NISSAN ALMERA N16 2001 Electronic Repair Manual

ALMERA N16 2001

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57351/w960_57351-0.png

NISSAN ALMERA N16 2001 Electronic Repair Manual

Trending: spark plugs replace, p0325, audio cable, brake sensor, seats, engine oil capacity, four wheel drive

Page 661 of 2493

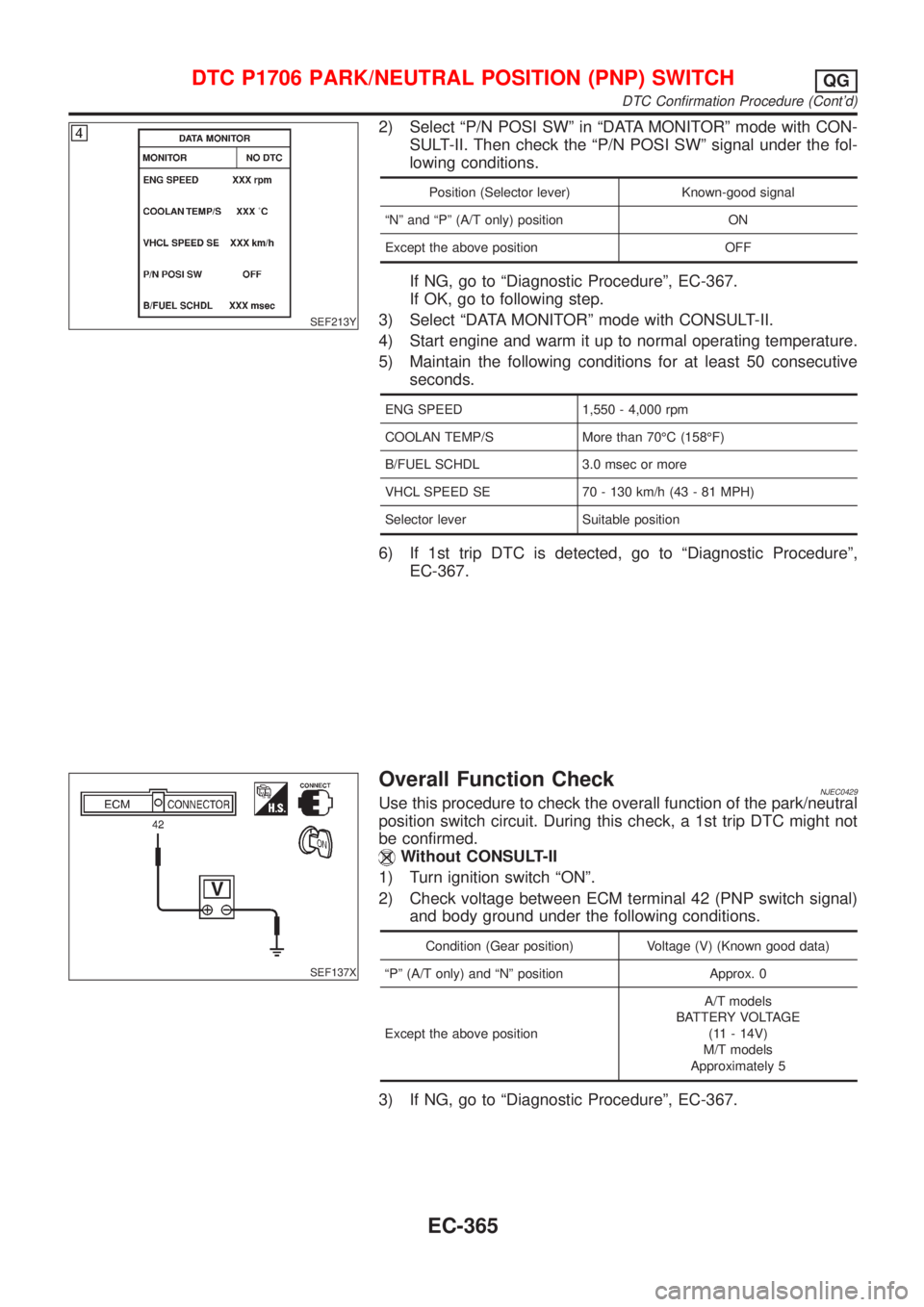

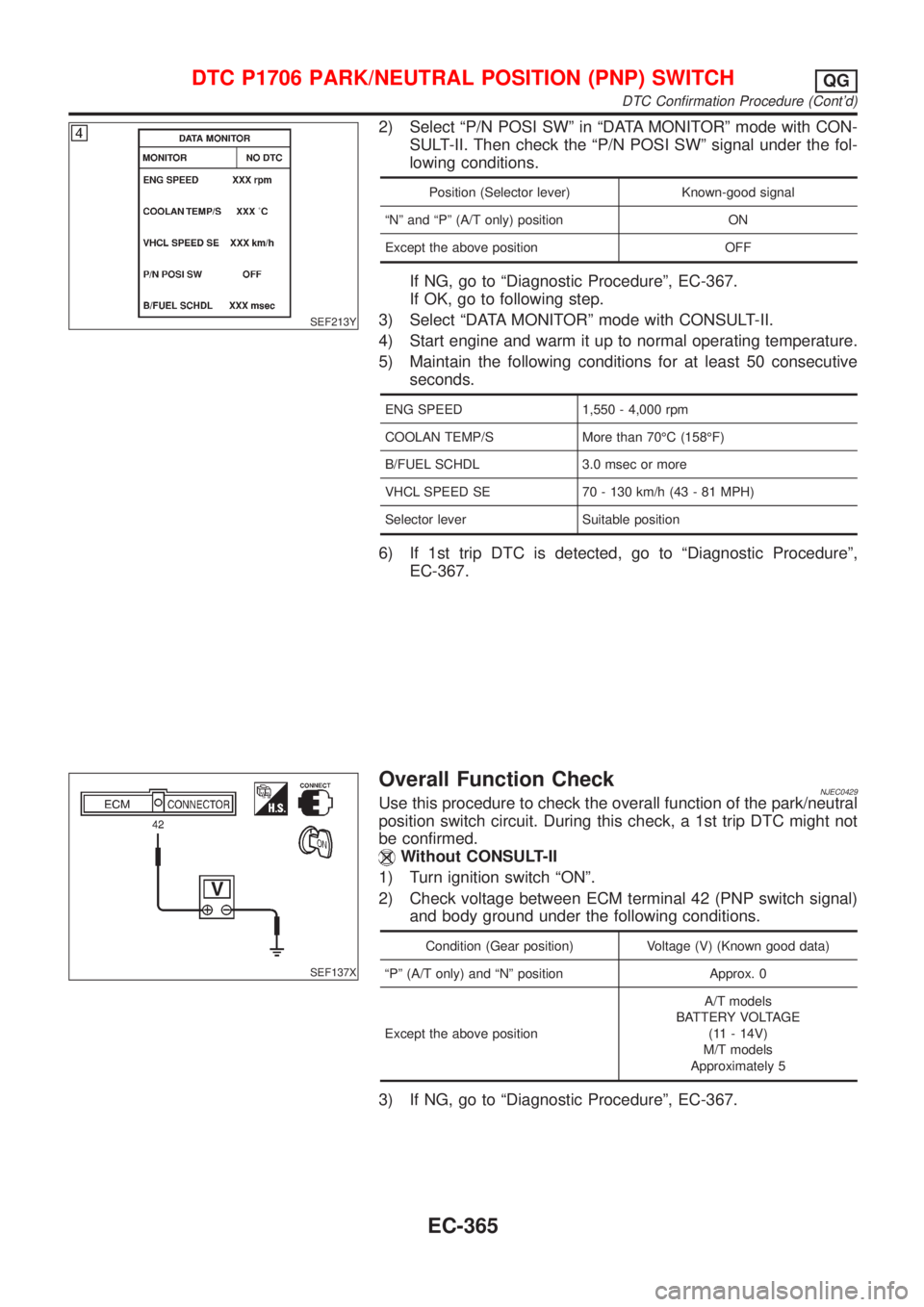

SEF213Y

2) Select ªP/N POSI SWº in ªDATA MONITORº mode with CON-

SULT-II. Then check the ªP/N POSI SWº signal under the fol-

lowing conditions.

