engine NISSAN ALMERA N15 1995 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 845 of 1701

Checkthefollowing.

• Harness continuity

between ECMand

intake airtemperature

sensor

If NG, repair harness or

connectors.

NG

INSPECTION

START

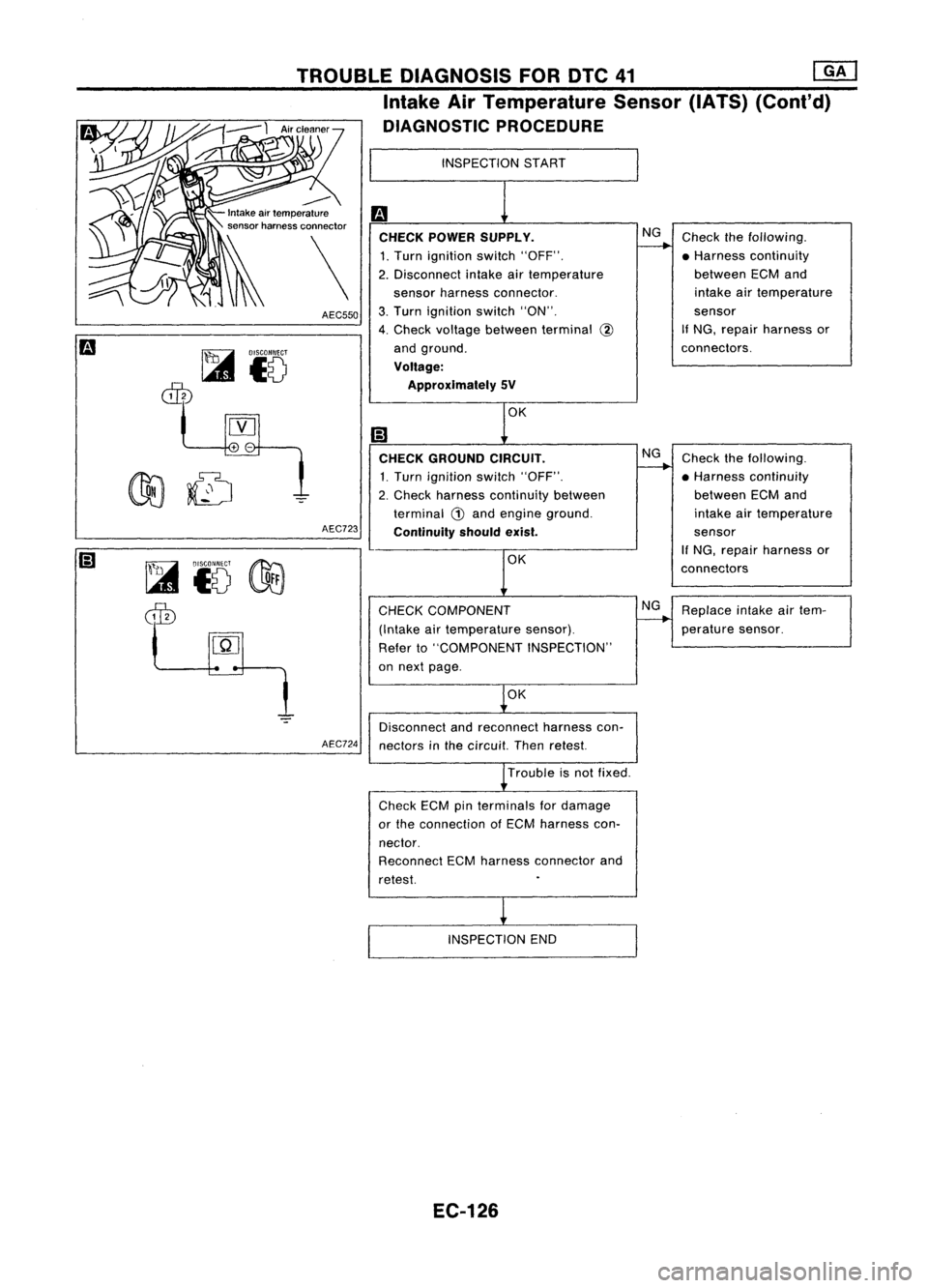

CHECK POWER SUPPLY.

1. Turn ignition switch"OFF".

2. Disconnect intakeairtemperature

sensor harness connector.

3. Turn ignition switch"ON".

4. Check voltage between terminal @

and ground.

Voltage: Approximately SV

TROUBLE

DIAGNOSIS FORDTC41

rnJ

Intake AirTemperature Sensor(IATS)(Cont'd)

DIAGNOSTIC PROCEDURE

--

~

Intake airtemperature

'" '\ sensor harness connector

AEC550

~ DISCONNECT

ciili

10

AEC723

~i5 ~

dID

CHECK

GROUND CIRCUIT.

1. Turn ignition switch"OFF".

2. Check harness continuity between

terminal

G)

and engine ground.

Continuity shouldexist.

OK

CHECK COMPONENT

(Intake airtemperature sensor).

Refer to"COMPONENT INSPECTION"

on next page.

NG

NG

Check

thefollowing.

• Harness continuity

between ECMand

intake airtemperature

sensor

If NG, repair harness or

connectors

Replace intakeairtem-

perature sensor.

OK

Disconnect andreconnect harnesscon-

AEC724

nectorsinthe circuit. Thenretest.

Trouble isnot fixed.

Check ECMpinterminals fordamage

or the connection ofECM harness con-

nector.

Reconnect ECMharness connector and

retest.

