engine NISSAN ALMERA N15 1995 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 906 of 1701

•

Check

thefollowing.

• Harness connectors

@,@

• 10A fuse

• Harness continuity

between EGRvalve

&

EVAP canister purge

control solenoid valve

and fuse

If

NG, repair harness or

connectors.

NG

OK

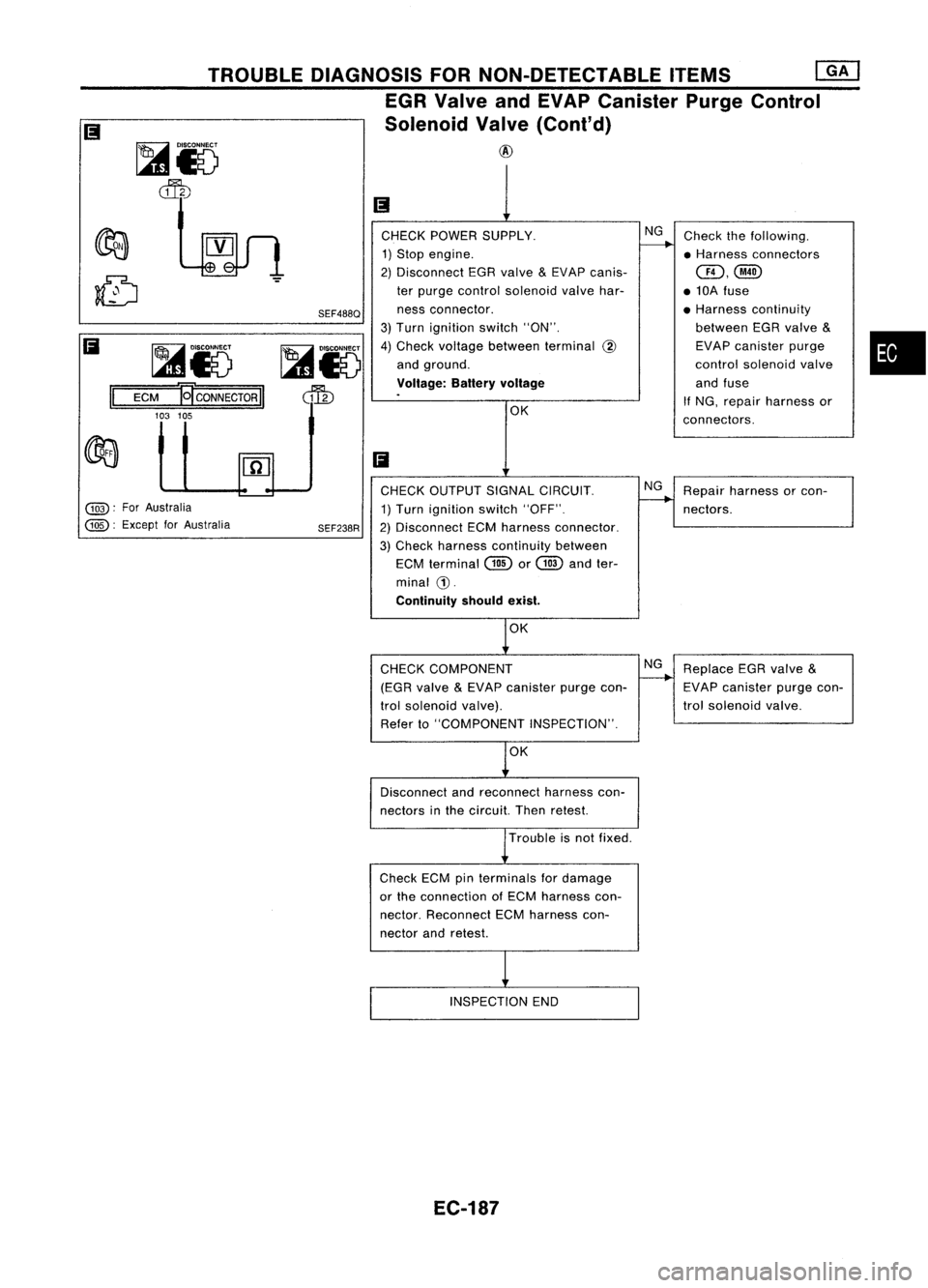

CHECK

POWER SUPPLY.

1) Stop engine.

2) Disconnect EGRvalve

&

EVAP canis-

ter purge control solenoid valvehar-

ness connector.

3) Turn ignition switch"ON".

4) Check voltage between terminal

@

and ground.

Voltage: Batteryvoltage

SEF488Q

~i8

dfu

TROUBLE

DIAGNOSIS FORNON-DETECTABLE ITEMS

[QK]

EGR Valve andEVAP Canister PurgeControl

Solenoid Valve(Cont'd)

@

~i8

~

~i5

ECM

]gCONNECTORII

103 105

II

Ii

Ii

@:

ForAustralia

@:

Except forAustralia CHECK

OUTPUT SIGNALCIRCUIT.

1) Turn ignition switch"OFF".

SEF238R

2)Disconnect ECMharness connector.

3) Check harness continuity between

ECM terminal Gillor

@

andter-

minal

G).

Continuity shouldexist. NG

Repair harness orcon-

nectors.

OK

CHECK COMPONENT

(EGR valve

&

EVAP canister purgecon-

trol solenoid valve).

Refer to"COMPONENT INSPECTION".

NG

Replace EGRvalve

&

EVAP canister purgecon-

trol solenoid valve.

OK

Disconnect andreconnect harnesscon-

nectors inthe circuit. Thenretest.

Trouble isnot fixed.

Check ECMpinterminals fordamage

or the connection ofECM harness con-

nector. Reconnect ECMharness con-

nector andretest.

INSPECTION END

EC-187

Page 910 of 1701

2:

1

:>

Q)

Ol

~

0

>

::;

c.

::;

