engine NISSAN ALMERA N15 1995 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 881 of 1701

Checkcooling fanlow

speed control circuit.

(Go to

I

PROCEDURE A

I.)

Check cooling fanhigh

speed control circuit.

(Go to

I

PROCEDURE B

I.)

NG

NG

OK

INSPECTION

START

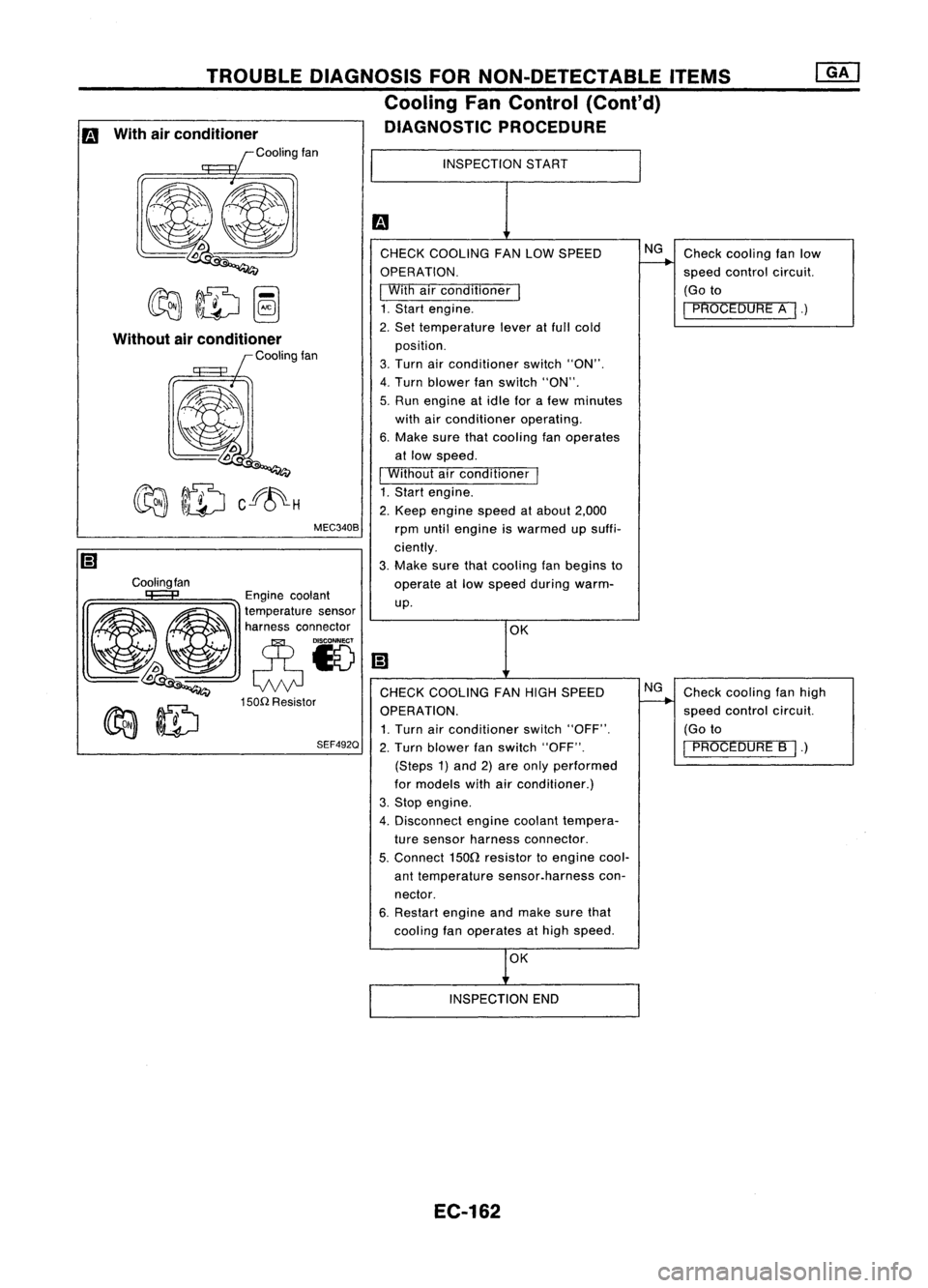

CHECK COOLING FANLOW SPEED

OPERATION.

I

With airconditioner

I

1. Start engine.

2. Set temperature leveratfull cold

position.

3. Turn airconditioner switch"ON".

4. Turn blower fanswitch "ON".

5. Run engine atidle forafew minutes

with airconditioner operating.

6. Make surethatcooling fanoperates

at low speed.

I

Without airconditioner

I

1. Start engine.

2. Keep engine speedatabout 2,000

rpm until engine iswarmed upsuffi-

ciently.

3. Make surethatcooling fanbegins to

operate atlow speed during warm-

up.

MEC340B

TROUBLE

DIAGNOSIS FORNON-DETECTABLE ITEMS

Cooling FanControl (Cant'd)

DIAGNOSTIC PROCEDURE

Cooling fan

Without

airconditioner

Coolingfan

Engine coolant

~ ~ ~a~~:;:t:a::;'~~'

~~ eN

lDoo

Q

CHECKCOOLING FANHIGH SPEED

150n

Resistor

~ ~ OPERATION.

~ ~ 1.Turn airconditioner switch"OFF".

SEF492Q

2.Turn blower fanswitch "OFF".

(Steps 1)and 2)are only performed

for models withairconditioner.)

3. Stop engine.

4. Disconnect enginecoolant tempera-

ture sensor harness connector.

5.

Connect

1500

resistor toengine cool-

ant temperature sensor.harness con-

nector.

6. Restart engineandmake surethat

cooling fanoperates athigh speed.

m

With airconditioner

Coolingfan

OK

INSPECTION END

EC-162

Page 882 of 1701

•

Check

thefollowing.

• 10A fuse

• 30A fusible link

• Harness foropen or

short between cooling

fan relay-1 andfuse

• Harness foropen or

short between cooling

fan relay-1 andbattery

If NG, repair harness or

connectors.

