NISSAN ALMERA N16 2001 Electronic Repair Manual

Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2001Pages: 2493, PDF Size: 66.97 MB

Page 671 of 2493

Diagnostic ProcedureNJEC1221

1 INSPECTION START

Do you have CONSULT-II?

YesorNo

Ye s©GO TO 2.

No©GO TO 3.

2 CHECK OVERALL FUNCTION

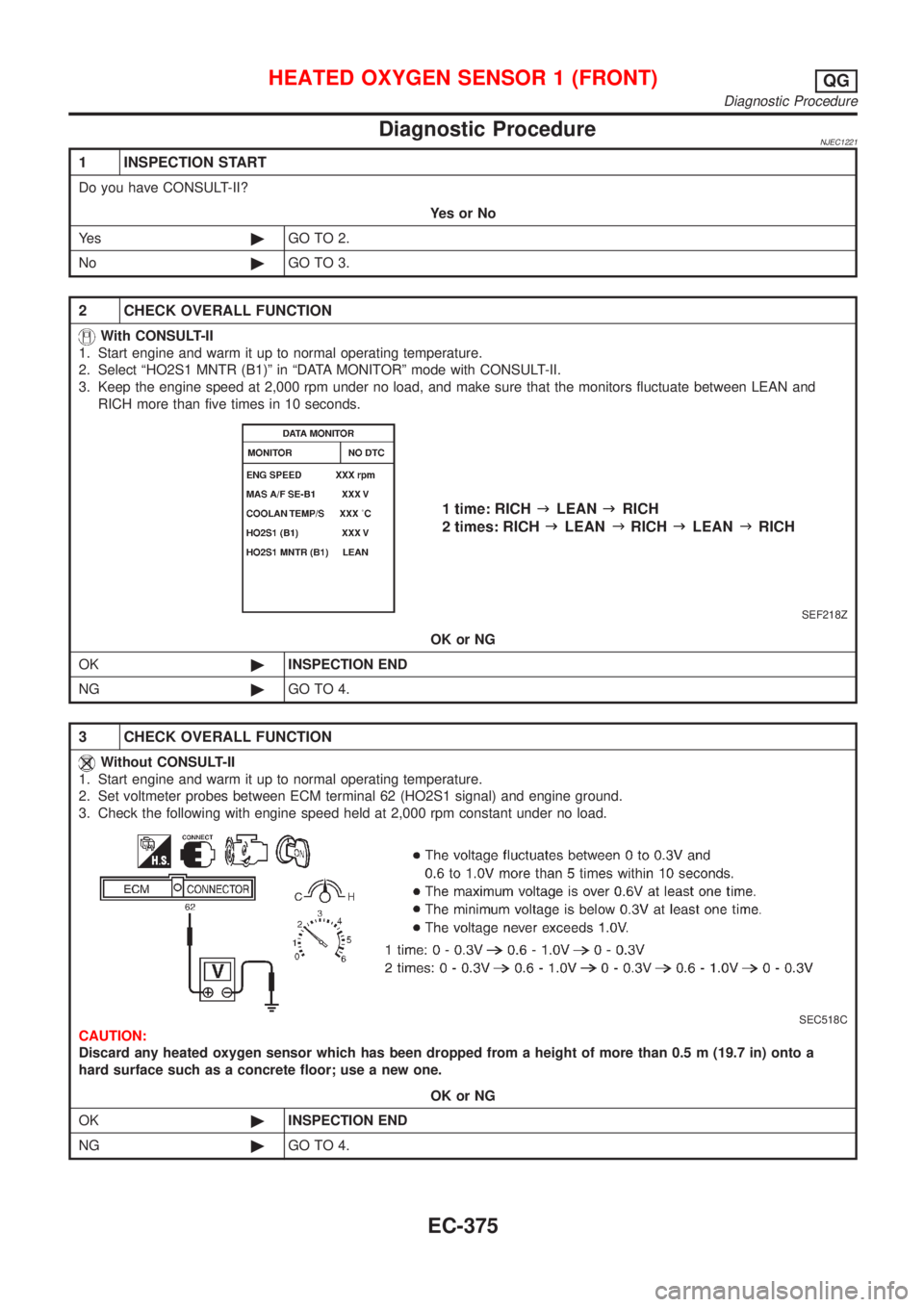

With CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Select ªHO2S1 MNTR (B1)º in ªDATA MONITORº mode with CONSULT-II.

3. Keep the engine speed at 2,000 rpm under no load, and make sure that the monitors fluctuate between LEAN and

RICH more than five times in 10 seconds.

SEF218Z

OK or NG

OK©INSPECTION END

NG©GO TO 4.

