NISSAN ALMERA N16 2001 Electronic Repair Manual

Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2001Pages: 2493, PDF Size: 66.97 MB

Page 1761 of 2493

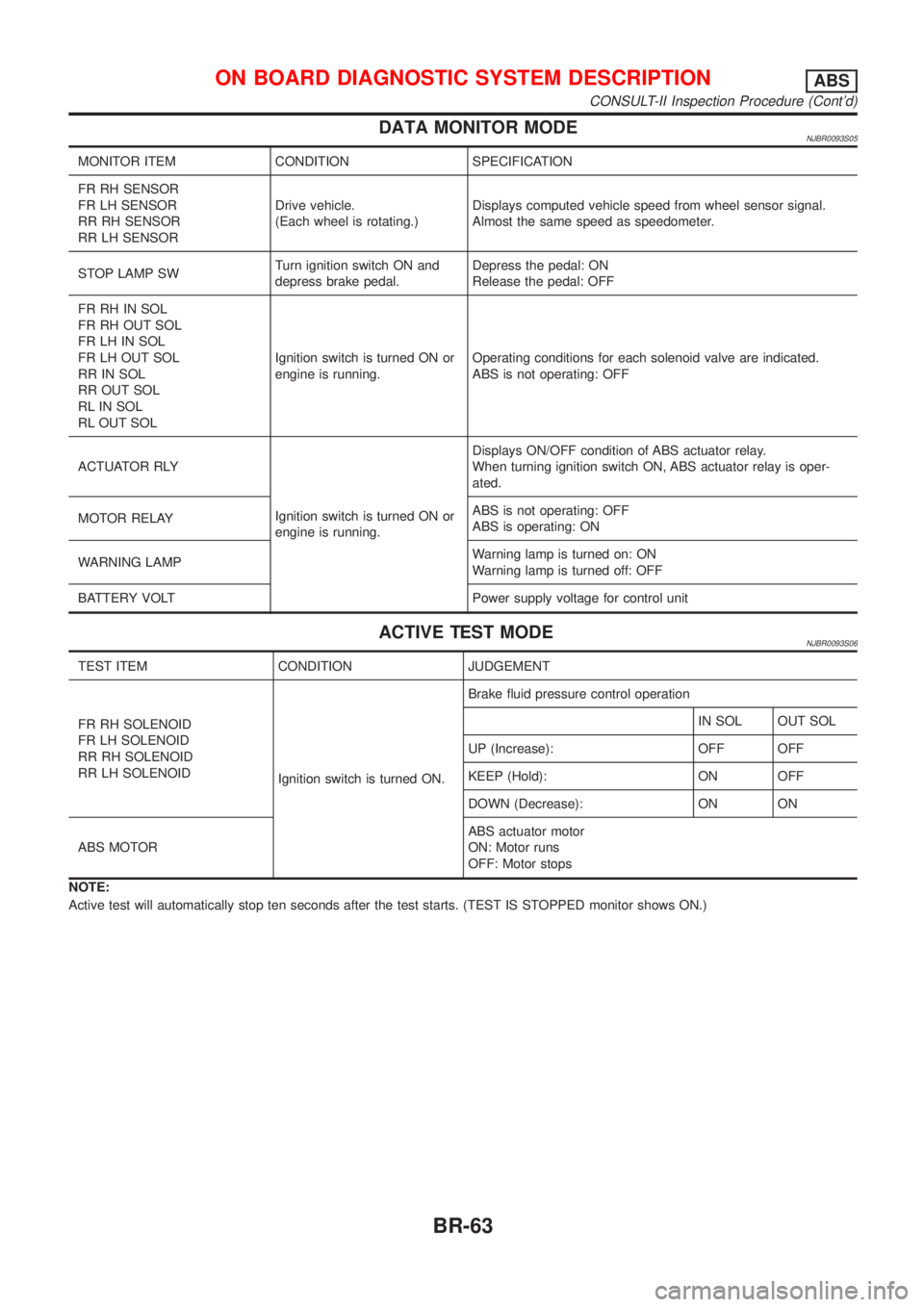

DATA MONITOR MODENJBR0093S05

MONITOR ITEM CONDITION SPECIFICATION

FR RH SENSOR

FR LH SENSOR

RR RH SENSOR

RR LH SENSORDrive vehicle.

(Each wheel is rotating.)Displays computed vehicle speed from wheel sensor signal.

Almost the same speed as speedometer.

STOP LAMP SWTurn ignition switch ON and

depress brake pedal.Depress the pedal: ON

Release the pedal: OFF

FR RH IN SOL

FR RH OUT SOL

FR LH IN SOL

FR LH OUT SOL

RR IN SOL

RR OUT SOL

RL IN SOL

RL OUT SOLIgnition switch is turned ON or

engine is running.Operating conditions for each solenoid valve are indicated.

ABS is not operating: OFF

ACTUATOR RLY

Ignition switch is turned ON or

engine is running.Displays ON/OFF condition of ABS actuator relay.

When turning ignition switch ON, ABS actuator relay is oper-

ated.

MOTOR RELAYABS is not operating: OFF

ABS is operating: ON

WARNING LAMPWarning lamp is turned on: ON

Warning lamp is turned off: OFF

BATTERY VOLT Power supply voltage for control unit

ACTIVE TEST MODENJBR0093S06

TEST ITEM CONDITION JUDGEMENT

FR RH SOLENOID

FR LH SOLENOID

RR RH SOLENOID

RR LH SOLENOID

Ignition switch is turned ON.Brake fluid pressure control operation

IN SOL OUT SOL

UP (Increase): OFF OFF

KEEP (Hold): ON OFF

DOWN (Decrease): ON ON

ABS MOTORABS actuator motor

ON: Motor runs

OFF: Motor stops

NOTE:

Active test will automatically stop ten seconds after the test starts. (TEST IS STOPPED monitor shows ON.)

