engine NISSAN ALMERA N15 1995 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 963 of 1701

@

START

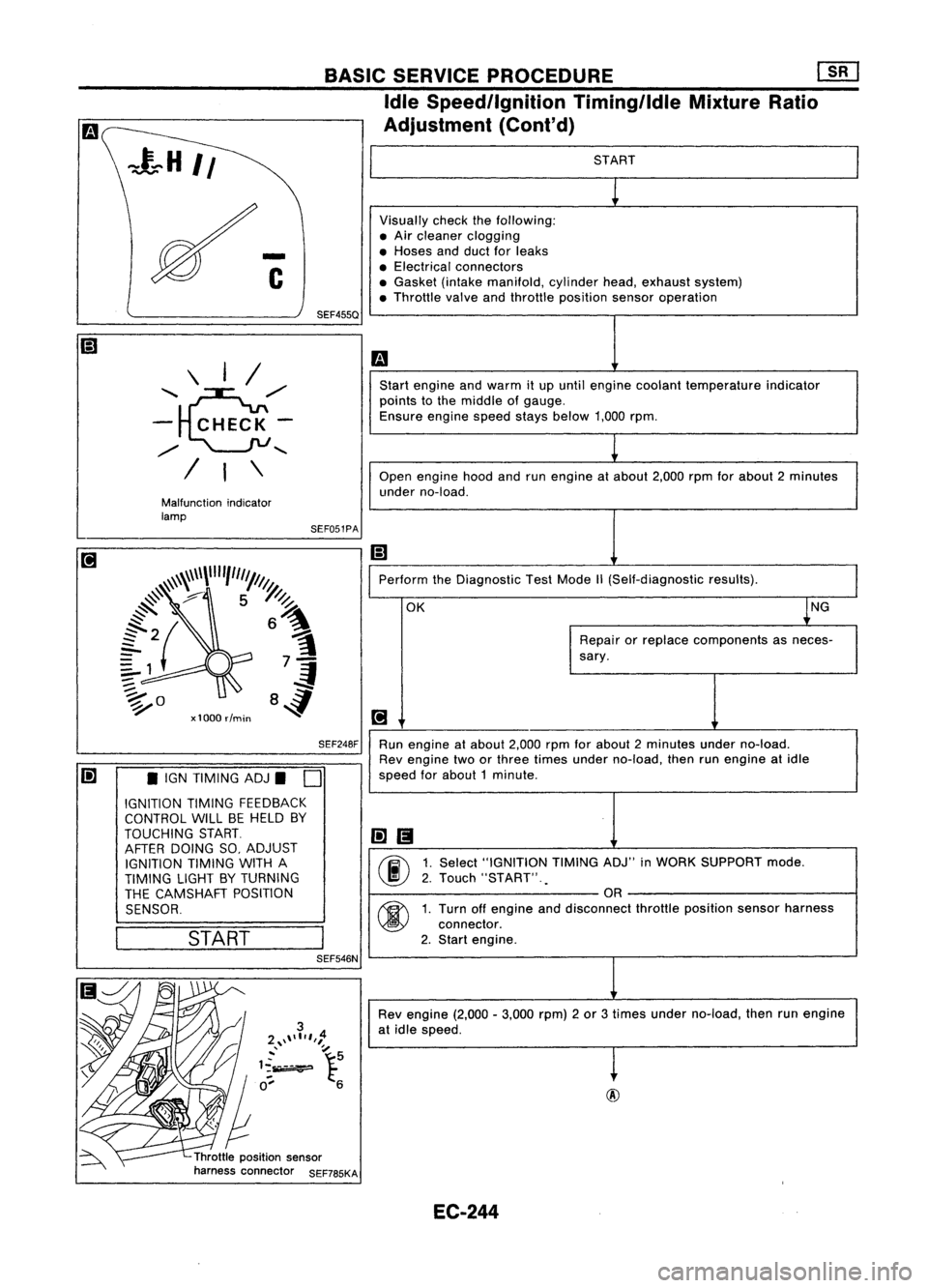

Visually checkthefollowing:

• Air cleaner clogging

• Hoses andduct forleaks

• Electrical connectors

• Gasket (intakemanifold, cylinderhead,exhaust system)

• Throttle valveandthrottle position sensoroperation

m

Start engine andwarm itup until engine coolant temperature indicator

points tothe middle ofgauge.

Ensure enginespeedstaysbelow 1,000rpm.

1

Open engine hoodandrunengine atabout 2,000rpmforabout 2minutes

under no-load.

Ii]

Perform theDiagnostic TestMode

1\

(Self-diagnostic results).

OK ~NG

Repair orreplace components asneces-

sary.

[!J

Run engine atabout 2,000rpmforabout 2minutes underno-load.

Rev engine twoorthree times under no-load, thenrunengine atidle

speed forabout 1minute .

li]1!I

00

1.

Select "IGNITION TIMINGADJ"inWORK SUPPORT mode.

2. Touch "START" .

.

OR

00

1.

Turn offengine anddisconnect throttleposition sensorharness

connector.

2. Start engine.

Rev engine (2,000-3,000 rpm)2or 3times under no-load, thenrunengine

at idle speed.

t

Throttle position sensor

harness connector SEF785KASEF051PA

BASIC

SERVICE PROCEDURE Em

Idle Speedllgnition TiminglldleMixtureRatio

Adjustment (Cont'd)

SEF248F

SEF455Q

Malfunction indicator

lamp \

I/

'~,,/

- CHECK-

,,/

........

/ I\

Ii] •IGN TIMING ADJ.

