coolant NISSAN ALMERA N15 1995 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1995, Model line: ALMERA N15, Model: NISSAN ALMERA N15 1995Pages: 1701, PDF Size: 82.27 MB

Page 447 of 1701

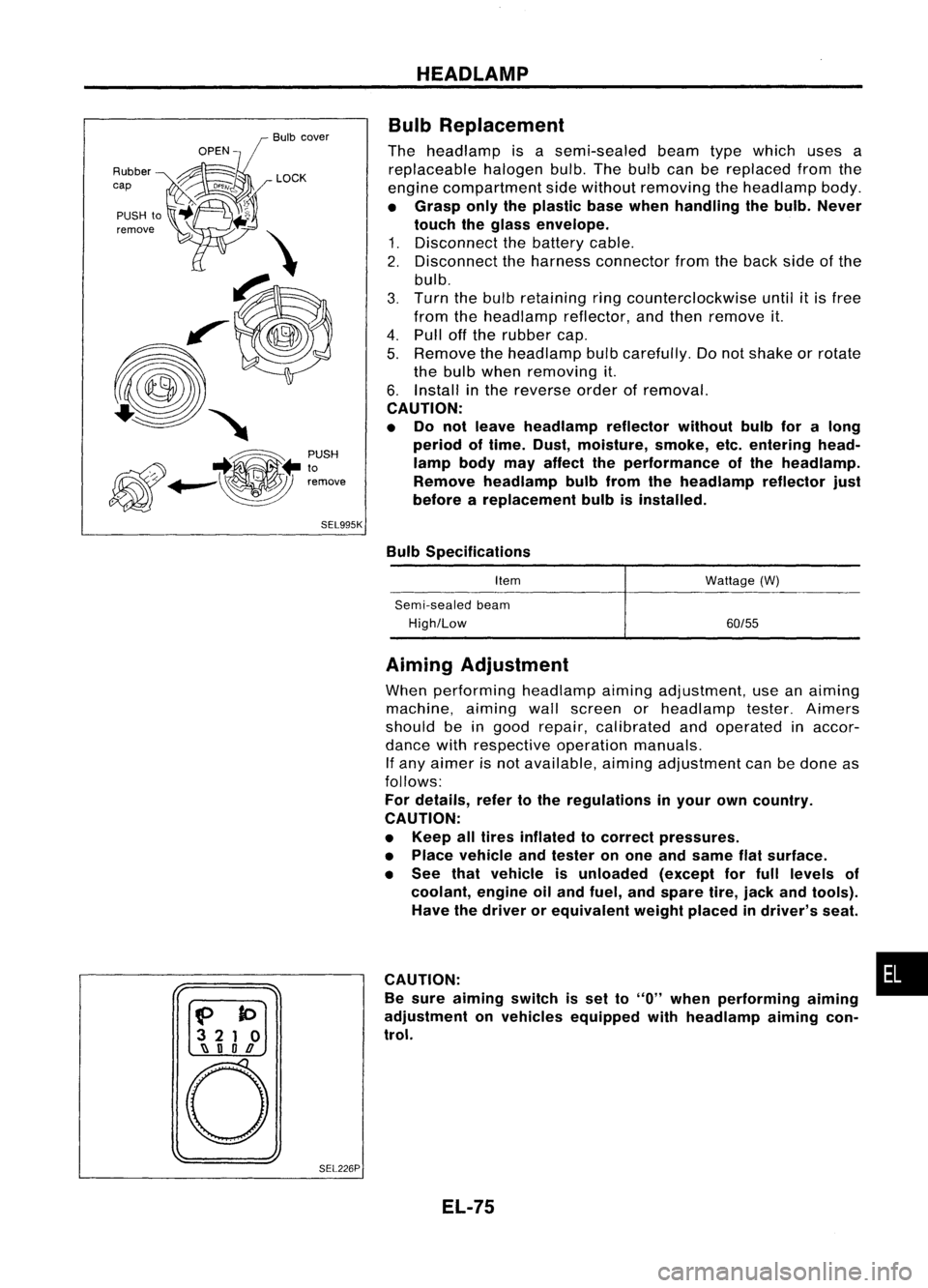

Bulbcover

SEL995K HEADLAMP

Bulb Replacement

The headlamp isasemi-sealed beamtypewhich usesa

replaceable halogenbulb.Thebulb canbereplaced fromthe

engine compartment sidewithout removing theheadlamp body.

• Grasp onlytheplastic basewhen handling thebulb. Never

touch theglass envelope.

1. Disconnect thebattery cable.

2. Disconnect theharness connector fromtheback sideofthe

bulb.

3. Turn thebulb retaining ringcounterclockwise until

it

is free

from theheadlamp reflector,andthen remove it.

4. Pull offthe rubber cap.

5. Remove theheadlamp bulbcarefully. Donot shake orrotate

the bulb when removing it.

6. Install inthe reverse orderofremoval.

CAUTION:

• Do not leave headlamp reflector withoutbulbforalong

period oftime. Dust,moisture, smoke,etc.entering head-

lamp bodymayaffect theperformance ofthe head lamp.

Remove headlamp bulbfrom thehead lamp reflector just

before areplacement bulbisinstalled.

Bulb Specifications

Item

Semi-sealed beam

High/Low Wattage

(W)

60/55

f>

to

3 21 0

~ nOD

o

SEL226PAiming

Adjustment

When performing headlamp aiming adjustment, useanaiming

machine, aimingwallscreen orheadlamp tester.Aimers

should beingood repair, calibrated andoperated inaccor-

dance withrespective operationmanuals.

If any aimer isnot available, aimingadjustment canbedone as

follows:

For details, refertothe regulations inyour owncountry.

CAUTION:

• Keep alltires inflated tocorrect pressures.

• Place vehicle andtester onone and same flatsurface.

• See thatvehicle isunloaded (exceptforfull levels of

coolant, engineoiland fuel, andspare tire,jack andtools).

Have thedriver orequivalent weightplaced indriver's seat.

CAUTION: •

Be sure aiming switchisset to

"0"

when performing aiming

adjustment onvehicles equipped withheadlamp aiming con-

trol.