OK

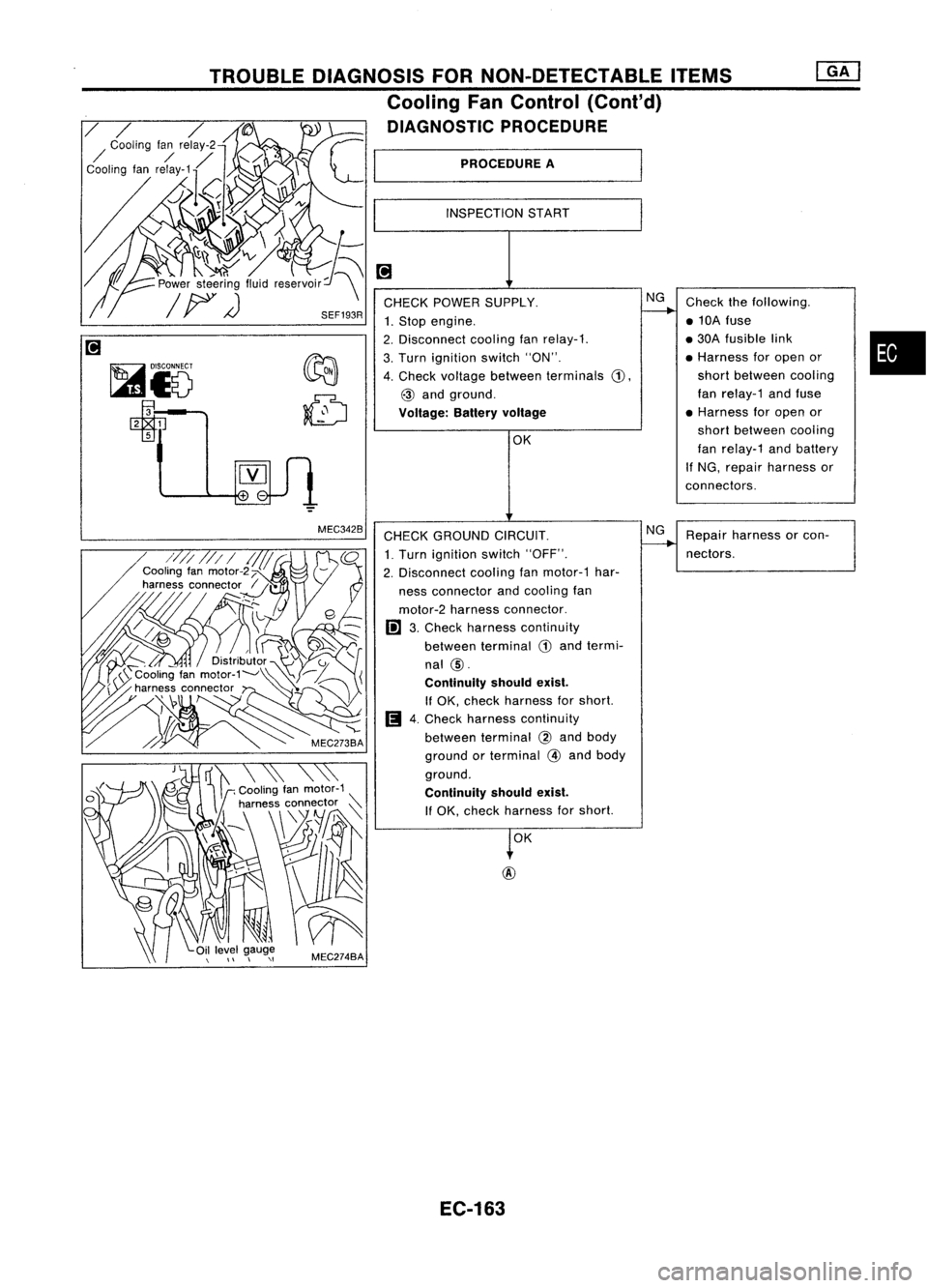

PROCEDURE

A

INSPECTION START

CHECK POWER SUPPLY. NG

1. Stop engine.

2. Disconnect coolingfanrelay-1.

3. Turn ignition switch"ON".

4. Check voltage between terminals

G),

@

and ground.

Voltage: Batteryvoltage

SEF193R

TROUBLE

DIAGNOSIS FORNON-DETECTABLE ITEMS

Cooling FanControl (Cont'd)

DIAGNOSTIC PROCEDURE

MEC342B

CHECKGROUND CIRCUIT.

1. Turn ignition switch"OFF".

2. Disconnect coolingfanmotor-1 har-

ness connector andcooling fan

motor-2 harness connector.

I!l

3.Check harness continuity

between terminal

CD

and termi-

nal

@.

Continuity shouldexist.

If OK, check harness forshort.

Ii

4.Check harness continuity

between terminal

@

and body

ground orterminal

@

and body

ground.

Continuity shouldexist.

If OK, check harness forshort.

OK

@

NG

Repair harness orcon-

nectors.

EC-163

Page 884 of 1701

TROUBLEDIAGNOSIS FORNON-DETECTABLE ITEMS

Cooling FanControl (Cont'd)