D

IGNITION TIMINGFEEDBACK

CONTROL WILLBEHELD BY

TOUCHING START.

AFTER DOING SO,ADJUST

IGNITION TIMINGWITHA

TIMING LIGHTBYTURNING

THE CAMSHAFT POSITION

SENSOR.

I

START

I

SEF546N

EC-244

Page 964 of 1701

AEC804

•

Ii

L

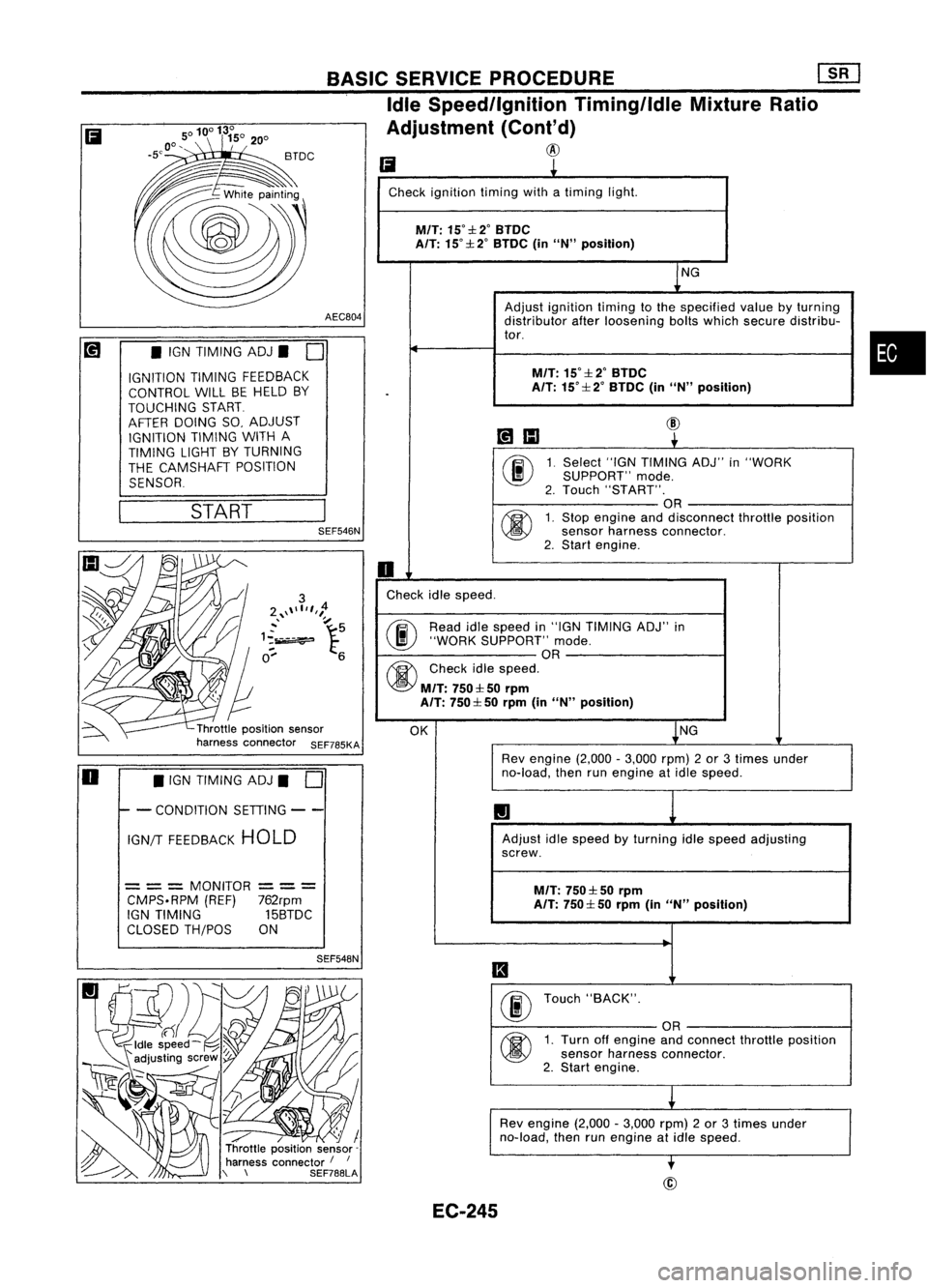

Check ignition timingwithatiming light.

M/T:

15°::l:2°BTDC

A/T: 15°::l: 2°BTDC (inUN" position)

NG

Adjust ignition timingtothe specified valuebyturning

distributor afterloosening boltswhich secure distribu-

tor.

M/T:

15°::l:2°BTDC

.

A/T:

15°::l: 2°BTDC (inUN" position)

~IIJ

@

~

00

1.

Select

"IGNTIMING ADJ"in"WORK

SUPPORT" mode.

2. Touch "START".

OR

@

1.

Stop engine anddisconnect throttleposition

sensor harness connector.

2. Start engine.

0

Check idlespeed.

@ Read

idlespeed in"IGN TIMING ADJ"in

"WORK SUPPORT" mode.

OR

@

Checkidlespeed.

M/T:

750::l: 50rprn

A/T: 750::l: 50rprn (inUN" position)

OK NG

Rev engine (2,000-3,000 rpm)2or 3times under

no-load, thenrunengine atidle speed.

1.1

Adjust idlespeed byturning idlespeed adjusting

screw.

M/T:

750::l: 50rpm

A/T: 750::l: 50rprn (inUN" position)

II

00

Touch

"BACK".

OR

@

1.

Turn offengine andconnect throttleposition

sensor harness connector.

