NISSAN ALMERA N16 2001 Electronic Repair Manual

Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2001Pages: 2493, PDF Size: 66.97 MB

Page 991 of 2493

4 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-559.

©INSPECTION END

START SIGNALYD

Diagnostic Procedure (Cont'd)

EC-695

Page 992 of 2493

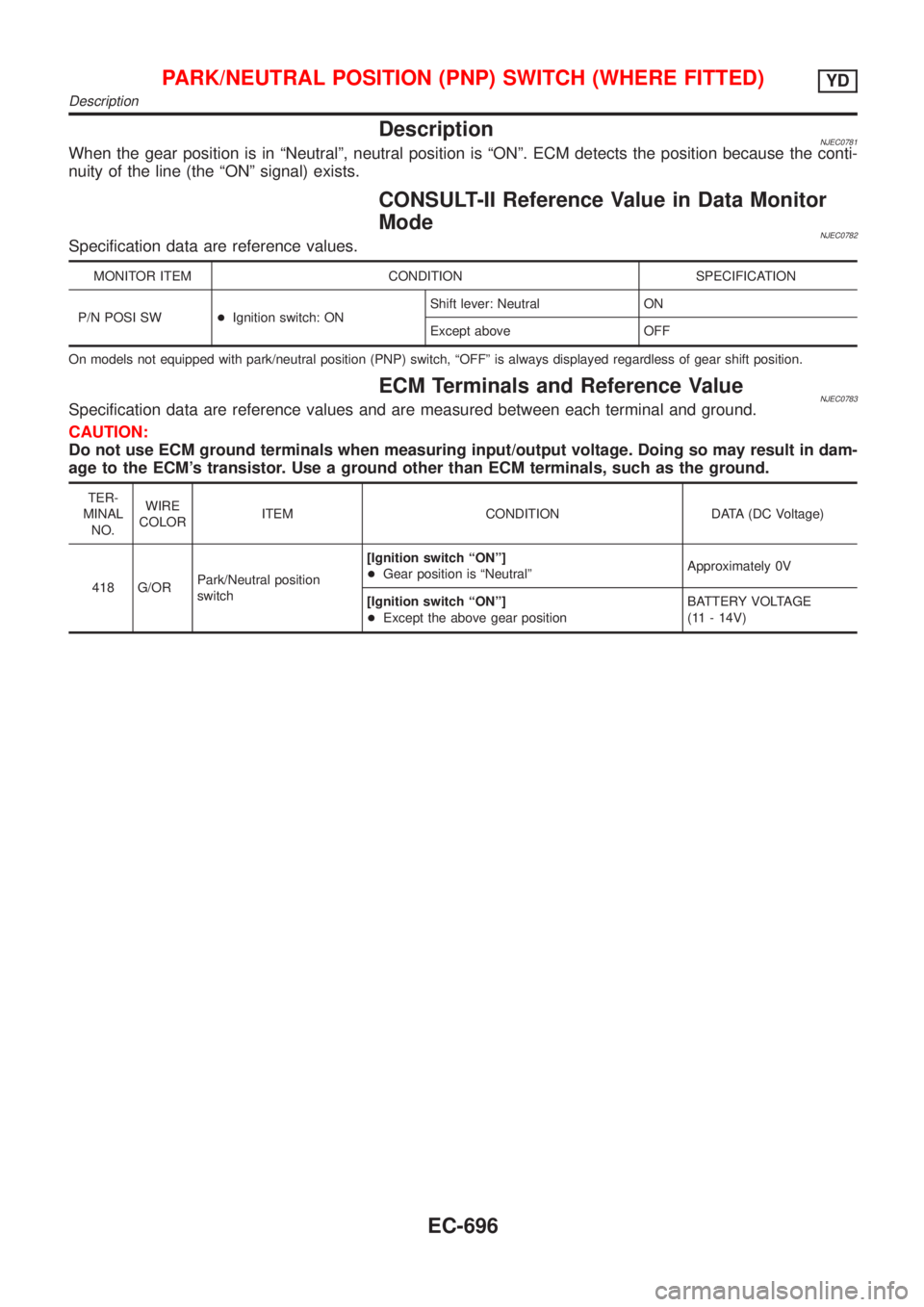

DescriptionNJEC0781When the gear position is in ªNeutralº, neutral position is ªONº. ECM detects the position because the conti-

nuity of the line (the ªONº signal) exists.

CONSULT-II Reference Value in Data Monitor

Mode

NJEC0782Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

P/N POSI SW+Ignition switch: ONShift lever: Neutral ON

Except above OFF

On models not equipped with park/neutral position (PNP) switch, ªOFFº is always displayed regardless of gear shift position.