EL-75

Page 473 of 1701

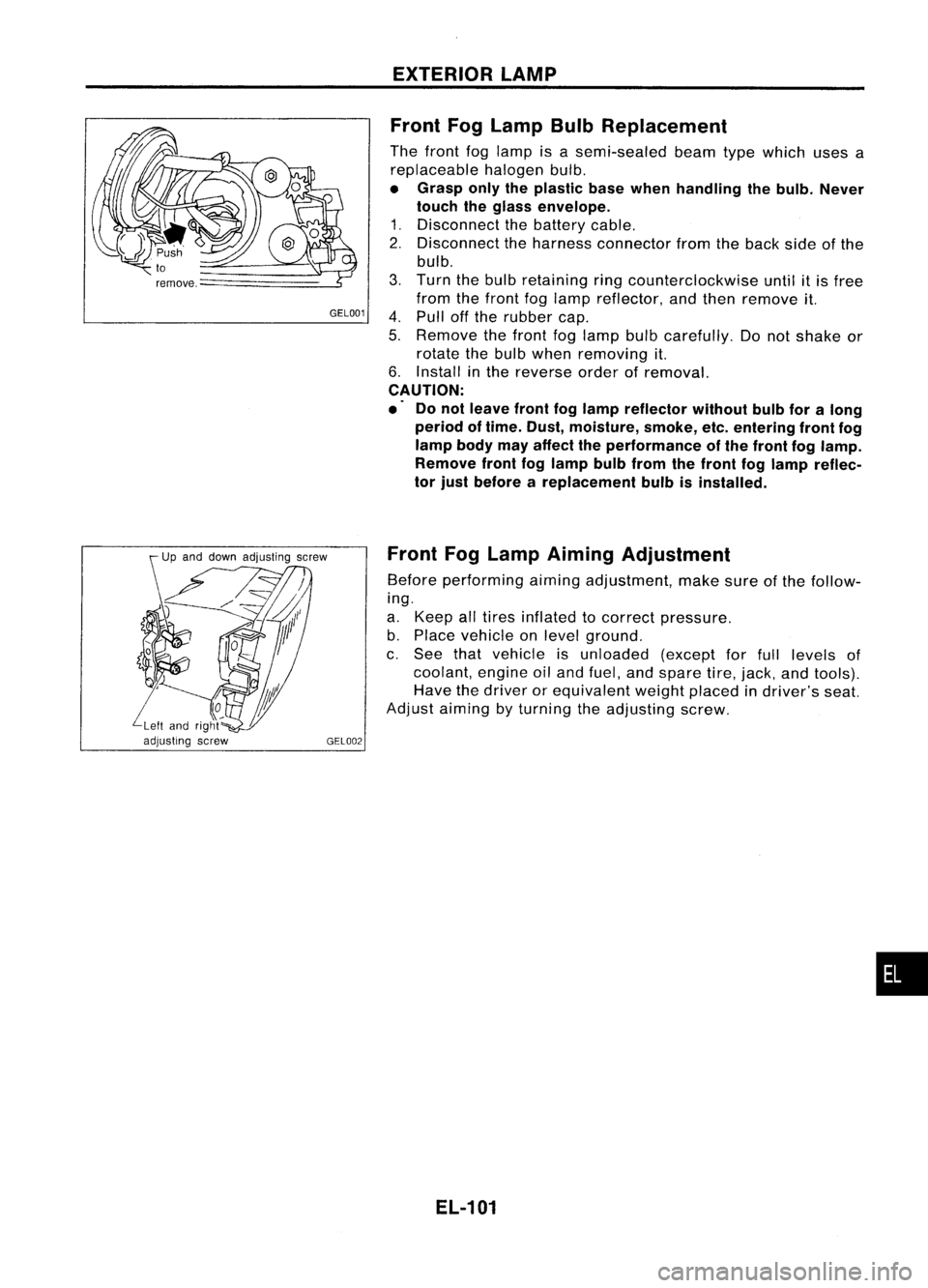

GEL001EXTERIOR

LAMP

Front FogLamp BulbReplacement

The front foglamp isasemi-sealed beamtypewhich usesa

replaceable halogenbulb.

• Grasp onlytheplastic basewhen handling thebulb. Never

touch theglass envelope.

1. Disconnect thebattery cable.

2. Disconnect theharness connector fromtheback sideofthe

bulb.

3. Turn thebulb retaining ringcounterclockwise untilitis free

from thefront foglamp reflector, andthen remove it.

4. Pull offthe rubber cap.

5. Remove thefront foglamp bulbcarefully. Donot shake or

rotate thebulb when removing it.

6. Install inthe reverse orderofremoval.

CAUTION:

.' Donot leave frontfoglamp reflector withoutbulbforalong

period oftime. Dust, moisture, smoke,etc.entering frontfog

lamp bodymayaffect theperformance ofthe front foglamp.

Remove frontfoglamp bulbfrom thefront foglamp reflec-

tor just before areplacement bulbisinstalled.

Front FogLamp Aiming Adjustment

Before performing aimingadjustment, makesureofthe follow-

ing.

a. Keep alltires inflated tocorrect pressure.

b. Place vehicle onlevel ground.

c. See thatvehicle isunloaded (exceptforfull levels of

coolant, engineoiland fuel, andspare tire,jack, andtools).

Have thedriver orequivalent weightplaced indriver's seat.

Adjust aiming byturning theadjusting screw.

