NISSAN ALMERA N16 2003 Electronic Repair Manual

Manufacturer: NISSAN, Model Year: 2003, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2003Pages: 3189, PDF Size: 54.76 MB

Page 2171 of 3189

INSPECTIONNJSU0019Transverse LinkNJSU0019S01Check transverse link for damage, cracks or deformation.

Replace it if necessary.

Check rubber bushing for damage, cracks and deformation.

Replace transverse link if necessary.

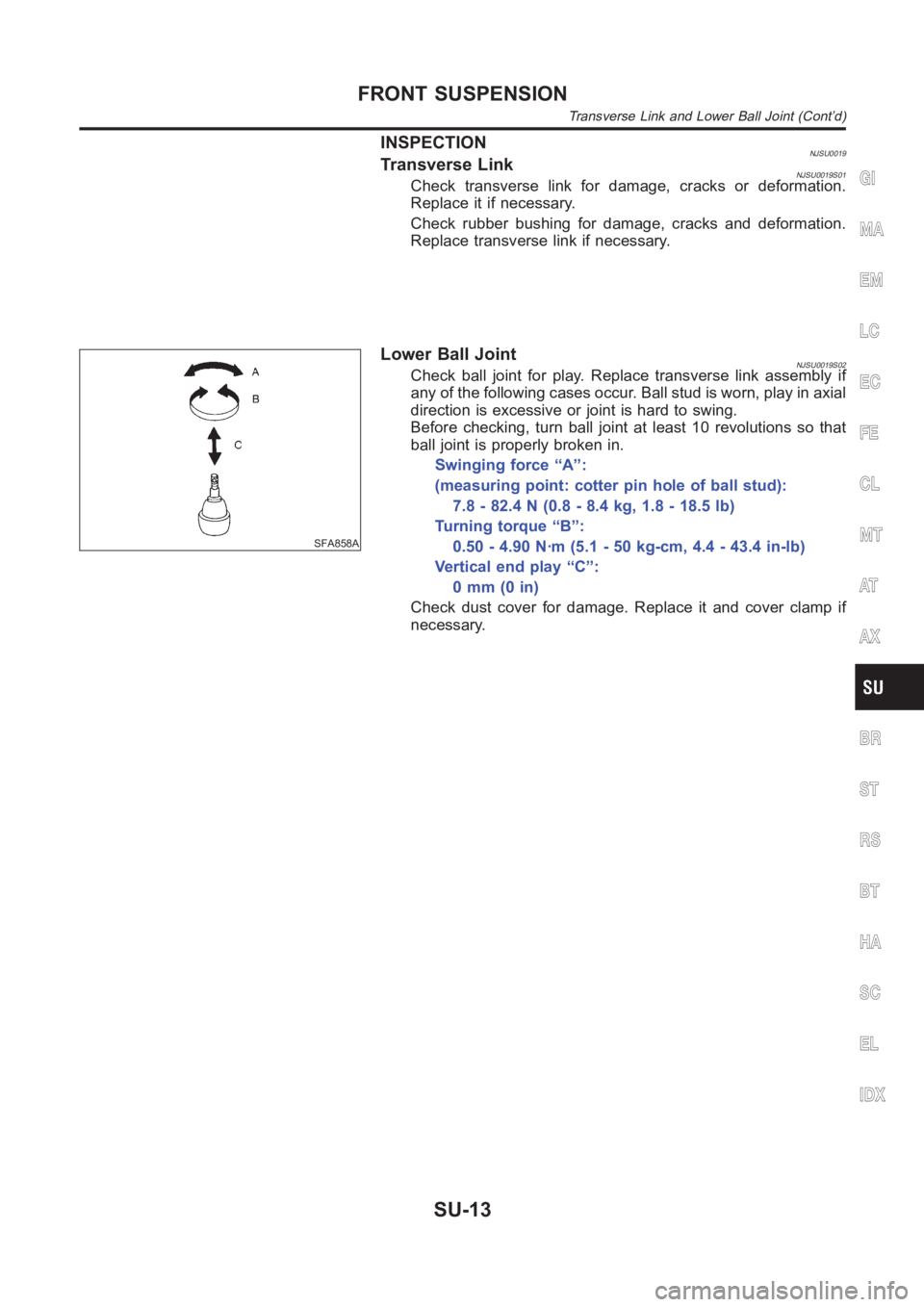

SFA858A

Lower Ball JointNJSU0019S02Check ball joint for play. Replace transverse link assembly if

any of the following cases occur. Ball stud is worn, play in axial

direction is excessive or joint is hard to swing.