3 CHECK OVERALL FUNCTION

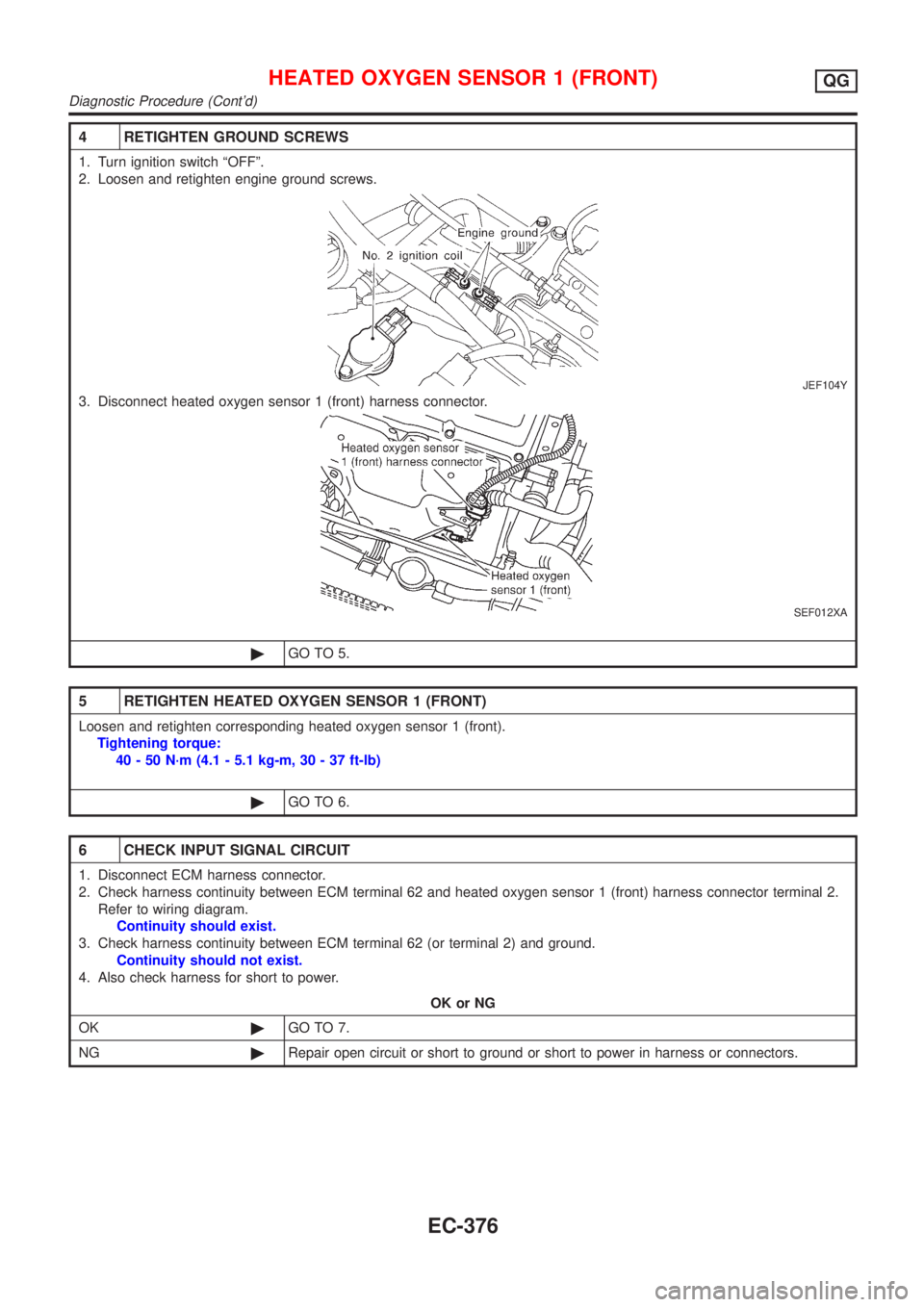

Without CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Set voltmeter probes between ECM terminal 62 (HO2S1 signal) and engine ground.

3. Check the following with engine speed held at 2,000 rpm constant under no load.

SEC518C

CAUTION:

Discard any heated oxygen sensor which has been dropped from a height of more than 0.5 m (19.7 in) onto a

hard surface such as a concrete floor; use a new one.

OK or NG

OK©INSPECTION END

NG©GO TO 4.

HEATED OXYGEN SENSOR 1 (FRONT)QG

Diagnostic Procedure

EC-375

Page 672 of 2493

4 RETIGHTEN GROUND SCREWS

1. Turn ignition switch ªOFFº.

2. Loosen and retighten engine ground screws.

JEF104Y

3. Disconnect heated oxygen sensor 1 (front) harness connector.

SEF012XA

©GO TO 5.

5 RETIGHTEN HEATED OXYGEN SENSOR 1 (FRONT)

Loosen and retighten corresponding heated oxygen sensor 1 (front).

Tightening torque:

40 - 50 N´m (4.1 - 5.1 kg-m, 30 - 37 ft-lb)

©GO TO 6.

6 CHECK INPUT SIGNAL CIRCUIT

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminal 62 and heated oxygen sensor 1 (front) harness connector terminal 2.

Refer to wiring diagram.

Continuity should exist.

3. Check harness continuity between ECM terminal 62 (or terminal 2) and ground.

Continuity should not exist.

4. Also check harness for short to power.

OK or NG

OK©GO TO 7.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

HEATED OXYGEN SENSOR 1 (FRONT)QG

Diagnostic Procedure (Cont'd)

EC-376

Page 673 of 2493

7 CHECK HEATED OXYGEN SENSOR 1 (FRONT)

Refer to ªComponent Inspectionº, EC-377.

OK or NG

OK©GO TO 8.

NG©Replace heated oxygen sensor 1 (front).

8 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-144.