EL-101

•

Page 684 of 1701

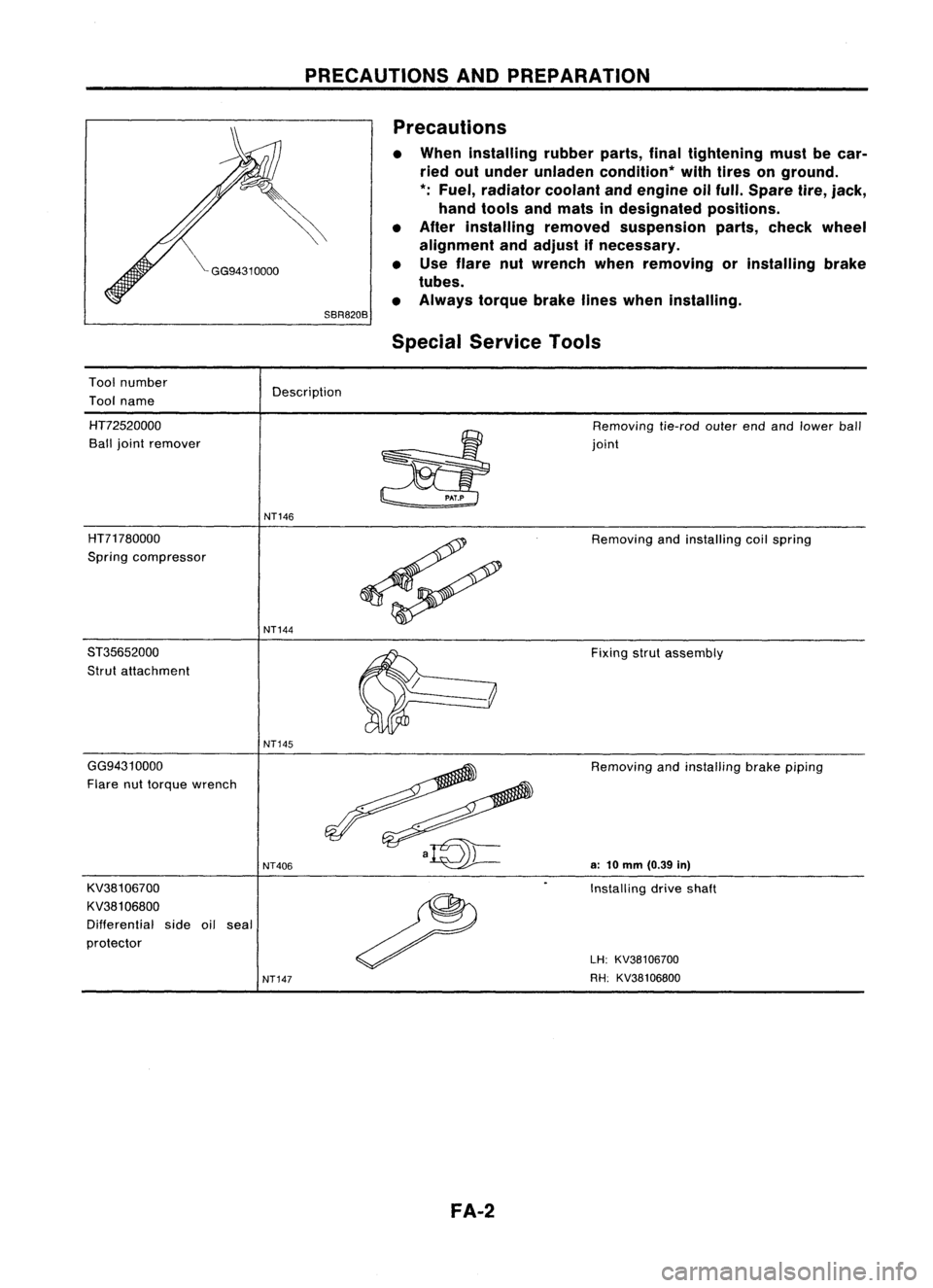

PRECAUTIONSANDPREPARATION

Precautions

• When installing rubberparts,finaltightening mustbecar-

ried outunder unladen condition* withtires onground.

*: Fuel, radiator coolantandengine oilfull. Spare tire,

jack,

hand tools andmats indesignated positions.

• After installing removedsuspension parts,check wheel

alignment andadjust ifnecessary.

• Use flare nutwrench whenremoving orinstalling brake

tubes.

• Always torquebrakelineswhen installing.

Tool number

Tool name

SBR820B

Special Service Tools

Description

HT72520000

Ball joint remover Removing

tie-rodouterendandlower ball

joint

NT146

HT71780000

Spring compressor

ST35652000

Strut attachment

NT144

Removing

andinstalling coilspring

Fixing strutassembly

NT145

GG94310000

Flare nuttorque wrench

KV38106700

KV381 06800

Differential sideoilseal

protector

NT406

NT147

FA-2

Removing

andinstalling brakepiping

a:

10mm (0.39 in)

Installing driveshaft

LH: KV38106700

RH: KV38106800

Page 686 of 1701

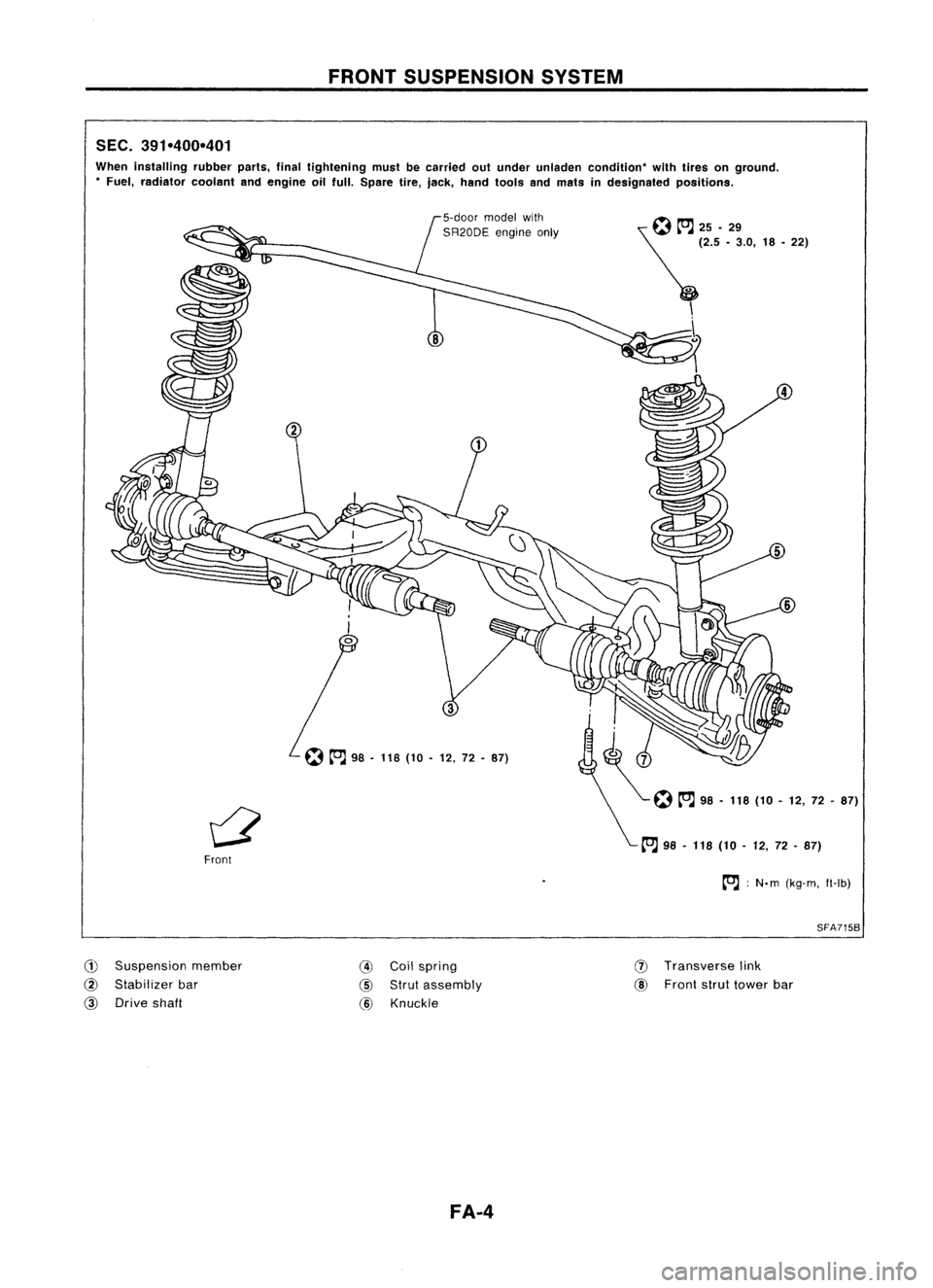

FRONTSUSPENSION SYSTEM

SEC. 391-400-401

When installing rubberparts,finaltightening mustbecarried outunder unladen condition" withtires onground .

• Fuel, radiator coolantandengine oilfull. Spare tire,jack, hand tools andmats indesignated positions.

