Meter NISSAN ALMERA N16 2001 Electronic Manual PDF

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2001Pages: 2493, PDF Size: 66.97 MB

Page 240 of 2493

VALVE LIFTERNJEM0078S05Unit: mm (in)

Valve lifter outer diameter 29.960 - 29.975 (1.1795 - 1.1801)

Lifter guide inner diameter 30.000 - 30.021 (1.1181 - 1.1819)

Clearance between lifter and lifter guide 0.025 - 0.061 (0.0010 - 0.0024)

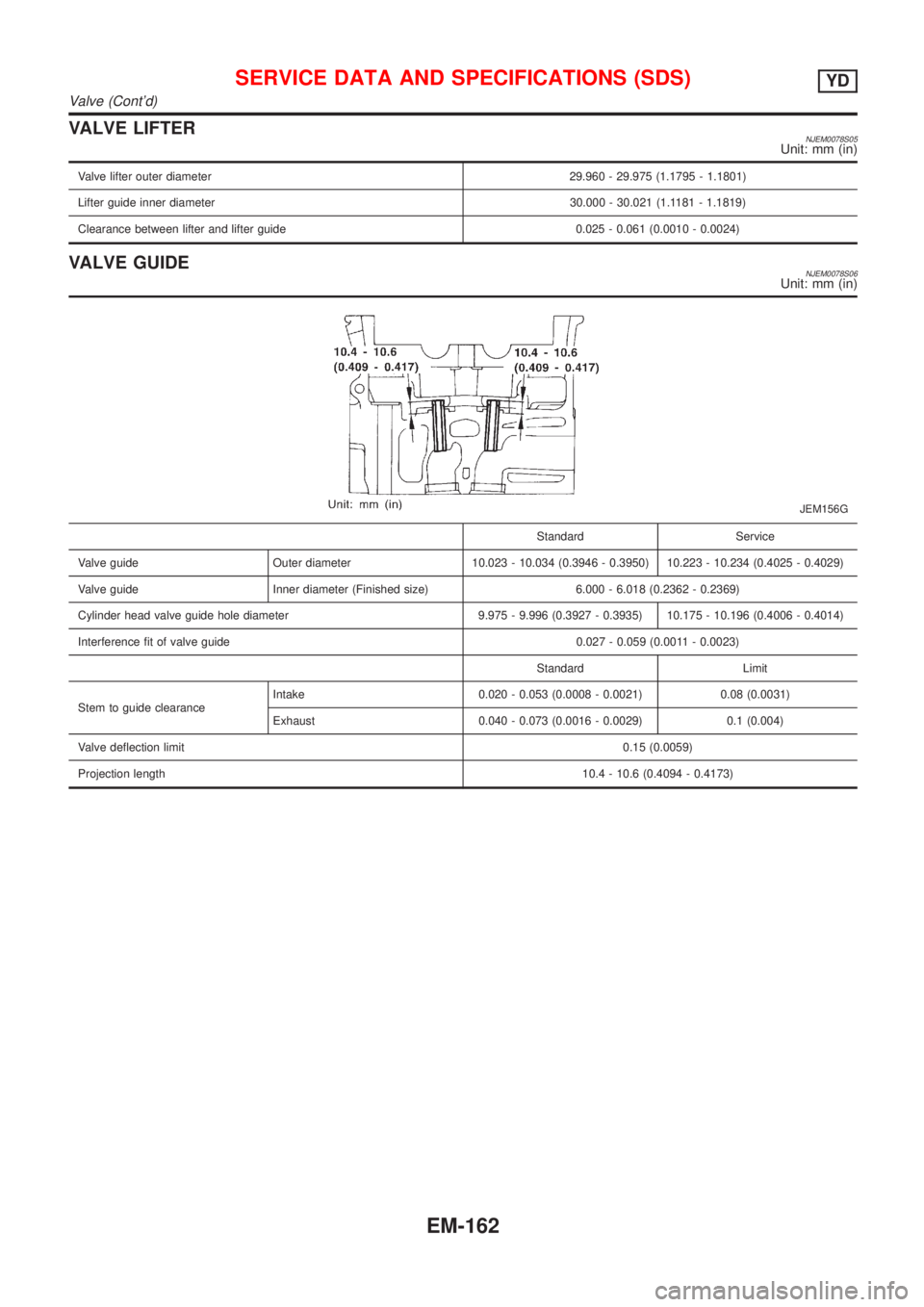

VALVE GUIDENJEM0078S06Unit: mm (in)

JEM156G

Standard Service

Valve guide Outer diameter 10.023 - 10.034 (0.3946 - 0.3950) 10.223 - 10.234 (0.4025 - 0.4029)

Valve guide Inner diameter (Finished size) 6.000 - 6.018 (0.2362 - 0.2369)

Cylinder head valve guide hole diameter 9.975 - 9.996 (0.3927 - 0.3935) 10.175 - 10.196 (0.4006 - 0.4014)

Interference fit of valve guide 0.027 - 0.059 (0.0011 - 0.0023)

Standard Limit

Stem to guide clearanceIntake 0.020 - 0.053 (0.0008 - 0.0021) 0.08 (0.0031)

Exhaust 0.040 - 0.073 (0.0016 - 0.0029) 0.1 (0.004)

Valve deflection limit0.15 (0.0059)

Projection length10.4 - 10.6 (0.4094 - 0.4173)

SERVICE DATA AND SPECIFICATIONS (SDS)YD

Valve (Cont'd)

