Meter NISSAN ALMERA N16 2001 Electronic Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2001Pages: 2493, PDF Size: 66.97 MB

Page 136 of 2493

SEM588A

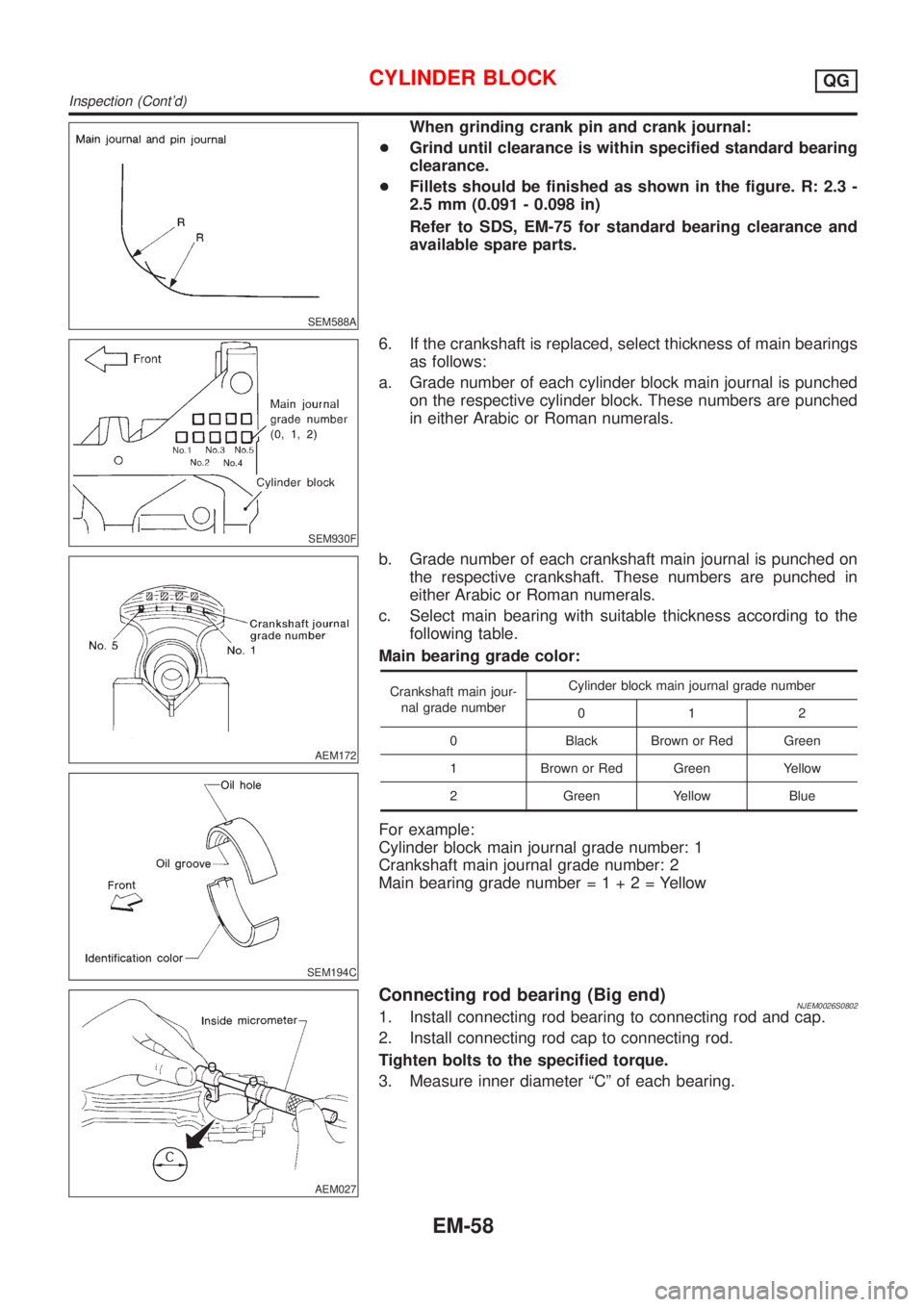

When grinding crank pin and crank journal:

+Grind until clearance is within specified standard bearing

clearance.

+Fillets should be finished as shown in the figure. R: 2.3 -

2.5 mm (0.091 - 0.098 in)

Refer to SDS, EM-75 for standard bearing clearance and

available spare parts.

SEM930F

6. If the crankshaft is replaced, select thickness of main bearings

as follows:

a. Grade number of each cylinder block main journal is punched

on the respective cylinder block. These numbers are punched

in either Arabic or Roman numerals.

AEM172

SEM194C

b. Grade number of each crankshaft main journal is punched on

the respective crankshaft. These numbers are punched in

either Arabic or Roman numerals.

c. Select main bearing with suitable thickness according to the

following table.

Main bearing grade color:

Crankshaft main jour-

nal grade numberCylinder block main journal grade number

012

0 Black Brown or Red Green

1 Brown or Red Green Yellow

2 Green Yellow Blue

For example:

