NISSAN ALMERA N16 2003 Electronic Repair Manual

Manufacturer: NISSAN, Model Year: 2003, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2003Pages: 3189, PDF Size: 54.76 MB

Page 2201 of 3189

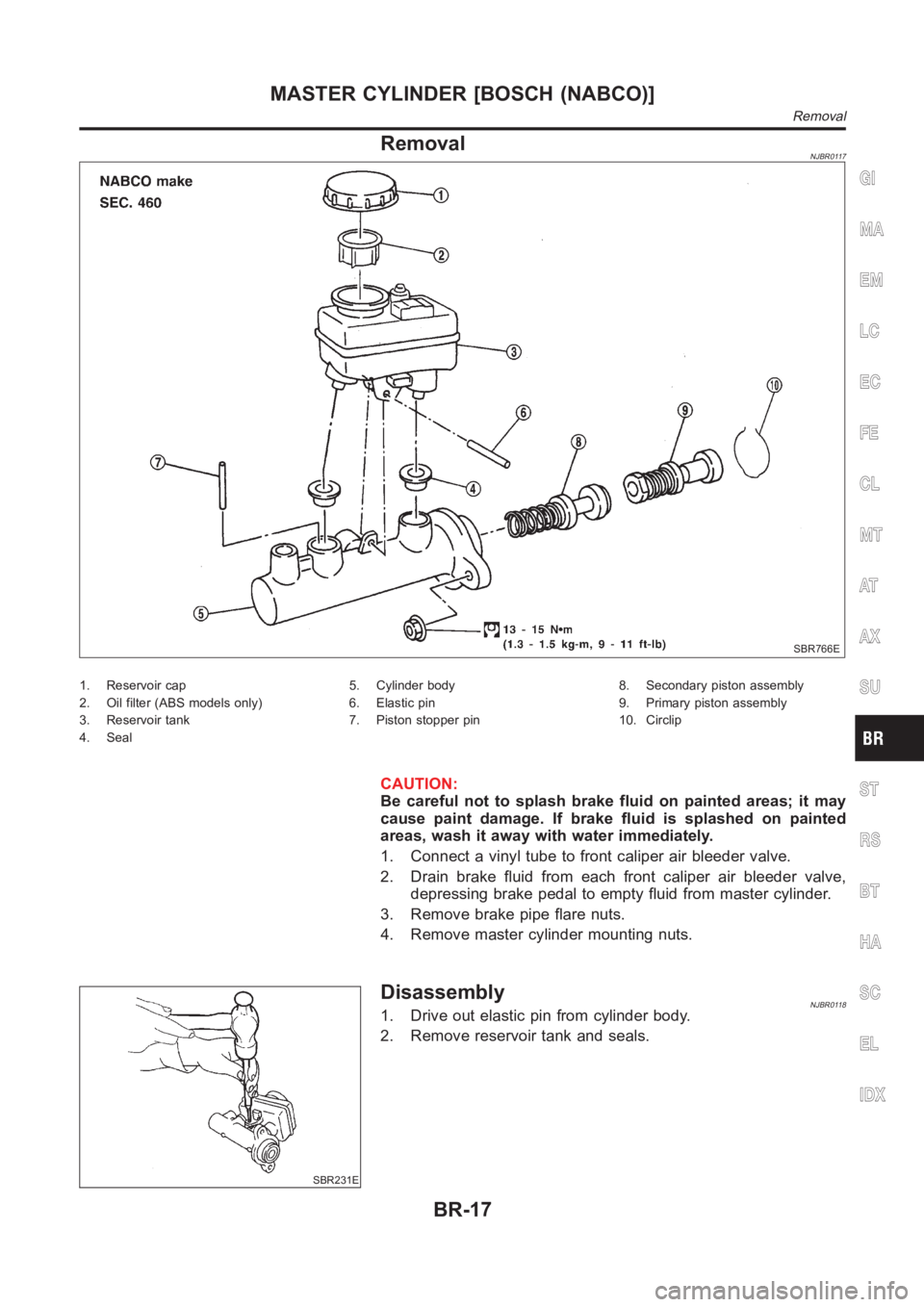

RemovalNJBR0117

SBR766E

1. Reservoir cap

2. Oil filter (ABS models only)

3. Reservoir tank

4. Seal5. Cylinder body

6. Elastic pin

7. Piston stopper pin8. Secondary piston assembly

9. Primary piston assembly

10. Circlip

CAUTION:

Be careful not to splash brake fluid on painted areas; it may

cause paint damage. If brake fluid is splashed on painted

areas, wash it away with water immediately.

1. Connect a vinyl tube to front caliper air bleeder valve.

2. Drain brake fluid from each front caliper air bleeder valve,

depressing brake pedal to empty fluid from master cylinder.

3. Remove brake pipe flare nuts.

4. Remove master cylinder mounting nuts.

SBR231E

DisassemblyNJBR01181. Drive out elastic pin from cylinder body.

2. Remove reservoir tank and seals.

GI

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

ST

RS

BT

HA

SC

EL

IDX

MASTER CYLINDER [BOSCH (NABCO)]