ECM Terminals and Reference ValueNJEC0783Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TER-

MINAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

418 G/ORPark/Neutral position

switch[Ignition switch ªONº]

+Gear position is ªNeutralºApproximately 0V

[Ignition switch ªONº]

+Except the above gear positionBATTERY VOLTAGE

(11 - 14V)

PARK/NEUTRAL POSITION (PNP) SWITCH (WHERE FITTED)YD

Description

EC-696

Page 993 of 2493

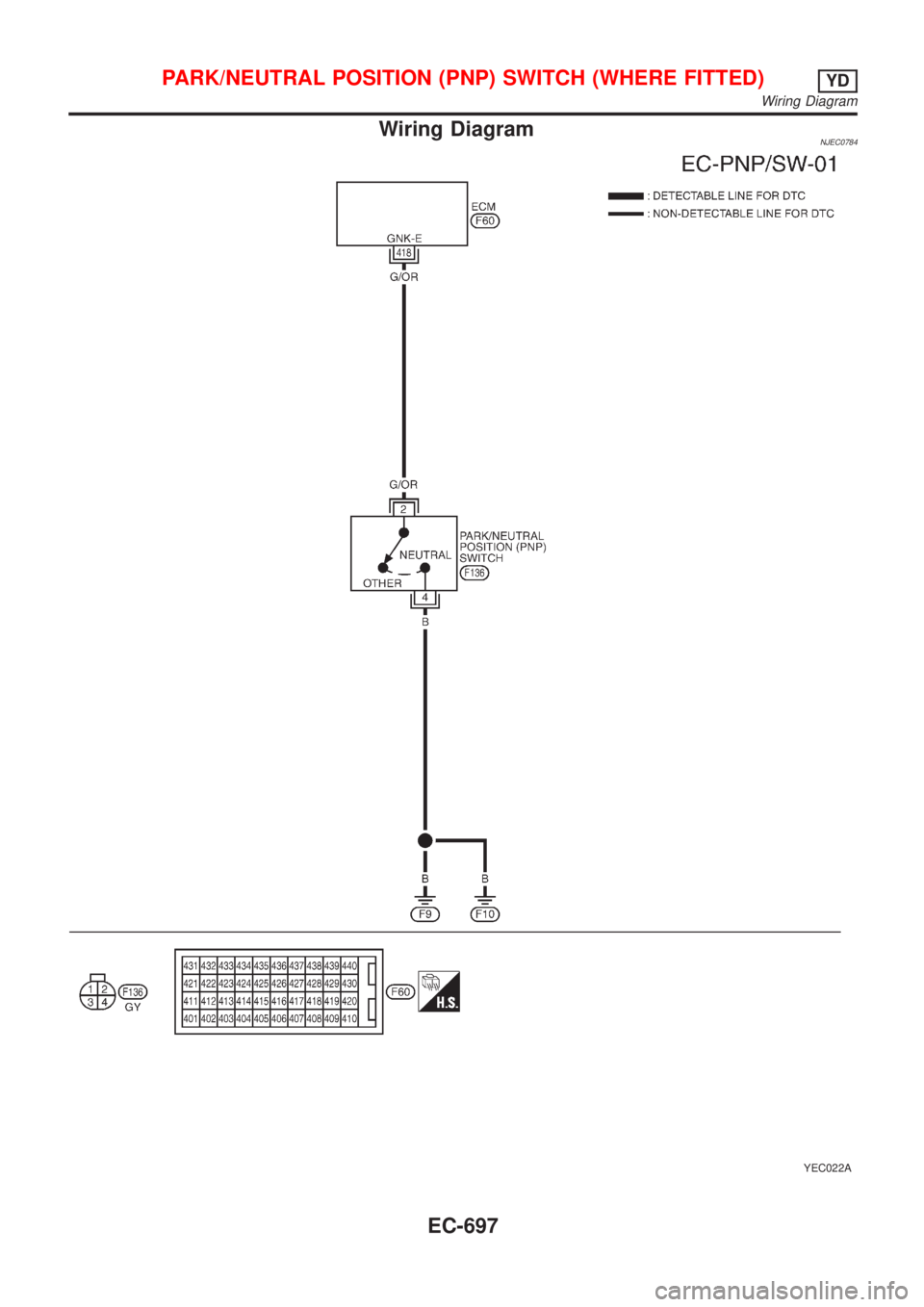

Wiring DiagramNJEC0784

YEC022A