Cylinder block main journal grade number: 1

Crankshaft main journal grade number: 2

Main bearing grade number=1+2=Yellow

AEM027

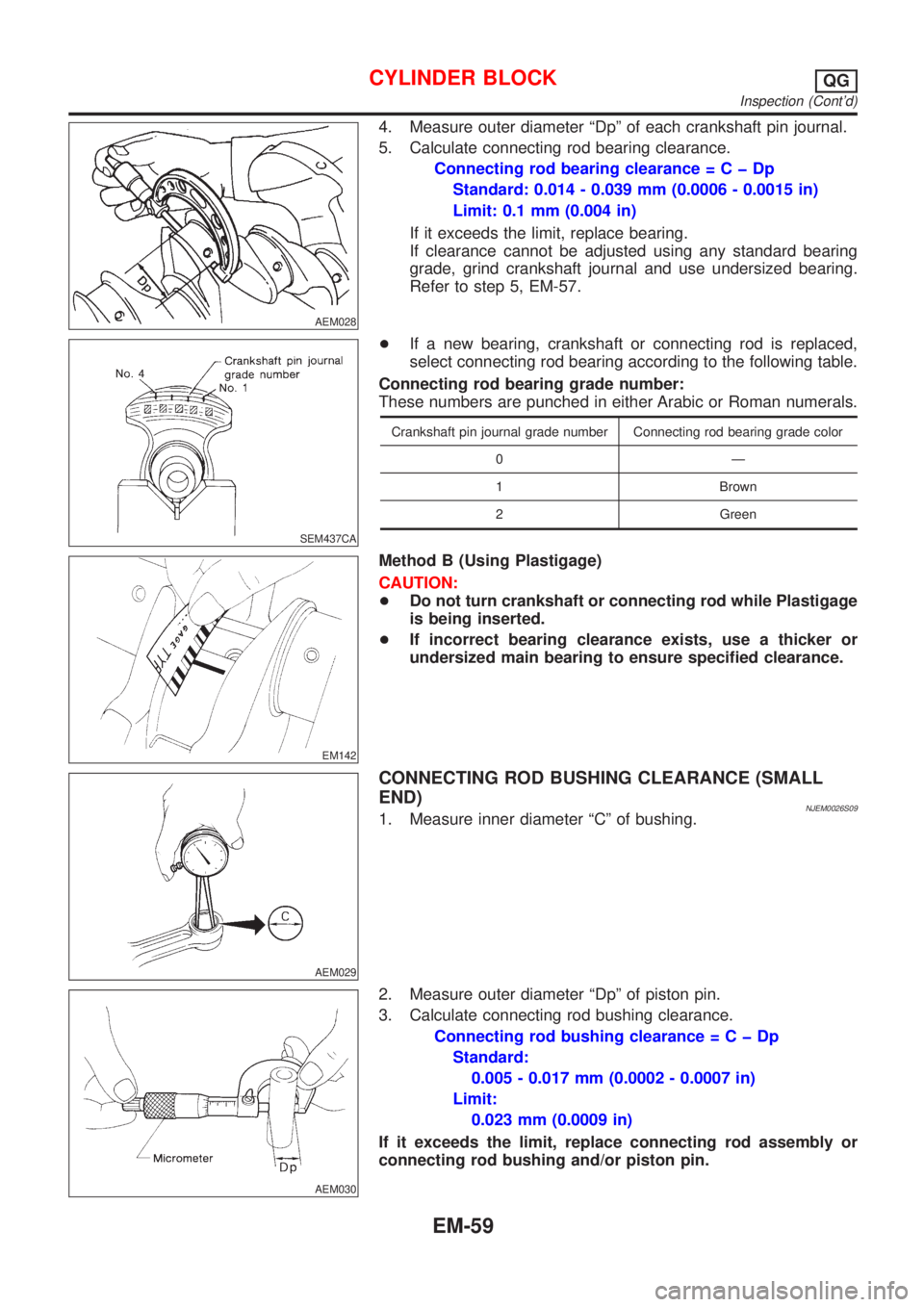

Connecting rod bearing (Big end)NJEM0026S08021. Install connecting rod bearing to connecting rod and cap.

2. Install connecting rod cap to connecting rod.

Tighten bolts to the specified torque.

3. Measure inner diameter ªCº of each bearing.

CYLINDER BLOCKQG

Inspection (Cont'd)

EM-58

Page 137 of 2493

AEM028

4. Measure outer diameter ªDpº of each crankshaft pin journal.

5. Calculate connecting rod bearing clearance.

Connecting rod bearing clearance=CþDp

Standard: 0.014 - 0.039 mm (0.0006 - 0.0015 in)

Limit: 0.1 mm (0.004 in)

If it exceeds the limit, replace bearing.

If clearance cannot be adjusted using any standard bearing

grade, grind crankshaft journal and use undersized bearing.

Refer to step 5, EM-57.

SEM437CA

+If a new bearing, crankshaft or connecting rod is replaced,

select connecting rod bearing according to the following table.

Connecting rod bearing grade number:

These numbers are punched in either Arabic or Roman numerals.

Crankshaft pin journal grade number Connecting rod bearing grade color

0Ð

1 Brown

2 Green

EM142

Method B (Using Plastigage)

CAUTION:

+Do not turn crankshaft or connecting rod while Plastigage

is being inserted.

+If incorrect bearing clearance exists, use a thicker or

undersized main bearing to ensure specified clearance.

AEM029

CONNECTING ROD BUSHING CLEARANCE (SMALL

END)

NJEM0026S091. Measure inner diameter ªCº of bushing.

AEM030

2. Measure outer diameter ªDpº of piston pin.

3. Calculate connecting rod bushing clearance.

Connecting rod bushing clearance=CþDp

Standard:

0.005 - 0.017 mm (0.0002 - 0.0007 in)

Limit:

0.023 mm (0.0009 in)

If it exceeds the limit, replace connecting rod assembly or

connecting rod bushing and/or piston pin.

CYLINDER BLOCKQG

Inspection (Cont'd)

