NISSAN ALMERA N16 2001 Electronic Repair Manual

Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2001Pages: 2493, PDF Size: 66.97 MB

Page 1091 of 2493

SMT604A

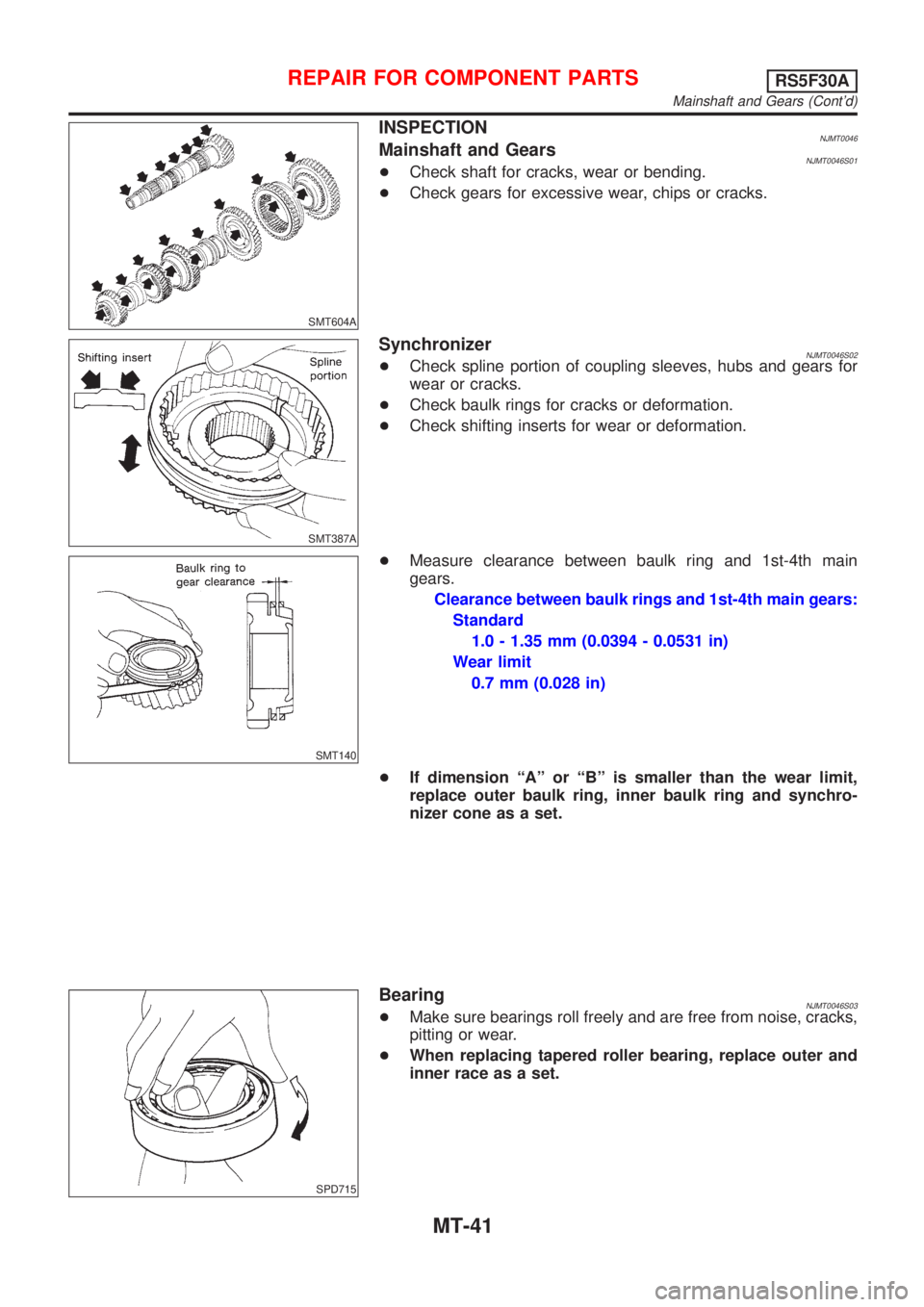

INSPECTIONNJMT0046Mainshaft and GearsNJMT0046S01+Check shaft for cracks, wear or bending.

+Check gears for excessive wear, chips or cracks.

SMT387A

SynchronizerNJMT0046S02+Check spline portion of coupling sleeves, hubs and gears for

wear or cracks.

+Check baulk rings for cracks or deformation.

+Check shifting inserts for wear or deformation.

SMT140

+Measure clearance between baulk ring and 1st-4th main

gears.

Clearance between baulk rings and 1st-4th main gears:

Standard

1.0 - 1.35 mm (0.0394 - 0.0531 in)

Wear limit

0.7 mm (0.028 in)

+If dimension ªAº or ªBº is smaller than the wear limit,

replace outer baulk ring, inner baulk ring and synchro-

nizer cone as a set.

SPD715

BearingNJMT0046S03+Make sure bearings roll freely and are free from noise, cracks,

pitting or wear.

+When replacing tapered roller bearing, replace outer and

inner race as a set.