2. Start engine.

L

Rev engine (2,000-3,000 rpm)2or 3times under

no-load, thenrunengine atidle speed.

-.

BASIC

SERVICE PROCEDURE

[]K]

Idle Speed/Ignition Timing/IdleMixtureRatio

Adjustment (Cont'd)

@

SEF548N

/ / I

Throttle position sensor-

harness connector /

I

\ \ SEF788LASEF546N

START

•

IGN TIMING ADJ.

0

IGNITION TIMINGFEEDBACK

CONTROL WILLBEHELD BY

TOUCHING START

AFTER DOING SO,ADJUST

IGNITION TIMINGWITHA

TIMING LIGHTBYTURNING

THE CAMSHAFT POSITION

SENSOR

= ==

MONITOR

==

=

CMPS.RPM (REF)762rpm

IGN TIMING 15BTDC

CLOSED TH/POS ON

Ii

o •

IGN TIMING ADJ.

0

I- -

CONDITION SETIING--

IGN/T FEEDBACK HOLD

EC-245

Page 965 of 1701

BASICSERVICE PROCEDURE

mJ

Idle Speed/Ignition Timing/IdleMixtureRatio

Adjustment (Cont'd)

@

SEF909P SEF913J

RECORD

@

M

may bethe

se ofa

blem, butthis

arely thecase

II

1

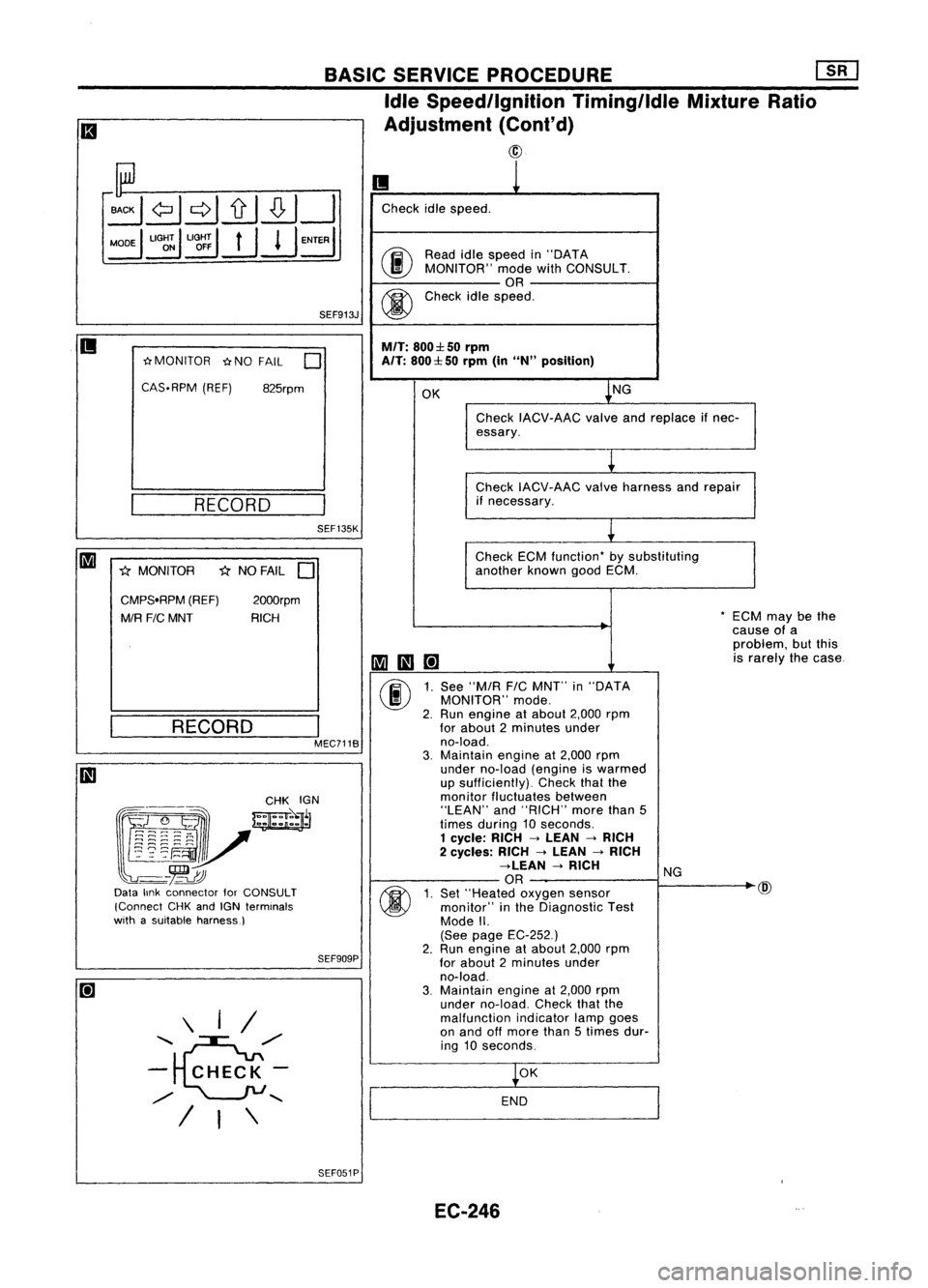

Check idlespeed.

00

Read

idlespeed in"DATA

MONITOR" modewithCONSULT.

OR

@

Check

idlespeed.

M/T:

800:l: 50rpm

A/T:

800:l: 50rpm (in

uN"

position)

OK ~NG

Check IACV-AAC valveandreplace ifnec-

essary.