Before checking, turn ball joint at least 10 revolutions so that

ball joint is properly broken in.

Swinging force “A”:

(measuring point: cotter pin hole of ball stud):

7.8 - 82.4 N (0.8 - 8.4 kg, 1.8 - 18.5 lb)

Turning torque “B”:

0.50 - 4.90 N·m (5.1 - 50 kg-cm, 4.4 - 43.4 in-lb)

Vertical end play “C”:

0mm(0in)

Check dust cover for damage. Replace it and cover clamp if

necessary.

GI

MA

EM

LC

EC

FE

CL

MT

AT

AX

BR

ST

RS

BT

HA

SC

EL

IDX

FRONT SUSPENSION

Transverse Link and Lower Ball Joint (Cont’d)

SU-13

Page 2172 of 3189

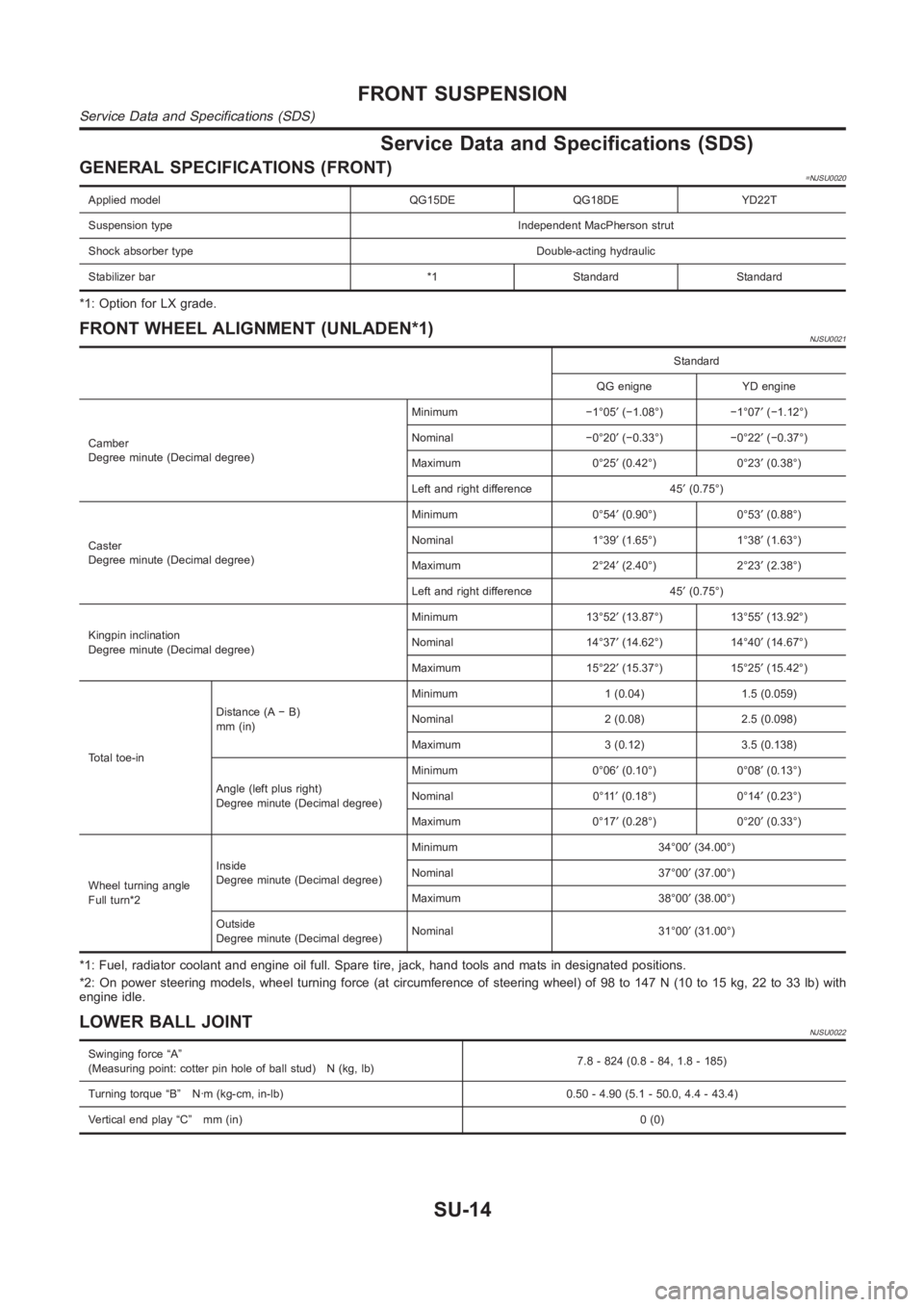

Service Data and Specifications (SDS)

GENERAL SPECIFICATIONS (FRONT)=NJSU0020

Applied model QG15DE QG18DE YD22T

Suspension type Independent MacPherson strut

Shock absorber type Double-acting hydraulic

Stabilizer bar *1 Standard Standard

*1: Option for LX grade.

FRONT WHEEL ALIGNMENT (UNLADEN*1)NJSU0021

Standard

QG enigne YD engine

Camber

Degree minute (Decimal degree)Minimum −1°05′(−1.08°) −1°07′(−1.12°)

Nominal −0°20′(−0.33°) −0°22′(−0.37°)

Maximum 0°25′(0.42°) 0°23′(0.38°)

Left and right difference 45′(0.75°)