~~25.29

~ (2.5•3.0, 18•22)

\ \

...

5

~ 98•118 (10•12, 72•87)

Front

to.J:

N. m (kg-m, ft-Ib)

SFA715B

CD

Suspension member

@

Stabilizer bar

@

Drive shaft

@

Coilspring

@

Strut assembly

@

Knuckle

FA-4

(J)

Transverse link

@

Front struttower bar

Page 688 of 1701

ON-VEHICLESERVICE

Front Wheel Alignment

Before checking frontwheel alignment, besure tomake apre-

liminary inspection (Unladen*).

*: Fuel, radiator coolantandengine oilfull. Spare tire,jack,

hand tools andmats indesignated positions.

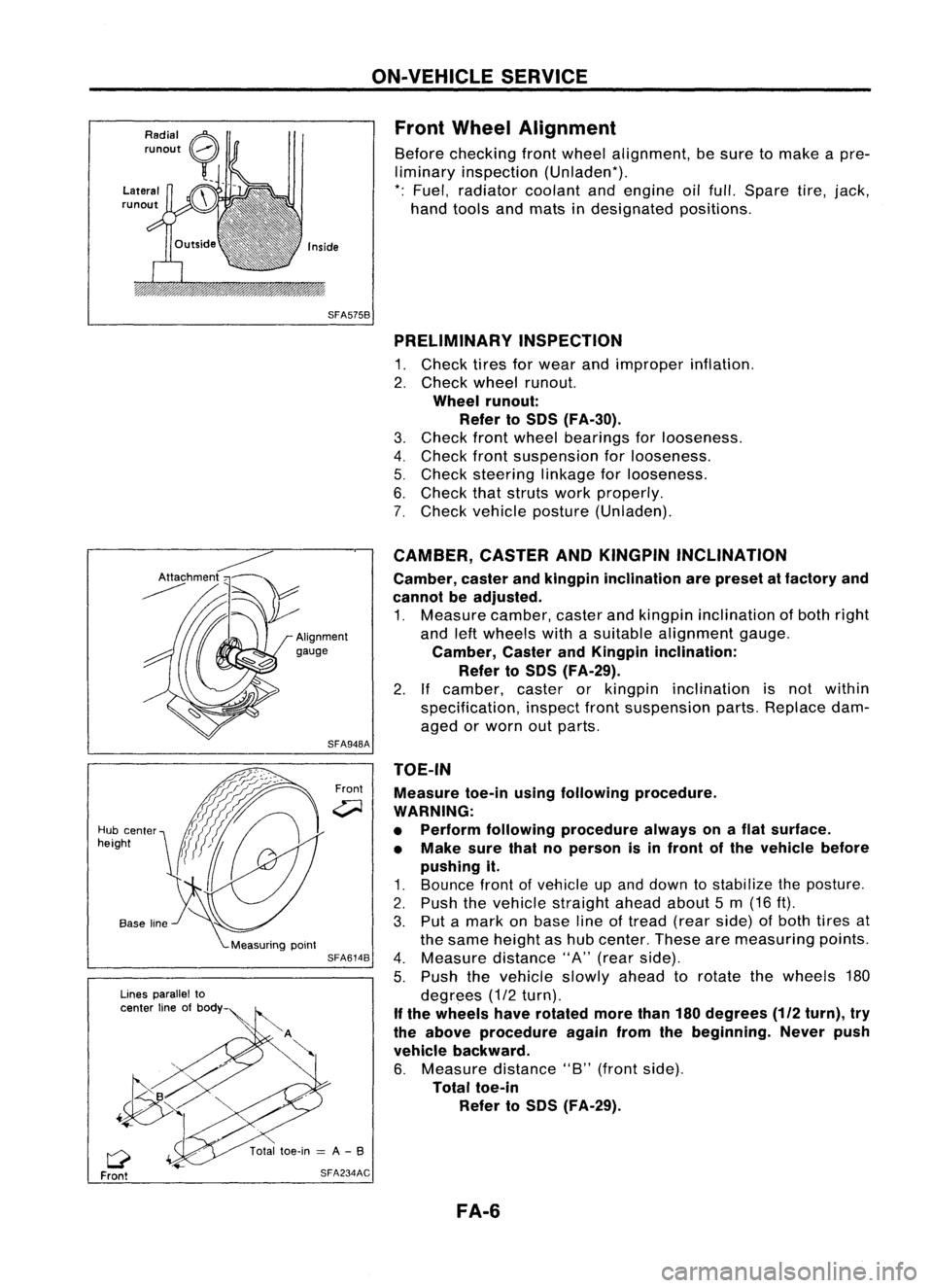

SFA575B PRELIMINARY INSPECTION

1. Check tiresforwear andimproper inflation.

2. Check wheelrunout.

Wheel runout:

Refer toSOS (FA-30).

3. Check frontwheel bearings forlooseness.

4. Check frontsuspension forlooseness.

5. Check steering linkageforlooseness.

6. Check thatstruts workproperly.

7. Check vehicle posture (Unladen).

TOE-IN Measure toe-inusingfollowing procedure.

WARNING:

• Perform following procedure alwaysonaflat surface.

• Make surethatnoperson isin front ofthe vehicle before

pushing it.

1. Bounce frontofvehicle upand down tostabilize theposture.

2. Push thevehicle straight aheadabout5m (16 ft).

3. Put amark onbase lineoftread (rearside) ofboth tires at

the same height ashub center. Thesearemeasuring points.

4. Measure distance"A"(rear side).

5. Push thevehicle slowlyaheadtorotate thewheels 180

degrees (1/2turn).

If the wheels haverotated morethan180degrees

(112

turn), try

the above procedure againfromthebeginning. Neverpush

vehicle backward.

6. Measure distance"B"(front side).

Total toe-in

Refer toSOS (FA-29).

CAMBER,

CASTERANDKINGPIN INCLINATION

Camber, casterandkingpin inclination arepreset atfactory and

cannot beadjusted.

1. Measure camber,casterandkingpin inclination ofboth right

and leftwheels withasuitable alignment gauge.

Camber, CasterandKingpin inclination:

Refer toSOS (FA-29).

2. Ifcamber, casterorkingpin inclination isnot within

specification, inspectfrontsuspension parts.Replace dam-

aged orworn outparts.

