NISSAN ALMERA N16 2001 Electronic Repair Manual

ALMERA N16 2001

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57351/w960_57351-0.png

NISSAN ALMERA N16 2001 Electronic Repair Manual

Trending: diagnostic menu, brakes, Clutch, radio antenna, bolt pattern, clock, length

Page 731 of 2493

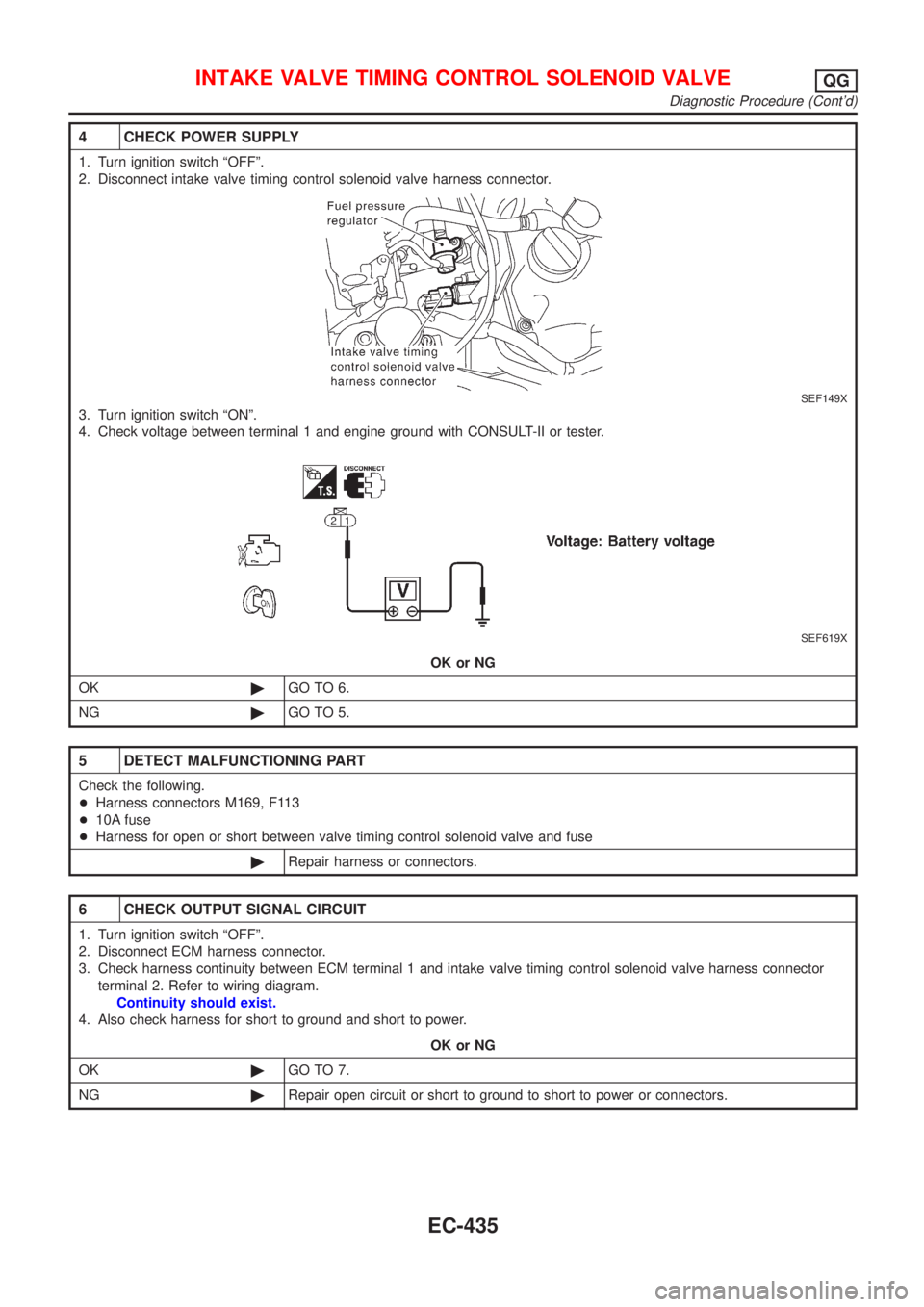

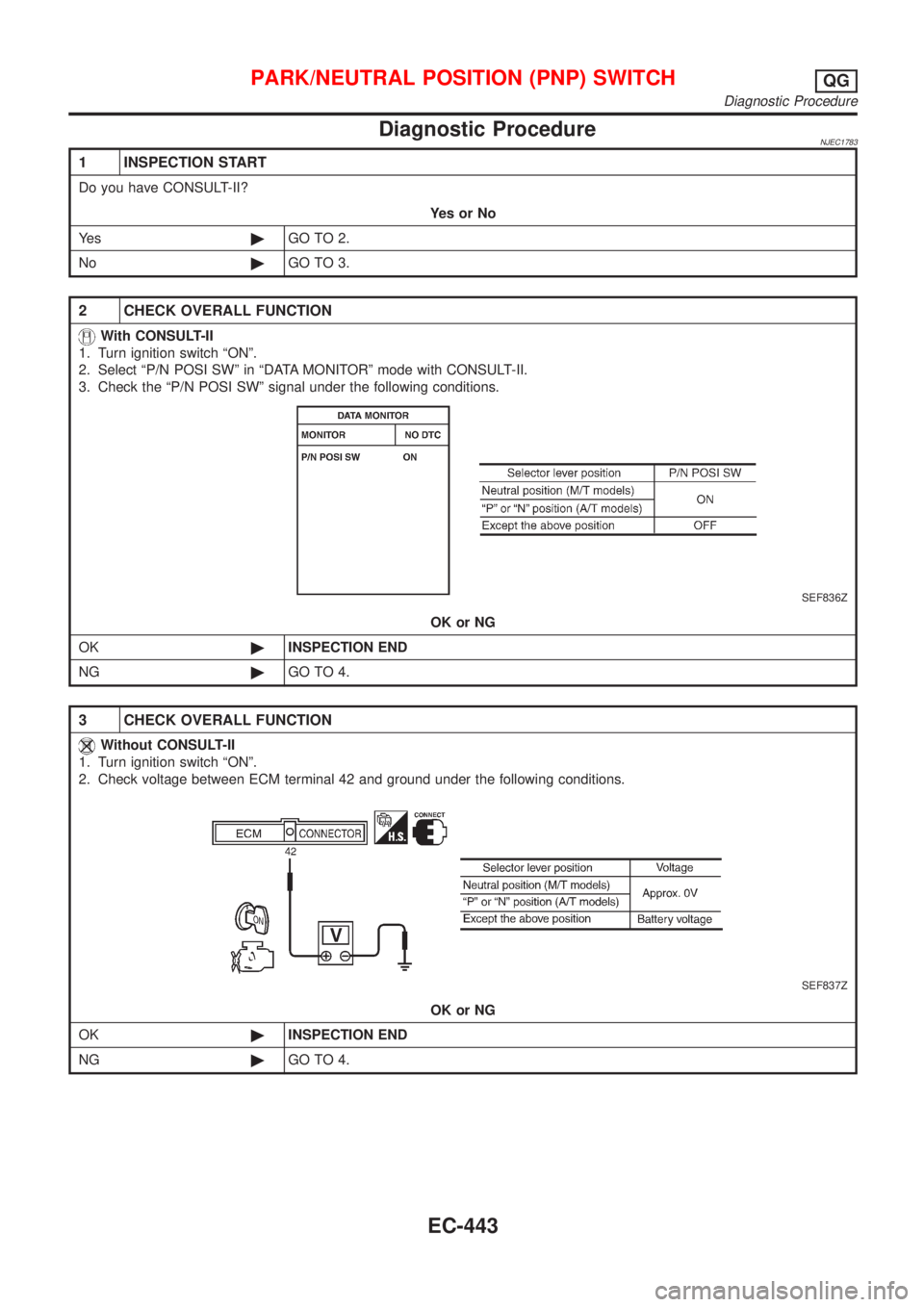

4 CHECK POWER SUPPLY

1. Turn ignition switch ªOFFº.

2. Disconnect intake valve timing control solenoid valve harness connector.

SEF149X

3. Turn ignition switch ªONº.

4. Check voltage between terminal 1 and engine ground with CONSULT-II or tester.

SEF619X

OK or NG

OK©GO TO 6.

NG©GO TO 5.

5 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors M169, F113

+10A fuse

+Harness for open or short between valve timing control solenoid valve and fuse

©Repair harness or connectors.