Caster

Degree minute (Decimal degree)Minimum 0°54′(0.90°) 0°53′(0.88°)

Nominal 1°39′(1.65°) 1°38′(1.63°)

Maximum 2°24′(2.40°) 2°23′(2.38°)

Left and right difference 45′(0.75°)

Kingpin inclination

Degree minute (Decimal degree)Minimum 13°52′(13.87°) 13°55′(13.92°)

Nominal 14°37′(14.62°) 14°40′(14.67°)

Maximum 15°22′(15.37°) 15°25′(15.42°)

Total toe-inDistance (A − B)

mm (in)Minimum 1 (0.04) 1.5 (0.059)

Nominal 2 (0.08) 2.5 (0.098)

Maximum 3 (0.12) 3.5 (0.138)

Angle (left plus right)

Degree minute (Decimal degree)Minimum 0°06′(0.10°) 0°08′(0.13°)

Nominal 0°11′(0.18°) 0°14′(0.23°)

Maximum 0°17′(0.28°) 0°20′(0.33°)

Wheel turning angle

Full turn*2Inside

Degree minute (Decimal degree)Minimum 34°00′(34.00°)

Nominal 37°00′(37.00°)

Maximum 38°00′(38.00°)

Outside

Degree minute (Decimal degree)Nominal 31°00′(31.00°)

*1: Fuel, radiator coolant and engine oil full. Spare tire, jack, hand tools and mats in designated positions.

*2: On power steering models, wheel turning force (at circumference of steering wheel) of 98 to 147 N (10 to 15 kg, 22 to 33 lb) with

engine idle.