EM-162

Page 241 of 2493

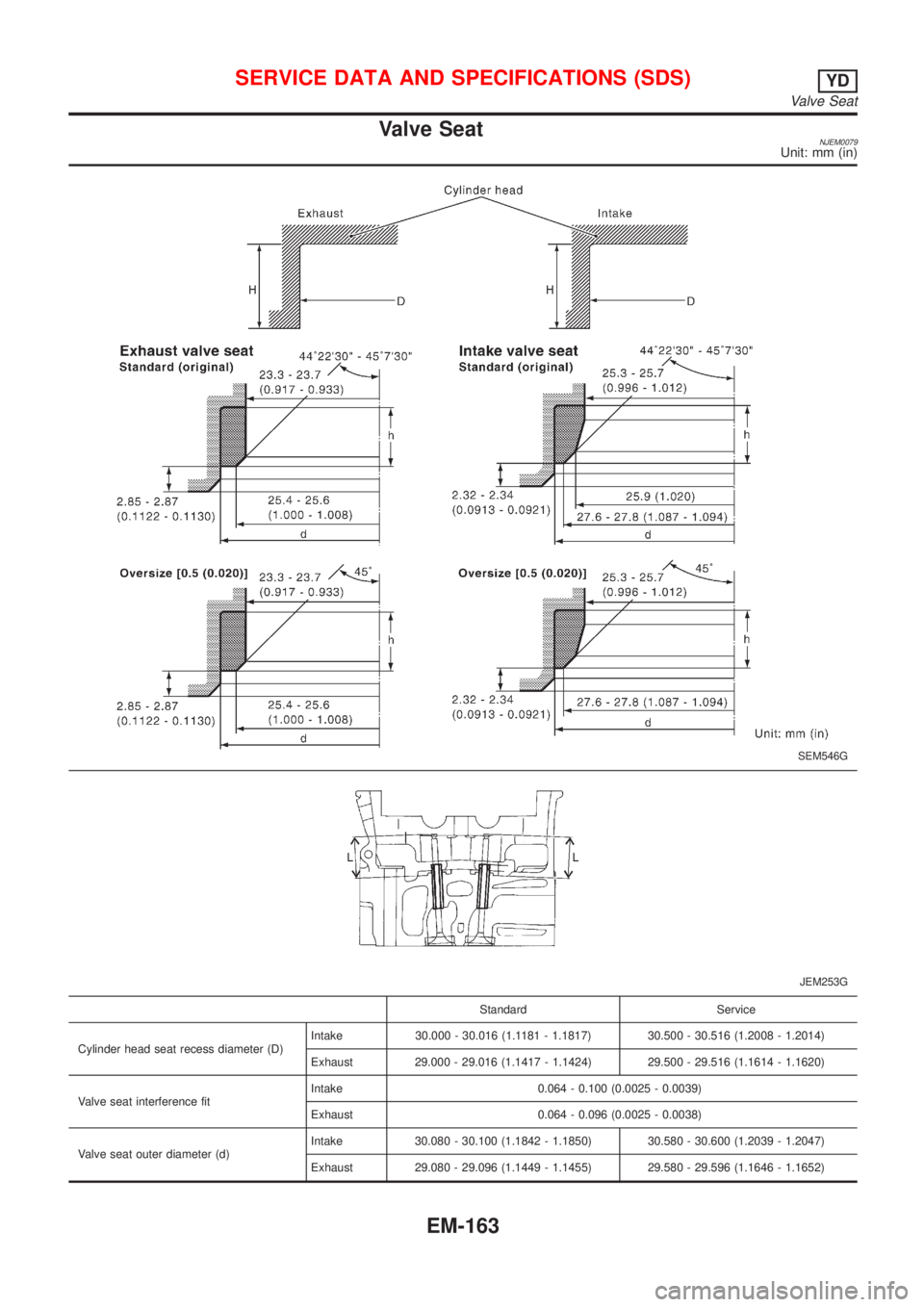

Valve SeatNJEM0079Unit: mm (in)

SEM546G

JEM253G

Standard Service

Cylinder head seat recess diameter (D)Intake 30.000 - 30.016 (1.1181 - 1.1817) 30.500 - 30.516 (1.2008 - 1.2014)

Exhaust 29.000 - 29.016 (1.1417 - 1.1424) 29.500 - 29.516 (1.1614 - 1.1620)

Valve seat interference fitIntake 0.064 - 0.100 (0.0025 - 0.0039)

Exhaust 0.064 - 0.096 (0.0025 - 0.0038)

Valve seat outer diameter (d)Intake 30.080 - 30.100 (1.1842 - 1.1850) 30.580 - 30.600 (1.2039 - 1.2047)

Exhaust 29.080 - 29.096 (1.1449 - 1.1455) 29.580 - 29.596 (1.1646 - 1.1652)