PARK/NEUTRAL POSITION (PNP) SWITCH (WHERE FITTED)YD

Wiring Diagram

EC-697

Page 994 of 2493

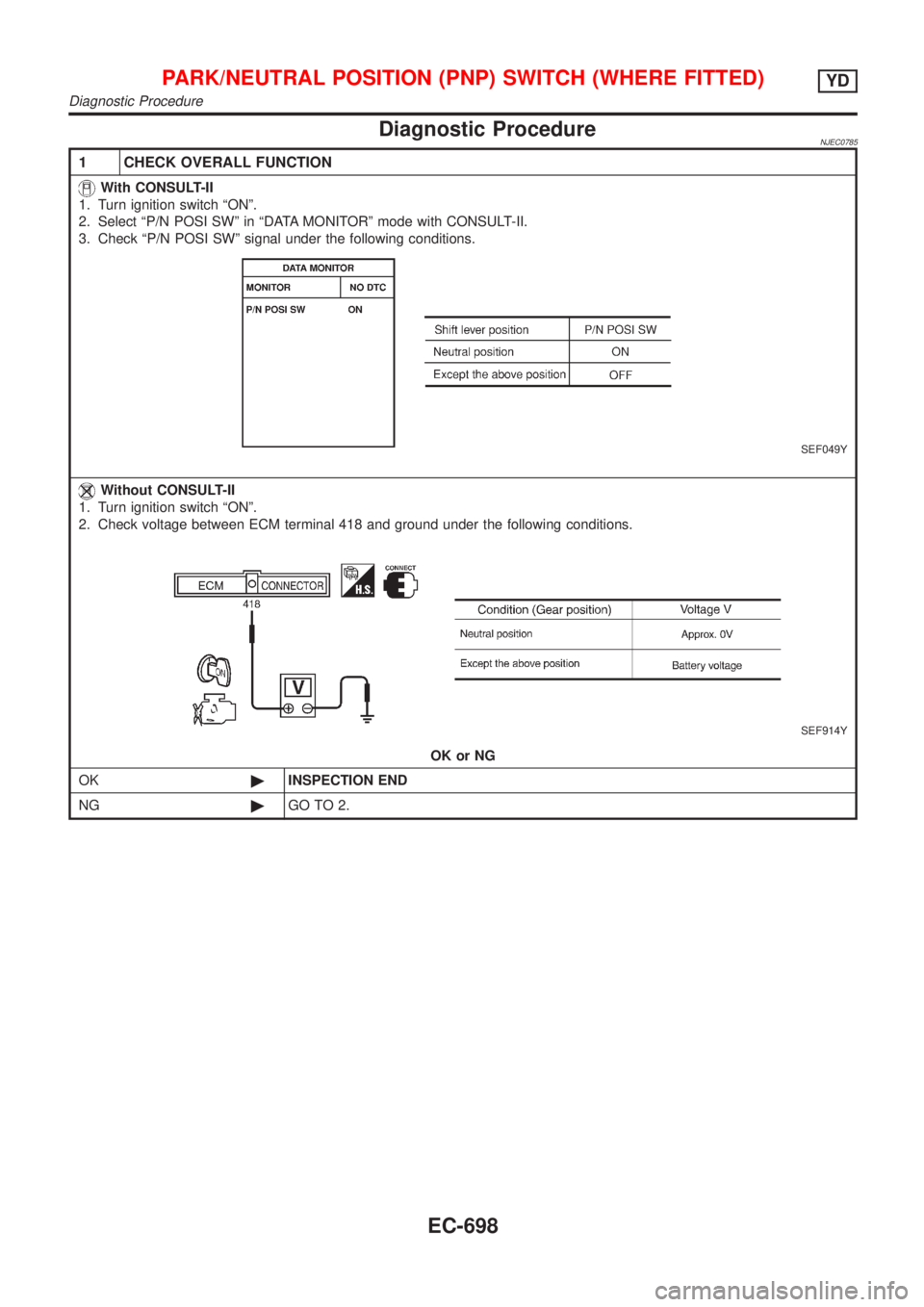

Diagnostic ProcedureNJEC0785

1 CHECK OVERALL FUNCTION

With CONSULT-II

1. Turn ignition switch ªONº.

2. Select ªP/N POSI SWº in ªDATA MONITORº mode with CONSULT-II.

3. Check ªP/N POSI SWº signal under the following conditions.

SEF049Y

Without CONSULT-II

1. Turn ignition switch ªONº.

2. Check voltage between ECM terminal 418 and ground under the following conditions.

SEF914Y

OK or NG

OK©INSPECTION END

NG©GO TO 2.