Front

SFA948A

SFA614B

SFA234AC

Lines

parallel to

center lineofbody

Q

Front

Hub

center

height

FA-6

Page 706 of 1701

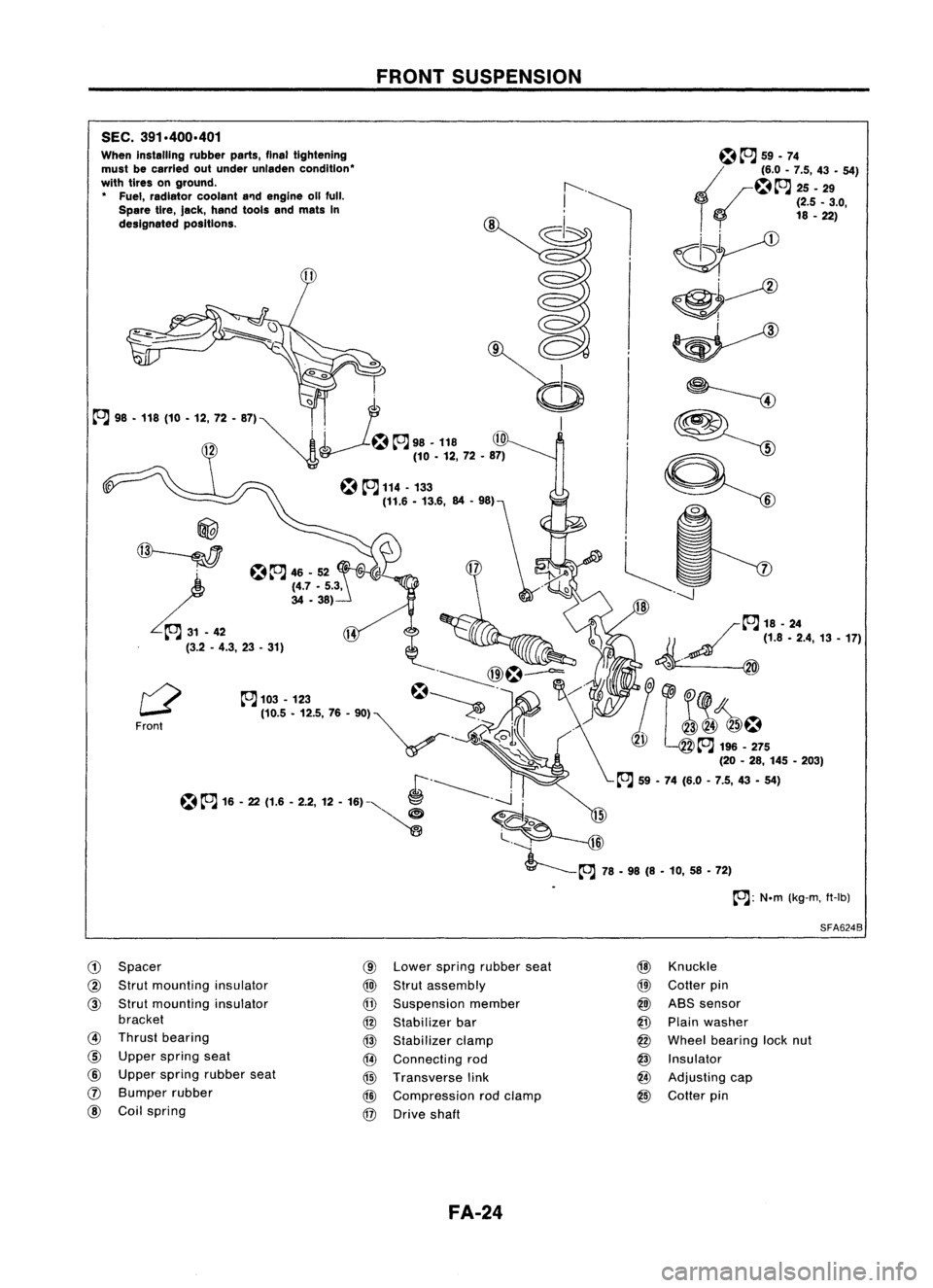

SEC.391.400.401

When installing rubberparts,finaltightening

must becarried outunder unladen condition'

with tires onground.

• Fuel, radiator coolanta'1dengine 011full.

Spare tire,Jack, hand toolsandmats In

designated positions.

@

~

L.~

(3.2-4.3, 23•31)

Front

CD

Spacer

@

Strut mounting insulator

@

Strut mounting insulator

bracket

@

Thrust bearing

@

Upper spring seat

@

Upper spring rubber seat

(J)

Bumper rubber

@

Coilspring

FRONT

SUSPENSION

@

Lower spring rubber seat

@)