0

,,"--

0

-

Rich- Idealratio _

Lean

Mixlure ratio

SEF288D

•

Zirconia

tube SEF406H

TROUBLE

DIAGNOSIS FORNON-DETECTABLE ITEMS

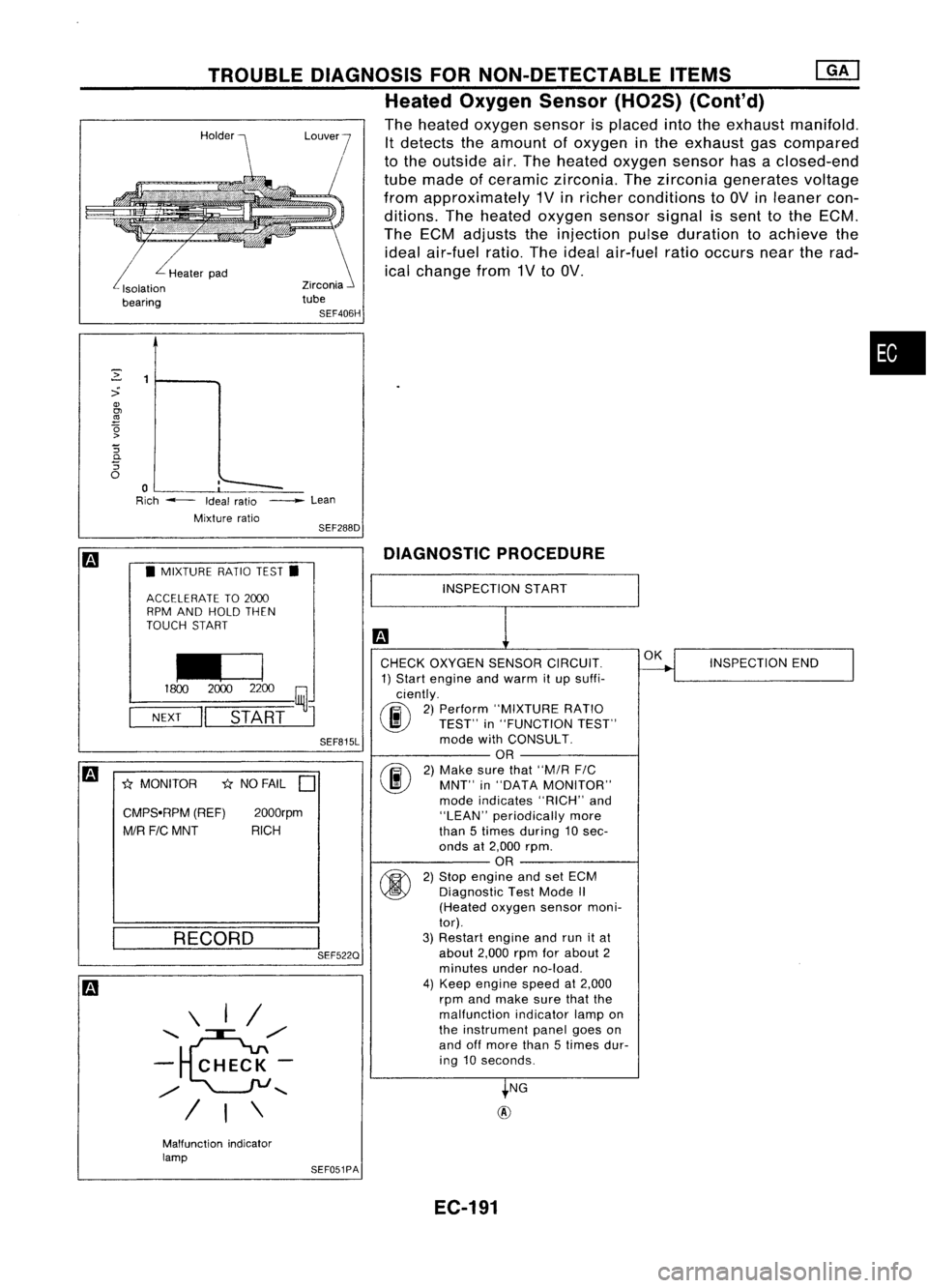

Heated Oxygen Sensor(H02S)(Cont'd)

The heated oxygen sensorisplaced intotheexhaust manifold.

It detects theamount ofoxygen inthe exhaust gascompared

to the outside air.The heated oxygen sensorhasaclosed-end

tube made ofceramic zirconia. Thezirconia generates voltage

from approximately 1Vinricher conditions to

av

inleaner con-

ditions. Theheated oxygen sensorsignalissent tothe ECM.

The ECM adjusts theinjection pulseduration toachieve the

ideal air-fuel ratio.Theideal air-fuel ratiooccurs neartherad-

ical change from1Vto

av.

L

Healerpad

Isolalion

bearing

m

•MIXTURE RATIOTEST.

ACCELERATE TO2000

RPM AND HOLD THEN

TOUCH START

I£J

1800

20002200

~J

NEXT

II

START

SEF815L

m

*

MONITOR

*

NO FAIL

D

CMPS.RPM (REF)2000rpm

MIR FICMNT RICH

DIAGNOSTIC

PROCEDURE

RECORD

\ I/

........ e",/

- CHECK-

",/

........

/ I\

I

SEF522Q

INSPECTION

START

CHECK OXYGEN SENSORCIRCUIT.

1) Start engine andwarm itup suffi-

ciently.

(F.i\

2)Perform "MIXTURE RATIO

~ TEST"in"FUNCTION TEST"

mode withCONSULT.

OR

(F.i\

2)Make surethat"M/R

FIC

~ MNT"in"DATA MONITOR"

mode indicates "RICH"and

"LEAN" periodically more

than 5times during 10 sec-

onds at2,000 rpm.

OR

fti>\

2)Stop engine andsetECM

~ Diagnostic TestMode

/I

(Heated oxygensensormoni-

tor).

3) Restart engineandrunitat

about 2,000rpmforabout 2

minutes underno-load.

4) Keep engine speedat2,000

rpm andmake surethatthe

malfunction indicatorlampon

the instrument panelgoeson

and offmore than5times dur-

ing 10seconds.