INSPECTION END

EC-126

Page 847 of 1701

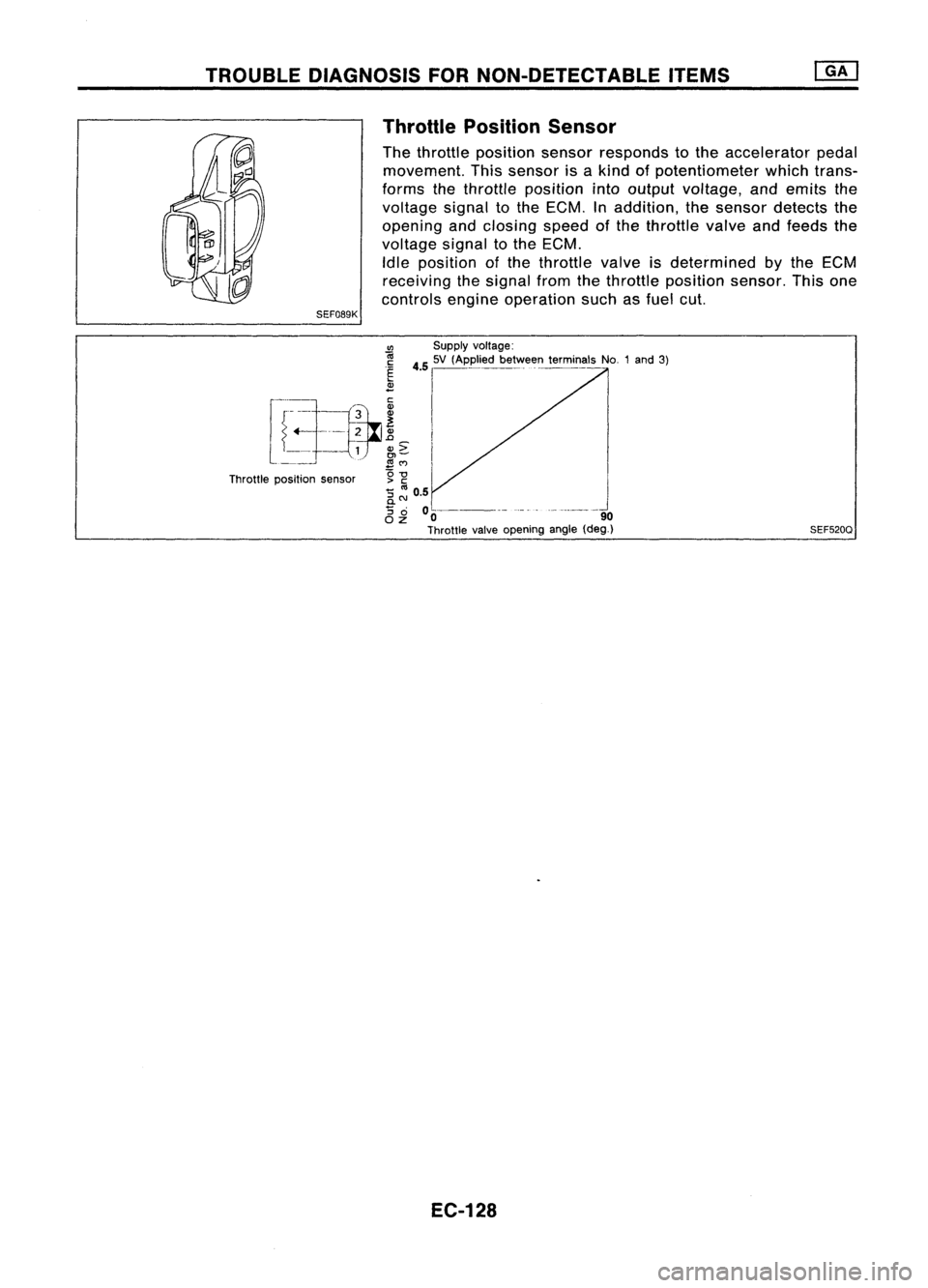

TROUBLEDIAGNOSIS FORNON-DETECTABLE ITEMS

Throttle Position Sensor

The throttle position sensorresponds tothe accelerator pedal

movement. Thissensor isakind ofpotentiometer whichtrans-

forms thethrottle position intooutput voltage, andemits the

voltage signaltothe ECM. Inaddition, thesensor detects the

opening andclosing speedofthe throttle valveandfeeds the

voltage signaltothe ECM.

Idle position ofthe throttle valveisdetermined

by

the ECM

receiving thesignal fromthethrottle position sensor.Thisone

controls engineoperation suchasfuel cut.

SEF089K

CIl

Supplyvoltage:

r

-i.~h __

~3_

i

45

I

'V ,Appl.' b....

ffi

t~miMI,

No1,,'

31

~_ =r--=-tfr ~

I

l ~

1

N~

I

Throttle position sensor g

-g

'5 ::: 0.5

0-

'5

0 0----- -_.- --------_.

OZ 0 90

Throttle valveopening angle(deg_)

EC-128 SEF520Q

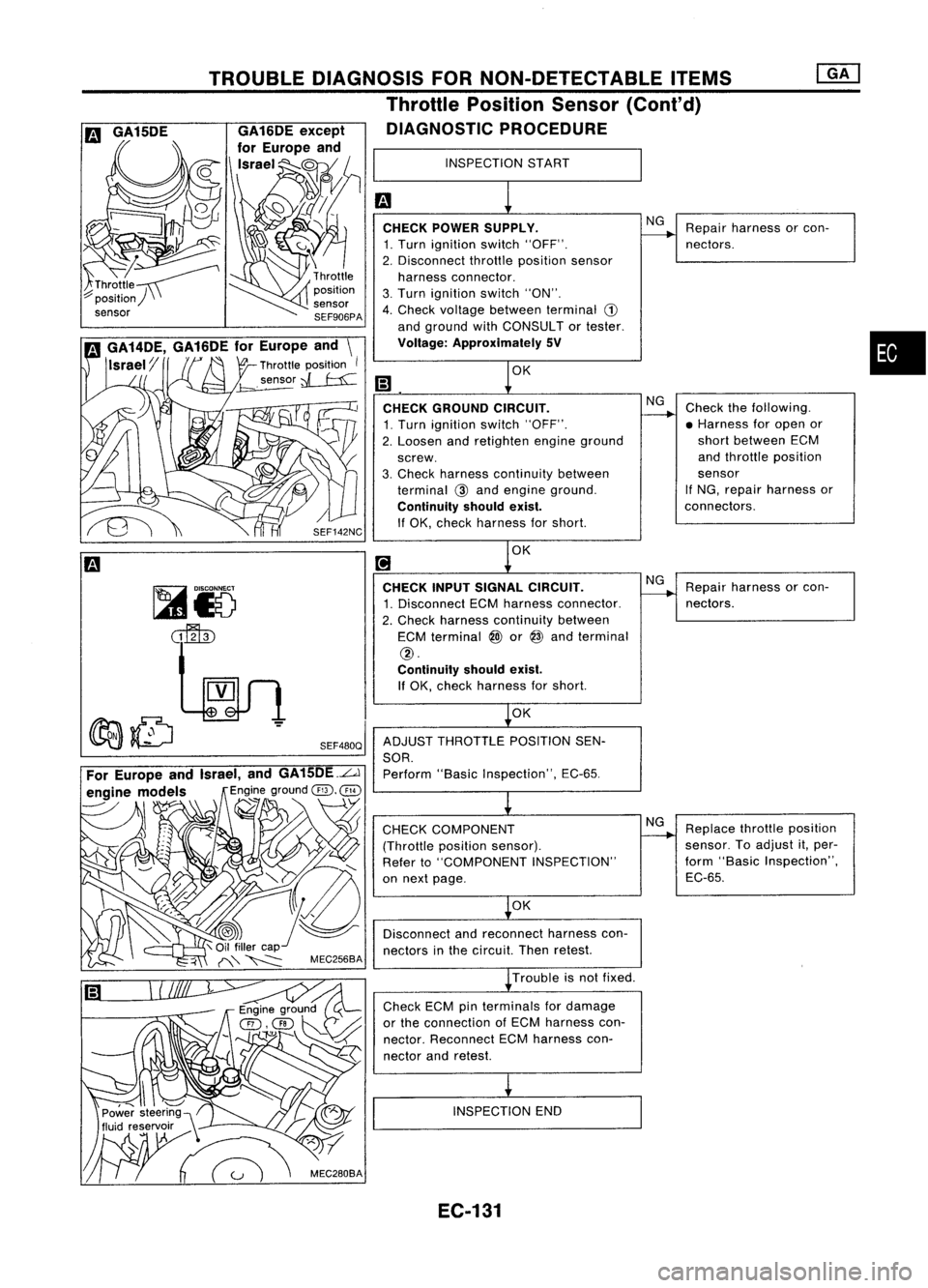

Page 850 of 1701

•

INSPECTION

START

m

1

CHECK POWER SUPPLY.