Removal

BR-17

Page 2202 of 3189

NBR353

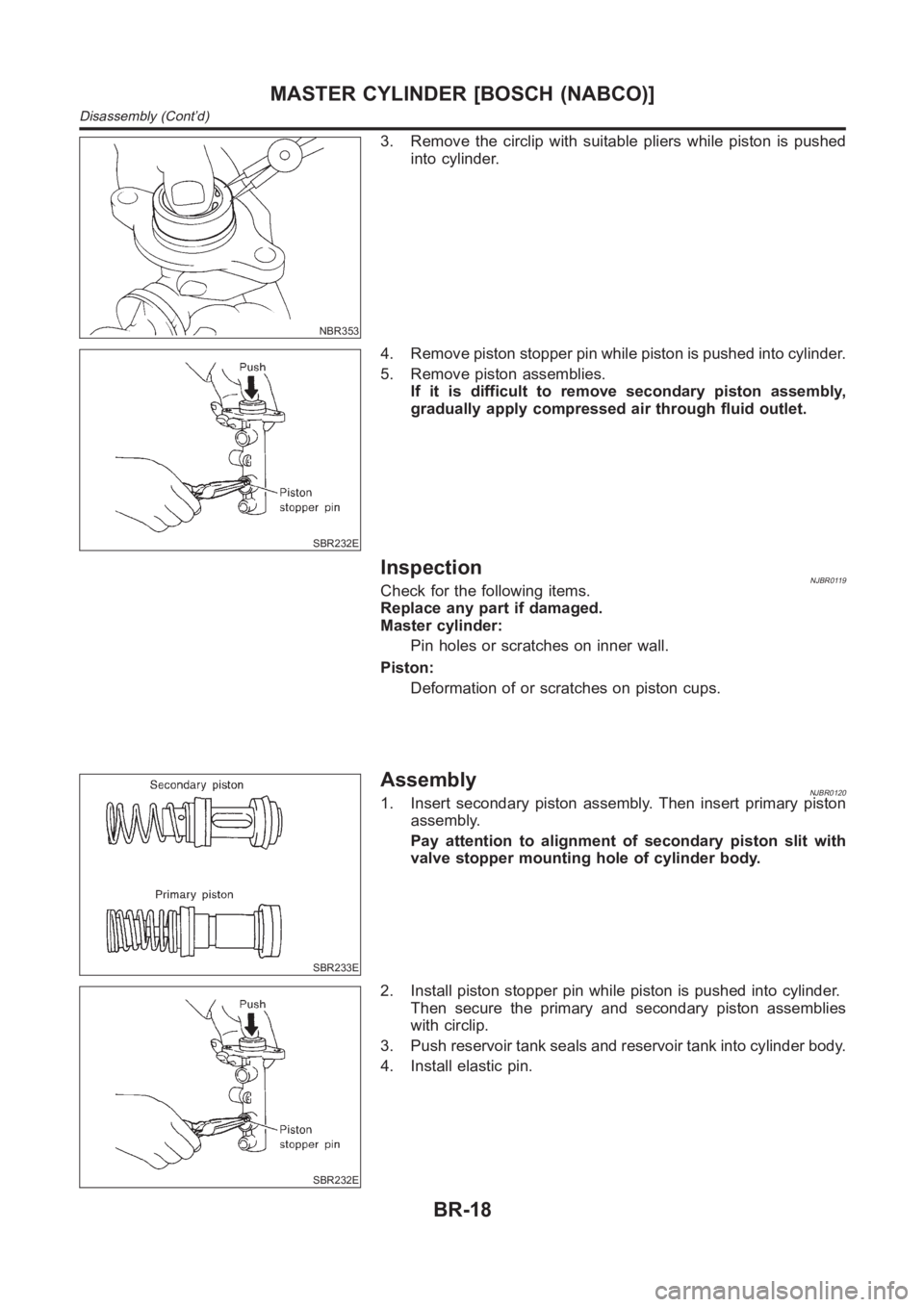

3. Remove the circlip with suitable pliers while piston is pushed

into cylinder.

SBR232E

4. Remove piston stopper pin while piston is pushed into cylinder.

5. Remove piston assemblies.

If it is difficult to remove secondary piston assembly,

gradually apply compressed air through fluid outlet.

InspectionNJBR0119Check for the following items.

Replace any part if damaged.

Master cylinder:

Pin holes or scratches on inner wall.

Piston:

Deformation of or scratches on piston cups.

SBR233E

AssemblyNJBR01201. Insert secondary piston assembly. Then insert primary piston

assembly.

Pay attention to alignment of secondary piston slit with

valve stopper mounting hole of cylinder body.

SBR232E

2. Install piston stopper pin while piston is pushed into cylinder.

Then secure the primary and secondary piston assemblies

with circlip.

3. Push reservoir tank seals and reservoir tank into cylinder body.

4. Install elastic pin.

MASTER CYLINDER [BOSCH (NABCO)]

Disassembly (Cont’d)