PARK/NEUTRAL POSITION (PNP) SWITCH (WHERE FITTED)YD

Diagnostic Procedure

EC-698

Page 995 of 2493

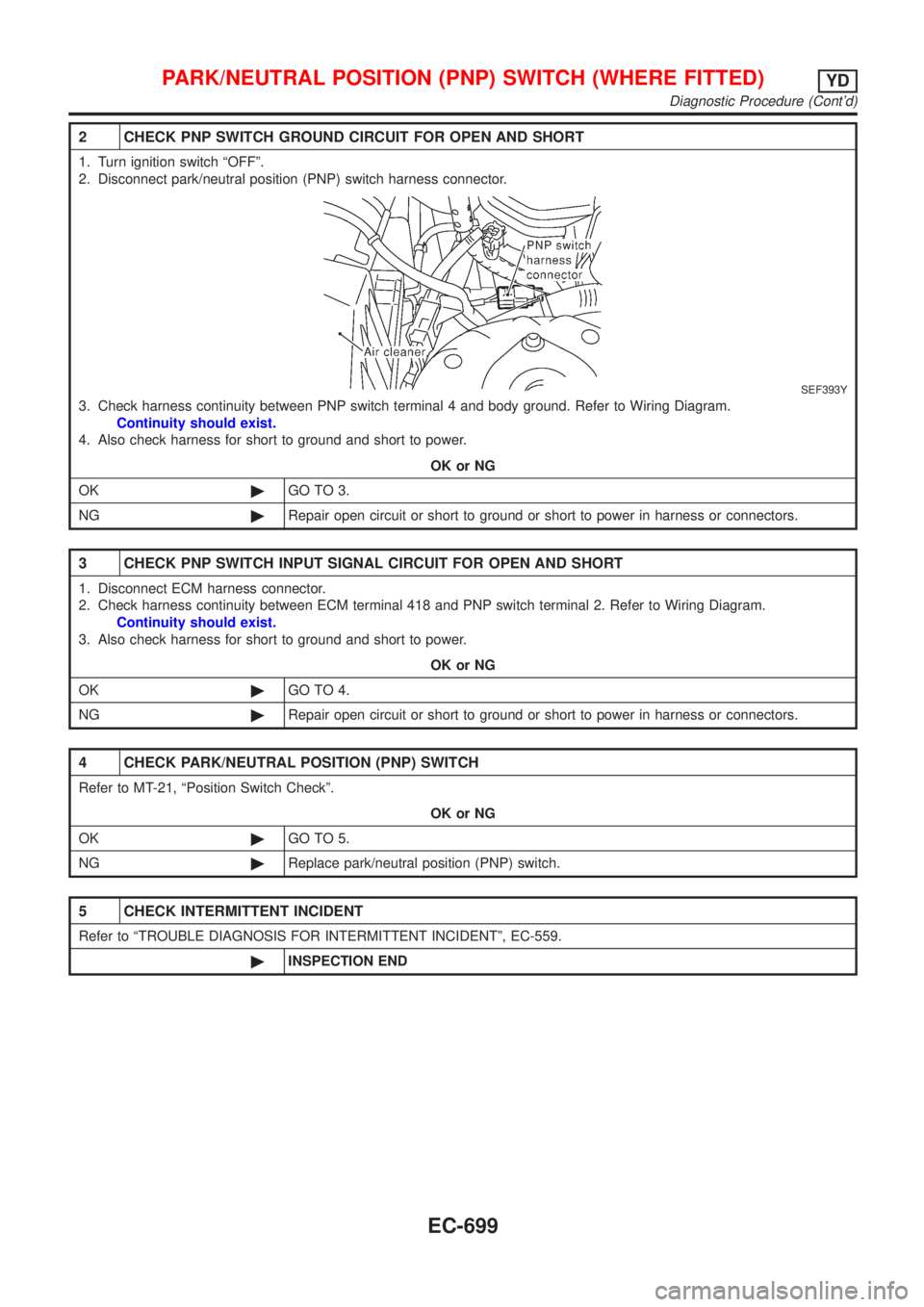

2 CHECK PNP SWITCH GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Disconnect park/neutral position (PNP) switch harness connector.

SEF393Y

3. Check harness continuity between PNP switch terminal 4 and body ground. Refer to Wiring Diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 3.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

3 CHECK PNP SWITCH INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminal 418 and PNP switch terminal 2. Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 4.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

4 CHECK PARK/NEUTRAL POSITION (PNP) SWITCH

Refer to MT-21, ªPosition Switch Checkº.

OK or NG

OK©GO TO 5.

NG©Replace park/neutral position (PNP) switch.

5 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-559.

©INSPECTION END

PARK/NEUTRAL POSITION (PNP) SWITCH (WHERE FITTED)YD

Diagnostic Procedure (Cont'd)