REPAIR FOR COMPONENT PARTSRS5F30A

Mainshaft and Gears (Cont'd)

MT-41

Page 1092 of 2493

SMT603A

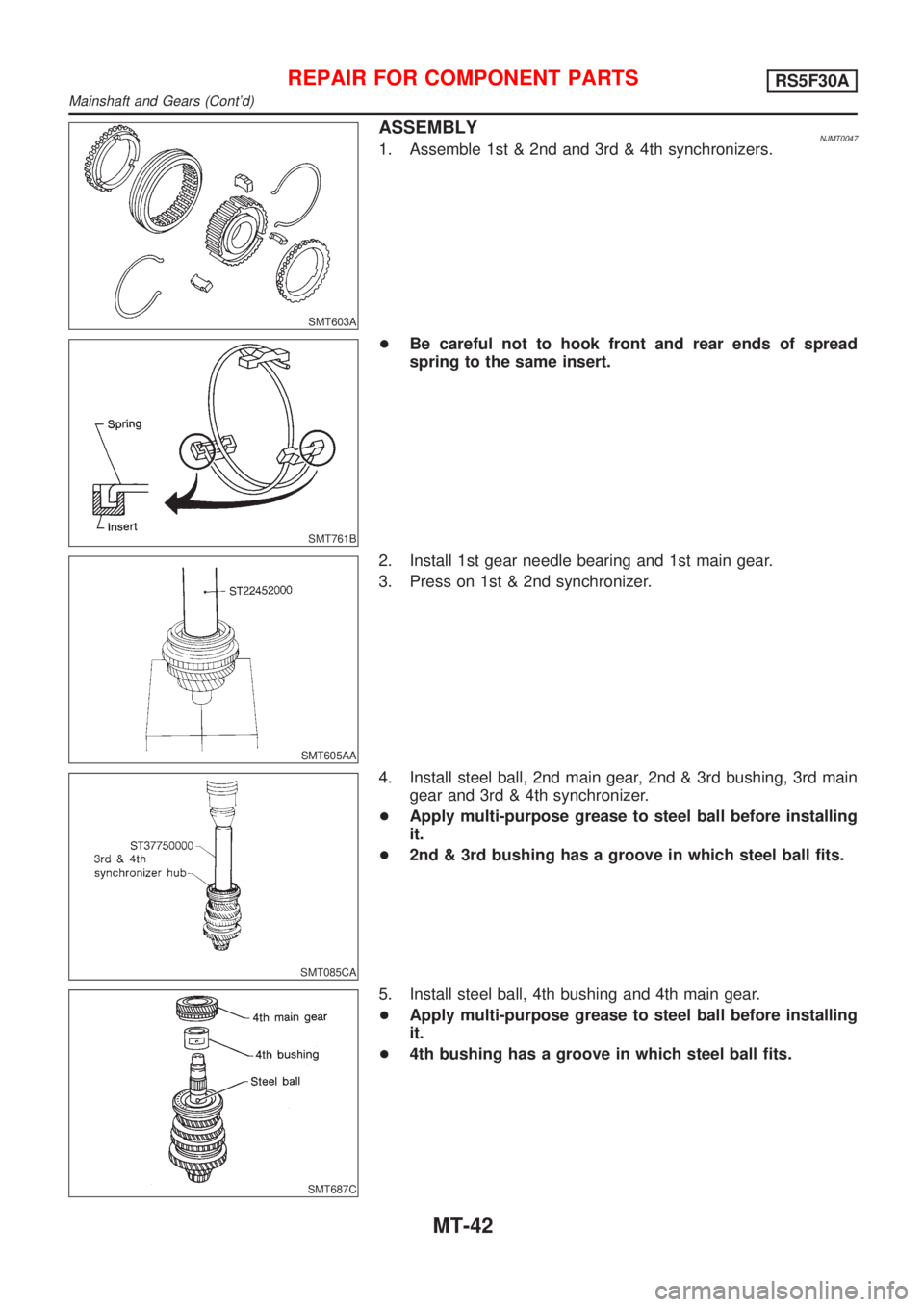

ASSEMBLYNJMT00471. Assemble 1st & 2nd and 3rd & 4th synchronizers.

SMT761B

+Be careful not to hook front and rear ends of spread

spring to the same insert.

SMT605AA

2. Install 1st gear needle bearing and 1st main gear.

3. Press on 1st & 2nd synchronizer.

SMT085CA

4. Install steel ball, 2nd main gear, 2nd & 3rd bushing, 3rd main

gear and 3rd & 4th synchronizer.

+Apply multi-purpose grease to steel ball before installing

it.

+2nd & 3rd bushing has a groove in which steel ball fits.

SMT687C

5. Install steel ball, 4th bushing and 4th main gear.

+Apply multi-purpose grease to steel ball before installing

it.

+4th bushing has a groove in which steel ball fits.

REPAIR FOR COMPONENT PARTSRS5F30A

Mainshaft and Gears (Cont'd)

