NISSAN ALMERA N16 2001 Electronic Repair Manual

Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2001Pages: 2493, PDF Size: 66.97 MB

Page 1041 of 2493

AssemblyNJCL00231. Apply recommended rubber grease to piston cup and piston,

and insert piston assembly.

2. Install dust cover.

InstallationNJCL0024Install the components in the reverse order of removal. Adhere to

the operations described below.

CAUTION:

Install the hose without twisting it.

+The copper washer of the union bolt should not be reused.

Always use a new copper washer for installation.

+After finishing the operation, bleed air from the clutch

piping connector and operating cylinder. Refer to ªAir

Bleeding Procedureº, CL-10.

OPERATING CYLINDER

Assembly

CL-15

Page 1042 of 2493

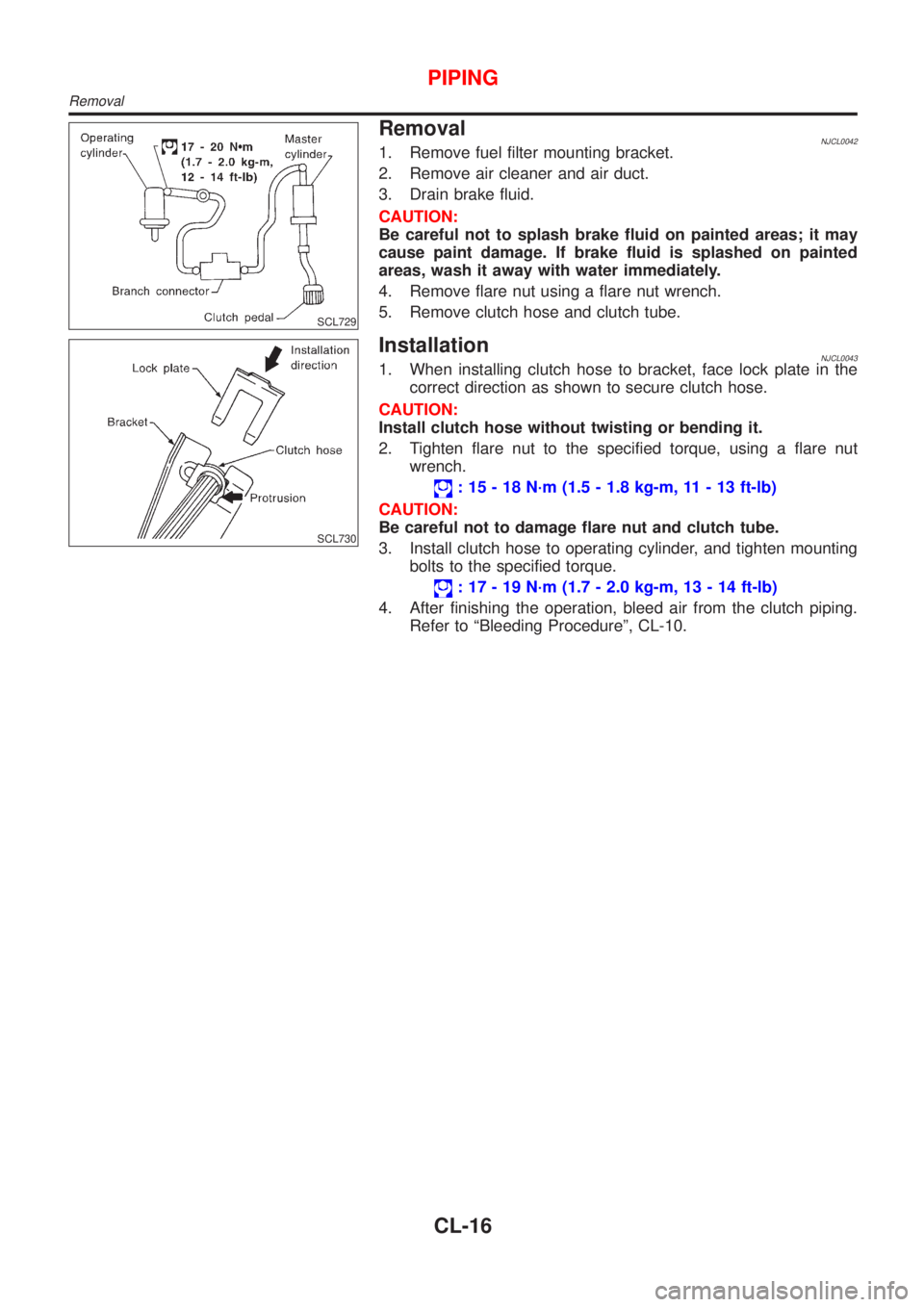

SCL729

RemovalNJCL00421. Remove fuel filter mounting bracket.

2. Remove air cleaner and air duct.

3. Drain brake fluid.

CAUTION:

Be careful not to splash brake fluid on painted areas; it may

cause paint damage. If brake fluid is splashed on painted

areas, wash it away with water immediately.