BR-18

Page 2203 of 3189

SBR236E

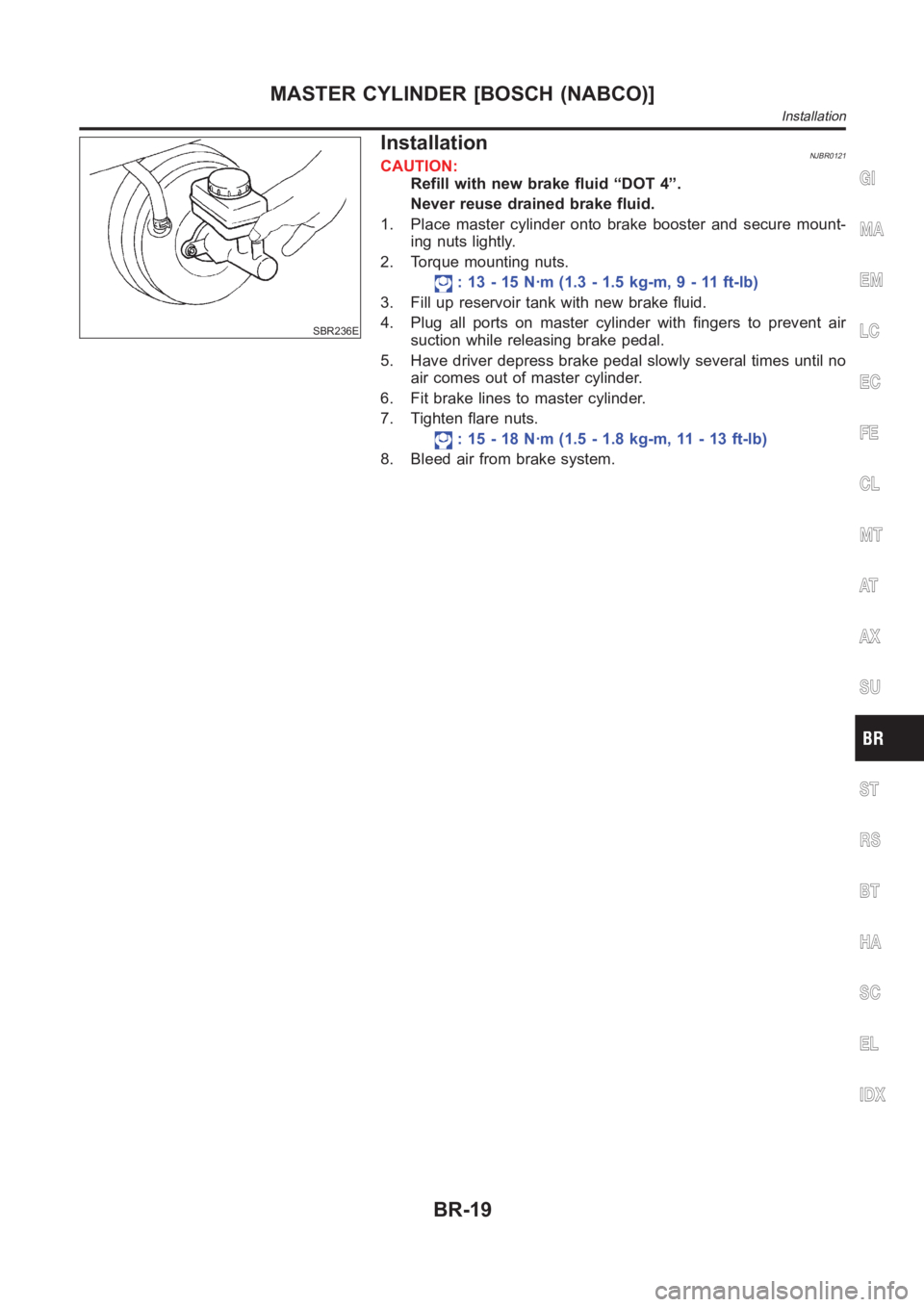

InstallationNJBR0121CAUTION:

Refill with new brake fluid “DOT 4”.

Never reuse drained brake fluid.

1. Place master cylinder onto brake booster and secure mount-

ing nuts lightly.

2. Torque mounting nuts.

:13-15N·m(1.3-1.5kg-m,9-11ft-lb)

3. Fill up reservoir tank with new brake fluid.

4. Plug all ports on master cylinder with fingers to prevent air

suction while releasing brake pedal.

5. Have driver depress brake pedal slowly several times until no

air comes out of master cylinder.

6. Fit brake lines to master cylinder.

7. Tighten flare nuts.

: 15 - 18 N·m (1.5 - 1.8 kg-m, 11 - 13 ft-lb)

8. Bleed air from brake system.

GI

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

ST

RS

BT

HA

SC

EL

IDX

MASTER CYLINDER [BOSCH (NABCO)]