NG

@

OK

INSPECTION END

Malfunction indicator

lamp SEF051PA

EC-191

Page 911 of 1701

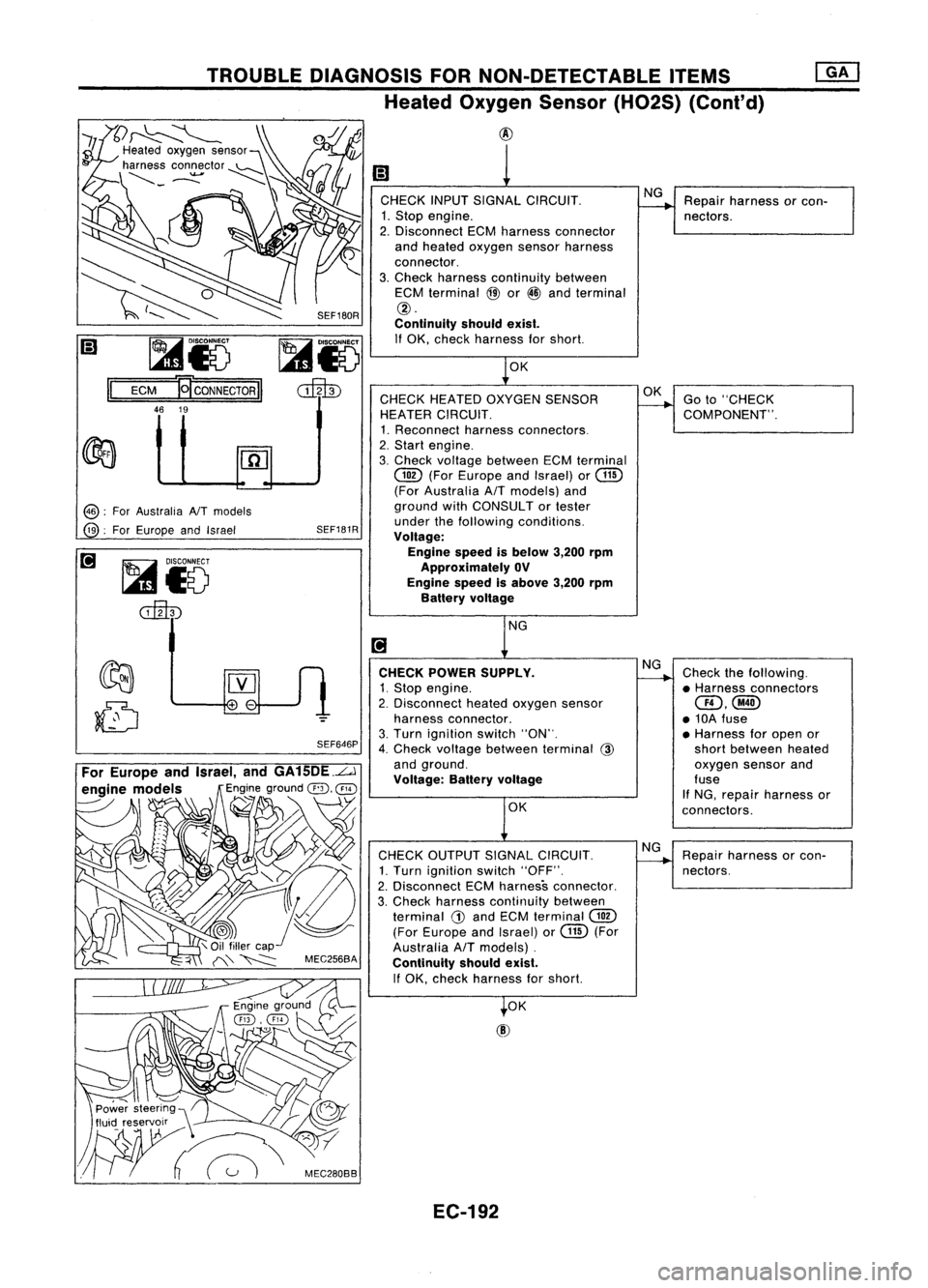

I;)

1

CHECK INPUTSIGNAL CIRCUIT. NG

Repair harness orcon-

1. Stop engine.

--.

nectors.

2. Disconnect ECMharness connector

and heated oxygen sensorharness

connector.

3. Check harness continuity between

ECM terminal

@

or

@

and terminal

@.

Continuity shouldexist.

If OK, check harness forshort.

1

0K

CHECK HEATED OXYGEN SENSOR OK

Goto"CHECK

HEATER CIRCUIT.

--.

COMPONENT".

1. Reconnect harnessconnectors.

2. Start engine.

3. Check voltage between ECMterminal

@

(ForEurope andIsrael) or

@

(For Australia AfTmodels) and

ground withCONSULTor tester

under thefollowing conditions.

Voltage:

Engine speedisbelow 3,200rpm

Approximately OV

Engine speedisabove 3,200rpm

Battery voltage

NG

[!J

CHECK POWER SUPPLY. NG

Check thefollowing.

1. Stop engine.

~

•Harness connectors

2. Disconnect heatedoxygen sensor

aD,@

harness connector. •10A fuse

3. Turn ignition switch"ON".

•Harness foropen or

4. Check voltage between terminal

@

shortbetween heated

and ground. oxygensensorand

Voltage: Batteryvoltage fuse

If NG, repair harness or

OK connectors.

CHECK OUTPUT SIGNALCIRCUIT. NG

Repair harness orcon-

1. Turn ignition switch"OFF".

-----...

nectors.

2. Disconnect ECMharness connector.

3, Check harness continuity between

terminal

G)

and ECM terminal

@

(For Europe andIsrael) orGill (For

Australia

AfT

models) .

Continuity shouldexist.

If OK, check harness forshort.

t

OK

SEF180R

SEF646P

SEF181R

~i5

cilltD

@:

ForAustralia NTmodels

@:

ForEurope andIsrael

TROUBLE

DIAGNOSIS FORNON-DETECTABLE ITEMS

Heated Oxygen Sensor(H02S) (Cont'd)