4. Remove flare nut using a flare nut wrench.

5. Remove clutch hose and clutch tube.

SCL730

InstallationNJCL00431. When installing clutch hose to bracket, face lock plate in the

correct direction as shown to secure clutch hose.

CAUTION:

Install clutch hose without twisting or bending it.

2. Tighten flare nut to the specified torque, using a flare nut

wrench.

: 15 - 18 N´m (1.5 - 1.8 kg-m, 11 - 13 ft-lb)

CAUTION:

Be careful not to damage flare nut and clutch tube.

3. Install clutch hose to operating cylinder, and tighten mounting

bolts to the specified torque.

: 17 - 19 N´m (1.7 - 2.0 kg-m, 13 - 14 ft-lb)

4. After finishing the operation, bleed air from the clutch piping.

Refer to ªBleeding Procedureº, CL-10.

PIPING

Removal

CL-16

Page 1043 of 2493

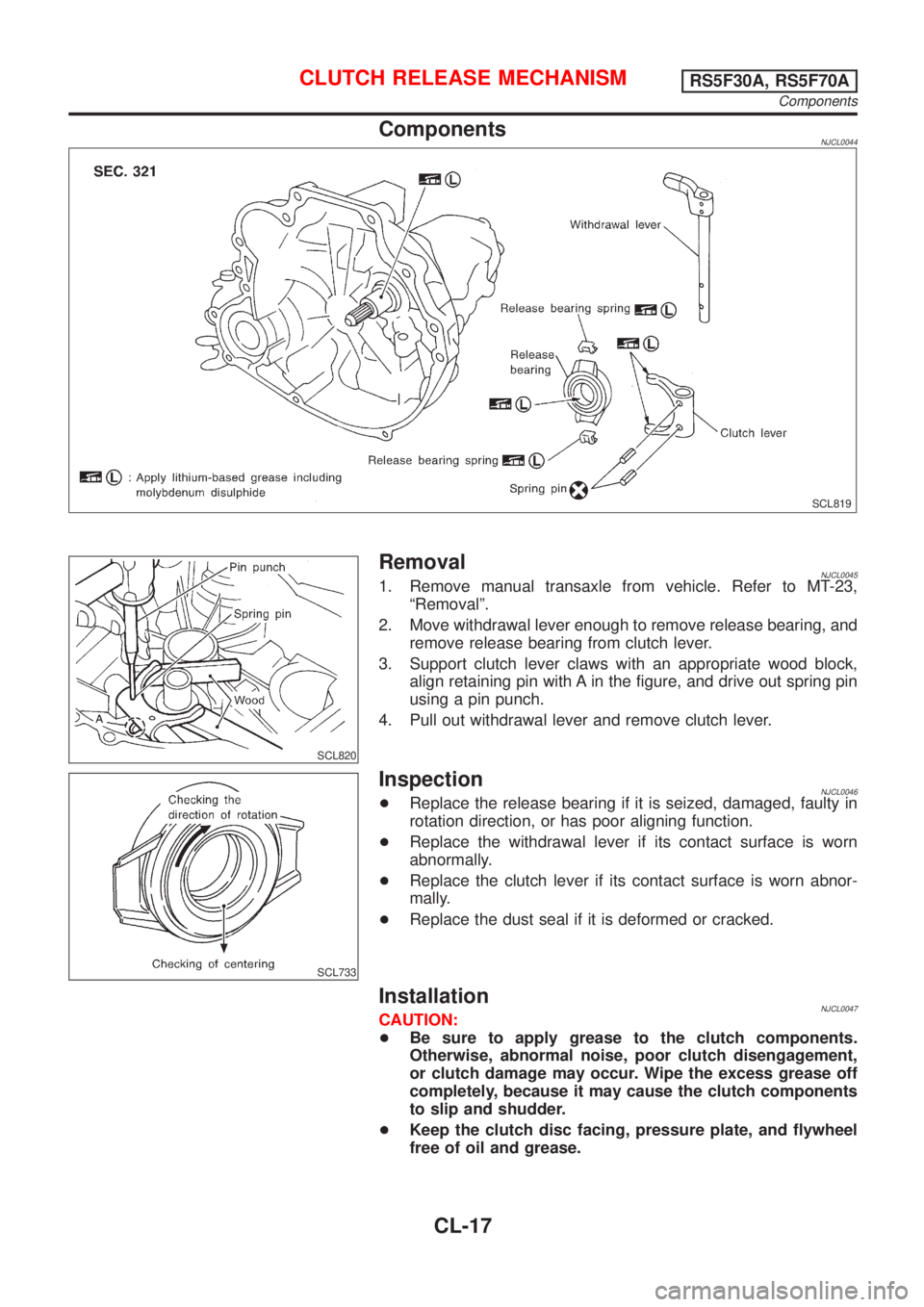

ComponentsNJCL0044

SCL819

SCL820

RemovalNJCL00451. Remove manual transaxle from vehicle. Refer to MT-23,

ªRemovalº.