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONABS

CONSULT-II Inspection Procedure (Cont'd)

BR-63

Page 1762 of 2493

SEF233G

SEF234G

How to Perform Trouble Diagnoses for Quick

and Accurate Repair

NJBR0094INTRODUCTIONNJBR0094S01The ABS system has an electronic control unit to control major

functions. The control unit accepts input signals from sensors and

instantly drives actuator. It is essential that both kinds of signals are

proper and stable. It is also important to check for conventional

problems: such as air leaks in the booster or lines, lack of brake

fluid, or other problems with the brake system.

It is much more difficult to diagnose a problem that occurs intermit-

tently rather than continuously. Most intermittent problems are

caused by poor electric connections or faulty wiring. In this case,

careful checking of suspicious circuits may help prevent the

replacement of good parts.

A visual check only may not find the cause of the problems, so a

road test should be performed.

Before undertaking actual checks, take just a few minutes to talk

with a customer who approaches with a ABS complaint. The cus-

tomer is a very good source of information on such problems;

especially intermittent ones. Through the talks with the customer,

find out what symptoms are present and under what conditions

they occur.

Start your diagnosis by looking for ªconventionalº problems first.

This is one of the best ways to troubleshoot brake problems on an

ABS controlled vehicle. Also check related Service Bulletins for

information.

TROUBLE DIAGNOSIS Ð INTRODUCTIONABS

How to Perform Trouble Diagnoses for Quick and Accurate Repair

BR-64

Page 1763 of 2493

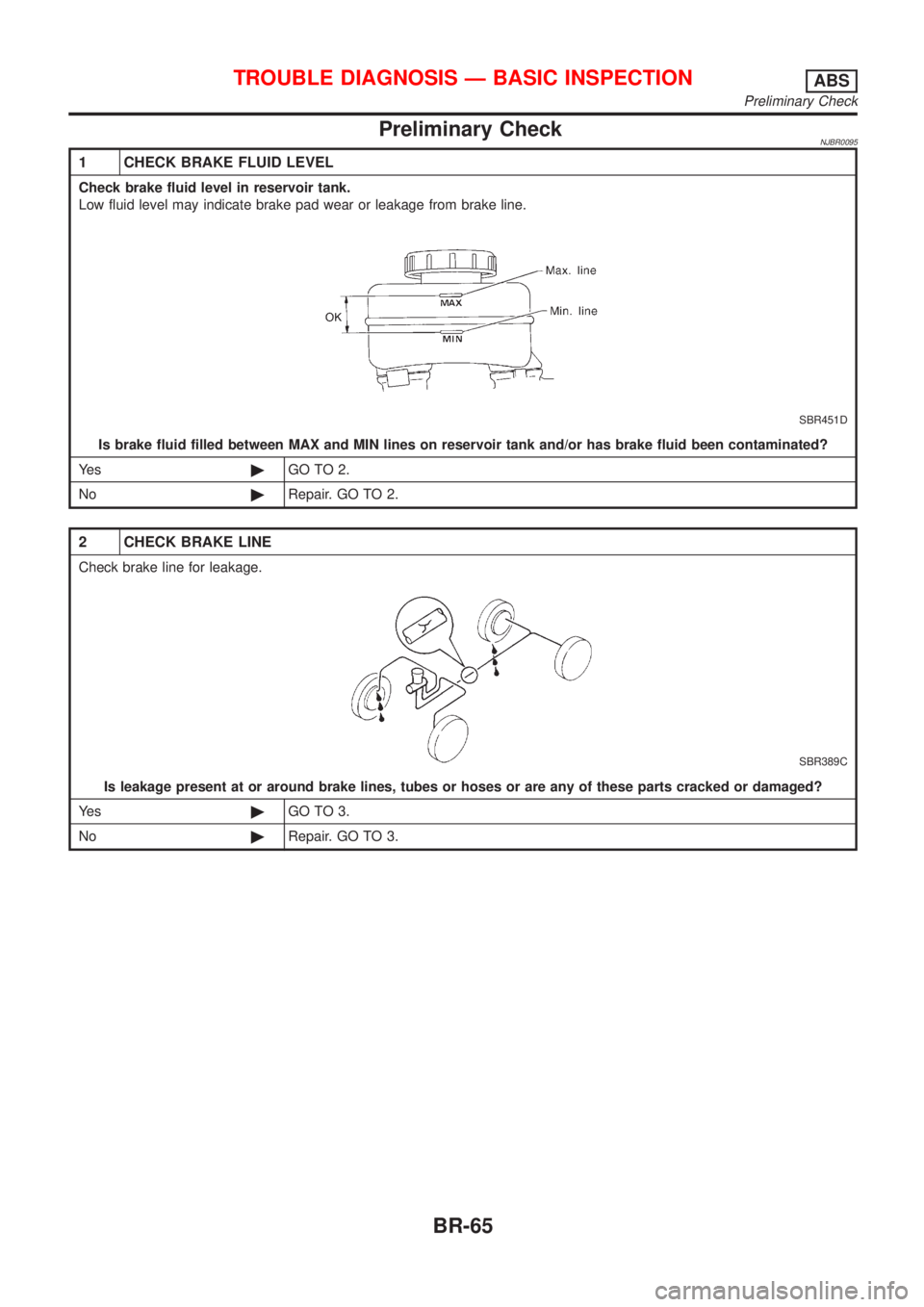

Preliminary CheckNJBR0095

1 CHECK BRAKE FLUID LEVEL

Check brake fluid level in reservoir tank.