Installation

BR-19

Page 2204 of 3189

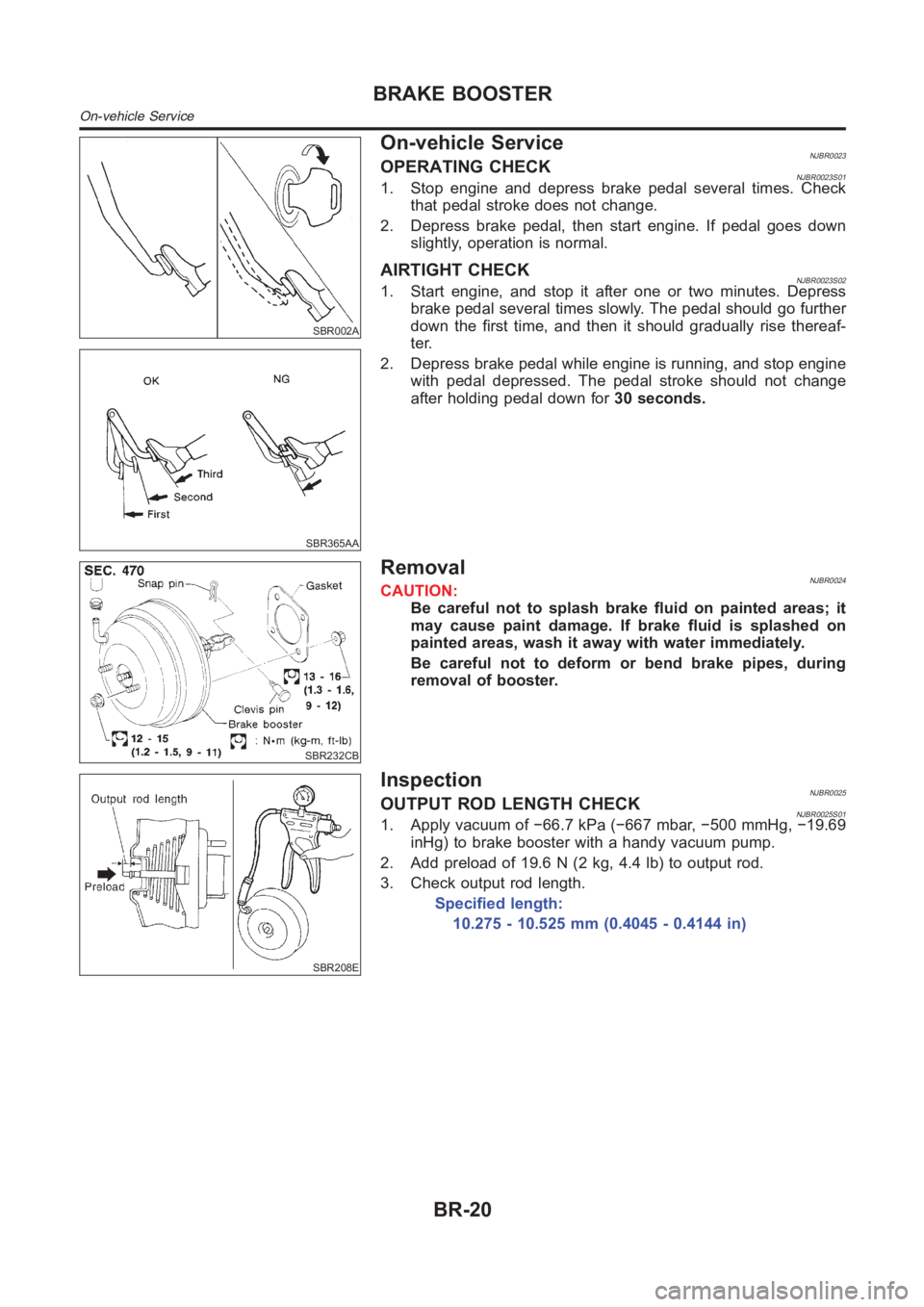

SBR002A

SBR365AA

On-vehicle ServiceNJBR0023OPERATING CHECKNJBR0023S011. Stop engine and depress brake pedal several times. Check

that pedal stroke does not change.

2. Depress brake pedal, then start engine. If pedal goes down

slightly, operation is normal.

AIRTIGHT CHECKNJBR0023S021. Start engine, and stop it after one or two minutes. Depress

brake pedal several times slowly. The pedal should go further

down the first time, and then it should gradually rise thereaf-

ter.

2. Depress brake pedal while engine is running, and stop engine

with pedal depressed. The pedal stroke should not change

after holding pedal down for30 seconds.

SBR232CB

RemovalNJBR0024CAUTION:

Be careful not to splash brake fluid on painted areas; it

may cause paint damage. If brake fluid is splashed on

painted areas, wash it away with water immediately.

Be careful not to deform or bend brake pipes, during

removal of booster.

SBR208E

InspectionNJBR0025OUTPUT ROD LENGTH CHECKNJBR0025S011. Apply vacuum of −66.7 kPa (−667 mbar, −500 mmHg, −19.69

inHg) to brake booster with a handy vacuum pump.

2. Add preload of 19.6 N (2 kg, 4.4 lb) to output rod.

3. Check output rod length.

Specified length:

10.275 - 10.525 mm (0.4045 - 0.4144 in)