2. Move withdrawal lever enough to remove release bearing, and

remove release bearing from clutch lever.

3. Support clutch lever claws with an appropriate wood block,

align retaining pin with A in the figure, and drive out spring pin

using a pin punch.

4. Pull out withdrawal lever and remove clutch lever.

SCL733

InspectionNJCL0046+Replace the release bearing if it is seized, damaged, faulty in

rotation direction, or has poor aligning function.

+Replace the withdrawal lever if its contact surface is worn

abnormally.

+Replace the clutch lever if its contact surface is worn abnor-

mally.

+Replace the dust seal if it is deformed or cracked.

InstallationNJCL0047CAUTION:

+Be sure to apply grease to the clutch components.

Otherwise, abnormal noise, poor clutch disengagement,

or clutch damage may occur. Wipe the excess grease off

completely, because it may cause the clutch components

to slip and shudder.

+Keep the clutch disc facing, pressure plate, and flywheel

free of oil and grease.

CLUTCH RELEASE MECHANISMRS5F30A, RS5F70A

Components

CL-17

Page 1044 of 2493

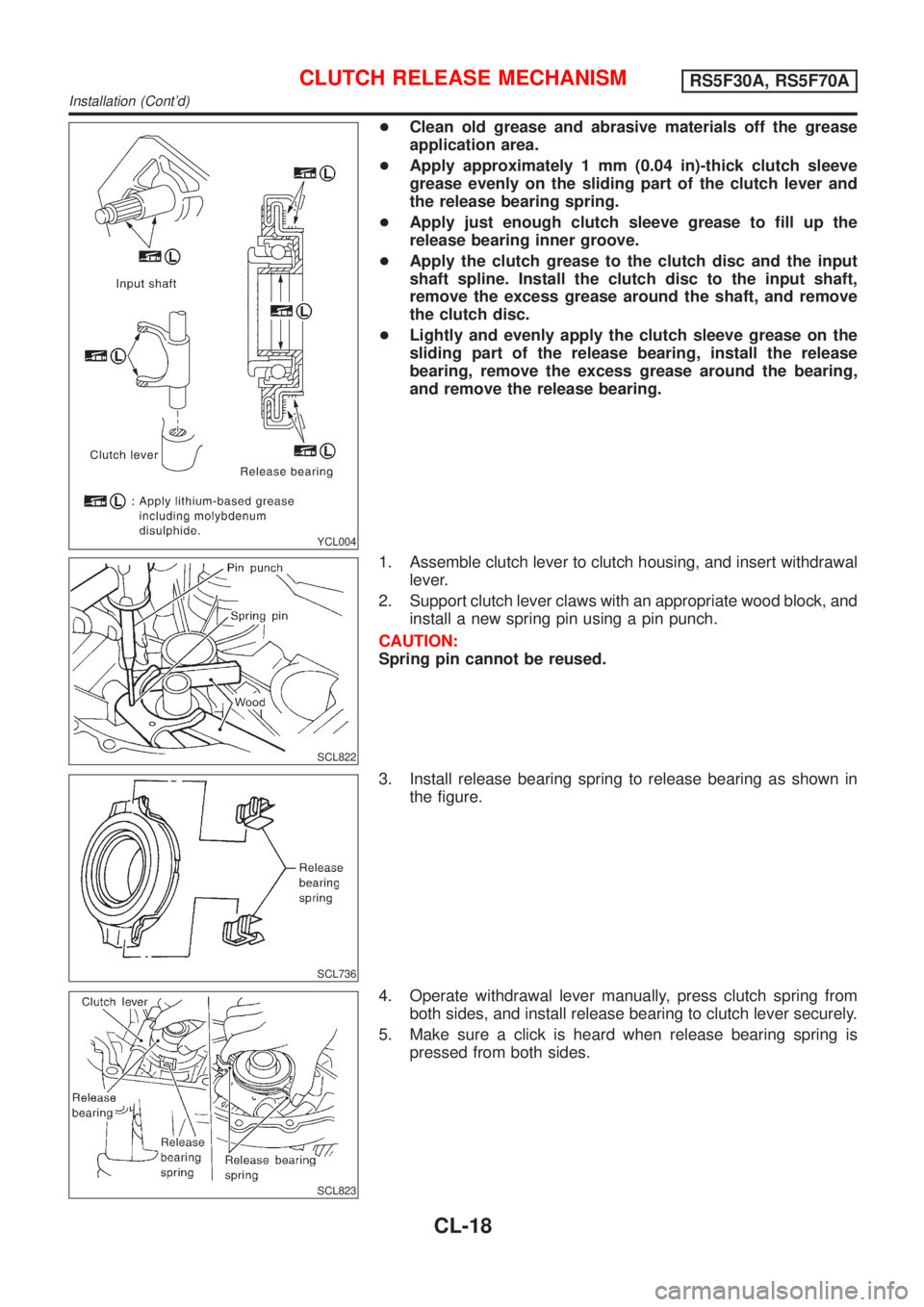

YCL004

+Clean old grease and abrasive materials off the grease

application area.