EC-699

Page 996 of 2493

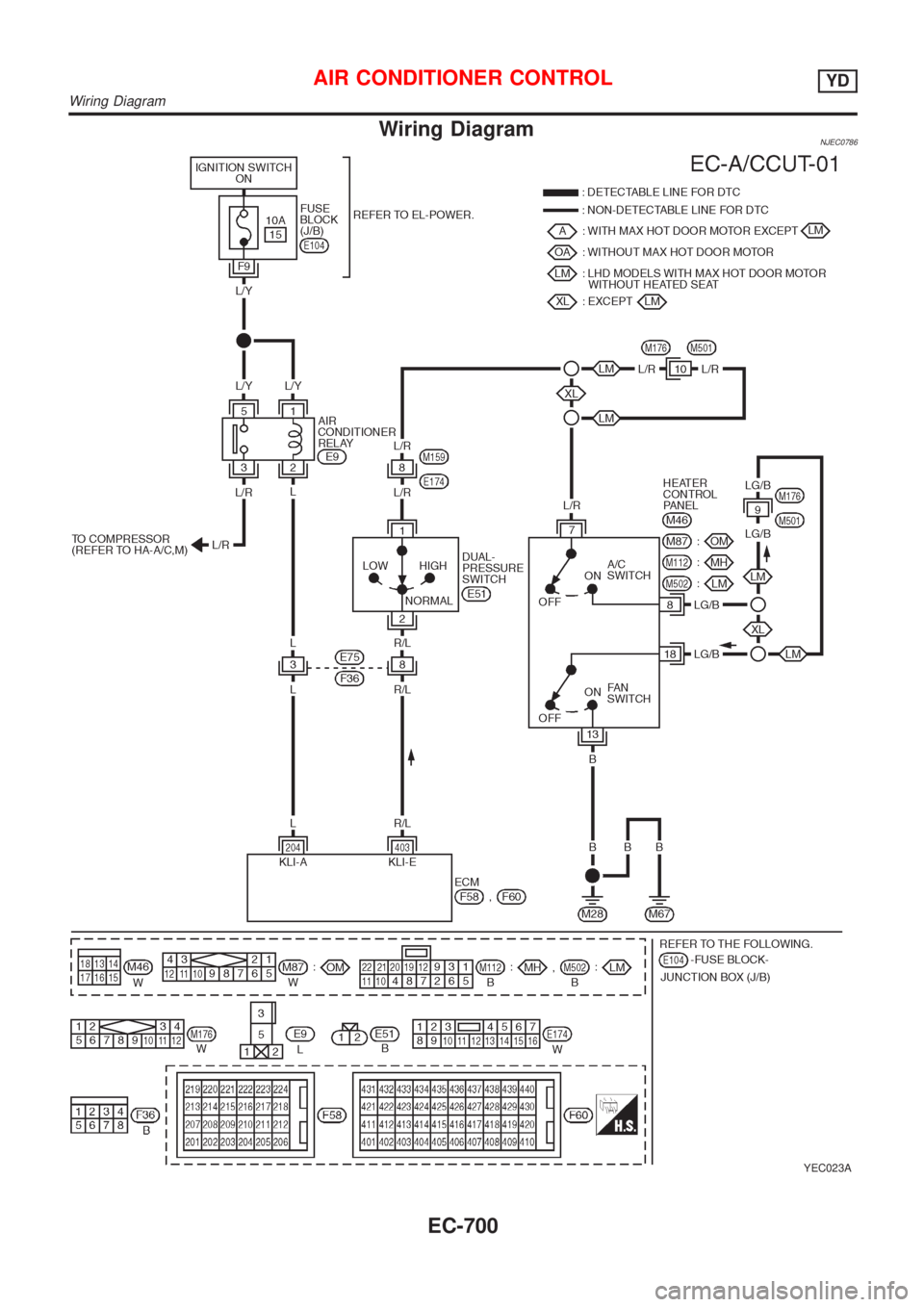

Wiring DiagramNJEC0786

YEC023A

AIR CONDITIONER CONTROLYD

Wiring Diagram

EC-700

Page 997 of 2493

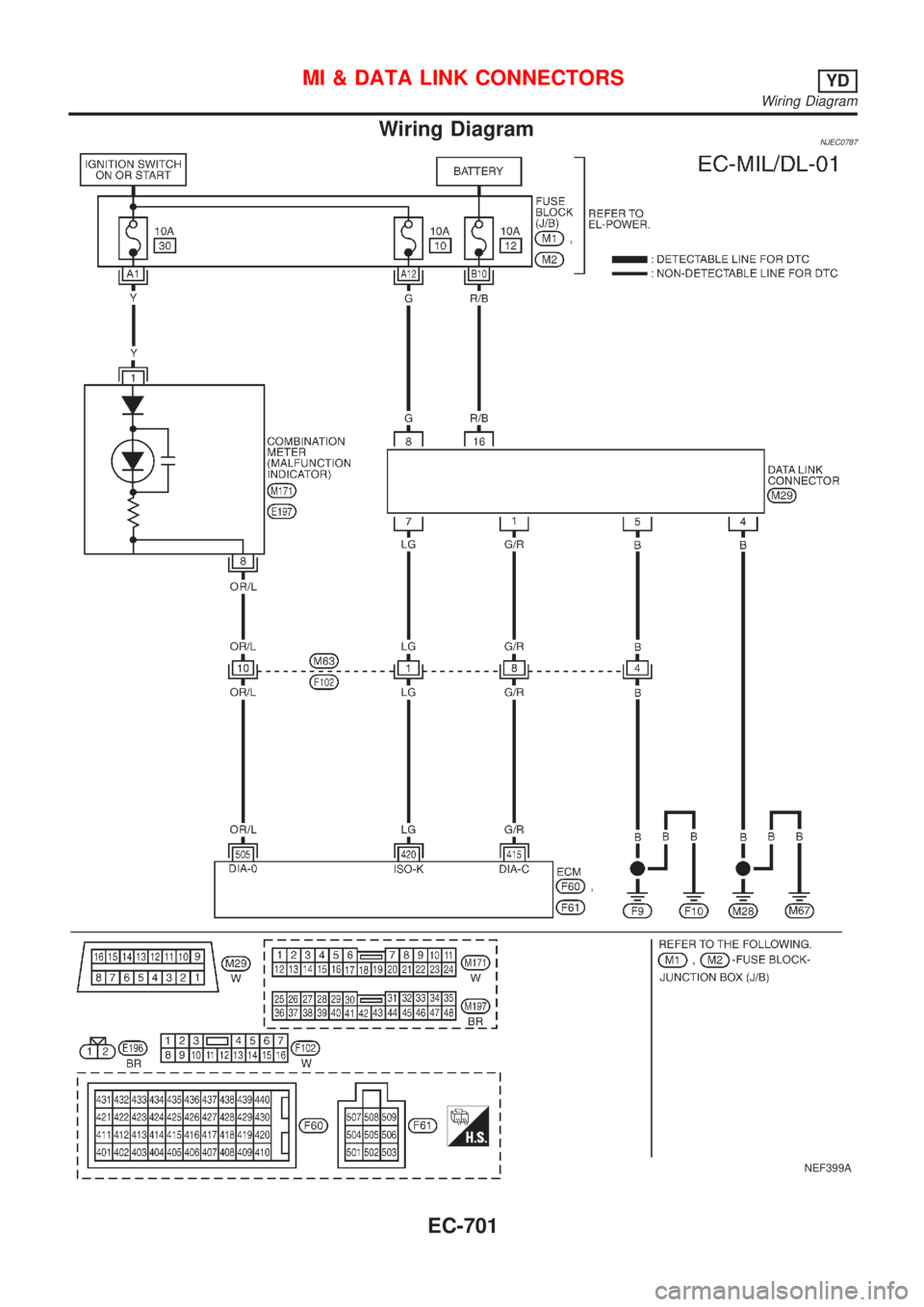

Wiring DiagramNJEC0787

NEF399A

MI & DATA LINK CONNECTORSYD

Wiring Diagram

EC-701

Page 998 of 2493

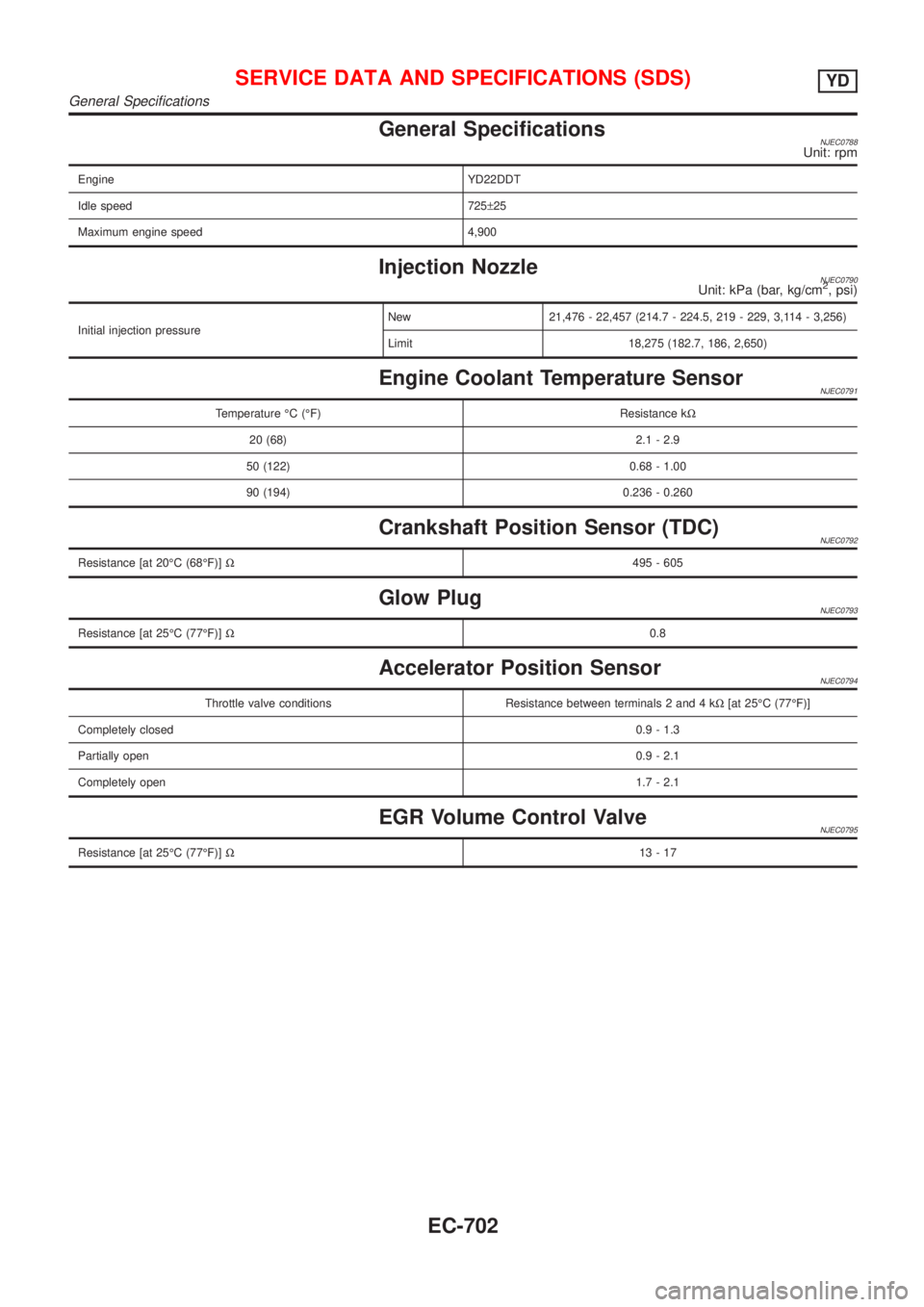

General SpecificationsNJEC0788Unit: rpm

Engine YD22DDT

Idle speed 725±25

Maximum engine speed 4,900

Injection NozzleNJEC0790Unit: kPa (bar, kg/cm2, psi)

Initial injection pressureNew 21,476 - 22,457 (214.7 - 224.5, 219 - 229, 3,114 - 3,256)

Limit 18,275 (182.7, 186, 2,650)

Engine Coolant Temperature SensorNJEC0791

Temperature ÉC (ÉF) Resistance kW

20 (68) 2.1 - 2.9

50 (122) 0.68 - 1.00

90 (194) 0.236 - 0.260

Crankshaft Position Sensor (TDC)NJEC0792

Resistance [at 20ÉC (68ÉF)]W495 - 605

Glow PlugNJEC0793

Resistance [at 25ÉC (77ÉF)]W0.8

Accelerator Position SensorNJEC0794