BRAKE BOOSTER

On-vehicle Service

BR-20

Page 2205 of 3189

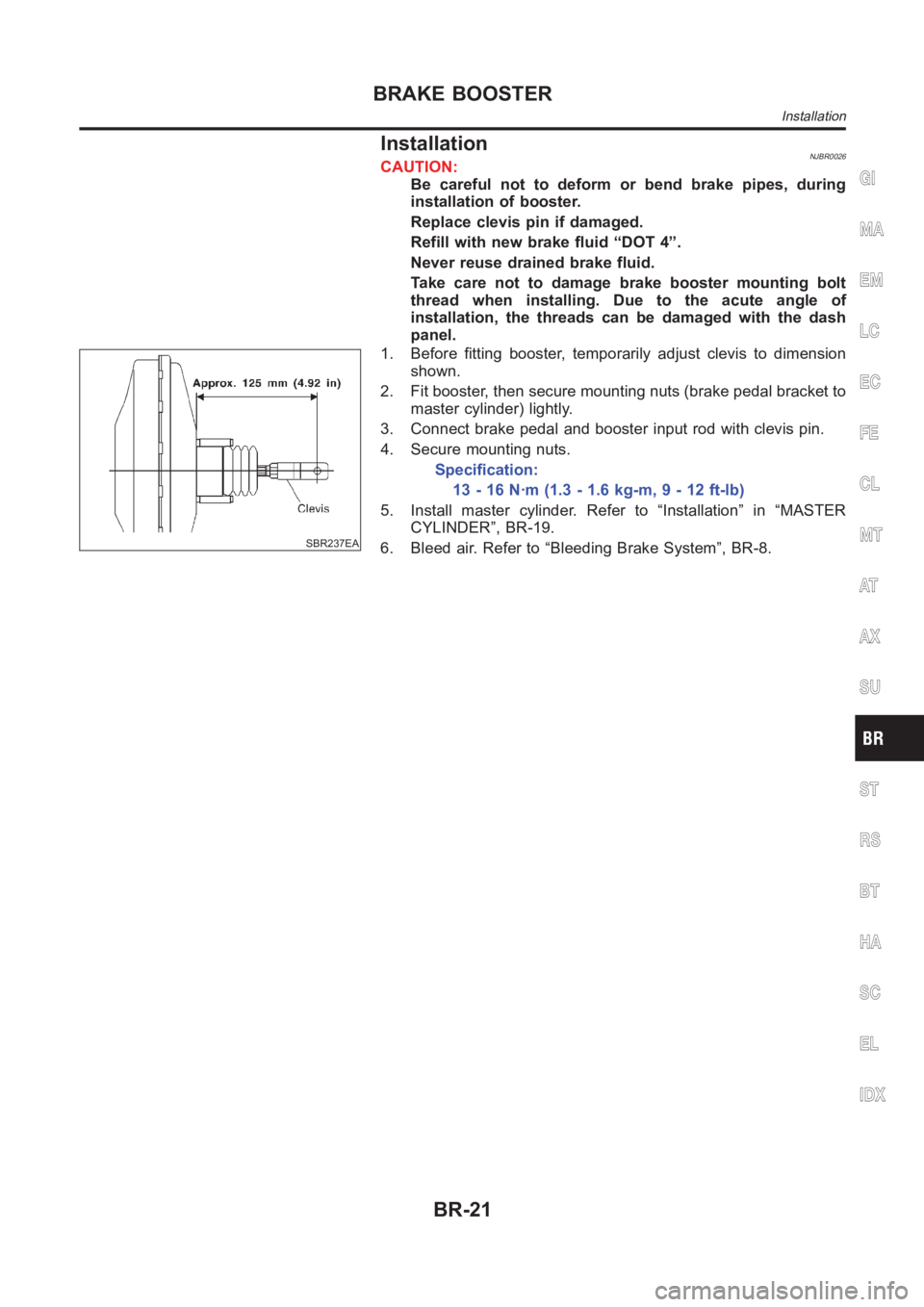

InstallationNJBR0026CAUTION:

Be careful not to deform or bend brake pipes, during

installation of booster.

Replace clevis pin if damaged.

Refill with new brake fluid “DOT 4”.

Never reuse drained brake fluid.

Take care not to damage brake booster mounting bolt

thread when installing. Due to the acute angle of

installation, the threads can be damaged with the dash

panel.

SBR237EA

1. Before fitting booster, temporarily adjust clevis to dimension

shown.

2. Fit booster, then secure mounting nuts (brake pedal bracket to

master cylinder) lightly.

3. Connect brake pedal and booster input rod with clevis pin.

4. Secure mounting nuts.

Specification:

13 - 16 N·m (1.3 - 1.6 kg-m, 9 - 12 ft-lb)

5. Install master cylinder. Refer to “Installation” in “MASTER

CYLINDER”, BR-19.

6. Bleed air. Refer to “Bleeding Brake System”, BR-8.

GI

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

ST

RS

BT

HA

SC

EL

IDX

BRAKE BOOSTER

Installation

BR-21

Page 2206 of 3189

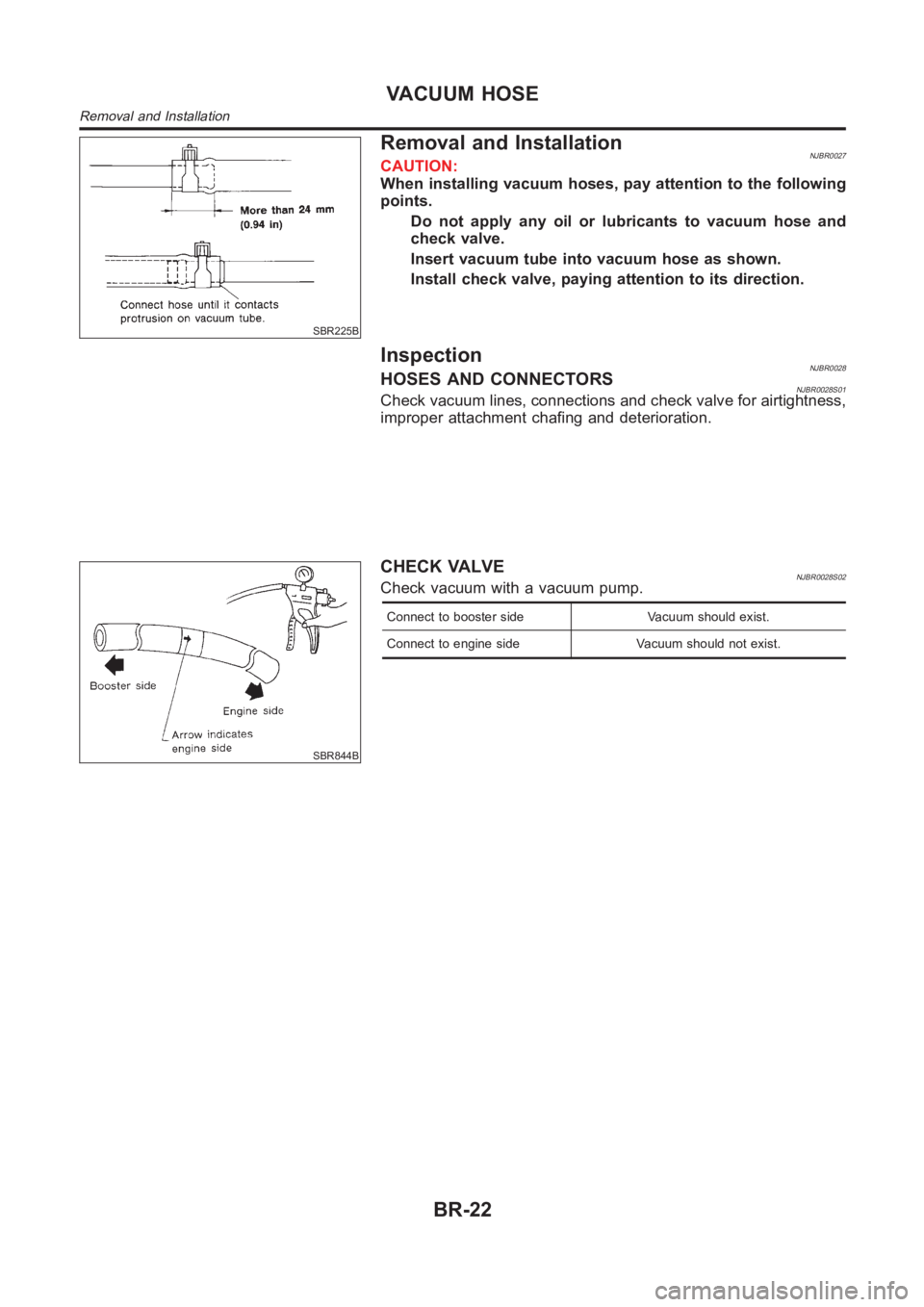

SBR225B

Removal and InstallationNJBR0027CAUTION:

When installing vacuum hoses, pay attention to the following

points.