@

~

~

I;) ~i5

Il

ECM

'QcoNNECTORII

46 19

For Europe andIsrael, andGA15DE.L.J

engine models

Engineground

@,

@

----- \

~ ~

'1

\

.~

,~\ C/

Power steering",

fluid reservoir __\ ~

W~

:'C"",,

EC-192

Page 912 of 1701

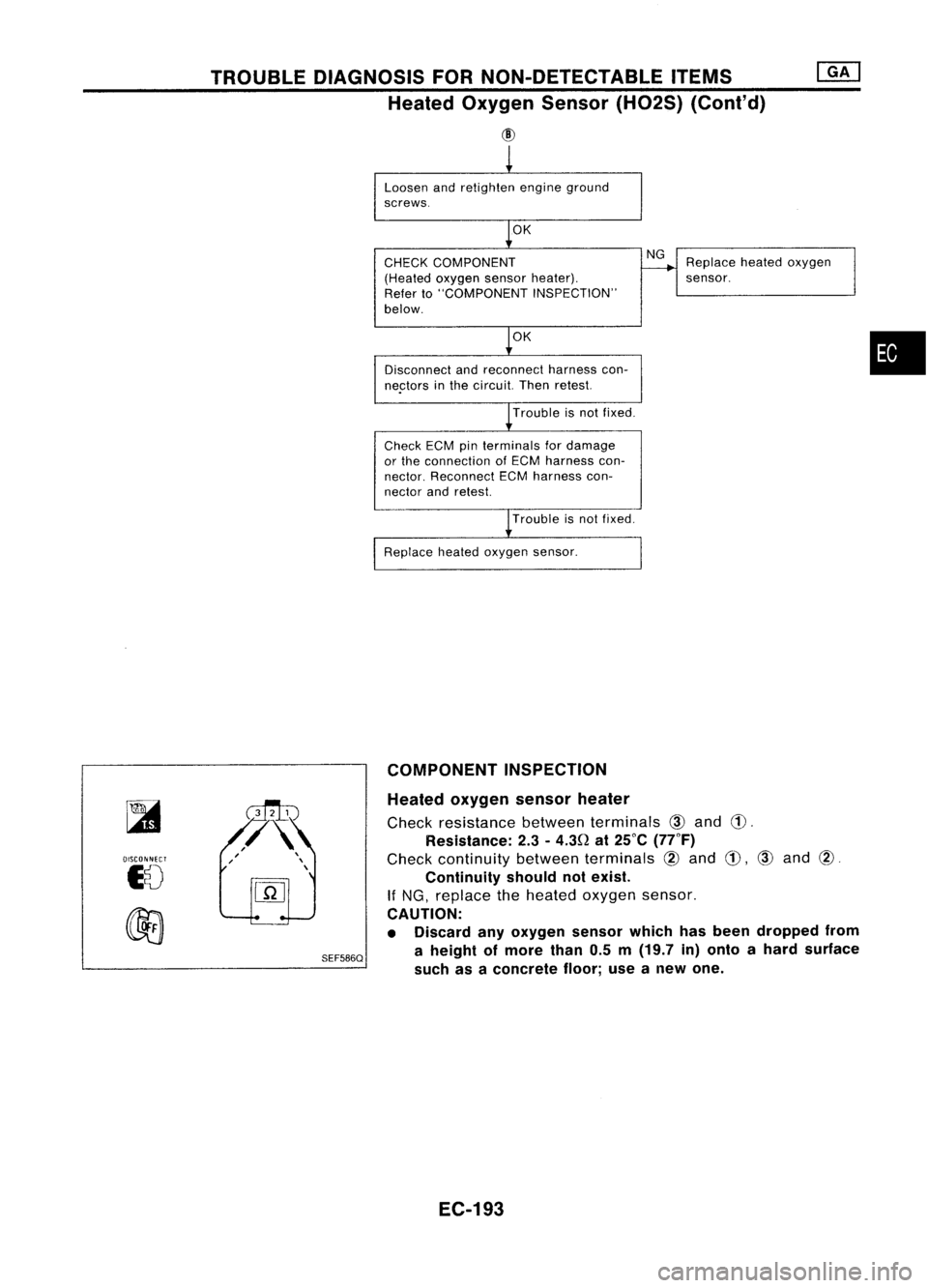

TROUBLEDIAGNOSIS FORNON-DETECTABLE ITEMS

Heated Oxygen Sensor(H02S)(Cont'd)

@

Loosen andretighten engineground

screws.

OK

CHECK COMPONENT

(Heated oxygensensorheater).

Refer to"COMPONENT INSPECTION"

below.

OK

Disconnect andreconnect harnesscon-

ne~tors inthe circuit. Thenretest.

Trouble isnot fixed.

Check ECMpinterminals fordamage

or the connection ofECM harness con-

nector. Reconnect ECMharness con-

nector andretest.

Troubleisnot fixed.

Replace heatedoxygen sensor.

COMPONENT INSPECTION NG

Replace heatedoxygen

sensor.

•

DISCONNECT

I~J

00

SEF586Q

Heated

oxygen sensorheater

Check resistance betweenterminals

@

and

CD.

Resistance: 2.3-4.3Q at25°C (77°F)

Check continuity betweenterminals @and

CD,

@

and @.

Continuity shouldnotexist.

If NG, replace theheated oxygen sensor.

CAUTION:

• Discard anyoxygen sensorwhichhasbeen dropped from

a height ofmore than0.5m(19.7 in)onto ahard surface

such asaconcrete floor;useanew one.

EC-193

Page 915 of 1701

TROUBLEDIAGNOSIS FORNON-DETECTABLE ITEMS

Oxygen Sensor(02S)(Cont'd)

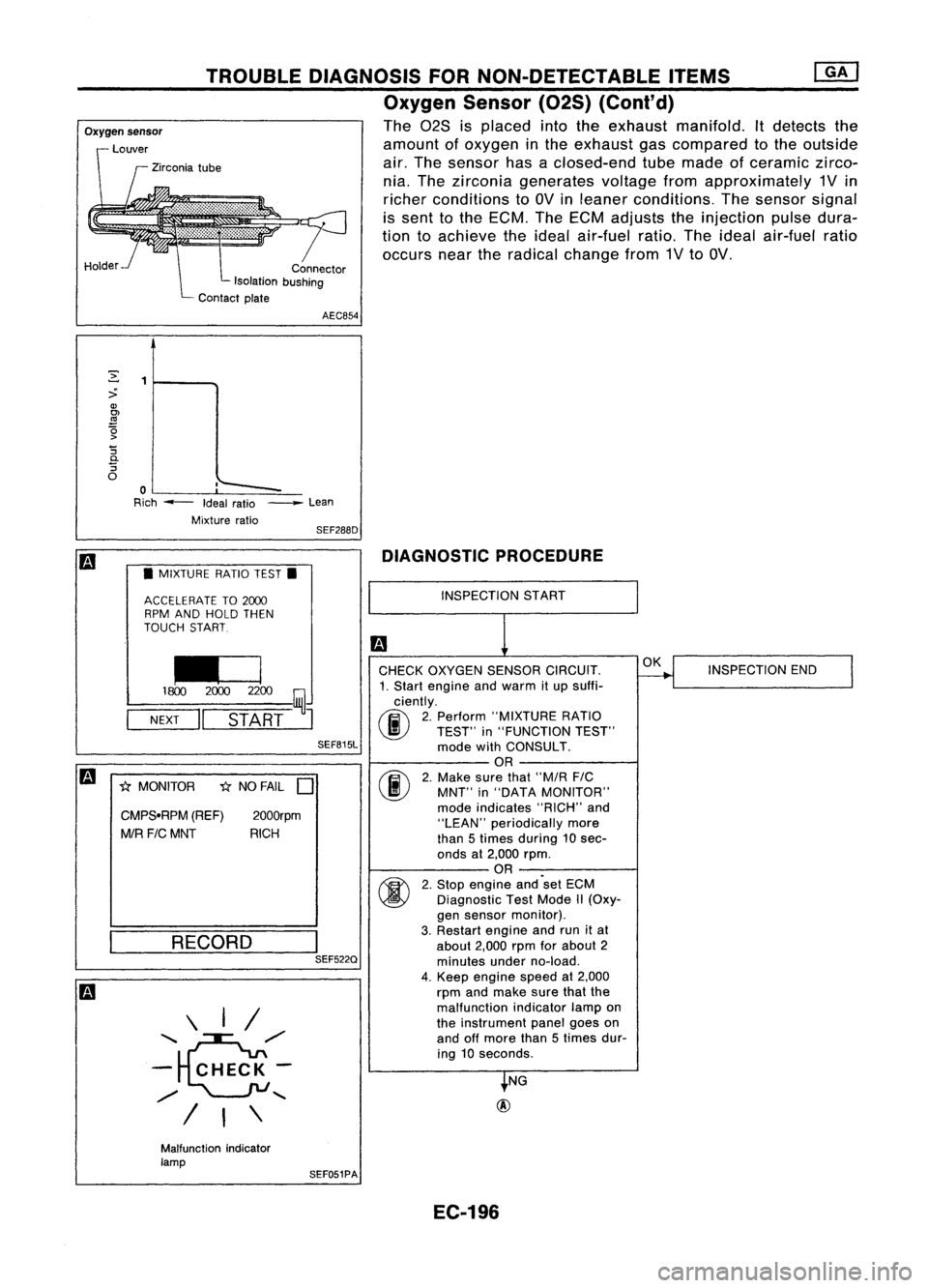

The 028 isplaced intotheexhaust manifold. Itdetects the

amount ofoxygen inthe exhaust gascompared tothe outside

air. The sensor hasaclosed-end tubemade ofceramic zirco-

nia. The zirconia generates voltagefromapproximately 1Vin

richer conditions toOV inleaner conditions. Thesensor signal

is sent tothe ECM. TheECM adjusts theinjection pulsedura-

tion toachieve theideal air-fuel ratio.Theideal air-fuel ratio

occurs neartheradical change from1VtoOV.

r

Connector

Isolation bushing

Contact plate

Oxygen

sensor

Louver

Zirconia tube

Holder AEC854

,'--

~

:>

Q)

OJ

.!!1

~ '5

0-

'5

o

o

Rich --- Idealratio

Mixture ratio_

Lean

SEF288D

m

•MIXTURE RATIOTEST.