Low fluid level may indicate brake pad wear or leakage from brake line.

SBR451D

Is brake fluid filled between MAX and MIN lines on reservoir tank and/or has brake fluid been contaminated?

Ye s©GO TO 2.

No©Repair. GO TO 2.

2 CHECK BRAKE LINE

Check brake line for leakage.

SBR389C

Is leakage present at or around brake lines, tubes or hoses or are any of these parts cracked or damaged?

Ye s©GO TO 3.

No©Repair. GO TO 3.

TROUBLE DIAGNOSIS Ð BASIC INSPECTIONABS

Preliminary Check

BR-65

Page 1764 of 2493

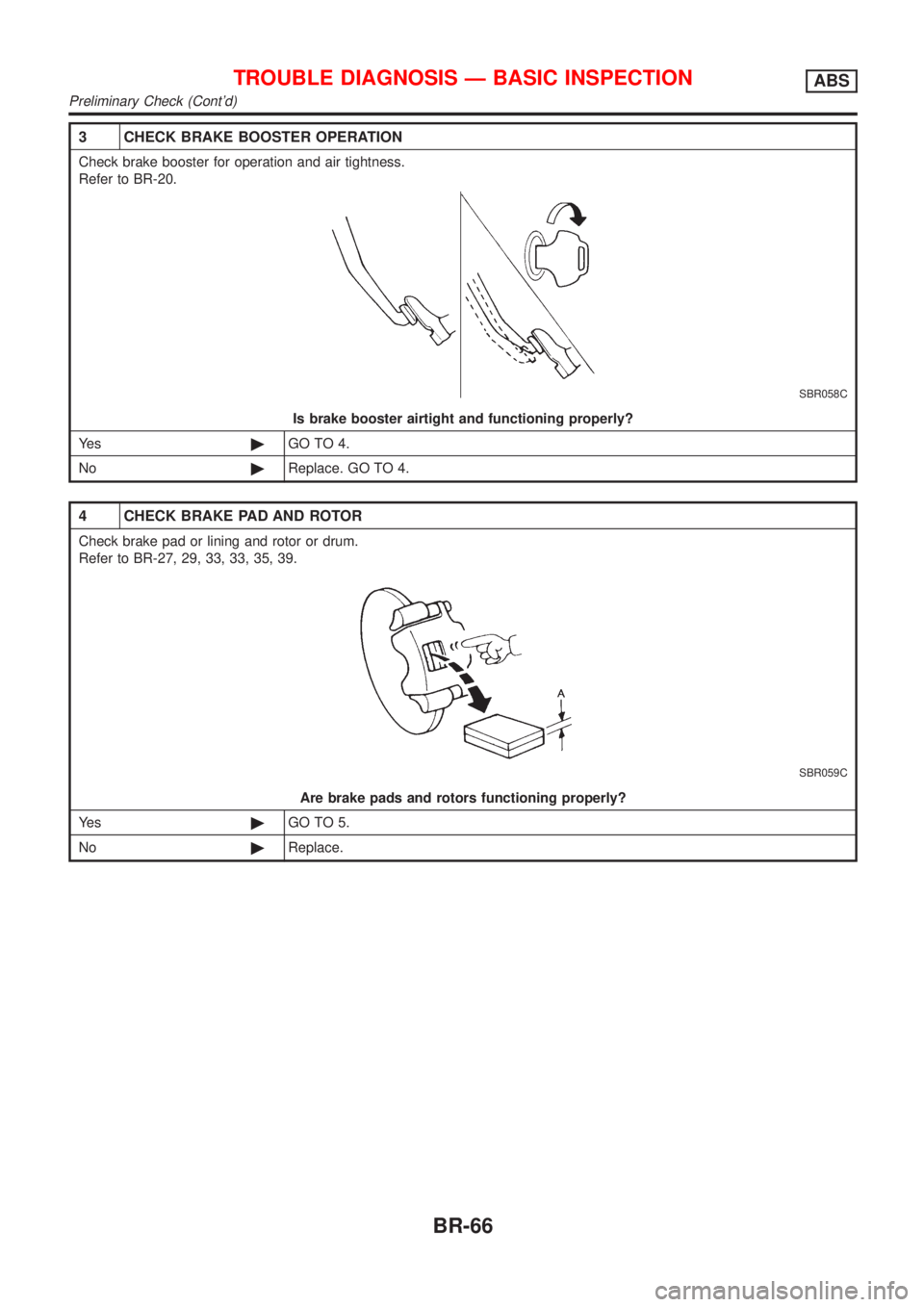

3 CHECK BRAKE BOOSTER OPERATION

Check brake booster for operation and air tightness.

Refer to BR-20.

SBR058C

Is brake booster airtight and functioning properly?

Ye s©GO TO 4.

No©Replace. GO TO 4.

4 CHECK BRAKE PAD AND ROTOR

Check brake pad or lining and rotor or drum.

Refer to BR-27, 29, 33, 33, 35, 39.

SBR059C

Are brake pads and rotors functioning properly?

Ye s©GO TO 5.

No©Replace.

