NISSAN ALMERA N16 2001 Electronic Repair Manual

Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2001Pages: 2493, PDF Size: 66.97 MB

Page 1021 of 2493

SFE642A

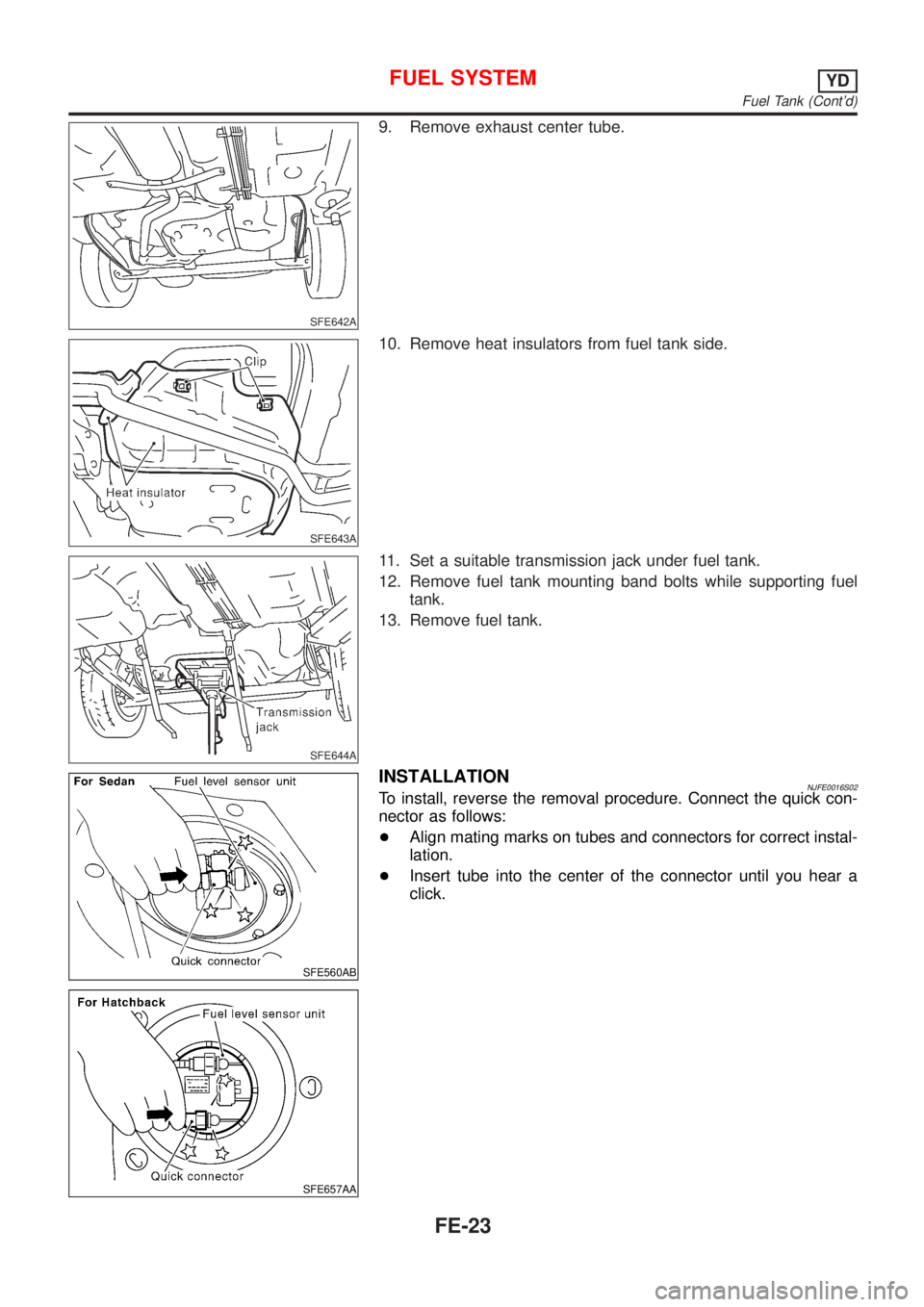

9. Remove exhaust center tube.

SFE643A

10. Remove heat insulators from fuel tank side.

SFE644A

11. Set a suitable transmission jack under fuel tank.

12. Remove fuel tank mounting band bolts while supporting fuel

tank.