•

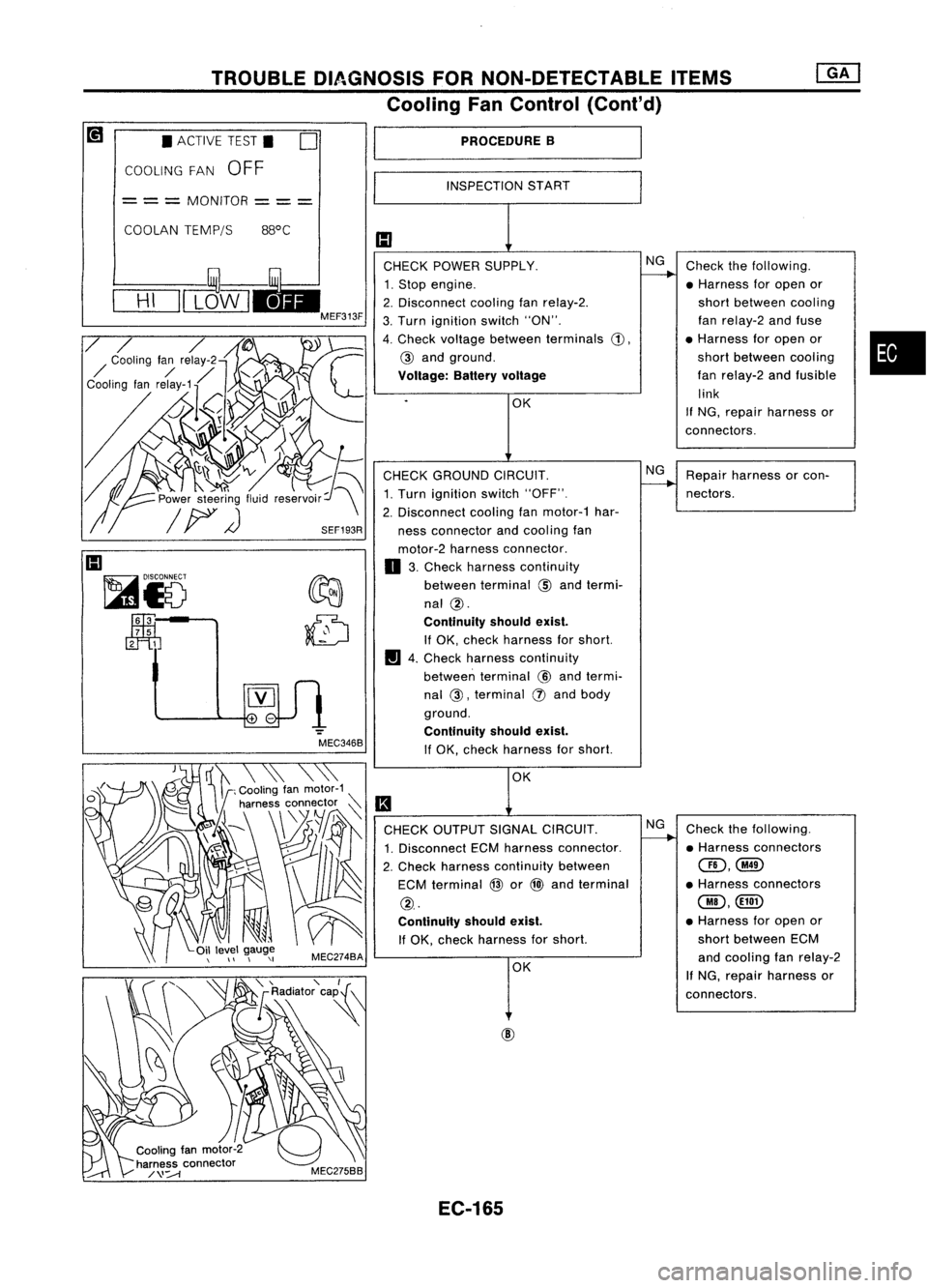

PROCEDURE

B

INSPECTION START

1:1

CHECK POWER SUPPLY. NG

Check thefollowing.

----..

1. Stop engine. •Harness foropen or

2. Disconnect coolingfanrelay-2. short

between cooling

3. Turn ignition switch"ON". fan

relay-2 andfuse

4. Check voltage between terminals

G),

•

Harness foropen or

@

and ground. short

between cooling

Voltage: Batteryvoltage

fan

relay-2 andfusible

.

OK link

If

NG, repair harness or

connectors.

CHECK GROUND CIRCUIT. NG

Repair harness orcon-

1. Turn ignition switch"OFF".

----..

nectors.

2. Disconnect coolingfanmotor-1 har-

ness connector andcooling fan

motor-2 harness connector.

o

3.Check harness continuity

between terminal

@

and termi-

nal

@.

Continuity shouldexist.

If OK, check harness forshort.

II

4.Check harness continuity

between terminal

@

and termi-

nal

@,

terminal

(!)

and body

ground.

Continuity shouldexist.

If OK, check harness forshort.

OK

II

CHECK OUTPUT SIGNALCIRCUIT. NG

Check thefollowing.

1. Disconnect ECMharness connector.

----..

•Harness connectors

2. Check harness continuity between

@,@

ECM terminal

@

or

@l

and terminal •

Harness connectors

@.

@,@D

Continuity shouldexist.

•

Harness foropen or

If OK, check harness forshort. short

between ECM

OK and

cooling fanrelay-2

If

NG, repair harness or

connectors.

MEC346B

o

•

ACTIVE TEST.

COOLING FAN

OFF

COOLAN TEMP/S 88°C

=

= =

MONITOR

== =

1:1

~i5

~3

7 5

2 1

EC-165

Page 885 of 1701

TROUBLEDIAGNOSIS FORNON-DETECTABLE ITEMS

Cooling FanControl (Cont'd)

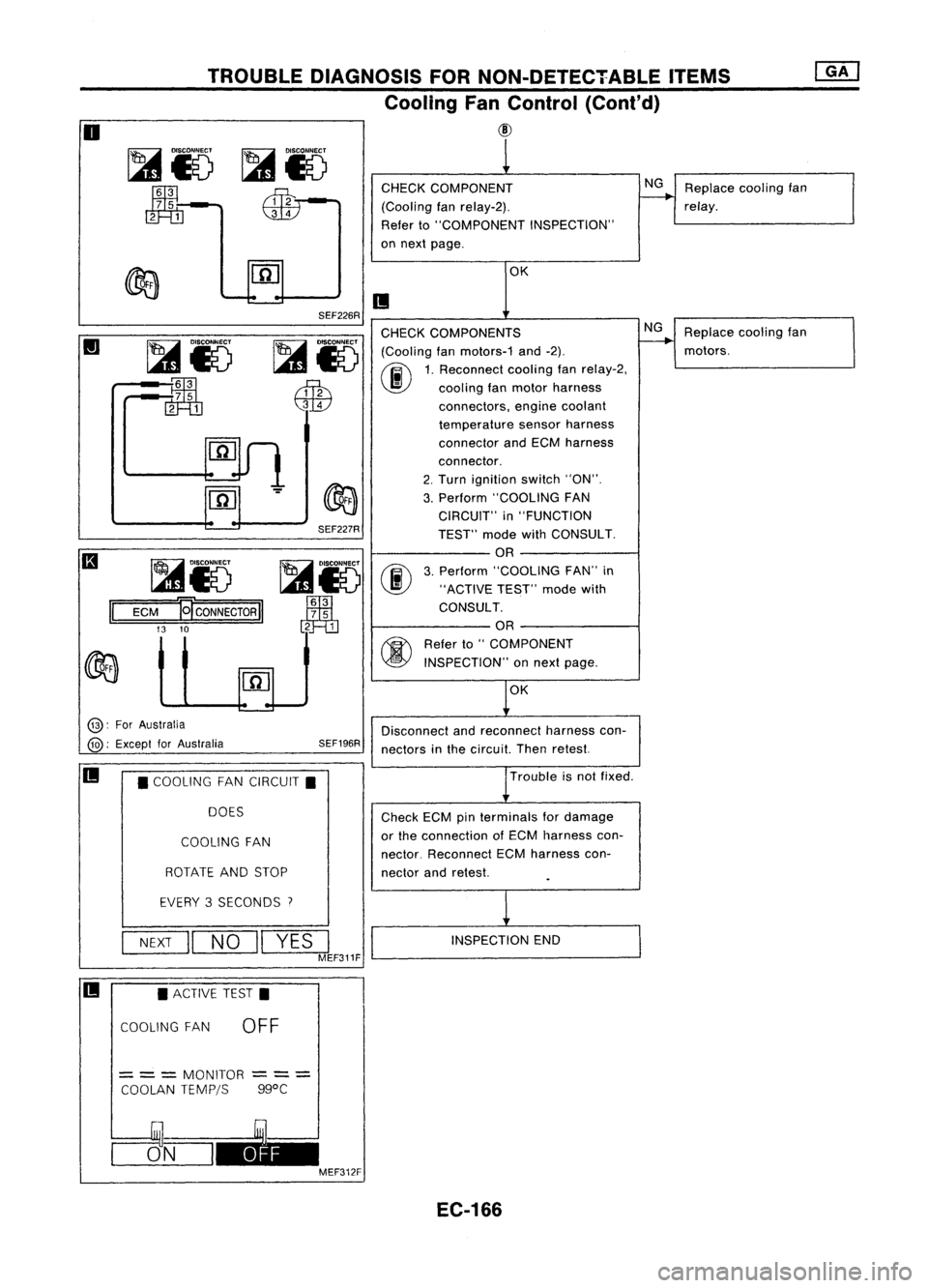

@

o

~i5

~-

m=m

CHECK

COMPONENT

(Cooling fanrelay-2).