EM-59

Page 144 of 2493

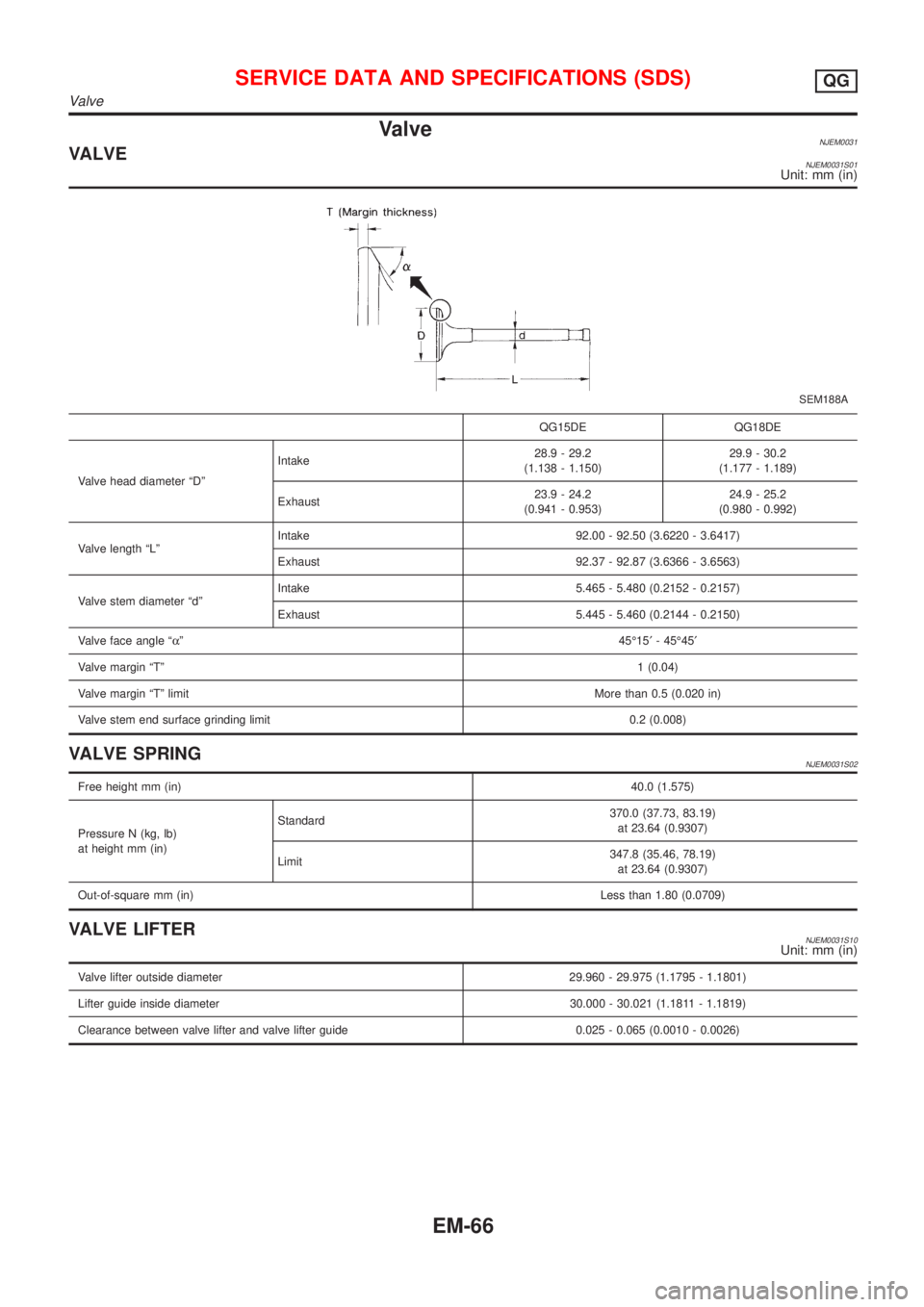

ValveNJEM0031VALVENJEM0031S01Unit: mm (in)

SEM188A

QG15DE QG18DE

Valve head diameter ªDºIntake28.9 - 29.2

(1.138 - 1.150)29.9 - 30.2

(1.177 - 1.189)

Exhaust23.9 - 24.2

(0.941 - 0.953)24.9 - 25.2

(0.980 - 0.992)

Valve length ªLºIntake 92.00 - 92.50 (3.6220 - 3.6417)

Exhaust 92.37 - 92.87 (3.6366 - 3.6563)

Valve stem diameter ªdºIntake 5.465 - 5.480 (0.2152 - 0.2157)

Exhaust 5.445 - 5.460 (0.2144 - 0.2150)

Valve face angle ªaº45É15¢- 45É45¢

Valve margin ªTº1 (0.04)

Valve margin ªTº limitMore than 0.5 (0.020 in)

Valve stem end surface grinding limit 0.2 (0.008)

VALVE SPRINGNJEM0031S02

Free height mm (in)40.0 (1.575)

Pressure N (kg, lb)

at height mm (in)Standard370.0 (37.73, 83.19)

at 23.64 (0.9307)

Limit347.8 (35.46, 78.19)

at 23.64 (0.9307)

Out-of-square mm (in)Less than 1.80 (0.0709)

VALVE LIFTERNJEM0031S10Unit: mm (in)

Valve lifter outside diameter 29.960 - 29.975 (1.1795 - 1.1801)

Lifter guide inside diameter 30.000 - 30.021 (1.1811 - 1.1819)

Clearance between valve lifter and valve lifter guide 0.025 - 0.065 (0.0010 - 0.0026)

SERVICE DATA AND SPECIFICATIONS (SDS)QG

Valve

EM-66

Page 145 of 2493

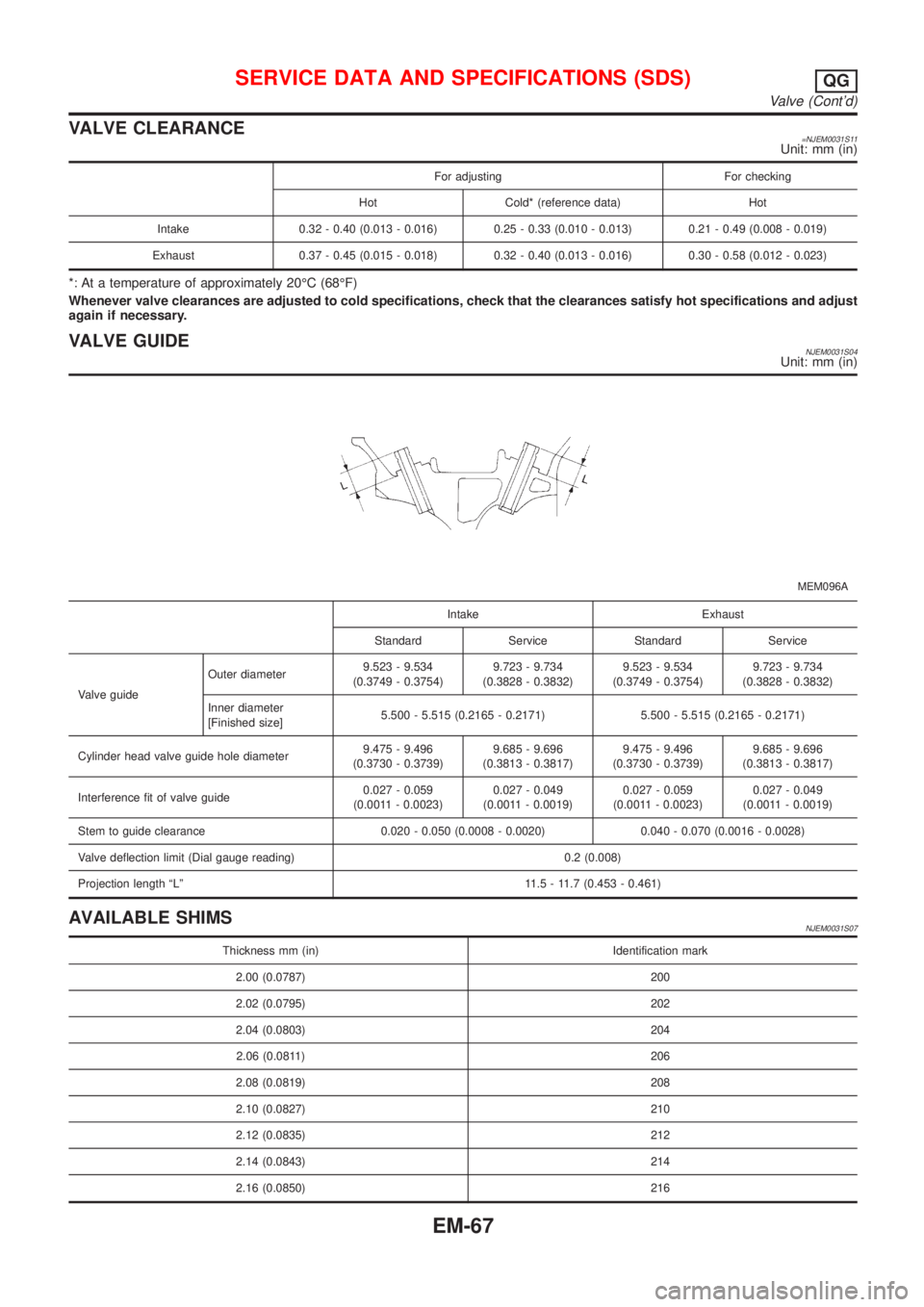

VALVE CLEARANCE=NJEM0031S11Unit: mm (in)

For adjusting For checking

Hot Cold* (reference data) Hot

Intake 0.32 - 0.40 (0.013 - 0.016) 0.25 - 0.33 (0.010 - 0.013) 0.21 - 0.49 (0.008 - 0.019)

Exhaust 0.37 - 0.45 (0.015 - 0.018) 0.32 - 0.40 (0.013 - 0.016) 0.30 - 0.58 (0.012 - 0.023)

*: At a temperature of approximately 20ÉC (68ÉF)

Whenever valve clearances are adjusted to cold specifications, check that the clearances satisfy hot specifications and adjust

again if necessary.