6 CHECK OUTPUT SIGNAL CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Check harness continuity between ECM terminal 1 and intake valve timing control solenoid valve harness connector

terminal 2. Refer to wiring diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 7.

NG©Repair open circuit or short to ground to short to power or connectors.

INTAKE VALVE TIMING CONTROL SOLENOID VALVEQG

Diagnostic Procedure (Cont'd)

EC-435

Page 732 of 2493

7 CHECK VALVE TIMING CONTROL SOLENOID VALVE

Refer to ªComponent Inspectionº, EC-436.

OK or NG

OK©GO TO 8.

NG©Replace valve timing control solenoid valve.

8 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-144.

©INSPECTION END

SEF159Y

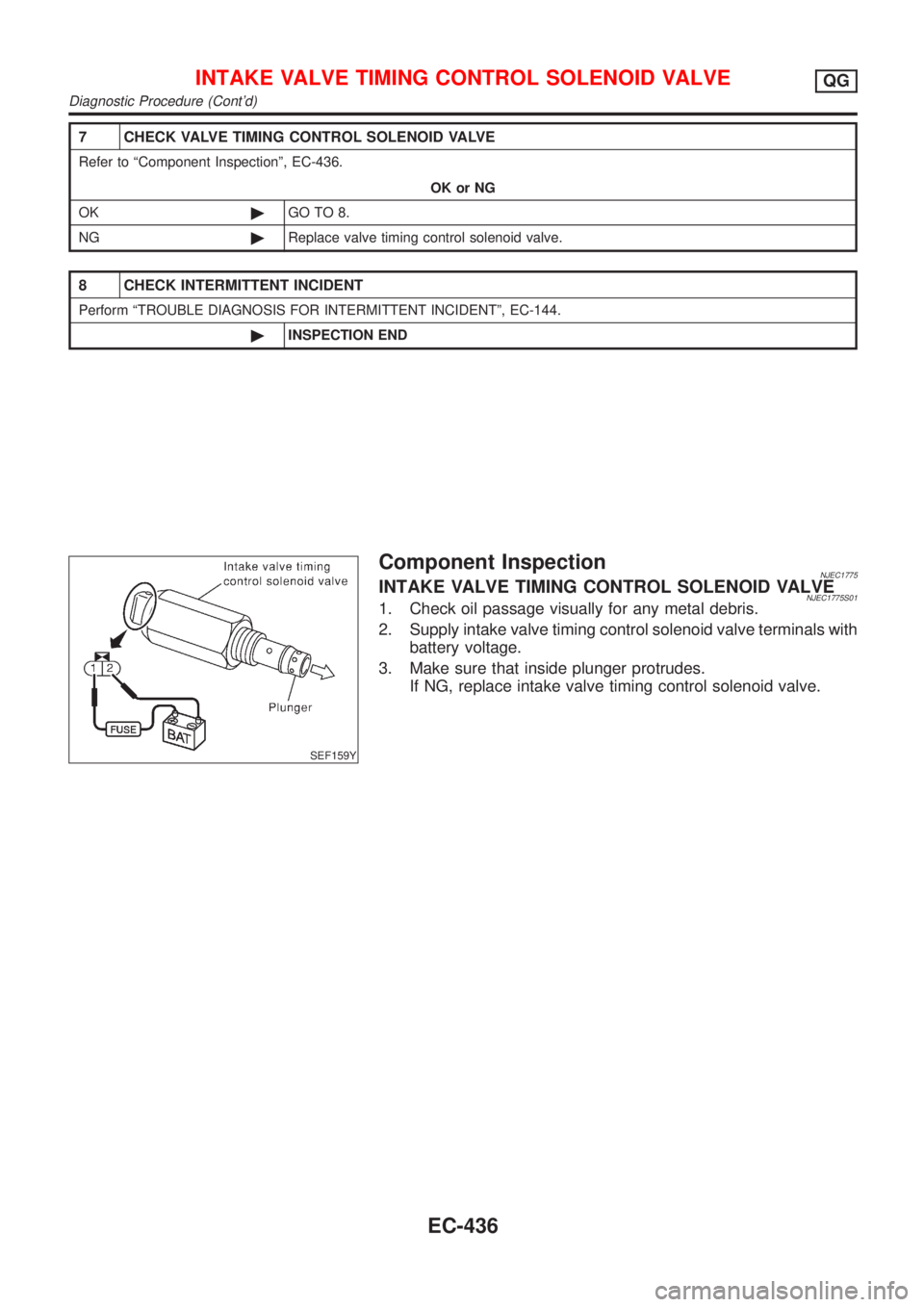

Component InspectionNJEC1775INTAKE VALVE TIMING CONTROL SOLENOID VALVENJEC1775S011. Check oil passage visually for any metal debris.