LOWER BALL JOINTNJSU0022

Swinging force “A”

(Measuring point: cotter pin hole of ball stud) N (kg, lb)7.8 - 824 (0.8 - 84, 1.8 - 185)

Turning torque “B” N·m (kg-cm, in-lb) 0.50 - 4.90 (5.1 - 50.0, 4.4 - 43.4)

Vertical end play “C” mm (in)0(0)

FRONT SUSPENSION

Service Data and Specifications (SDS)

SU-14

Page 2173 of 3189

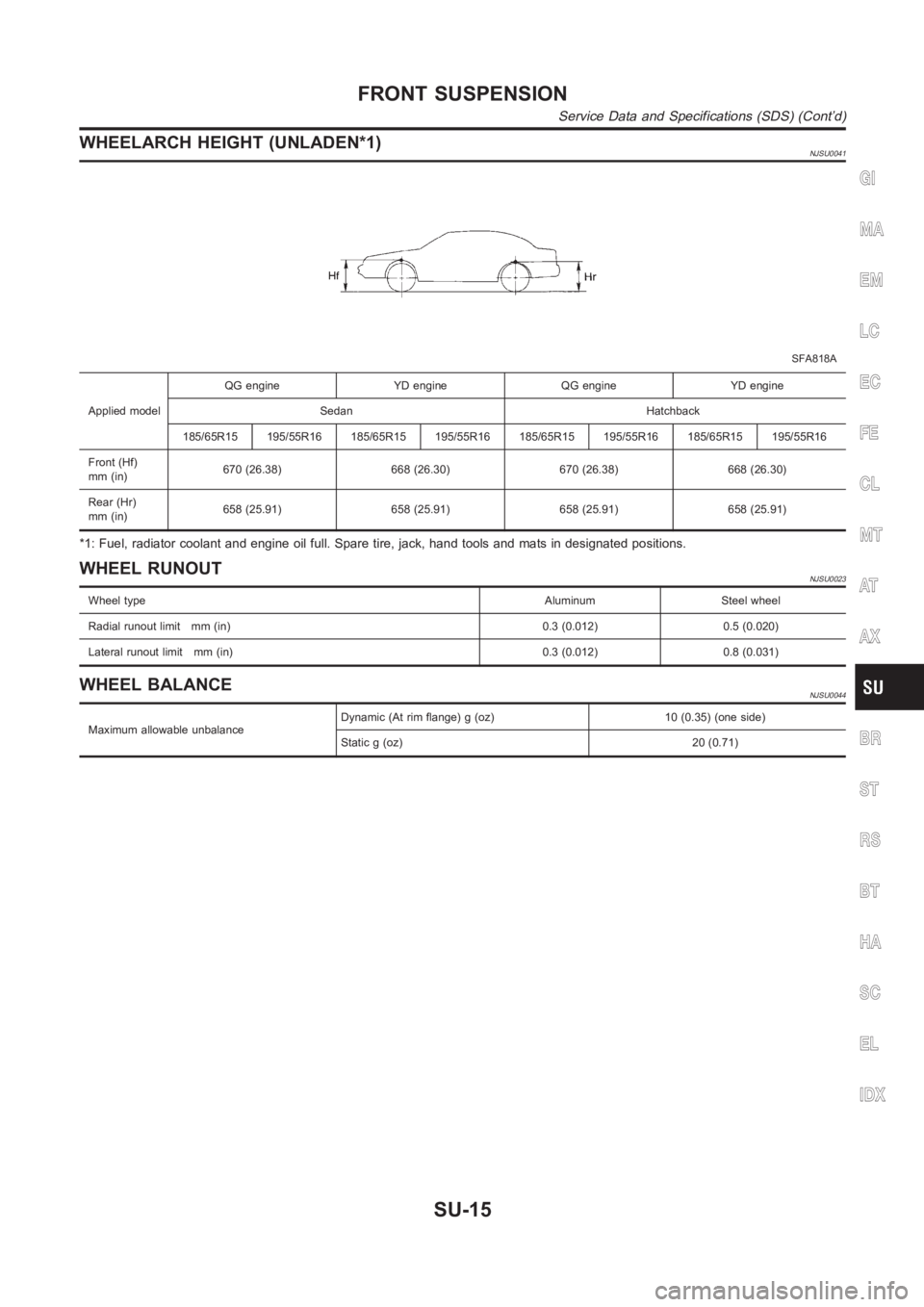

WHEELARCH HEIGHT (UNLADEN*1)NJSU0041

SFA818A

Applied modelQG engine YD engine QG engine YD engine

Sedan Hatchback

185/65R15 195/55R16 185/65R15 195/55R16 185/65R15 195/55R16 185/65R15195/55R16

Front (Hf)

mm (in)670 (26.38) 668 (26.30) 670 (26.38) 668 (26.30)

Rear (Hr)

mm (in)658 (25.91) 658 (25.91) 658 (25.91) 658 (25.91)

*1: Fuel, radiator coolant and engine oil full. Spare tire, jack, hand tools and mats in designated positions.