TROUBLE DIAGNOSIS Ð BASIC INSPECTIONABS

Preliminary Check (Cont'd)

BR-66

Page 1765 of 2493

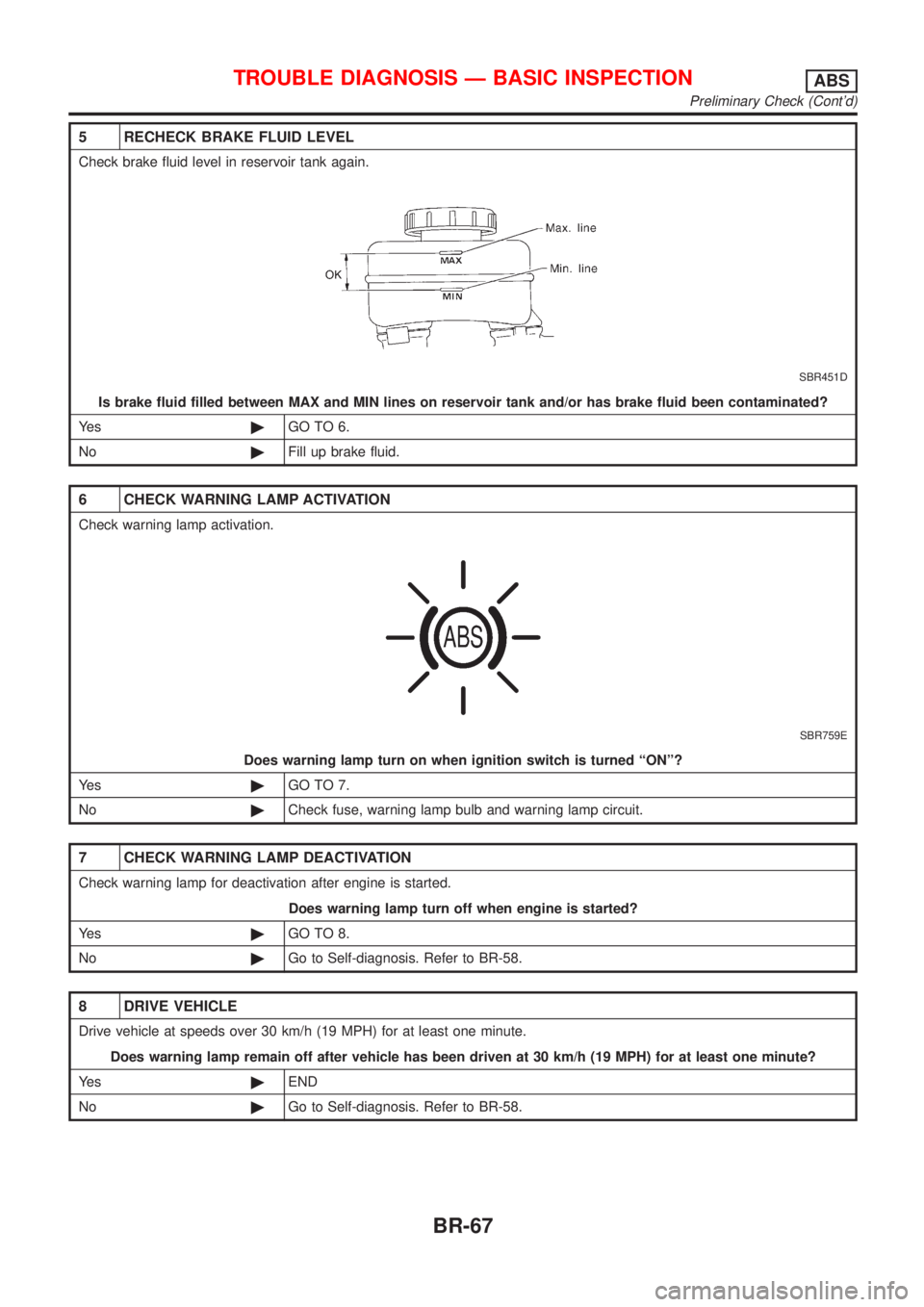

5 RECHECK BRAKE FLUID LEVEL

Check brake fluid level in reservoir tank again.

SBR451D

Is brake fluid filled between MAX and MIN lines on reservoir tank and/or has brake fluid been contaminated?

Ye s©GO TO 6.

No©Fill up brake fluid.

6 CHECK WARNING LAMP ACTIVATION

Check warning lamp activation.

SBR759E

Does warning lamp turn on when ignition switch is turned ªONº?

Ye s©GO TO 7.

No©Check fuse, warning lamp bulb and warning lamp circuit.

7 CHECK WARNING LAMP DEACTIVATION

Check warning lamp for deactivation after engine is started.

Does warning lamp turn off when engine is started?

Ye s©GO TO 8.

No©Go to Self-diagnosis. Refer to BR-58.

8 DRIVE VEHICLE

Drive vehicle at speeds over 30 km/h (19 MPH) for at least one minute.

Does warning lamp remain off after vehicle has been driven at 30 km/h (19 MPH) for at least one minute?

Ye s©END

No©Go to Self-diagnosis. Refer to BR-58.

TROUBLE DIAGNOSIS Ð BASIC INSPECTIONABS

Preliminary Check (Cont'd)