SERVICE DATA AND SPECIFICATIONS (SDS)YD

Valve Seat

EM-163

Page 243 of 2493

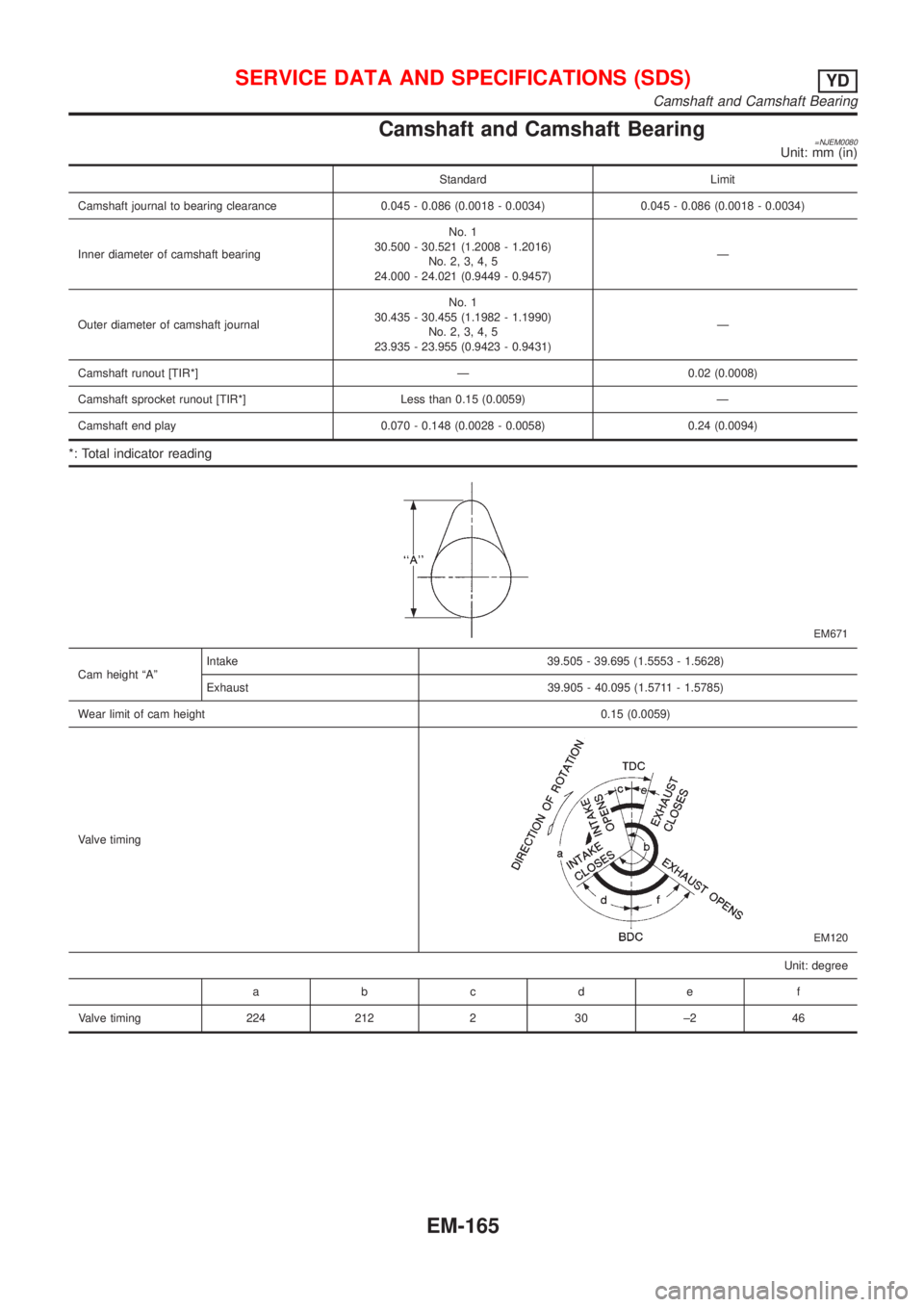

Camshaft and Camshaft Bearing=NJEM0080Unit: mm (in)

Standard Limit

Camshaft journal to bearing clearance 0.045 - 0.086 (0.0018 - 0.0034) 0.045 - 0.086 (0.0018 - 0.0034)

Inner diameter of camshaft bearingNo. 1

30.500 - 30.521 (1.2008 - 1.2016)

No. 2, 3, 4, 5

24.000 - 24.021 (0.9449 - 0.9457)Ð

Outer diameter of camshaft journalNo. 1

30.435 - 30.455 (1.1982 - 1.1990)

No. 2, 3, 4, 5

23.935 - 23.955 (0.9423 - 0.9431)Ð

Camshaft runout [TIR*] Ð 0.02 (0.0008)

Camshaft sprocket runout [TIR*] Less than 0.15 (0.0059) Ð

Camshaft end play 0.070 - 0.148 (0.0028 - 0.0058) 0.24 (0.0094)

*: Total indicator reading

EM671

Cam height ªAºIntake 39.505 - 39.695 (1.5553 - 1.5628)

Exhaust 39.905 - 40.095 (1.5711 - 1.5785)

Wear limit of cam height0.15 (0.0059)

Valve timing

EM120

Unit: degree

abcde f

Valve timing 224 212 2 30 ±2 46

SERVICE DATA AND SPECIFICATIONS (SDS)YD

Camshaft and Camshaft Bearing

EM-165

Page 244 of 2493

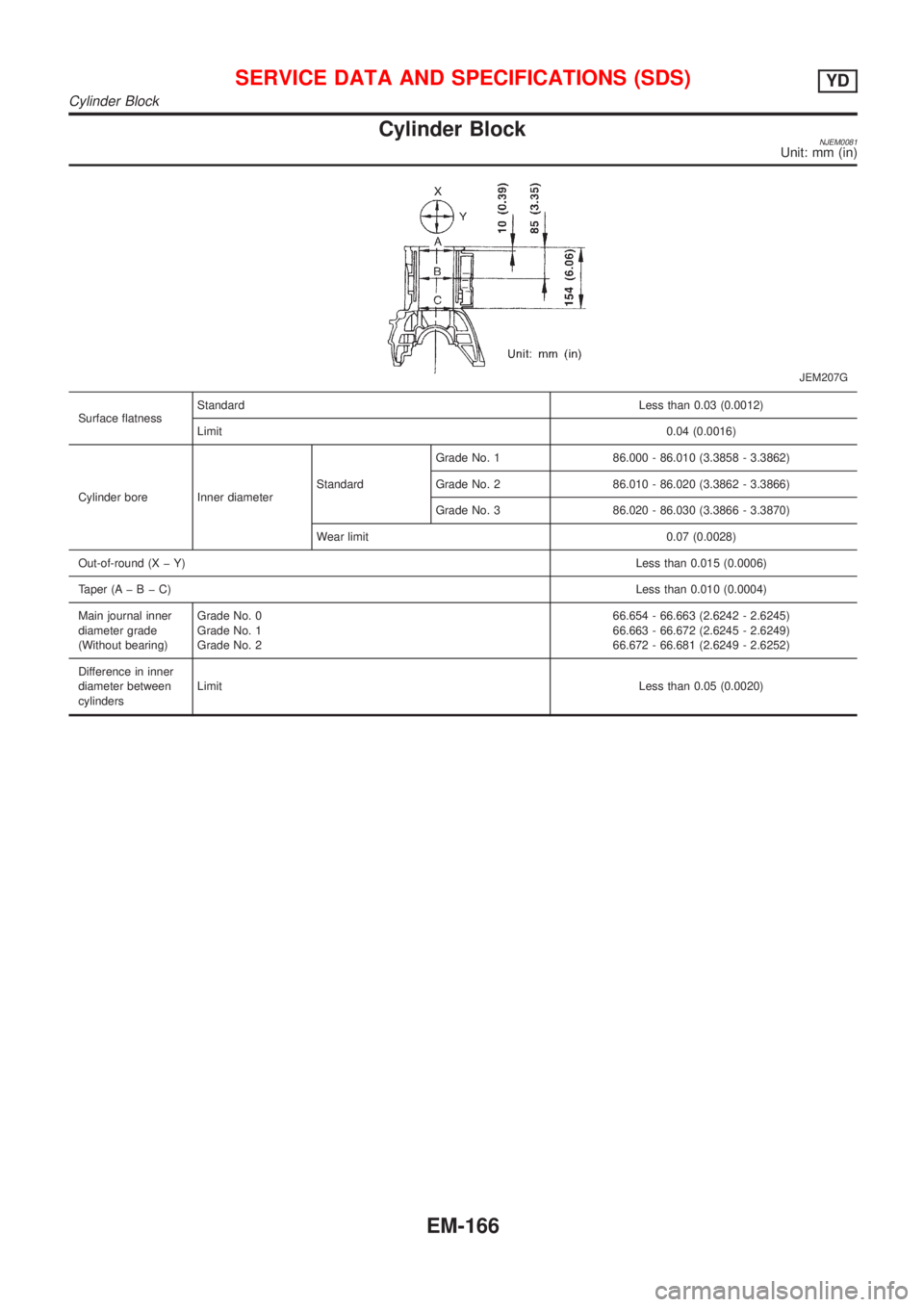

Cylinder BlockNJEM0081Unit: mm (in)