Position (Selector lever) Known-good signal

ªNº and ªPº (A/T only) position ON

Except the above position OFF

If NG, go to ªDiagnostic Procedureº, EC-367.

If OK, go to following step.

3) Select ªDATA MONITORº mode with CONSULT-II.

4) Start engine and warm it up to normal operating temperature.

5) Maintain the following conditions for at least 50 consecutive

seconds.

ENG SPEED 1,550 - 4,000 rpm

COOLAN TEMP/S More than 70ÉC (158ÉF)

B/FUEL SCHDL 3.0 msec or more

VHCL SPEED SE 70 - 130 km/h (43 - 81 MPH)

Selector lever Suitable position

6) If 1st trip DTC is detected, go to ªDiagnostic Procedureº,

EC-367.

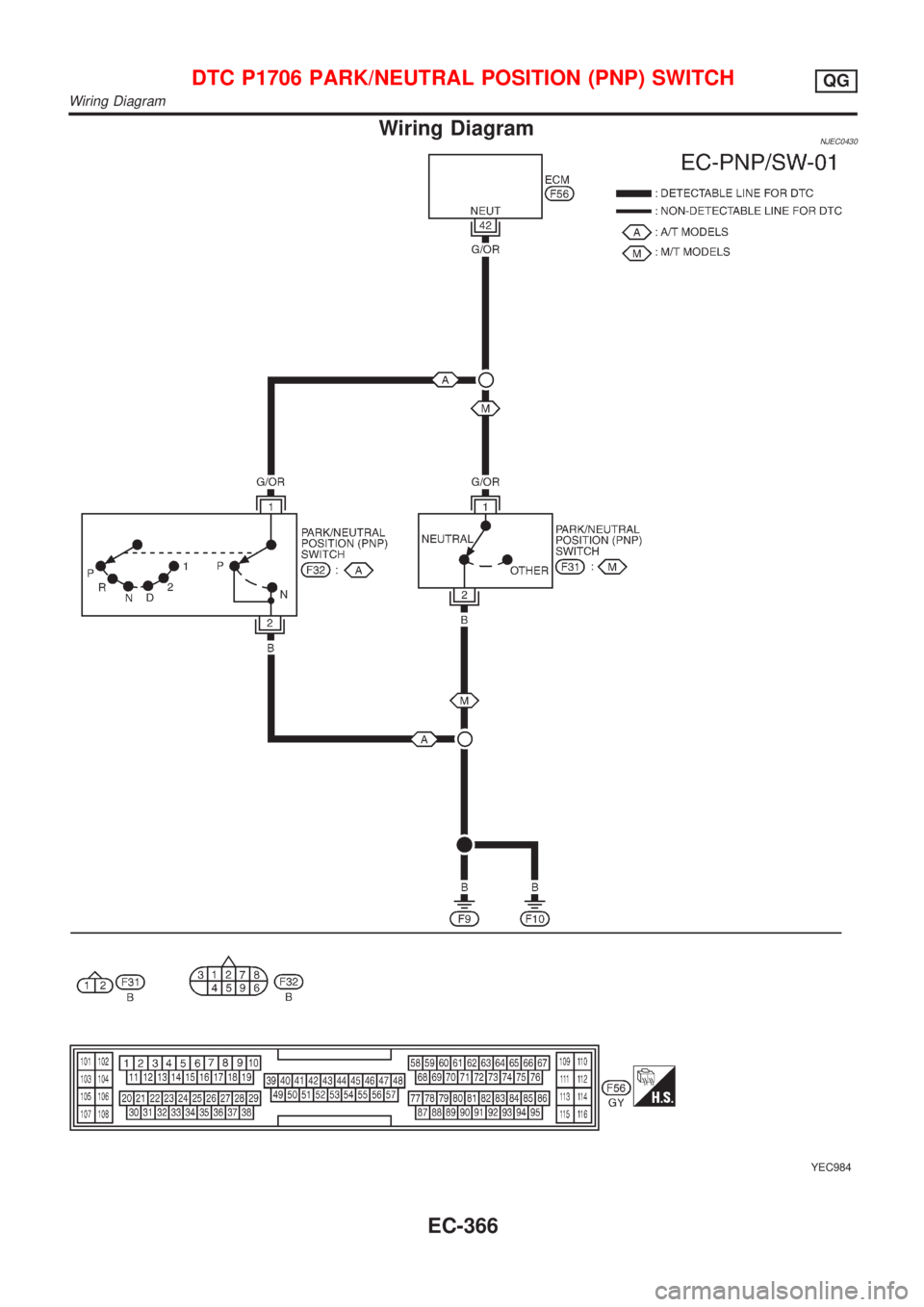

SEF137X

Overall Function CheckNJEC0429Use this procedure to check the overall function of the park/neutral

position switch circuit. During this check, a 1st trip DTC might not

be confirmed.

Without CONSULT-II

1) Turn ignition switch ªONº.

2) Check voltage between ECM terminal 42 (PNP switch signal)

and body ground under the following conditions.

Condition (Gear position) Voltage (V) (Known good data)

ªPº (A/T only) and ªNº position Approx. 0

Except the above positionA/T models

BATTERY VOLTAGE

(11 - 14V)

M/T models

Approximately 5

3) If NG, go to ªDiagnostic Procedureº, EC-367.

DTC P1706 PARK/NEUTRAL POSITION (PNP) SWITCHQG

DTC Confirmation Procedure (Cont'd)