Do not apply any oil or lubricants to vacuum hose and

check valve.

Insert vacuum tube into vacuum hose as shown.

Install check valve, paying attention to its direction.

InspectionNJBR0028HOSES AND CONNECTORSNJBR0028S01Check vacuum lines, connections and check valve for airtightness,

improper attachment chafing and deterioration.

SBR844B

CHECK VALVENJBR0028S02Check vacuum with a vacuum pump.

Connect to booster side Vacuum should exist.

Connect to engine side Vacuum should not exist.

VACUUM HOSE

Removal and Installation

BR-22

Page 2207 of 3189

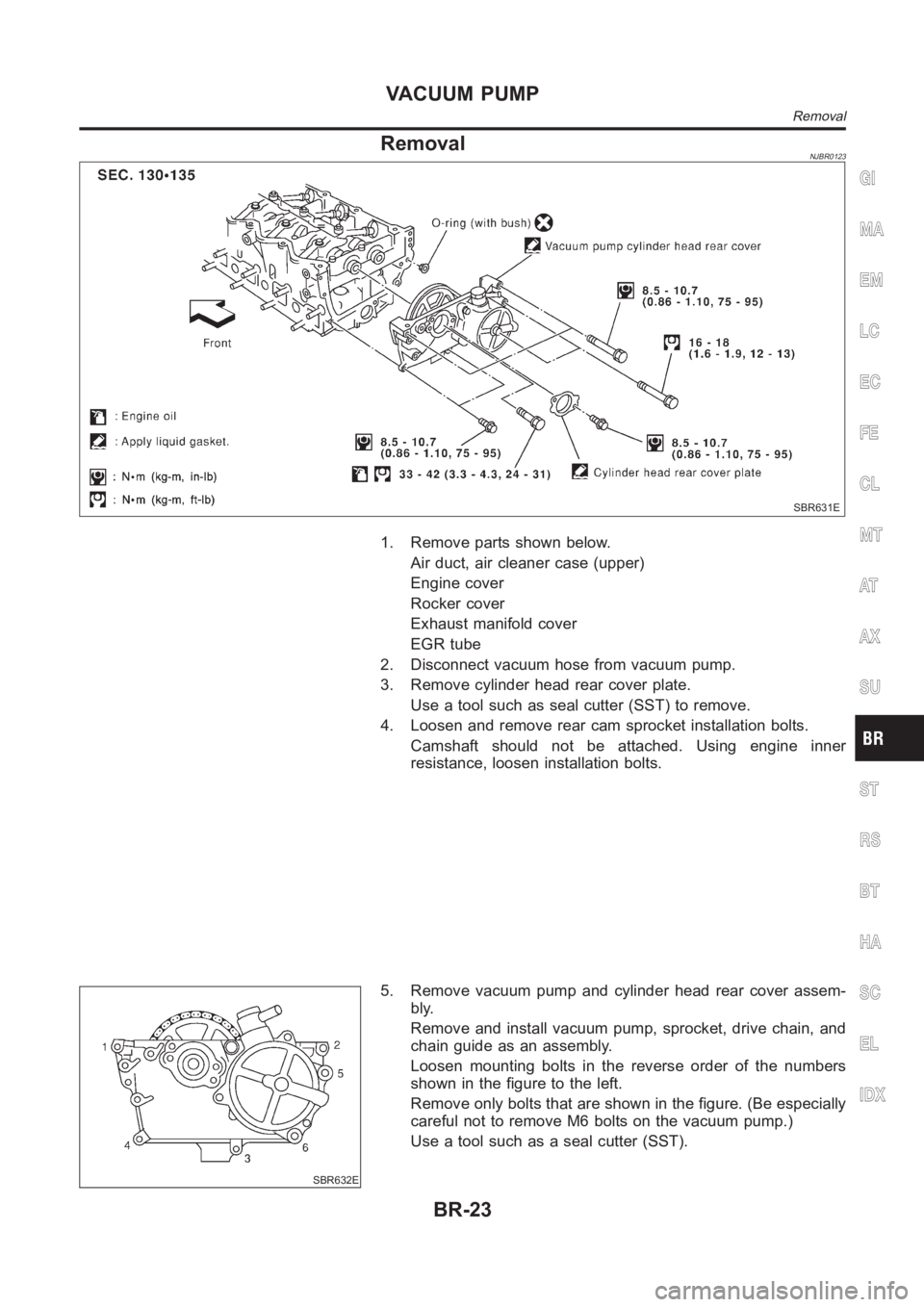

RemovalNJBR0123

SBR631E

1. Remove parts shown below.

Air duct, air cleaner case (upper)

Engine cover

Rocker cover

Exhaust manifold cover

EGR tube

2. Disconnect vacuum hose from vacuum pump.

3. Remove cylinder head rear cover plate.

Use a tool such as seal cutter (SST) to remove.

4. Loosen and remove rear cam sprocket installation bolts.

Camshaft should not be attached. Using engine inner

resistance, loosen installation bolts.

SBR632E

5. Remove vacuum pump and cylinder head rear cover assem-

bly.

Remove and install vacuum pump, sprocket, drive chain, and

chain guide as an assembly.

Loosen mounting bolts in the reverse order of the numbers

shown in the figure to the left.

Remove only bolts that are shown in the figure. (Be especially

careful not to remove M6 bolts on the vacuum pump.)

Use a tool such as a seal cutter (SST).