ACCELERATE TO2CXXJ

RPM AND HOLD THEN

TOUCH START

~

1800 2CXXJ2200

~J

NEXT

II

START

SEF815L

m

1;{MONITOR 1;{NO FAIL

D

CMPS.RPM (REF)

2000rpm

MIR FICMNT RICH

RECORD \ I/

'~/'

- CHECK-

/

"-

I

I\

I

SEF522Q DIAGNOSTIC

PROCEDURE

INSPECTION START

CHECK OXYGEN SENSORCIRCUIT.

1. Start engine andwarm itup suffi-

ciently.

(F.i\

2.Perform "MIXTURE RATIO

~ TEST"in"FUNCTION TEST"

mode withCONSULT.

OR

(F.i\

2.Make surethat"M/R FIC

\..!!J

MNT"in"DATA MONITOR"

mode indicates "RICH"and

"LEAN" periodically more

than 5times during 10sec-

onds at2,000 rpm.

OR

~ 2.Stop engine and'set ECM

~ Diagnostic TestMode II(Oxy-

gen sensor monitor).

3. Restart engineandrunitat

about 2,000rpmforabout 2

minutes underno-load.

4. Keep engine speedat2,000

rpm andmake surethatthe

malfunction indicatorlampon

the instrument panelgoeson

and offmore than5times dur-

ing 10seconds.

NG

@

OK

INSPECTION END

Malfunction indicator

lamp SEF051PA

EC-196

Page 916 of 1701

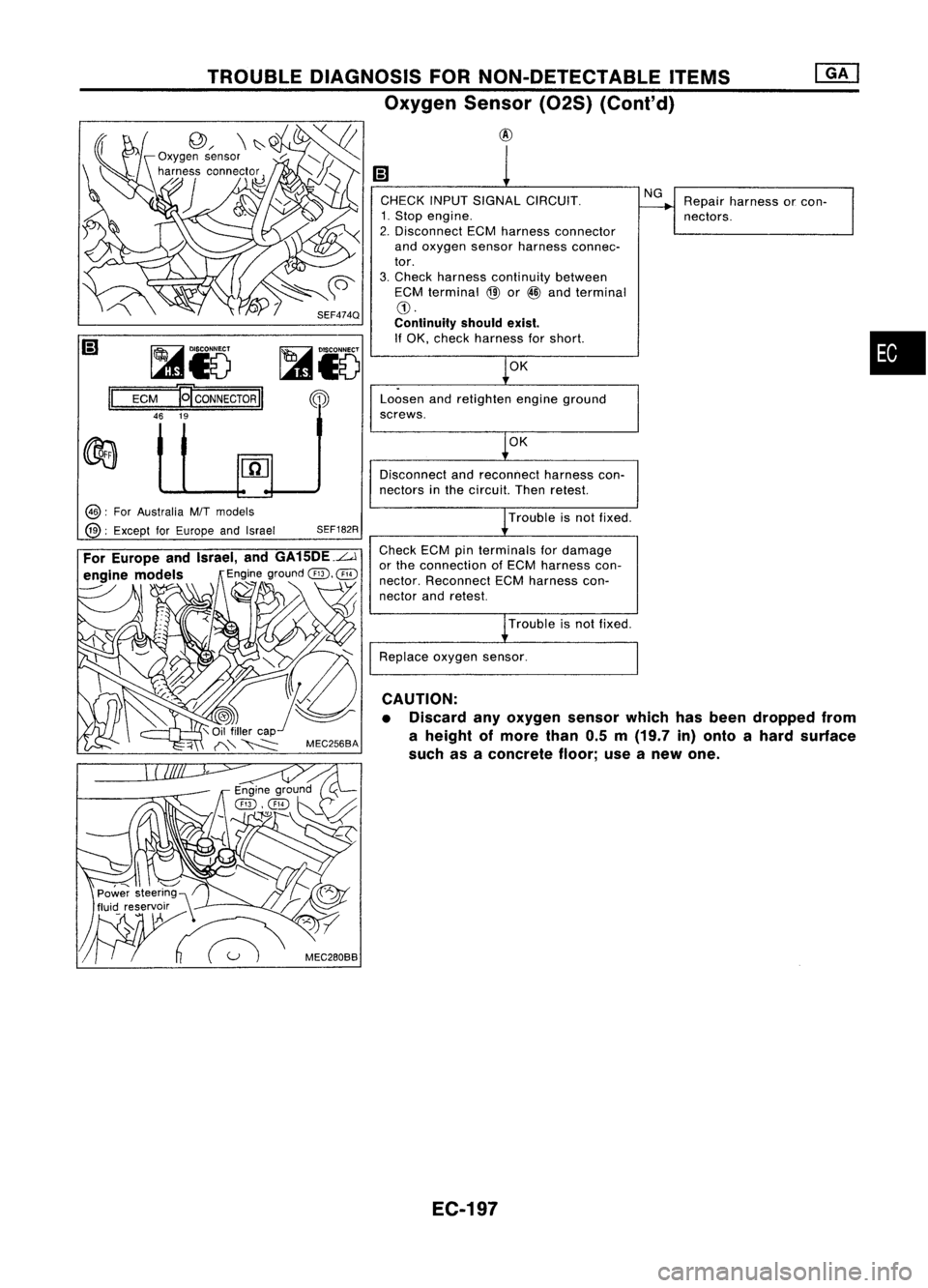

•

Repair

harness orcon-

nectors.

NG

OK

Loosen andretighten engineground

screws. CHECK

INPUTSIGNAL CIRCUIT.

1. Stop engine.

2. Disconnect ECMharness connector

and oxygen sensorharness connec-

tor.

3. Check harness continuity between

ECM terminal

@

or

@

and terminal

CD.

Continuity shouldexist.

If OK, check harness forshort.

~iV

@

TROUBLE

DIAGNOSIS FORNON-DETECTABLE ITEMS

Oxygen Sensor(02S)(Conl'd)

@

~Io

ECM

19'

CONNECTOR

II

46 19

II

OK

Disconnect andreconnect harnesscon-

nectors inthe circuit. Thenretest.

@:

ForAustralia M/Tmodels

@:

Except forEurope andIsrael

SEF182R

Trouble

isnot fixed.

Check ECMpinterminals fordamage

or the connection ofECM harness con-

nector. Reconnect ECMharness con-

nector andretest.

Troubleisnot fixed.

Replace oxygensensor.

CAUTION:

• Discard anyoxygen sensorwhichhasbeen dropped from

a height ofmore than0.5m(19.7 in)onto ahard surface

such asaconcrete floor;useanew one.