MT-42

Page 1093 of 2493

SMT606AA

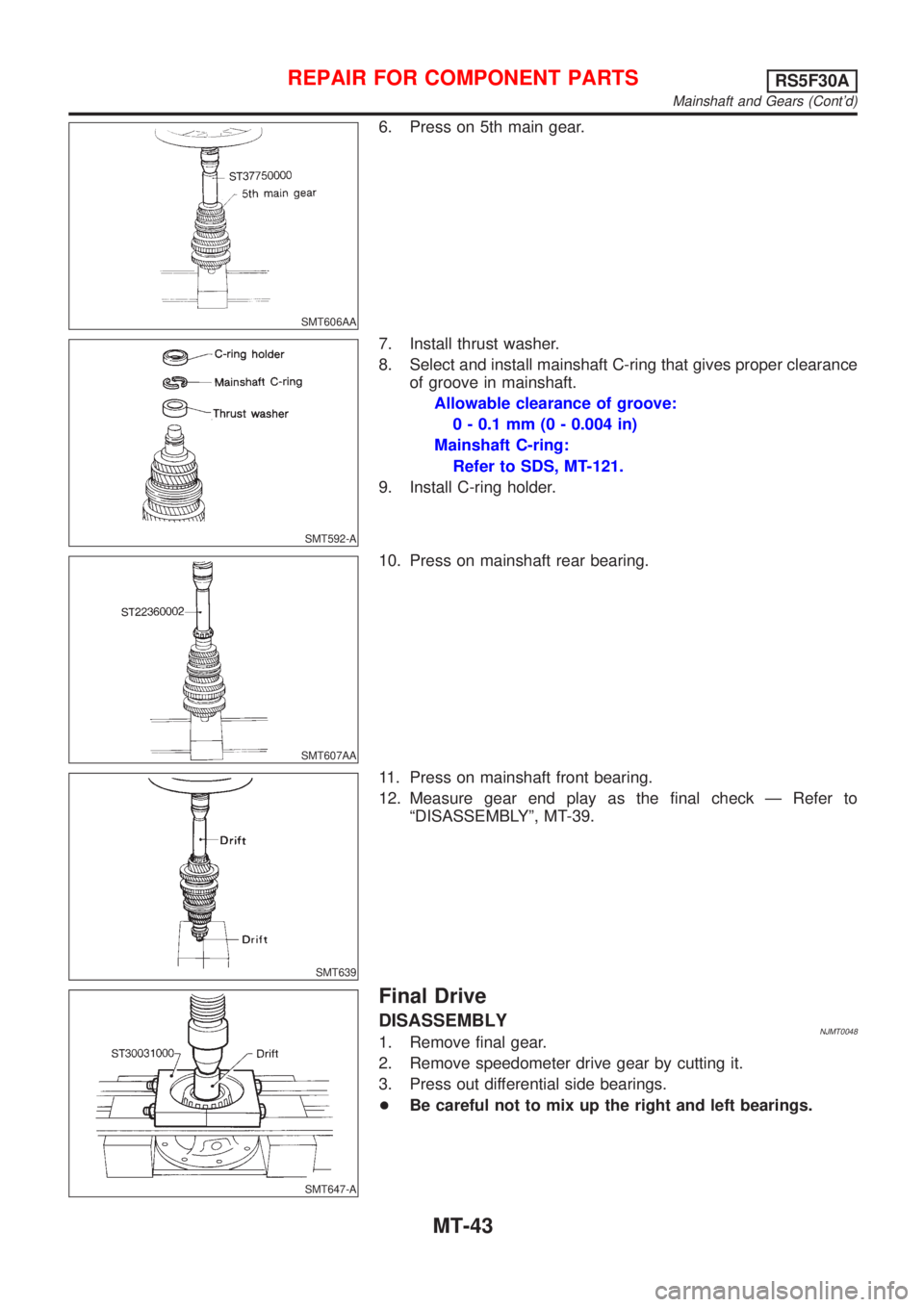

6. Press on 5th main gear.

SMT592-A

7. Install thrust washer.

8. Select and install mainshaft C-ring that gives proper clearance

of groove in mainshaft.

Allowable clearance of groove:

0 - 0.1 mm (0 - 0.004 in)

Mainshaft C-ring:

Refer to SDS, MT-121.

9. Install C-ring holder.

SMT607AA

10. Press on mainshaft rear bearing.

SMT639

11. Press on mainshaft front bearing.

12. Measure gear end play as the final check Ð Refer to

ªDISASSEMBLYº, MT-39.

SMT647-A

Final Drive

DISASSEMBLYNJMT00481. Remove final gear.

2. Remove speedometer drive gear by cutting it.

3. Press out differential side bearings.

+Be careful not to mix up the right and left bearings.

REPAIR FOR COMPONENT PARTSRS5F30A

Mainshaft and Gears (Cont'd)