©INSPECTION END

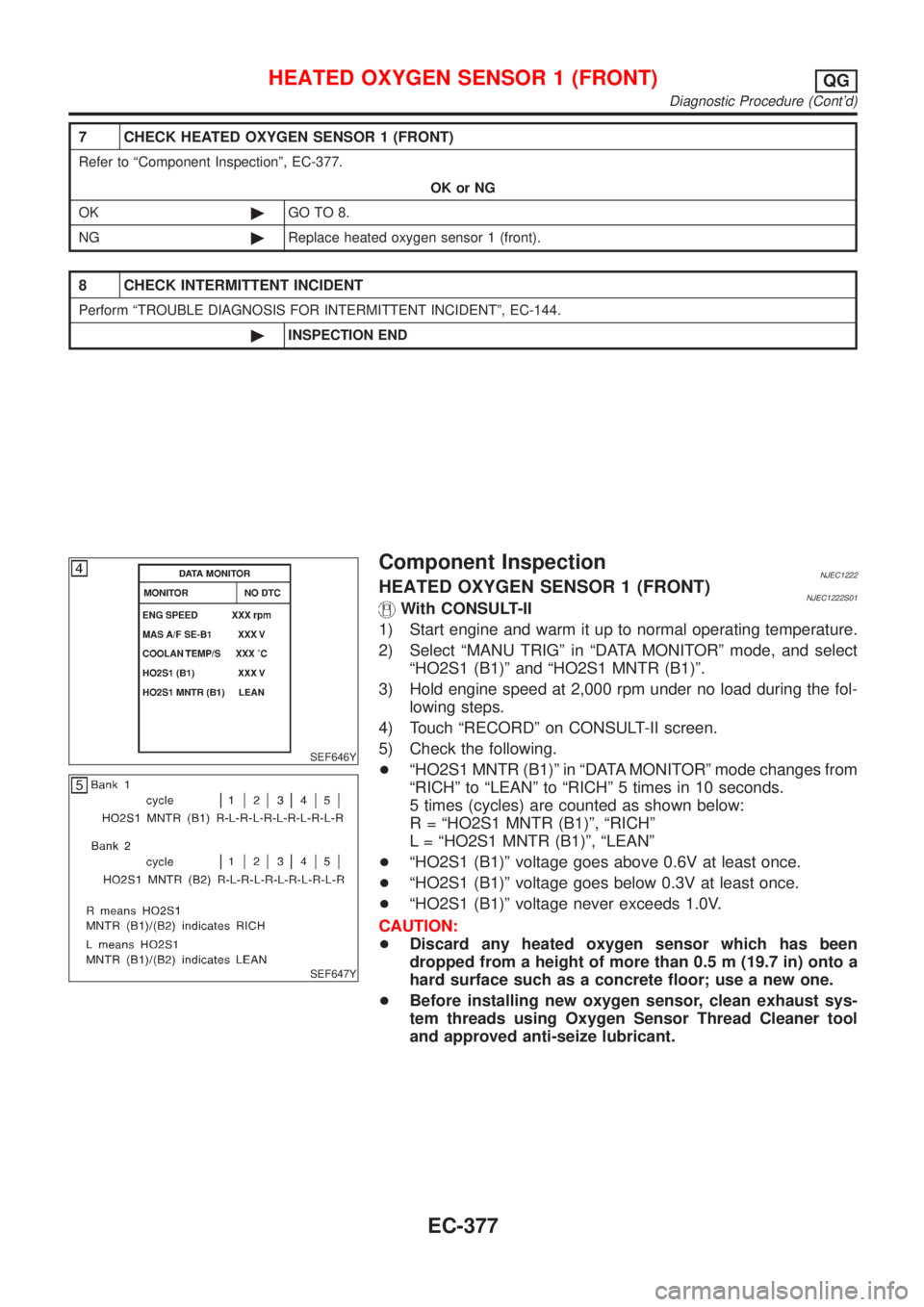

SEF646Y

SEF647Y

Component InspectionNJEC1222HEATED OXYGEN SENSOR 1 (FRONT)NJEC1222S01With CONSULT-II

1) Start engine and warm it up to normal operating temperature.

2) Select ªMANU TRIGº in ªDATA MONITORº mode, and select

ªHO2S1 (B1)º and ªHO2S1 MNTR (B1)º.

3) Hold engine speed at 2,000 rpm under no load during the fol-

lowing steps.

4) Touch ªRECORDº on CONSULT-II screen.

5) Check the following.

+ªHO2S1 MNTR (B1)º in ªDATA MONITORº mode changes from

ªRICHº to ªLEANº to ªRICHº 5 times in 10 seconds.

5 times (cycles) are counted as shown below:

R = ªHO2S1 MNTR (B1)º, ªRICHº

L = ªHO2S1 MNTR (B1)º, ªLEANº

+ªHO2S1 (B1)º voltage goes above 0.6V at least once.

+ªHO2S1 (B1)º voltage goes below 0.3V at least once.

+ªHO2S1 (B1)º voltage never exceeds 1.0V.

CAUTION:

+Discard any heated oxygen sensor which has been

dropped from a height of more than 0.5 m (19.7 in) onto a

hard surface such as a concrete floor; use a new one.

+Before installing new oxygen sensor, clean exhaust sys-

tem threads using Oxygen Sensor Thread Cleaner tool

and approved anti-seize lubricant.

HEATED OXYGEN SENSOR 1 (FRONT)QG

Diagnostic Procedure (Cont'd)