2. Supply intake valve timing control solenoid valve terminals with

battery voltage.

3. Make sure that inside plunger protrudes.

If NG, replace intake valve timing control solenoid valve.

INTAKE VALVE TIMING CONTROL SOLENOID VALVEQG

Diagnostic Procedure (Cont'd)

EC-436

Page 733 of 2493

System DescriptionNJEC1776These circuit lines are used to control the smooth shifting up and down of A/T during the hard acceleration/

deceleration.

Voltage signals are exchanged between ECM and TCM (Transmission Control Module).

A/T COMMUNICATION LINEQG

System Description

EC-437

Page 734 of 2493

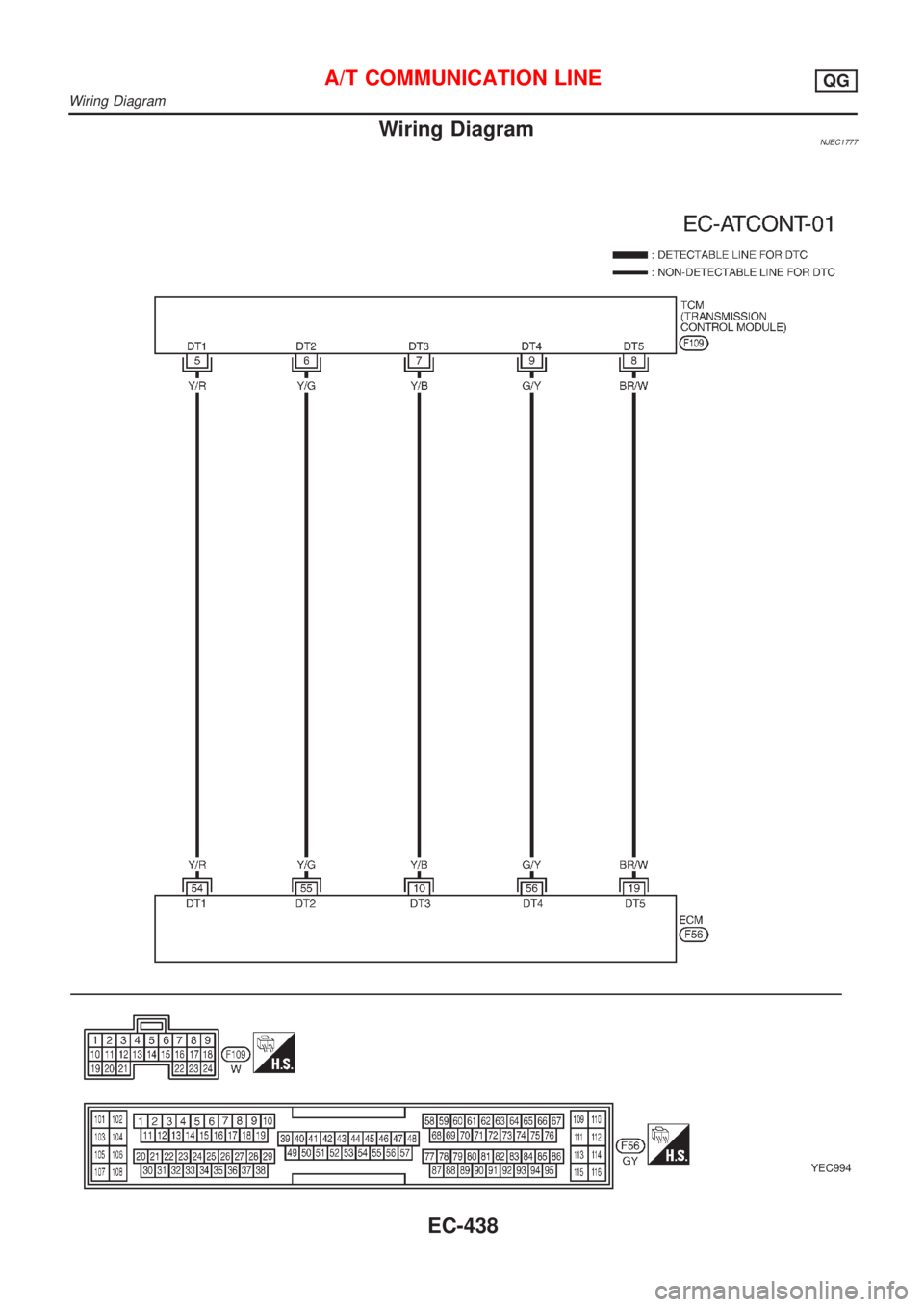

Wiring DiagramNJEC1777

YEC994

A/T COMMUNICATION LINEQG

Wiring Diagram

EC-438

Page 735 of 2493

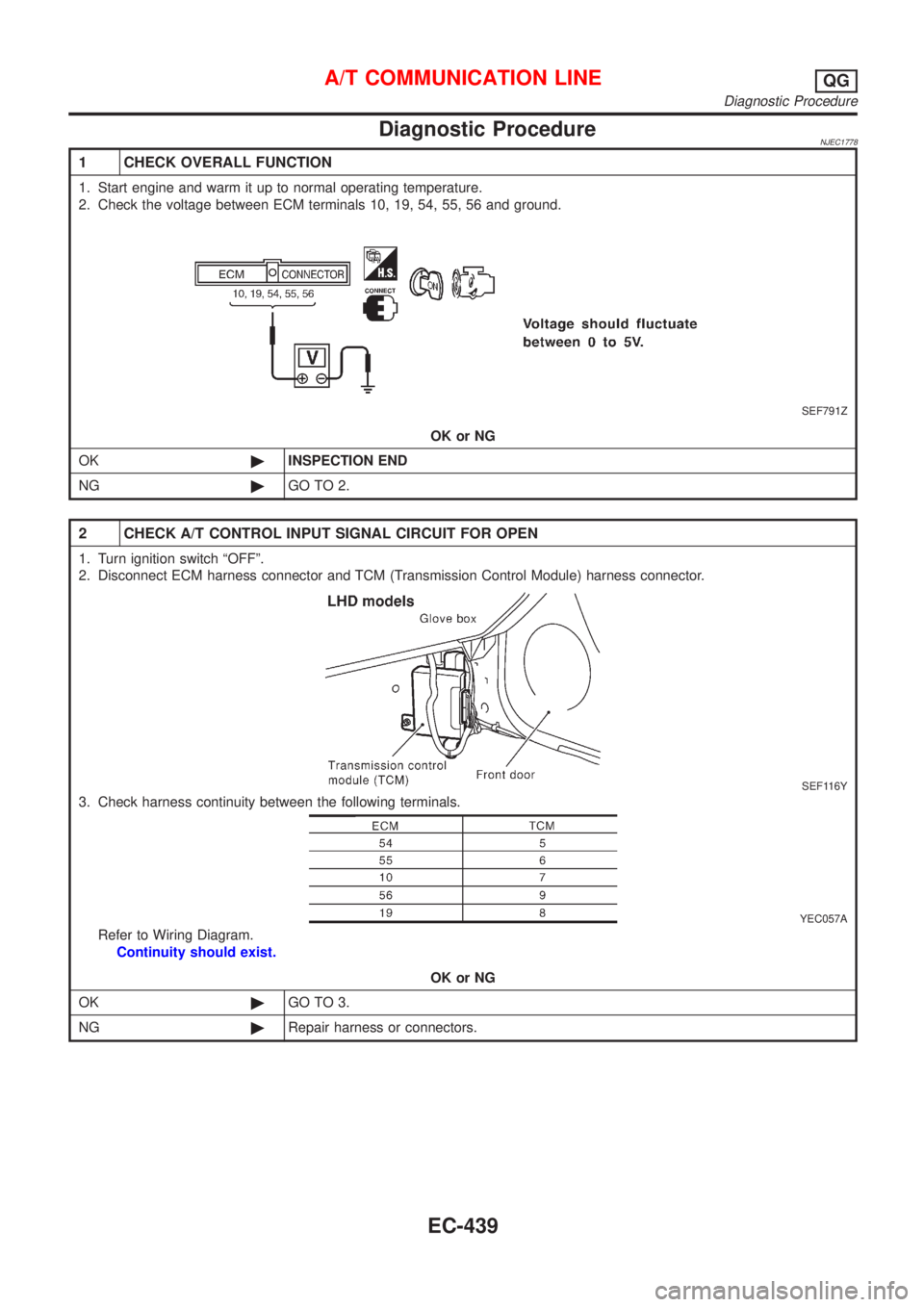

Diagnostic ProcedureNJEC1778

1 CHECK OVERALL FUNCTION

1. Start engine and warm it up to normal operating temperature.

2. Check the voltage between ECM terminals 10, 19, 54, 55, 56 and ground.

SEF791Z

OK or NG

OK©INSPECTION END

NG©GO TO 2.

2 CHECK A/T CONTROL INPUT SIGNAL CIRCUIT FOR OPEN

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector and TCM (Transmission Control Module) harness connector.

SEF116Y

3. Check harness continuity between the following terminals.

YEC057A

Refer to Wiring Diagram.

Continuity should exist.

OK or NG

OK©GO TO 3.

NG©Repair harness or connectors.

A/T COMMUNICATION LINEQG

Diagnostic Procedure

EC-439

Page 736 of 2493

3 CHECK A/T CONTROL INPUT SIGNAL CIRCUIT FOR SHORT

1. Check harness continuity between ECM terminals 10, 19, 54, 55, 56 and ground.

Refer to Wiring Diagram.

Continuity should not exist.

2. Also check harness for short to power.

OK or NG

OK©GO TO 4.

NG©Repair short to ground or short to power in harness or connectos.

4 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-144.

©INSPECTION END

A/T COMMUNICATION LINEQG

Diagnostic Procedure (Cont'd)