+Apply approximately 1 mm (0.04 in)-thick clutch sleeve

grease evenly on the sliding part of the clutch lever and

the release bearing spring.

+Apply just enough clutch sleeve grease to fill up the

release bearing inner groove.

+Apply the clutch grease to the clutch disc and the input

shaft spline. Install the clutch disc to the input shaft,

remove the excess grease around the shaft, and remove

the clutch disc.

+Lightly and evenly apply the clutch sleeve grease on the

sliding part of the release bearing, install the release

bearing, remove the excess grease around the bearing,

and remove the release bearing.

SCL822

1. Assemble clutch lever to clutch housing, and insert withdrawal

lever.

2. Support clutch lever claws with an appropriate wood block, and

install a new spring pin using a pin punch.

CAUTION:

Spring pin cannot be reused.

SCL736

3. Install release bearing spring to release bearing as shown in

the figure.

SCL823

4. Operate withdrawal lever manually, press clutch spring from

both sides, and install release bearing to clutch lever securely.

5. Make sure a click is heard when release bearing spring is

pressed from both sides.

CLUTCH RELEASE MECHANISMRS5F30A, RS5F70A

Installation (Cont'd)

CL-18

Page 1045 of 2493

SCL738

6. Make sure each sliding part operates smoothly when with-

drawal lever is moved.

CAUTION:

Remove any excess grease with a shop towel.

CLUTCH RELEASE MECHANISMRS5F30A, RS5F70A

Installation (Cont'd)