BR-67

Page 1766 of 2493

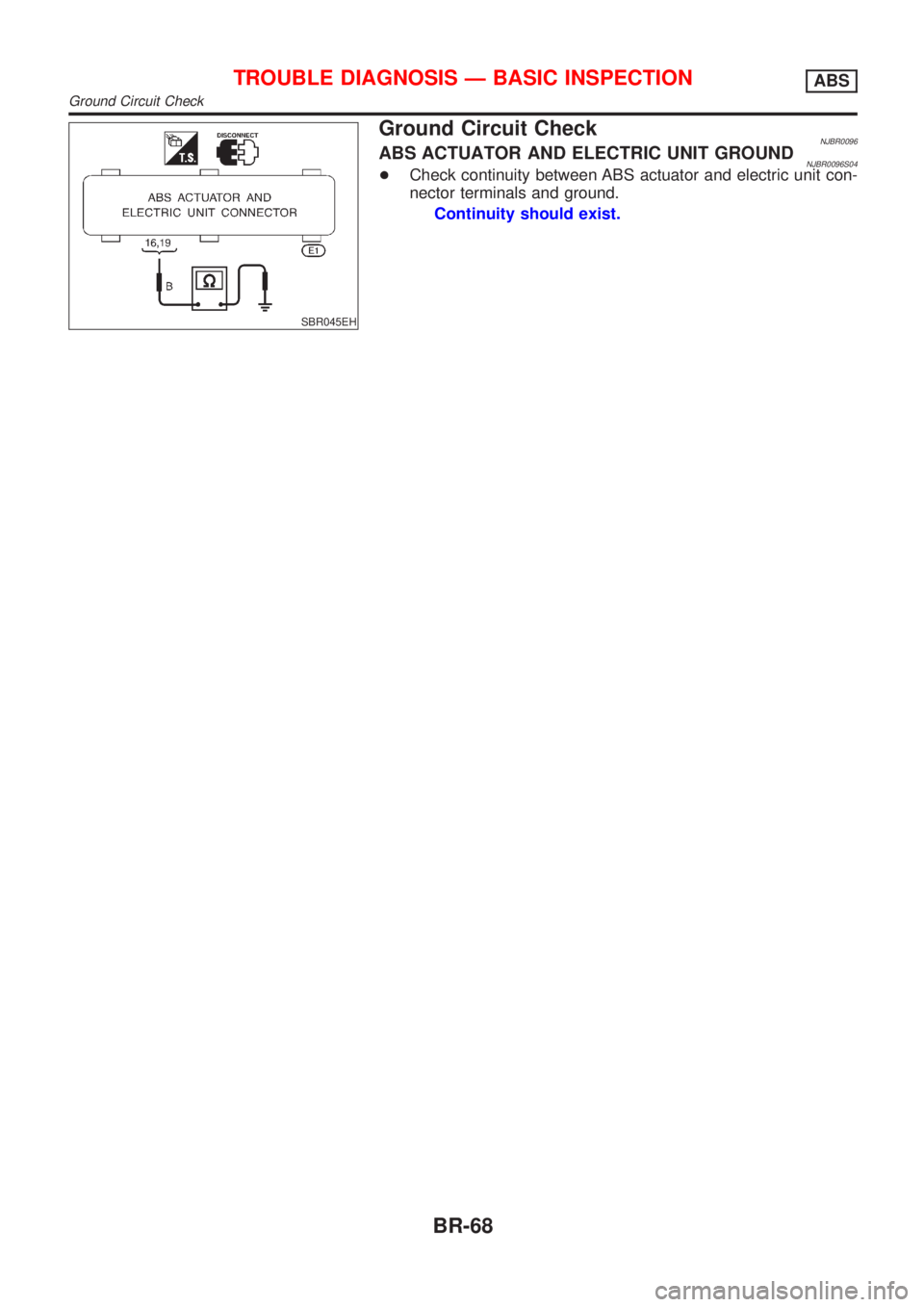

SBR045EH

Ground Circuit CheckNJBR0096ABS ACTUATOR AND ELECTRIC UNIT GROUNDNJBR0096S04+Check continuity between ABS actuator and electric unit con-

nector terminals and ground.

Continuity should exist.