Strut assembly

@

Suspension member

@

Stabilizer bar

@

Stabilizer clamp

@

Connecting rod

@

Transverse link

@

Compression rodclamp

@

Drive shaft

FA-24

~~

59.74

~~~.~ ::'.4:9- 54)

o

(2.5_3.0,

18 -22)

~

~~

~ ~

9=:

~~

-----J

/~18-24

1/ ~

(1.8.2.4,13.17)

~. @

&1

(@

~ J~!~5

(20-28, 145 •203)

~ 59•74 (6.0 -7.5, 43•54)

SFA624B

@

Knuckle

@

Cotter pin

@)

ABS sensor

@

Plain washer

@

Wheel bearing locknut

@

Insulator

@

Adjusting cap

@

Cotter pin

Page 711 of 1701

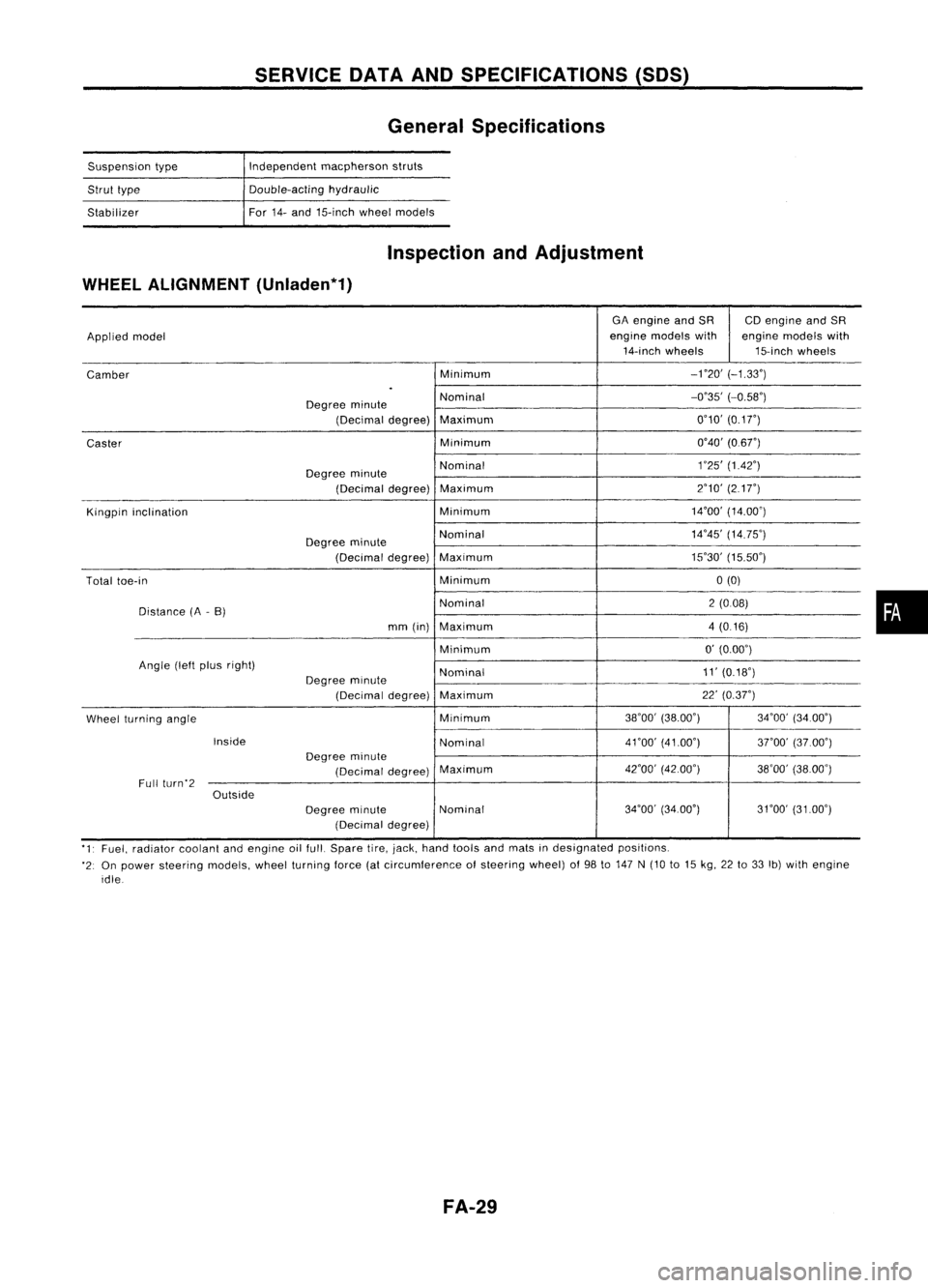

SERVICEDATAANDSPECIFICATIONS (50S)

General Specifications

Suspension type

Strut type

Stabilizer Independent

macpherson struts

Double-acting hydraulic

For 14-and 15-inch wheelmodels

Inspection andAdjustment

WHEEL ALIGNMENT (Unladen*1)

GAengine andSR CDengine andSR

Applied model engine

models with enginemodels with

14-inch wheels 15-inchwheels

Camber Minimum

-no'

(-1.33')

.

Degree minute Nominal

-0'35'

(-0.58')

(Decimal degree)Maximum 0'10'

(0.1

r)

Caster Minimum

0'40'(0.6r)

Degree minute Nominal

1

'25' (1.42')

(Decimal degree)Maximum 2'10'

(217")

Kingpin inclination Minimum14'00'

(14.00')

Degree minute Nominal

14'45'

(14.75')

(Decimal degree)Maximum 15'30'

(15.50')

Total toe-in Minimum0(0)

Distance (A-B) Nominal

2(008)

mm (in) Maximum 4(0.16)

Minimum 0'

(0.00')

Angle (leftplus right)

Nominal 11'

(0.18')

Degree minute

(Decimal degree)Maximum 22'

(0.37")

Wheel turning angle Minimum

38'00'

(38.00') 34'00'(34.00')

Inside Nominal4nO'

(41.00')

3rOO'(37.00')

Degree minute

(Decimal degree)Maximum

42'00'

(42.00')

38'00'(38.00')

Full (urn'2

Outside

Degreeminute Nominal 34'00'

(34.00') 31'00'(3100')

(Decimal degree)

'1' Fuel, radiator coolantandengine oilfull. Spare tire,jack, hand tools andmats indesignated positions.

'2: On power steering models,wheelturning force(atcircumference ofsteering wheel)of98 to147 N(10 to15 kg, 22to33 Ib)with engine

idle

FA-29

•

Page 721 of 1701