EC-440

Page 737 of 2493

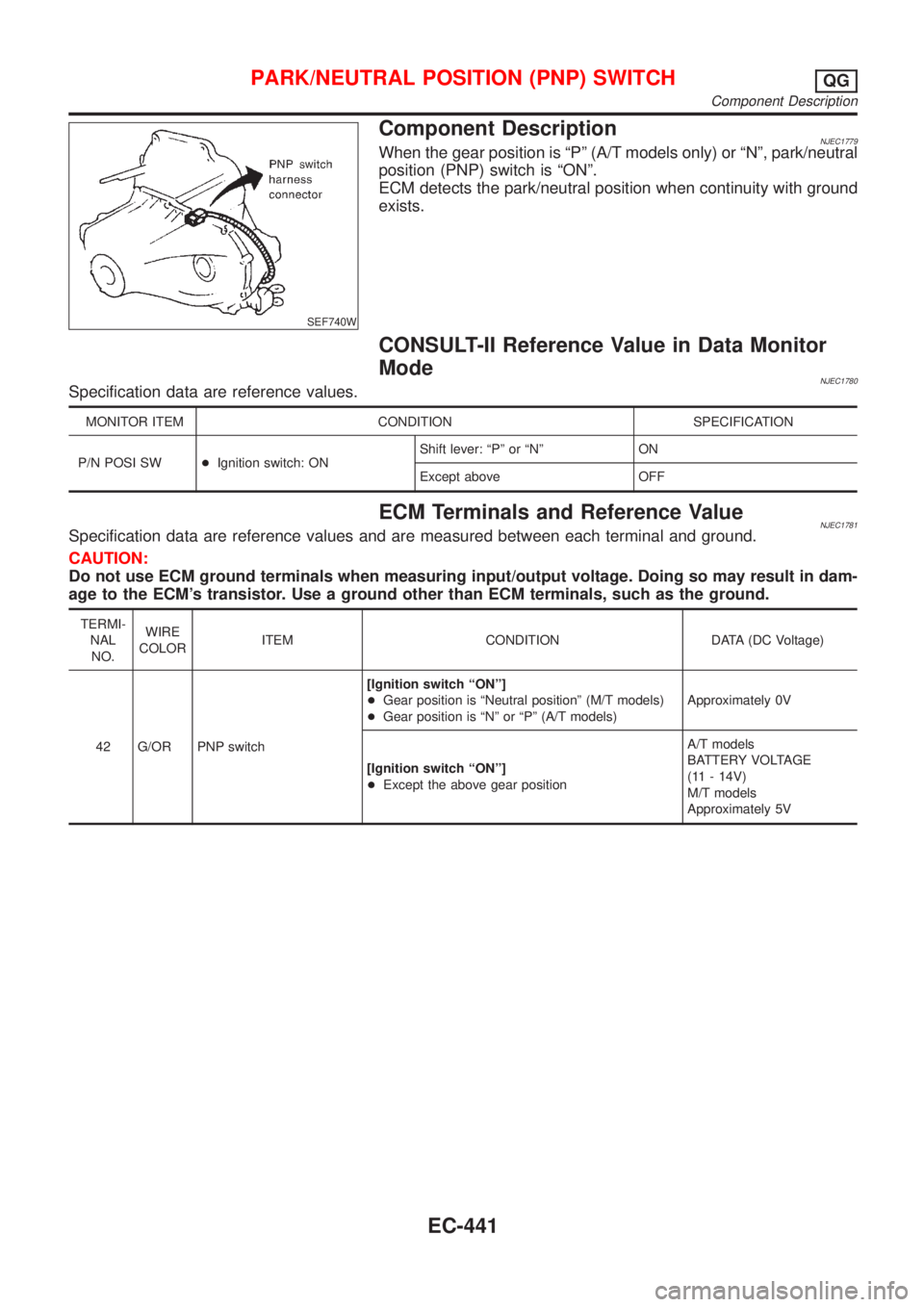

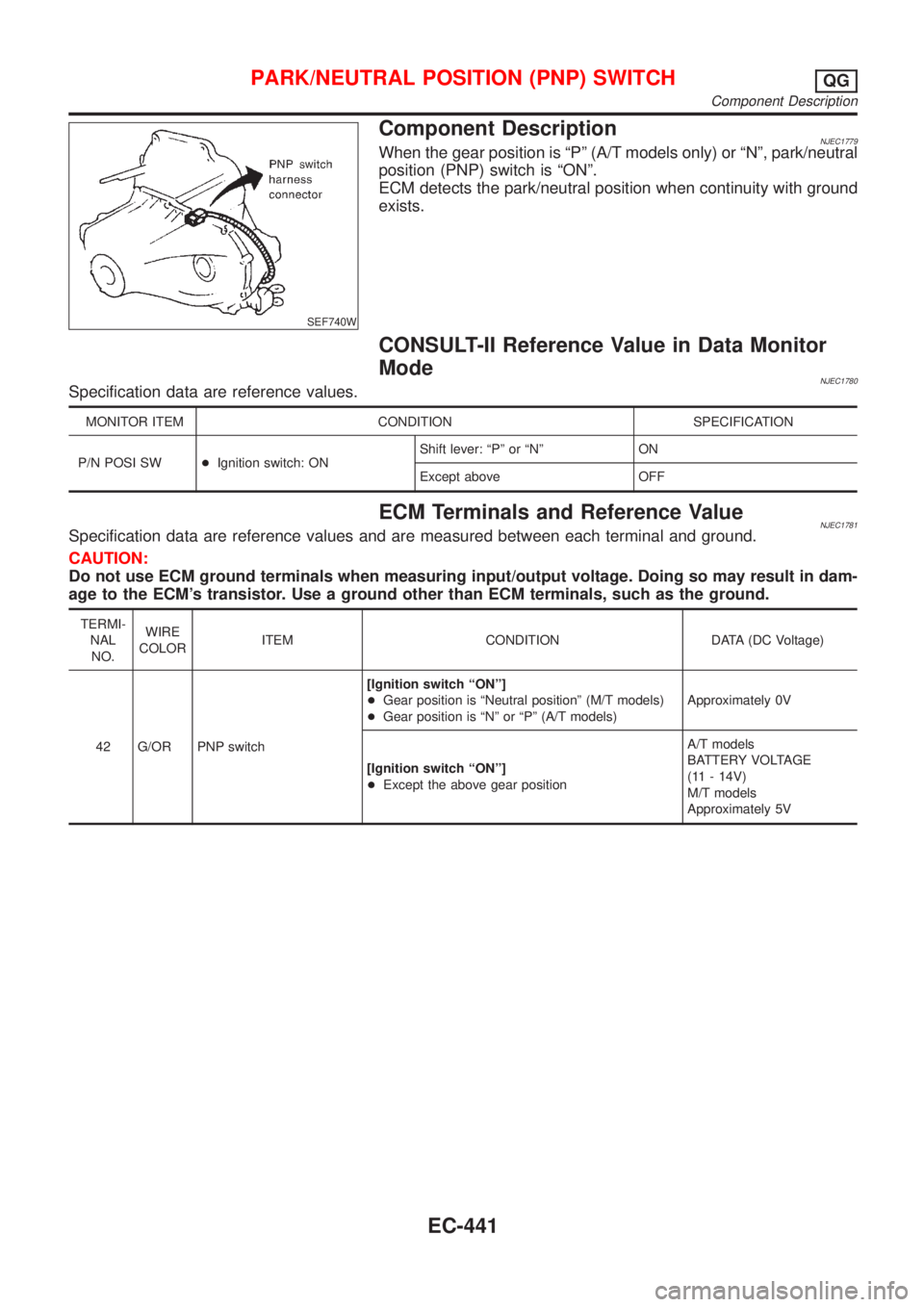

SEF740W

Component DescriptionNJEC1779When the gear position is ªPº (A/T models only) or ªNº, park/neutral

position (PNP) switch is ªONº.