EC-377

Page 674 of 2493

SEF648Y

SEF011X

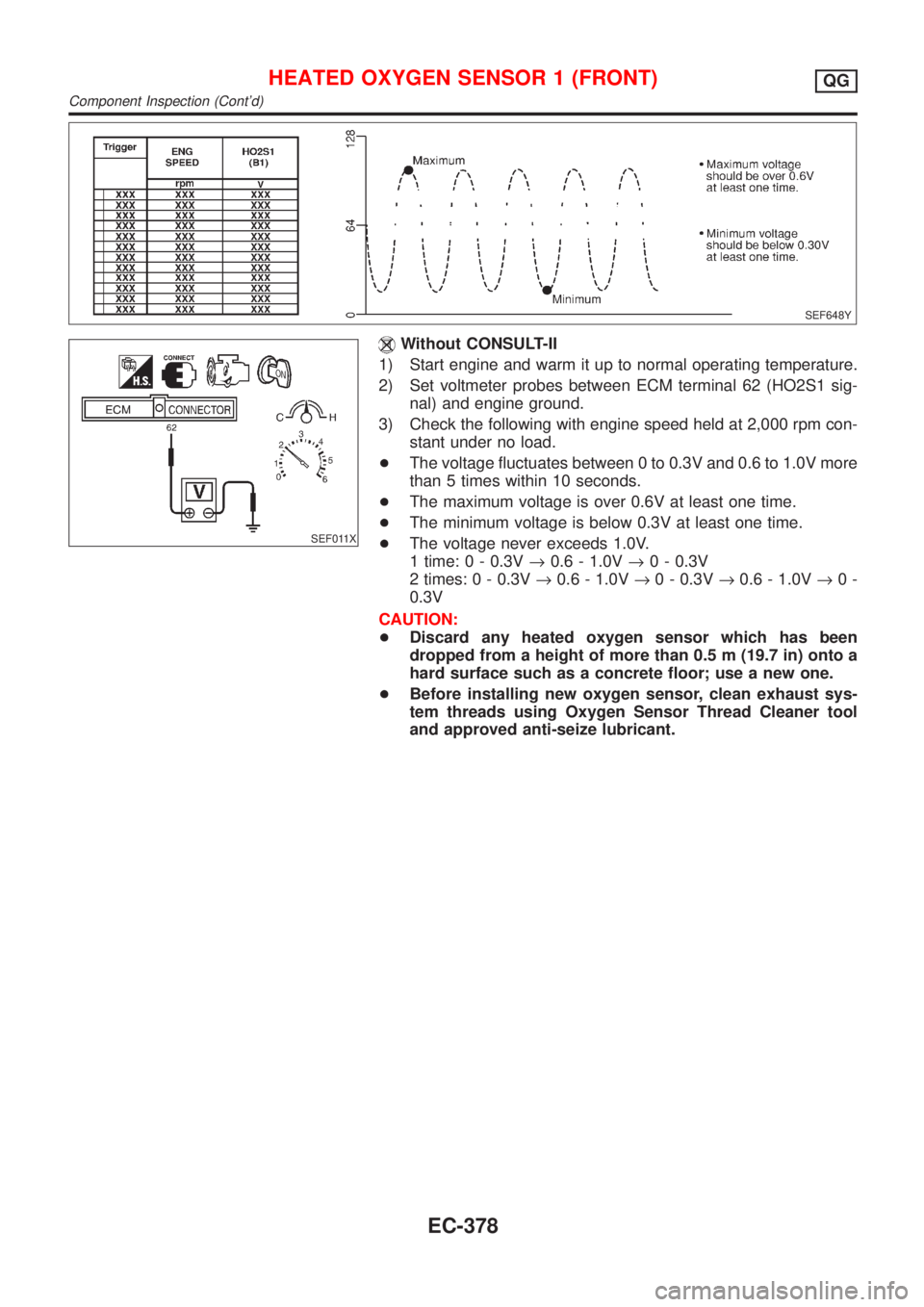

Without CONSULT-II

1) Start engine and warm it up to normal operating temperature.

2) Set voltmeter probes between ECM terminal 62 (HO2S1 sig-

nal) and engine ground.

3) Check the following with engine speed held at 2,000 rpm con-

stant under no load.

+The voltage fluctuates between 0 to 0.3V and 0.6 to 1.0V more

than 5 times within 10 seconds.

+The maximum voltage is over 0.6V at least one time.

+The minimum voltage is below 0.3V at least one time.

+The voltage never exceeds 1.0V.

1 time: 0 - 0.3V®0.6 - 1.0V®0 - 0.3V

2 times: 0 - 0.3V®0.6 - 1.0V®0 - 0.3V®0.6 - 1.0V®0-

0.3V

CAUTION:

+Discard any heated oxygen sensor which has been

dropped from a height of more than 0.5 m (19.7 in) onto a

hard surface such as a concrete floor; use a new one.

+Before installing new oxygen sensor, clean exhaust sys-

tem threads using Oxygen Sensor Thread Cleaner tool

and approved anti-seize lubricant.

HEATED OXYGEN SENSOR 1 (FRONT)QG

Component Inspection (Cont'd)