MT-43

Page 1094 of 2493

SMT147AA

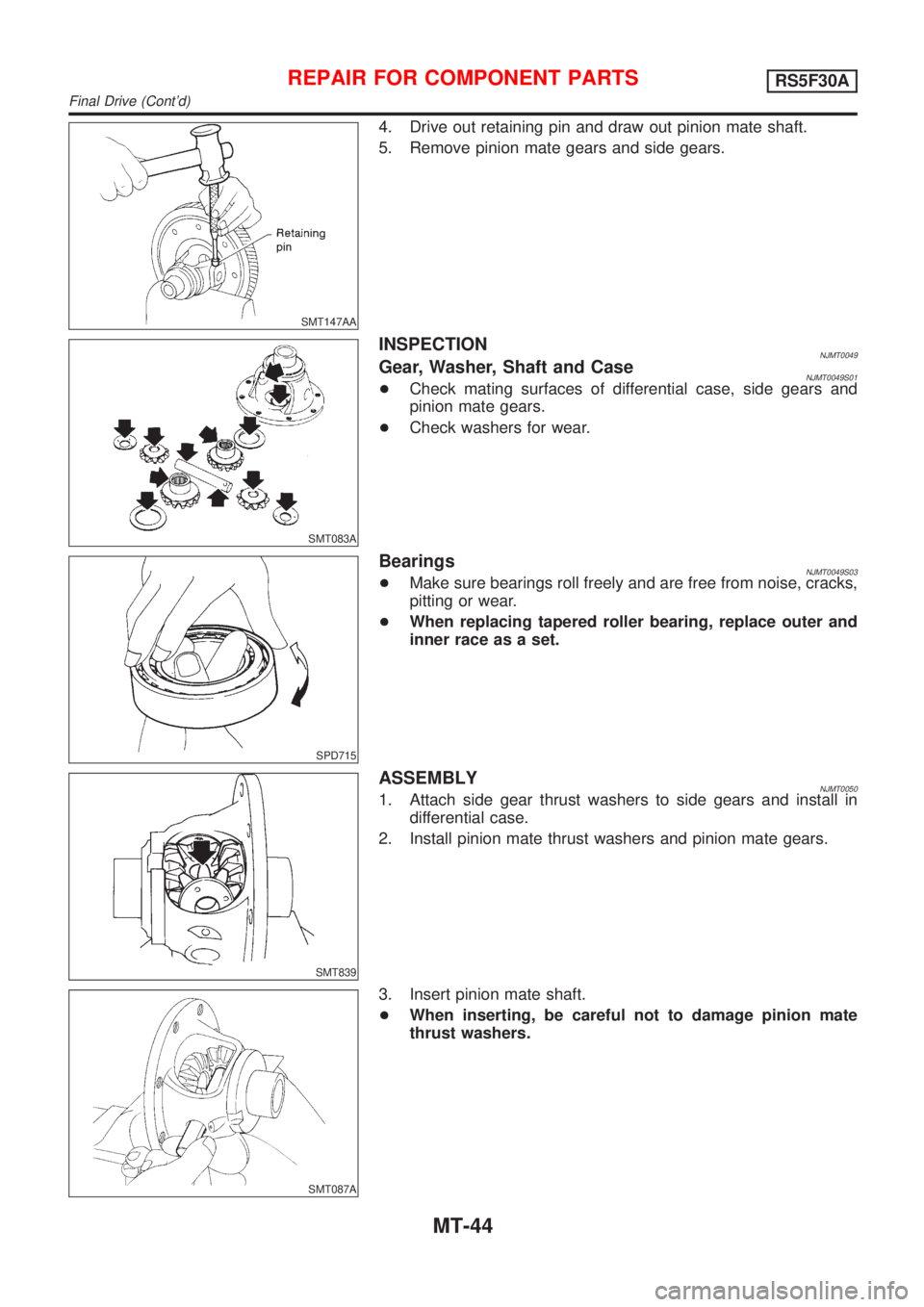

4. Drive out retaining pin and draw out pinion mate shaft.

5. Remove pinion mate gears and side gears.

SMT083A

INSPECTIONNJMT0049Gear, Washer, Shaft and CaseNJMT0049S01+Check mating surfaces of differential case, side gears and

pinion mate gears.

+Check washers for wear.

SPD715

BearingsNJMT0049S03+Make sure bearings roll freely and are free from noise, cracks,

pitting or wear.

+When replacing tapered roller bearing, replace outer and

inner race as a set.

SMT839

ASSEMBLYNJMT00501. Attach side gear thrust washers to side gears and install in

differential case.

2. Install pinion mate thrust washers and pinion mate gears.

SMT087A

3. Insert pinion mate shaft.

+When inserting, be careful not to damage pinion mate

thrust washers.

REPAIR FOR COMPONENT PARTSRS5F30A

Final Drive (Cont'd)

