NISSAN ALMERA N16 2001 Electronic Repair Manual

Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2001Pages: 2493, PDF Size: 66.97 MB

Page 691 of 2493

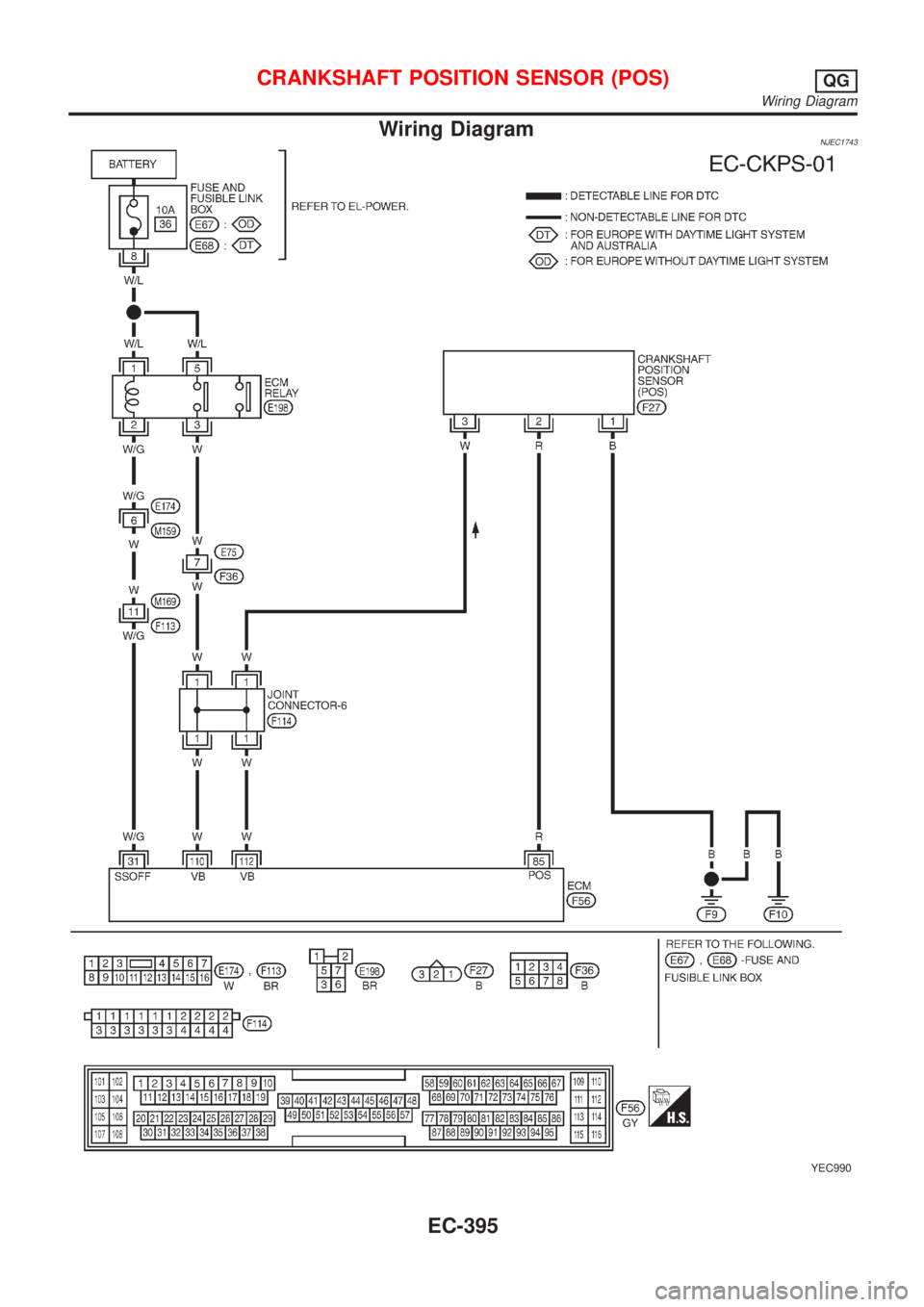

Wiring DiagramNJEC1743

YEC990

CRANKSHAFT POSITION SENSOR (POS)QG

Wiring Diagram

EC-395

Page 692 of 2493

Diagnostic ProcedureNJEC1744

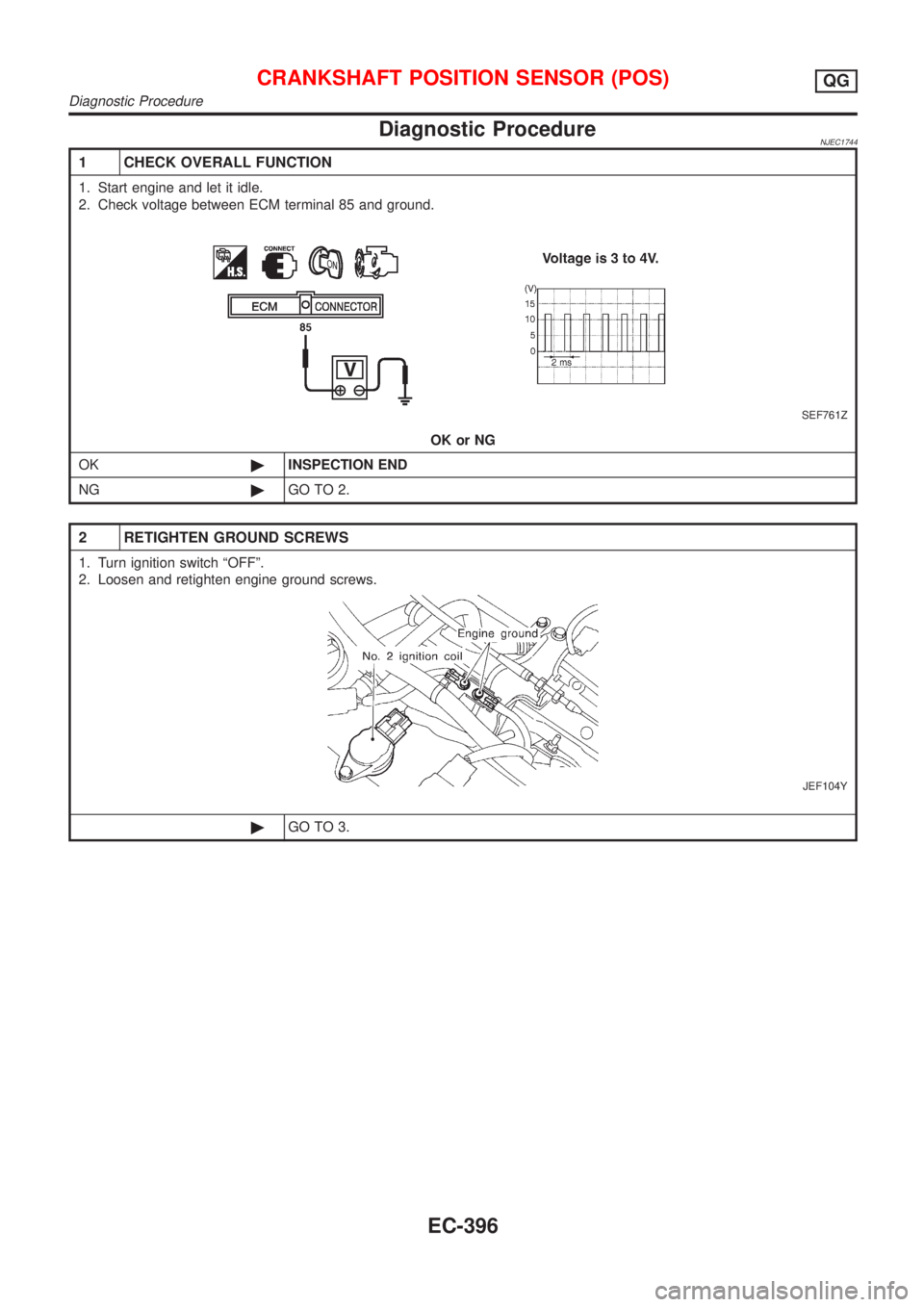

1 CHECK OVERALL FUNCTION

1. Start engine and let it idle.

2. Check voltage between ECM terminal 85 and ground.

SEF761Z

OK or NG

OK©INSPECTION END

NG©GO TO 2.

2 RETIGHTEN GROUND SCREWS

1. Turn ignition switch ªOFFº.

2. Loosen and retighten engine ground screws.

JEF104Y

©GO TO 3.