EC-365

Page 662 of 2493

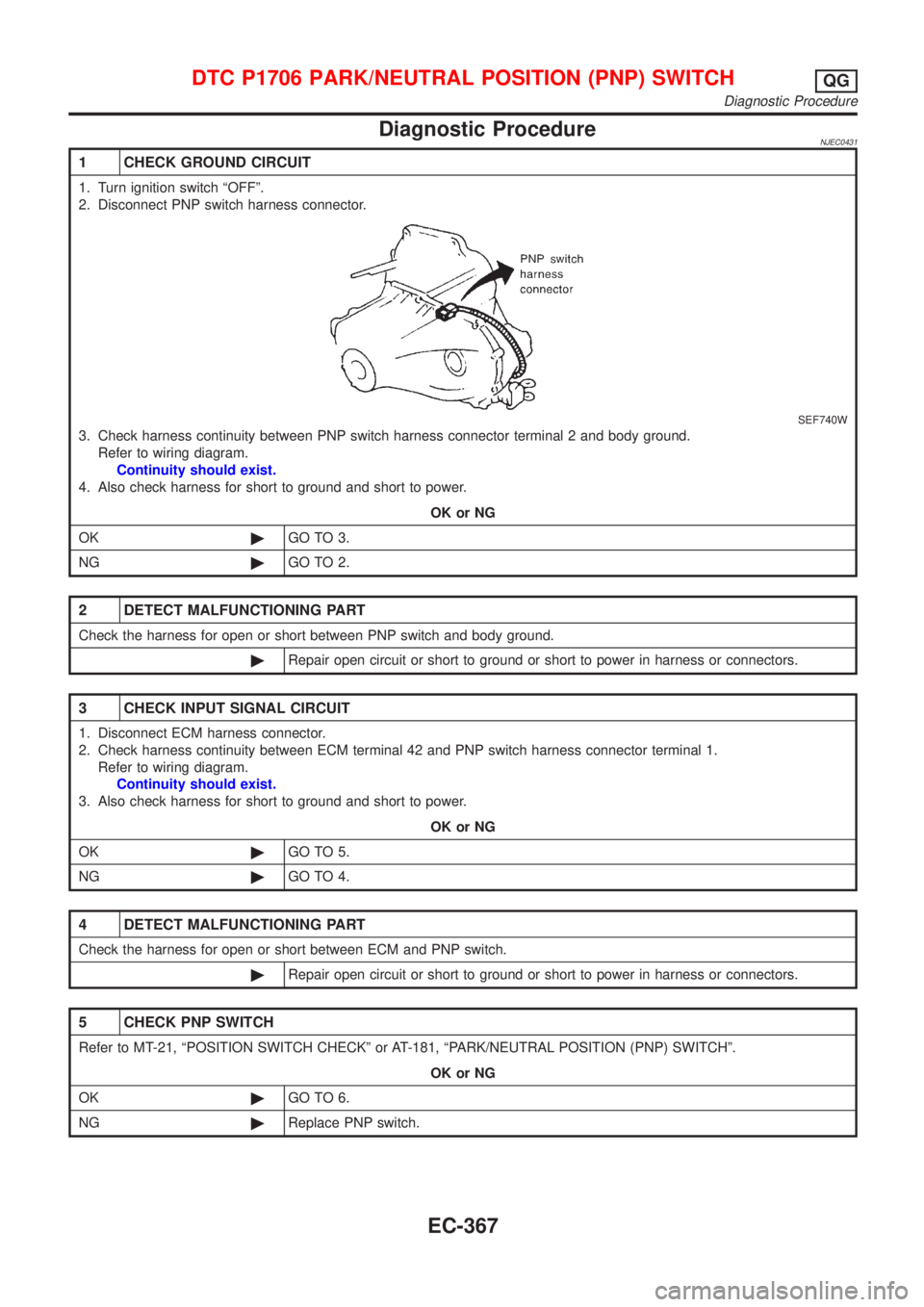

Wiring DiagramNJEC0430

YEC984

DTC P1706 PARK/NEUTRAL POSITION (PNP) SWITCHQG

Wiring Diagram

EC-366

Page 663 of 2493

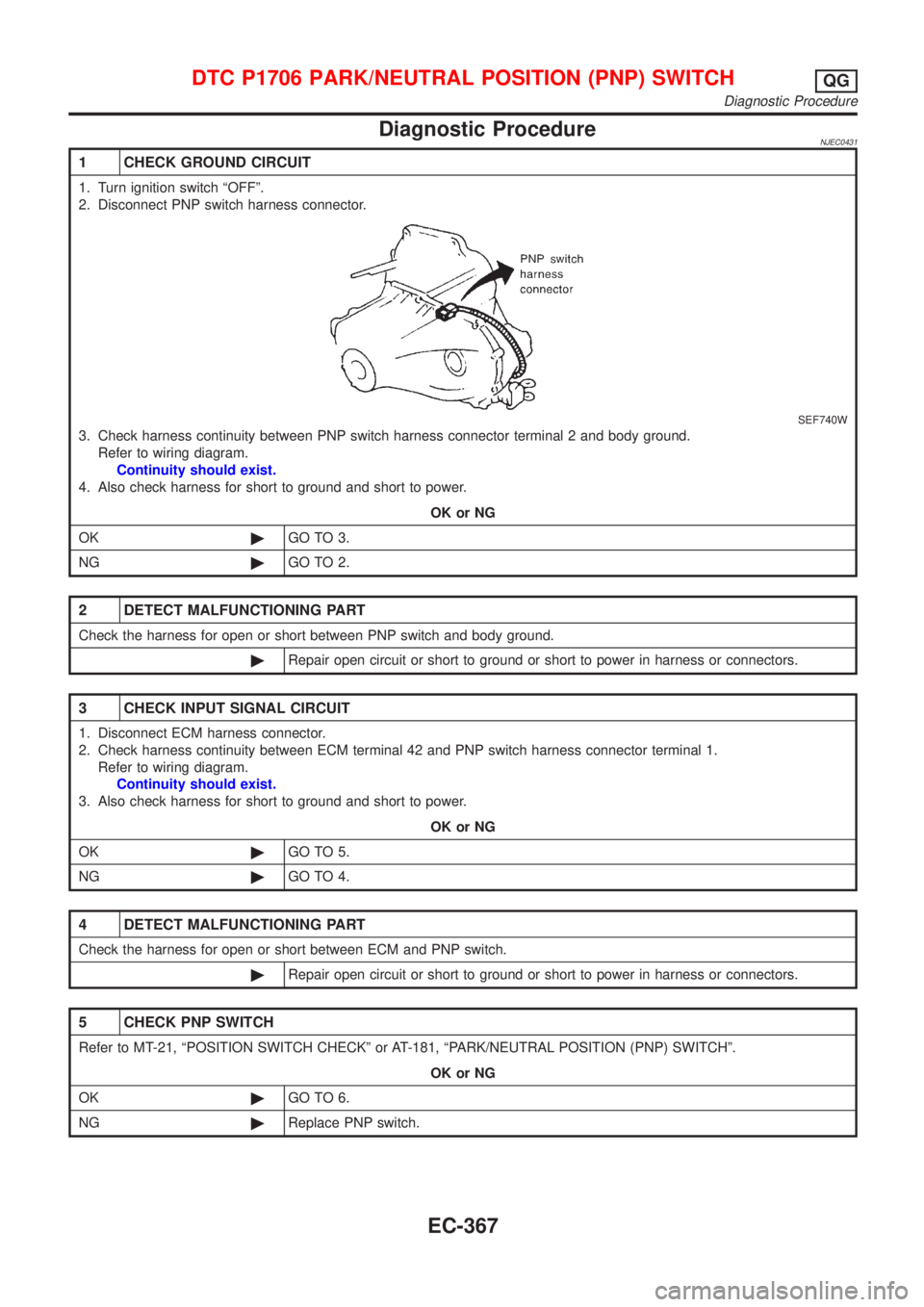

Diagnostic ProcedureNJEC0431

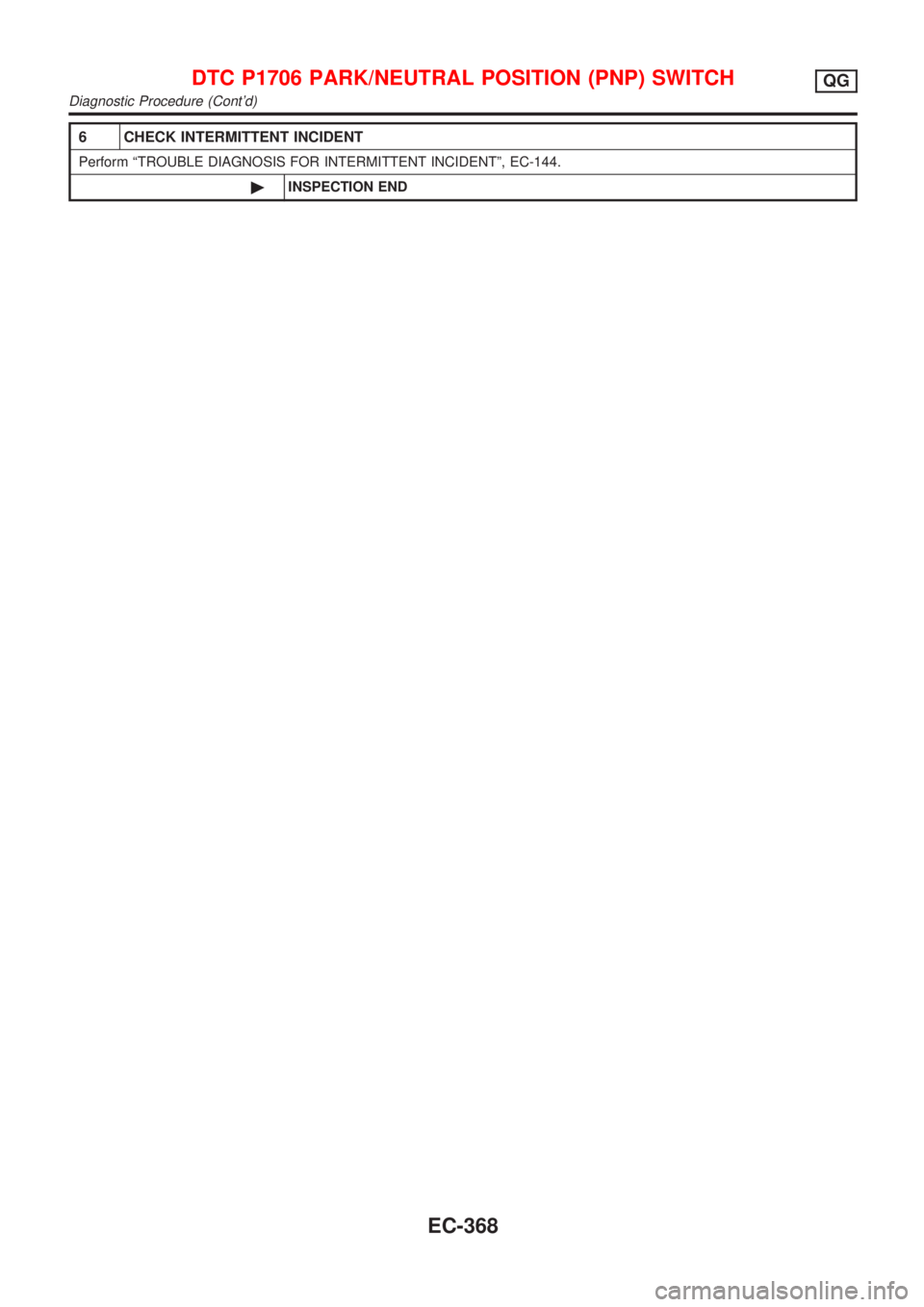

1 CHECK GROUND CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect PNP switch harness connector.

SEF740W

3. Check harness continuity between PNP switch harness connector terminal 2 and body ground.

Refer to wiring diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 3.

NG©GO TO 2.

2 DETECT MALFUNCTIONING PART

Check the harness for open or short between PNP switch and body ground.

©Repair open circuit or short to ground or short to power in harness or connectors.

3 CHECK INPUT SIGNAL CIRCUIT

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminal 42 and PNP switch harness connector terminal 1.

Refer to wiring diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 5.

NG©GO TO 4.

4 DETECT MALFUNCTIONING PART

Check the harness for open or short between ECM and PNP switch.

©Repair open circuit or short to ground or short to power in harness or connectors.

5 CHECK PNP SWITCH