ECM detects the park/neutral position when continuity with ground

exists.

CONSULT-II Reference Value in Data Monitor

Mode

NJEC1780Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

P/N POSI SW+Ignition switch: ONShift lever: ªPº or ªNº ON

Except above OFF

ECM Terminals and Reference ValueNJEC1781Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

42 G/OR PNP switch[Ignition switch ªONº]

+Gear position is ªNeutral positionº (M/T models)

+Gear position is ªNº or ªPº (A/T models)Approximately 0V

[Ignition switch ªONº]

+Except the above gear positionA/T models

BATTERY VOLTAGE

(11 - 14V)

M/T models

Approximately 5V

PARK/NEUTRAL POSITION (PNP) SWITCHQG

Component Description

EC-441

Page 738 of 2493

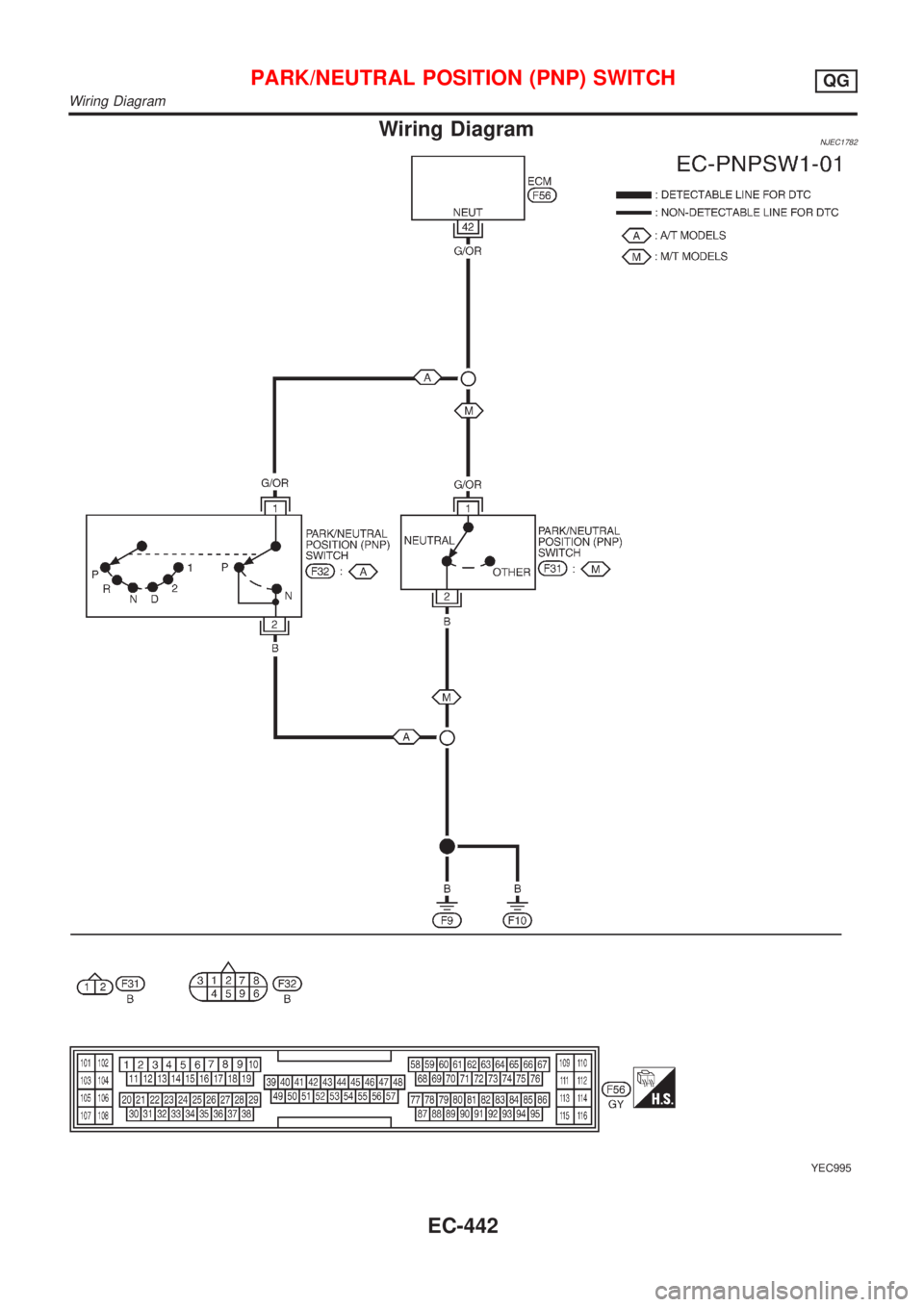

Wiring DiagramNJEC1782

YEC995

PARK/NEUTRAL POSITION (PNP) SWITCHQG

Wiring Diagram

EC-442

Page 739 of 2493

Diagnostic ProcedureNJEC1783

1 INSPECTION START

Do you have CONSULT-II?

YesorNo

Ye s©GO TO 2.

No©GO TO 3.