Throttle valve conditions Resistance between terminals 2 and 4 kW[at 25ÉC (77ÉF)]

Completely closed0.9 - 1.3

Partially open0.9 - 2.1

Completely open1.7 - 2.1

EGR Volume Control ValveNJEC0795

Resistance [at 25ÉC (77ÉF)]W13-17

SERVICE DATA AND SPECIFICATIONS (SDS)YD

General Specifications

EC-702

Page 999 of 2493

ACCELERATOR CONTROL, FUEL &

EXHAUST SYSTEMS

SECTION

FE

CONTENTS

QG

PREPARATION...............................................................2

Special Service Tools ..................................................2

Commercial Service Tools ...........................................2

ACCELERATOR CONTROL SYSTEM...........................3

Removal and Installation .............................................3

Adjusting Accelerator Wire ..........................................3

FUEL SYSTEM................................................................5

Checking Fuel Lines ....................................................5

Removal and Installation .............................................5

Fuel Tank .....................................................................6

REMOVAL.................................................................6

INSTALLATION..........................................................8

Fuel Pump, Fuel Level Sensor Unit and Fuel

Filter .............................................................................9

REMOVAL.................................................................9

INSTALLATION........................................................10

EXHAUST SYSTEM...................................................... 11

Checking Exhaust System......................................... 11

Removal and Installation ........................................... 11

YD

PREPARATION.............................................................14

Special Service Tool ..................................................14Commercial Service Tool ...........................................14