TROUBLE DIAGNOSIS Ð BASIC INSPECTIONABS

Ground Circuit Check

BR-68

Page 1767 of 2493

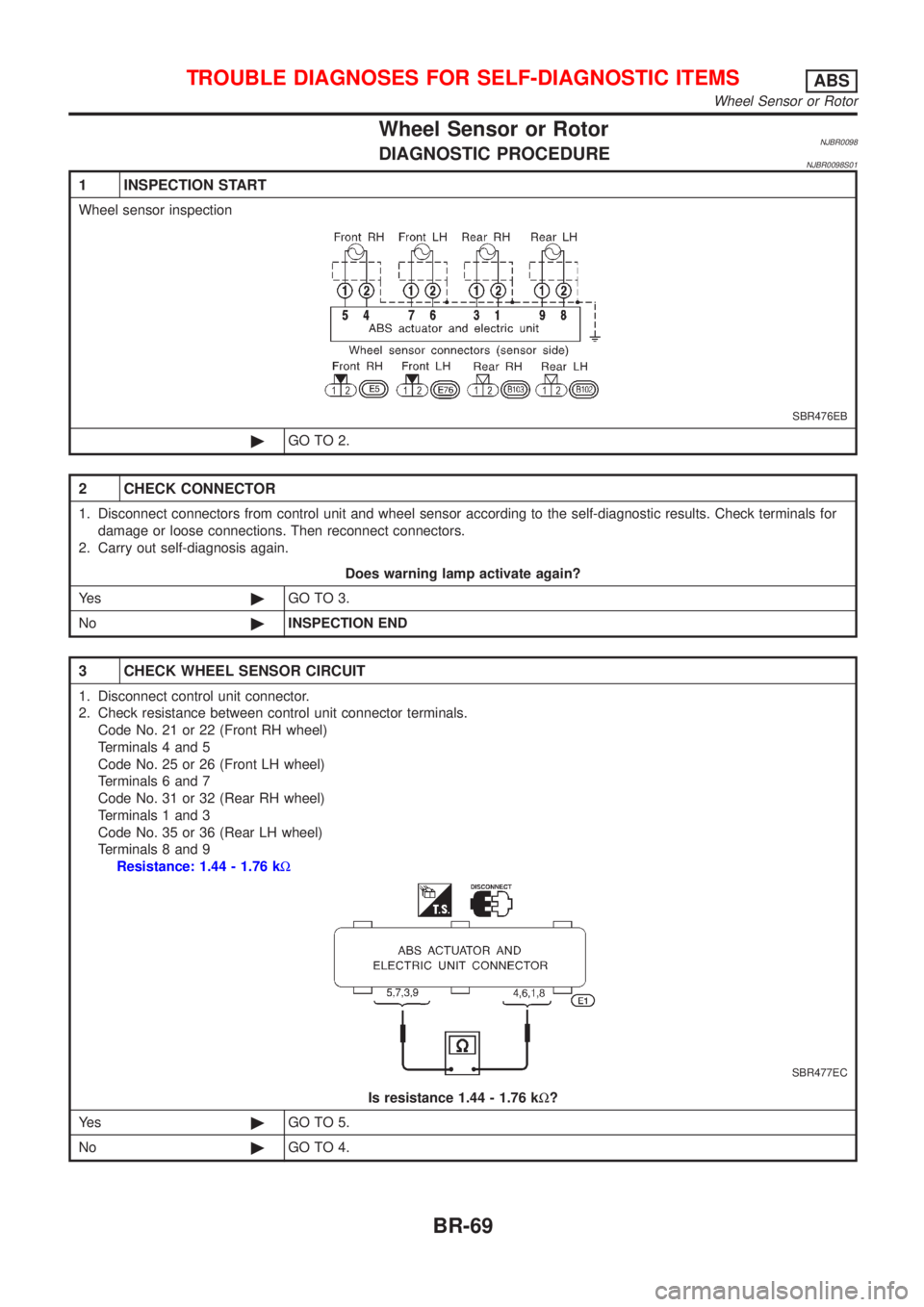

Wheel Sensor or RotorNJBR0098DIAGNOSTIC PROCEDURENJBR0098S01

1 INSPECTION START

Wheel sensor inspection

SBR476EB

©GO TO 2.

2 CHECK CONNECTOR

1. Disconnect connectors from control unit and wheel sensor according to the self-diagnostic results. Check terminals for

damage or loose connections. Then reconnect connectors.

2. Carry out self-diagnosis again.

Does warning lamp activate again?

Ye s©GO TO 3.

No©INSPECTION END

3 CHECK WHEEL SENSOR CIRCUIT

1. Disconnect control unit connector.

2. Check resistance between control unit connector terminals.

Code No. 21 or 22 (Front RH wheel)

Terminals 4 and 5

Code No. 25 or 26 (Front LH wheel)

Terminals 6 and 7

Code No. 31 or 32 (Rear RH wheel)

Terminals 1 and 3

Code No. 35 or 36 (Rear LH wheel)

Terminals 8 and 9

Resistance: 1.44 - 1.76 kW

SBR477EC

Is resistance 1.44 - 1.76 kW?

Ye s©GO TO 5.

No©GO TO 4.