Refer to MT-21, ªPOSITION SWITCH CHECKº or AT-181, ªPARK/NEUTRAL POSITION (PNP) SWITCHº.

OK or NG

OK©GO TO 6.

NG©Replace PNP switch.

DTC P1706 PARK/NEUTRAL POSITION (PNP) SWITCHQG

Diagnostic Procedure

EC-367

Page 664 of 2493

6 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-144.

©INSPECTION END

DTC P1706 PARK/NEUTRAL POSITION (PNP) SWITCHQG

Diagnostic Procedure (Cont'd)

EC-368

Page 665 of 2493

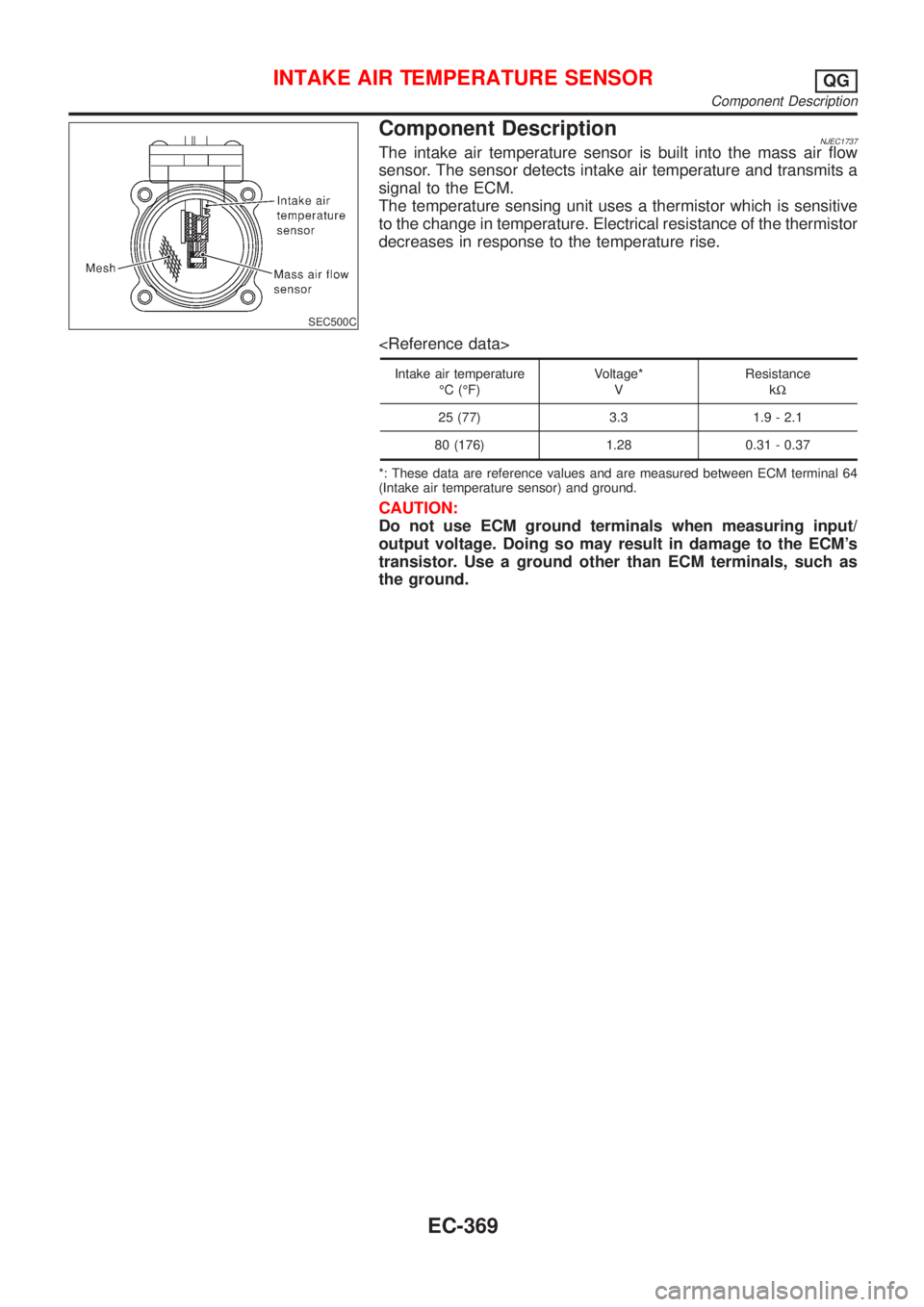

SEC500C

Component DescriptionNJEC1737The intake air temperature sensor is built into the mass air flow

sensor. The sensor detects intake air temperature and transmits a

signal to the ECM.

The temperature sensing unit uses a thermistor which is sensitive

to the change in temperature. Electrical resistance of the thermistor

decreases in response to the temperature rise.

Intake air temperature

ÉC (ÉF)Voltage*

VResistance

kW

25 (77) 3.3 1.9 - 2.1

80 (176) 1.28 0.31 - 0.37

*: These data are reference values and are measured between ECM terminal 64

(Intake air temperature sensor) and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/

output voltage. Doing so may result in damage to the ECM's

transistor. Use a ground other than ECM terminals, such as

the ground.