~

Check IACV-AAC valveharness andrepair

if necessary.

~

Check ECMfunction- bysubstituting

another knowngoodECM.

-EC

cau

pro

1II111[!]

is

r

(j)

1.

See "M/R

FIC

MNT" in"DATA

MONITOR" mode.

2. Run engine atabout 2,000rpm

for about 2minutes under

no-load.

3.

Maintain engineat2,000 rpm

under no-load (engineiswarmed

up sufficiently). Checkthatthe

monitor fluctuates between

"LEAN" and"RICH" morethan5

times during 10seconds.

1 cycle: RICH->LEAN ->RICH

2 cycles: RICH->LEAN ->RICH

->LEAN ->RICH

NG

OR

~

(j)

1.

Set "Heated oxygensensor

monitor" inthe Diagnostic Test

Mode II.

(See page EC-252.)

2. Run

engine atabout 2,000rpm

for about 2minutes under

no-load.

3.

Maintain

engineat2,000 rpm

under no-load. Checkthatthe

malfunction indicatorlampgoes

on and offmore than5times dur-

ing 10seconds.

~OK

END

SEF135K

I

MEC7118

825rpm

2000rpm

RICH

1<

NO FAIL

D

RECORD

\ I/

.........

~/"

- CHECK-

/

......

/ I\

~MONITOR

~NOFAIL

0

CAS-RPM (REF)

CMPS.RPM (REF)

MIR

FIC

MNT

1<

MONITOR

@~~

~~r

~~V

-

-~

Data linkconnector forCONSULT

(Connect CHKandIGN terminals

with asuitable harness)

II

SEF051PEC-246

Page 966 of 1701

![NISSAN ALMERA N15 1995 Service Manual Heatedoxygen sensor

harness connector BASIC

SERVICE PROCEDURE [][]

Idle Speed/Ignition Timing/IdleMixtureRatio

Adjustment (Cont'd)

@

II

MEF031DB

~io

ECM TIcoNNECTORl1

19

LEn

MEC712B

Check

NISSAN ALMERA N15 1995 Service Manual Heatedoxygen sensor

harness connector BASIC

SERVICE PROCEDURE [][]

Idle Speed/Ignition Timing/IdleMixtureRatio

Adjustment (Cont'd)

@

II

MEF031DB

~io

ECM TIcoNNECTORl1

19

LEn

MEC712B

Check](/img/5/57349/w960_57349-965.png)

Heatedoxygen sensor

harness connector BASIC

SERVICE PROCEDURE [][]

Idle Speed/Ignition Timing/IdleMixtureRatio

Adjustment (Cont'd)

@

II

MEF031DB

~io

ECM TIcoNNECTORl1

19

LEn

MEC712B

Check

heated oxygen sensorharness:

1. Turn offengine anddisconnect batteryground

cable.

2. Disconnect ECMharness connector fromECM.

3. Disconnect heatedoxygen sensorharness con-

nector. Thenconnect harness sideterminal for

heated oxygen sensortoground withajumper

wire.

4. Check forcontinuity betweenterminal

@

ofECM

harness connector andbody ground.

Continuity exists OK

Continuity doesnotexist NG

OK

Repairorreplace harness.

Connect ECMharness connector toECM .

•

OR

1.

Connect batteryground cable.

2. Select "ENGCOOLANT TEMP"in

"ACTIVE TEST"mode.

3. Set "COOLANT TEMP"to20"C (68"F) by

touching "Qu"and"Qd" and"UP",

"DWN".

Disconnect enginecoolant temperature

sensor harness connector.

2. Connect aresistor (2.5kQ)between termi-

nals ofengine coolant temperature sensor

harness connector.

3. Connect batteryground cable.

Ii

AEC681

•

ACTIVE TEST.

0

COOLANT TEMP 20°C

===MONITOR=== CMPS.RPM (REF)

Orpm

INJ PULSE

O.7msec

IGN TIMING 5BTDC

DISCONNFCT

Enginecoolant

10 temperature

sensor

harness connector

~ ~

00

2.5

k0 resistor

Start

engine andwarm itup until engine coolant

temperature indicatorpointstomiddle ofgauge.

(Be sure tostart engine aftersetting "COOLANT

'-- A_E_C6_8-l2

TEMP"orinstalling a2.5 kQresistor.)