VALVE GUIDENJEM0031S04Unit: mm (in)

MEM096A

Intake Exhaust

Standard Service Standard Service

Valve guideOuter diameter9.523 - 9.534

(0.3749 - 0.3754)9.723 - 9.734

(0.3828 - 0.3832)9.523 - 9.534

(0.3749 - 0.3754)9.723 - 9.734

(0.3828 - 0.3832)

Inner diameter

[Finished size]5.500 - 5.515 (0.2165 - 0.2171) 5.500 - 5.515 (0.2165 - 0.2171)

Cylinder head valve guide hole diameter9.475 - 9.496

(0.3730 - 0.3739)9.685 - 9.696

(0.3813 - 0.3817)9.475 - 9.496

(0.3730 - 0.3739)9.685 - 9.696

(0.3813 - 0.3817)

Interference fit of valve guide0.027 - 0.059

(0.0011 - 0.0023)0.027 - 0.049

(0.0011 - 0.0019)0.027 - 0.059

(0.0011 - 0.0023)0.027 - 0.049

(0.0011 - 0.0019)

Stem to guide clearance 0.020 - 0.050 (0.0008 - 0.0020) 0.040 - 0.070 (0.0016 - 0.0028)

Valve deflection limit (Dial gauge reading) 0.2 (0.008)

Projection length ªLº 11.5 - 11.7 (0.453 - 0.461)

AVAILABLE SHIMSNJEM0031S07

Thickness mm (in) Identification mark

2.00 (0.0787) 200

2.02 (0.0795) 202

2.04 (0.0803) 204

2.06 (0.0811) 206

2.08 (0.0819) 208

2.10 (0.0827) 210

2.12 (0.0835) 212

2.14 (0.0843) 214

2.16 (0.0850) 216

SERVICE DATA AND SPECIFICATIONS (SDS)QG

Valve (Cont'd)

EM-67

Page 149 of 2493

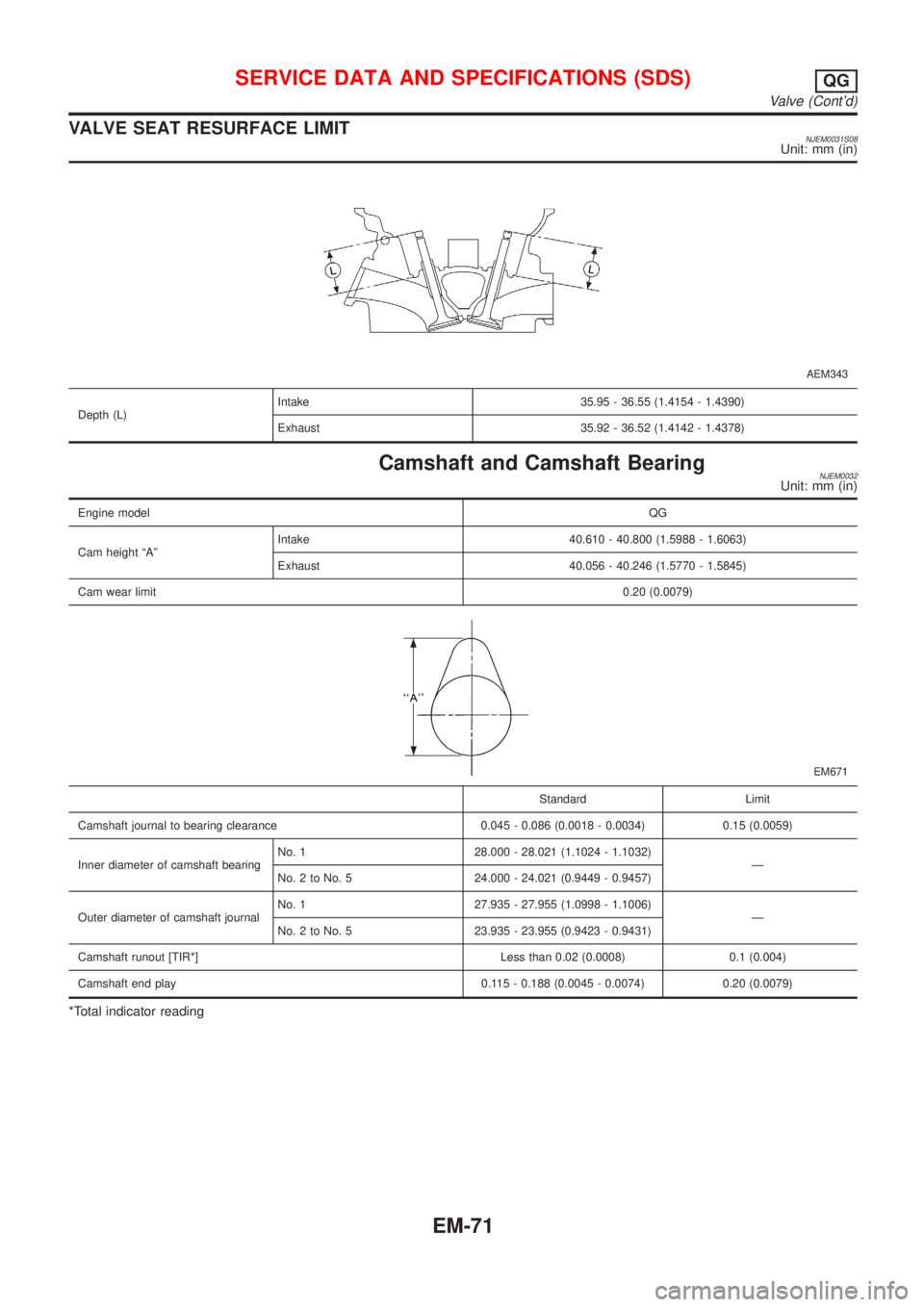

VALVE SEAT RESURFACE LIMITNJEM0031S08Unit: mm (in)