INTAKE AIR TEMPERATURE SENSORQG

Component Description

EC-369

Page 666 of 2493

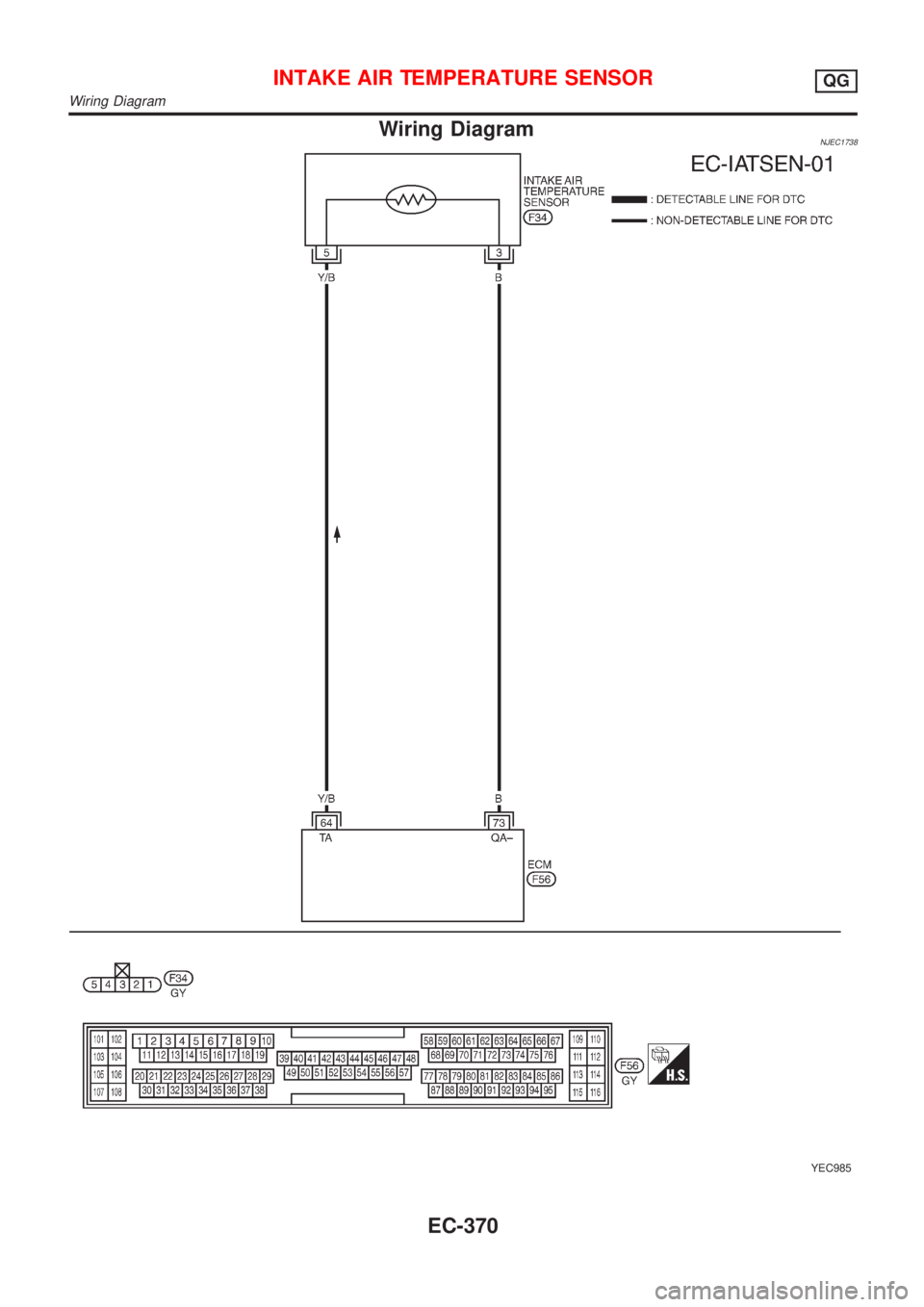

Wiring DiagramNJEC1738

YEC985

INTAKE AIR TEMPERATURE SENSORQG

Wiring Diagram

EC-370

Page 667 of 2493

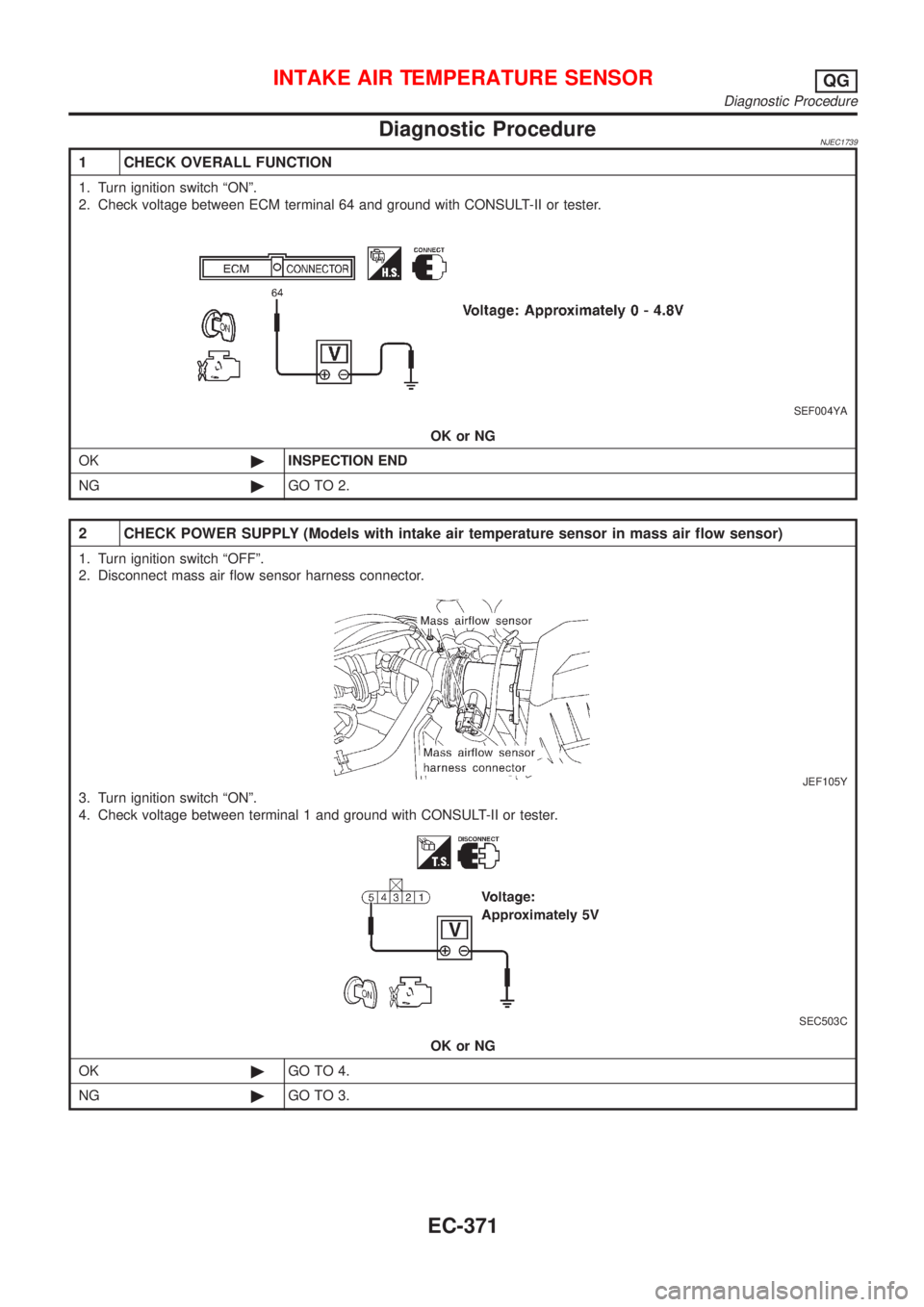

Diagnostic ProcedureNJEC1739

1 CHECK OVERALL FUNCTION

1. Turn ignition switch ªONº.

2. Check voltage between ECM terminal 64 and ground with CONSULT-II or tester.

SEF004YA

OK or NG

OK©INSPECTION END

NG©GO TO 2.