MT-44

Page 1095 of 2493

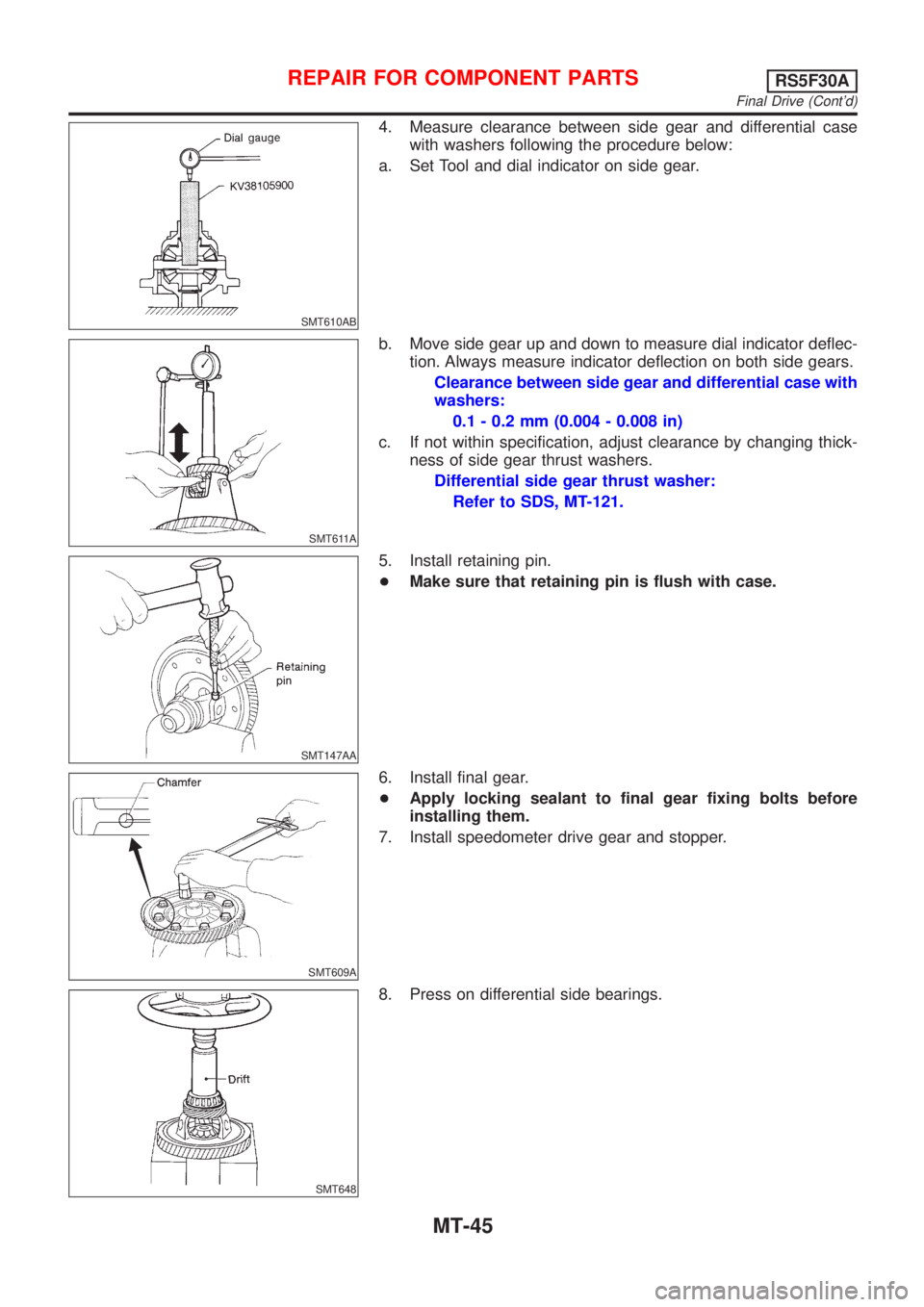

SMT610AB

4. Measure clearance between side gear and differential case

with washers following the procedure below:

a. Set Tool and dial indicator on side gear.

SMT611A

b. Move side gear up and down to measure dial indicator deflec-

tion. Always measure indicator deflection on both side gears.

Clearance between side gear and differential case with

washers:

0.1 - 0.2 mm (0.004 - 0.008 in)

c. If not within specification, adjust clearance by changing thick-

ness of side gear thrust washers.

Differential side gear thrust washer:

Refer to SDS, MT-121.

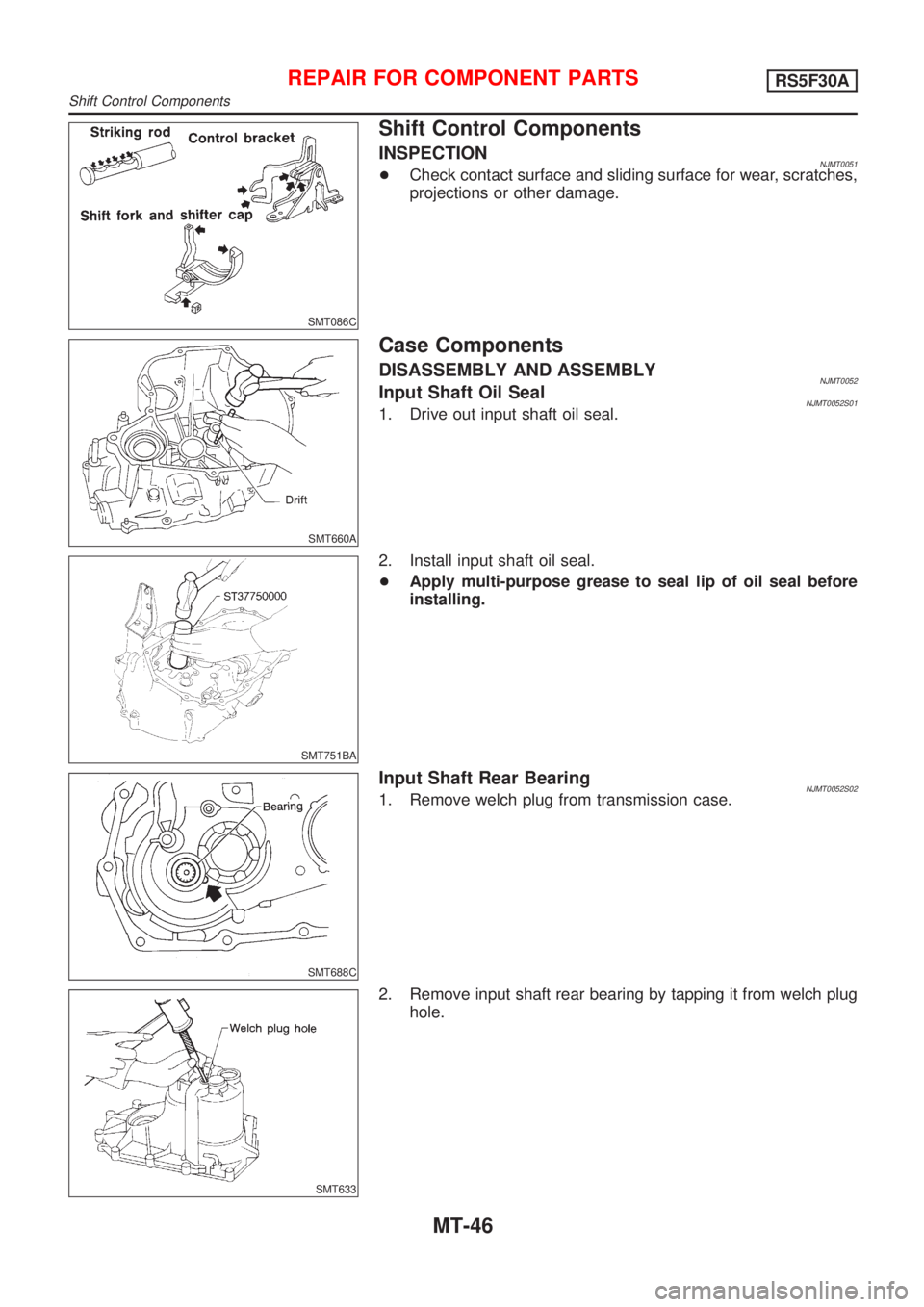

SMT147AA

5. Install retaining pin.

+Make sure that retaining pin is flush with case.