NG

Repair harness orcon-

------.

1. Turn ignition switch"OFF". nectors.

2. Disconnect throttleposition sensor

harness connector.

3. Turn ignition switch"ON".

4. Check voltage between terminal

CD

and ground withCONSULTor tester.

Voltage: Approximately SV

m

1

0K

CHECK GROUND CIRCUIT.

NG

Check thefollowing.

1. Turn ignition switch"OFF".

------.

•Harness foropen or

2. Loosen andretighten engineground short

between ECM

screw. and

throttle position

3. Check harness continuity between sensor

terminal

@

and engine ground. If

NG, repair harness or

Continuity shouldexist.

connectors.

If OK, check harness forshort.

[!J

1

0K

CHECK INPUTSIGNAL CIRCUIT.

NG

Repair harness orcon-

1. Disconnect ECMharness connector.

------.

nectors.

2. Check harness continuity between

ECM terminal

@)

or

@

and terminal

@.

Continuity shouldexist.

If OK, check harness forshort.

~OK

ADJUST THROTTLE POSITIONSEN-

SOR. Perform "BasicInspection", EC-65.

~

CHECK COMPONENT NG

Replace throttleposition

(Throttle positionsensor).

------.

sensor. Toadjust it,per-

Refer to"COMPONENT INSPECTION" form

"Basic Inspection",

on next page. EC-65.

~OK

Disconnect andreconnect harnesscon-

nectors inthe circuit. Thenretest.

~ Trouble isnot fixed.

Check ECMpinterminals fordamage

or the connection ofECM harness con-

nector. Reconnect ECMharness con-

nector andretest.

i

INSPECTION END

SEF480Q

TROUBLE

DIAGNOSIS FORNON-DETECTABLE ITEMS

Throttle Position Sensor(Cont'd)

DIAGNOSTIC PROCEDURE

,~\ C/

Power steering)\

~

m

GA15DE

EC-131

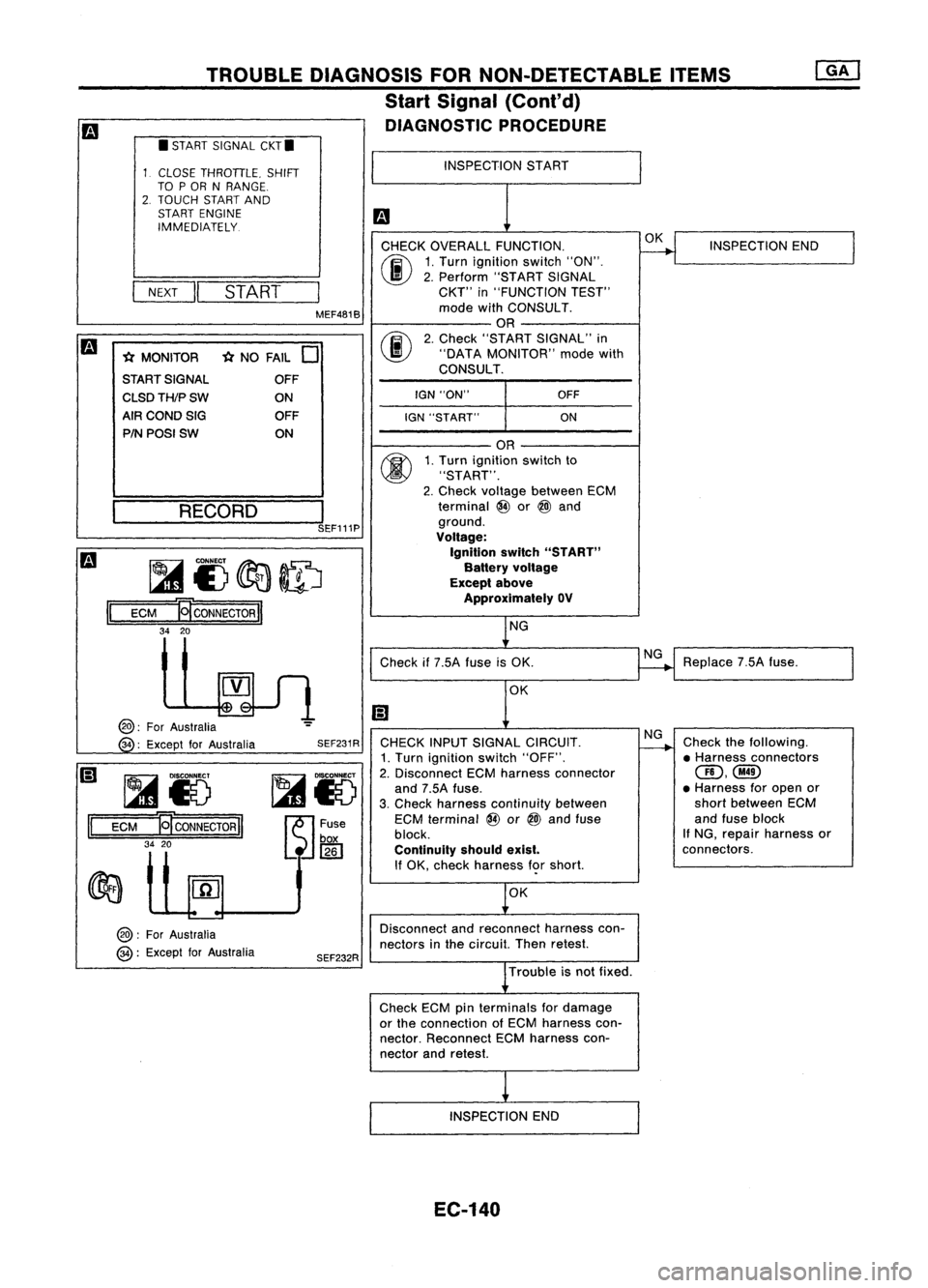

Page 859 of 1701

TROUBLEDIAGNOSIS FORNON-DETECTABLE ITEMS

Start Signal (Cont'd)

DIAGNOSTIC PROCEDURE

CHECK OVERALL FUNCTION.

00

1.

Turn ignition switch"ON".

I

II

2.

Perform "STARTSIGNAL

NEXT

START

CKT"

in"FUNCTION TEST"

MEF481B mode

withCONSULT.

OR

m

00

2.

Check "START SIGNAL" in

* MONITOR *

NO FAIL

0

"DATA

MONITOR" modewith

START SIGNAL CONSULT.

OFF

I

CLSDTH/PSW

ONIGN

"ON" OFF

AIR COND SIG OFF

IGN"START" ON

PIN POSI SW ON

II

•

START SIGNAL CKT.

CLOSE THROTTLE. SHIFT

TO POR NRANGE.

2. TOUCH STARTAND

START ENGINE

IMMEDIATELY.

~ __ RE_C_O_R_D_---,l

SEF111P

~I)~ID

ECM

B

CONNECTOR

II

34 20

INSPECTION

START

OR

1. Turn ignition switchto

"START".

2. Check voltage between ECM

terminal @or

@l

and

ground.