2 CHECK POWER SUPPLY (Models with intake air temperature sensor in mass air flow sensor)

1. Turn ignition switch ªOFFº.

2. Disconnect mass air flow sensor harness connector.

JEF105Y

3. Turn ignition switch ªONº.

4. Check voltage between terminal 1 and ground with CONSULT-II or tester.

SEC503C

OK or NG

OK©GO TO 4.

NG©GO TO 3.

INTAKE AIR TEMPERATURE SENSORQG

Diagnostic Procedure

EC-371

Page 668 of 2493

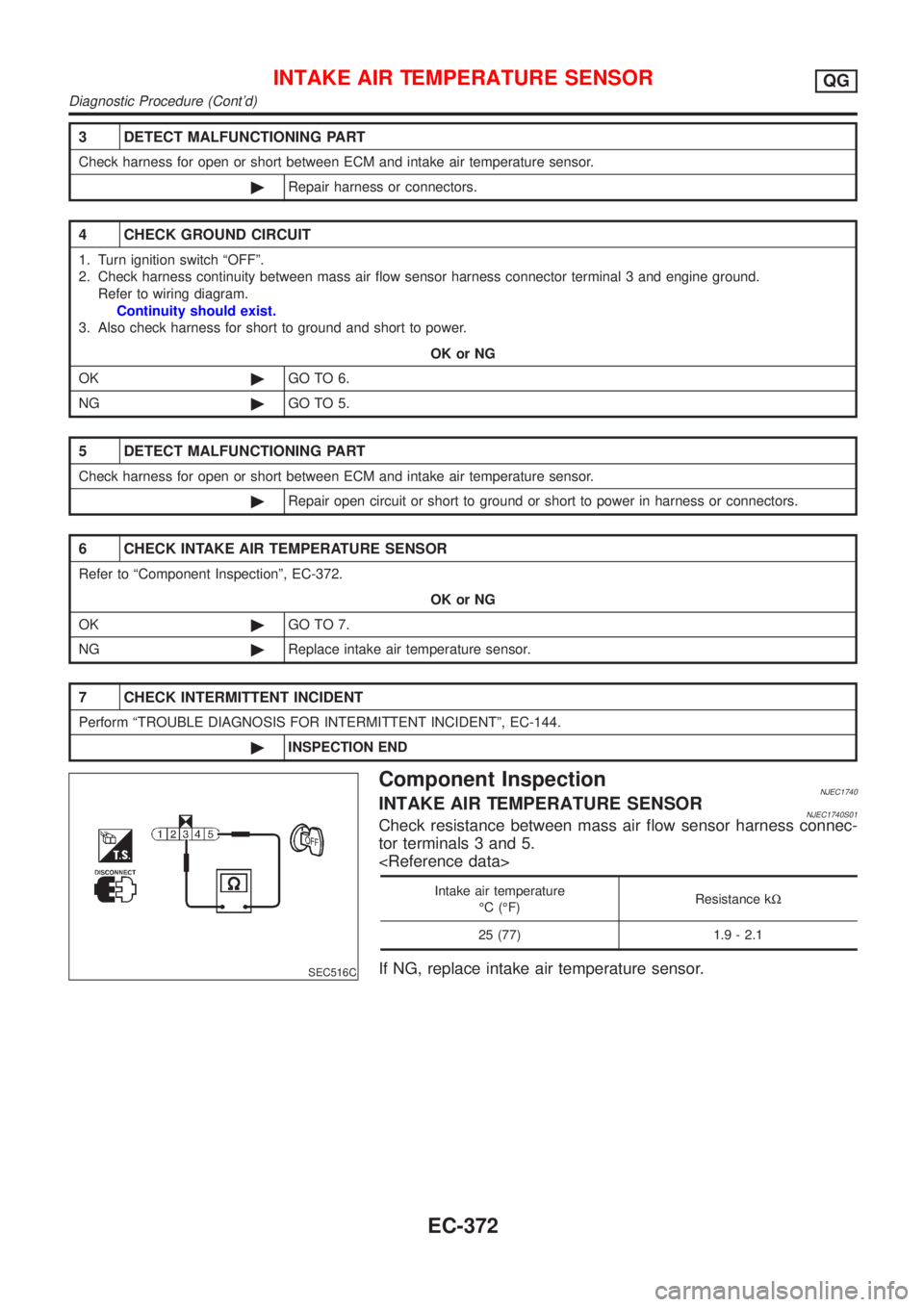

3 DETECT MALFUNCTIONING PART

Check harness for open or short between ECM and intake air temperature sensor.

©Repair harness or connectors.

4 CHECK GROUND CIRCUIT

1. Turn ignition switch ªOFFº.

2. Check harness continuity between mass air flow sensor harness connector terminal 3 and engine ground.

Refer to wiring diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OK©GO TO 6.

NG©GO TO 5.

5 DETECT MALFUNCTIONING PART

Check harness for open or short between ECM and intake air temperature sensor.

©Repair open circuit or short to ground or short to power in harness or connectors.

6 CHECK INTAKE AIR TEMPERATURE SENSOR

Refer to ªComponent Inspectionº, EC-372.

OK or NG

OK©GO TO 7.

NG©Replace intake air temperature sensor.

7 CHECK INTERMITTENT INCIDENT

Perform ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-144.