SMT609A

6. Install final gear.

+Apply locking sealant to final gear fixing bolts before

installing them.

7. Install speedometer drive gear and stopper.

SMT648

8. Press on differential side bearings.

REPAIR FOR COMPONENT PARTSRS5F30A

Final Drive (Cont'd)

MT-45

Page 1096 of 2493

SMT086C

Shift Control Components

INSPECTIONNJMT0051+Check contact surface and sliding surface for wear, scratches,

projections or other damage.

SMT660A

Case Components

DISASSEMBLY AND ASSEMBLYNJMT0052Input Shaft Oil SealNJMT0052S011. Drive out input shaft oil seal.

SMT751BA

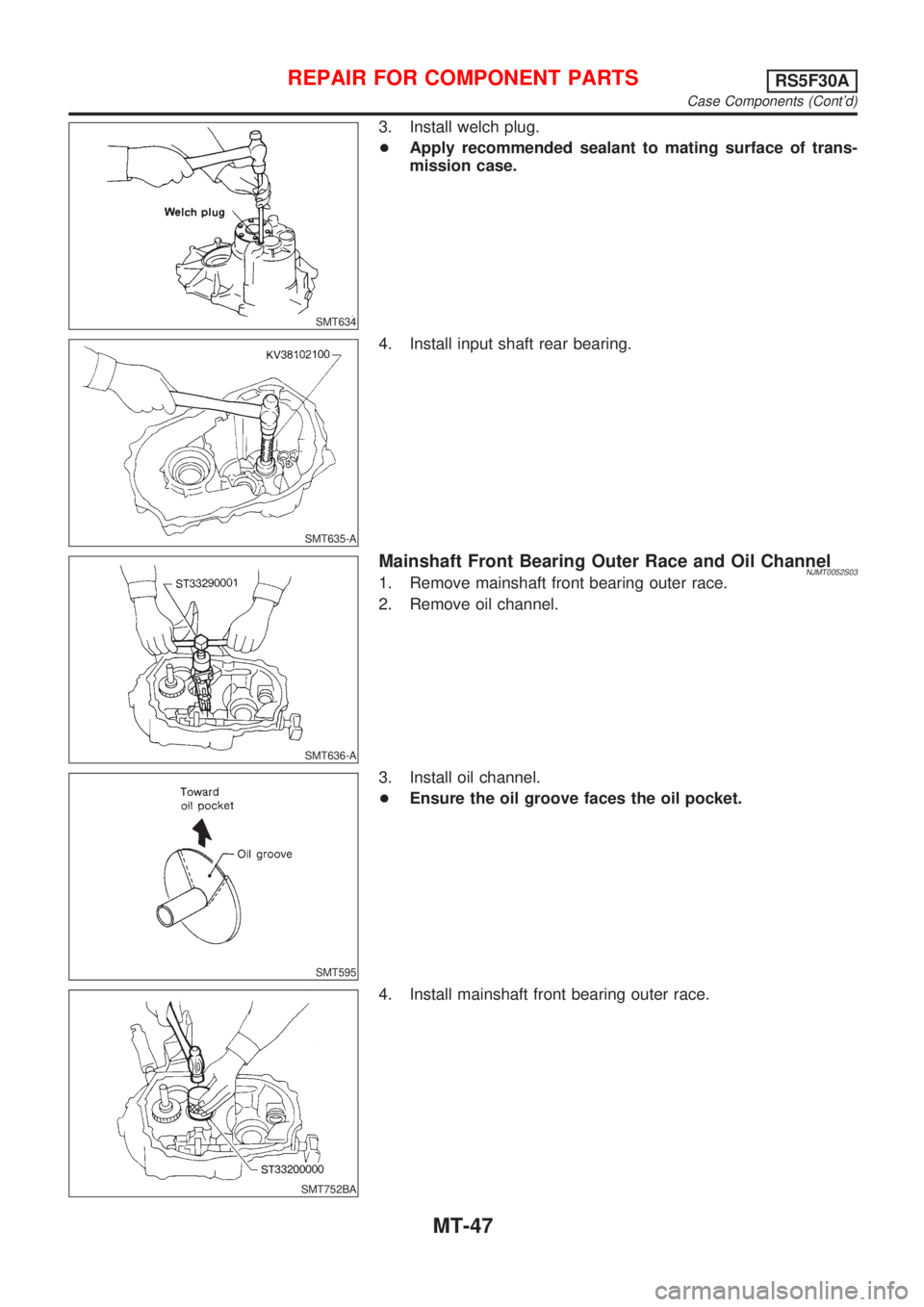

2. Install input shaft oil seal.

+Apply multi-purpose grease to seal lip of oil seal before

installing.

SMT688C

Input Shaft Rear BearingNJMT0052S021. Remove welch plug from transmission case.

SMT633

2. Remove input shaft rear bearing by tapping it from welch plug

hole.

REPAIR FOR COMPONENT PARTSRS5F30A

Shift Control Components

MT-46

Page 1097 of 2493

SMT634

3. Install welch plug.

+Apply recommended sealant to mating surface of trans-

mission case.

SMT635-A

4. Install input shaft rear bearing.

SMT636-A

Mainshaft Front Bearing Outer Race and Oil ChannelNJMT0052S031. Remove mainshaft front bearing outer race.

2. Remove oil channel.

SMT595

3. Install oil channel.

+Ensure the oil groove faces the oil pocket.