13. Remove fuel tank.

SFE560AB

SFE657AA

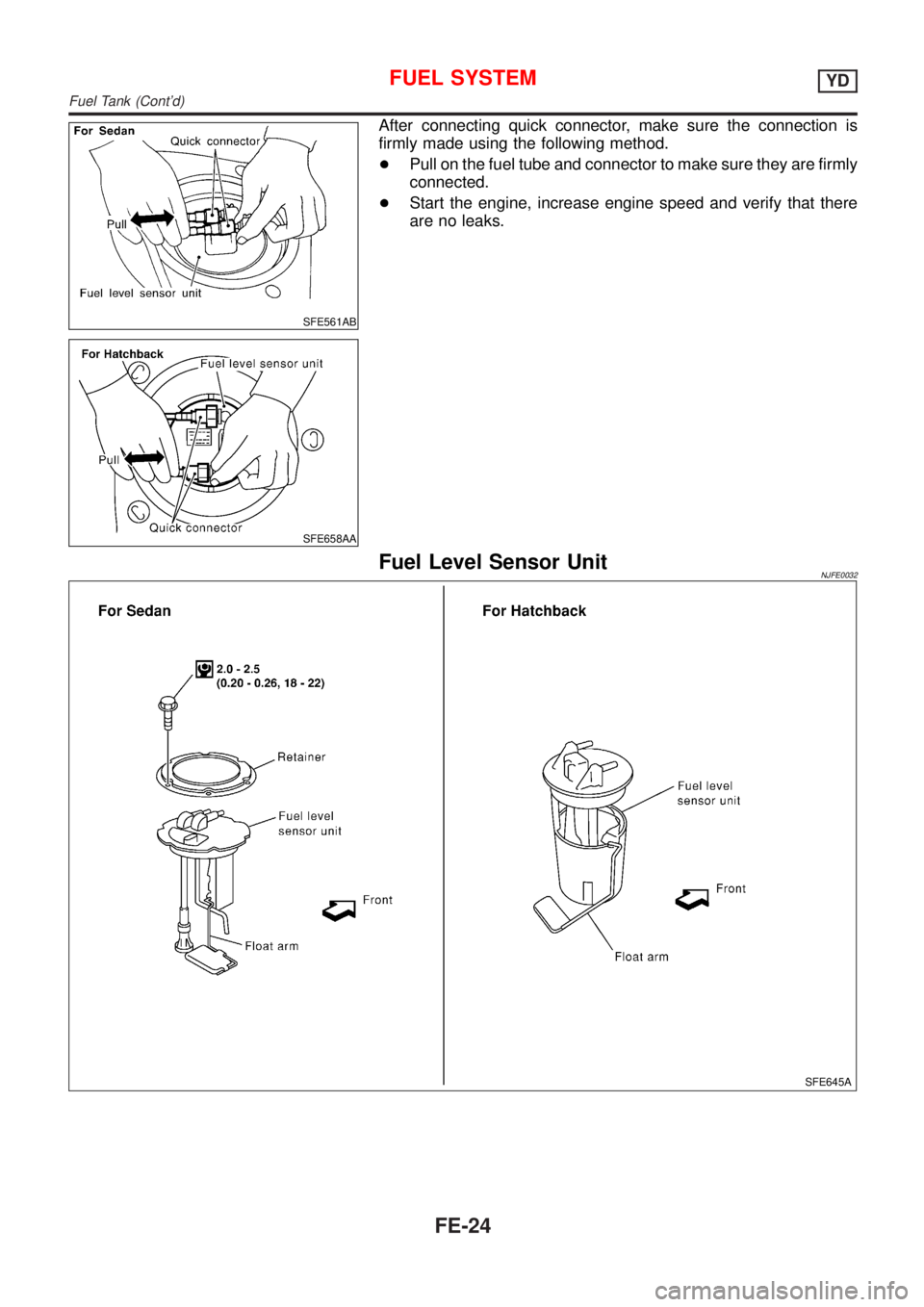

INSTALLATIONNJFE0016S02To install, reverse the removal procedure. Connect the quick con-

nector as follows:

+Align mating marks on tubes and connectors for correct instal-

lation.

+Insert tube into the center of the connector until you hear a

click.

FUEL SYSTEMYD

Fuel Tank (Cont'd)

FE-23

Page 1022 of 2493

SFE561AB

SFE658AA

After connecting quick connector, make sure the connection is

firmly made using the following method.

+Pull on the fuel tube and connector to make sure they are firmly

connected.

+Start the engine, increase engine speed and verify that there

are no leaks.