Ii

SEF455QEC-247

Page 967 of 1701

m

1

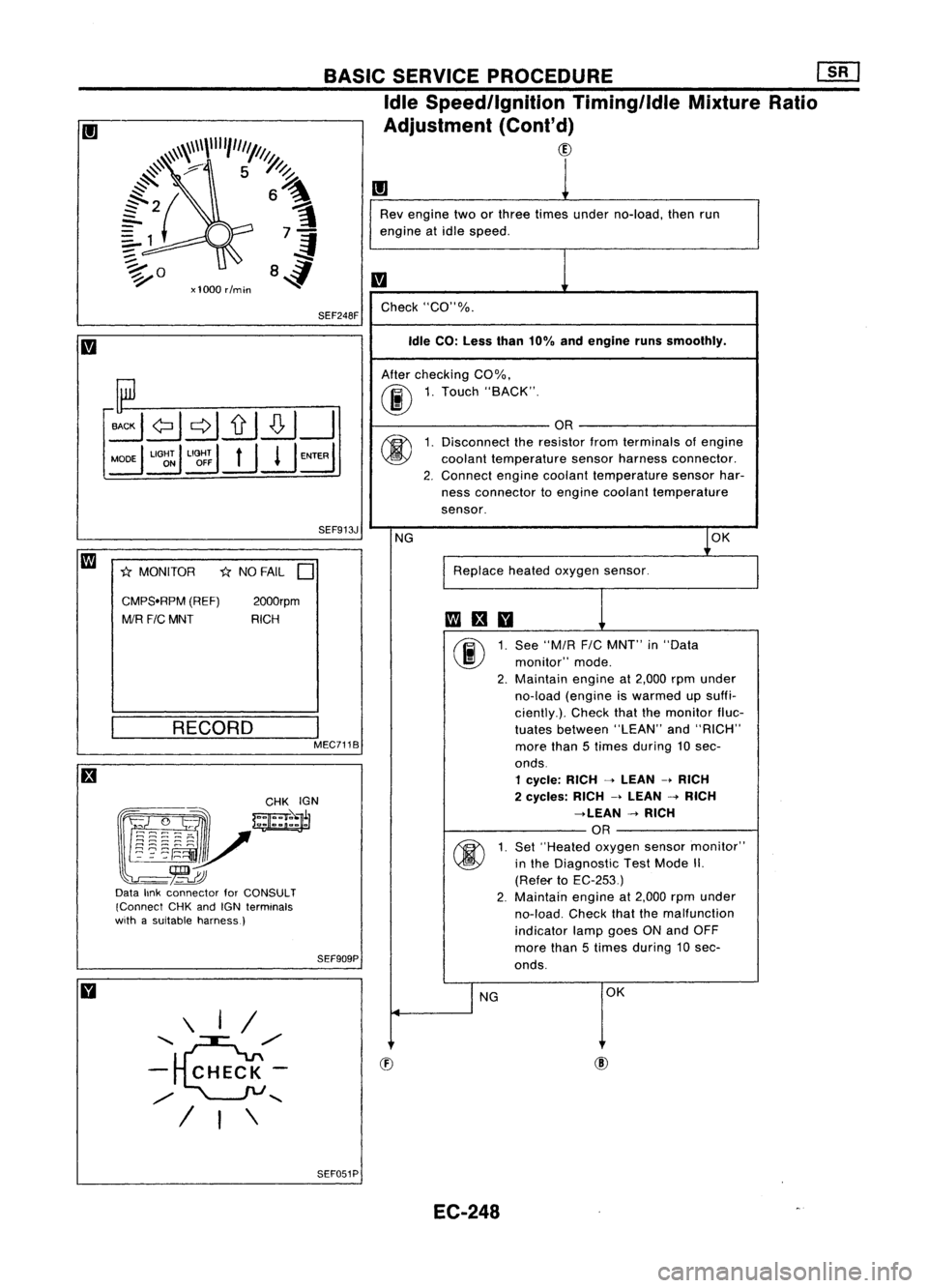

Rev engine twoorthree times under no-load, thenrun

engine atidle speed.

m

Check "CO"%.

Idle CO: Less than10%andengine runssmoothly.

After checking CO%.

00

1.

Touch "BACK".

OR

(j)

1.

Disconnect theresistor fromterminals ofengine

coolant temperature sensorharness connector.

2. Connect

enginecoolant temperature sensorhar-

ness connector toengine coolant temperature

sensor.

NG

1

0K

Replace heatedoxygen sensor.

fa

an

00

1.

See

"MIR

FIC

MNT" in"Data

monitor" mode.

2. Maintain

engineat2,000 rpmunder

no-load (engine iswarmed upsuffi-

ciently.). Checkthatthemonitor fluc-

tuates between "LEAN"and"RICH"

more than5times during 10sec-

onds.

1 cycle: RICH-->LEAN -.RICH

2 cycles: RICH-->LEAN -->RICH

-->LEAN -->RICH

OR

(j)

1.

Set

"Heated oxygensensormonitor"

in the Diagnostic TestMode II.

(Refef'to EC-253)

2. Maintain

engineat2,000 rpmunder

no-load. Checkthatthemalfunction

indicator lampgoesONand OFF

more than5times during 10sec-

onds.

I

NG OK

SEF913J

I

MEC7118

2000rpm

RICH

*

NO FAIL

D

RECORD

SEF909PBASIC

SERVICE PROCEDURE

mJ

Idle Speed/Ignition Timing/ldleMixtureRatio

Adjustment (Cont'd)

CID

SEF248F

\ I/

.........

~/'

- CHECK-

/

.......

/ I\

CMPS.RPM

(REF)

MIR F/CMNT

*

MONITOR

~~~~:?_-~ .

w=jr

~~~~"v

-~

Data linkconnector forCONSULT

(Connect CHKandIGN terminals

with asuitable harness)

SEF051PEC-248

Page 968 of 1701

![NISSAN ALMERA N15 1995 Service Manual

,$

BASIC

SERVICE PROCEDURE

[]K]

Idle Speedllgnition TiminglldleMixtureRatio

Adjustment (Cont'd)

CD

•

ause ofaproblem, but

It

IS IS

rarely thecase.

1

Connect heatedoxygen sensorharness NISSAN ALMERA N15 1995 Service Manual

,$

BASIC

SERVICE PROCEDURE

[]K]

Idle Speedllgnition TiminglldleMixtureRatio

Adjustment (Cont'd)

CD

•

ause ofaproblem, but

It

IS IS

rarely thecase.

1

Connect heatedoxygen sensorharness](/img/5/57349/w960_57349-967.png)

,$

BASIC

SERVICE PROCEDURE

[]K]

Idle Speedllgnition TiminglldleMixtureRatio

Adjustment (Cont'd)

CD

•

ause ofaproblem, but

It

IS IS

rarely thecase.