EC-378

Page 675 of 2493

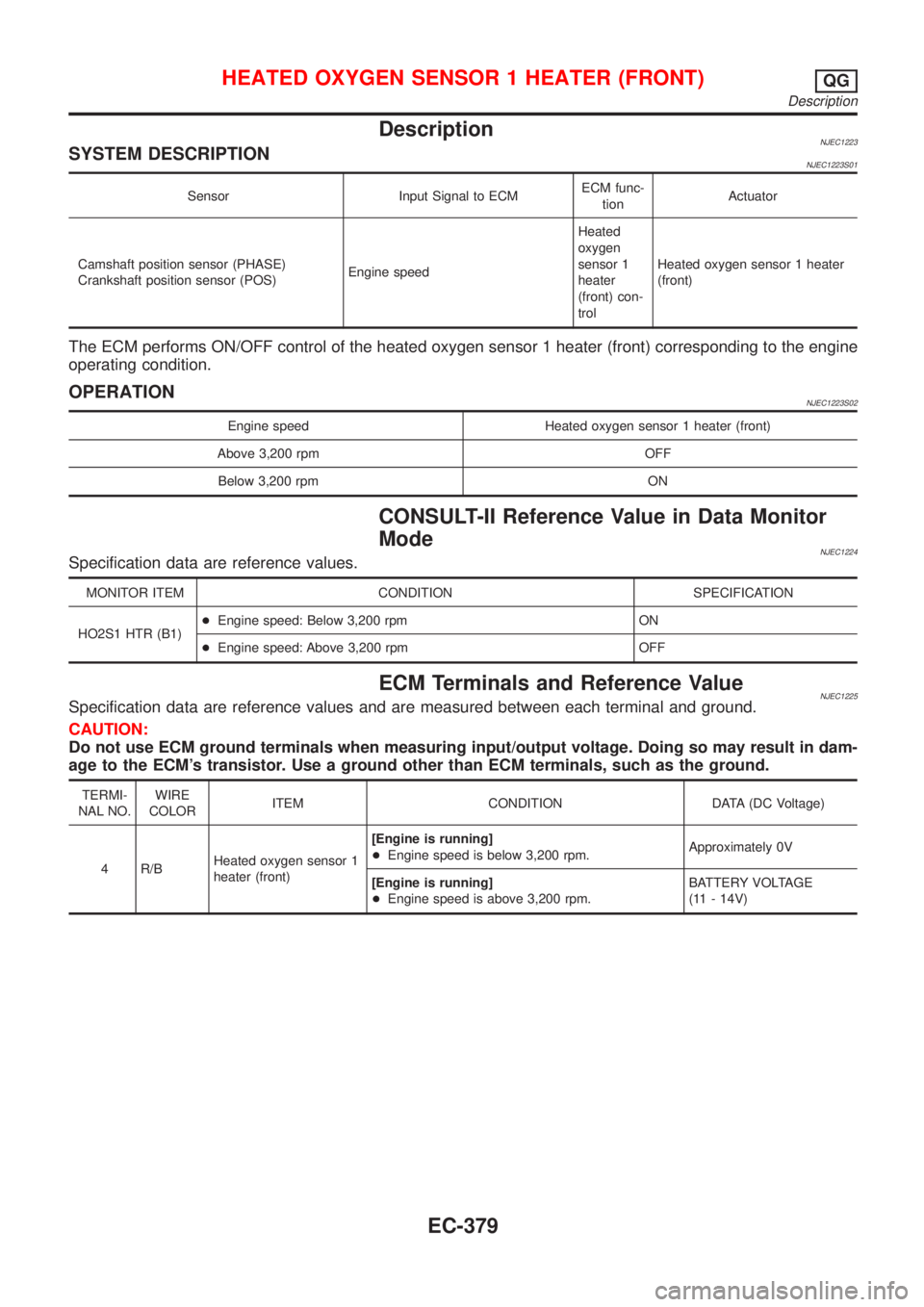

DescriptionNJEC1223SYSTEM DESCRIPTIONNJEC1223S01

Sensor Input Signal to ECMECM func-

tionActuator

Camshaft position sensor (PHASE)

Crankshaft position sensor (POS)Engine speedHeated

oxygen

sensor 1

heater

(front) con-

trolHeated oxygen sensor 1 heater

(front)

The ECM performs ON/OFF control of the heated oxygen sensor 1 heater (front) corresponding to the engine

operating condition.

OPERATIONNJEC1223S02

Engine speed Heated oxygen sensor 1 heater (front)

Above 3,200 rpm OFF

Below 3,200 rpm ON

CONSULT-II Reference Value in Data Monitor

Mode

NJEC1224Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

HO2S1 HTR (B1)+Engine speed: Below 3,200 rpm ON

+Engine speed: Above 3,200 rpm OFF

ECM Terminals and Reference ValueNJEC1225Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

4 R/BHeated oxygen sensor 1

heater (front)[Engine is running]

+Engine speed is below 3,200 rpm.Approximately 0V

[Engine is running]

+Engine speed is above 3,200 rpm.BATTERY VOLTAGE

(11 - 14V)