AEM343

Depth (L)Intake 35.95 - 36.55 (1.4154 - 1.4390)

Exhaust 35.92 - 36.52 (1.4142 - 1.4378)

Camshaft and Camshaft BearingNJEM0032Unit: mm (in)

Engine modelQG

Cam height ªAºIntake 40.610 - 40.800 (1.5988 - 1.6063)

Exhaust 40.056 - 40.246 (1.5770 - 1.5845)

Cam wear limit0.20 (0.0079)

EM671

Standard Limit

Camshaft journal to bearing clearance 0.045 - 0.086 (0.0018 - 0.0034) 0.15 (0.0059)

Inner diameter of camshaft bearingNo. 1 28.000 - 28.021 (1.1024 - 1.1032)

Ð

No. 2 to No. 5 24.000 - 24.021 (0.9449 - 0.9457)

Outer diameter of camshaft journalNo. 1 27.935 - 27.955 (1.0998 - 1.1006)

Ð

No. 2 to No. 5 23.935 - 23.955 (0.9423 - 0.9431)

Camshaft runout [TIR*] Less than 0.02 (0.0008) 0.1 (0.004)

Camshaft end play 0.115 - 0.188 (0.0045 - 0.0074) 0.20 (0.0079)

*Total indicator reading

SERVICE DATA AND SPECIFICATIONS (SDS)QG

Valve (Cont'd)

EM-71

Page 150 of 2493

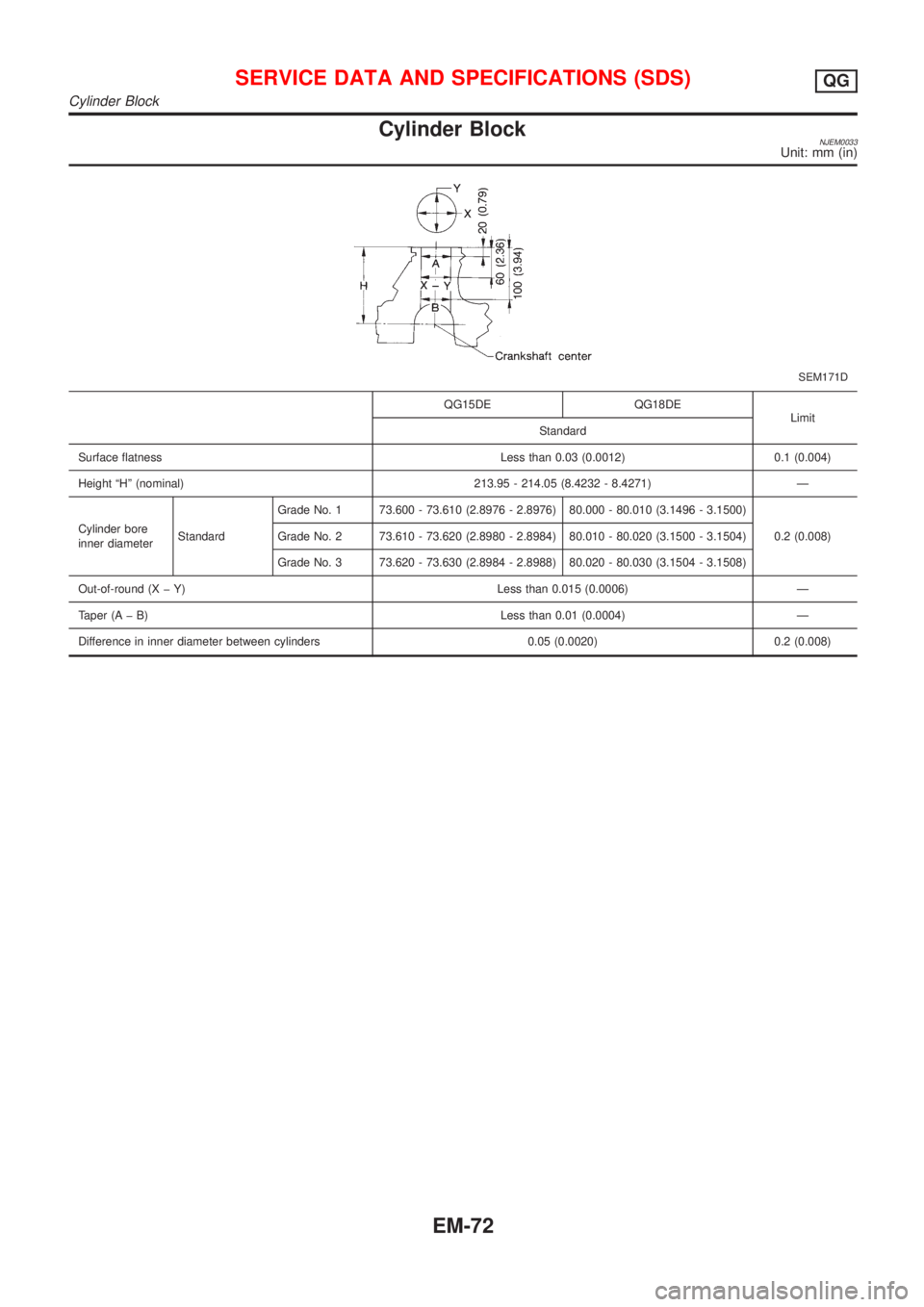

Cylinder BlockNJEM0033Unit: mm (in)

SEM171D

QG15DE QG18DE

Limit

Standard

Surface flatness Less than 0.03 (0.0012) 0.1 (0.004)

Height ªHº (nominal) 213.95 - 214.05 (8.4232 - 8.4271) Ð

Cylinder bore

inner diameterStandardGrade No. 1 73.600 - 73.610 (2.8976 - 2.8976) 80.000 - 80.010 (3.1496 - 3.1500)

0.2 (0.008) Grade No. 2 73.610 - 73.620 (2.8980 - 2.8984) 80.010 - 80.020 (3.1500 - 3.1504)

Grade No. 3 73.620 - 73.630 (2.8984 - 2.8988) 80.020 - 80.030 (3.1504 - 3.1508)

Out-of-round (X þ Y) Less than 0.015 (0.0006) Ð

Taper (A þ B) Less than 0.01 (0.0004) Ð

Difference in inner diameter between cylinders 0.05 (0.0020) 0.2 (0.008)