Voltage:

Ignition switch"START"

Battery voltage

Except above

Approximately OV

NG OK

INSPECTION END

II

@:

ForAustralia

34 :Except forAustralia

~Io

ECM

ET

CONNECTOR

II

34 20

@:

ForAustralia

@:

Except forAustralia SEF231R

SEF232R Check

if7.5A fuseisOK.

OK

CHECK INPUTSIGNAL CIRCUIT.

1. Turn ignition switch"OFF".

2. Disconnect ECMharness connector

and 7.5A fuse.

3. Check harness continuity between

ECM terminal @or

@l

and fuse

block.

Continuity shouldexist.

If OK, check harness f<;>rshort.

OK

Disconnect andreconnect harnesscon-

nectors inthe circuit. Thenretest.

Trouble isnot fixed.

Check ECMpinterminals fordamage

or the connection ofECM harness con-

nector. Reconnect ECMharness con-

nector andretest.

INSPECTION END

EC-140

NG

NG

Replace

7.5Afuse.

Check thefollowing.

• Harness connectors

(ID,@

• Harness foropen or

short between ECM

and fuse block

If NG, repair harness or

connectors.

Page 862 of 1701

•

INSPECTION END

Check thefollowing.

• Harness connectors

@,@or@,

@

• Harness connectors

@,CillD

• Harness foropen or

short between injector

and ignition switch

If NG, repair harness or

connectors.

OK

NG

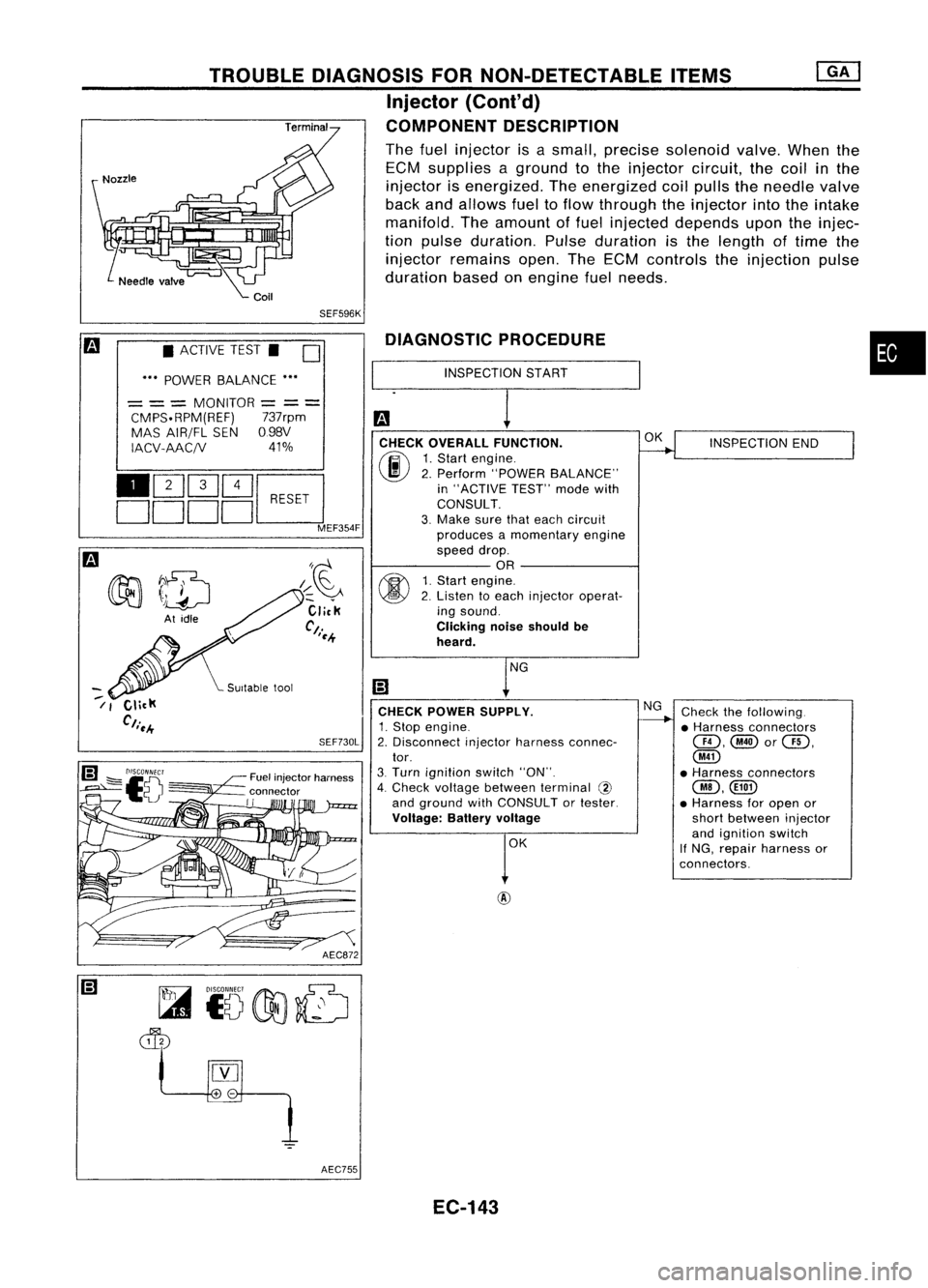

DIAGNOSTIC

PROCEDURE

INSPECTION START

CHECK OVERALL FUNCTION.

(F.I\

1.Start engine.

~ 2.Perform "POWER BALANCE"

in "ACTIVE TEST"modewith

CONSULT.

3. Make surethateach circuit

produces amomentary engine

speed drop.

OR

fff\

1.Start engine.

~ 2.Listen toeach injector operat-

ing sound.

Clicking noiseshould be

heard.

CHECK POWER SUPPLY.

1. Stop engine.

2. Disconnect injectorharness connec-

tor.

3. Turn ignition switch"ON".

4. Check voltage between terminal @

and ground withCONSULT ortester.

Voltage: Batteryvoltage

AEC872

SEF730L

/~~

Click

Ct.

'~.+

Fuel injector harness

connector

II

TROUBLE

DIAGNOSIS FORNON-DETECTABLE ITEMS

Injector (Cont'd)

COMPONENT DESCRIPTION

The fuel injector isasmall, precise solenoid valve.Whenthe

ECM supplies aground tothe injector circuit,thecoil

in

the

injector isenergized. Theenergized coilpulls theneedle valve

back andallows fueltoflow through theinjector intotheintake

manifold. Theamount offuel injected depends upontheinjec-

tion pulse duration. Pulseduration isthe length oftime the

injector remains open.TheECM controls theinjection pulse

duration basedonengine fuelneeds.

SEF596K

• ACTIVE TEST.