CL-19

Page 1046 of 2493

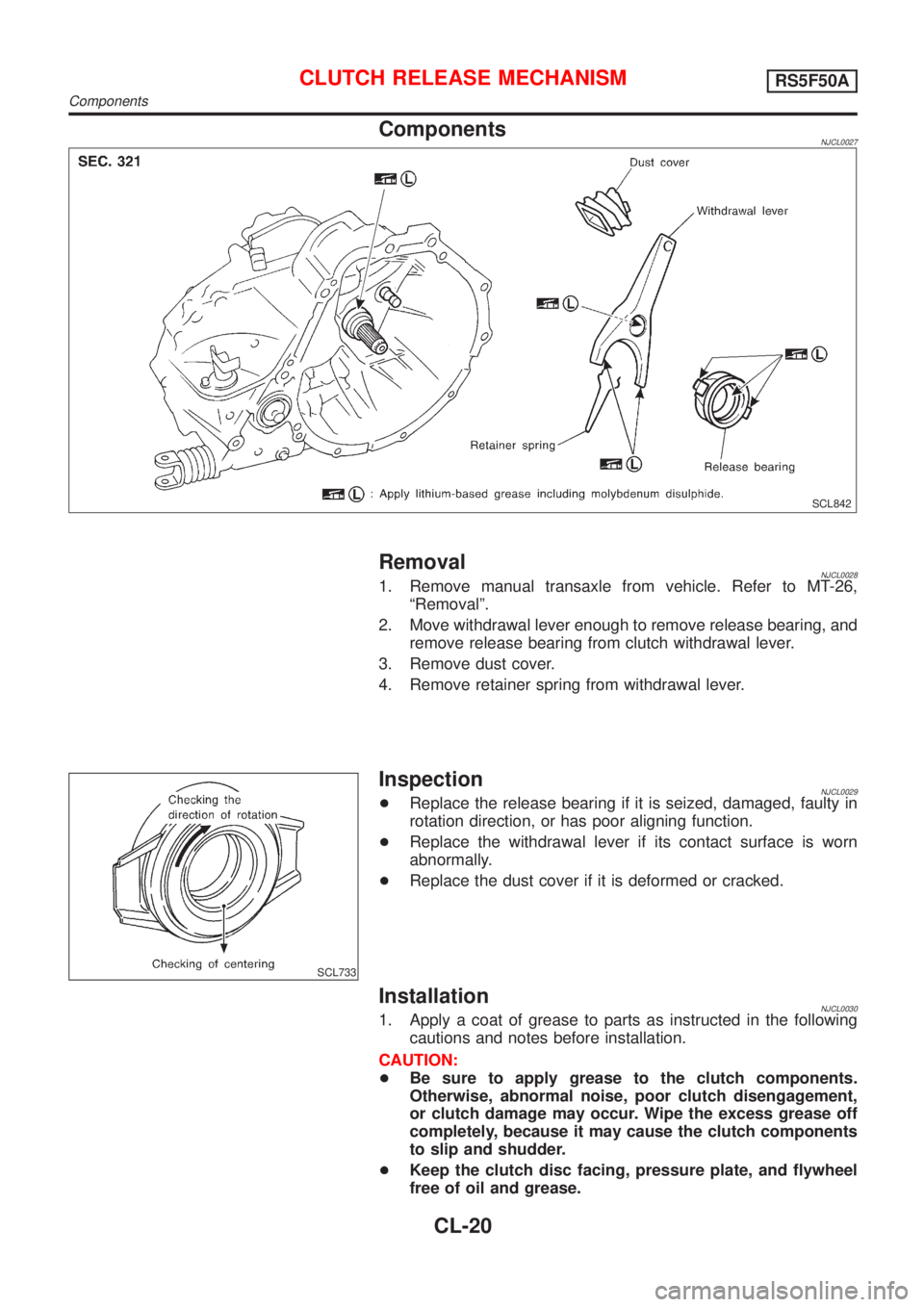

ComponentsNJCL0027

SCL842

RemovalNJCL00281. Remove manual transaxle from vehicle. Refer to MT-26,

ªRemovalº.

2. Move withdrawal lever enough to remove release bearing, and

remove release bearing from clutch withdrawal lever.

3. Remove dust cover.

4. Remove retainer spring from withdrawal lever.

SCL733

InspectionNJCL0029+Replace the release bearing if it is seized, damaged, faulty in

rotation direction, or has poor aligning function.

+Replace the withdrawal lever if its contact surface is worn

abnormally.

+Replace the dust cover if it is deformed or cracked.

InstallationNJCL00301. Apply a coat of grease to parts as instructed in the following

cautions and notes before installation.

CAUTION:

+Be sure to apply grease to the clutch components.

Otherwise, abnormal noise, poor clutch disengagement,

or clutch damage may occur. Wipe the excess grease off

completely, because it may cause the clutch components

to slip and shudder.

+Keep the clutch disc facing, pressure plate, and flywheel

free of oil and grease.

CLUTCH RELEASE MECHANISMRS5F50A

Components

CL-20

Page 1047 of 2493

![NISSAN ALMERA N16 2001 Electronic Repair Manual +Clean old grease and abrasive materials off the grease

application area.

SCL815

NOTE:

+Equally apply a coat [approximately 1 mm (0.04 in) thick] of

clutch sleeve grease to withdrawal lever and holder NISSAN ALMERA N16 2001 Electronic Repair Manual +Clean old grease and abrasive materials off the grease

application area.

SCL815

NOTE:

+Equally apply a coat [approximately 1 mm (0.04 in) thick] of

clutch sleeve grease to withdrawal lever and holder](/img/5/57351/w960_57351-1046.png)

+Clean old grease and abrasive materials off the grease

application area.

SCL815

NOTE:

+Equally apply a coat [approximately 1 mm (0.04 in) thick] of

clutch sleeve grease to withdrawal lever and holder spring

frictional surfaces.

+Apply a coat of clutch sleeve grease to the grooves on contact

surfaces of the withdrawal lever ball pin and inner surface of

release bearing so that grease application, make sure that

grease is flush with grooves.

+Equally apply a thin coat of clutch sleeve grease to release

bearing frictional surface. After grease application, install

release bearing. Wipe off excess grease forced out during

bearing installation. Remove release bearing.

2. Installation is in the reverse order of removal.

CLUTCH RELEASE MECHANISMRS5F50A

Installation (Cont'd)