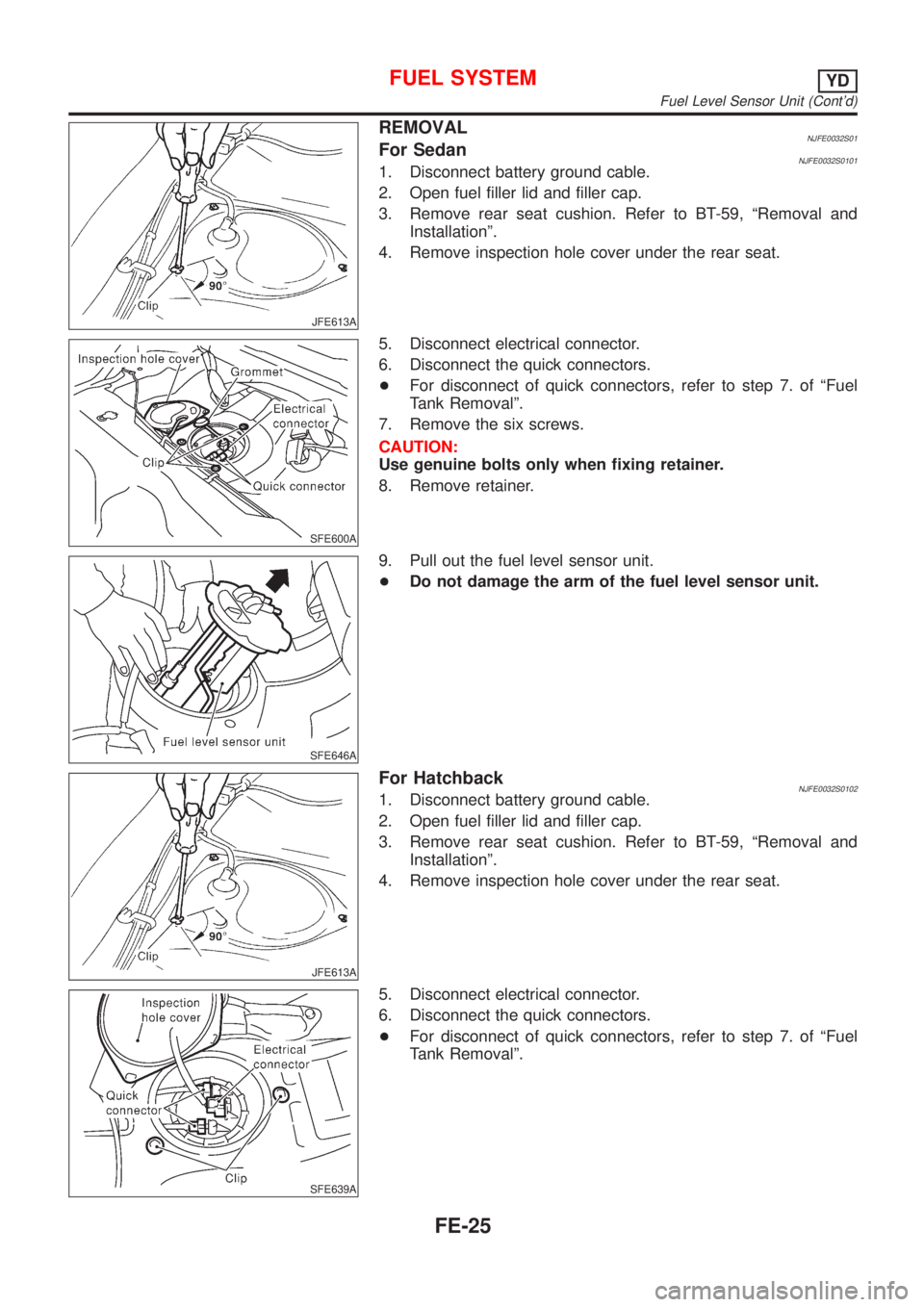

Fuel Level Sensor UnitNJFE0032

SFE645A

FUEL SYSTEMYD

Fuel Tank (Cont'd)

FE-24

Page 1023 of 2493

JFE613A

REMOVALNJFE0032S01For SedanNJFE0032S01011. Disconnect battery ground cable.

2. Open fuel filler lid and filler cap.

3. Remove rear seat cushion. Refer to BT-59, ªRemoval and

Installationº.

4. Remove inspection hole cover under the rear seat.

SFE600A

5. Disconnect electrical connector.

6. Disconnect the quick connectors.

+For disconnect of quick connectors, refer to step 7. of ªFuel

Tank Removalº.

7. Remove the six screws.

CAUTION:

Use genuine bolts only when fixing retainer.

8. Remove retainer.

SFE646A

9. Pull out the fuel level sensor unit.

+Do not damage the arm of the fuel level sensor unit.

JFE613A

For HatchbackNJFE0032S01021. Disconnect battery ground cable.

2. Open fuel filler lid and filler cap.

3. Remove rear seat cushion. Refer to BT-59, ªRemoval and

Installationº.

4. Remove inspection hole cover under the rear seat.

SFE639A

5. Disconnect electrical connector.

6. Disconnect the quick connectors.

+For disconnect of quick connectors, refer to step 7. of ªFuel

Tank Removalº.

FUEL SYSTEMYD

Fuel Level Sensor Unit (Cont'd)