CRANKSHAFT POSITION SENSOR (POS)QG

Diagnostic Procedure

EC-396

Page 693 of 2493

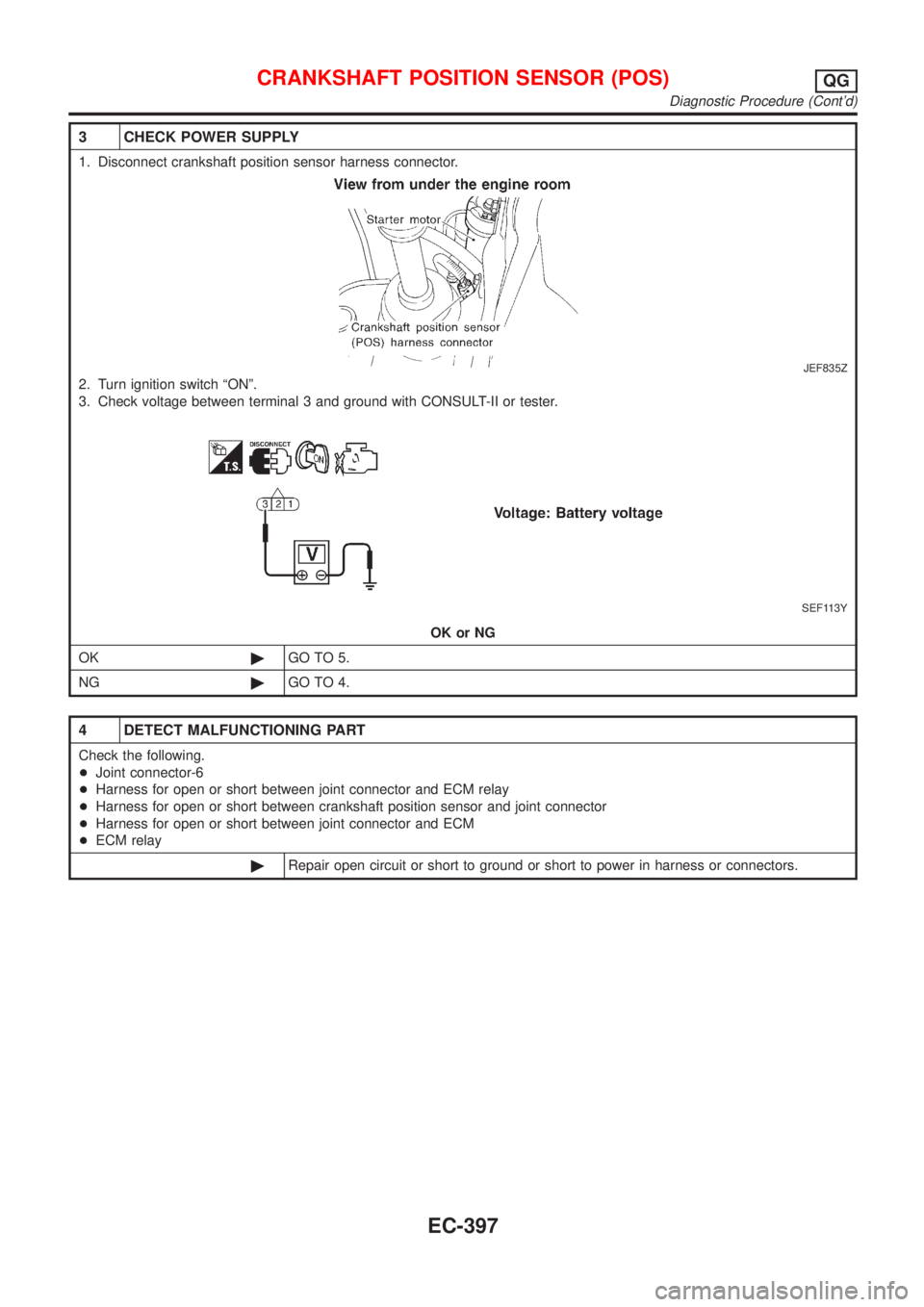

3 CHECK POWER SUPPLY

1. Disconnect crankshaft position sensor harness connector.

JEF835Z

2. Turn ignition switch ªONº.

3. Check voltage between terminal 3 and ground with CONSULT-II or tester.

SEF113Y

OK or NG

OK©GO TO 5.

NG©GO TO 4.

4 DETECT MALFUNCTIONING PART

Check the following.

+Joint connector-6

+Harness for open or short between joint connector and ECM relay

+Harness for open or short between crankshaft position sensor and joint connector

+Harness for open or short between joint connector and ECM

+ECM relay

©Repair open circuit or short to ground or short to power in harness or connectors.

CRANKSHAFT POSITION SENSOR (POS)QG

Diagnostic Procedure (Cont'd)

EC-397