GI

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

ST

RS

BT

HA

SC

EL

IDX

VACUUM PUMP

Removal

BR-23

Page 2208 of 3189

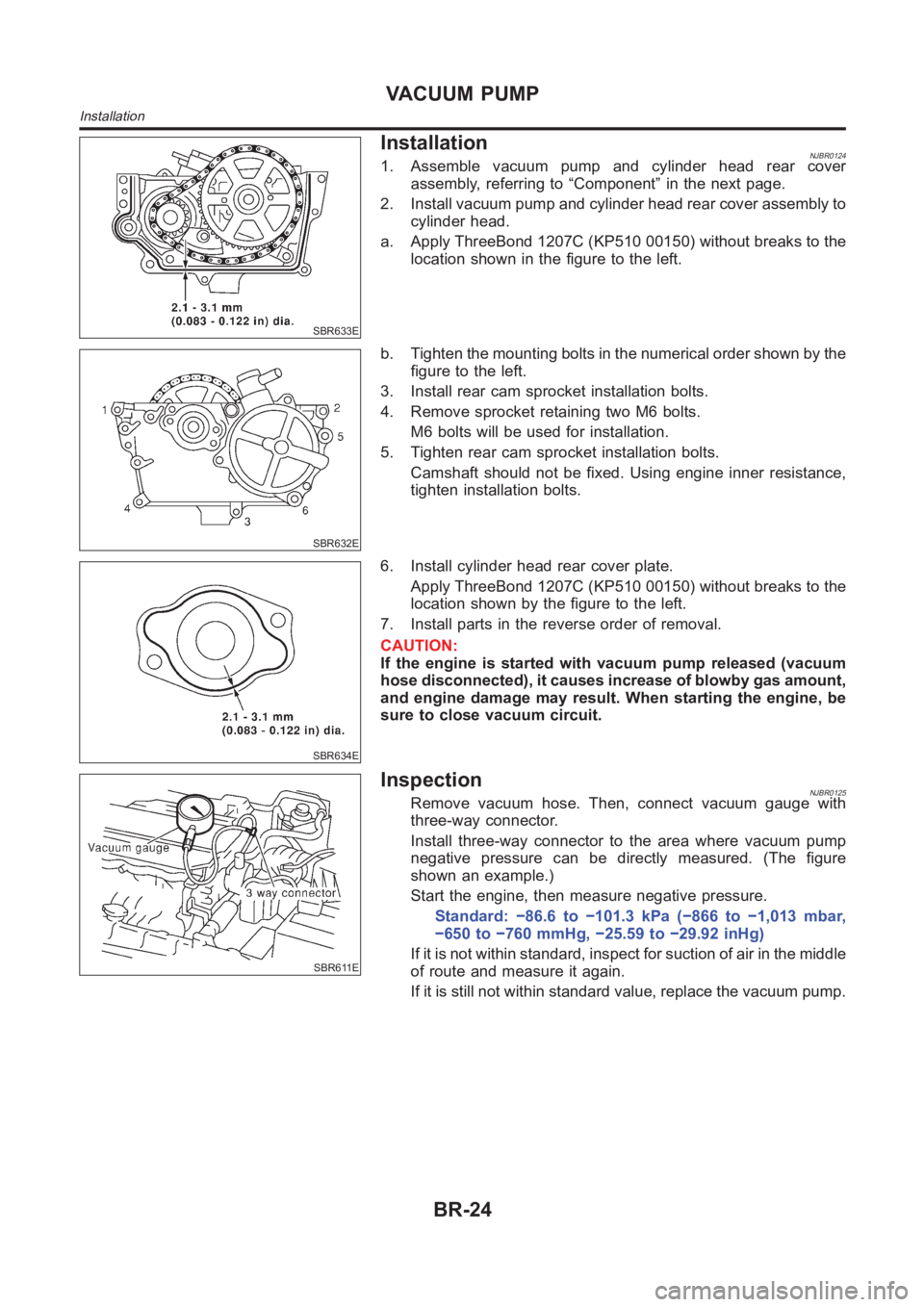

SBR633E

InstallationNJBR01241. Assemble vacuum pump and cylinder head rear cover

assembly, referring to “Component” in the next page.

2. Install vacuum pump and cylinder head rear cover assembly to

cylinder head.

a. Apply ThreeBond 1207C (KP510 00150) without breaks to the

location shown in the figure to the left.

SBR632E

b. Tighten the mounting bolts in the numerical order shown by the

figure to the left.

3. Install rear cam sprocket installation bolts.

4. Remove sprocket retaining two M6 bolts.

M6 bolts will be used for installation.

5. Tighten rear cam sprocket installation bolts.

Camshaft should not be fixed. Using engine inner resistance,

tighten installation bolts.

SBR634E

6. Install cylinder head rear cover plate.

Apply ThreeBond 1207C (KP510 00150) without breaks to the

location shown by the figure to the left.

7. Install parts in the reverse order of removal.

CAUTION:

If the engine is started with vacuum pump released (vacuum

hose disconnected), it causes increase of blowby gas amount,

and engine damage may result. When starting the engine, be

sure to close vacuum circuit.

SBR611E

InspectionNJBR0125Remove vacuum hose. Then, connect vacuum gauge with

three-way connector.

Install three-way connector to the area where vacuum pump

negative pressure can be directly measured. (The figure

shown an example.)

Start the engine, then measure negative pressure.

Standard: −86.6 to −101.3 kPa (−866 to −1,013 mbar,

−650 to −760 mmHg, −25.59 to −29.92 inHg)

If it is not within standard, inspect for suction of air in the middle

of route and measure it again.

If it is still not within standard value, replace the vacuum pump.