FE-25

Page 1024 of 2493

SFE376A

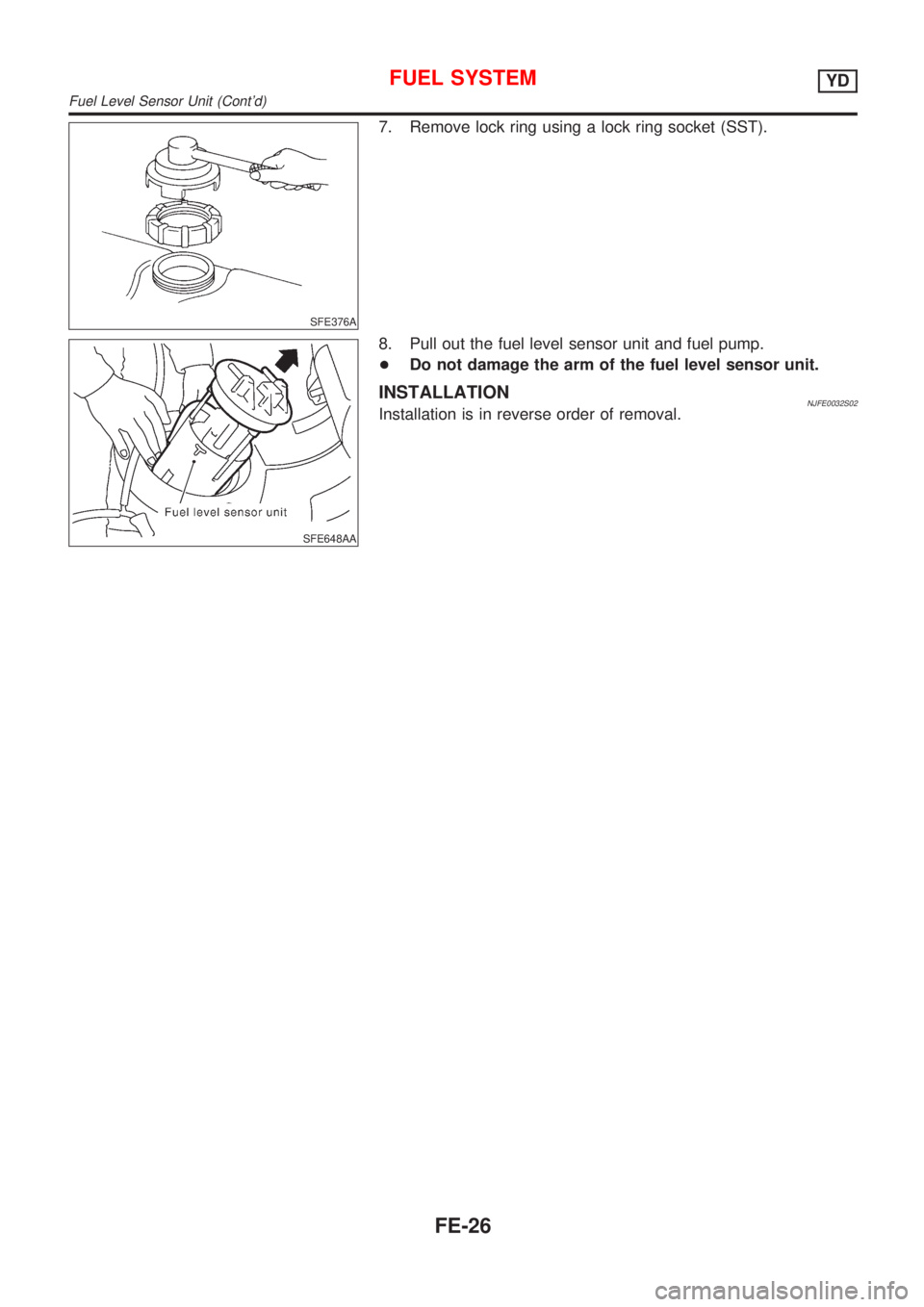

7. Remove lock ring using a lock ring socket (SST).

SFE648AA

8. Pull out the fuel level sensor unit and fuel pump.

+Do not damage the arm of the fuel level sensor unit.

INSTALLATIONNJFE0032S02Installation is in reverse order of removal.

FUEL SYSTEMYD

Fuel Level Sensor Unit (Cont'd)

FE-26

Page 1025 of 2493

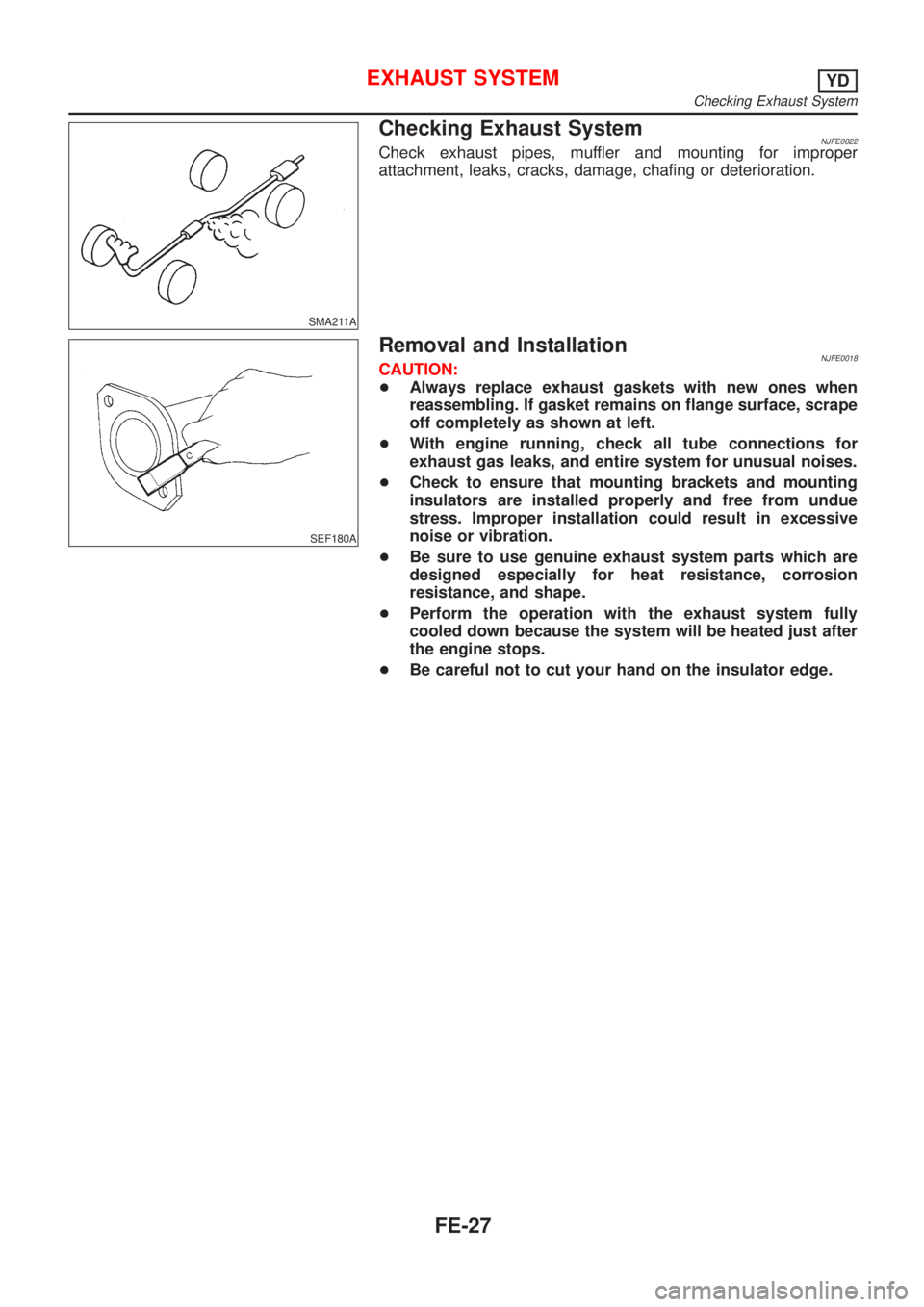

SMA211A

Checking Exhaust SystemNJFE0022Check exhaust pipes, muffler and mounting for improper

attachment, leaks, cracks, damage, chafing or deterioration.