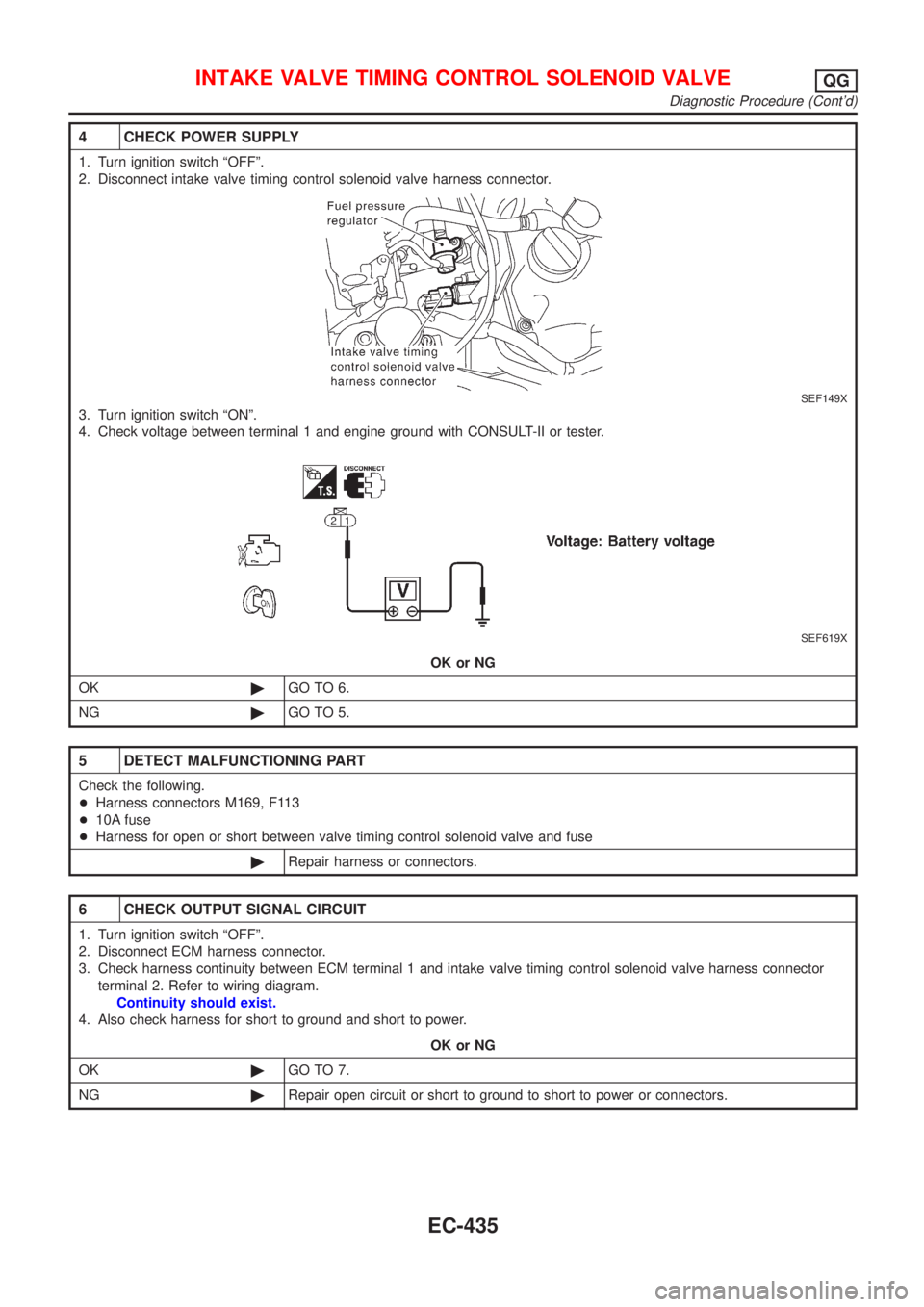

2 CHECK OVERALL FUNCTION

With CONSULT-II

1. Turn ignition switch ªONº.

2. Select ªP/N POSI SWº in ªDATA MONITORº mode with CONSULT-II.

3. Check the ªP/N POSI SWº signal under the following conditions.

SEF836Z

OK or NG

OK©INSPECTION END

NG©GO TO 4.

3 CHECK OVERALL FUNCTION

Without CONSULT-II

1. Turn ignition switch ªONº.

2. Check voltage between ECM terminal 42 and ground under the following conditions.

SEF837Z

OK or NG

OK©INSPECTION END

NG©GO TO 4.