D

••• POWER BALANCE •••

= ==

MONITOR

=

==

CMPS.RPM(REF) 737rpm

MAS AIR/FL SEN098V

IACV-AAC/V 41%

110Q]Q]~

DDDDc:J

MEF354F

~7~

~ \)drJ

At idle

--

/ I

AEC755EC-143

Page 864 of 1701

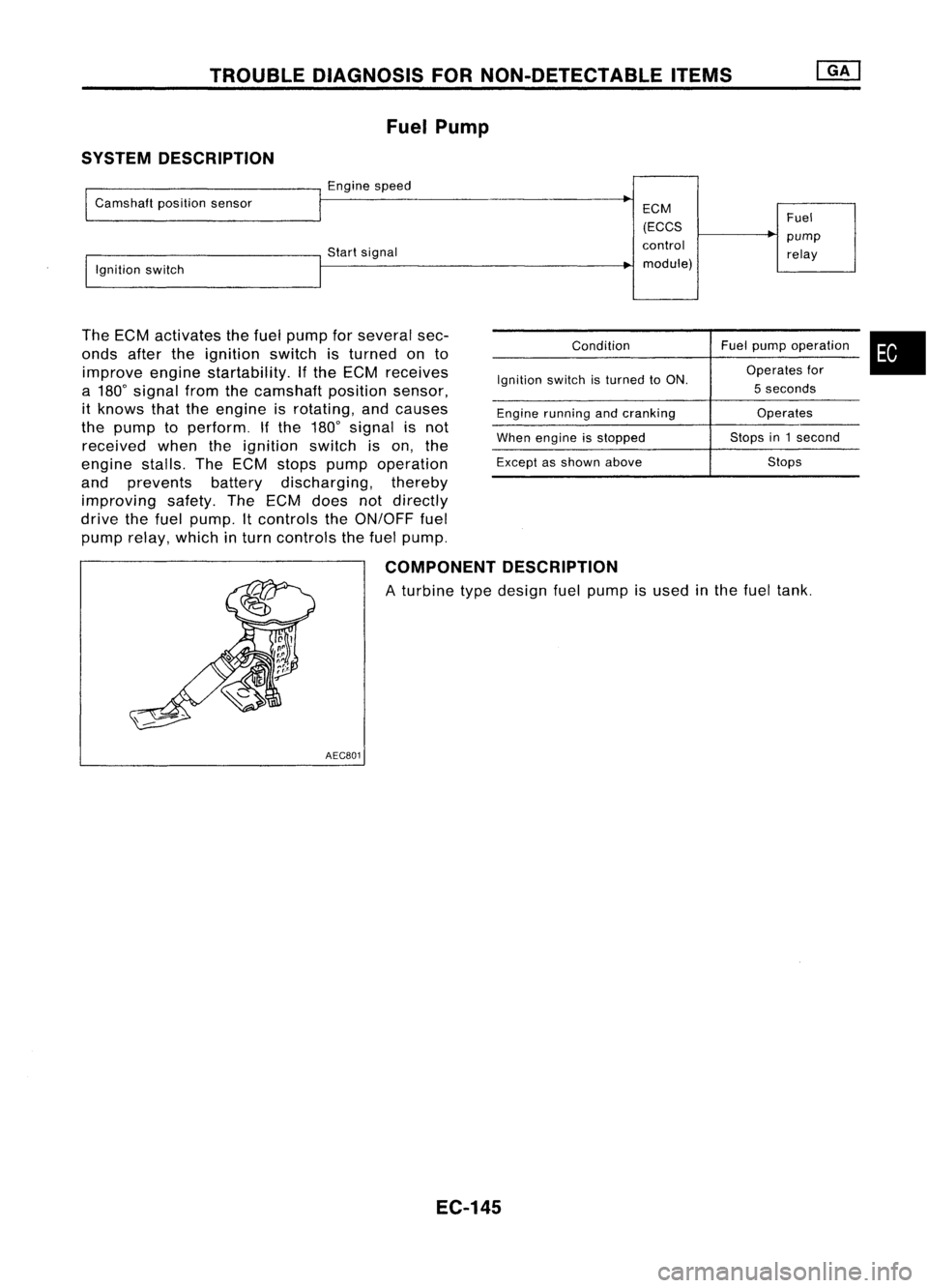

TROUBLEDIAGNOSIS FORNON-DETECTABLE ITEMS

Fuel Pump

SYSTEM DESCRIPTION

Enginespeed

Camshaft positionsensor

Startsignal

Ignition switch

The ECM activates thefuel pump forseveral sec-

onds aftertheignition switchisturned onto

improve enginestartability. Ifthe ECM receives

a 180

0

signal fromthecamshaft positionsensor,

it knows thattheengine isrotating, andcauses

the pump toperform. Ifthe 180

0

signal isnot

received whentheignition switchison, the

engine stalls.TheECM stops pump operation

and prevents batterydischarging, thereby

improving safety.TheECM does notdirectly

drive thefuel pump. Itcontrols theON/OFF fuel

pump relay, which inturn controls thefuel pump.

ECM

(ECCS

control module)

Condition

Ignition switchisturned toON.

Engine running andcranking

When engine isstopped

Except asshown above Fuel

pump relay

Fuel pump operation

Operates for

5 seconds

Operates

Stops in1second

Stops

•

COMPONENT DESCRIPTION

A turbine typedesign fuelpump isused inthe fuel tank.