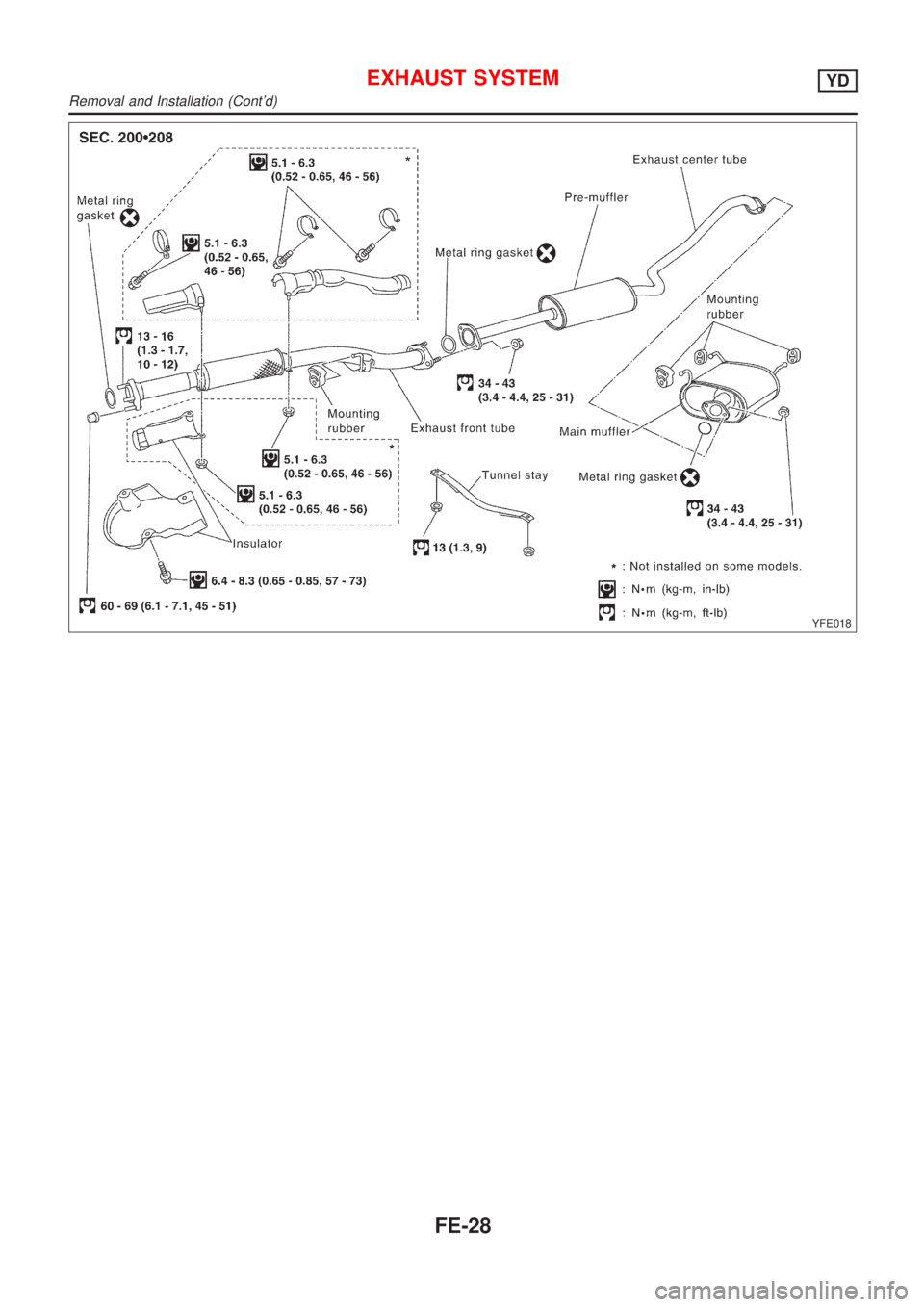

SEF180A

Removal and InstallationNJFE0018CAUTION:

+Always replace exhaust gaskets with new ones when

reassembling. If gasket remains on flange surface, scrape

off completely as shown at left.

+With engine running, check all tube connections for

exhaust gas leaks, and entire system for unusual noises.

+Check to ensure that mounting brackets and mounting

insulators are installed properly and free from undue

stress. Improper installation could result in excessive

noise or vibration.

+Be sure to use genuine exhaust system parts which are

designed especially for heat resistance, corrosion

resistance, and shape.

+Perform the operation with the exhaust system fully

cooled down because the system will be heated just after

the engine stops.

+Be careful not to cut your hand on the insulator edge.