CL-21

Page 1048 of 2493

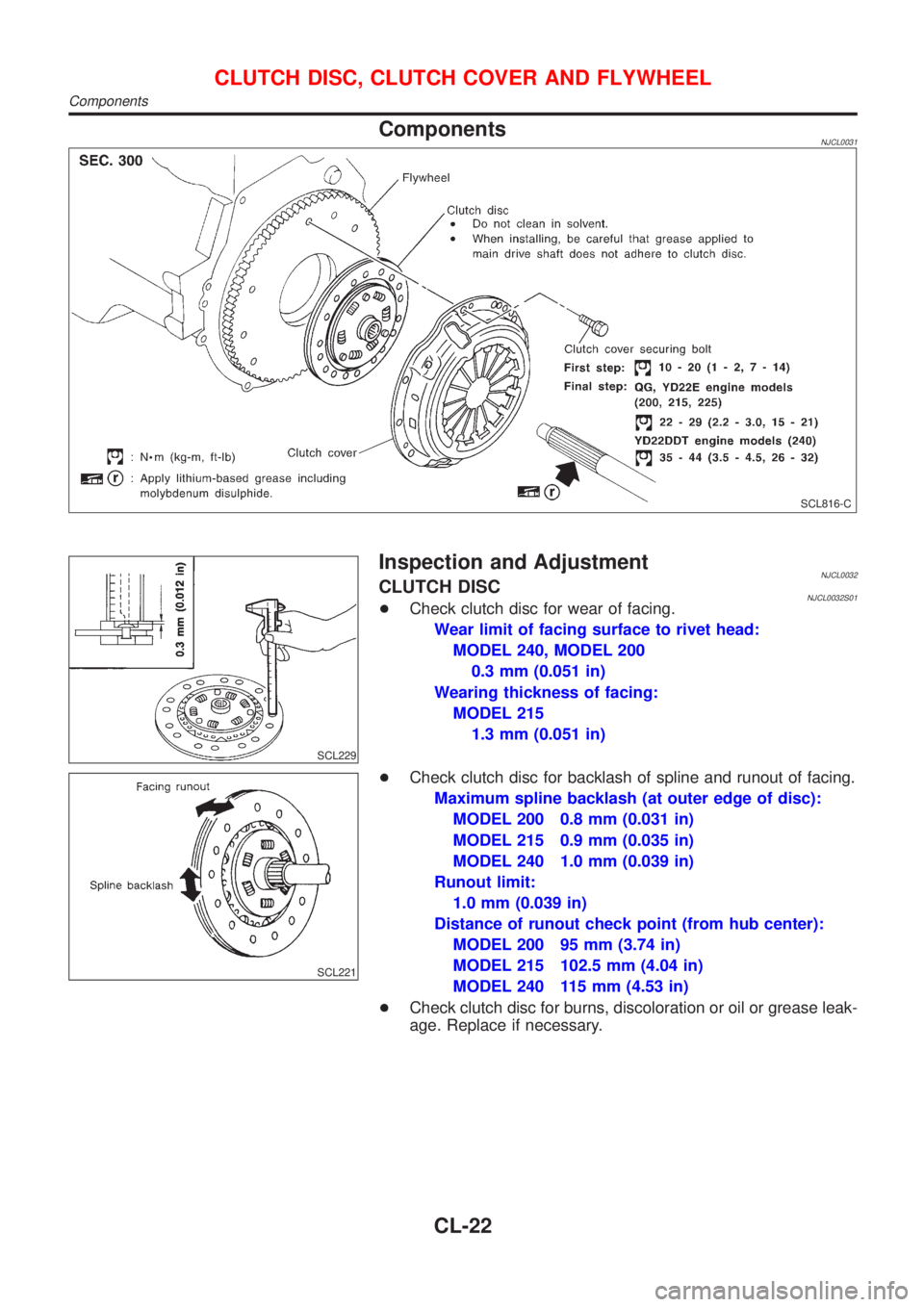

ComponentsNJCL0031

SCL816-C

SCL229

Inspection and AdjustmentNJCL0032CLUTCH DISCNJCL0032S01+Check clutch disc for wear of facing.

Wear limit of facing surface to rivet head:

MODEL 240, MODEL 200

0.3 mm (0.051 in)

Wearing thickness of facing:

MODEL 215

1.3 mm (0.051 in)

SCL221

+Check clutch disc for backlash of spline and runout of facing.

Maximum spline backlash (at outer edge of disc):

MODEL 200 0.8 mm (0.031 in)

MODEL 215 0.9 mm (0.035 in)

MODEL 240 1.0 mm (0.039 in)

Runout limit:

1.0 mm (0.039 in)

Distance of runout check point (from hub center):

MODEL 200 95 mm (3.74 in)

MODEL 215 102.5 mm (4.04 in)

MODEL 240 115 mm (4.53 in)

+Check clutch disc for burns, discoloration or oil or grease leak-

age. Replace if necessary.