HEATED OXYGEN SENSOR 1 HEATER (FRONT)QG

Description

EC-379

Page 676 of 2493

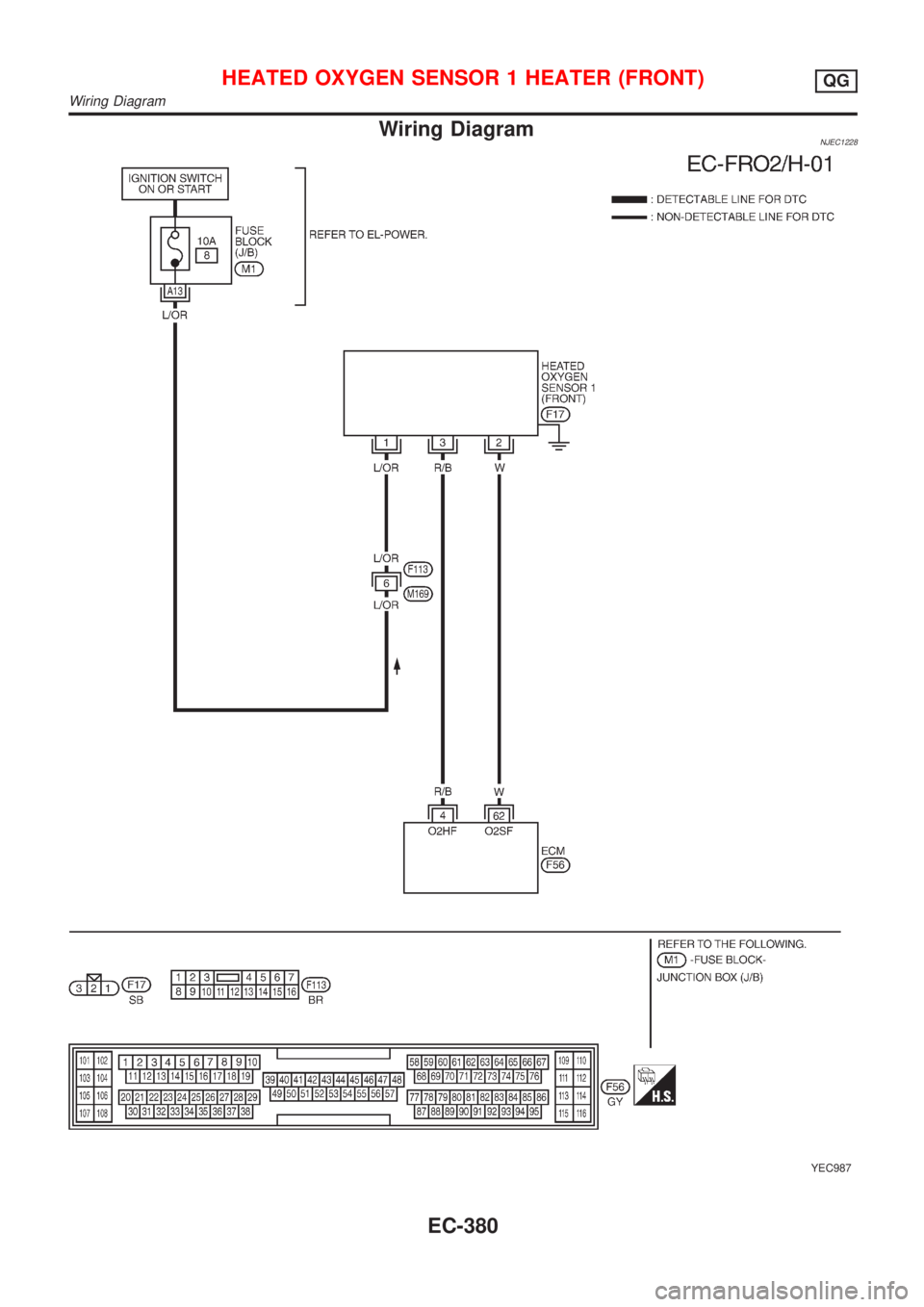

Wiring DiagramNJEC1228

YEC987

HEATED OXYGEN SENSOR 1 HEATER (FRONT)QG

Wiring Diagram

EC-380

Page 677 of 2493

![NISSAN ALMERA N16 2001 Electronic Repair Manual Diagnostic ProcedureNJEC1229

1 CHECK OVERALL FUNCTION

1. Turn ignition switch ªONº.

2. Set the tester probe between ECM terminals 4 [HO2S1 Heater (front) signal] and ground.

3. Start engine and let NISSAN ALMERA N16 2001 Electronic Repair Manual Diagnostic ProcedureNJEC1229

1 CHECK OVERALL FUNCTION

1. Turn ignition switch ªONº.

2. Set the tester probe between ECM terminals 4 [HO2S1 Heater (front) signal] and ground.

3. Start engine and let](/img/5/57351/w960_57351-676.png)

Diagnostic ProcedureNJEC1229

1 CHECK OVERALL FUNCTION

1. Turn ignition switch ªONº.

2. Set the tester probe between ECM terminals 4 [HO2S1 Heater (front) signal] and ground.

3. Start engine and let it idle.

4. Check the voltage under the following conditions.

SEF239Z

OK or NG

OK©INSPECTION END

NG©GO TO 2.

2 CHECK POWER SUPPLY

1. Turn ignition switch ªOFFº.

2. Disconnect heated oxygen sensor 1 (front) harness connector.

SEF012XA

3. Turn ignition switch ªONº.

4. Check voltage between terminal 1 and ground with CONSULT-II or tester.

SEF934X

OK or NG

OK©GO TO 4.

NG©GO TO 3.