ACCELERATOR CONTROL SYSTEM.........................15

Removal and Installation ...........................................15

Inspection...................................................................15

FUEL SYSTEM..............................................................16

Checking Fuel Lines ..................................................16

Water Draining from Fuel Filter .................................16

DRAINING WATER..................................................16

FUEL FILTER CHECK..............................................16

Changing Fuel Filter ..................................................16

REMOVAL...............................................................16

INSTALLATION........................................................16

Bleeding Fuel Filter....................................................17

Checking Priming Pump ............................................17

Removal and Installation ...........................................17

Fuel Tank ...................................................................18

REMOVAL...............................................................20

INSTALLATION........................................................23

Fuel Level Sensor Unit ..............................................24

REMOVAL...............................................................25

INSTALLATION........................................................26

EXHAUST SYSTEM......................................................27

Checking Exhaust System.........................................27

Removal and Installation ...........................................27

Page 1000 of 2493

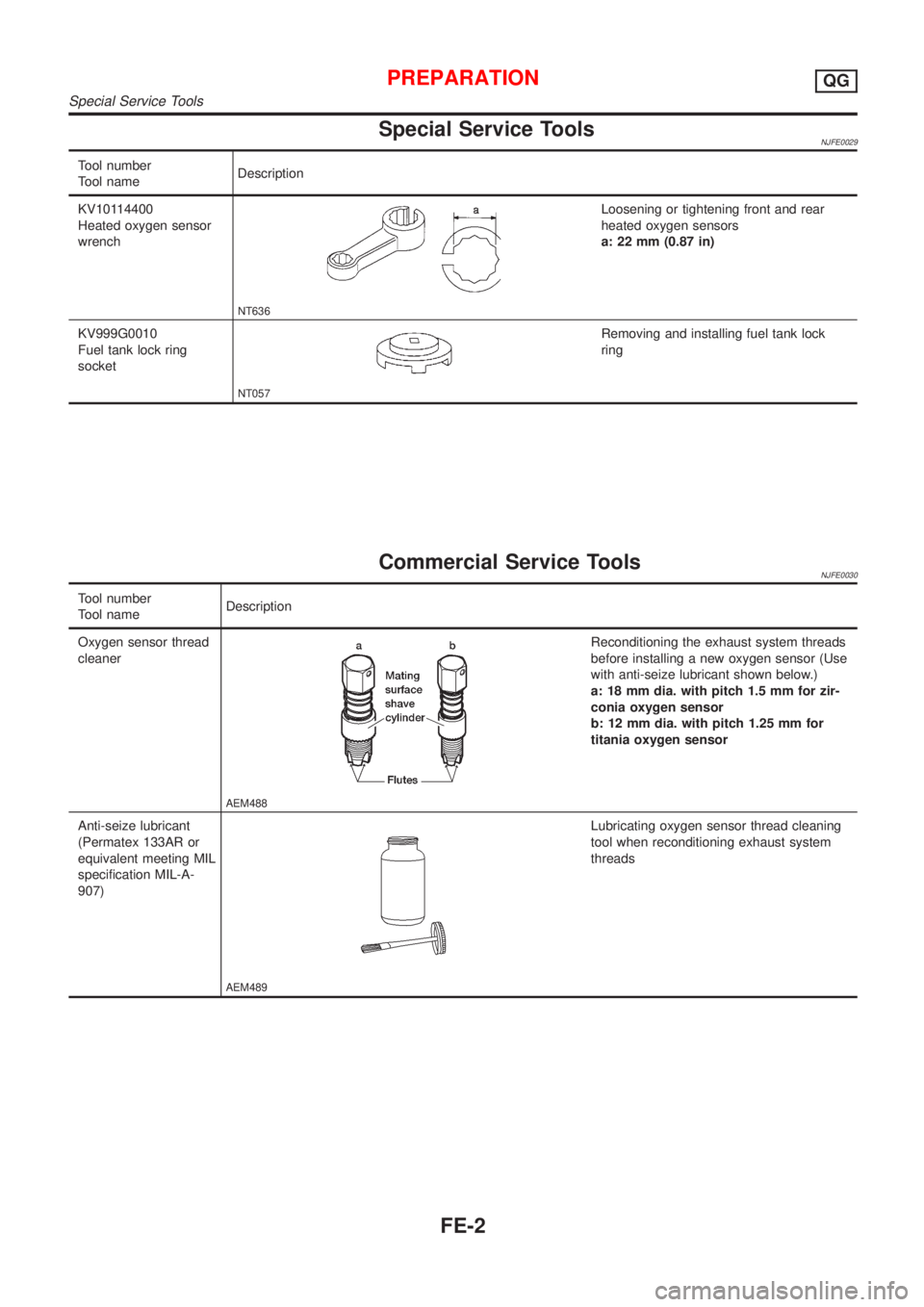

Special Service ToolsNJFE0029

Tool number

Tool nameDescription

KV10114400

Heated oxygen sensor

wrench

NT636

Loosening or tightening front and rear

heated oxygen sensors

a: 22 mm (0.87 in)

KV999G0010

Fuel tank lock ring

socket

NT057

Removing and installing fuel tank lock

ring

Commercial Service ToolsNJFE0030

Tool number

Tool nameDescription

Oxygen sensor thread

cleaner

AEM488

Reconditioning the exhaust system threads

before installing a new oxygen sensor (Use

with anti-seize lubricant shown below.)

a: 18 mm dia. with pitch 1.5 mm for zir-

conia oxygen sensor

b: 12 mm dia. with pitch 1.25 mm for

titania oxygen sensor

Anti-seize lubricant

(Permatex 133AR or

equivalent meeting MIL

specification MIL-A-

907)

AEM489

Lubricating oxygen sensor thread cleaning

tool when reconditioning exhaust system

threads

PREPARATIONQG

Special Service Tools

FE-2