Refer to"COMPONENT INSPECTION"

on next page.

NG

Replace coolingfan

relay.

OK

II

Replacecoolingfan

motors.

NG

OK

SEF226R

SEF227R

~i5

00

Jm1

3

7 5

2 1

CHECK

COMPONENTS

~ IDlsco~

(Coolingfanmotors-1 and-2).

I...s1

0~

1.Rec~nnect coolingfanrelay-2,

~ \J!}

coolingfanmotor harness

QW

connectors,enginecoolant

temperature sensorharness

connector andECM harness

connector.

2. Turn ignition switch"ON".

3. Perform "COOLING FAN

CIRCUIT" in"FUNCTION

TEST" modewithCONSULT.

OR

3. Perform "COOLING FAN"in

"ACTIVE TEST"modewith

CONSULT.

OR

~ Referto"COMPONENT

~ INSPECTION" onnext page.

~i5

:~

rn=m

~i5

ECM

El'CONNECTORII

13 10

II

@:

ForAustralia

@:

Except forAustralia SEF196R

Disconnect

andreconnect harnesscon-

nectors inthe circuit. Thenretest.

II

•COOLING FANCIRCUIT.

DOES

COOLING FAN

ROTATE ANDSTOP

Trouble

isnot fixed .

Check ECMpinterminals fordamage

or the connection ofECM harness con-

nector. Reconnect ECMharness con-

nector andretest.

EVERY 3SECONDS

7

NEXT

II

NO

II

YES

I

MEF311F

INSPECTION

END

II •

ACTIVE TEST.

COOLING FAN

OFF

=

= =

MONITOR

COOLAN TEMPjS

---

---

ggoC

CJ5_N_I~ MEF312F

EC-166

Page 890 of 1701

•

INSPECTION END

OK

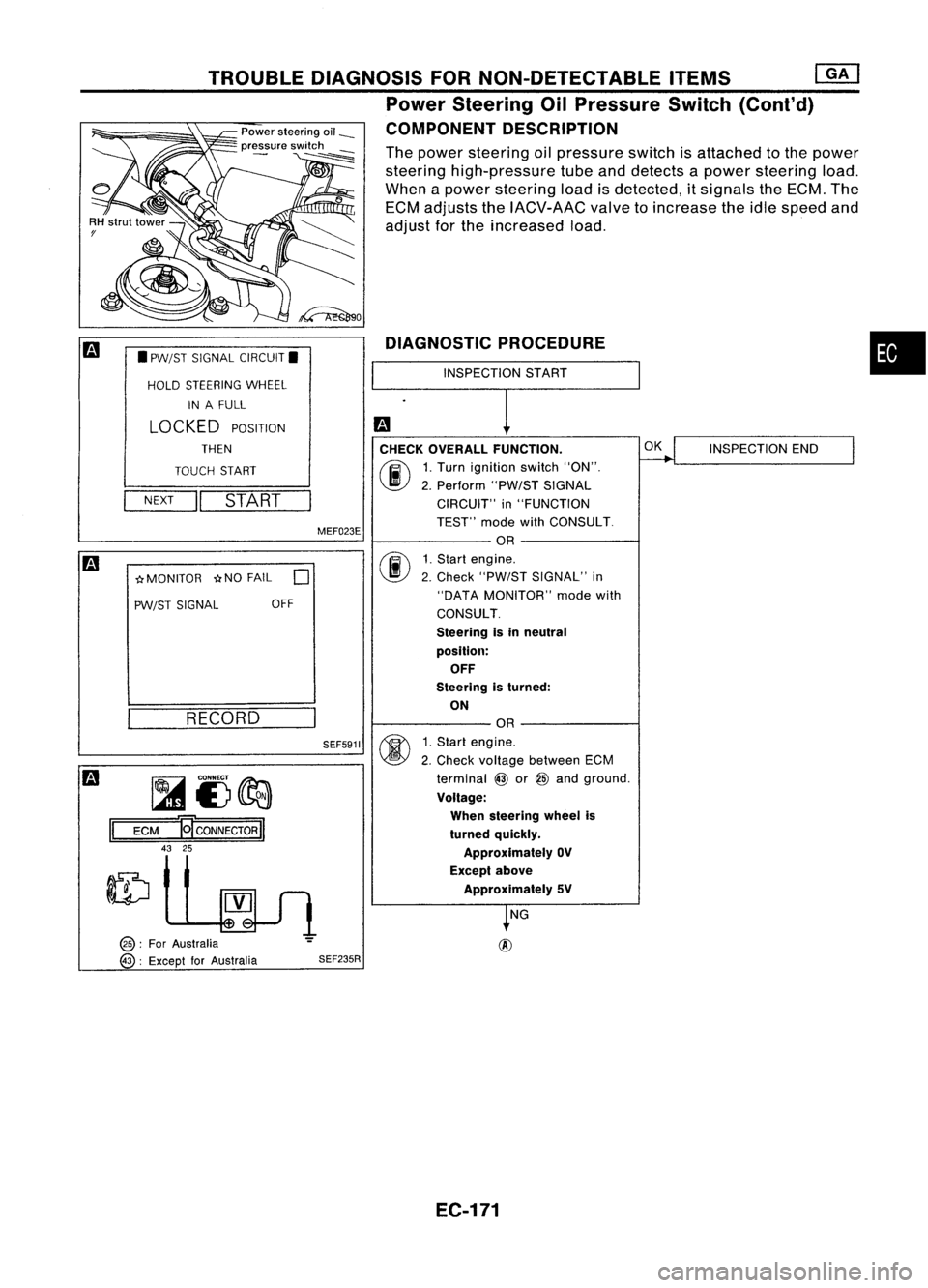

The

power steering oilpressure switchisattached tothe power

steering high-pressure tubeanddetects apower steering load.

When apower steering loadisdetected,

it

signals theECM. The

ECM adjusts theIACV-AAC valvetoincrease theidle speed and

adjust forthe increased load.

INSPECTION START

OR

1. Start engine.

2. Check voltage between ECM

terminal

@

or

@

and ground.

Voltage: When steering wheelis

turned quickly.

Approximately OV

Except above

Approximately 5V

NG

DIAGNOSTIC

PROCEDURE

CHECK OVERALL FUNCTION.

fiii\

1.Turn ignition switch"ON".

~ 2.Perform "PW/STSIGNAL

CIRCUIT" in"FUNCTION

TEST" modewithCONSULT.

OR

(F.i\

1.Start engine.

~ 2.Check "PW/ST SIGNAL" in

"DATA MONITOR" modewith

CONSULT.