SMT752BA

4. Install mainshaft front bearing outer race.

REPAIR FOR COMPONENT PARTSRS5F30A

Case Components (Cont'd)

MT-47

Page 1098 of 2493

Mainshaft Rear Bearing Outer RaceNJMT0052S04+Refer to ªMainshaft Bearing Preloadº, MT-122.

Differential Side Bearing Outer RaceNJMT0052S06+Refer to ªDifferential Side Bearing Preloadº, MT-122.

REPAIR FOR COMPONENT PARTSRS5F30A

Case Components (Cont'd)

MT-48

Page 1099 of 2493

NJMT0091

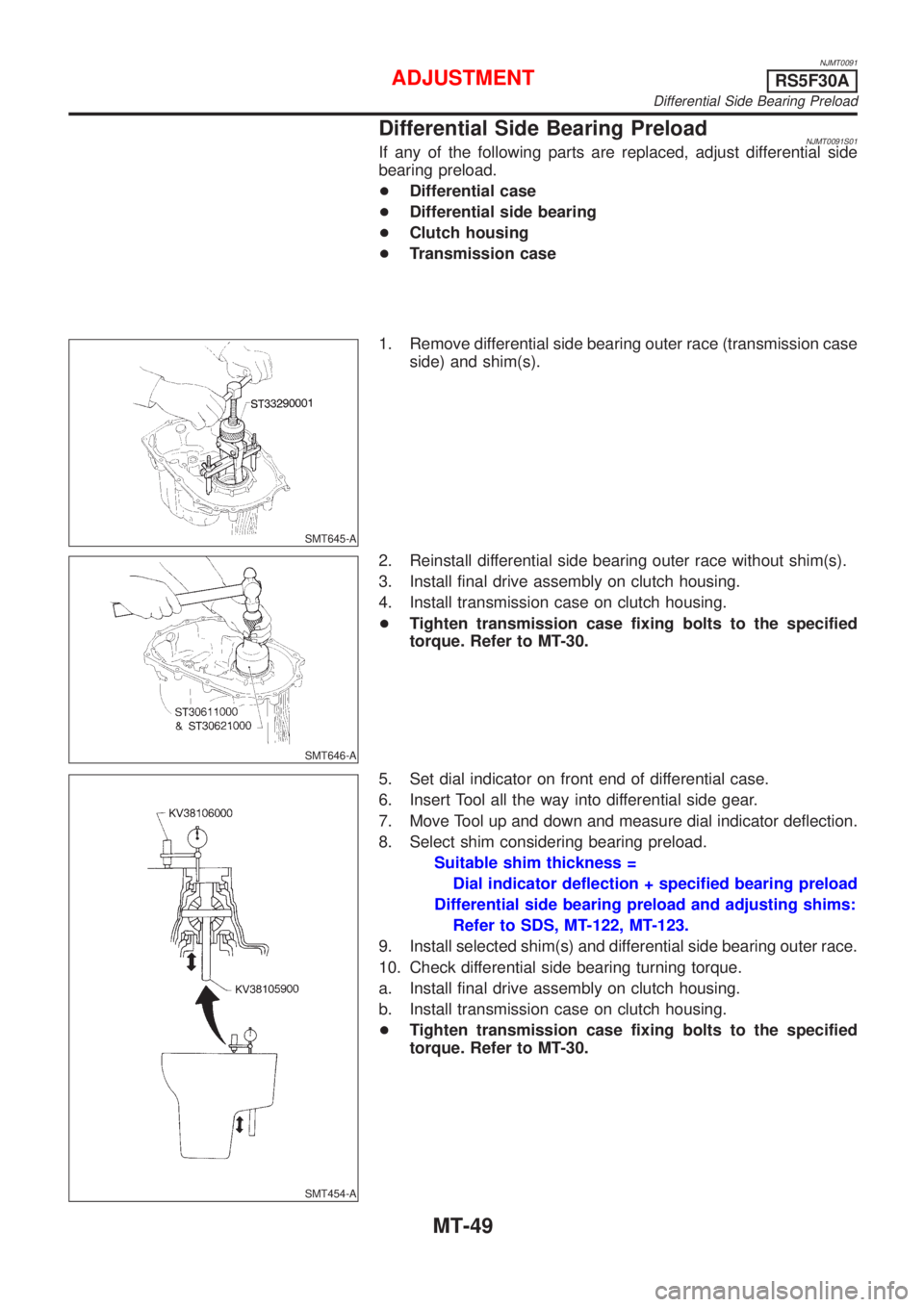

Differential Side Bearing PreloadNJMT0091S01If any of the following parts are replaced, adjust differential side

bearing preload.

+Differential case

+Differential side bearing

+Clutch housing

+Transmission case

SMT645-A

1. Remove differential side bearing outer race (transmission case

side) and shim(s).

SMT646-A

2. Reinstall differential side bearing outer race without shim(s).

3. Install final drive assembly on clutch housing.

4. Install transmission case on clutch housing.

+Tighten transmission case fixing bolts to the specified

torque. Refer to MT-30.

SMT454-A

5. Set dial indicator on front end of differential case.

6. Insert Tool all the way into differential side gear.

7. Move Tool up and down and measure dial indicator deflection.

8. Select shim considering bearing preload.

Suitable shim thickness =

Dial indicator deflection + specified bearing preload

Differential side bearing preload and adjusting shims:

Refer to SDS, MT-122, MT-123.

9. Install selected shim(s) and differential side bearing outer race.

10. Check differential side bearing turning torque.

a. Install final drive assembly on clutch housing.

b. Install transmission case on clutch housing.

+Tighten transmission case fixing bolts to the specified

torque. Refer to MT-30.

