements ofHM Inspectorate of

Pollution forsmall burners ofless than 0.4MW. Ifin doubt check

with theappropriate localauthority and/ormanufacturer ofthe

approved appliance.

Dispose ofused oiland used oilfilters through authorized

waste disposal contractors tolicensed wastedisposal sites,or

to the waste oilreclamation trade.Ifin doubt, contact thelocal

authority foradvice ondisposal facilities.

It is illegal topour used oilontothe ground, downsewers or

drains, orinto water courses.

The regulations concerningthepollution ofthe environment

will vary between regions.

Precautions forFuel

GASOLINE ENGINE:

For Europe

Unleaded gasolineofat least 95octane (RON)

CAUTION: Do not use leaded gasoline. Usingleaded gasoline willdamage

the catalytic converter.

Except Europe

Unleaded gasolineofat least 91octane (RON)

DIESEL ENGINE*:

Diesel fuelofat least 50cetane

If two types ofdiesel fuelareavailable, usesummer or

winter fuelproperly according tothe following temperature

conditions.

• Above -rc(20°F) Summer typediesel fuel.

• Below

-rc

(20°F) Wintertypediesel fuel.

CAUTION:

• Donot use home heating oil,gasoline, orother alternate

fuels inyour diesel engine. Theuseofthose cancause

engine damage.

• Donot use summer fuelattemperature below_7°C(20°F).

The cold temperatures willcause waxtoform inthe fuel. As

a result, itmay prevent theengine fromrunning smoothly.

• Donot add gasoline orother alternate fuelstodiesel fuel.

GI-6

Page 1362 of 1701

HOWTOUSE THIS MANUAL

ManualTransaxle/Transmission

Automatic Transaxle/

Transmission

Air Conditioner

Power Steering

Special Service Tools

Society ofAutomotive Engineers,

Inc.

Automatic Transmission Fluid

Drive range 1stgear

Drive range 2ndgear

Drive range 3rdgear

Drive range 4thgear

Overdrive

2nd range 2ndgear

2nd range 1stgear

1st range 2ndgear

1st range 1stgear

A/C

PIS

Tool SAE

ATF

0

1

O

2

0

3

0

4

00

2

2

2

1

1

2

1

1

•

The following

SYMBOLS ANDABBREVIATIONS

areused:

to;J,

l\tI

Tightening torque M/T

IE!

Shouldbelubricated withgrease. A/T

Unless otherwise indicated,use

recommended multi-purpose

grease.

Should belubricated withoil.

Sealing point

Checking point

Always replaceafterevery disas-

sembly.

Apply petroleum jelly.

Apply ATF.

Select withproper thickness.

Adjustment isrequired.

Service DataandSpecifications

Left-Hand, Right-Hand

Front, Rear

IE!

~

@

*

1I

SDS LH, RH

FR, RR

• The

UNITS

giveninthis manual areprimarily expressed asthe SlUNIT (International SystemofUnit),

and alternatively expressedinthe metric system andinthe yard/pound system.

"Example" Tightening torque:

59 -78 N'm (6.0-8.0 kg-m, 43-58 ft-Ib)

• TROUBLE DIAGNOSES

areincluded insections dealingwithcomplicated components.

• SERVICE DATAANDSPECIFICATIONS

arecontained atthe end ofeach section forquick reference

of data.

• The captions

WARNING

and

CAUTION

warnyouofsteps thatmust befollowed toprevent personal

injury and/or damage tosome partofthe vehicle.

WARNING

indicatesthepossibility ofpersonal injuryifinstructions arenotfollowed.

CAUTION

indicatesthepossibility ofcomponent damageifinstructions arenotfollowed.

BOLD TYPED STATEMENTS

except

WARNING

and

CAUTION

giveyouhelpful information.