CLUTCH DISC, CLUTCH COVER AND FLYWHEEL

Components

CL-22

Page 1049 of 2493

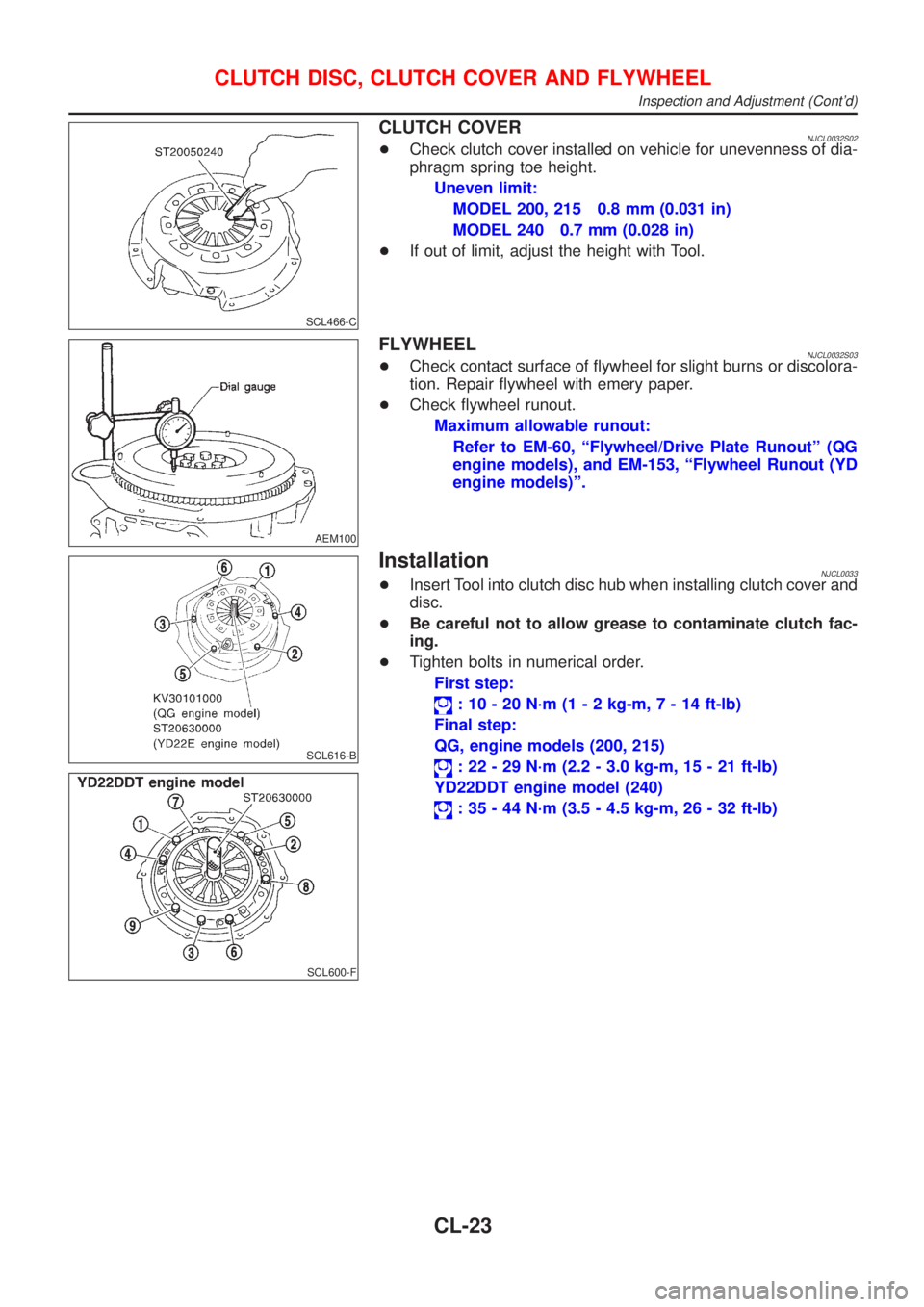

SCL466-C

CLUTCH COVERNJCL0032S02+Check clutch cover installed on vehicle for unevenness of dia-

phragm spring toe height.

Uneven limit:

MODEL 200, 215 0.8 mm (0.031 in)

MODEL 240 0.7 mm (0.028 in)

+If out of limit, adjust the height with Tool.

AEM100

FLYWHEELNJCL0032S03+Check contact surface of flywheel for slight burns or discolora-

tion. Repair flywheel with emery paper.

+Check flywheel runout.

Maximum allowable runout:

Refer to EM-60, ªFlywheel/Drive Plate Runoutº (QG

engine models), and EM-153, ªFlywheel Runout (YD

engine models)º.

SCL616-B

SCL600-F

InstallationNJCL0033+Insert Tool into clutch disc hub when installing clutch cover and

disc.

+Be careful not to allow grease to contaminate clutch fac-

ing.

+Tighten bolts in numerical order.

First step:

: 10 - 20 N´m (1 - 2 kg-m,7-14ft-lb)

Final step:

QG, engine models (200, 215)

: 22 - 29 N´m (2.2 - 3.0 kg-m, 15 - 21 ft-lb)

YD22DDT engine model (240)

: 35 - 44 N´m (3.5 - 4.5 kg-m, 26 - 32 ft-lb)

CLUTCH DISC, CLUTCH COVER AND FLYWHEEL

Inspection and Adjustment (Cont'd)