Page 694 of 2493

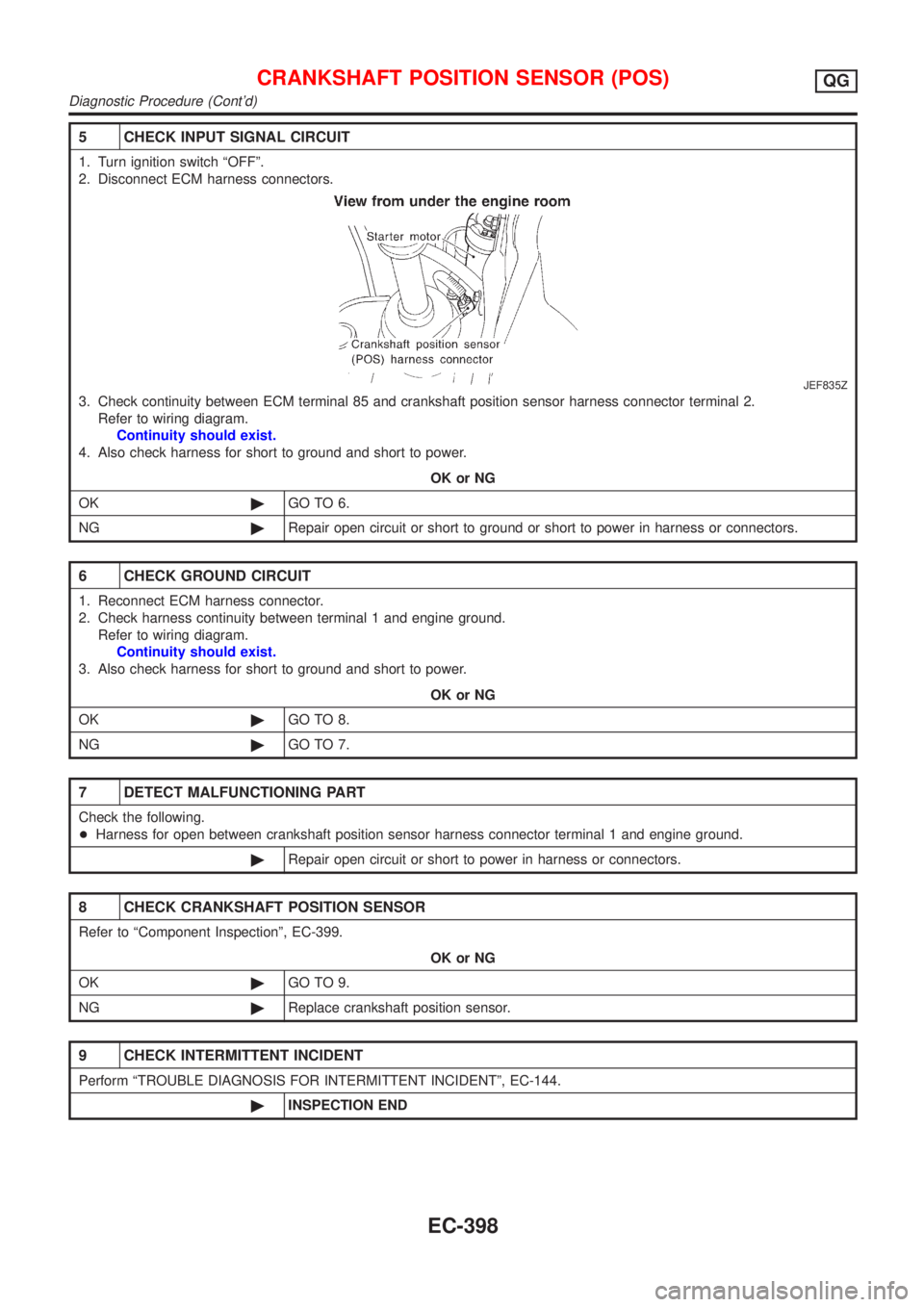

5 CHECK INPUT SIGNAL CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connectors.

JEF835Z

3. Check continuity between ECM terminal 85 and crankshaft position sensor harness connector terminal 2.

Refer to wiring diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 6.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

6 CHECK GROUND CIRCUIT

1. Reconnect ECM harness connector.

2. Check harness continuity between terminal 1 and engine ground.

Refer to wiring diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 8.

NG©GO TO 7.

7 DETECT MALFUNCTIONING PART

Check the following.

+Harness for open between crankshaft position sensor harness connector terminal 1 and engine ground.

©Repair open circuit or short to power in harness or connectors.