JEM207G

Surface flatnessStandardLess than 0.03 (0.0012)

Limit0.04 (0.0016)

Cylinder bore Inner diameterStandardGrade No. 1 86.000 - 86.010 (3.3858 - 3.3862)

Grade No. 2 86.010 - 86.020 (3.3862 - 3.3866)

Grade No. 3 86.020 - 86.030 (3.3866 - 3.3870)

Wear limit 0.07 (0.0028)

Out-of-round (X þ Y)Less than 0.015 (0.0006)

Taper (AþBþC)Less than 0.010 (0.0004)

Main journal inner

diameter grade

(Without bearing)Grade No. 0

Grade No. 1

Grade No. 266.654 - 66.663 (2.6242 - 2.6245)

66.663 - 66.672 (2.6245 - 2.6249)

66.672 - 66.681 (2.6249 - 2.6252)

Difference in inner

diameter between

cylindersLimitLess than 0.05 (0.0020)

SERVICE DATA AND SPECIFICATIONS (SDS)YD

Cylinder Block

EM-166

Page 245 of 2493

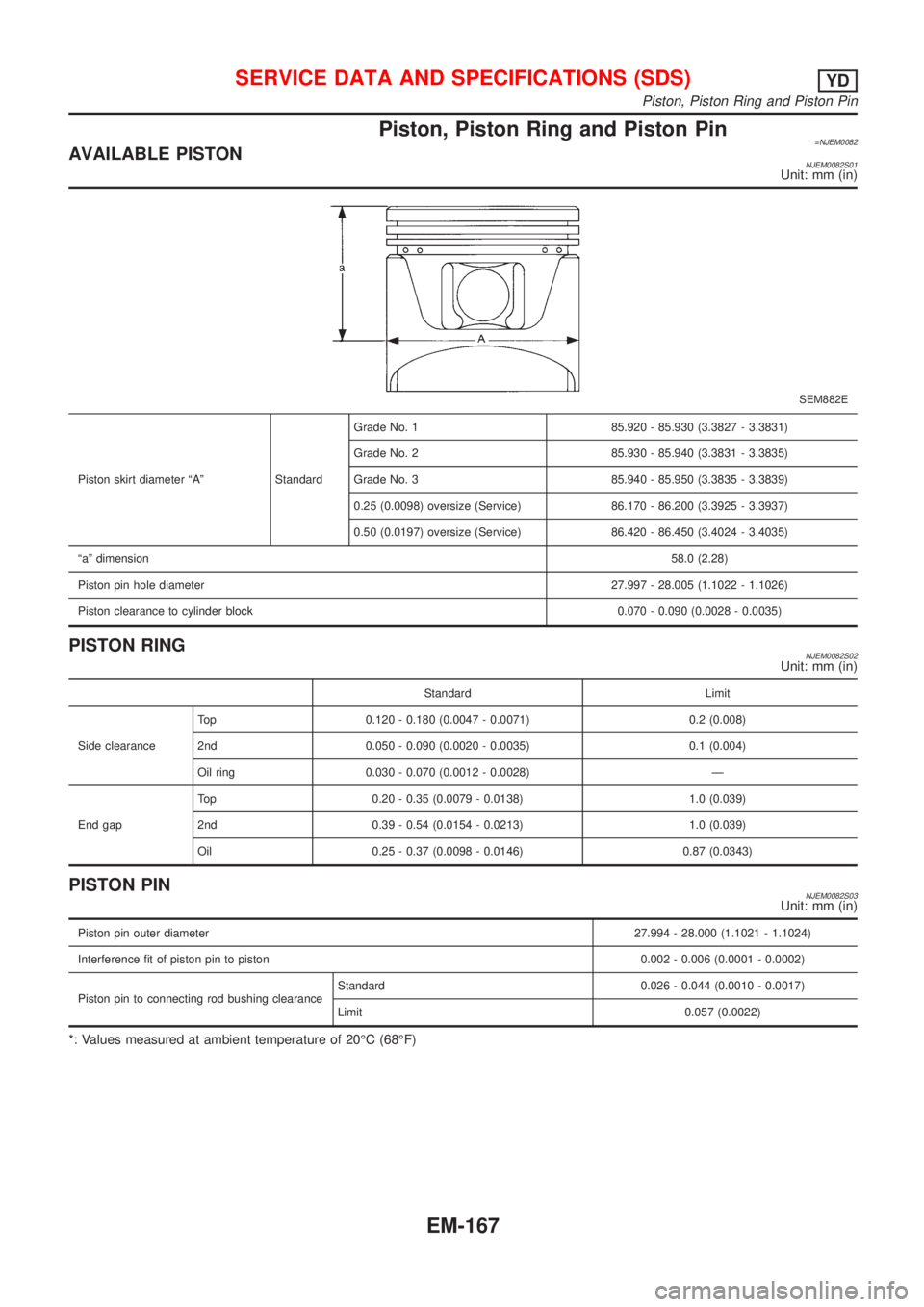

Piston, Piston Ring and Piston Pin=NJEM0082AVAILABLE PISTONNJEM0082S01Unit: mm (in)

SEM882E

Piston skirt diameter ªAº StandardGrade No. 1 85.920 - 85.930 (3.3827 - 3.3831)

Grade No. 2 85.930 - 85.940 (3.3831 - 3.3835)

Grade No. 3 85.940 - 85.950 (3.3835 - 3.3839)

0.25 (0.0098) oversize (Service) 86.170 - 86.200 (3.3925 - 3.3937)

0.50 (0.0197) oversize (Service) 86.420 - 86.450 (3.4024 - 3.4035)

ªaº dimension58.0 (2.28)

Piston pin hole diameter27.997 - 28.005 (1.1022 - 1.1026)

Piston clearance to cylinder block 0.070 - 0.090 (0.0028 - 0.0035)

PISTON RINGNJEM0082S02Unit: mm (in)