1

Connect heatedoxygen sensorharness connec-

tor toheated oxygen sensor.

Check fuelpressure regulator.

(Refer toEC-242.)

Check massairflow sensor anditscircuit.

Refer toTROUBLE DIAGNOSIS FORDTC12.

(Refer toEC-293.)

Check injector anditscircuit.

Refer toTROUBLE DIAGNOSIS FORNON

DETECTABLE ITEMS.

(Refer toEC-324.)

Clean orreplace ifnecessary.

Check engine coolant temperature sensorand

its circuit. RefertoTROUBLE DIAGNOSIS FOR

DTC 13.

(Refer toEC-297.)

Check ECMfunction' bysubstituting another

known goodECM

•.ECM maybethe c

1

EC-249

Page 969 of 1701

ON-BOARDDIAGNOSTIC SYSTEMDESCRIPTION

\ I/

'~/'

- CHECK-

/

.......

/ I\

SEF051P

Malfunction

Indicatorlamp(Mil)

1. The malfunction indicatorlampwilllight upwhen theigni-

tion switch isturned ONwithout theengine running. Thisis

a bulb check.

• Ifthe malfunction indicatorlampdoes notlight up,refer to

EL section ("WARNING LAMPSANDCHIME") orsee

EC-370.

2. When theengine isstarted, themalfunction indicatorlamp

should gooff.

Condition Diagnostic

Diagnostic

Test Mode I TestMode II

Engine

stopped BULBCHECK SELF-DIAGNOSTIC

Ignition

0

RESULTS

switch in

"ON" posi-

tion Engine

HEATEDOXYGEN

~ running

MALFUNCTION

SENSORMONI-

ID

WARNING

TOR

EC-250

Page 970 of 1701

ON-BOARDDIAGNOSTIC SYSTEMDESCRIPTION

Malfunction IndicatorLamp(MIL)(Cont'd)

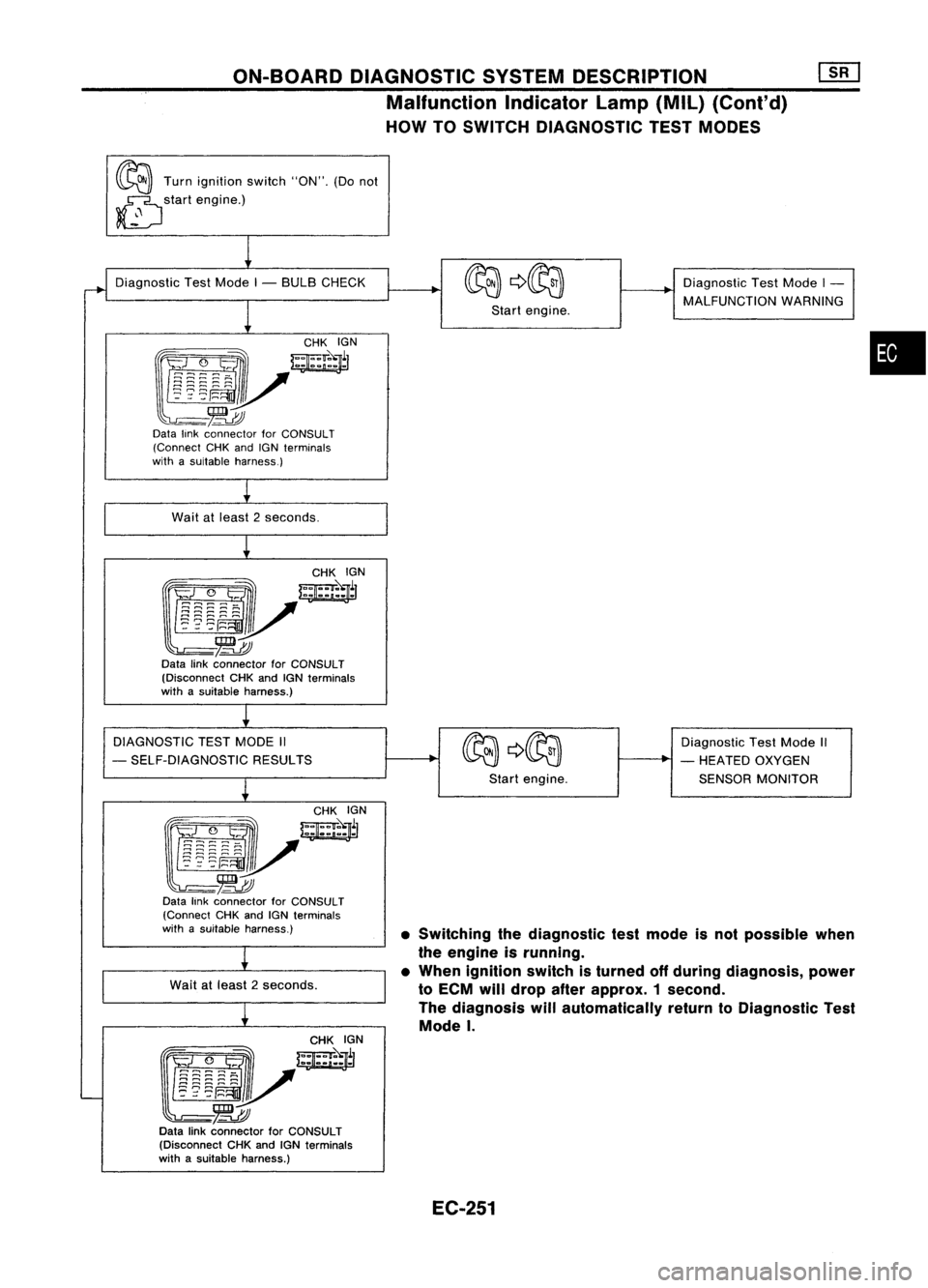

HOW TOSWITCH DIAGNOSTIC TESTMODES

~ Turnignition switch"ON".(Donot

~ startengine.)