8 CHECK CRANKSHAFT POSITION SENSOR

Refer to ªComponent Inspectionº, EC-399.

OK or NG

OK©GO TO 9.

NG©Replace crankshaft position sensor.

9 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-144.

©INSPECTION END

CRANKSHAFT POSITION SENSOR (POS)QG

Diagnostic Procedure (Cont'd)

EC-398

Page 695 of 2493

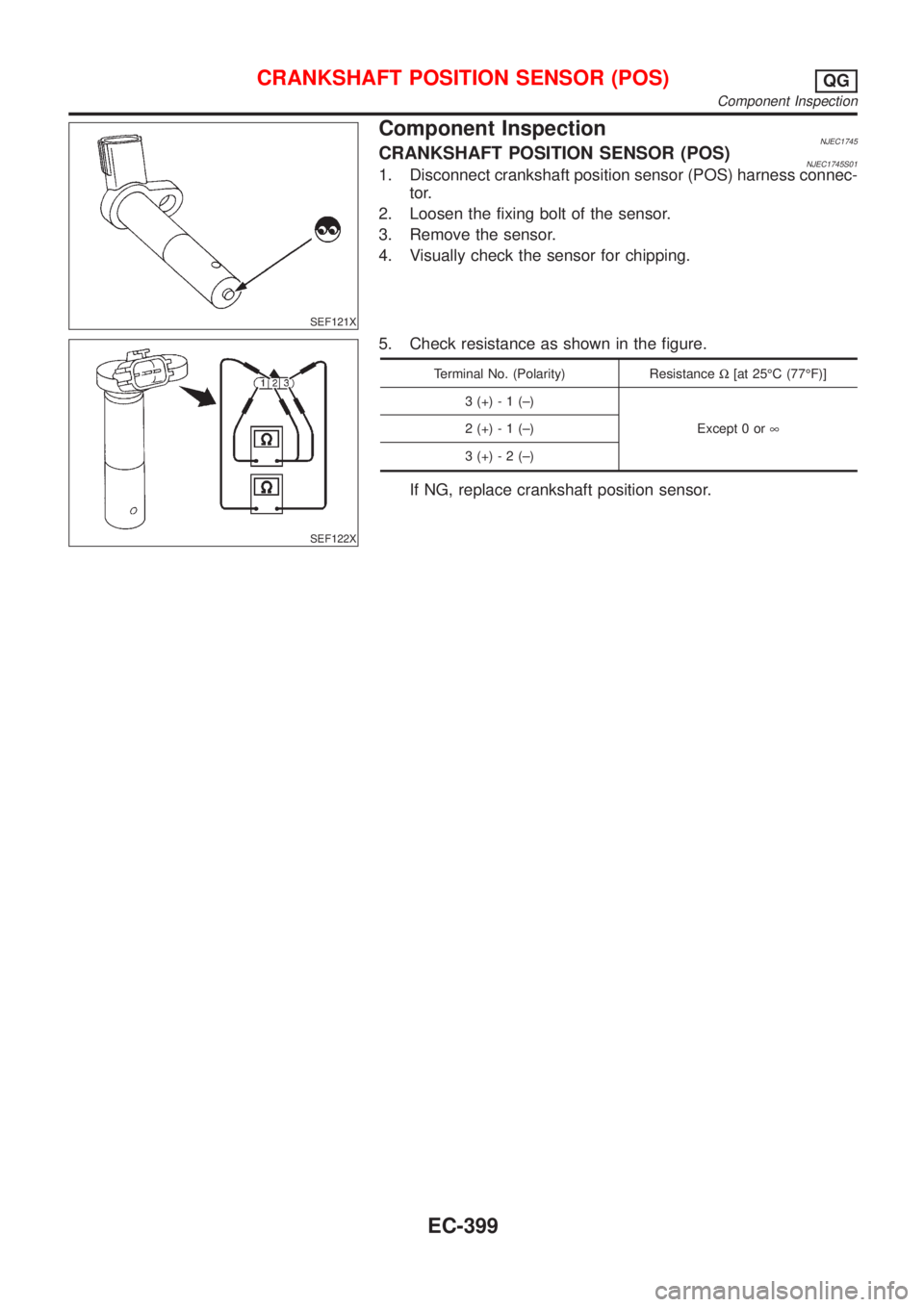

SEF121X

Component InspectionNJEC1745CRANKSHAFT POSITION SENSOR (POS)NJEC1745S011. Disconnect crankshaft position sensor (POS) harness connec-

tor.