ADJUSTMENTRS5F30A

Differential Side Bearing Preload

MT-49

Page 1100 of 2493

SMT600-A

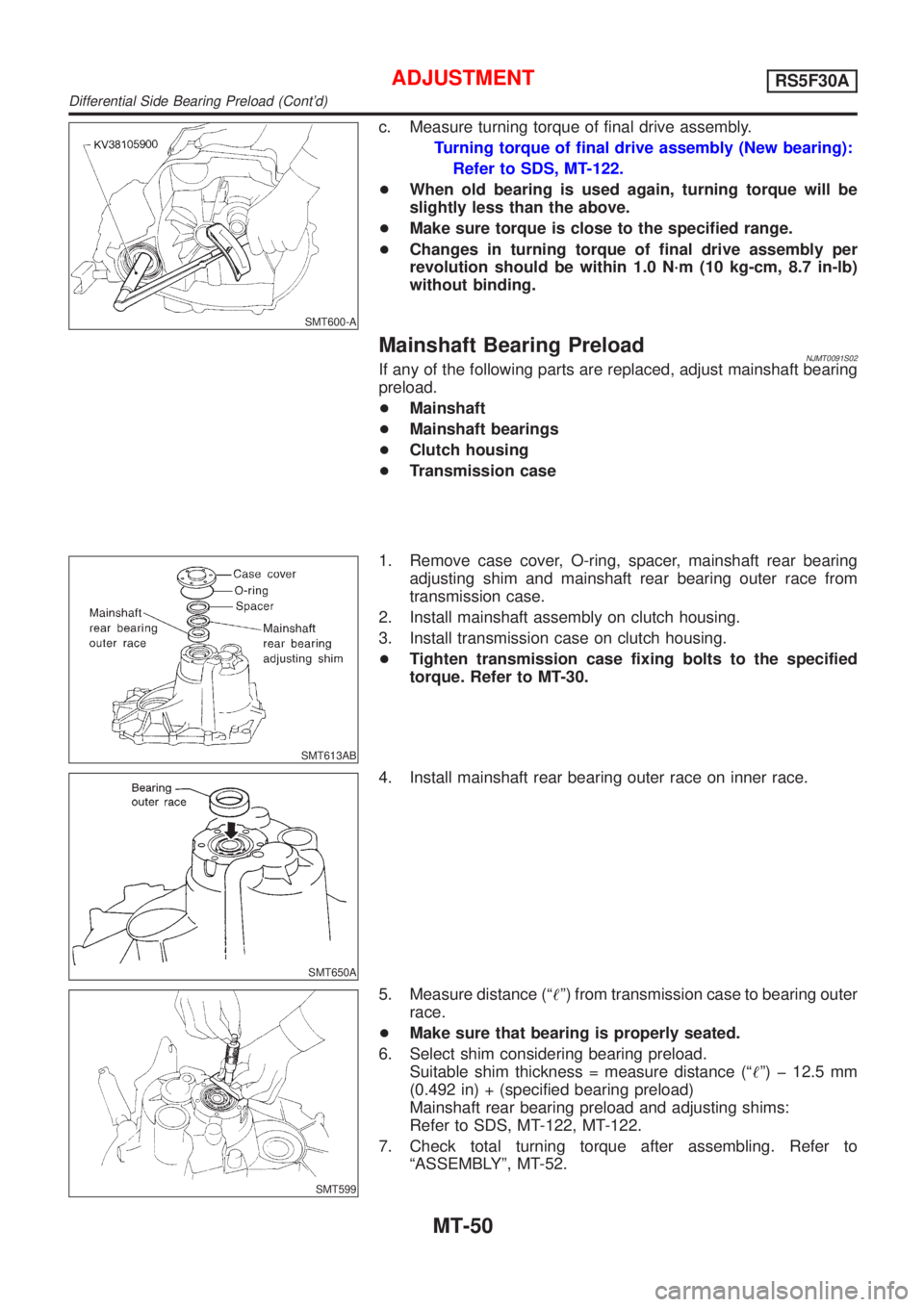

c. Measure turning torque of final drive assembly.

Turning torque of final drive assembly (New bearing):

Refer to SDS, MT-122.

+When old bearing is used again, turning torque will be

slightly less than the above.

+Make sure torque is close to the specified range.

+Changes in turning torque of final drive assembly per

revolution should be within 1.0 N´m (10 kg-cm, 8.7 in-lb)

without binding.

Mainshaft Bearing PreloadNJMT0091S02If any of the following parts are replaced, adjust mainshaft bearing

preload.

+Mainshaft

+Mainshaft bearings

+Clutch housing

+Transmission case

SMT613AB

1. Remove case cover, O-ring, spacer, mainshaft rear bearing

adjusting shim and mainshaft rear bearing outer race from

transmission case.

2. Install mainshaft assembly on clutch housing.

3. Install transmission case on clutch housing.

+Tighten transmission case fixing bolts to the specified

torque. Refer to MT-30.

SMT650A

4. Install mainshaft rear bearing outer race on inner race.

SMT599

5. Measure distance (ª!º) from transmission case to bearing outer

race.

+Make sure that bearing is properly seated.

6. Select shim considering bearing preload.

Suitable shim thickness = measure distance (ª!º) þ 12.5 mm

(0.492 in) + (specified bearing preload)

Mainshaft rear bearing preload and adjusting shims:

Refer to SDS, MT-122, MT-122.

7. Check total turning torque after assembling. Refer to

ªASSEMBLYº, MT-52.

ADJUSTMENTRS5F30A

Differential Side Bearing Preload (Cont'd)

MT-50