EXHAUST SYSTEMYD

Checking Exhaust System

FE-27

Page 1026 of 2493

YFE018

EXHAUST SYSTEMYD

Removal and Installation (Cont'd)

FE-28

Page 1027 of 2493

CLUTCH

SECTION

CL

CONTENTS

PRECAUTIONS...............................................................2

Precautions ..................................................................2

PREPARATION...............................................................3

Special Service Tools ..................................................3

Commercial Service Tools ...........................................3

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING.....................................................4

NVH Troubleshooting Chart.........................................4

CLUTCH...................................................................4

CLUTCH SYSTEM...........................................................5

Components - RHD Model with QG Engine - .............5

Components - LHD Model with QG Engine -..............6

Components - RHD Model with YD Engine -..............7

Components - LHD Model with YD Engine - ..............8

Inspection and Adjustment ..........................................9

CLUTCH PEDAL INSPECTION...................................9

CLUTCH PEDAL ADJUSTMENT...............................10

AIR BLEEDING PROCEDURE..................................10

CLUTCH MASTER CYLINDER..................................... 11

Components............................................................... 11

Removal .....................................................................12

Installation ..................................................................12

Disassembly...............................................................12

Inspection...................................................................12

Assembly ...................................................................13

OPERATING CYLINDER...............................................14

Components...............................................................14

Removal .....................................................................14

Disassembly...............................................................14

Inspection...................................................................14

Assembly ...................................................................15

Installation ..................................................................15

PIPING...........................................................................16

Removal .....................................................................16Installation ..................................................................16

RS5F30A, RS5F70A

CLUTCH RELEASE MECHANISM...............................17

Components...............................................................17

Removal .....................................................................17

Inspection...................................................................17

Installation ..................................................................17

RS5F50A

CLUTCH RELEASE MECHANISM...............................20

Components...............................................................20

Removal .....................................................................20

Inspection...................................................................20

Installation ..................................................................20

CLUTCH DISC, CLUTCH COVER AND

FLYWHEEL....................................................................22

Components...............................................................22

Inspection and Adjustment ........................................22

CLUTCH DISC.........................................................22

CLUTCH COVER.....................................................23

FLYWHEEL.............................................................23

Installation ..................................................................23