Steering isin neutral

position: OFF

Steering isturned:

ON

SEF591I

SEF235R

MEF023E

Power

steering oil___

pressure switch

-

~

to

TROUBLE

DIAGNOSIS FORNON-DETECTABLE ITEMS

@[]

Power Steering OilPressure Switch(Cont'd)

COMPONENT DESCRIPTION

RECORD

NEXT

II

START

•

PW/ST SIGNAL CIRCUIT.

HOLD STEERING WHEEL

IN AFULL

LOCKED

POSITION

THEN

TOUCH START

* MONITOR *NO FAIL

0

PW/ST SIGNAL OFF

@):

ForAustralia

@:

Except forAustralia

~i)~

II

ECM

Ef

CONNECTOR

II

43 25

EC-171

Page 891 of 1701

![NISSAN ALMERA N15 1995 Service Manual TROUBLEDIAGNOSIS FORNON-DETECTABLE ITEMS

@K]

Power Steering OilPressure Switch(Cont'd)

@:

ForAustralia

@:

Except forAustralia SEF176R

Repair

harness orcon-

nectors.

CHECK INPUTSIGNAL CIRCUIT. NISSAN ALMERA N15 1995 Service Manual TROUBLEDIAGNOSIS FORNON-DETECTABLE ITEMS

@K]

Power Steering OilPressure Switch(Cont'd)

@:

ForAustralia

@:

Except forAustralia SEF176R

Repair

harness orcon-

nectors.

CHECK INPUTSIGNAL CIRCUIT.](/img/5/57349/w960_57349-890.png)

TROUBLEDIAGNOSIS FORNON-DETECTABLE ITEMS

@K]

Power Steering OilPressure Switch(Cont'd)

@:

ForAustralia

@:

Except forAustralia SEF176R

Repair

harness orcon-

nectors.

CHECK INPUTSIGNAL CIRCUIT. NG

Check thefollowing .

1. Disconnect ECMharness connector.

......---..

•Harness connectors

2. Check harness continuity between

aD,

(MID

ECM terminal

@

or

@

and terminal •

Harness connectors

G).

@,@or@,

Continuity shouldexist.

If

OK, check harness forshort. •

Harness foropen or

OK short

between ECMand

power steering oilpres-

sure switch

If NG, repair harness or

connectors.

CHECK COMPONENT NG

Replace powersteering

(Power steering oilpressure switch).

--...

oilpressure switch.

Refer to"COMPONENT INSPECTION"

below.

OK

Disconnect andreconnect harnesscon-

nectors inthe circuit. Thenretest.

Trouble isnot fixed.

Check ECMpinterminals fordamage or

the connection ofECM harness connec-

tor. Reconnect ECMharness connector

and retest.

@

1

CHECK GROUND CIRCUIT.

1. Turn ignition switch"OFF".

2. Disconnect powersteering oilpres-

sure switch harness connector.

3. Check harness continuity between

terminal

@

and engine ground.

Continuity shouldexist.

AEC760

IfOK, check harness forshort.

~i5

[i

c:ITb

~i5

ECM

Ef

CONNECTOR

II

43 25

II

INSPECTIONEND

Power steering oilpressure switch

1. Disconnect powersteering oilpressure switchharness con-

nector thenstart engine.

2. Check continuity betweenterminals

@.

[At

IV

ID

~ COMPONENT

INSPECTION

Conditions

Steering wheelisbeing turned

Steering wheelisnot being turned Continuity

Yes

No

AEC762

IfNG, replace powersteering oilpressure switch.