WHEEL RUNOUTNJSU0023

Wheel typeAluminum Steel wheel

Radial runout limit mm (in) 0.3 (0.012) 0.5 (0.020)

Lateral runout limit mm (in) 0.3 (0.012) 0.8 (0.031)

WHEEL BALANCENJSU0044

Maximum allowable unbalanceDynamic (At rim flange) g (oz) 10 (0.35) (one side)

Static g (oz) 20 (0.71)

GI

MA

EM

LC

EC

FE

CL

MT

AT

AX

BR

ST

RS

BT

HA

SC

EL

IDX

FRONT SUSPENSION

Service Data and Specifications (SDS) (Cont’d)

SU-15

Page 2174 of 3189

SBR686C

Precautions

PRECAUTIONSNJSU0024When installing each rubber part, final tightening must be

carried out under unladen condition* with tires on ground.

Oil will shorten the life of rubber bushes. Be sure to wipe

off any spilled oil.

*: Fuel, radiator coolant and engine oil full. Spare tire, jack,

hand tools and mats in designated positions.

Use flare nut wrench when removing or installing brake

tubes.

After installing removed suspension parts, check wheel

alignment.

Do not jack up at the trailing arm and lateral link.

Always torque brake lines when installing.

Lock nuts are unreusable parts; always use new ones.

When replacing, do not wipe the oil off of the new lock nut

before tightening.

Preparation

COMMERCIAL SERVICE TOOLSNJSU0026

Tool name Description

Equivalent to

1 Flare nut crowfoot

2 Torque wrench

NT360

Removing and installing brake piping

a: 10 mm (0.39 in)

Spring compressor

NT717

Removing and installing coil spring

Noise, Vibration and Harshness (NVH)

Troubleshooting

NJSU0027Refer to “Noise, Vibration and Harshness (NVH) Troubleshooting”,

“FRONT SUSPENSION”, SU-4.