GI-8

Page 1370 of 1701

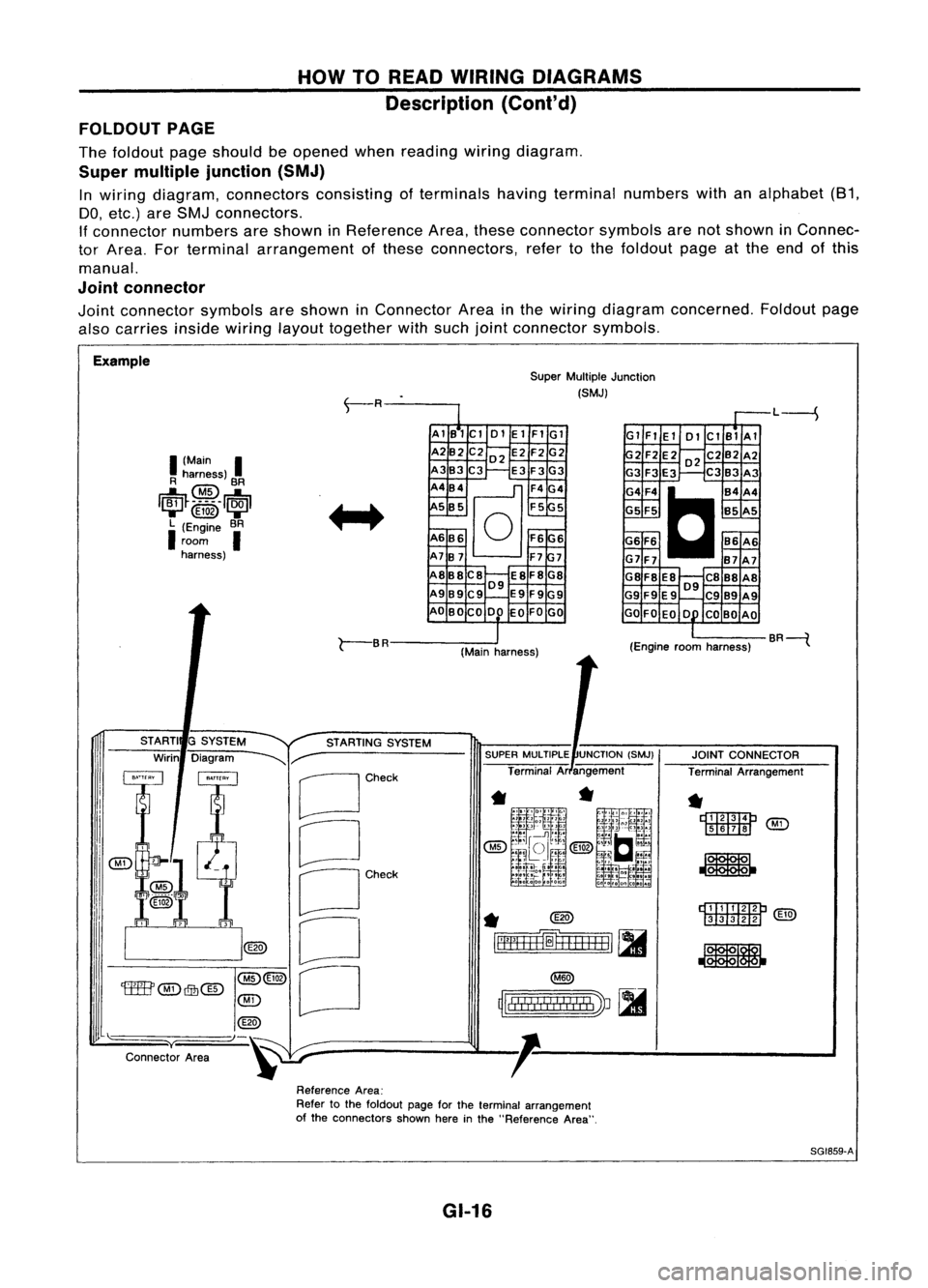

HOWTOREAD WIRING DIAGRAMS

Description (Cont'd)

FOLDOUT PAGE

The foldout pageshould beopened whenreading wiringdiagram.

Super multiple junction (SMJ)

In wiring diagram, connectors consistingofterminals havingterminal numbers withanalphabet (81,

DO, etc.) areSMJ connectors.

If connector numbersareshown inReference Area,these connector symbolsarenotshown inConnec-

tor Area. Forterminal arrangement ofthese connectors, refertothe foldout pageatthe end ofthis

manual.

Joint connector

Joint connector symbolsareshown inConnector Areainthe wiring diagram concerned. Foldoutpage

also carries

insidewiring

layouttogether withsuch jointconnector symbols.

Example SuperMultiple Junction

(SMJ)

L----S

I

(Main

I

R harness)

@

BR

1~~_~_5 __

1~1

....... @ID .......

L (Engine BR

I

room

I

harness) AlB1Cl

01ElFIGl

A2B2 C202 E2F2G2

A3B3C3 E3F3G3

A4B4

@]

F4G4

5 B5 F55

A6B6

0

F6G6

A7B7 F77

A8B8C8 E8F8G8

09

A989C9 E9F9G9

AO BOCO DO EOFOGO Gl

FlEl 01ClBlAl

2F2E202C2B2A2

G3 F3E3 C3B3 A3

G4F4

C

B4A4

G5 F5 B5A5

G6 F6 86A6

G7F7 B7A7

G8F8 E8 C888A8

09

G9 F9E9 C989A9

GO FOEO 0 COBO AO

r-

BR

(Mainharness) (Engine

roomharness) BR----{

rDI.TI:IImP

[ill![ill]

@g)

JOINT

CONNECTOR

Terminal Arrangement

*

r::t::rrm::m:J

'M'i'

[ill]II!J ~

*

~

rll"

!! !

I

!

I II

!I

I

'J ~

~lllll!I!!lIllbV ~

SUPER

MULTIPLE UNCTION(SMJ)

Terminal Arangement

*

@)

~=fH+H=1

[II

STARTING

SYSTEM

G

SYSTEM

Diagram

~r-

[Jcheck

CJ

OCh~'

o

[J

STARTI

Wirin

@(3)

'tffB'

@)

Qfu@

@)

@

"-)-~

y

Connector Area

ReferenceArea:

Refer tothe foldout pageforthe terminal arrangement

of the connectors shownhereinthe "Reference Area".

SG1859-A

GI-16