HEATED OXYGEN SENSOR 1 HEATER (FRONT)QG

Diagnostic Procedure

EC-381

Page 678 of 2493

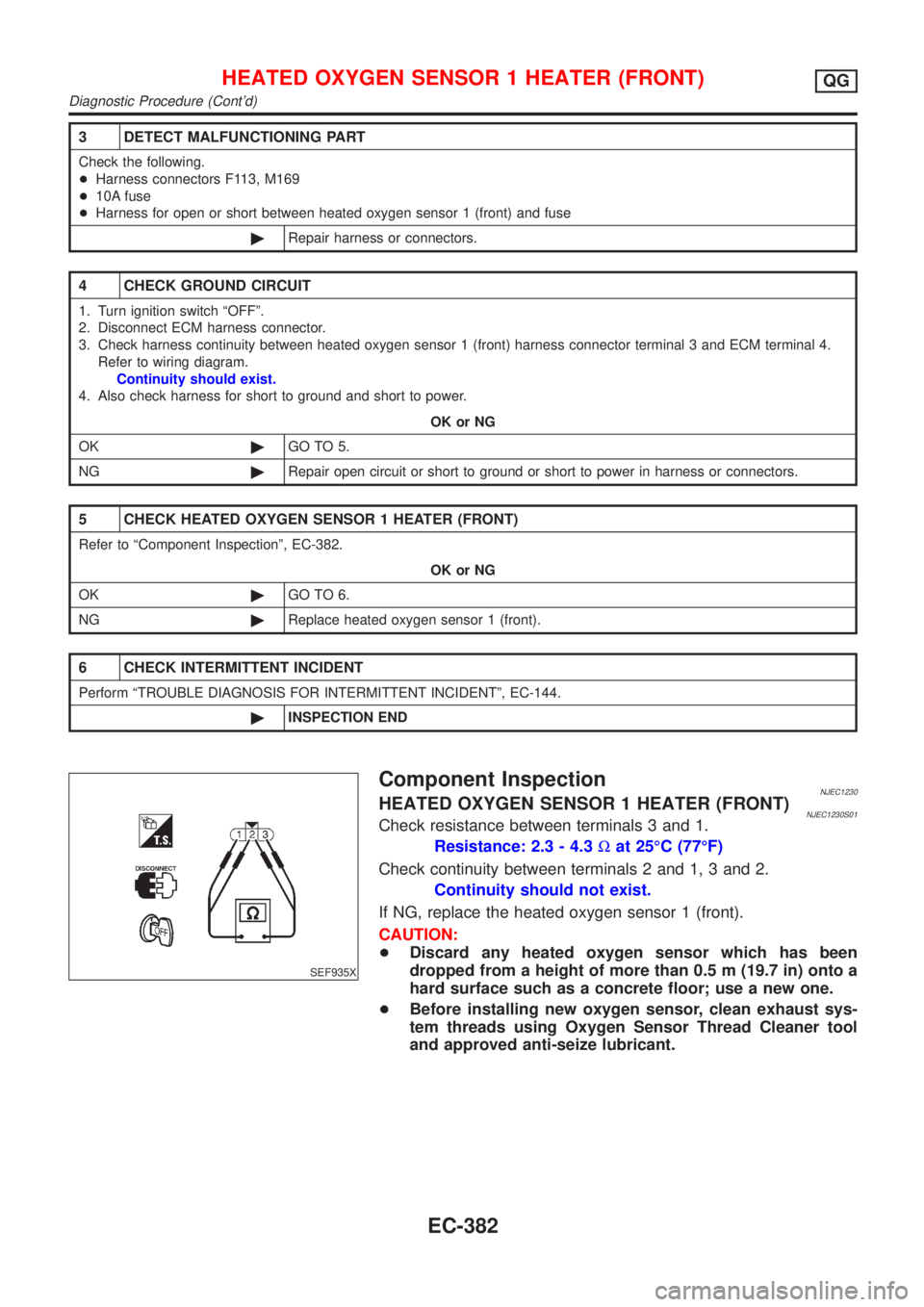

3 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors F113, M169

+10A fuse

+Harness for open or short between heated oxygen sensor 1 (front) and fuse

©Repair harness or connectors.

4 CHECK GROUND CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect ECM harness connector.

3. Check harness continuity between heated oxygen sensor 1 (front) harness connector terminal 3 and ECM terminal 4.

Refer to wiring diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 5.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

5 CHECK HEATED OXYGEN SENSOR 1 HEATER (FRONT)

Refer to ªComponent Inspectionº, EC-382.

OK or NG

OK©GO TO 6.

NG©Replace heated oxygen sensor 1 (front).

6 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-144.

©INSPECTION END

SEF935X

Component InspectionNJEC1230HEATED OXYGEN SENSOR 1 HEATER (FRONT)NJEC1230S01Check resistance between terminals 3 and 1.

Resistance: 2.3 - 4.3Wat 25ÉC (77ÉF)

Check continuity between terminals 2 and 1, 3 and 2.

Continuity should not exist.

If NG, replace the heated oxygen sensor 1 (front).

CAUTION:

+Discard any heated oxygen sensor which has been

dropped from a height of more than 0.5 m (19.7 in) onto a

hard surface such as a concrete floor; use a new one.

+Before installing new oxygen sensor, clean exhaust sys-

tem threads using Oxygen Sensor Thread Cleaner tool

and approved anti-seize lubricant.

HEATED OXYGEN SENSOR 1 HEATER (FRONT)QG

Diagnostic Procedure (Cont'd)

EC-382

Page 679 of 2493

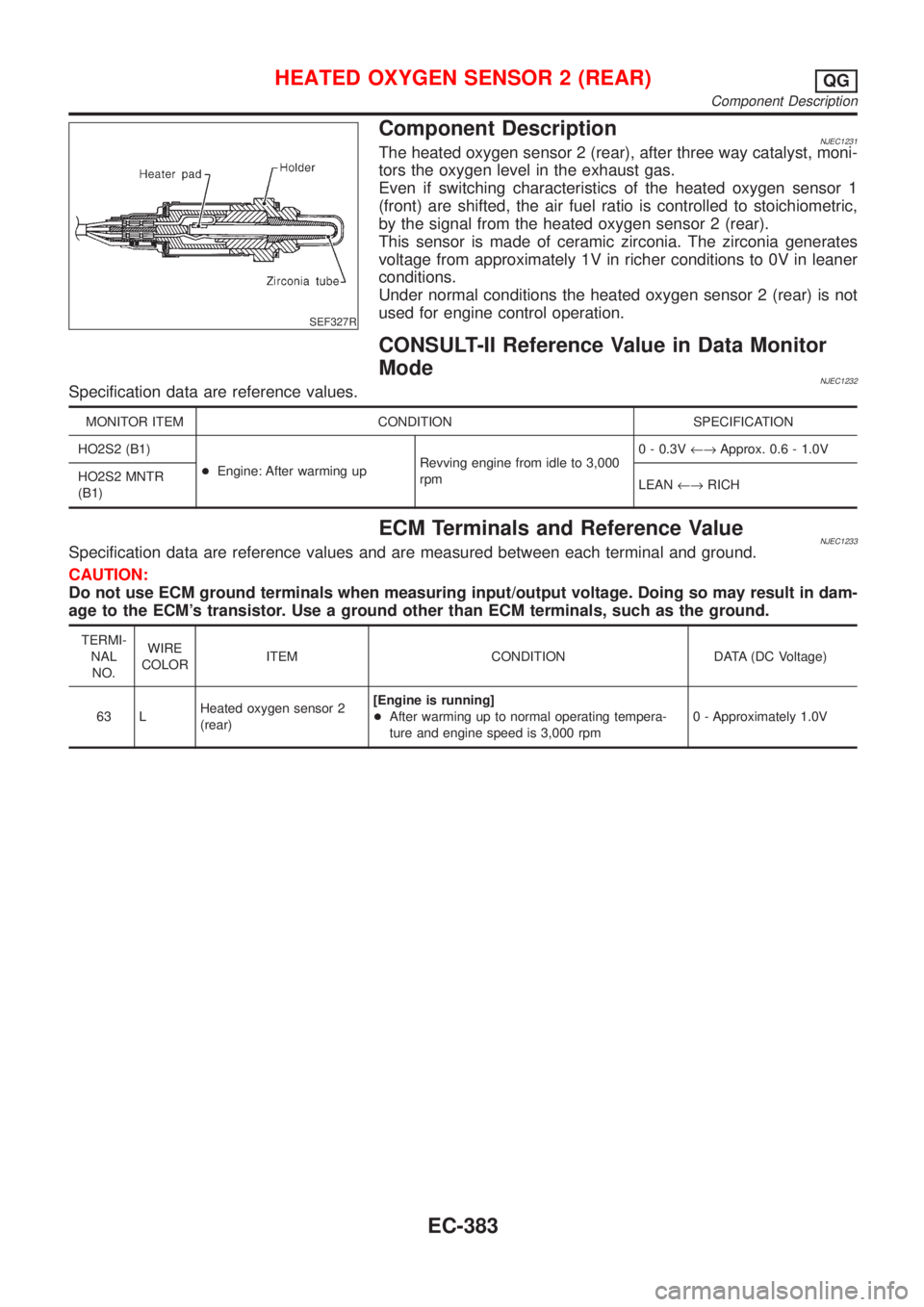

SEF327R

Component DescriptionNJEC1231The heated oxygen sensor 2 (rear), after three way catalyst, moni-

tors the oxygen level in the exhaust gas.