PARK/NEUTRAL POSITION (PNP) SWITCHQG

Diagnostic Procedure

EC-443

Page 740 of 2493

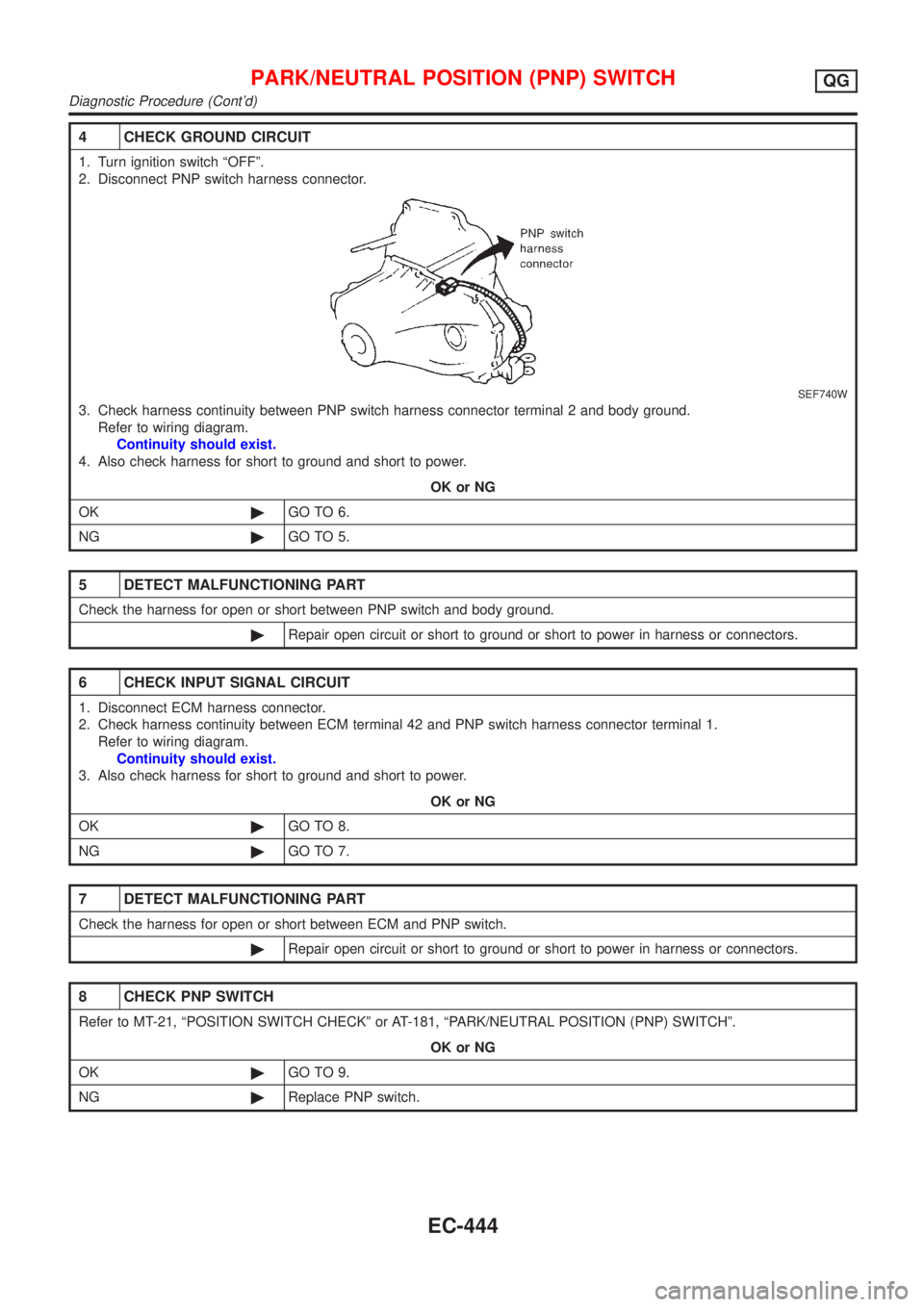

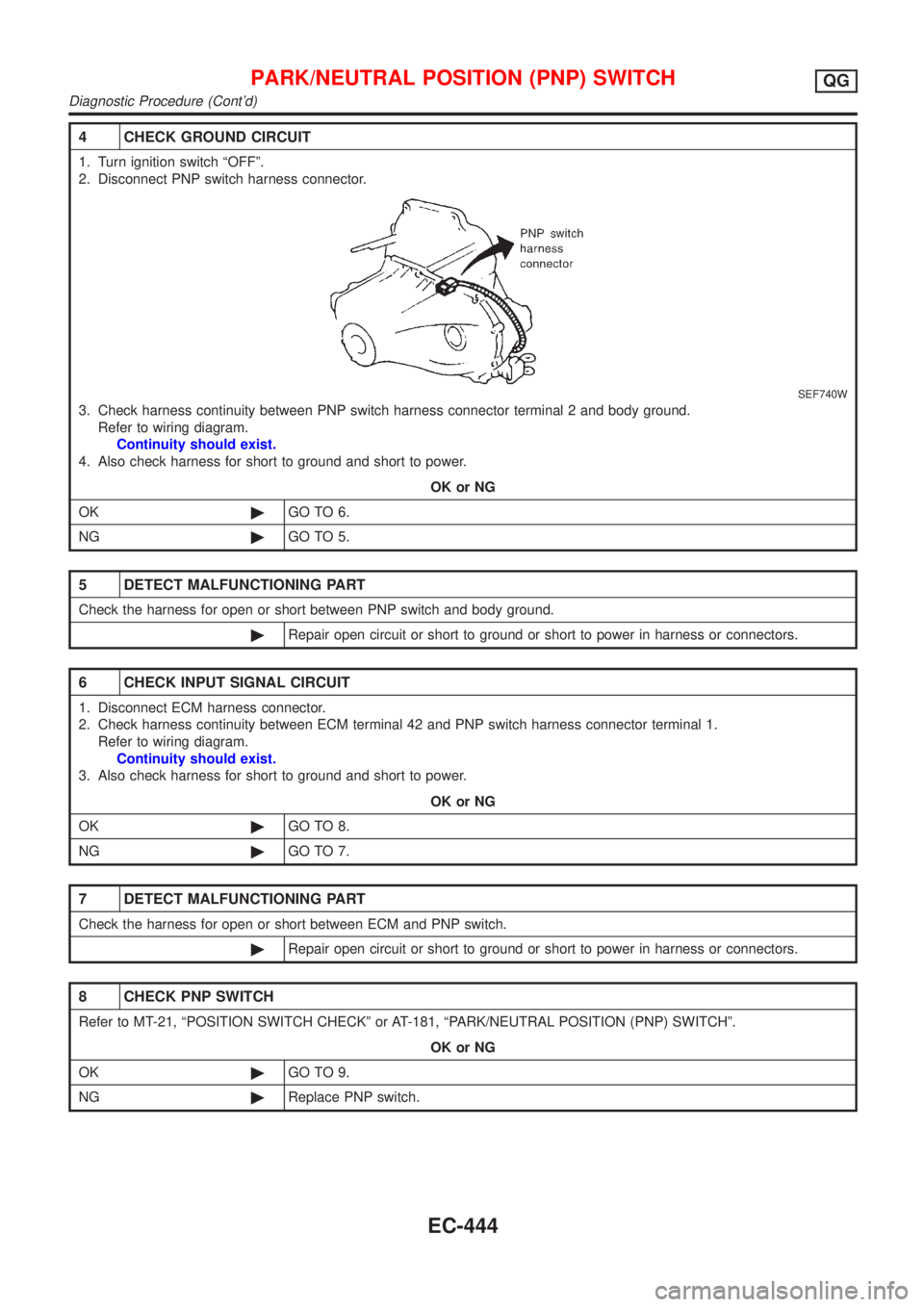

4 CHECK GROUND CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect PNP switch harness connector.

SEF740W

3. Check harness continuity between PNP switch harness connector terminal 2 and body ground.

Refer to wiring diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 6.

NG©GO TO 5.

5 DETECT MALFUNCTIONING PART

Check the harness for open or short between PNP switch and body ground.

©Repair open circuit or short to ground or short to power in harness or connectors.

6 CHECK INPUT SIGNAL CIRCUIT

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminal 42 and PNP switch harness connector terminal 1.

Refer to wiring diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 8.

NG©GO TO 7.

7 DETECT MALFUNCTIONING PART

Check the harness for open or short between ECM and PNP switch.

©Repair open circuit or short to ground or short to power in harness or connectors.

8 CHECK PNP SWITCH

Refer to MT-21, ªPOSITION SWITCH CHECKº or AT-181, ªPARK/NEUTRAL POSITION (PNP) SWITCHº.

OK or NG

OK©GO TO 9.

NG©Replace PNP switch.

PARK/NEUTRAL POSITION (PNP) SWITCHQG

Diagnostic Procedure (Cont'd)

EC-444

Trending: towing, starter motor, jump start, jacking, brake pads, filter, clock setting