©INSPECTION END

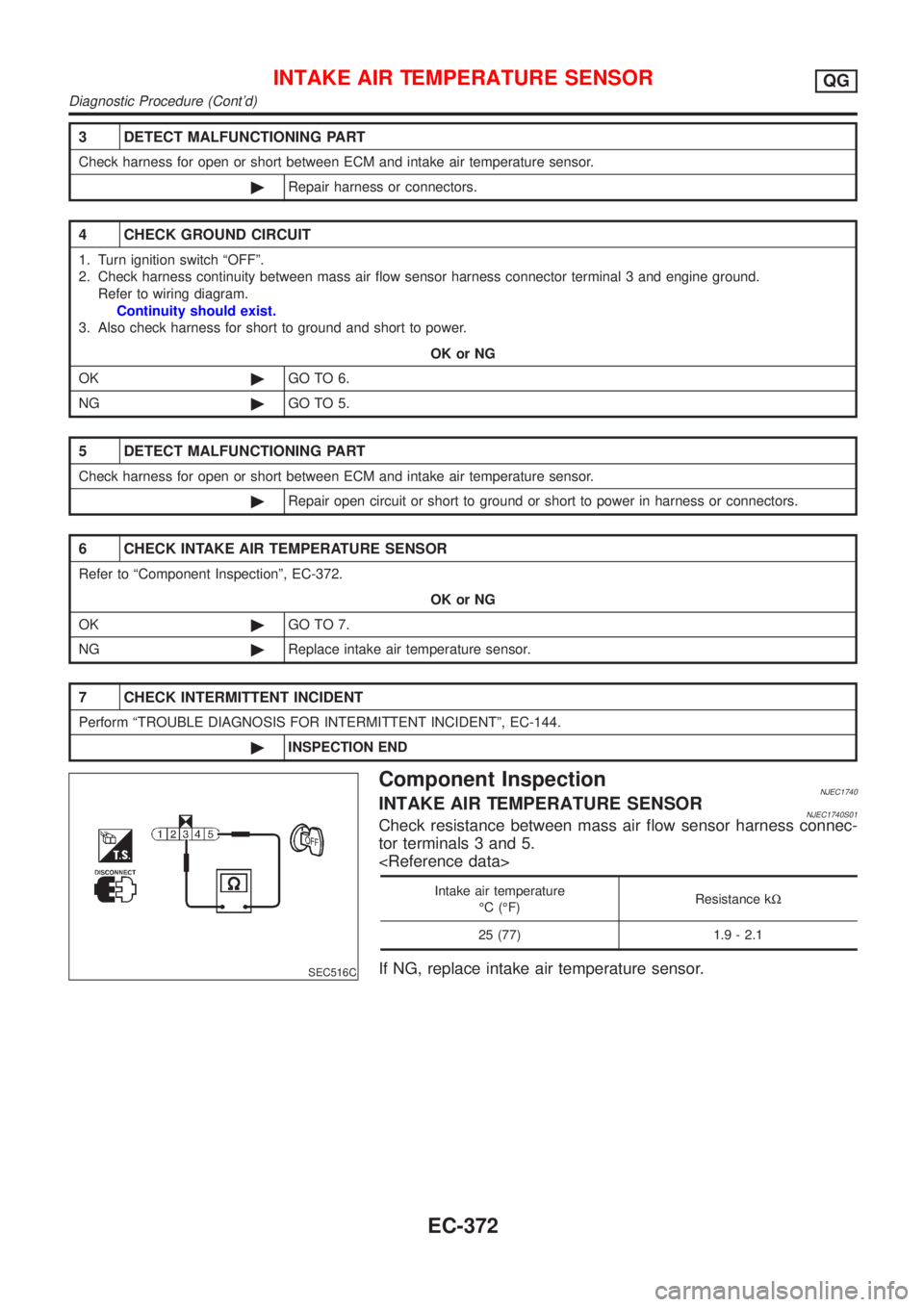

SEC516C

Component InspectionNJEC1740INTAKE AIR TEMPERATURE SENSORNJEC1740S01Check resistance between mass air flow sensor harness connec-

tor terminals 3 and 5.

Intake air temperature

ÉC (ÉF)Resistance kW

25 (77) 1.9 - 2.1

If NG, replace intake air temperature sensor.

INTAKE AIR TEMPERATURE SENSORQG

Diagnostic Procedure (Cont'd)