Even if switching characteristics of the heated oxygen sensor 1

(front) are shifted, the air fuel ratio is controlled to stoichiometric,

by the signal from the heated oxygen sensor 2 (rear).

This sensor is made of ceramic zirconia. The zirconia generates

voltage from approximately 1V in richer conditions to 0V in leaner

conditions.

Under normal conditions the heated oxygen sensor 2 (rear) is not

used for engine control operation.

CONSULT-II Reference Value in Data Monitor

Mode

NJEC1232Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

HO2S2 (B1)

+Engine: After warming upRevving engine from idle to 3,000

rpm0 - 0.3V¨Approx. 0.6 - 1.0V

HO2S2 MNTR

(B1)LEAN¨RICH

ECM Terminals and Reference ValueNJEC1233Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

63 LHeated oxygen sensor 2

(rear)[Engine is running]

+After warming up to normal operating tempera-

ture and engine speed is 3,000 rpm0 - Approximately 1.0V

HEATED OXYGEN SENSOR 2 (REAR)QG

Component Description

EC-383

Page 680 of 2493

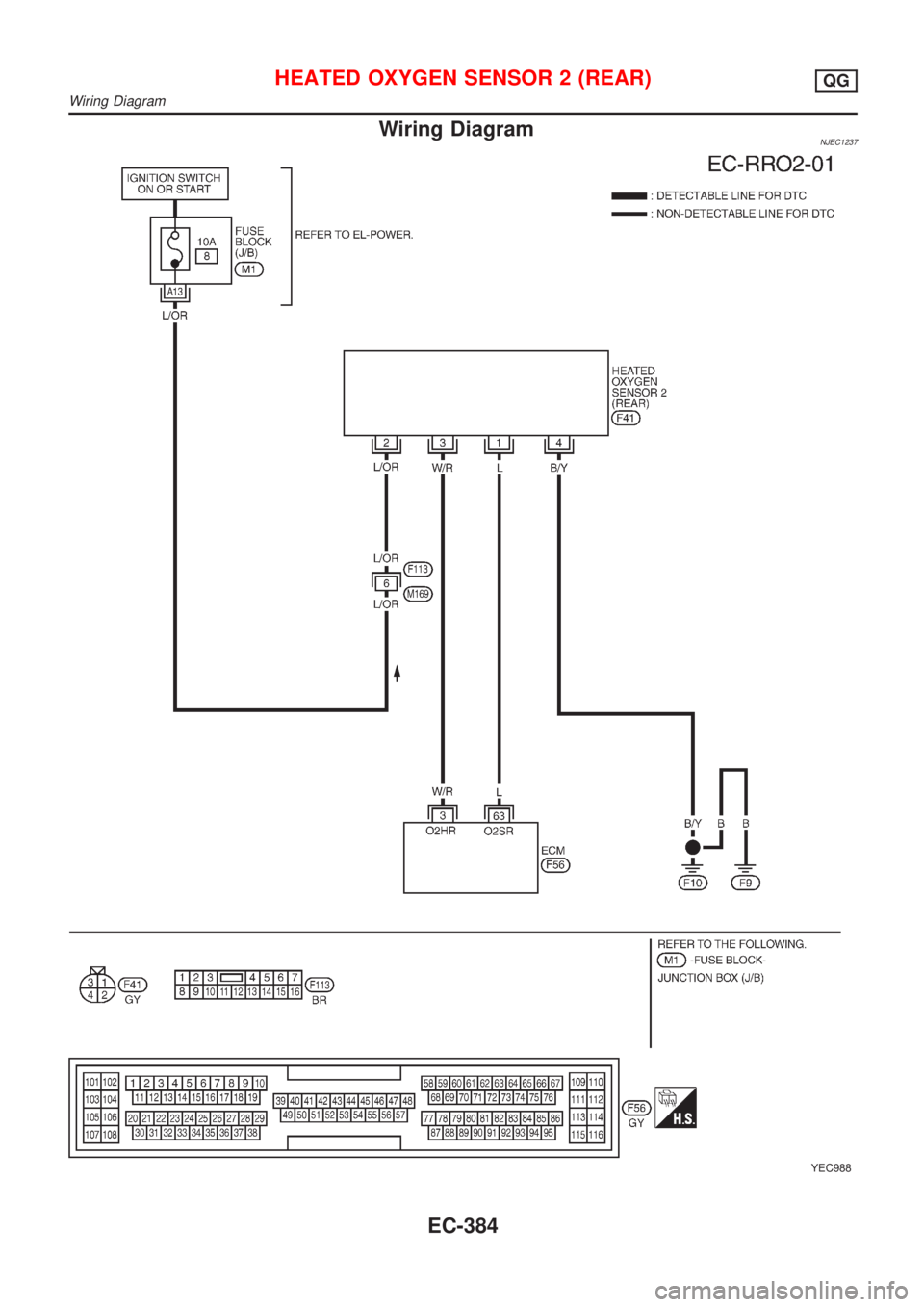

Wiring DiagramNJEC1237

YEC988

HEATED OXYGEN SENSOR 2 (REAR)QG

Wiring Diagram

EC-384