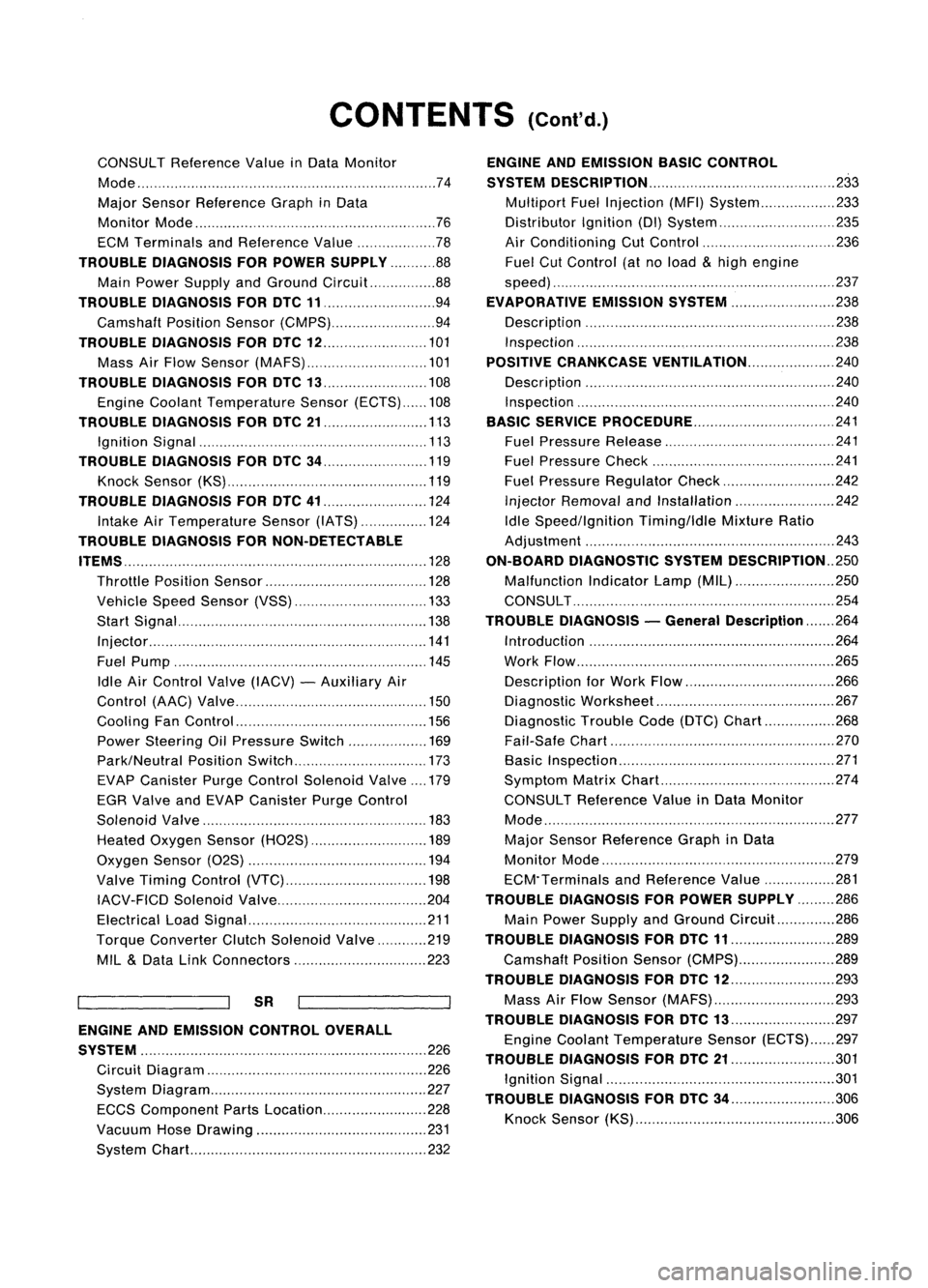

CONTENTS(Cont'd.)

CONSULT Reference ValueinData Monitor

Mode 74

Major Sensor Reference GraphinData

Monitor Mode 76

ECM Terminals andReference Value 78

TROUBLE DIAGNOSIS FORPOWER SUPPLY 88

Main Power Supply andGround Circuit.. 88

TROUBLE DIAGNOSIS FORDTC11 94

Camshaft PositionSensor(CMPS) 94

TROUBLE DIAGNOSIS FORDTC

12 101

Mass AirFlow Sensor (MAFS) 101

TROUBLE DIAGNOSIS FORDTC

13 108

Engine Coolant Temperature Sensor(ECTS) 108

TROUBLE DIAGNOSIS FORDTC

21 113

Ignition Signal 113

TROUBLE DIAGNOSIS FORDTC

34 119

Knock Sensor (KS) 119

TROUBLE DIAGNOSIS FORDTC

41 124

Intake AirTemperature Sensor(IATS) 124

TROUBLE DIAGNOSIS FORNON-DETECTABLE

ITEMS , '"

.128

Throttle Position Sensor 128

Vehicle SpeedSensor (VSS) 133

Start Signal 138

Injector 141

Fuel Pump 145

Idle AirControl Valve(IACV) -Auxiliary Air

Control (AAC)Valve 150

Cooling FanControl 156

Power Steering OilPressure Switch 169

Park/Neutral PositionSwitch 173

EVAP Canister PurgeControl Solenoid Valve179

EGR Valve andEVAP Canister PurgeControl

Solenoid Valve 183

Heated Oxygen Sensor(H02S) 189

Oxygen Sensor(02S) 194

Valve Timing Control (VTC) 198

IACV-FICD SolenoidValve 204

Electrical LoadSignal 211

Torque Converter ClutchSolenoid Valve 219

MIL

&

Data LinkConnectors 223

SR

ENGINE ANDEMISSION CONTROL OVERALL

SYSTE M

226

Circuit Diagram 226

System Diagram 227

ECCS Component PartsLocation 228

Vacuum HoseDrawing 231

System Chart... 232

ENGINE

ANDEMISSION BASICCONTROL

SYSTEM DESCRiPTION

233

Multipart FuelInjection (MFI)System 233

Distributor Ignition

(01)

System 235

Air Conditioning CutControl 236

Fuel CutControl (atnoload

&

high engine

speed) 237

EVAPORATIVE EMISSIONSYSTEM

238

Description 238

Inspection 238

POSITIVE CRANKCASE VENTILATION

240

Description 240

Inspection 240

BASIC SERVICE

PROCEDURE 241

Fuel Pressure Release 241

Fuel Pressure Check 241

Fuel Pressure Regulator Check 242

Injector Removal andInstallation 242