EC-197

Page 917 of 1701

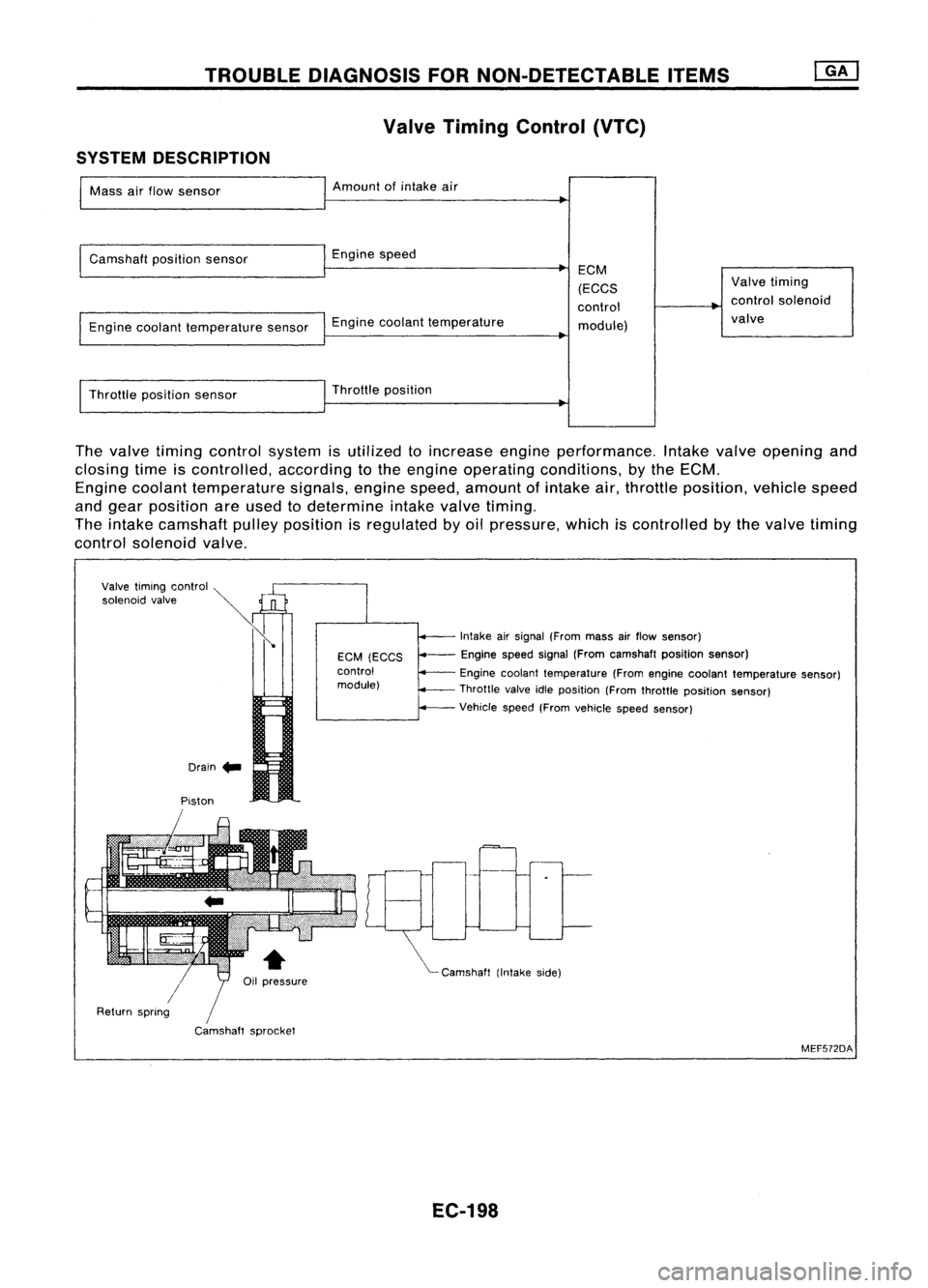

TROUBLEDIAGNOSIS FORNON-DETECTABLE ITEMS

Valve Timing Control (VTC)

SYSTEM DESCRIPTION

Mass airflow sensor Amount

ofintake air

Camshaft positionsensor Enginespeed

Engine coolant temperature sensorEnginecoolant temperature ECM

(ECCS

control module) Valve

timing

control solenoid

valve

Throttle positionsensor Throttle

position

The valve timing control system isutilized toincrease engineperformance. Intakevalveopening and

closing timeiscontrolled, accordingtothe engine operating conditions, bythe ECM.

Engine coolant temperature signals,enginespeed,amount ofintake air,throttle position, vehiclespeed

and gear position areused todetermine intakevalvetiming.

The intake camshaft pulleyposition isregulated byoil pressure, whichiscontrolled bythe valve timing

control solenoid valve.

Drain .. Intake

airsignal (From massairflow sensor)

Engine speedsignal(From camshaft positionsensor)

Engine coolant temperature (Fromengine coolant temperature sensor)

Throttle valveidleposition (Fromthrottle position sensor)

Vehicle speed(Fromvehicle speedsensor)

"'- Camshaft (Intakeside)

EGM

(EGGS

control

module)

/

Camshaft sprocket

Piston

Valve

timing control ~

»

'o'""oid ,,',"