TROUBLE DIAGNOSES FOR SELF-DIAGNOSTIC ITEMSABS

Wheel Sensor or Rotor

BR-69

Page 1768 of 2493

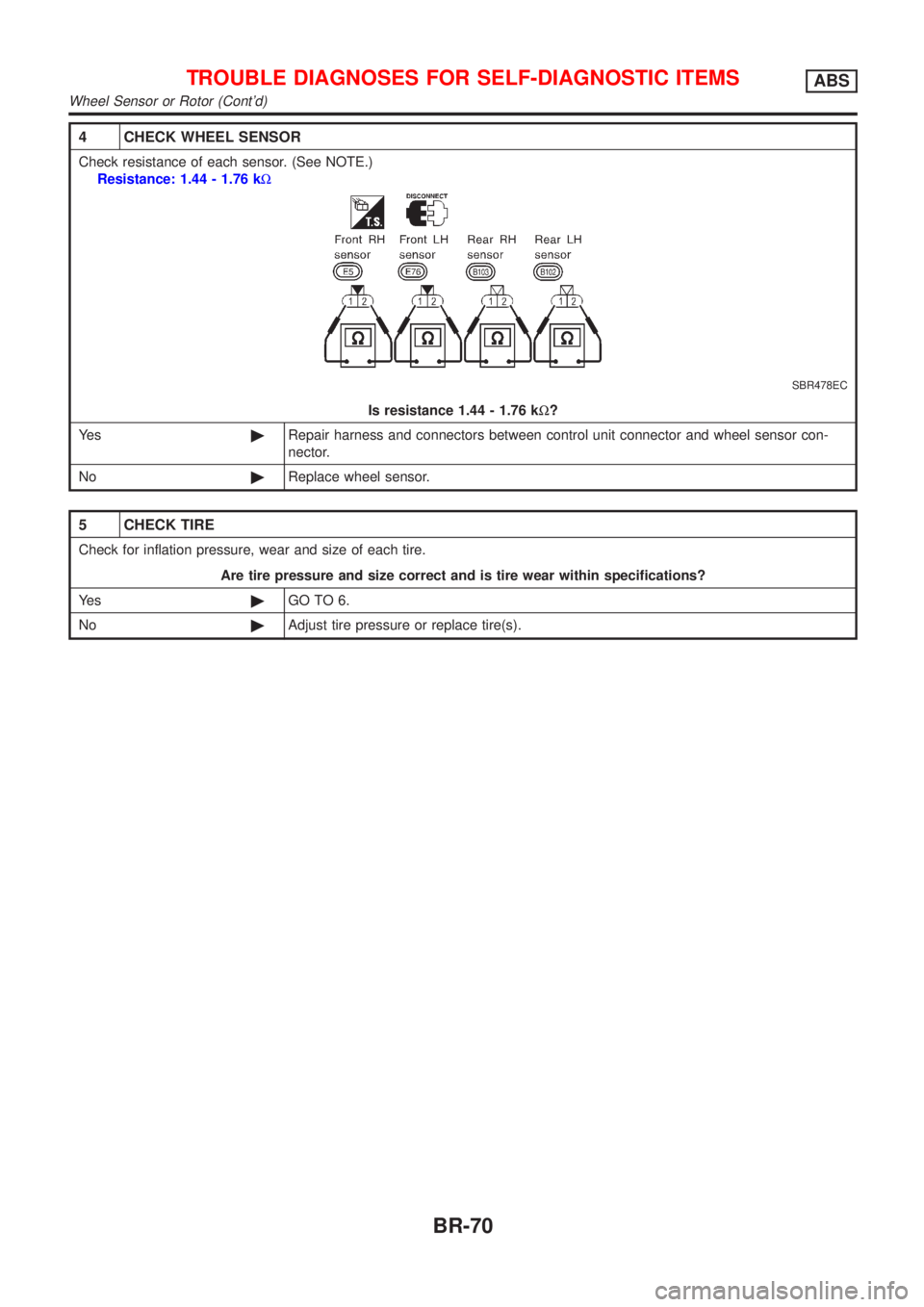

4 CHECK WHEEL SENSOR

Check resistance of each sensor. (See NOTE.)

Resistance: 1.44 - 1.76 kW

SBR478EC

Is resistance 1.44 - 1.76 kW?

Ye s©Repair harness and connectors between control unit connector and wheel sensor con-

nector.

No©Replace wheel sensor.

5 CHECK TIRE

Check for inflation pressure, wear and size of each tire.

Are tire pressure and size correct and is tire wear within specifications?

Ye s©GO TO 6.

No©Adjust tire pressure or replace tire(s).

TROUBLE DIAGNOSES FOR SELF-DIAGNOSTIC ITEMSABS

Wheel Sensor or Rotor (Cont'd)

BR-70

Page 1769 of 2493

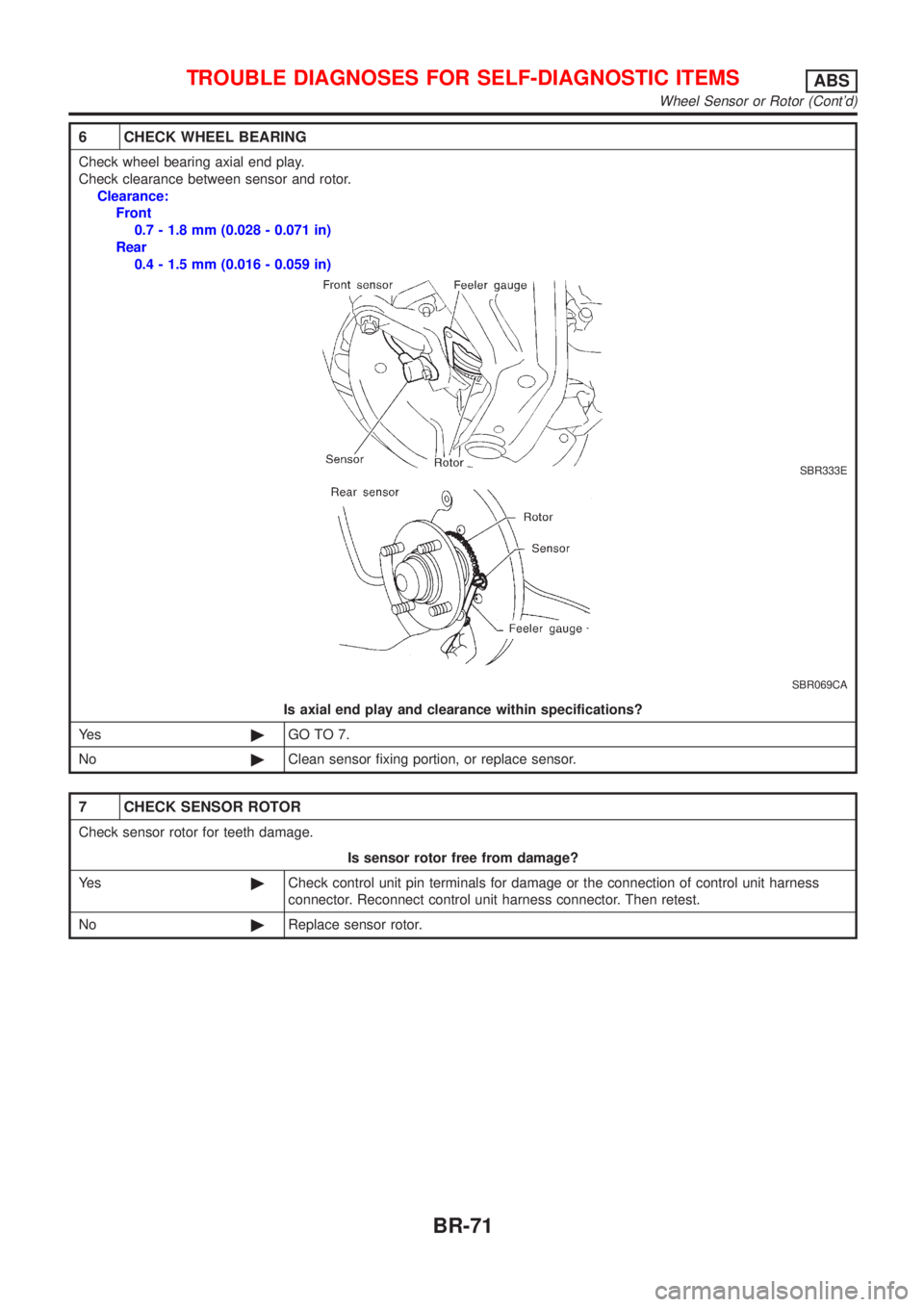

6 CHECK WHEEL BEARING

Check wheel bearing axial end play.