EC-172

Page 898 of 1701

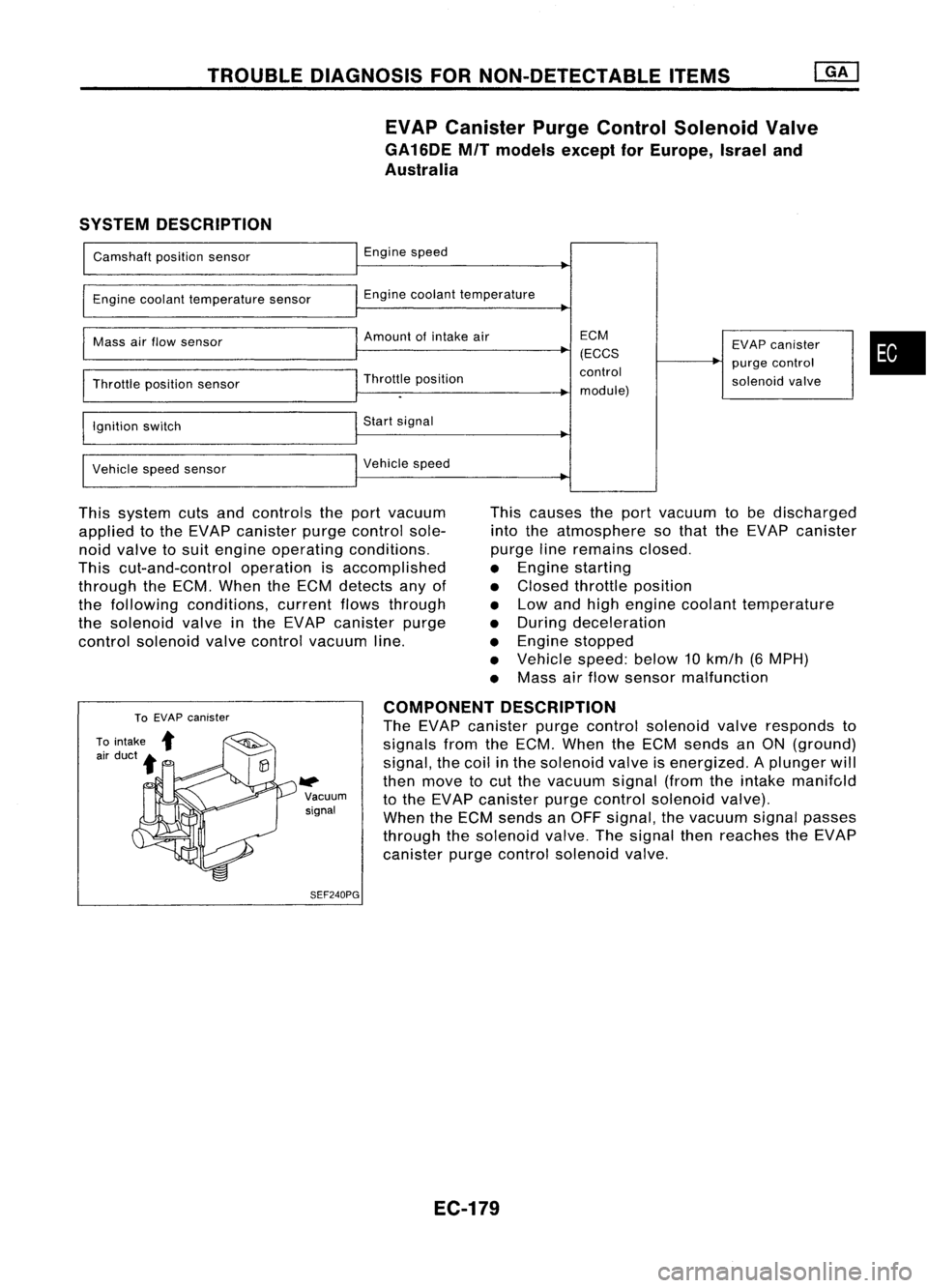

TROUBLEDIAGNOSIS FORNON-DETECTABLE ITEMS

EVAP Canister PurgeControl Solenoid Valve

GA16DE MITmodels exceptforEurope, Israeland

Australia

SYSTEM DESCRIPTION

Camshaft positionsensor

Engine coolant temperature sensor

Mass airflow sensor

Throttle positionsensor

Ignition switch

Vehicle speedsensor Engine

speed

Engine coolant temperature

Amount ofintake air

Throttle position

Start signal

Vehicle speed ECM

(ECCS

control

module) EVAP

canister

purge control

solenoid valve

•

This system cutsandcontrols theport vacuum

applied tothe EVAP canister purgecontrol sole-

noid valve tosuit engine operating conditions.

This cut-and-control operationisaccomplished

through theECM. When theECM detects anyof

the following conditions, currentflowsthrough

the solenoid valveinthe EVAP canister purge

control solenoid valvecontrol vacuum line. This

causes theport vacuum tobe discharged

into theatmosphere sothat theEVAP canister

purge lineremains closed.

• Engine starting

• Closed throttle position

• Low andhigh engine coolant temperature

• During deceleration

• Engine stopped

• Vehicle speed:below10km/h (6MPH)

• Mass airflow sensor malfunction

W>

Vacuum

signal

SEF240PG COMPONENT

DESCRIPTION

The EVAP canister purgecontrol solenoid valveresponds to

signals fromtheECM. When theECM sends anON (ground)

signal, thecoil inthe solenoid valveisenergized. Aplunger will

then move tocut the vacuum signal(fromtheintake manifc,ld

to the EVAP canister purgecontrol solenoid valve).

When theECM sends anOFF signal, thevacuum signalpasses

through thesolenoid valve.Thesignal thenreaches theEVAP

canister purgecontrol solenoid valve.

EC-179

Page 900 of 1701

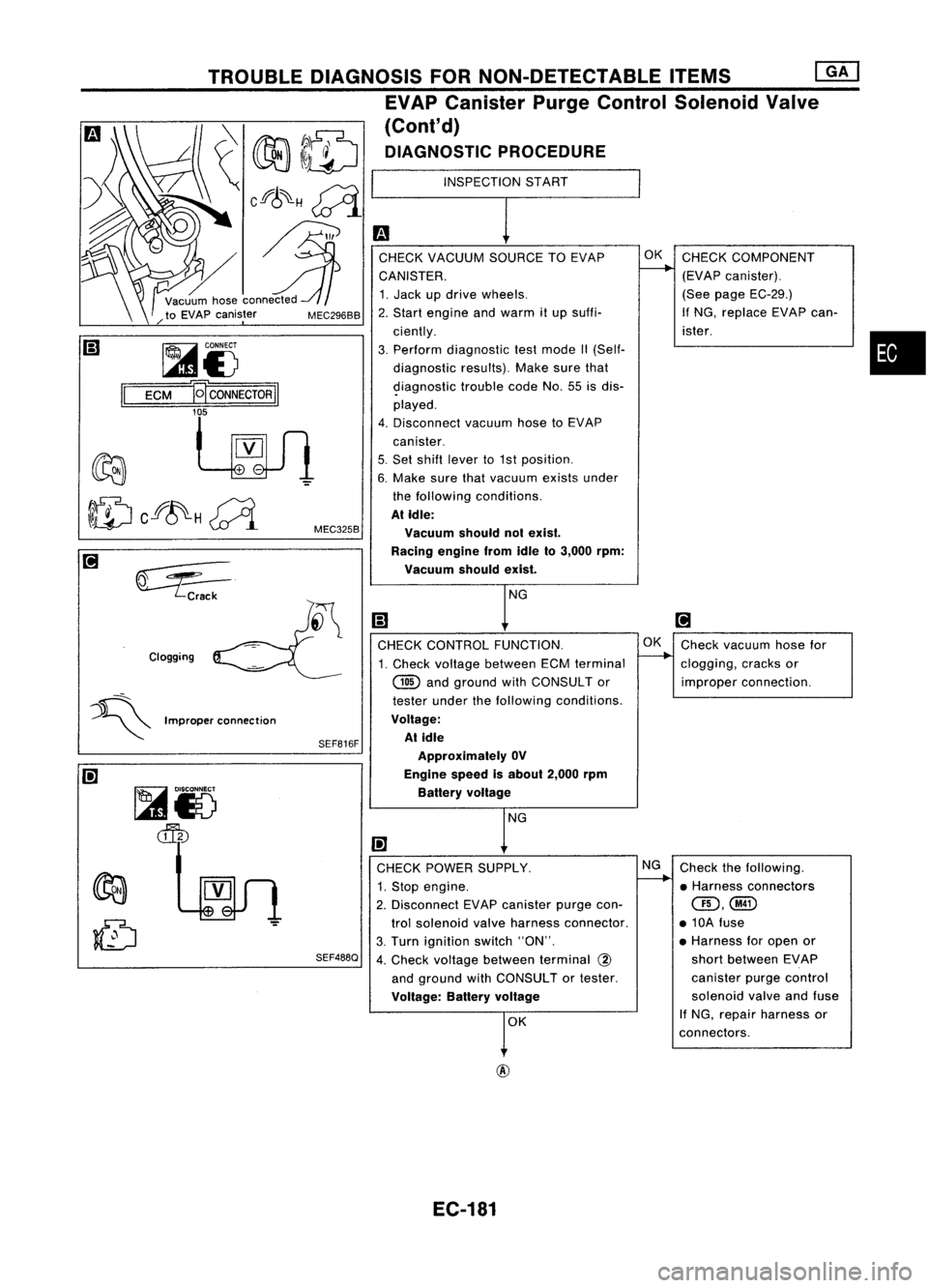

•

INSPECTION

START

m

CHECK VACUUM SOURCETOEVAP OK

CHECK COMPONENT

CANISTER.

L---.

(EVAPcanister).

1. Jack updrive wheels. (See

page EC-29.)

2. Start engine andwarm itup suffi- If

NG, replace EVAPcan-

ciently. ister.

3. Perform diagnostic testmode II(Self-

diagnostic results).Makesurethat

9iagnostic troublecodeNo.55isdis-

played.

4. Disconnect vacuumhosetoEVAP

canister.