Ii

/

Return spring

MEF572DA

EC-198

Page 918 of 1701

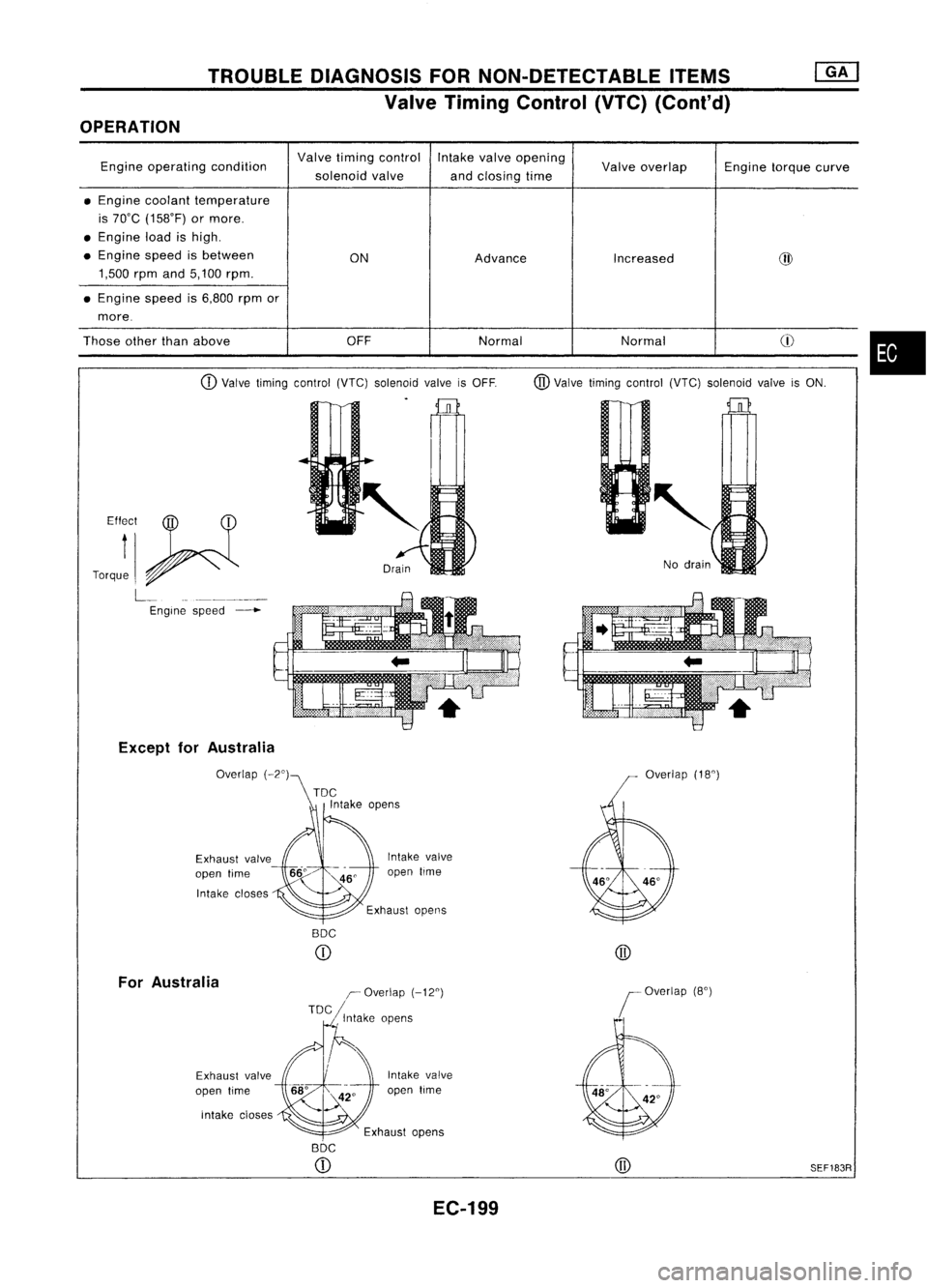

TROUBLEDIAGNOSIS FORNON-DETECTABLE ITEMS

Valve Timing Control (VTC)(Cont'd)

OPERATION

Engine operating condition Valve

timing control Intakevalveopening

Valveoverlap Enginetorquecurve

solenoid valve

andclosing time

• Engine coolant temperature

is 70"C (158"F) ormore .

• Engine loadishigh .

• Engine speedisbetween

ONAdvance

Increased @

1,500 rpmand5,100 rpm.

• Engine speedis6,800 rpmor

more.

Those otherthanabove OFFNormal Normal

CD

CD

Valve timing control (VTC)solenoid valveisOFF. @Valve timing control (VTC)solenoid valveisON.

•

Effr

t

f__ ~

Torque ~

L__ _

Engine speed

--+-

Except forAustralia

Exhaust valve

open time

Intake closes

For Australia

Exhaust valve

open time

intake cioses Intake

valve

open lime

BOC

CD

I~Overlap (-12°)

TOC ,Intake opens

Intake valve

open time Overlap

(18°)

@

BOC

CD

EC-199 @

SEF183R

Page 919 of 1701

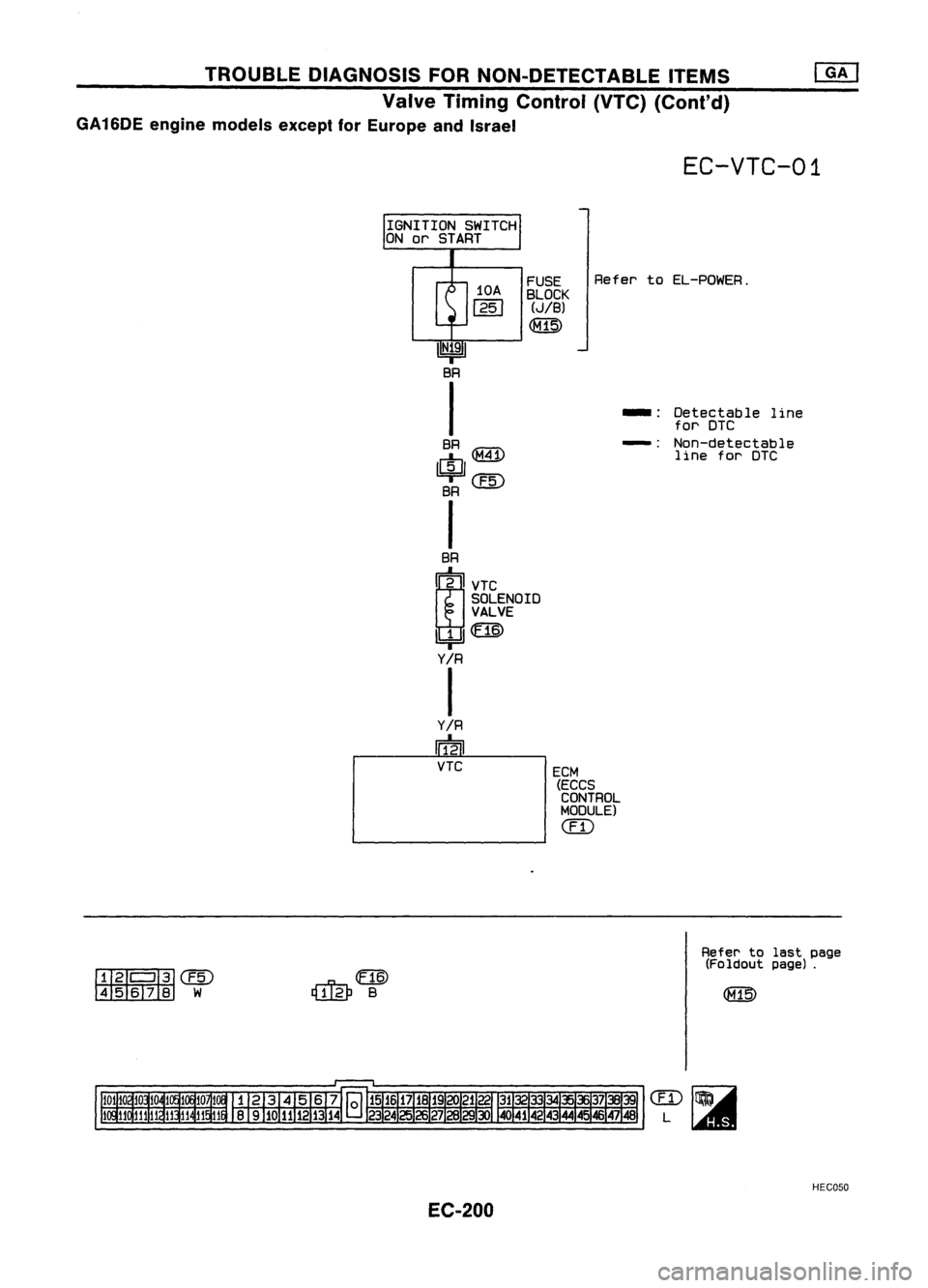

TROUBLEDIAGNOSIS FORNON-DETECTABLE ITEMS

Valve Timing Control (VTC)(Cont'd)

GA 16DE engine models exceptforEurope andIsrael

EC-VTC-01

IGNITION SWITCH

ON orSTART

10A

1251

FUSE

BLOCK

(JIB)

toEL-POWER.

fill

I

,~@

45678 W

~

Y.1.J.gjJ

B

IN~91

BR

I

8R

rn@)

U4Jl@

BR

I

BR

~VTC SOLENOIDVALVE

14=JJ~

Y/R

I

Y/R

~

VTC

-:

Oetectable line

for DTC

-: Non-detectable

line forDTC

ECM (ECCS CONTROL

MODULE)

ill)

Refertolast page

(Foldout page).