Standard Limit

Side clearanceTop 0.120 - 0.180 (0.0047 - 0.0071) 0.2 (0.008)

2nd 0.050 - 0.090 (0.0020 - 0.0035) 0.1 (0.004)

Oil ring 0.030 - 0.070 (0.0012 - 0.0028) Ð

End gapTop 0.20 - 0.35 (0.0079 - 0.0138) 1.0 (0.039)

2nd 0.39 - 0.54 (0.0154 - 0.0213) 1.0 (0.039)

Oil 0.25 - 0.37 (0.0098 - 0.0146) 0.87 (0.0343)

PISTON PINNJEM0082S03Unit: mm (in)

Piston pin outer diameter27.994 - 28.000 (1.1021 - 1.1024)

Interference fit of piston pin to piston 0.002 - 0.006 (0.0001 - 0.0002)

Piston pin to connecting rod bushing clearanceStandard 0.026 - 0.044 (0.0010 - 0.0017)

Limit 0.057 (0.0022)

*: Values measured at ambient temperature of 20ÉC (68ÉF)

SERVICE DATA AND SPECIFICATIONS (SDS)YD

Piston, Piston Ring and Piston Pin

EM-167

Page 246 of 2493

![NISSAN ALMERA N16 2001 Electronic Manual PDF Connecting RodNJEM0083Unit: mm (in)

Center distance157.5 (6.201)

Bend [per 100 (3.94)] Limit 0.12 (0.0047)

Torsion [per 100 (3.94)] Limit 0.12 (0.0047)

Connecting rod small end inner diameter 30.080 - NISSAN ALMERA N16 2001 Electronic Manual PDF Connecting RodNJEM0083Unit: mm (in)

Center distance157.5 (6.201)

Bend [per 100 (3.94)] Limit 0.12 (0.0047)

Torsion [per 100 (3.94)] Limit 0.12 (0.0047)

Connecting rod small end inner diameter 30.080 -](/img/5/57351/w960_57351-245.png)

Connecting RodNJEM0083Unit: mm (in)

Center distance157.5 (6.201)

Bend [per 100 (3.94)] Limit 0.12 (0.0047)

Torsion [per 100 (3.94)] Limit 0.12 (0.0047)

Connecting rod small end inner diameter 30.080 - 31.000 (1.1842 - 1.2205)

Piston pin bushing inner diameter* 28.026 - 28.038 (1.1034 - 1.1039)

Connecting rod big end inner diameter 55.000 - 55.013 (2.1654 - 2.1659)

Side clearanceStandard 0.200 - 0.350 (0.0079 - 0.0138)

Limit 0.4 (0.016)

*: After installing in connecting rod

CrankshaftNJEM0084Unit: mm (in)

Main journal dia. ªDmº gradeGrade No. 0

Grade No. 1

Grade No. 262.967 - 62.975 (2.4790 - 2.4793)

62.959 - 62.967 (2.4787 - 2.4790)

62.951 - 62.959 (2.4784 - 2.4787)

Pin journal dia. ªDpºGrade No. 0 51.968 - 51.974 (2.0460 - 2.0462)

Grade No. 1 51.961 - 51.968 (2.0457 - 2.0460)

Grade No. 2 51.954 - 51.961 (2.0454 - 2.0457)

Center distance ªrº46.97 - 47.03 (1.8492 - 1.8516)

Out-of-round (X þ Y) Standard/Limit Less than 0.003 (0.0001)/Less than 0.005 (0.0002)

Taper (A þ B) Standard/Limit Less than 0.003 (0.0001)/Less than 0.005 (0.0002)

Runout [TIR*]Standard Less than 0.05 (0.0020)

Limit Less than 0.10 (0.0039)

Free end playStandard 0.10 - 0.25 (0.0039 - 0.0098)

Limit 0.30 (0.0118)