SERVICE DATA AND SPECIFICATIONS (SDS)QG

Cylinder Block

EM-72

Page 151 of 2493

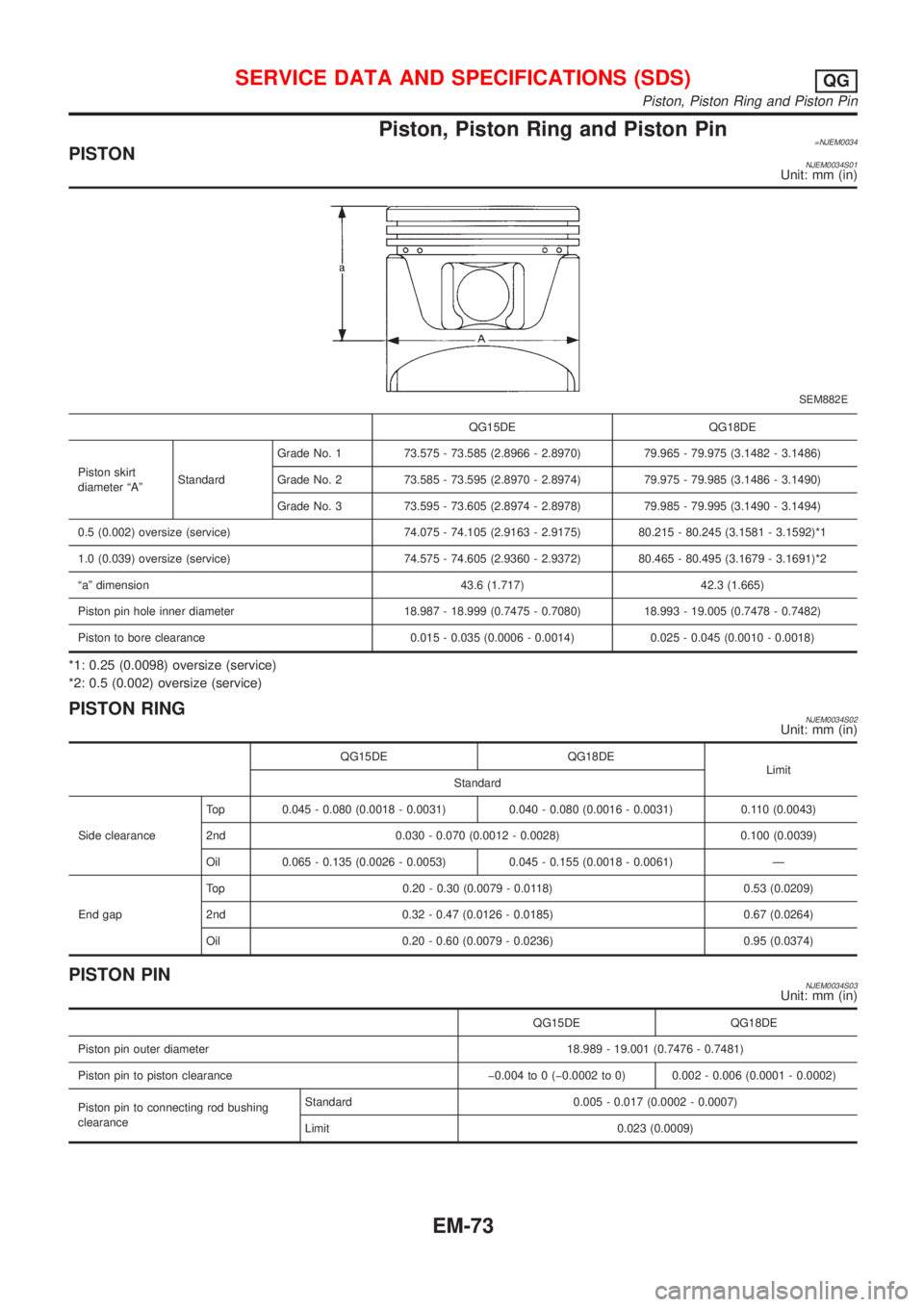

Piston, Piston Ring and Piston Pin=NJEM0034PISTONNJEM0034S01Unit: mm (in)

SEM882E

QG15DE QG18DE

Piston skirt

diameter ªAºStandardGrade No. 1 73.575 - 73.585 (2.8966 - 2.8970) 79.965 - 79.975 (3.1482 - 3.1486)

Grade No. 2 73.585 - 73.595 (2.8970 - 2.8974) 79.975 - 79.985 (3.1486 - 3.1490)

Grade No. 3 73.595 - 73.605 (2.8974 - 2.8978) 79.985 - 79.995 (3.1490 - 3.1494)

0.5 (0.002) oversize (service) 74.075 - 74.105 (2.9163 - 2.9175) 80.215 - 80.245 (3.1581 - 3.1592)*1

1.0 (0.039) oversize (service) 74.575 - 74.605 (2.9360 - 2.9372) 80.465 - 80.495 (3.1679 - 3.1691)*2

ªaº dimension 43.6 (1.717) 42.3 (1.665)

Piston pin hole inner diameter 18.987 - 18.999 (0.7475 - 0.7080) 18.993 - 19.005 (0.7478 - 0.7482)

Piston to bore clearance 0.015 - 0.035 (0.0006 - 0.0014) 0.025 - 0.045 (0.0010 - 0.0018)

*1: 0.25 (0.0098) oversize (service)

*2: 0.5 (0.002) oversize (service)

PISTON RINGNJEM0034S02Unit: mm (in)

QG15DE QG18DE

Limit

Standard

Side clearanceTop 0.045 - 0.080 (0.0018 - 0.0031) 0.040 - 0.080 (0.0016 - 0.0031) 0.110 (0.0043)

2nd 0.030 - 0.070 (0.0012 - 0.0028) 0.100 (0.0039)

Oil 0.065 - 0.135 (0.0026 - 0.0053) 0.045 - 0.155 (0.0018 - 0.0061) Ð

End gapTop 0.20 - 0.30 (0.0079 - 0.0118) 0.53 (0.0209)

2nd 0.32 - 0.47 (0.0126 - 0.0185) 0.67 (0.0264)

Oil 0.20 - 0.60 (0.0079 - 0.0236) 0.95 (0.0374)

PISTON PINNJEM0034S03Unit: mm (in)

QG15DE QG18DE

Piston pin outer diameter 18.989 - 19.001 (0.7476 - 0.7481)

Piston pin to piston clearance þ0.004 to 0 (þ0.0002 to 0) 0.002 - 0.006 (0.0001 - 0.0002)

Piston pin to connecting rod bushing

clearanceStandard 0.005 - 0.017 (0.0002 - 0.0007)

Limit 0.023 (0.0009)

SERVICE DATA AND SPECIFICATIONS (SDS)QG

Piston, Piston Ring and Piston Pin

EM-73

Page 152 of 2493

![NISSAN ALMERA N16 2001 Electronic Owners Guide Connecting RodNJEM0035Unit: mm (in)

Center distance140.45 - 140.55 (5.5295 - 5.5335)

Bend limit [per 100 (3.94)]0.15 (0.0059)

Torsion limit [per 100 (3.94)]0.3 (0.012)