AEC801

EC-145

Page 869 of 1701

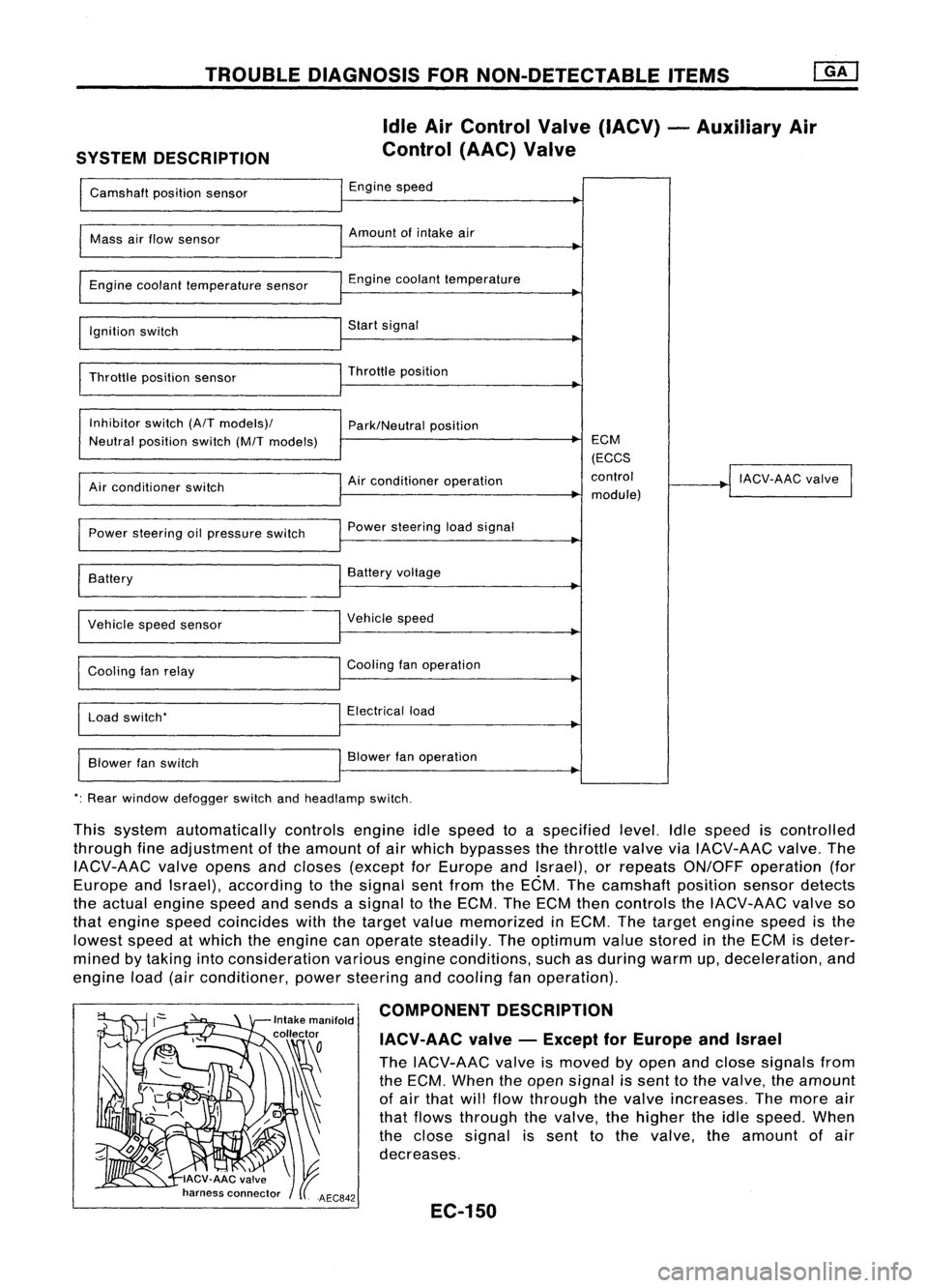

TROUBLEDIAGNOSIS FORNON-DETECTABLE ITEMS

SYSTEM DESCRIPTION Idle

AirControl Valve(IACV) -Auxiliary Air

Control (AAC)Valve

Camshaft positionsensor Engine

speed

I

Mass

airflow sensor Amount

ofintake air

I

Engine coolant temperature sensor Engine

coolant temperature

~

I

Ignition switch Start

signal

I

Throttle positionsensor Throttle

position

~

I

Inhibitor switch(A/Tmodels)/

Park/Neutralposition

Neutral position switch(M/Tmodels) ECM

(ECCS

Air conditioner operation control

!

IACV-AAC valve

I

Air conditioner switch

module)

Power steering oilpressure switch Power

steering loadsignal

I

Battery

~

Battery voltage

Vehicle speedsensor Vehicle

speed

Cooling fanrelay Cooling

fanoperation

Load switch' Electrical

load

Blower fanswitch Blower

fanoperation

': Rear window defogger switchandheadlamp switch.

This system automatically controlsengineidlespeed toaspecified level.Idlespeed iscontrolled

through fineadjustment ofthe amount ofair which bypasses thethrottle valveviaIACV-AAC valve.The

IACV-AAC valveopens andcloses (except forEurope andIsrael), orrepeats ON/OFF operation (for

Europe andIsrael), according tothe signal sentfrom theECM. Thecamshaft positionsensordetects

the actual engine speedandsends asignal tothe ECM. TheECM thencontrols theIACV-AAC valveso

that engine speedcoincides withthetarget valuememorized inECM. Thetarget engine speedisthe

lowest speedatwhich theengine canoperate steadily. Theoptimum valuestored inthe ECM isdeter-

mined bytaking intoconsideration variousengineconditions, suchasduring warmup,deceleration, and

engine load(airconditioner, powersteering andcooling fanoperation).

COMPONENT DESCRIPTION

IACV-AAC valve-Except forEurope andIsrael

The IACV-AAC valveismoved byopen andclose signals from

the ECM. When theopen signal issent tothe valve, theamount

of air that willflow through thevalve increases. Themore air

that flows through thevalve, thehigher theidle speed. When

the close signal issent tothe valve. theamount ofair

decreases.

EC-150

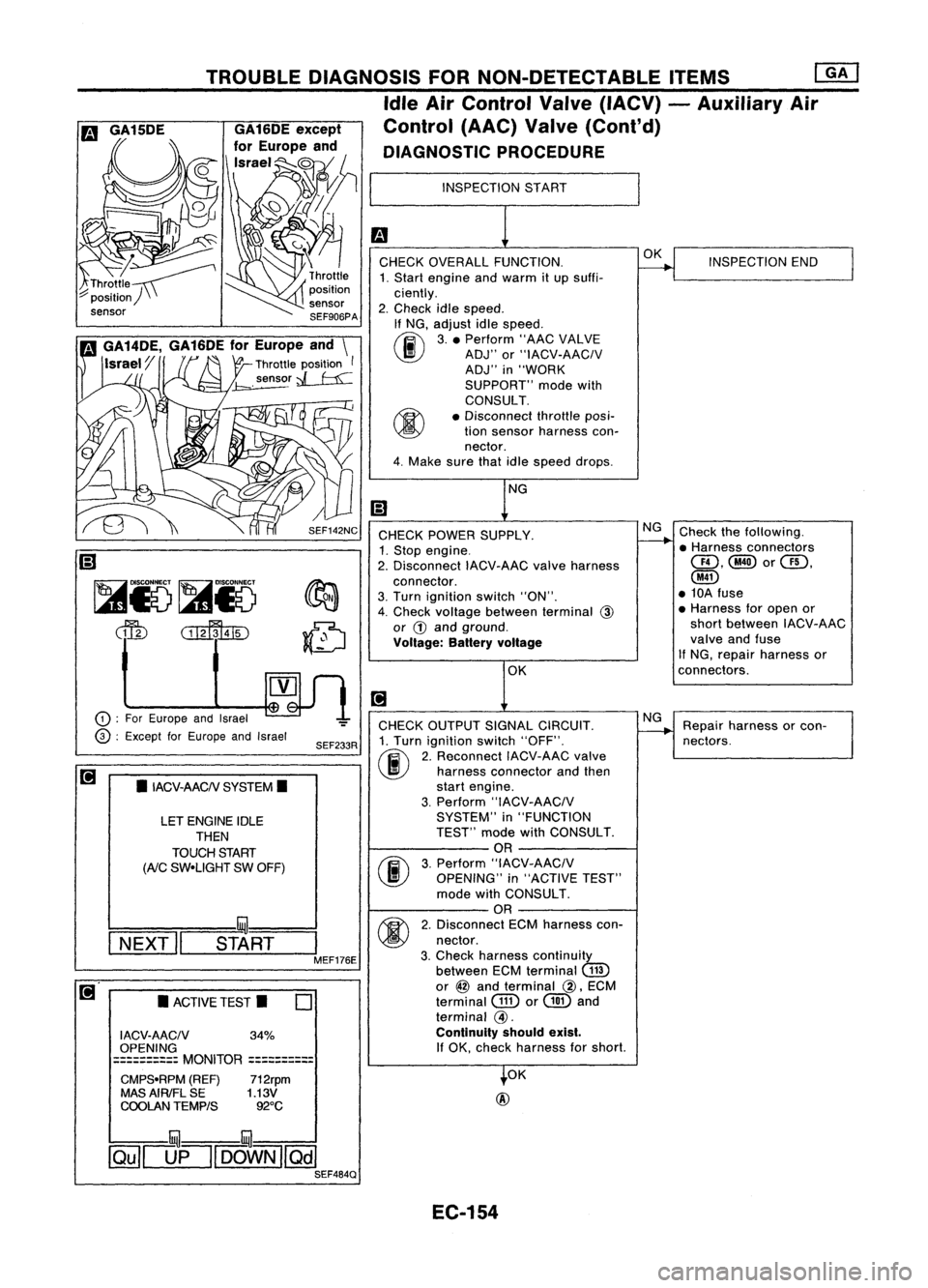

Page 873 of 1701

Repairharness orcon-

nectors. INSPECTION

END

Check thefollowing.