~

•SWitching thediagnostic testmode isnot possible when

the engine isrunning.

• When ignition switchisturned offduring diagnosis, power

to ECM willdrop afterapprox. 1second.

The diagnosis willautomatically returntoDiagnostic Test

Mode

I.

Diagnostic

TestMode I- BULB CHECK

1

~yW~r

~-~

Data linkconnector forCONSULT

(Connect CHKandIGNterminals

with asuitable harness.)

Wait atleast 2seconds.

CHKIGN

~J/~l

~-~

Data linkconnector forCONSULT

(Disconnect CHKandIGNterminals

with asuitable harness.)

DIAGNOSTIC TESTMODE II

- SELF-DIAGNOSTIC RESULTS

~

f!i~:~~-~

w;ir

l~mv

-~

Data linkconnector forCONSULT

(Connect CHKandIGN terminals

with asuitable harness.)

Wait atleast 2seconds.

~

~/~~N

~-~

Data linkconnector forCONSULT

(Disconnect CHKandIGNterminals

with asuitable harness.)

I

Startengine.

Start engine. Diagnostic

TestMode I-

MALFUNCTION WARNING

Diagnostic TestMode II

- HEATED OXYGEN

SENSOR MONITOR

•

EC-251

Page 971 of 1701

ON-BOARDDIAGNOSTIC SYSTEMDESCRIPTION ~

Malfunction IndicatorLamp(MIL)(Cont'd)

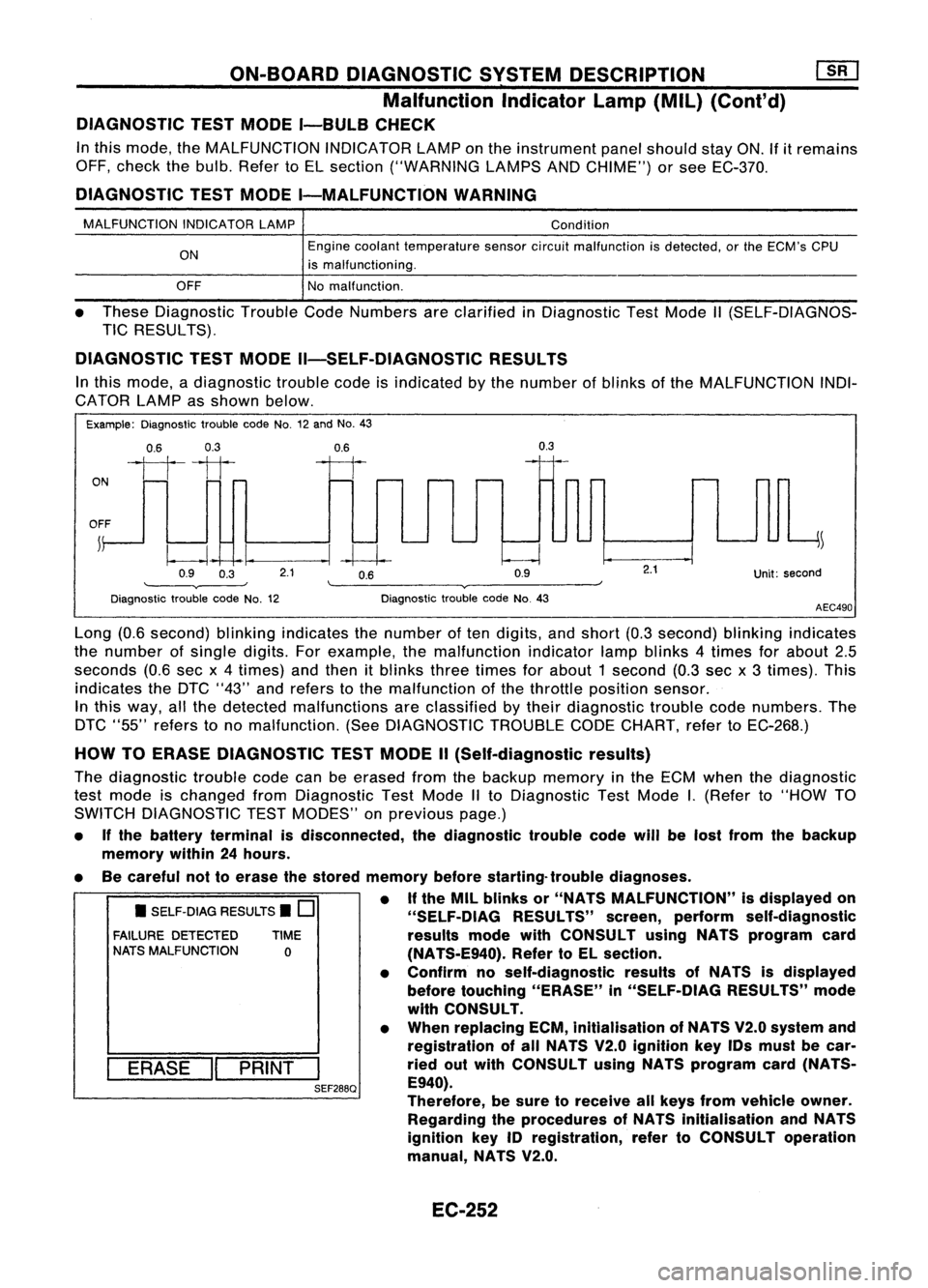

DIAGNOSTIC TESTMODE I-BULB CHECK

In this mode, theMALFUNCTION INDICATORLAMPonthe instrument panelshould stayON.If

it

remains

OFF, check thebulb. Refer toEL section ("WARNING LAMPSANDCHIME") orsee EC-370.