2. Loosen the fixing bolt of the sensor.

3. Remove the sensor.

4. Visually check the sensor for chipping.

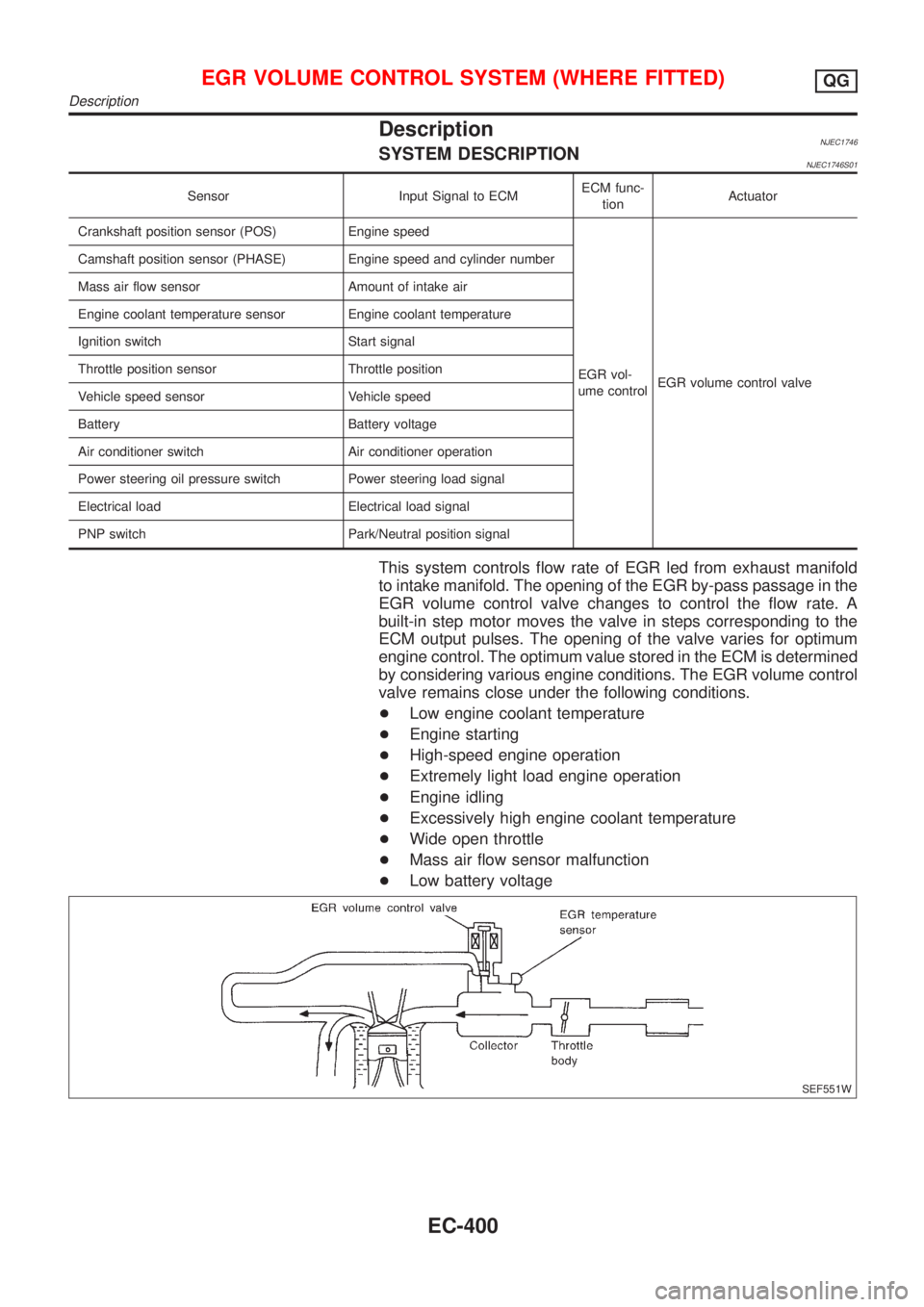

SEF122X

5. Check resistance as shown in the figure.

Terminal No. (Polarity) ResistanceW[at 25ÉC (77ÉF)]

3 (+) - 1 (±)

Except 0 or¥ 2 (+) - 1 (±)

3 (+) - 2 (±)

If NG, replace crankshaft position sensor.