Connecting rod bushing inner dia NISSAN ALMERA N16 2001 Electronic Owners Guide Connecting RodNJEM0035Unit: mm (in)

Center distance140.45 - 140.55 (5.5295 - 5.5335)

Bend limit [per 100 (3.94)]0.15 (0.0059)

Torsion limit [per 100 (3.94)]0.3 (0.012)

Connecting rod bushing inner dia](/img/5/57351/w960_57351-151.png)

Connecting RodNJEM0035Unit: mm (in)

Center distance140.45 - 140.55 (5.5295 - 5.5335)

Bend limit [per 100 (3.94)]0.15 (0.0059)

Torsion limit [per 100 (3.94)]0.3 (0.012)

Connecting rod bushing inner diameter* (small end) 19.000 - 19.012 (0.7480 - 0.7485)

Connecting rod big end inner diameter 43.000 - 43.013 (1.6929 - 1.6934)

Side clearanceStandard 0.200 - 0.470 (0.0079 - 0.0185)

Limit 0.5 (0.020)

*After installing in connecting rod

CrankshaftNJEM0036Unit: mm (in)

Main journal dia. ªDmºGrade No. 0 49.956 - 49.964 (1.9668 - 1.9671)

Grade No. 1 49.948 - 49.956 (1.9665 - 1.9668)

Grade No. 2 49.940 - 49.948 (1.9661 - 1.9665)

Pin journal dia. ªDpºGrade No. 0 39.968 - 39.974 (1.5735 - 1.5738)

Grade No. 1 39.962 - 39.968 (1.5733 - 1.5735)

Grade No. 2 39.956 - 39.962 (1.5731 - 1.5733)

Center distance ªrº43.95 - 44.05 (1.7303 - 1.7342)

Out-of-round (X þ Y)Standard Less than 0.003 (0.0001)

Limit Less than 0.005 (0.0002)

Taper (A þ B)Standard Less than 0.004 (0.0002)

Limit Less than 0.005 (0.0002)

Runout [TIR*]Standard Less than 0.04 (0.0016)

Limit Less than 0.05 (0.0020)

Free end playStandard 0.060 - 0.260 (0.0024 - 0.0102)

Limit 0.3 (0.012)

*: Total indicator reading

Main BearingNJEM0037STANDARDNJEM0037S01

Grade No. Thickness ªTº mm (in) Identification color

0 1.826 - 1.830 (0.0719 - 0.0720) Black

1 1.830 - 1.834 (0.0720 - 0.0722) Red

2 1.834 - 1.838 (0.0722 - 0.0724) Green

3 1.838 - 1.842 (0.0724 - 0.0725) Yellow

4 1.842 - 1.846 (0.0725 - 0.0727) Blue

UNDERSIZENJEM0037S02Unit: mm (in)

Thickness ªTº

0.25 (0.0098) 1.960 - 1.964 (0.0772 - 0.0773)

0.50 (0.0197) 2.085 - 2.089 (0.0821 - 0.0822)

SERVICE DATA AND SPECIFICATIONS (SDS)QG

Connecting Rod

EM-74

Page 154 of 2493

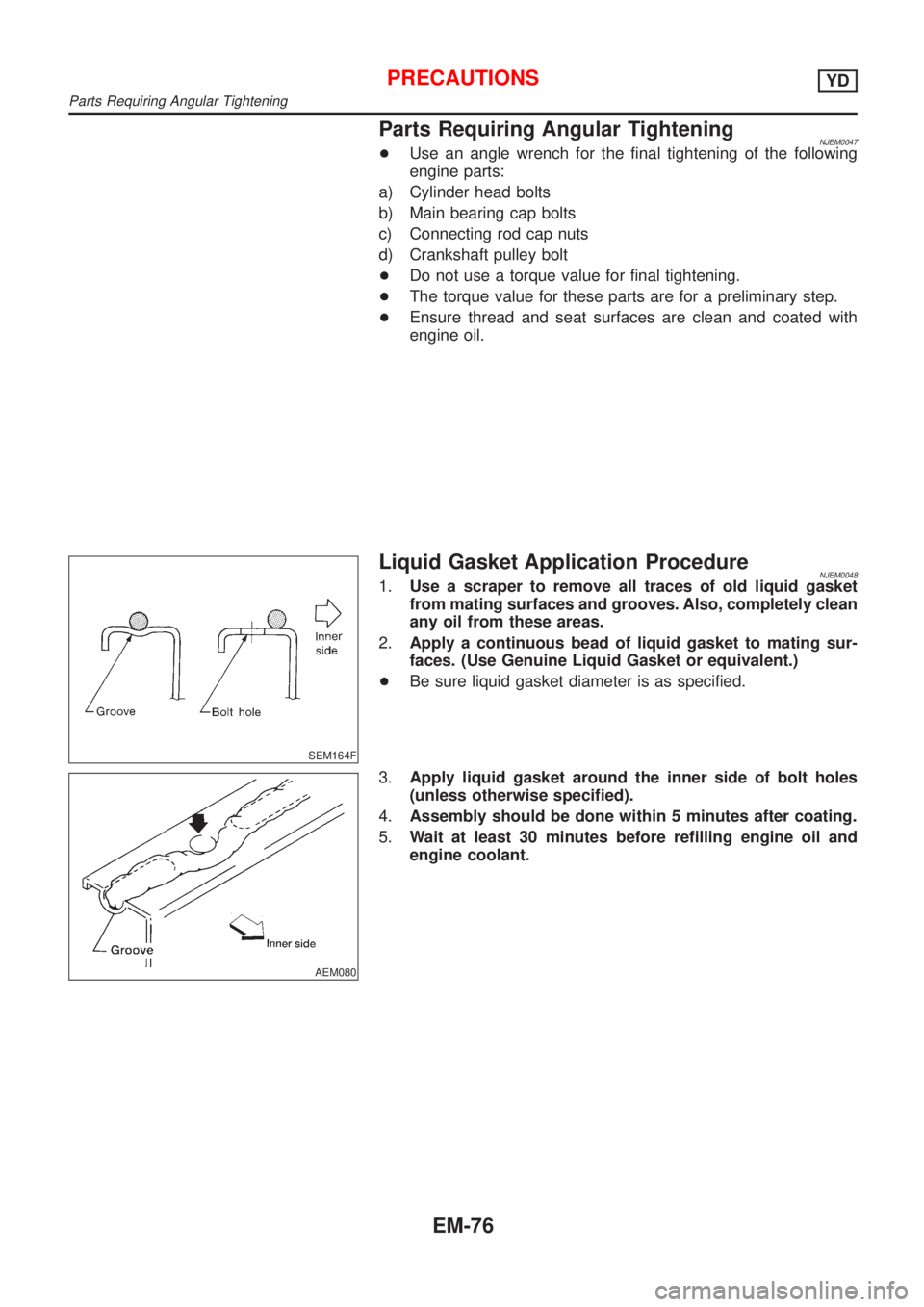

Parts Requiring Angular TighteningNJEM0047+Use an angle wrench for the final tightening of the following

engine parts:

a) Cylinder head bolts

b) Main bearing cap bolts

c) Connecting rod cap nuts

d) Crankshaft pulley bolt

+Do not use a torque value for final tightening.