Idle Speed/Ignition Timing/IdleMixtureRatio

Adjustment 243

ON-BOARD DIAGNOSTIC SYSTEMDESCRIPTION ..250

Malfunction IndicatorLamp(MIL) 250

CONSULT 254

TROUBLE DIAGNOSIS -General Description

264

Introduction 264

Work Flow 265

Description forWork Flow 266

Diagnostic Worksheet 267

Diagnostic TroubleCode(DTC) Chart 268

Fail-Safe Chart 270

Basic Inspection 271

Symptom MatrixChart. 274

CONSULT Reference ValueinData Monitor

Mode 277

Major Sensor Reference GraphinData

Monitor Mode 279

ECM"Terminals andReference Value 281

TROUBLE DIAGNOSIS FORPOWER SUPPLY

286

Main Power Supply andGround Circuit.. 286

TROUBLE DIAGNOSIS FORDTC

11 289

Camshaft PositionSensor(CMPS) 289

TROUBLE DIAGNOSIS FORDTC

12 293

Mass AirFlow Sensor (MAFS) 293

TROUBLE DIAGNOSIS FORDTC

13 297

Engine Coolant Temperature Sensor(ECTS) 297

TROUBLE DIAGNOSIS FORDTC

21 301

Ignition Signal 301

TROUBLE DIAGNOSIS FORDTC

34 306

Knock Sensor (KS) 306

Page 736 of 1701

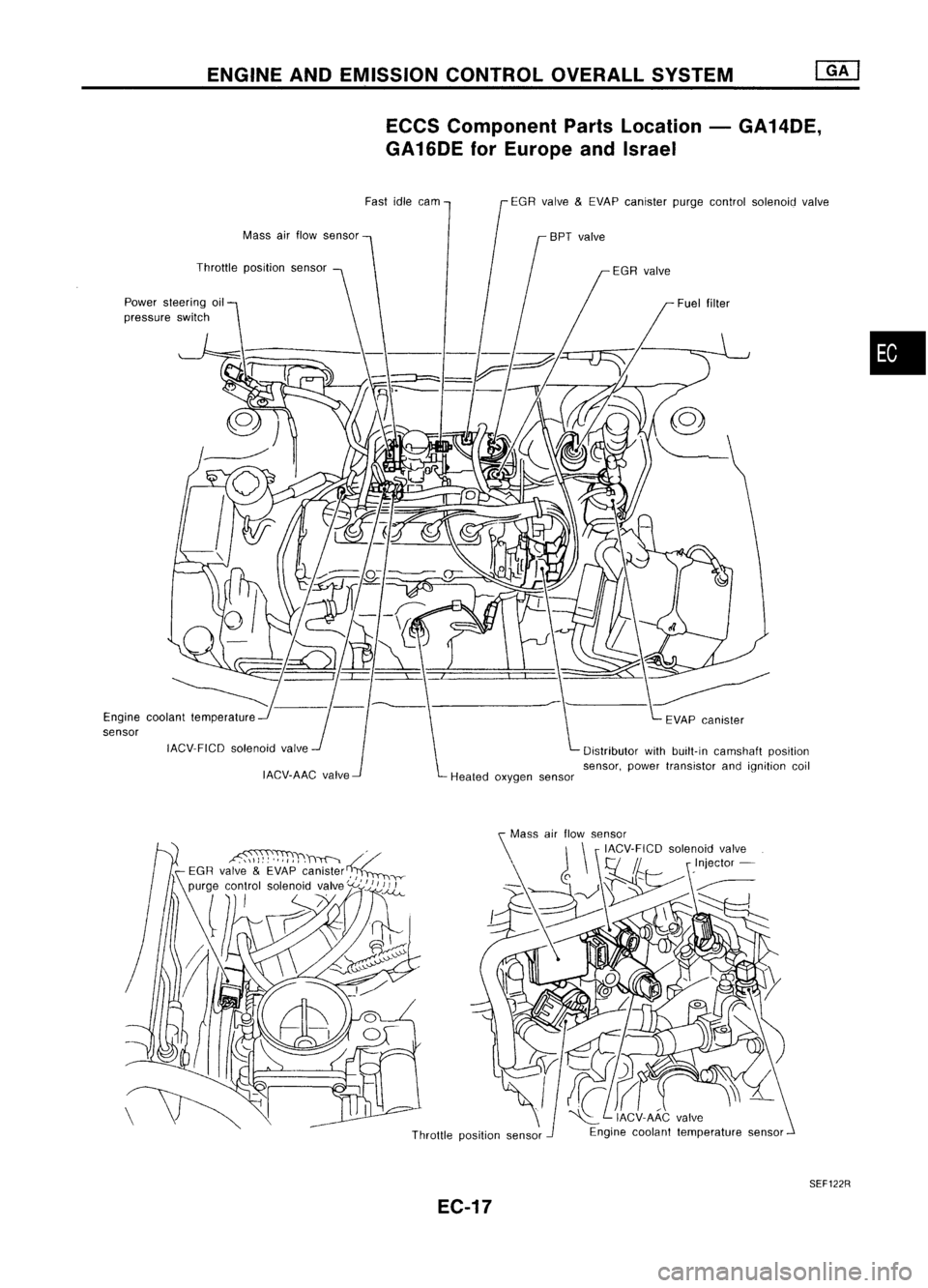

ENGINEANDEMISSION CONTROLOVERALLSYSTEM

ECCS Component PartsLocation -GA14DE,

GA 16DE forEurope andIsrael

Mass airflow sensor

Throttle positionsensor

Power steering oil

pressure switch

Engine coolant temperature

sensor

IACV-FICDsolenoidvalve

IACV-AAC valveFast

idlecam EGRvalve

&

EVAP canister purgecontrol solenoid valve

Distributor withbuilt-in camshaft position

sensor, powertransistor andignition coil

•

Throttle positionsensor

SEF122R

EC-17

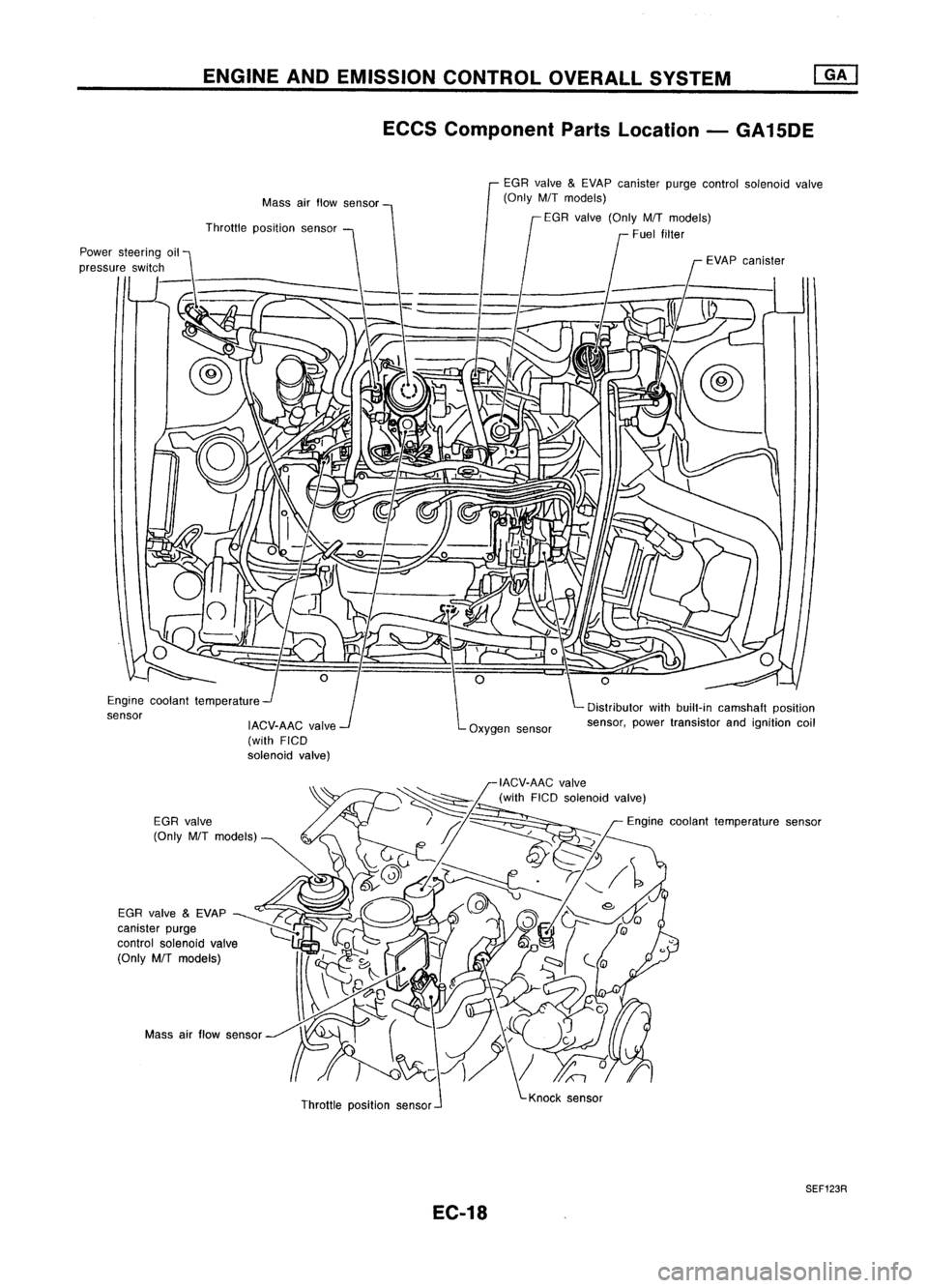

Page 737 of 1701

ENGINEANDEMISSION CONTROL OVERALLSYSTEM

ECCS Component PartsLocation -GA15DE

Distributor withbuilt-in camshaft position

sensor, powertransistor andignition coil

EGR

valve

&

EVAP canister purgecontrol solenoid valve

(Only M/Tmodels)

f

EGR valve (Only M/Tmodels)

Fuel filter

EVAPcanister

Oxygen sensor

Mass

airflow sensor

IACV-AAC valve

(with FICD

solenoid valve)

Throttle

position sensor

Engine coolant temperature

sensor

Massairflow sensor

Throttleposition sensor

SEF123R

EC-18