CL-23

Page 1050 of 2493

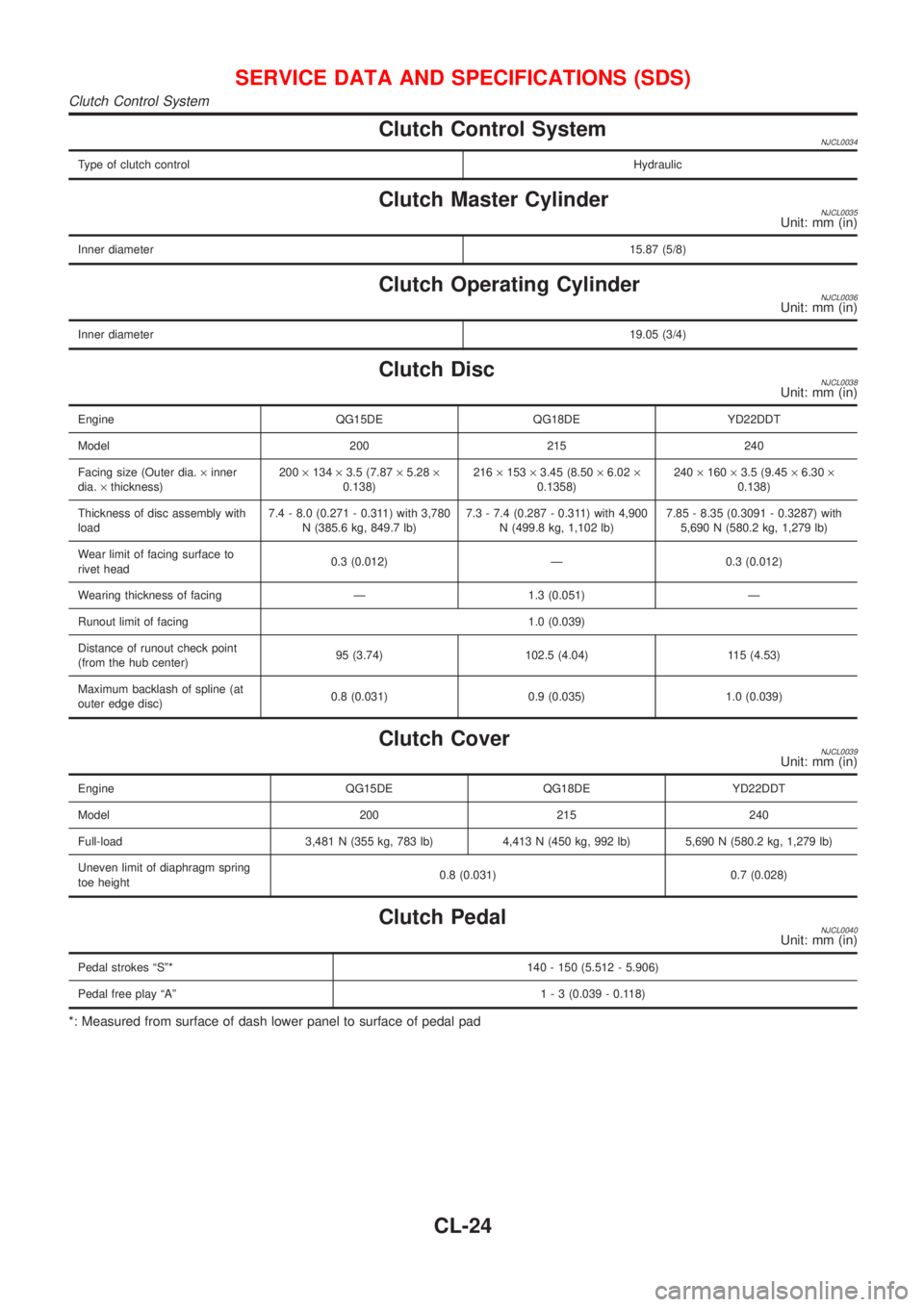

Clutch Control SystemNJCL0034

Type of clutch controlHydraulic

Clutch Master CylinderNJCL0035Unit: mm (in)

Inner diameter15.87 (5/8)

Clutch Operating CylinderNJCL0036Unit: mm (in)

Inner diameter19.05 (3/4)

Clutch DiscNJCL0038Unit: mm (in)

Engine QG15DE QG18DE YD22DDT

Model 200 215 240

Facing size (Outer dia.´inner

dia.´thickness)200´134´3.5 (7.87´5.28´

0.138)216´153´3.45 (8.50´6.02´

0.1358)240´160´3.5 (9.45´6.30´

0.138)

Thickness of disc assembly with

load7.4 - 8.0 (0.271 - 0.311) with 3,780

N (385.6 kg, 849.7 lb)7.3 - 7.4 (0.287 - 0.311) with 4,900

N (499.8 kg, 1,102 lb)7.85 - 8.35 (0.3091 - 0.3287) with

5,690 N (580.2 kg, 1,279 lb)

Wear limit of facing surface to

rivet head0.3 (0.012) Ð 0.3 (0.012)

Wearing thickness of facing Ð 1.3 (0.051) Ð

Runout limit of facing 1.0 (0.039)

Distance of runout check point

(from the hub center)95 (3.74) 102.5 (4.04) 115 (4.53)

Maximum backlash of spline (at

outer edge disc)0.8 (0.031) 0.9 (0.035) 1.0 (0.039)

Clutch CoverNJCL0039Unit: mm (in)

Engine QG15DE QG18DE YD22DDT

Model 200 215 240

Full-load 3,481 N (355 kg, 783 lb) 4,413 N (450 kg, 992 lb) 5,690 N (580.2 kg, 1,279 lb)

Uneven limit of diaphragm spring

toe height0.8 (0.031) 0.7 (0.028)

Clutch PedalNJCL0040Unit: mm (in)

Pedal strokes ªSº* 140 - 150 (5.512 - 5.906)

Pedal free play ªAº1 - 3 (0.039 - 0.118)

*: Measured from surface of dash lower panel to surface of pedal pad

SERVICE DATA AND SPECIFICATIONS (SDS)

Clutch Control System

CL-24