+The torque value for these parts are for a preliminary step.

+Ensure thread and seat surfaces are clean and coated with

engine oil.

SEM164F

Liquid Gasket Application ProcedureNJEM00481.Use a scraper to remove all traces of old liquid gasket

from mating surfaces and grooves. Also, completely clean

any oil from these areas.

2.Apply a continuous bead of liquid gasket to mating sur-

faces. (Use Genuine Liquid Gasket or equivalent.)

+Be sure liquid gasket diameter is as specified.

AEM080

3.Apply liquid gasket around the inner side of bolt holes

(unless otherwise specified).

4.Assembly should be done within 5 minutes after coating.

5.Wait at least 30 minutes before refilling engine oil and

engine coolant.

PRECAUTIONSYD

Parts Requiring Angular Tightening

EM-76

Page 168 of 2493

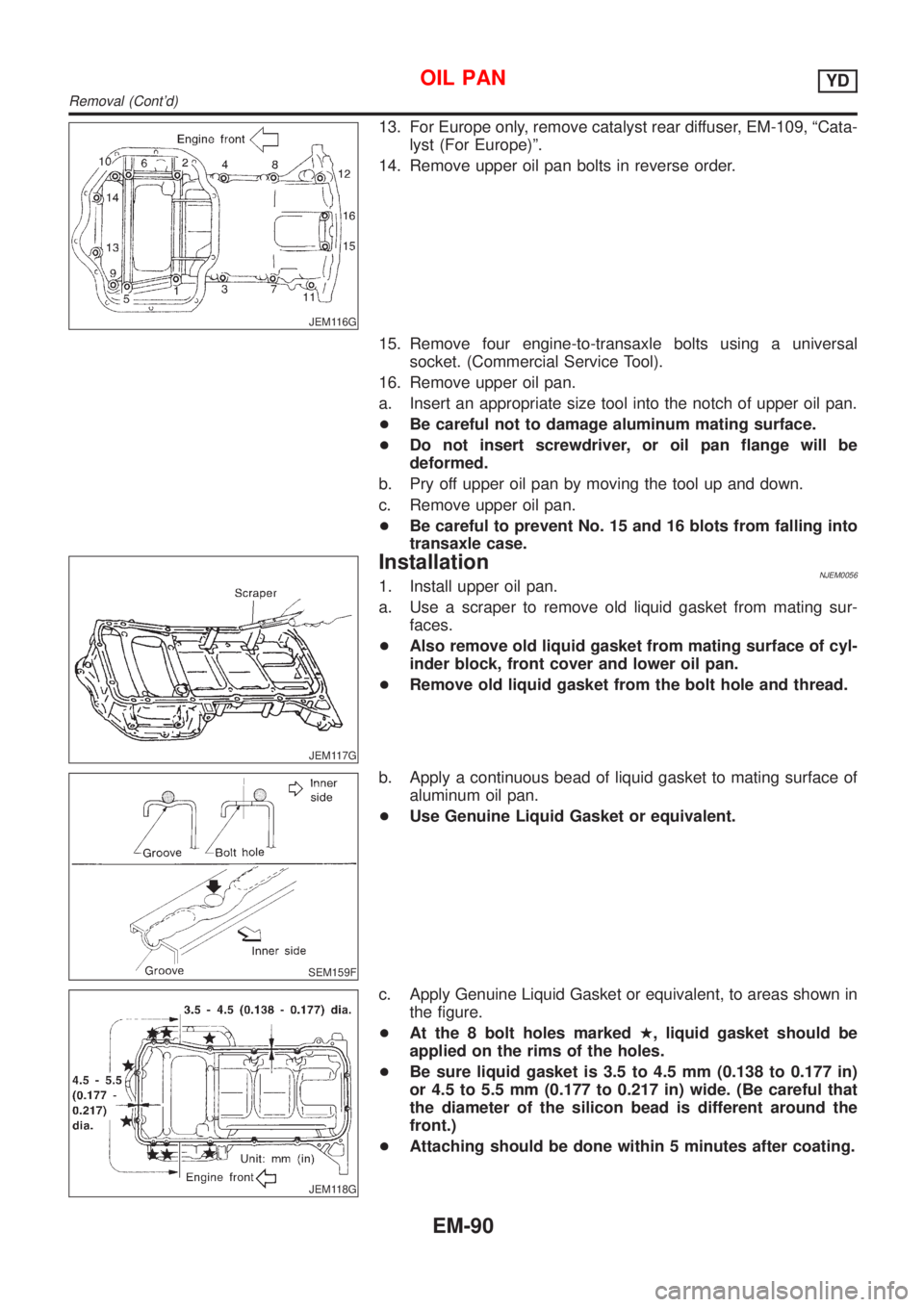

JEM116G

13. For Europe only, remove catalyst rear diffuser, EM-109, ªCata-

lyst (For Europe)º.

14. Remove upper oil pan bolts in reverse order.

15. Remove four engine-to-transaxle bolts using a universal

socket. (Commercial Service Tool).

16. Remove upper oil pan.

a. Insert an appropriate size tool into the notch of upper oil pan.

+Be careful not to damage aluminum mating surface.

+Do not insert screwdriver, or oil pan flange will be

deformed.

b. Pry off upper oil pan by moving the tool up and down.

c. Remove upper oil pan.

+Be careful to prevent No. 15 and 16 blots from falling into

transaxle case.

JEM117G

InstallationNJEM00561. Install upper oil pan.

a. Use a scraper to remove old liquid gasket from mating sur-

faces.

+Also remove old liquid gasket from mating surface of cyl-

inder block, front cover and lower oil pan.

+Remove old liquid gasket from the bolt hole and thread.

SEM159F

b. Apply a continuous bead of liquid gasket to mating surface of

aluminum oil pan.

+Use Genuine Liquid Gasket or equivalent.

JEM118G

c. Apply Genuine Liquid Gasket or equivalent, to areas shown in

the figure.

+At the 8 bolt holes markedH, liquid gasket should be

applied on the rims of the holes.

+Be sure liquid gasket is 3.5 to 4.5 mm (0.138 to 0.177 in)

or 4.5 to 5.5 mm (0.177 to 0.217 in) wide. (Be careful that

the diameter of the silicon bead is different around the

front.)

+Attaching should be done within 5 minutes after coating.

OIL PANYD

Removal (Cont'd)

EM-90