5. Set shift lever to1st position.

6. Make surethatvacuum existsunder

the following conditions.

At Idle:

Vacuum shouldnotexist.

Racing enginefromIdleto3,000 rpm:

Vacuum shouldexist.

NG

Ii)

[!J

CHECK CONTROL FUNCTION. OK

Check vacuum hosefor

1. Check voltage between ECMterminal

--..

clogging, cracksor

@

andground withCONSULTor improperconnection.

tester underthefollowing conditions.

Voltage: At idle

Approximately OV

Engine speedisabout 2,000rpm

Battery voltage

NG

I!l

CHECK POWER SUPPLY. NG

Check thefollowing.

1. Stop engine.

I-----.

•Harness connectors

2. Disconnect EVAPcanister purgecon-

QD,@

trol solenoid valveharness connector. •10A fuse

3. Turn ignition switch"ON". •

Harness foropen or

4. Check voltage between terminal

@

short

between EVAP

and ground withCONSULTor tester. canister

purgecontrol

Voltage: Batteryvoltage

solenoid

valveandfuse

r

K If

NG, repair harness or

connectors.

SEF816F

SEF488Q

MEC325B

MEC296BB

Clogging TROUBLE

DIAGNOSIS FORNON-DETECTABLE ITEMS

[ill

EVAP Canister PurgeControl Solenoid Valve

(Cont'd)

DIAGNOSTIC PROCEDURE

~i5

ECM

B

CONNECTOR

II

'f

~VV1

~ Crack

~i5

~

=:5---

~ Improperconnection

@

EC-181

Page 902 of 1701

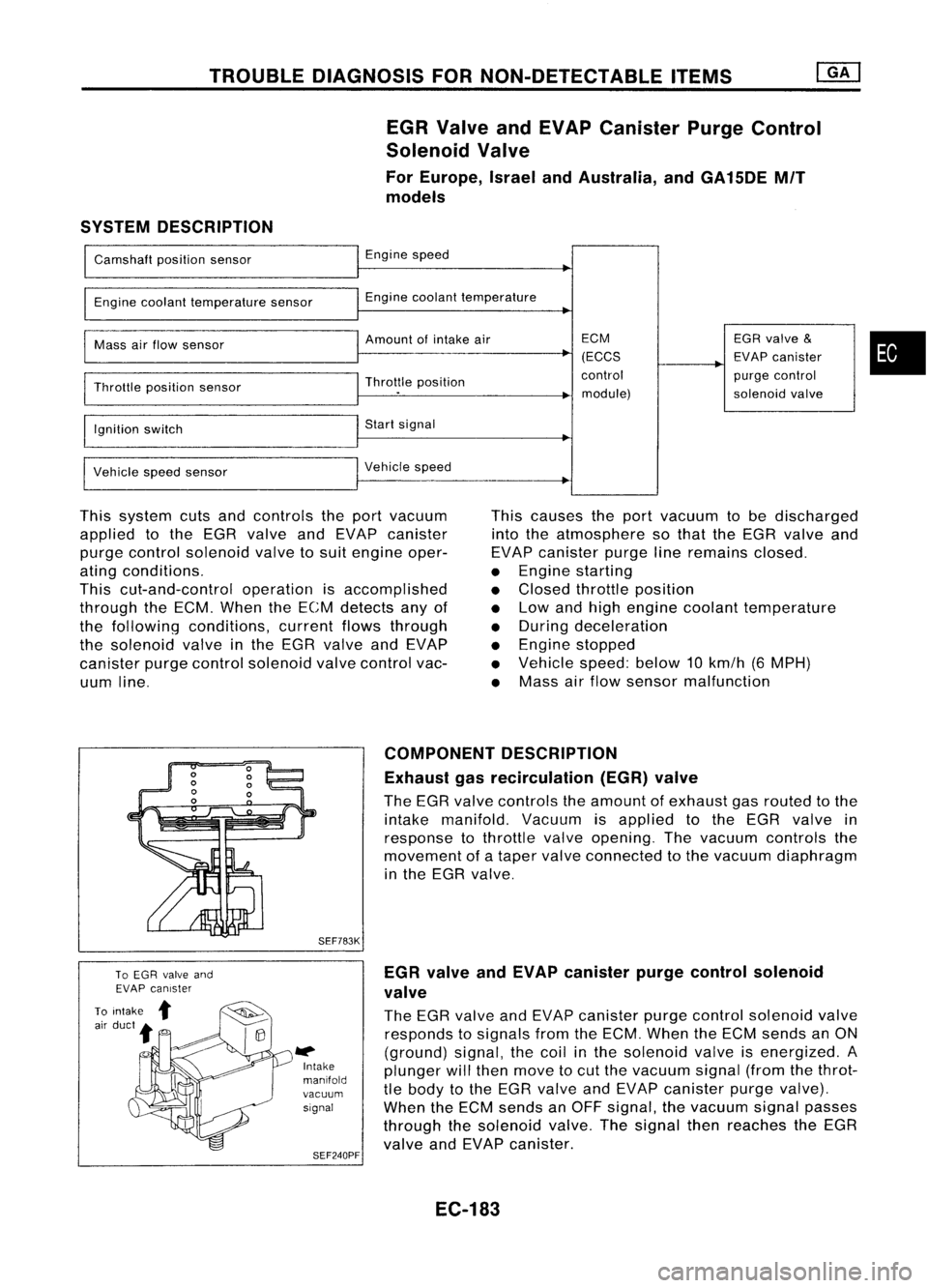

TROUBLEDIAGNOSIS FORNON-DETECTABLE ITEMS

EGR Valve andEVAP Canister PurgeControl

Solenoid Valve

For Europe, IsraelandAustralia, andGA15DE MIT

models

SYSTEM DESCRIPTION

Camshaft positionsensor

Engine coolant temperature sensor

Mass airflow sensor

Throttle position sensor

Ignition switch

Vehicle speedsensor Engine

speed

Engine coolant temperature

Amount ofintake air

Throttle position

Start signal

Vehicle speed ECM

(ECCS

control module) EGR

valve

&

EVAP canister

purge control

solenoid valve

•

This system cutsandcontrols theport vacuum

applied tothe EGR valve andEVAP canister

purge control solenoid valvetosuit engine oper-

ating conditions.

This cut-and-control operationisaccomplished

through theECM. When theECM detects anyof

the following conditions, currentflowsthrough

the solenoid valveinthe EGR valve andEVAP

canister purgecontrol solenoid valvecontrol vac-

uum line. This

causes theport vacuum tobe discharged

into theatmosphere sothat theEGR valve and

EVAP canister purgelineremains closed.