DIAGNOSTIC TESTMODE I-MALFUNCTION WARNING

MALFUNCTION INDICATORLAMP

ON

OFF Condition

Engine coolant temperature sensorcircuitmalfunction isdetected, orthe ECM's CPU

is malfunctioning.

No malfunction.

• These Diagnostic TroubleCodeNumbers areclarified inDiagnostic TestMode II(SELF-DIAGNOS-

TIC RESULTS).

DIAGNOSTIC TESTMODE II-SELF-DIAGNOSTIC RESULTS

In this mode, adiagnostic troublecodeisindicated bythe number ofblinks ofthe MALFUNCTION INDI-

CATOR LAMPasshown below.

Example: Diagnostic troublecodeNo.12and No.43

0.6 0.3

ON

1111

OFF ~

0.9 0.3

0.6

--I~

2.1 0.6

0.9

0.3

Unit:second

Diagnostic troublecodeNo.12 Diagnostic

troublecodeNo.43

AEC490

• SELF-DIAG RESULTS.

0

FAILURE DETECTED TIME

NATS MALFUNCTION

0

I

ERASE

II

PRINT

I

SEF288Q

Long

(0.6second) blinkingindicates thenumber often digits, andshort (0.3second) blinkingindicates

the number ofsingle digits.Forexample, themalfunction indicatorlampblinks 4times forabout 2.5

seconds (0.6secx4times) andthen itblinks threetimes forabout 1second (0.3sec x3 times). This

indicates theDTC "43" andrefers tothe malfunction ofthe throttle position sensor.

In this way, allthe detected malfunctions areclassified bytheir diagnostic troublecodenumbers. The

DTC "55" refers tono malfunction. (SeeDIAGNOSTIC TROUBLECODECHART, refertoEC-268.)

HOW TOERASE DIAGNOSTIC TESTMODE II(Self-diagnostic results)

The diagnostic troublecodecanbeerased fromthebackup memory inthe ECM when thediagnostic

test mode ischanged fromDiagnostic TestMode IIto Diagnostic TestMode

I.

(Refer to"HOW TO

SWITCH DIAGNOSTIC TESTMODES" onprevious page.)

• Ifthe battery terminal isdisconnected, thediagnostic troublecodewillbelost from thebackup

memory within24hours.

• Becareful nottoerase thestored memory beforestarting- troublediagnoses.

• Ifthe MIL blinks or"NATS MALFUNCTION" isdisplayed on

"SELF-OIAG RESULTS"screen,perform self-diagnostic

results modewithCONSULT usingNATS program card

(NA TS-E940). RefertoEL section.

• Confirm noself-diagnostic resultsofNATS isdisplayed

before touching "ERASE" in"SELF-DiAG RESULTS"mode

with CONSULT.

• When replacing ECM,inltialisation ofNATS V2.0system and

registration ofall NATS V2.0 Ignition keyIDsmust becar-

ried outwith CONSULT usingNATS program card(NATS-

E940).

Therefore, besure toreceive allkeys from vehicle owner.

Regarding theprocedures ofNATS initialisation andNATS

ignition key

10

registration, refertoCONSULT operation

manual, NATS V2.0.

EC-252

Page 972 of 1701

![NISSAN ALMERA N15 1995 Service Manual ON-BOARDDIAGNOSTIC SYSTEMDESCRIPTION

[]K]

Malfunction Indicatorlamp(Mil)(Cont'd)

DIAGNOSTIC TESTMODE II-HEATED OXYGENSENSORMONITOR

In this mode, theMALFUNCTION INDICATORLAMPdisplays theconditi NISSAN ALMERA N15 1995 Service Manual ON-BOARDDIAGNOSTIC SYSTEMDESCRIPTION

[]K]

Malfunction Indicatorlamp(Mil)(Cont'd)

DIAGNOSTIC TESTMODE II-HEATED OXYGENSENSORMONITOR

In this mode, theMALFUNCTION INDICATORLAMPdisplays theconditi](/img/5/57349/w960_57349-971.png)

ON-BOARDDIAGNOSTIC SYSTEMDESCRIPTION

[]K]

Malfunction Indicatorlamp(Mil)(Cont'd)

DIAGNOSTIC TESTMODE II-HEATED OXYGENSENSORMONITOR

In this mode, theMALFUNCTION INDICATORLAMPdisplays thecondition ofthe fuel mixture (leanor

rich) which ismonitored bythe heated oxygen sensor.

MALFUNCTION INDICATORLAMPFuelmixture condition inthe exhaust gasAirfuel ratio feedback controlcondition

ON Lean

Closedloopsystem

OFF Rich

Remains ONorOFF Anycondition

Openloopsystem

To check theheated oxygen sensorfunction, startengine inDiagnostic TestMode II.Then warm itup

until engine coolant temperature indicatorpointstomiddle ofgauge.

Next runengine atabout 2,000rpmforabout 2minutes underno-load conditions. Makesurethatthe•

MALFUNCTION INDICATORLAMPcomes ONmore than5times within 10seconds withengine running

at 2,000 rpmunder no-load.

EC-253