VACUUM PUMP

Installation

BR-24

Page 2209 of 3189

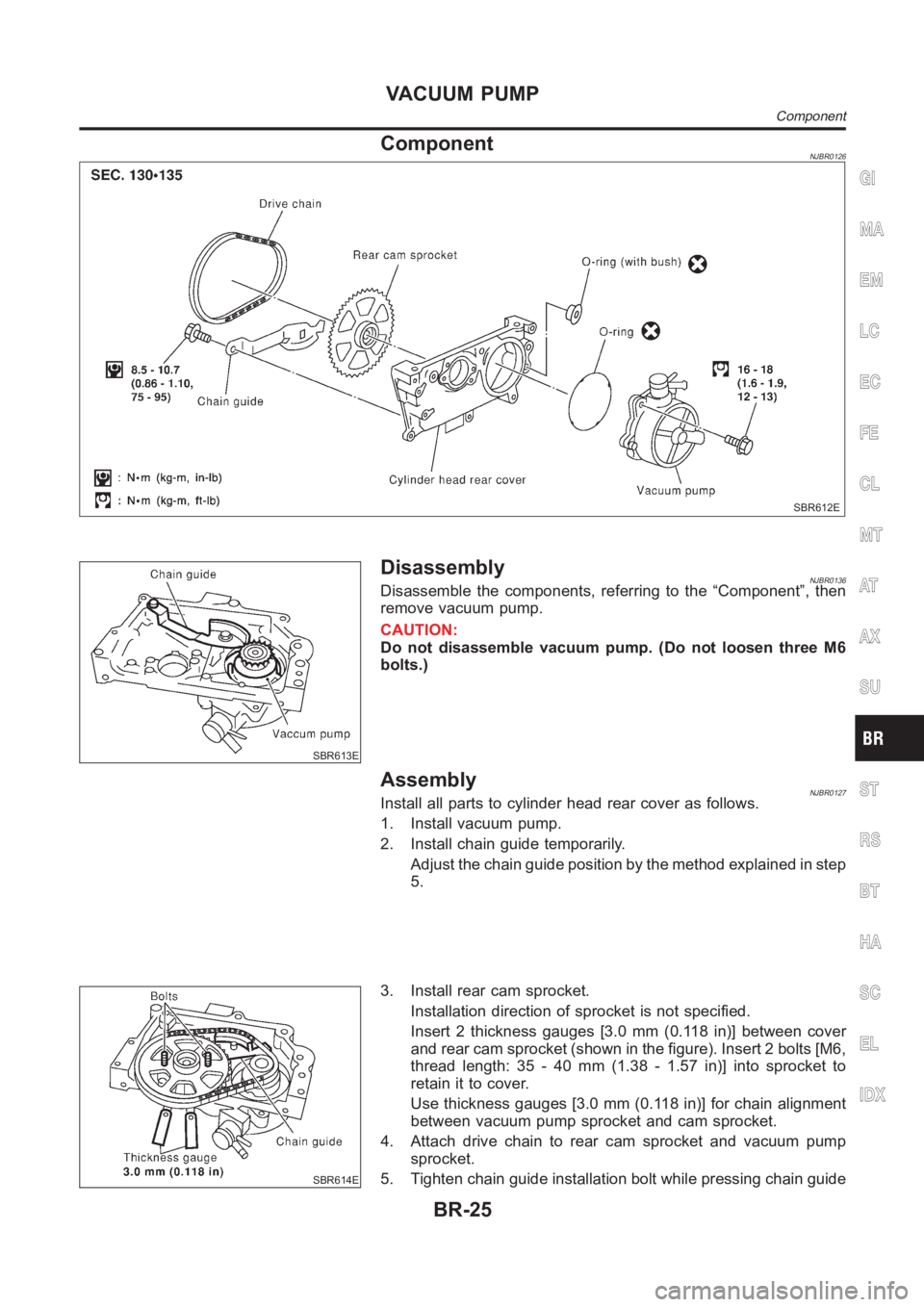

ComponentNJBR0126

SBR612E

SBR613E

DisassemblyNJBR0136Disassemble the components, referring to the “Component”, then

remove vacuum pump.

CAUTION:

Do not disassemble vacuum pump. (Do not loosen three M6

bolts.)

AssemblyNJBR0127Install all parts to cylinder head rear cover as follows.

1. Install vacuum pump.

2. Install chain guide temporarily.

Adjust the chain guide position by the method explained in step

5.

SBR614E

3. Install rear cam sprocket.

Installation direction of sprocket is not specified.

Insert 2 thickness gauges [3.0 mm (0.118 in)] between cover

and rear cam sprocket (shown in the figure). Insert 2 bolts [M6,

thread length: 35 - 40 mm (1.38 - 1.57 in)] into sprocket to

retain it to cover.

Use thickness gauges [3.0 mm (0.118 in)] for chain alignment

between vacuum pump sprocket and cam sprocket.

4. Attach drive chain to rear cam sprocket and vacuum pump

sprocket.

5. Tighten chain guide installation bolt while pressing chain guide

GI

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

ST

RS

BT

HA

SC

EL

IDX

VACUUM PUMP

Component

BR-25

Page 2210 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual lightly [approximately 9.8 N (1.0 kg, 2.2 lb)].

6. Remove thickness gauges (2).

Leave sprocket retaining bolts (M6) until installation.

VACUUM PUMP

Assembly (Cont’d)

BR-26 NISSAN ALMERA N16 2003 Electronic Repair Manual lightly [approximately 9.8 N (1.0 kg, 2.2 lb)].

6. Remove thickness gauges (2).

Leave sprocket retaining bolts (M6) until installation.

VACUUM PUMP

Assembly (Cont’d)

BR-26](/img/5/57350/w960_57350-2209.png)

lightly [approximately 9.8 N (1.0 kg, 2.2 lb)].

6. Remove thickness gauges (2).

Leave sprocket retaining bolts (M6) until installation.

VACUUM PUMP

Assembly (Cont’d)

BR-26