• Engine starting

• Closed throttle position

• Low andhigh engine coolant temperature

• During deceleration

• Engine stopped

• Vehicle speed:below10km/h (6MPH)

• Mass airflow sensor malfunction

SEF783K

l#

Intake

manifold

vacuum signal

SEF240PF COMPONENT

DESCRIPTION

Exhaust gasrecirculation (EGR)valve

The EGR valve controls theamount ofexhaust gasrouted tothe

intake manifold. Vacuumisapplied tothe EGR valve in

response tothrottle valveopening. Thevacuum controls the

movement ofataper valve connected tothe vacuum diaphragm

in the EGR valve.

EGR valve andEVAP canister purgecontrol solenoid

valve

The EGR valve andEVAP canister purgecontrol solenoid valve

responds tosignals fromtheECM. When theECM sends anON

(ground) signal,thecoil inthe solenoid valveisenergized. A

plunger willthen move tocut the vacuum signal(fromthethrot-

tle body tothe EGR valve andEVAP canister purgevalve).

When theECM sends anOFF signal, thevacuum signalpasses

through thesolenoid valve.Thesignal thenreaches theEGR

valve andEVAP canister.

EC-183

Page 905 of 1701

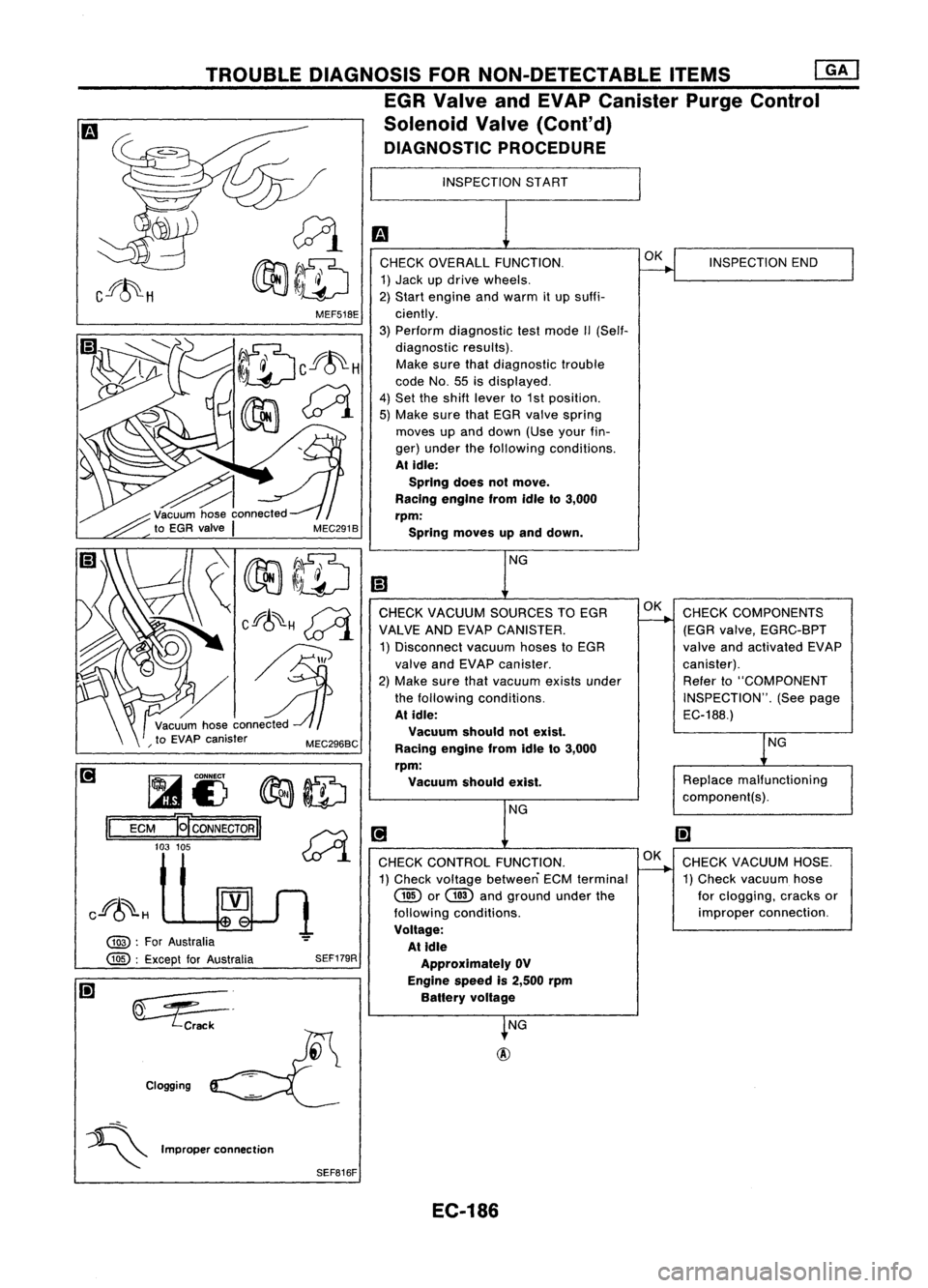

INSPECTIONSTART

m

CHECK OVERALL FUNCTION.

~INSPECTION

END

1) Jack updrive wheels.

2) Start engine andwarm itup suffi-

ciently.

3) Perform diagnostic testmode II(Self-

diagnostic results).

Make surethatdiagnostic trouble

code No.55isdisplayed.

4) Set theshift lever to1st position.

5) Make surethatEGR valve spring

moves upand down (Useyourfin-

ger) under thefollowing conditions.

At idle:

SprIng doesnotmove.

RacIng engIne fromidleto3,000

rpm:

Spring moves upand down.

NG

l!1

CHECK VACUUM SOURCES TOEGR OK

CHECK COMPONENTS

VALVE ANDEVAP CANISTER.

-----...

(EGRvalve, EGRC-BPT

1) Disconnect vacuumhosestoEGR valveandactivated EVAP

valve andEVAP canister. canister).

2) Make surethatvacuum existsunder Refer

to"COMPONENT

the following conditions. INSPECTION".(Seepage

At idle:

EC-188.)

Vacuum shouldnotexist.

lNG

Racing engine fromidleto3,000

rpm: Vacuum shouldexist.

Replace

malfunctioning

component(s).

NG

[!J

I!l

CHECK CONTROL FUNCTION. OK

CHECK VACUUM HOSE.

1) Check voltage between ECMterminal

----..

1)Check vacuum hose

@

or

GID

andground underthe forclogging, cracksor

following conditions. improper

connection.

Voltage: At Idle

Approximately OV

Engine speedis2,500 rpm

Battery voltage

~NG

SEF179R

~=.

Crack

Clogging MEF51BE

TROUBLE

DIAGNOSIS FORNON-DETECTABLE ITEMS

[]K]

EGR Valve andEVAP Canister PurgeControl

Solenoid Valve(Cont'd)

DIAGNOSTIC PROCEDURE

~I)

~ID

ECM

-gcoNNEcTORII ~

103 105

~.1

@ :

For Australia

@ :

Except forAustralia

II

Cf~H

~

~ Improperconnection

SEFB16F

EC-186