CRANKSHAFT POSITION SENSOR (POS)QG

Component Inspection

EC-399

Page 696 of 2493

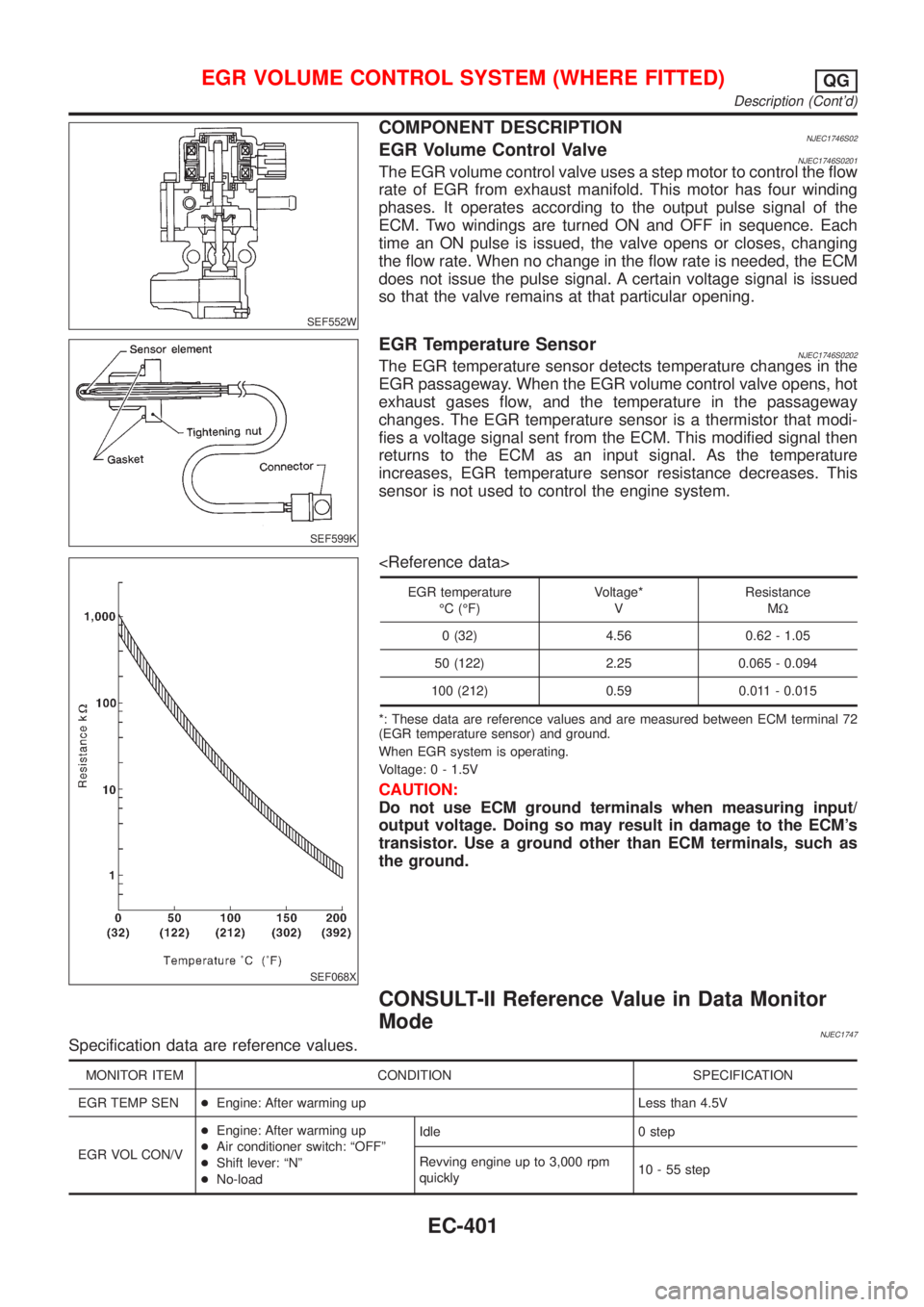

DescriptionNJEC1746SYSTEM DESCRIPTIONNJEC1746S01

Sensor Input Signal to ECMECM func-

tionActuator

Crankshaft position sensor (POS) Engine speed

EGR vol-

ume controlEGR volume control valve Camshaft position sensor (PHASE) Engine speed and cylinder number

Mass air flow sensor Amount of intake air

Engine coolant temperature sensor Engine coolant temperature

Ignition switch Start signal

Throttle position sensor Throttle position

Vehicle speed sensor Vehicle speed

Battery Battery voltage

Air conditioner switch Air conditioner operation

Power steering oil pressure switch Power steering load signal

Electrical load Electrical load signal

PNP switch Park/Neutral position signal

This system controls flow rate of EGR led from exhaust manifold

to intake manifold. The opening of the EGR by-pass passage in the

EGR volume control valve changes to control the flow rate. A

built-in step motor moves the valve in steps corresponding to the

ECM output pulses. The opening of the valve varies for optimum

engine control. The optimum value stored in the ECM is determined

by considering various engine conditions. The EGR volume control

valve remains close under the following conditions.

+Low engine coolant temperature

+Engine starting

+High-speed engine operation

+Extremely light load engine operation

+Engine idling

+Excessively high engine coolant temperature

+Wide open throttle

+Mass air flow sensor malfunction

+Low battery voltage

SEF551W

EGR VOLUME CONTROL SYSTEM (WHERE FITTED)QG

Description

EC-400

Page 697 of 2493

SEF552W

COMPONENT DESCRIPTIONNJEC1746S02EGR Volume Control ValveNJEC1746S0201The EGR volume control valve uses a step motor to control the flow

rate of EGR from exhaust manifold. This motor has four winding

phases. It operates according to the output pulse signal of the

ECM. Two windings are turned ON and OFF in sequence. Each

time an ON pulse is issued, the valve opens or closes, changing

the flow rate. When no change in the flow rate is needed, the ECM

does not issue the pulse signal. A certain voltage signal is issued

so that the valve remains at that particular opening.