SEM645EM715

*: Total indicator reading

SERVICE DATA AND SPECIFICATIONS (SDS)YD

Connecting Rod

EM-168

Page 247 of 2493

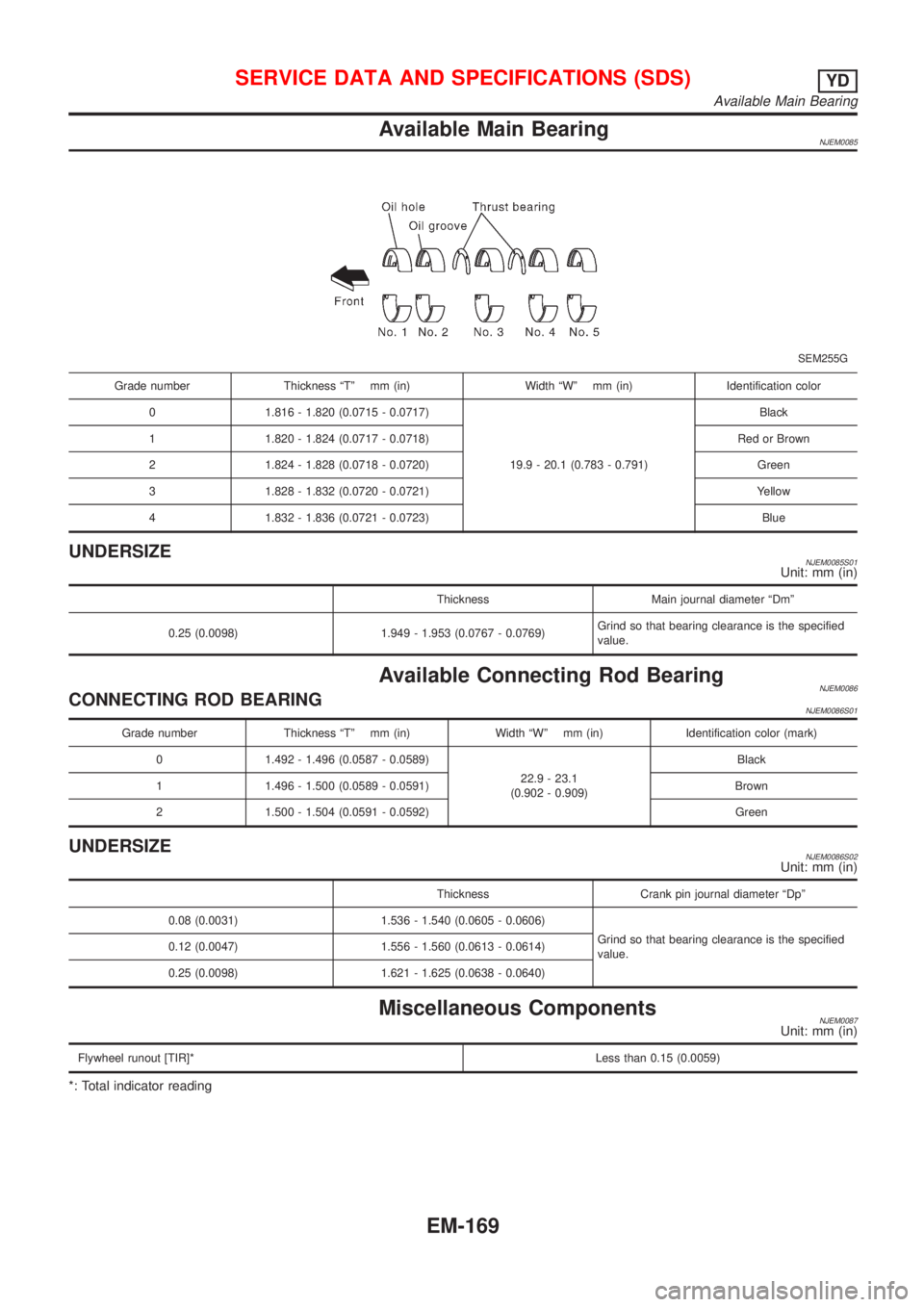

Available Main BearingNJEM0085

SEM255G

Grade number Thickness ªTº mm (in) Width ªWº mm (in) Identification color

0 1.816 - 1.820 (0.0715 - 0.0717)

19.9 - 20.1 (0.783 - 0.791)Black

1 1.820 - 1.824 (0.0717 - 0.0718) Red or Brown

2 1.824 - 1.828 (0.0718 - 0.0720) Green

3 1.828 - 1.832 (0.0720 - 0.0721) Yellow

4 1.832 - 1.836 (0.0721 - 0.0723) Blue

UNDERSIZENJEM0085S01Unit: mm (in)

Thickness Main journal diameter ªDmº

0.25 (0.0098) 1.949 - 1.953 (0.0767 - 0.0769)Grind so that bearing clearance is the specified

value.

Available Connecting Rod BearingNJEM0086CONNECTING ROD BEARINGNJEM0086S01

Grade number Thickness ªTº mm (in) Width ªWº mm (in) Identification color (mark)

0 1.492 - 1.496 (0.0587 - 0.0589)

22.9 - 23.1

(0.902 - 0.909)Black

1 1.496 - 1.500 (0.0589 - 0.0591) Brown

2 1.500 - 1.504 (0.0591 - 0.0592) Green

UNDERSIZENJEM0086S02Unit: mm (in)

Thickness Crank pin journal diameter ªDpº

0.08 (0.0031) 1.536 - 1.540 (0.0605 - 0.0606)

Grind so that bearing clearance is the specified

value. 0.12 (0.0047) 1.556 - 1.560 (0.0613 - 0.0614)

0.25 (0.0098) 1.621 - 1.625 (0.0638 - 0.0640)

Miscellaneous ComponentsNJEM0087Unit: mm (in)

Flywheel runout [TIR]*Less than 0.15 (0.0059)