• Harness connectors

QD,@orQD,

@

• 10A fuse

• Harness foropen or

short between IACV-AAC

valve andfuse

If NG, repair harness or

connectors.

NG OK

NG

OK

INSPECTION

START

CHECK OVERALL FUNCTION.

1. Start engine andwarm itup suffi-

ciently.

2. Check idlespeed.

If NG, adjust idlespeed.

~ 3.• Perform "AACVALVE

~ ADJ"or"IACV-AACIV

ADJ" in"WORK

SUPPORT" modewith

CONSULT.

• Disconnect throttleposi-

tion sensor harness con-

nector.

4. Make surethatidlespeed drops.

OK

@

CHECK

POWER SUPPLY.

1. Stop engine.

2. Disconnect IACV-AACvalveharness

connector.

3. Turn ignition switch"ON".

4. Check voltage between terminal

@

or

G)

and ground.

Voltage: Batteryvoltage

CHECK OUTPUT SIGNALCIRCUIT.

1. Turn ignition switch"OFF".

(ij\

2.Reconnect IACV-AACvalve

~ harnessconnector andthen

start engine.

3. Perform "IACV-AACIV

SYSTEM" in"FUNCTION

TEST" modewithCONSULT.

OR

(F.I\

3.Perform "IACV-AACIV

~ OPENING" in"ACTIVE TEST"

mode withCONSULT.

OR

M

2.Disconnect ECMharness con-

~ nectar.

3. Check harness continuity

between ECMterminal

(ill)

or

@

and terminal

@,

ECM

terminal

GID

or

@

and

terminal

@.

Continuity shouldexist.

If

OK, check harness forshort.

SEF233R

SEF142NC

o

•

ACTIVE TEST.

LET

ENGINE IDLE

THEN

TOUCH START

(AiC

SW-UGHT SWOFF)

•

IACV-AACN SYSTEM.

I ACV-AACN 34%

OPENING

==========

MONITOR

==========

CMPS-RPM (REF)712rpm

MAS AIRIFL SE 1.13V

COOLAN TEMPtS 92°C

TROUBLE

DIAGNOSIS FORNON-DETECTABLE ITEMS

ffiJ

Idle AirControl Valve(IACV) -Auxiliary Air

Control (AAC)Valve(Cont'd)

DIAGNOSTIC PROCEDURE

!:::=====mul===

I

NEXT" START

I

MEF176E

CD

:

For Europe andIsrael

@ :

Except forEurope andIsrael

~

Ii)

~i5~i5

dfu

CillffuID

illU--illU

~[]fl[OOWN][Qill SEF484Q

EC-154

Page 875 of 1701

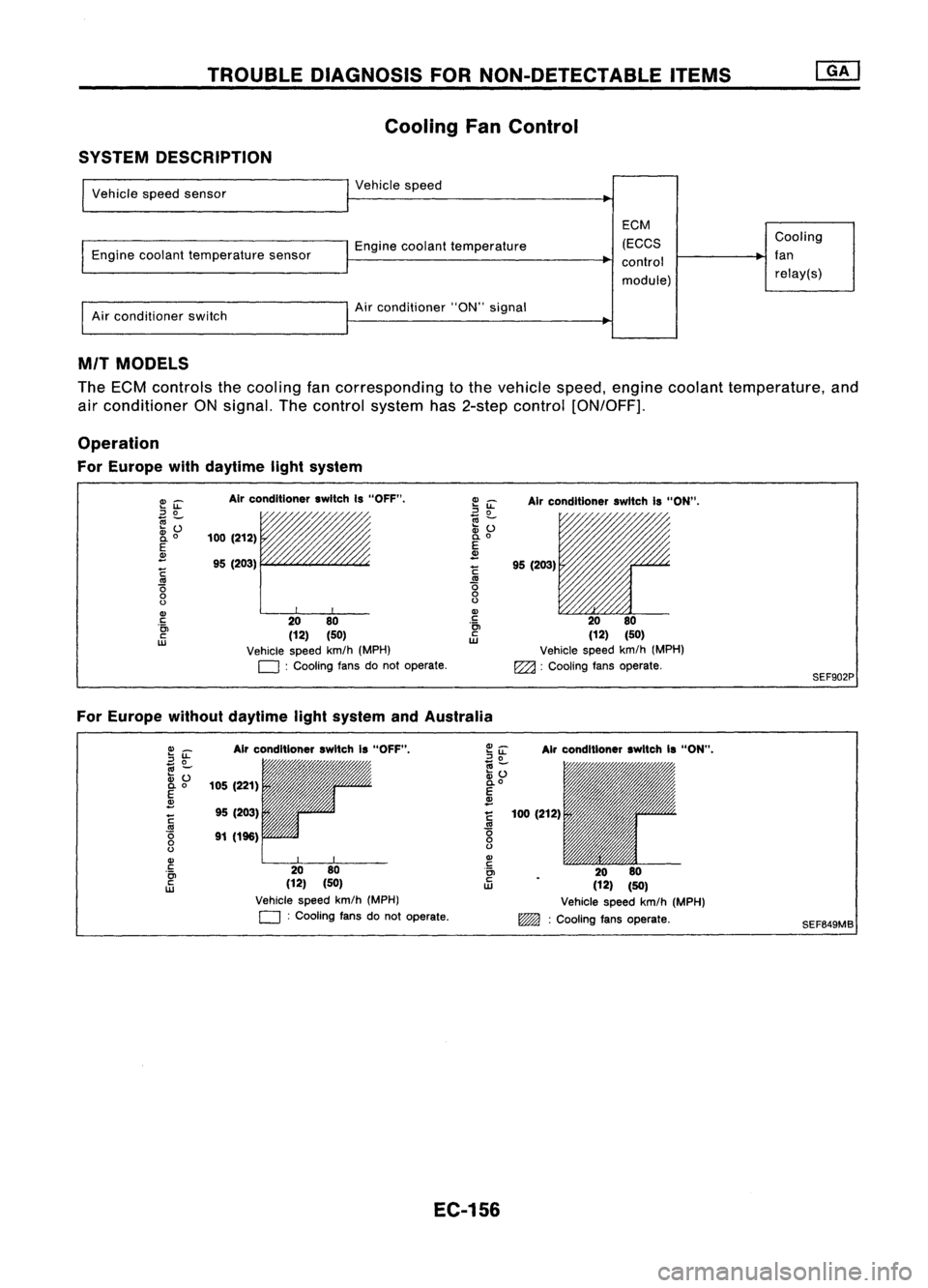

TROUBLEDIAGNOSIS FORNON-DETECTABLE ITEMS

Cooling FanControl

SYSTEM DESCRIPTION

Vehicle speedsensor

Engine coolant temperature sensor

Air conditioner switch Vehicle

speed

Engine coolant temperature

Air conditioner "ON"signal

EGM

(EGGS

control

module) Gooling

fan relay(s)

MIT MODELS

The ECM controls thecooling fancorresponding tothe vehicle speed,engine coolant temperature, and

air conditioner ONsignal. Thecontrol system has2-step control [ON/OFF].