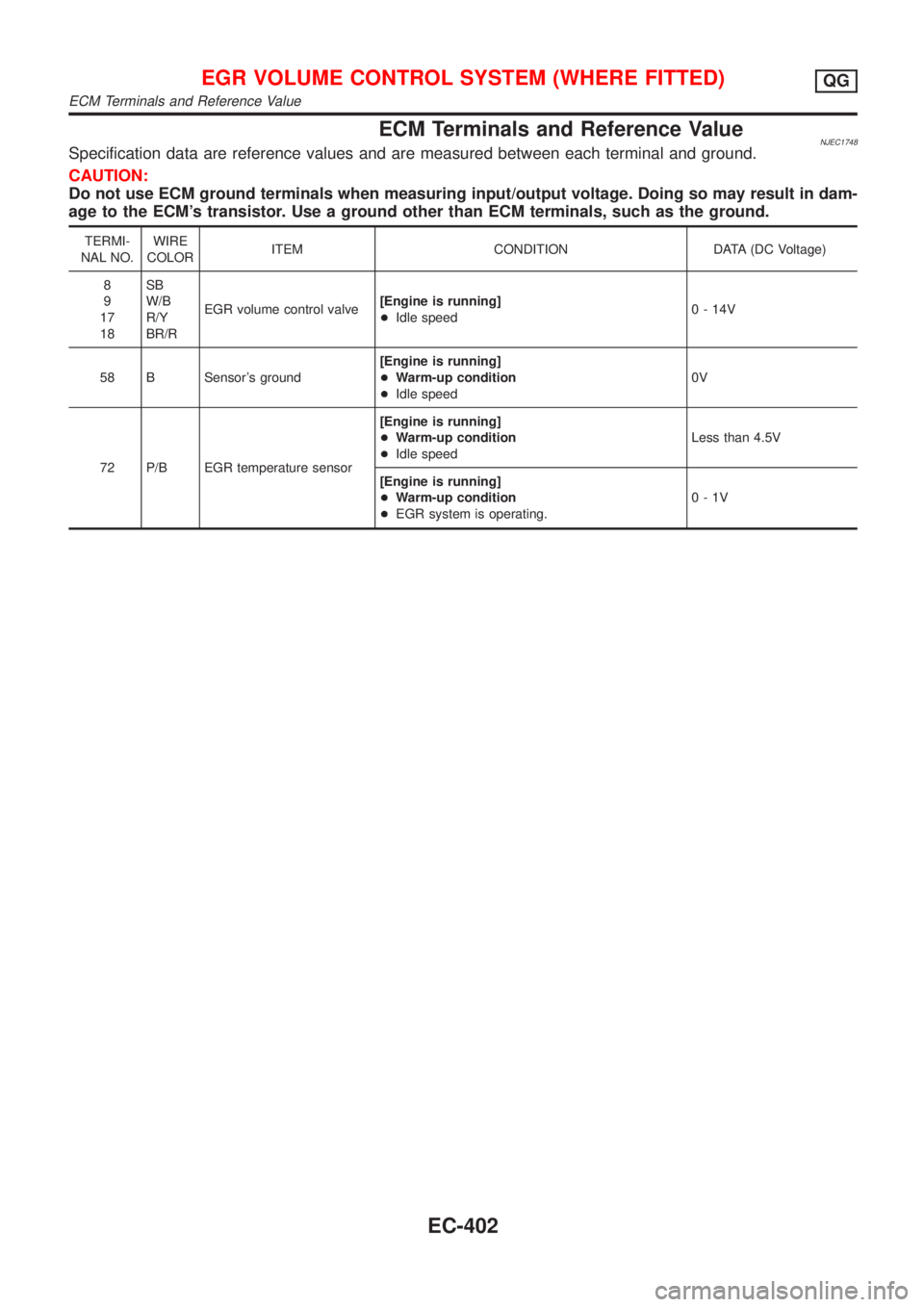

SEF599K

EGR Temperature SensorNJEC1746S0202The EGR temperature sensor detects temperature changes in the

EGR passageway. When the EGR volume control valve opens, hot

exhaust gases flow, and the temperature in the passageway

changes. The EGR temperature sensor is a thermistor that modi-

fies a voltage signal sent from the ECM. This modified signal then

returns to the ECM as an input signal. As the temperature

increases, EGR temperature sensor resistance decreases. This

sensor is not used to control the engine system.

SEF068X

EGR temperature

ÉC (ÉF)Voltage*

VResistance

MW

0 (32) 4.56 0.62 - 1.05

50 (122) 2.25 0.065 - 0.094

100 (212) 0.59 0.011 - 0.015

*: These data are reference values and are measured between ECM terminal 72

(EGR temperature sensor) and ground.

When EGR system is operating.

Voltage: 0 - 1.5V

CAUTION:

Do not use ECM ground terminals when measuring input/

output voltage. Doing so may result in damage to the ECM's

transistor. Use a ground other than ECM terminals, such as

the ground.

CONSULT-II Reference Value in Data Monitor

Mode

NJEC1747Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

EGR TEMP SEN+Engine: After warming up Less than 4.5V

EGR VOL CON/V+Engine: After warming up

+Air conditioner switch: ªOFFº

+Shift lever: ªNº

+No-loadIdle 0 step

Revving engine up to 3,000 rpm

quickly10 - 55 step

EGR VOLUME CONTROL SYSTEM (WHERE FITTED)QG

Description (Cont'd)

EC-401

Page 698 of 2493

ECM Terminals and Reference ValueNJEC1748Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

8

9

17

18SB

W/B

R/Y

BR/REGR volume control valve[Engine is running]

+Idle speed0 - 14V

58 B Sensor's ground[Engine is running]

+Warm-up condition

+Idle speed0V

72 P/B EGR temperature sensor[Engine is running]

+Warm-up condition

+Idle speedLess than 4.5V

[Engine is running]