Check clearance between sensor and rotor.

Clearance:

Front

0.7 - 1.8 mm (0.028 - 0.071 in)

Rear

0.4 - 1.5 mm (0.016 - 0.059 in)

SBR333E

SBR069CA

Is axial end play and clearance within specifications?

Ye s©GO TO 7.

No©Clean sensor fixing portion, or replace sensor.

7 CHECK SENSOR ROTOR

Check sensor rotor for teeth damage.

Is sensor rotor free from damage?

Ye s©Check control unit pin terminals for damage or the connection of control unit harness

connector. Reconnect control unit harness connector. Then retest.

No©Replace sensor rotor.

TROUBLE DIAGNOSES FOR SELF-DIAGNOSTIC ITEMSABS

Wheel Sensor or Rotor (Cont'd)

BR-71

Page 1770 of 2493

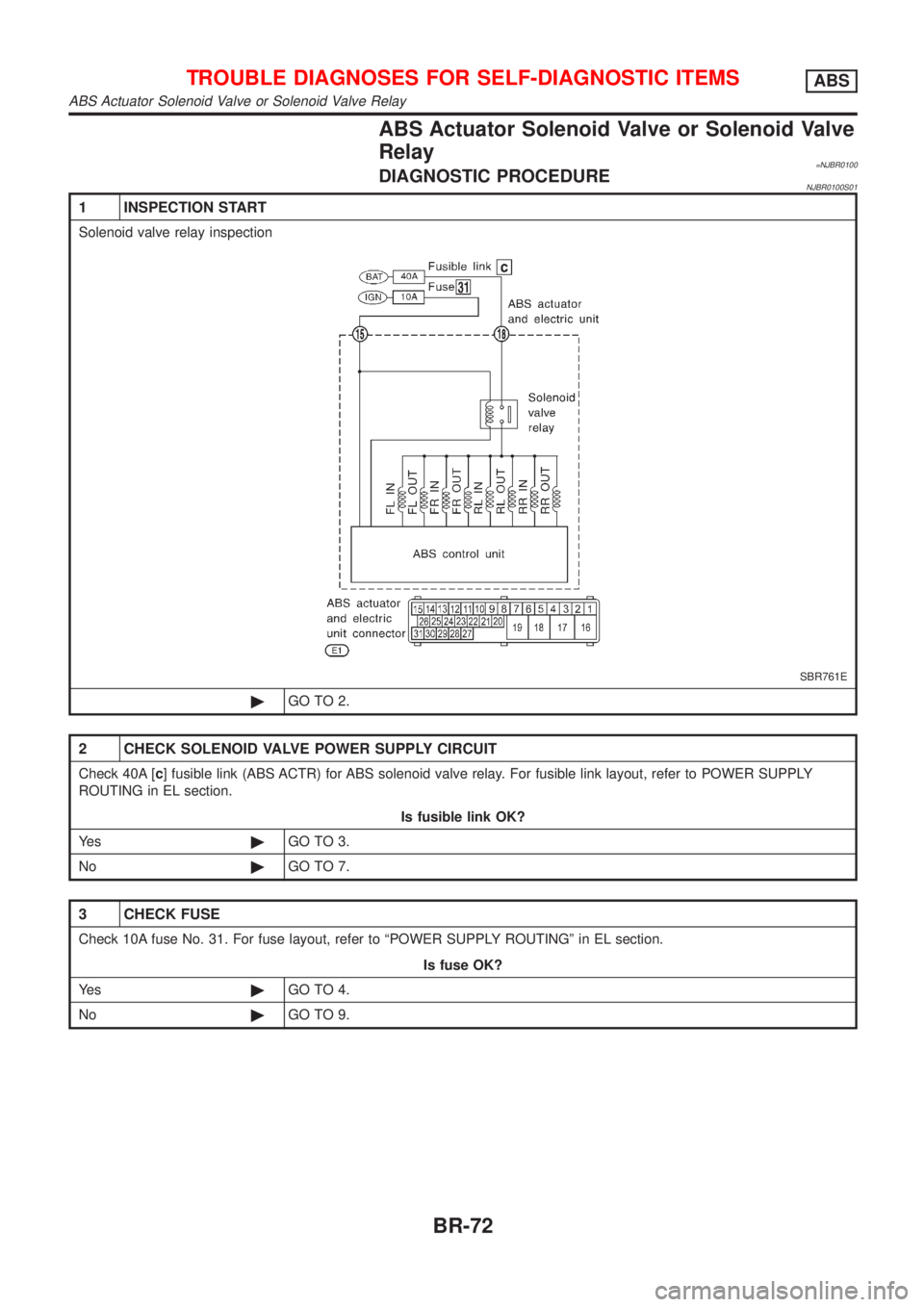

ABS Actuator Solenoid Valve or Solenoid Valve

Relay

=NJBR0100DIAGNOSTIC PROCEDURENJBR0100S01

1 INSPECTION START

Solenoid valve relay inspection

SBR761E

©GO TO 2.

2 CHECK SOLENOID VALVE POWER SUPPLY CIRCUIT

Check 40A [c] fusible link (ABS ACTR) for ABS solenoid valve relay. For fusible link layout, refer to POWER SUPPLY

ROUTING in EL section.

Is fusible link OK?

Ye s©GO TO 3.

No©GO TO 7.

3 CHECK FUSE

Check 10A fuse No. 31. For fuse layout, refer to ªPOWER SUPPLY ROUTINGº in EL section.

Is fuse OK?

Ye s©GO TO 4.

No©GO TO 9.

TROUBLE DIAGNOSES FOR SELF-DIAGNOSTIC ITEMSABS

ABS Actuator Solenoid Valve or Solenoid Valve Relay

BR-72