Operation

For Europe withdaytime lightsystem

E~

::J

0

~Z;

2i

o

E

~

~

'0

o

o

Gl

c

'0>

c

w

Air

conditioner switchIs"OFF".

/,

100 (212)

95 (203)

rr

20 80

(12) (50)

Vehicle speedkm/h(MPH)

D :

Cooling fansdonot operate.

~

iL

Airconditioner switchIs"ON".

~ ~ 11'l1/1~~~

:v

() /'/"

0.

0

E

~

!

95(203)

.~ 2080

ill

(12)(50)

Vehicle speedkm/h(MPH)

EZ2l :

Cooling fansoperate.

SEF902P

For Europe withoutdaytime lightsystem andAustralia

Gl_

2~

.,

-

:v ()

0.0

E

~

~

'0

o

o

Gl

c

'0>

c

w

Air

conditioner switchIs"OFF",

105 (221)

95 (203)

91 (196)

2080

(12) (50)

Vehicle speedkm/h(MPH)

D :

Cooling fansdonot operate.

Air

conditioner switchIs"ON",

100 (212)

2080

(12) (50)

Vehicle speedkm/h(MPH)

~ :Cooling fansoperate.

SEF649MB

EC-156

Page 876 of 1701

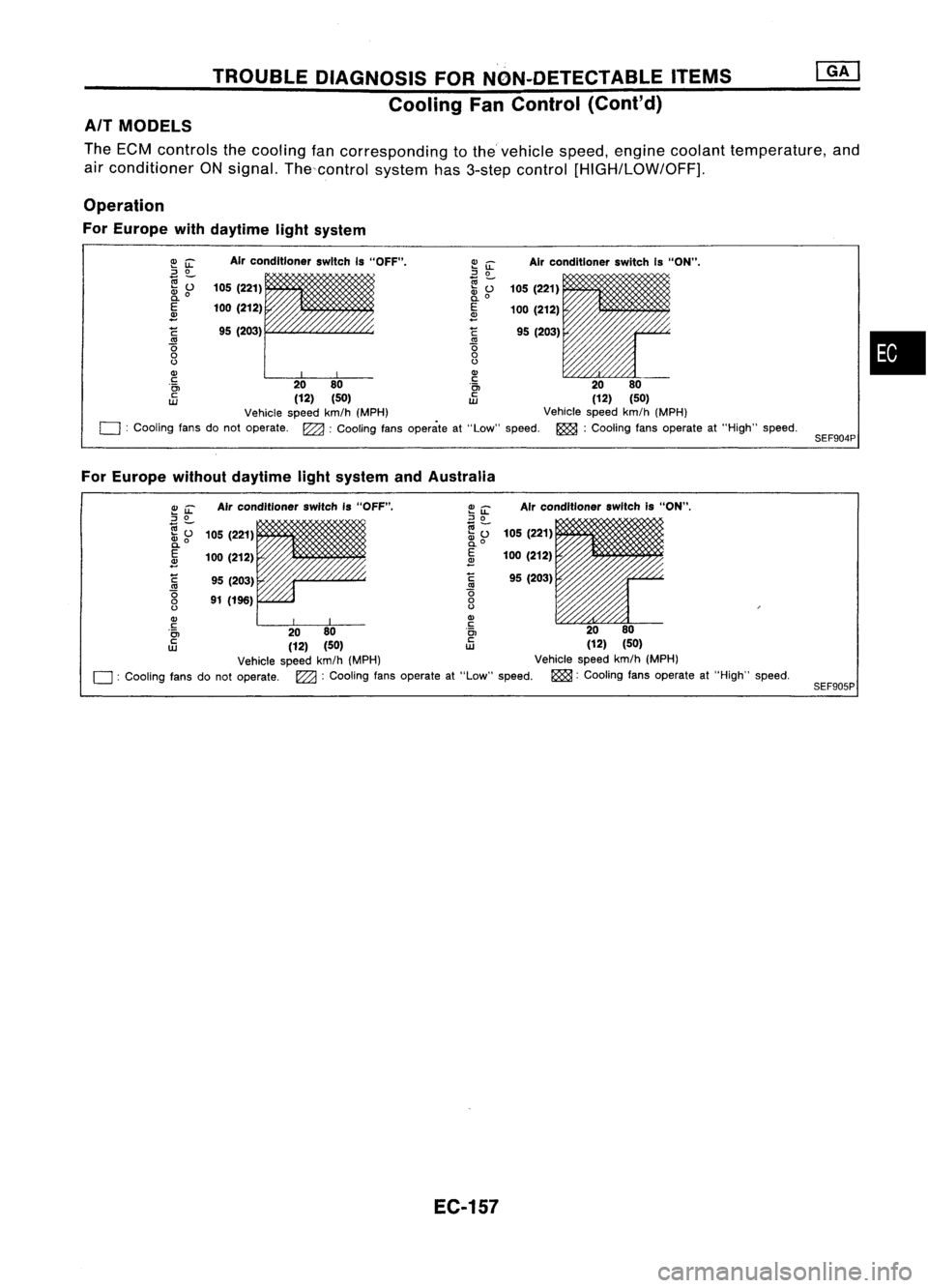

TROUBLEDIAGNOSIS FORNON-DETECTABLE ITEMS

Cooling FanControl (Cont'd)

AIT MODELS

The ECM controls thecooling fancorresponding tothevehicle speed,engine coolant temperature, and

air conditioner ONsignal. Thecontrol system has3-step control

[HIGH/LOW/OFF],

Operation

For Europe withdaytime lightsystem

•

SEF904P

Air

conditioner switchIs"ON".

105 (221)

100 (212)

95 (203)

Air

conditioner switchIs"OFF".

95 (203)

105

(221)

100 (212)

C

'0

o

()

Q)

c

'0>

c

UJ

~

iL

::J

0

e;-

~o

E

~

C

'0

o

()

Q)

~ 00

i~

00

(12) (50)

tD

(12)(50)

Vehicle speedkm/h(MPH) Vehiclespeedkm/h(MPH)

o :

Cooling fansdonot operate. ~:Cooling fansoperate at"Low" speed. ~:Cooling fansoperate at"High" speed.

For Europe withoutdaytime lightsystem andAustralia

SEF905P

Air

conditioner switchis"ON",

105 (221)

100 (212)

95 (203)

Air

conditioner switchIs"OFF".

95 (203)

91 (196)

105

(221)

100 (212)

~

'0

o

()

Q)

c

'0>

c

UJ

~~

::J

0

(;j-

.... 0

~o

E

2

C

'0

o

()

Q)

~ 00

i~

00

(12) (50)

tD

(12)(50)

Vehicle speedkm/h(MPH) Vehiclespeedkm/h(MPH)

o :

Cooling fansdonot operate.

l22a:

Cooling fansoperate at"Low" speed. ~:Cooling fansoperate at"High" speed.

EC-157