*: Total indicator reading

SERVICE DATA AND SPECIFICATIONS (SDS)YD

Available Main Bearing

EM-169

Page 251 of 2493

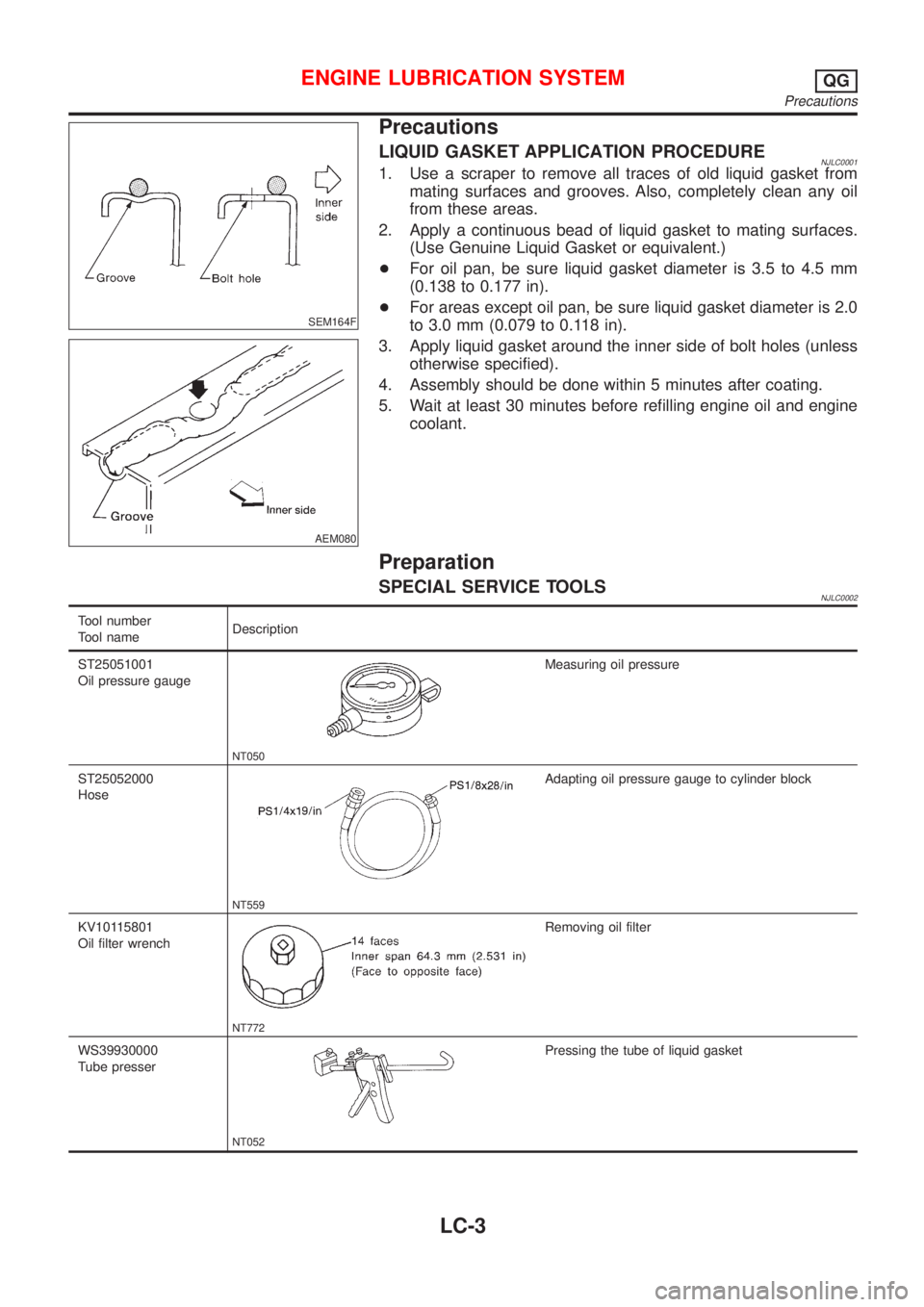

SEM164F

AEM080

Precautions

LIQUID GASKET APPLICATION PROCEDURENJLC00011. Use a scraper to remove all traces of old liquid gasket from

mating surfaces and grooves. Also, completely clean any oil

from these areas.

2. Apply a continuous bead of liquid gasket to mating surfaces.

(Use Genuine Liquid Gasket or equivalent.)

+For oil pan, be sure liquid gasket diameter is 3.5 to 4.5 mm

(0.138 to 0.177 in).

+For areas except oil pan, be sure liquid gasket diameter is 2.0

to 3.0 mm (0.079 to 0.118 in).

3. Apply liquid gasket around the inner side of bolt holes (unless

otherwise specified).

4. Assembly should be done within 5 minutes after coating.

5. Wait at least 30 minutes before refilling engine oil and engine

coolant.

Preparation

SPECIAL SERVICE TOOLSNJLC0002

Tool number

Tool nameDescription

ST25051001

Oil pressure gauge

NT050

Measuring oil pressure

ST25052000

Hose

NT559

Adapting oil pressure gauge to cylinder block

KV10115801

Oil filter wrench

NT772

Removing oil filter

WS39930000

Tube presser

NT052

Pressing the tube of liquid gasket

ENGINE LUBRICATION SYSTEMQG

Precautions

LC-3

Page 259 of 2493

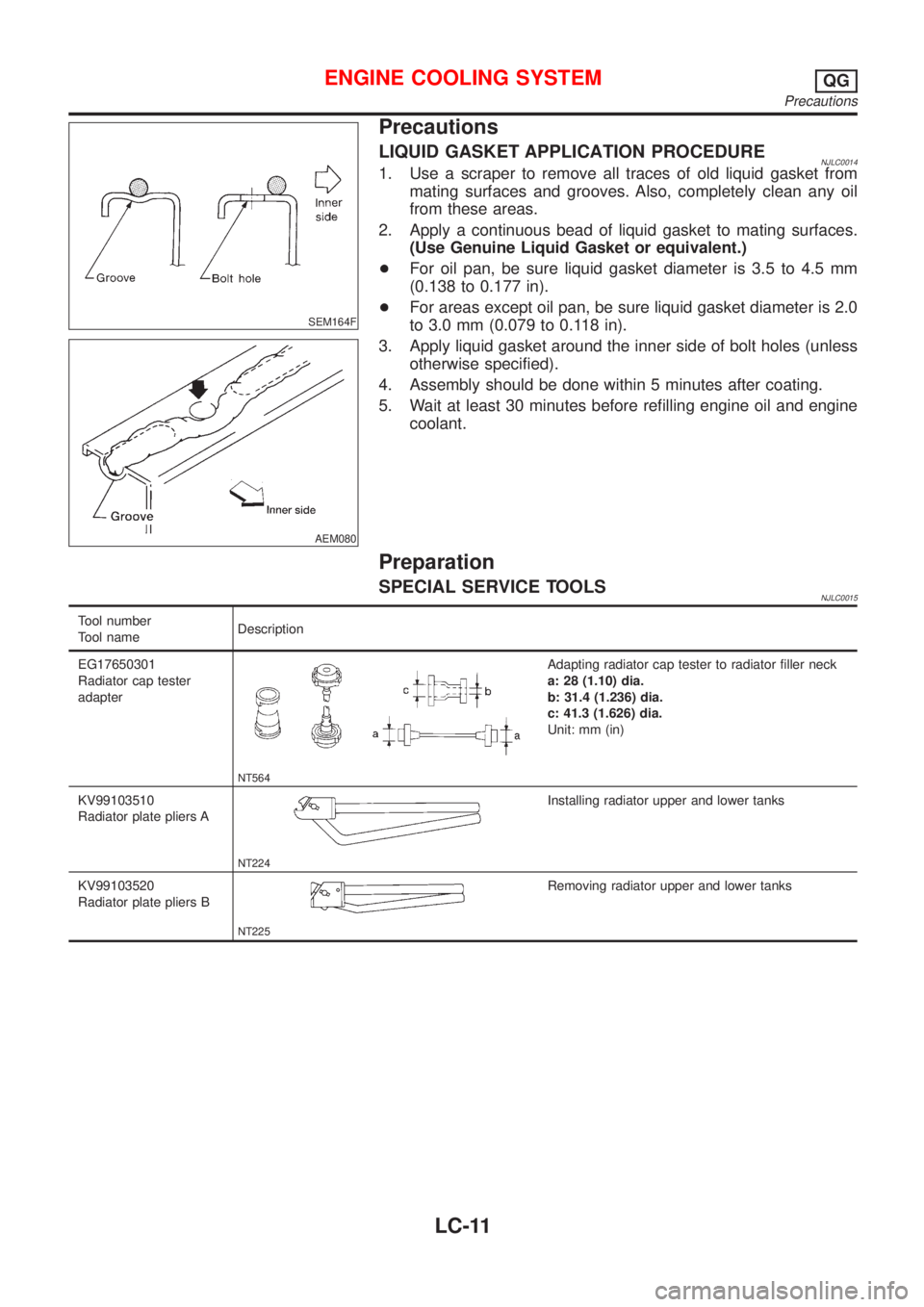

SEM164F

AEM080

Precautions

LIQUID GASKET APPLICATION PROCEDURENJLC00141. Use a scraper to remove all traces of old liquid gasket from

mating surfaces and grooves. Also, completely clean any oil

from these areas.