EC-372

Page 669 of 2493

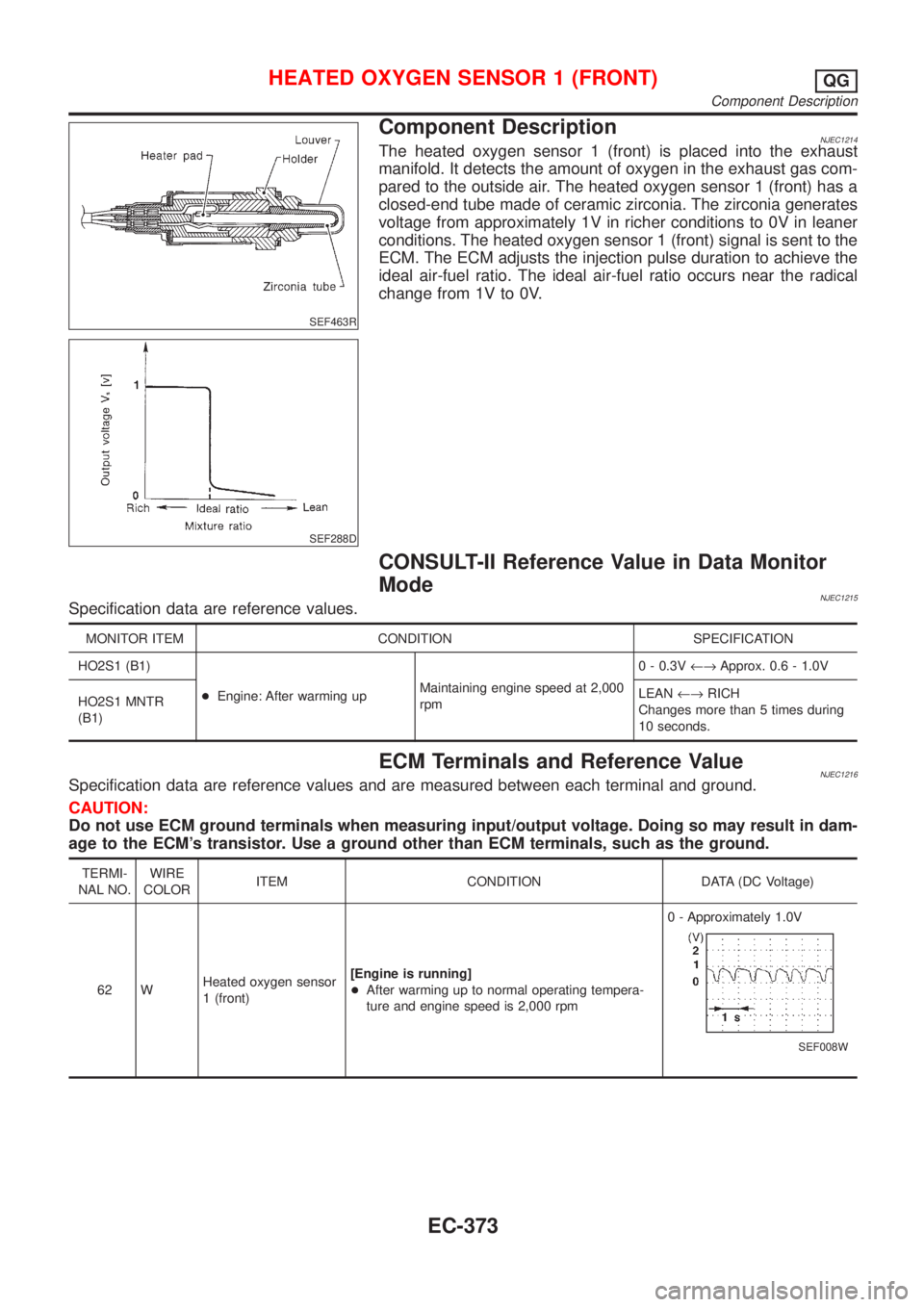

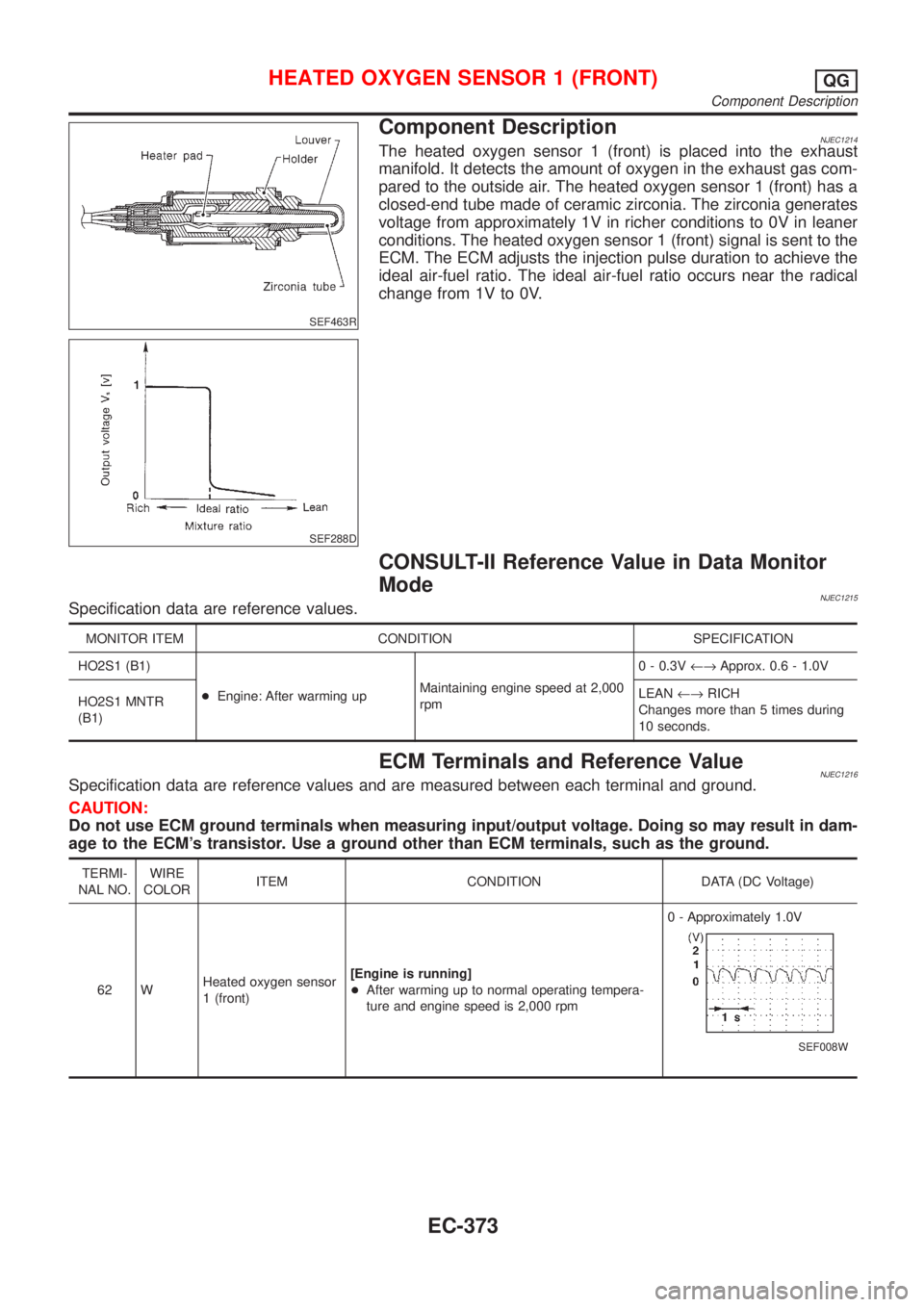

SEF463R

SEF288D

Component DescriptionNJEC1214The heated oxygen sensor 1 (front) is placed into the exhaust

manifold. It detects the amount of oxygen in the exhaust gas com-

pared to the outside air. The heated oxygen sensor 1 (front) has a

closed-end tube made of ceramic zirconia. The zirconia generates

voltage from approximately 1V in richer conditions to 0V in leaner

conditions. The heated oxygen sensor 1 (front) signal is sent to the

ECM. The ECM adjusts the injection pulse duration to achieve the

ideal air-fuel ratio. The ideal air-fuel ratio occurs near the radical

change from 1V to 0V.

CONSULT-II Reference Value in Data Monitor

Mode

NJEC1215Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

HO2S1 (B1)

+Engine: After warming upMaintaining engine speed at 2,000

rpm0 - 0.3V¨Approx. 0.6 - 1.0V

HO2S1 MNTR

(B1)LEAN¨RICH

Changes more than 5 times during

10 seconds.

ECM Terminals and Reference ValueNJEC1216Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

62 WHeated oxygen sensor

1 (front)[Engine is running]

+After warming up to normal operating tempera-

ture and engine speed is 2,000 rpm0 - Approximately 1.0V

SEF008W

HEATED OXYGEN SENSOR 1 (FRONT)QG

Component Description

EC-373

Page 670 of 2493

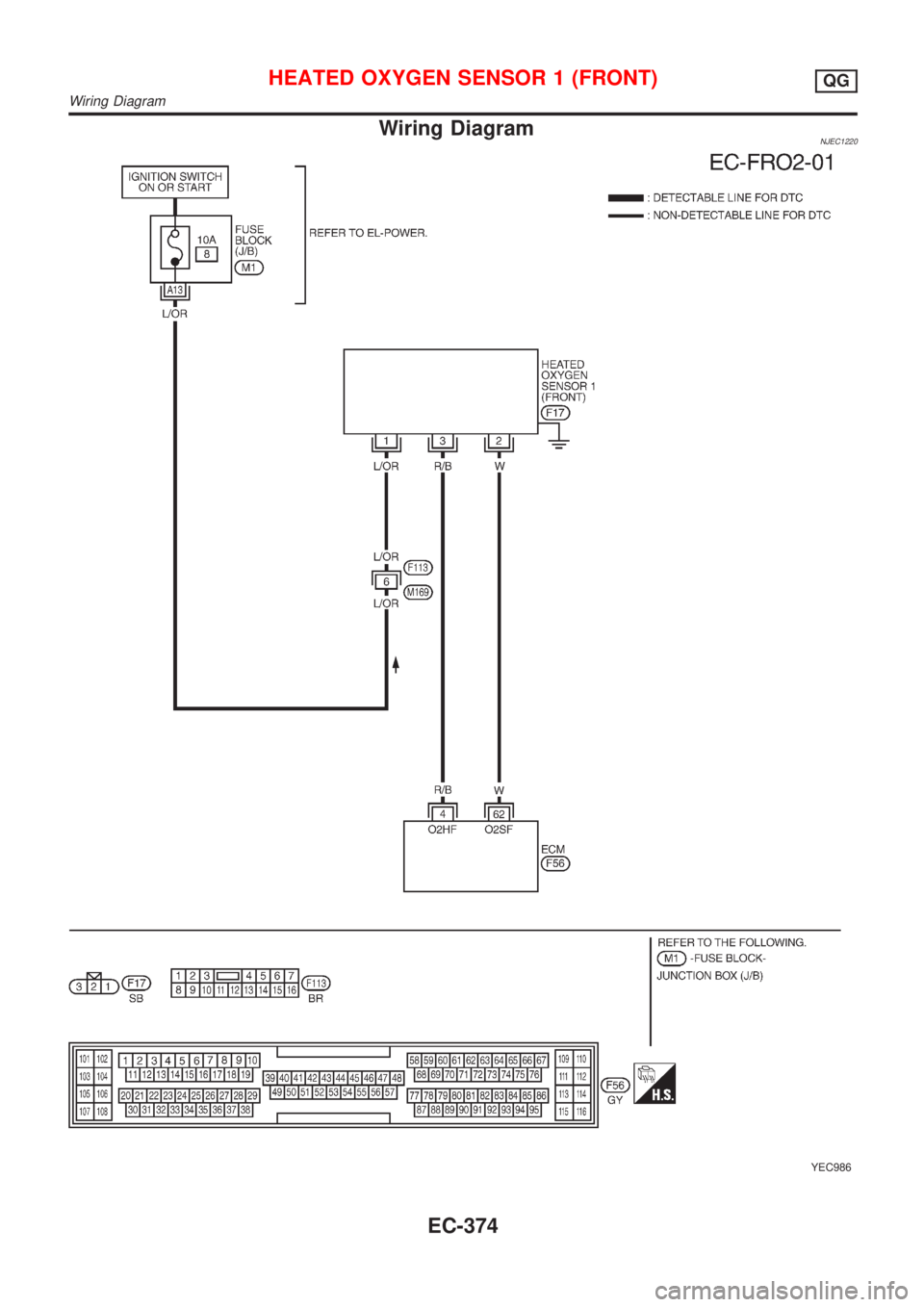

Wiring DiagramNJEC1220

YEC986

HEATED OXYGEN SENSOR 1 (FRONT)QG

Wiring Diagram

EC-374

Trending: audio, Rad fan, clock reset, rear lam, sat nav, AUX, el-149