SERVICE DATA AND SPECIFICATIONS (SDS).........24

Clutch Control System ...............................................24

Clutch Master Cylinder ..............................................24

Clutch Operating Cylinder .........................................24

Clutch Disc.................................................................24

Clutch Cover ..............................................................24

Clutch Pedal ..............................................................24

Page 1028 of 2493

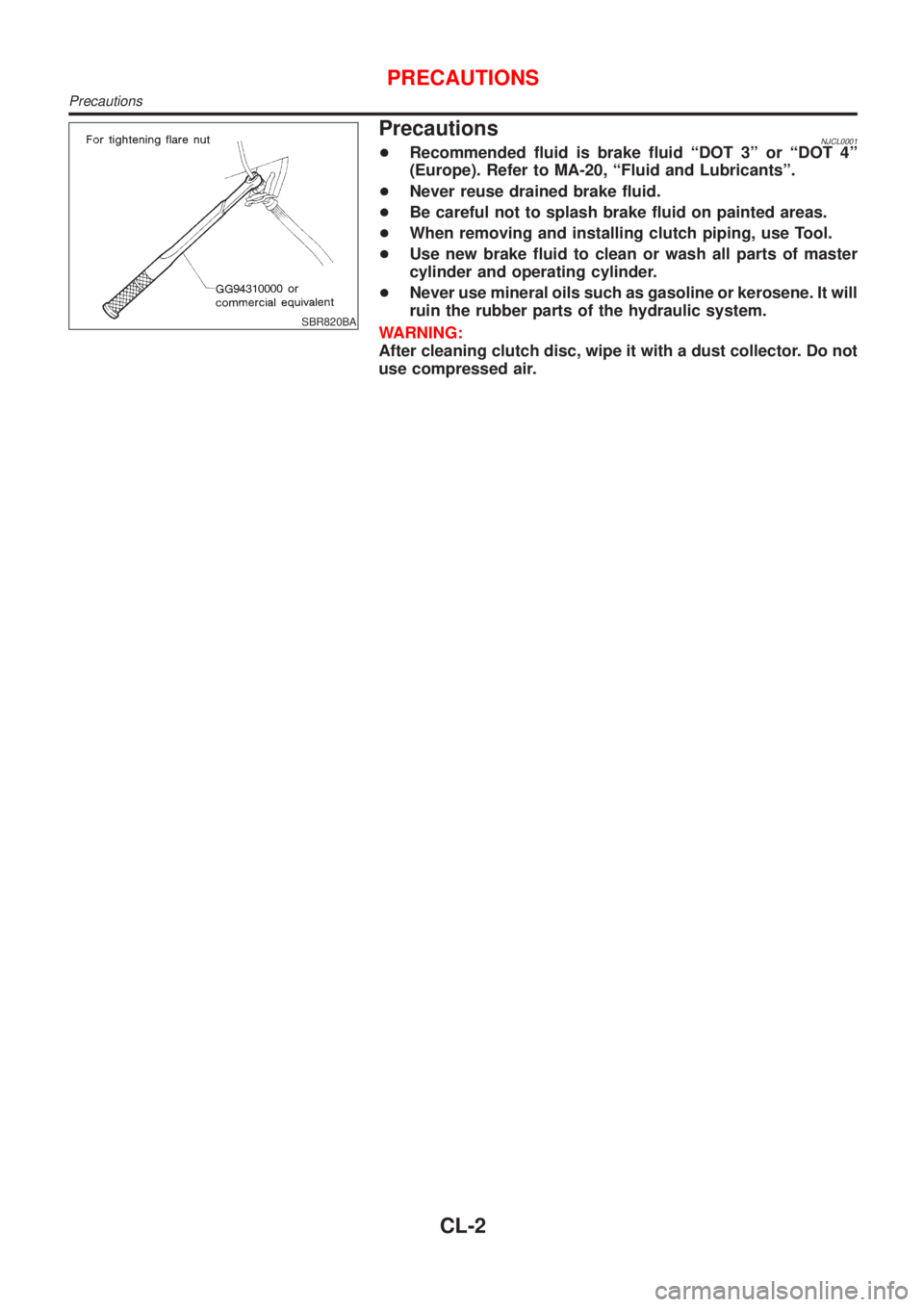

SBR820BA

PrecautionsNJCL0001+Recommended fluid is brake fluid ªDOT 3º or ªDOT 4º

(Europe). Refer to MA-20, ªFluid and Lubricantsº.

+Never reuse drained brake fluid.

+Be careful not to splash brake fluid on painted areas.

+When removing and installing clutch piping, use Tool.

+Use new brake fluid to clean or wash all parts of master

cylinder and operating cylinder.

+Never use mineral oils such as gasoline or kerosene. It will

ruin the rubber parts of the hydraulic system.

WARNING:

After cleaning clutch disc, wipe it with a dust collector. Do not

use compressed air.

PRECAUTIONS

Precautions

CL-2

Page 1029 of 2493

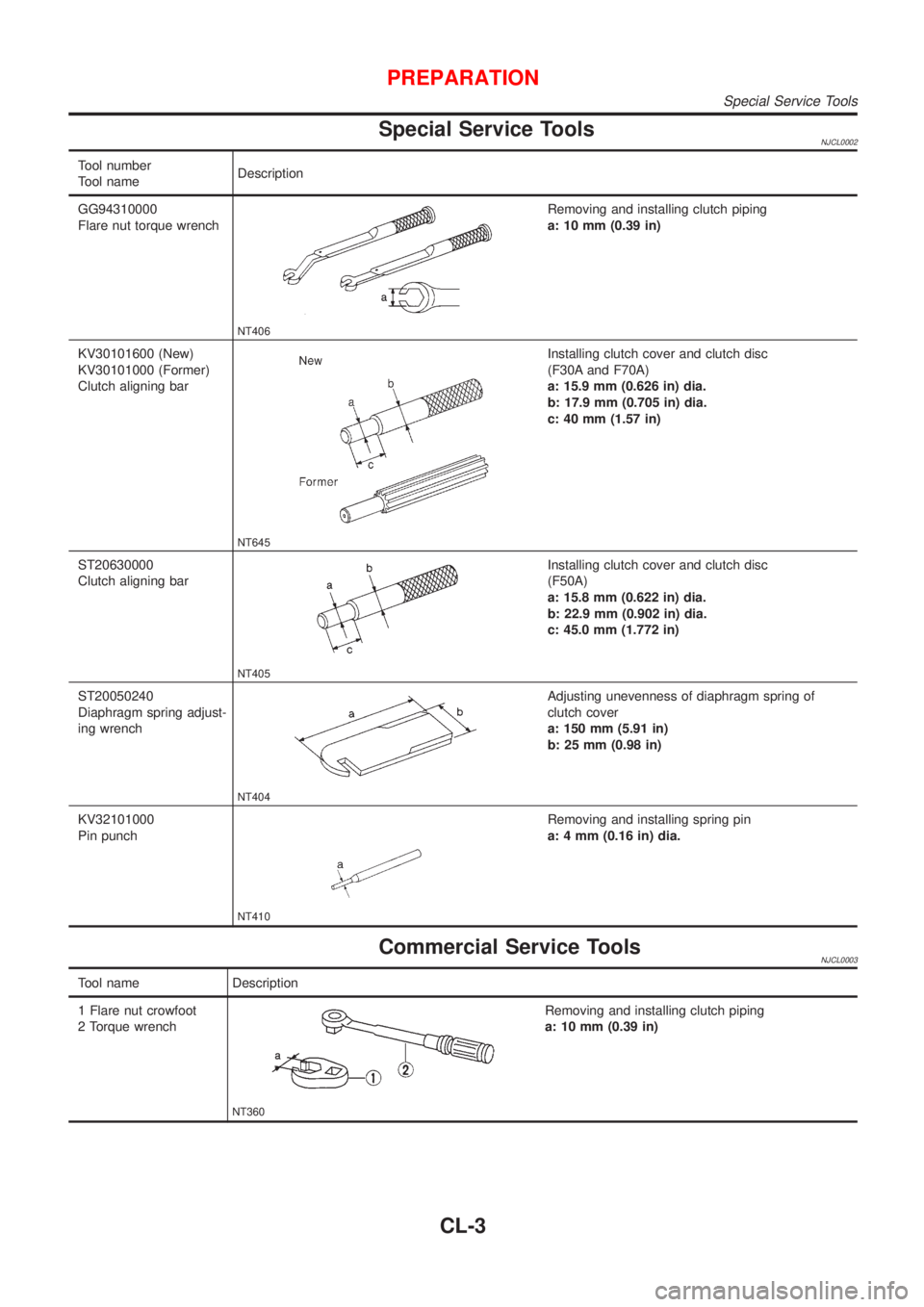

Special Service ToolsNJCL0002

Tool number

Tool nameDescription

GG94310000

Flare nut torque wrench

NT406

Removing and installing clutch piping

a: 10 mm (0.39 in)