2. Apply a continuous bead of liquid gasket to mating surfaces.

(Use Genuine Liquid Gasket or equivalent.)

+For oil pan, be sure liquid gasket diameter is 3.5 to 4.5 mm

(0.138 to 0.177 in).

+For areas except oil pan, be sure liquid gasket diameter is 2.0

to 3.0 mm (0.079 to 0.118 in).

3. Apply liquid gasket around the inner side of bolt holes (unless

otherwise specified).

4. Assembly should be done within 5 minutes after coating.

5. Wait at least 30 minutes before refilling engine oil and engine

coolant.

Preparation

SPECIAL SERVICE TOOLSNJLC0015

Tool number

Tool nameDescription

EG17650301

Radiator cap tester

adapter

NT564

Adapting radiator cap tester to radiator filler neck

a: 28 (1.10) dia.

b: 31.4 (1.236) dia.

c: 41.3 (1.626) dia.

Unit: mm (in)

KV99103510

Radiator plate pliers A

NT224

Installing radiator upper and lower tanks

KV99103520

Radiator plate pliers B

NT225

Removing radiator upper and lower tanks

ENGINE COOLING SYSTEMQG

Precautions

LC-11

Page 273 of 2493

SEM164F

AEM080

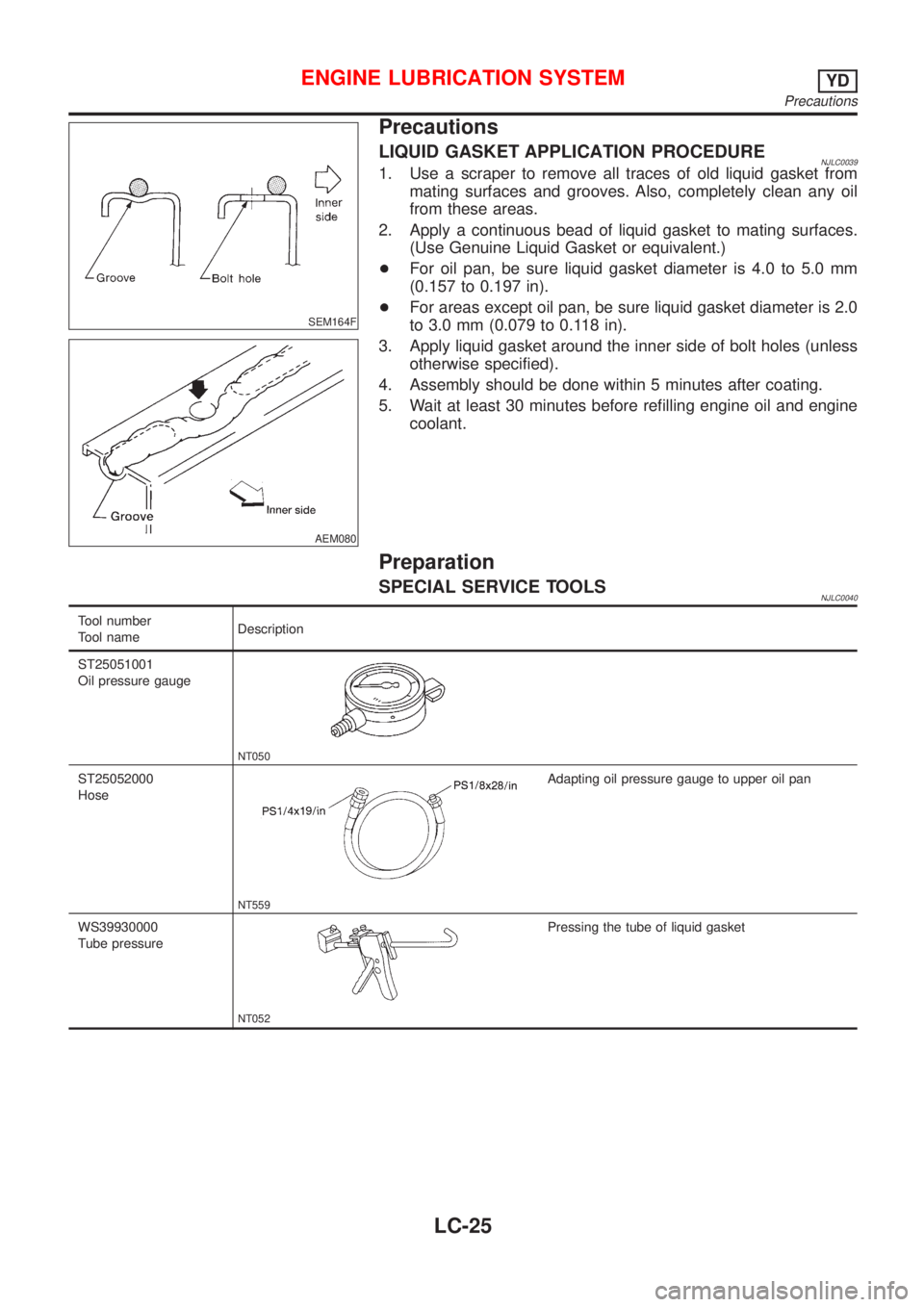

Precautions

LIQUID GASKET APPLICATION PROCEDURENJLC00391. Use a scraper to remove all traces of old liquid gasket from

mating surfaces and grooves. Also, completely clean any oil

from these areas.

2. Apply a continuous bead of liquid gasket to mating surfaces.

(Use Genuine Liquid Gasket or equivalent.)

+For oil pan, be sure liquid gasket diameter is 4.0 to 5.0 mm

(0.157 to 0.197 in).

+For areas except oil pan, be sure liquid gasket diameter is 2.0

to 3.0 mm (0.079 to 0.118 in).

3. Apply liquid gasket around the inner side of bolt holes (unless

otherwise specified).

4. Assembly should be done within 5 minutes after coating.

5. Wait at least 30 minutes before refilling engine oil and engine

coolant.

Preparation

SPECIAL SERVICE TOOLSNJLC0040

Tool number

Tool nameDescription

ST25051001

Oil pressure gauge

NT050

ST25052000

Hose

NT559

Adapting oil pressure gauge to upper oil pan

WS39930000

Tube pressure

NT052

Pressing the tube of liquid gasket

ENGINE LUBRICATION SYSTEMYD

Precautions

LC-25