+Warm-up condition

+EGR system is operating.0-1V

EGR VOLUME CONTROL SYSTEM (WHERE FITTED)QG

ECM Terminals and Reference Value

EC-402

Page 699 of 2493

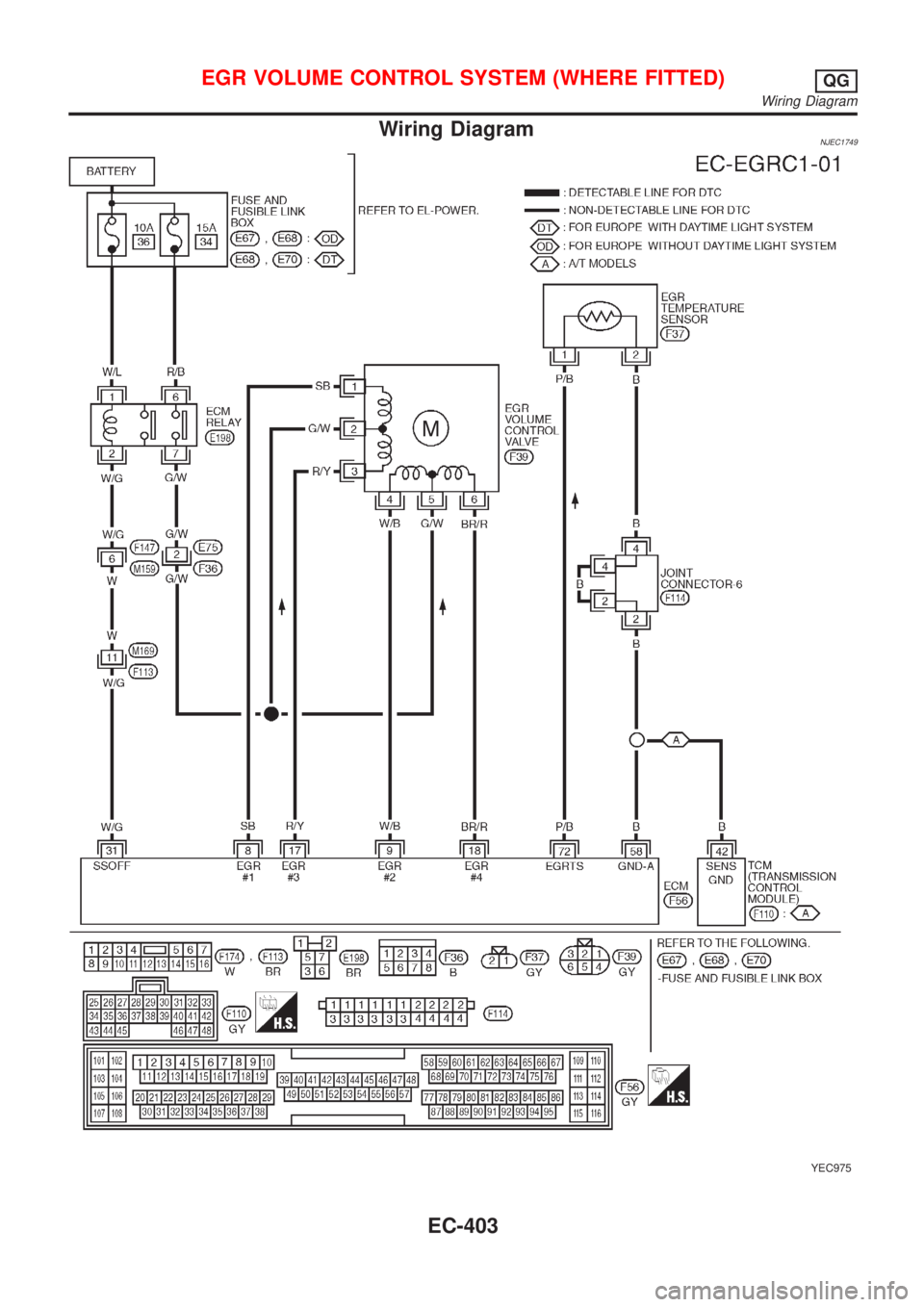

Wiring DiagramNJEC1749

YEC975

EGR VOLUME CONTROL SYSTEM (WHERE FITTED)QG

Wiring Diagram

EC-403

Page 700 of 2493

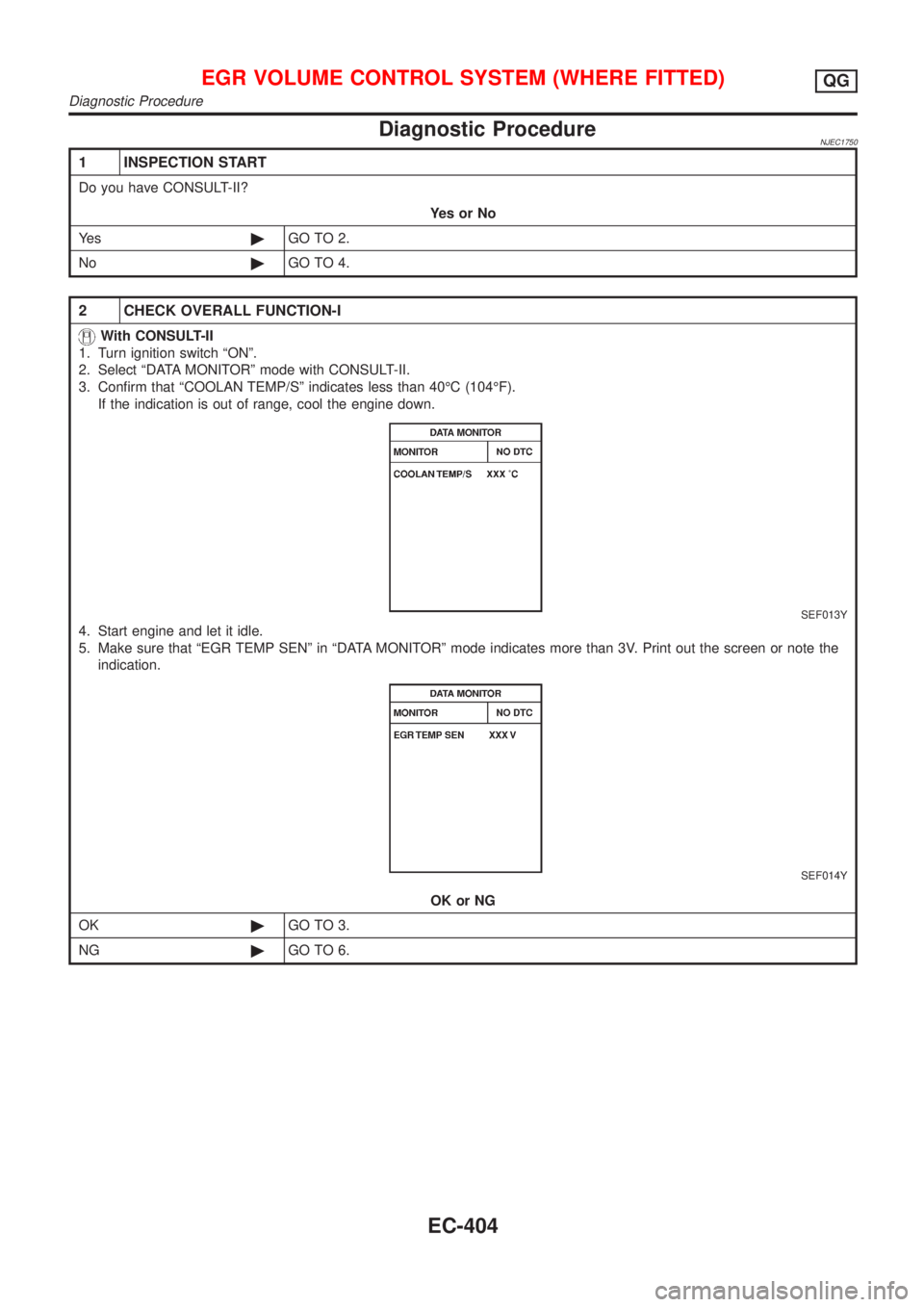

Diagnostic ProcedureNJEC1750

1 INSPECTION START

Do you have CONSULT-II?

YesorNo

Ye s©GO TO 2.

No©GO TO 4.

2 CHECK OVERALL FUNCTION-I

With CONSULT-II

1. Turn ignition switch ªONº.

2. Select ªDATA MONITORº mode with CONSULT-II.

3. Confirm that ªCOOLAN TEMP/Sº indicates less than 40ÉC (104ÉF).

If the indication is out of range, cool the engine down.

SEF013Y

4. Start engine and let it idle.

5. Make sure that ªEGR TEMP SENº in ªDATA MONITORº mode indicates more than 3V. Print out the screen or note the

indication.

SEF014Y

OK or NG

OK©GO TO 3.

NG©GO TO 6.

EGR VOLUME CONTROL SYSTEM (WHERE FITTED)QG

Diagnostic Procedure

EC-404