KV30101600 (New)

KV30101000 (Former)

Clutch aligning bar

NT645

Installing clutch cover and clutch disc

(F30A and F70A)

a: 15.9 mm (0.626 in) dia.

b: 17.9 mm (0.705 in) dia.

c: 40 mm (1.57 in)

ST20630000

Clutch aligning bar

NT405

Installing clutch cover and clutch disc

(F50A)

a: 15.8 mm (0.622 in) dia.

b: 22.9 mm (0.902 in) dia.

c: 45.0 mm (1.772 in)

ST20050240

Diaphragm spring adjust-

ing wrench

NT404

Adjusting unevenness of diaphragm spring of

clutch cover

a: 150 mm (5.91 in)

b: 25 mm (0.98 in)

KV32101000

Pin punch

NT410

Removing and installing spring pin

a: 4 mm (0.16 in) dia.

Commercial Service ToolsNJCL0003

Tool name Description

1 Flare nut crowfoot

2 Torque wrench

NT360

Removing and installing clutch piping

a: 10 mm (0.39 in)

PREPARATION

Special Service Tools

CL-3

Page 1030 of 2493

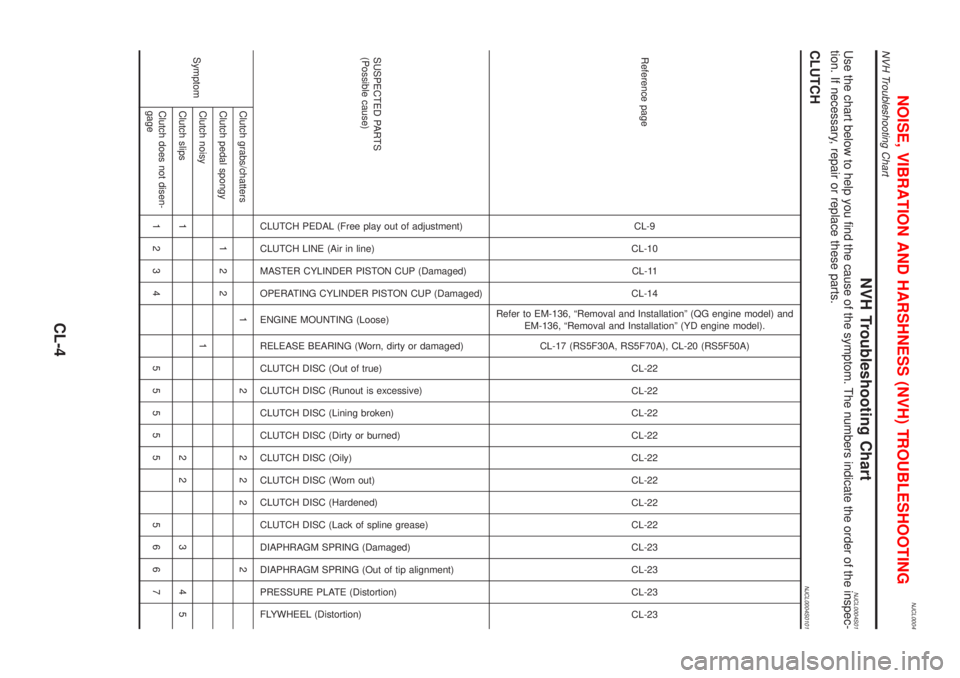

NJCL0004

NVH Troubleshooting ChartNJCL0004S01Use the chart below to help you find the cause of the symptom. The numbers indicate the order of the inspec-

tion. If necessary, repair or replace these parts.

CLUTCHNJCL0004S0101

Reference pageCL-9

CL-10

CL-11

CL-14

Refer to EM-136, ªRemoval and Installationº (QG engine model) and

EM-136, ªRemoval and Installationº (YD engine model).

CL-17 (RS5F30A, RS5F70A), CL-20 (RS5F50A)

CL-22

CL-22

CL-22

CL-22

CL-22

CL-22

CL-22

CL-22

CL-23

CL-23

CL-23

CL-23

SUSPECTED PARTS

(Possible cause)

CLUTCH PEDAL (Free play out of adjustment)

CLUTCH LINE (Air in line)

MASTER CYLINDER PISTON CUP (Damaged)

OPERATING CYLINDER PISTON CUP (Damaged)

ENGINE MOUNTING (Loose)

RELEASE BEARING (Worn, dirty or damaged)

CLUTCH DISC (Out of true)

CLUTCH DISC (Runout is excessive)

CLUTCH DISC (Lining broken)

CLUTCH DISC (Dirty or burned)

CLUTCH DISC (Oily)

CLUTCH DISC (Worn out)

CLUTCH DISC (Hardened)

CLUTCH DISC (Lack of spline grease)

DIAPHRAGM SPRING (Damaged)

DIAPHRAGM SPRING (Out of tip alignment)

PRESSURE PLATE (Distortion)

FLYWHEEL (Distortion)

SymptomClutch grabs/chatters 1 2 2 2 2 2

Clutch pedal spongy 1 2 2

Clutch noisy 1

Clutch slips 1 2 2 3 4 5

Clutch does not disen-

gage1234 55555 5667

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting Chart

CL-4