HEC050

EC-200

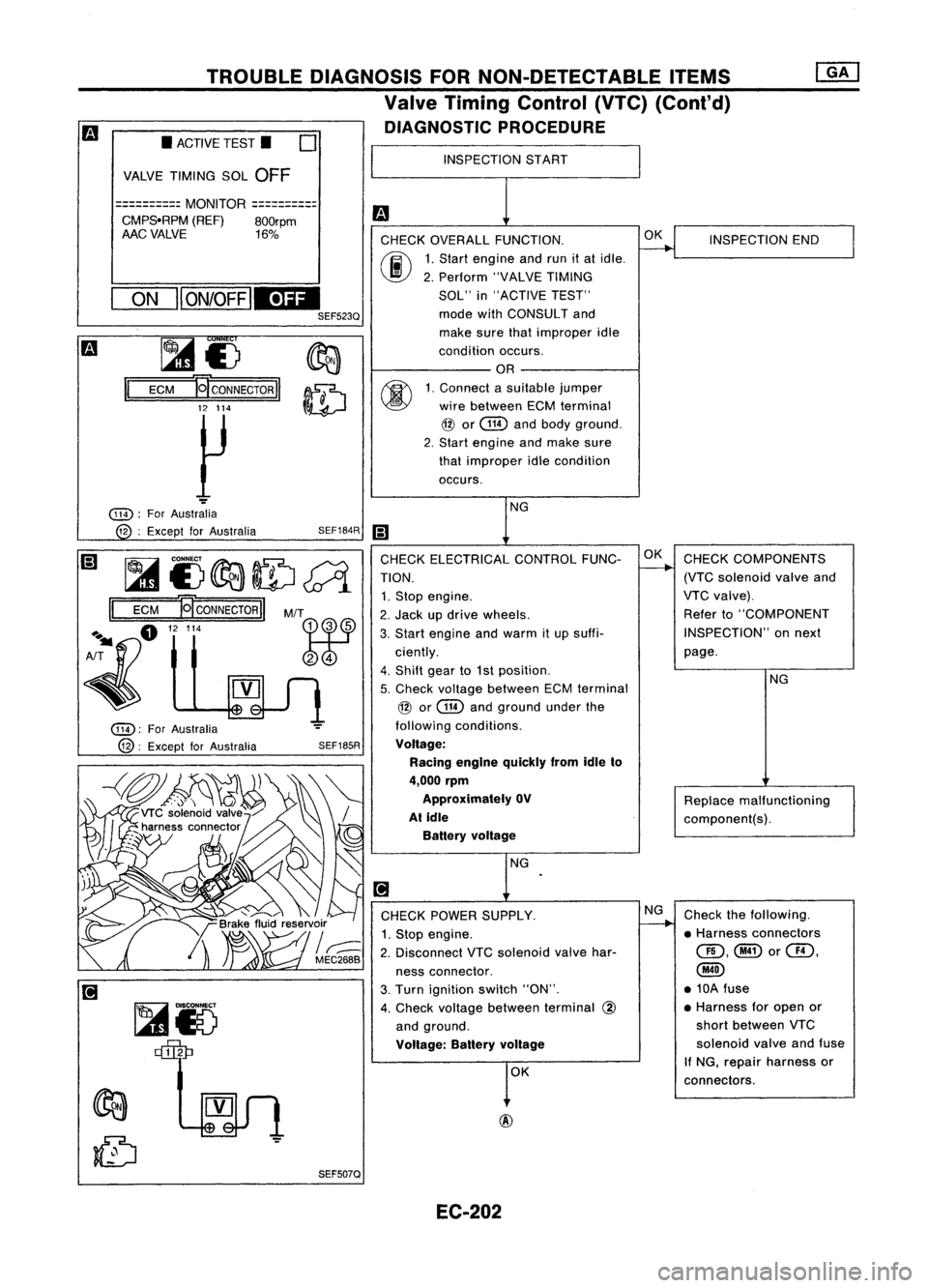

Page 921 of 1701

TROUBLEDIAGNOSIS FORNON-DETECTABLE ITEMS

Valve Timing Control (VTC)(Cant'd)

DIAGNOSTIC PROCEDURE

INSPECTION START

m

CHECK OVERALL FUNCTION.

~

INSPECTION

END

00

1.

Start engine andrunitat idle.

2. Perform "VALVETIMING

SOL" in"ACTIVE TEST"

mode withCONSULT and

make surethatimproper idle

condition occurs.

OR

00

1.

Connect asuitable jumper

wire between ECMterminal

@

or

@

andbody ground.

2. Start engine andmake sure

that improper idlecondition

occurs.

NG

iii

CHECK ELECTRICAL CONTROLFUNC-OK

CHECK COMPONENTS

TION.

-+

(VTCsolenoid valveand

1. Stop engine. VTC

valve).

2. Jack updrive wheels. Refer

to"COMPONENT

3. Start engine andwarm itup suffi- INSPECTION"

onnext

ciently. page.

4. Shift gearto1st position.

NG

5. Check voltage between ECMterminal

@

or

@

andground underthe

following conditions.

Voltage: Racing engine quickly fromidleto

4,000 rpm

Approximately OV

Replacemalfunctioning

At idle

component(s).

Battery voltage

NG

.

[!J

CHECK POWER SUPPLY. NG

Check thefollowing.

1. Stop engine.

~

•Harness connectors

2. Disconnect VTCsolenoid valvehar- QD,@or@,

ness connector.

@

3. Turn ignition switch"ON". •

10A fuse

4. Check voltage between terminal

@

•

Harness foropen or

and ground. short

between VTC

Voltage: Batteryvoltage

solenoid

valveandfuse

OK If

NG, repair harness or

connectors.

SEF185R

SEF507Q

SEF184R

M/T

~r5 ~

~£)

II

ECM

~CONNECTORII

12 114

~

ON

II

ON/OFF

IEDI

SEF523Q

•

ACTIVE TEST.

0

VALVE TIMING SOL

OFF

==========

MONITOR

==========

CMPS.RPM (REF)800rpm

AAC VALVE 16%

@):

ForAustralia

@:

Except forAustralia

@):

ForAustralia

12 :Except forAustralia

~i)~ID~

II

ECM

NCONNECTORII

A~fl "'"

~

EC-202