REAR SUSPENSION

Precautions

SU-16

Page 2175 of 3189

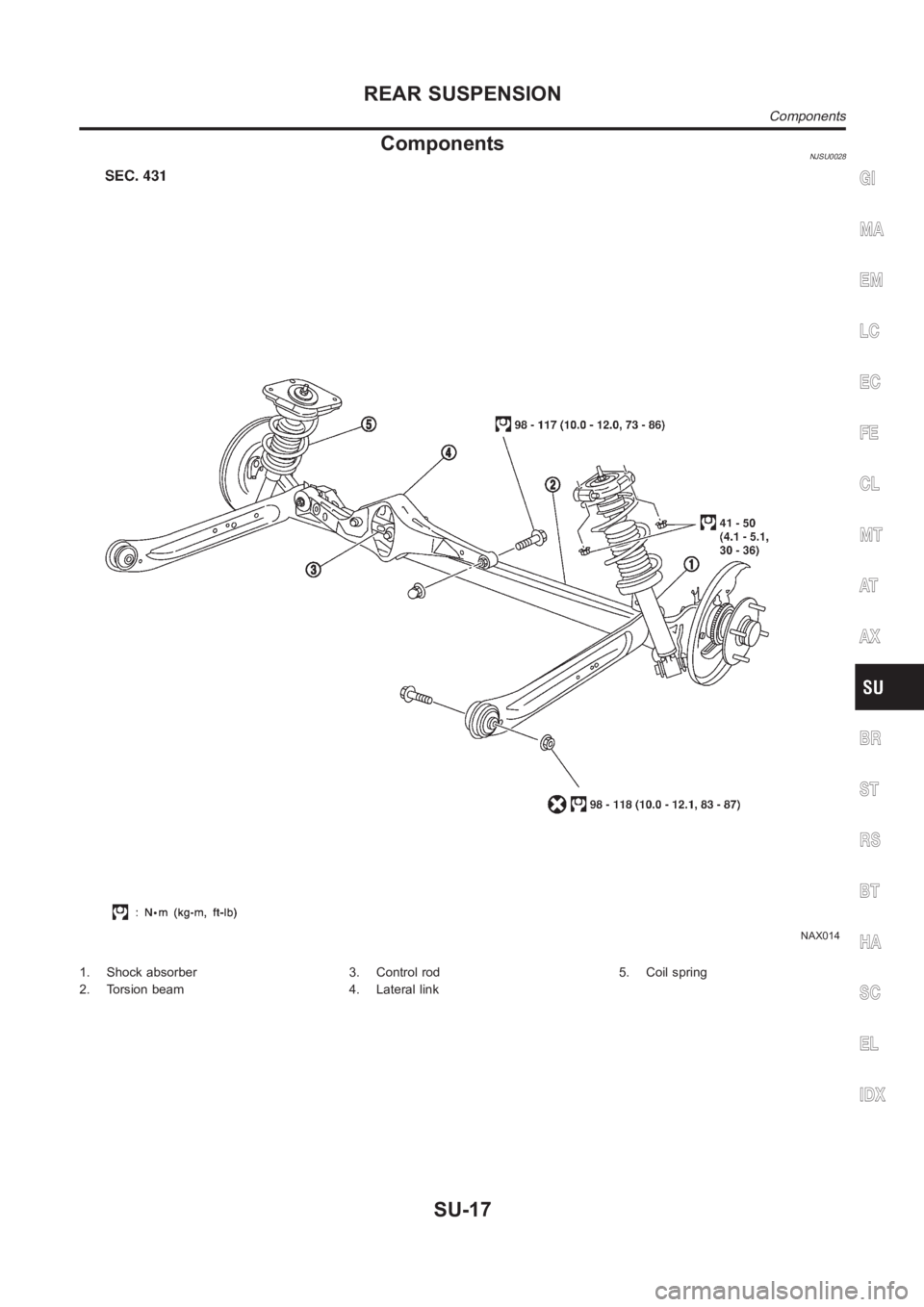

ComponentsNJSU0028

NAX014

1. Shock absorber

2. Torsion beam3. Control rod

4. Lateral link5. Coil spring

GI

MA

EM

LC

EC

FE

CL

MT

AT

AX

BR

ST

RS

BT

HA

SC

EL

IDX

REAR SUSPENSION

Components

SU-17

Page 2176 of 3189

SMA525A

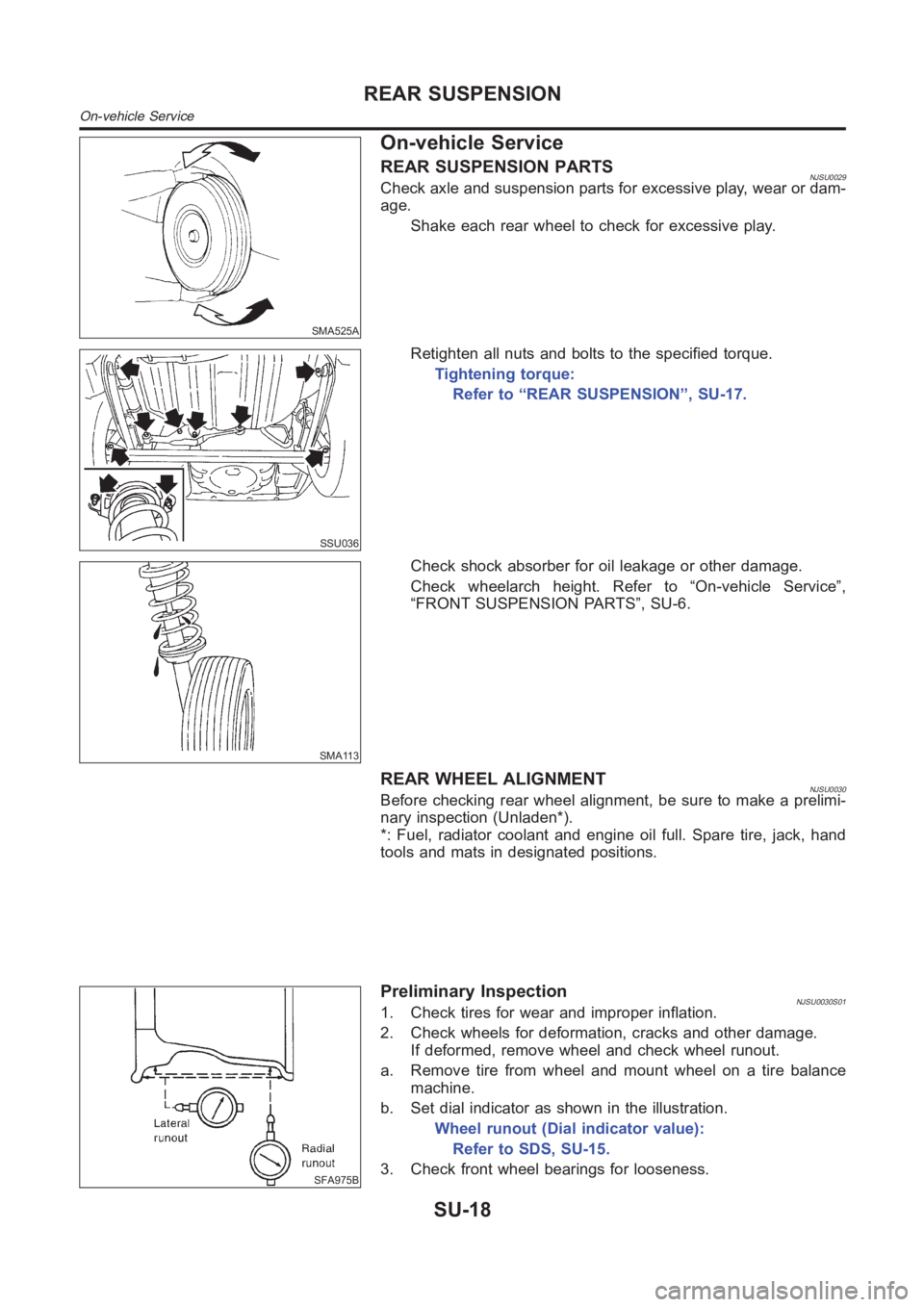

On-vehicle Service

REAR SUSPENSION PARTSNJSU0029Check axle and suspension parts for excessive play, wear or dam-

age.

Shake each rear wheel to check for excessive play.

SSU036

Retighten all nuts and bolts to the specified torque.

Tightening torque:

Refer to “REAR SUSPENSION”, SU-17.

SMA113

Check shock absorber for oil leakage or other damage.

Check wheelarch height. Refer to “On-vehicle Service”,

“FRONT SUSPENSION PARTS”, SU-6.

REAR WHEEL ALIGNMENTNJSU0030Before checking rear wheel alignment, be sure to make a prelimi-

nary inspection (Unladen*).

*: Fuel, radiator coolant and engine oil full. Spare tire, jack, hand

tools and mats in designated positions.

SFA975B

Preliminary InspectionNJSU0030S011. Check tires for wear and improper inflation.

2. Check wheels for deformation, cracks and other damage.

If deformed, remove wheel and check wheel runout.

a. Remove tire from wheel and mount wheel on a tire balance

machine.

b. Set dial indicator as shown in the illustration.

Wheel runout (Dial indicator value):

Refer to SDS, SU-15.

3. Check front wheel bearings for looseness.

REAR SUSPENSION

On-vehicle Service

SU-18

Page 2177 of 3189

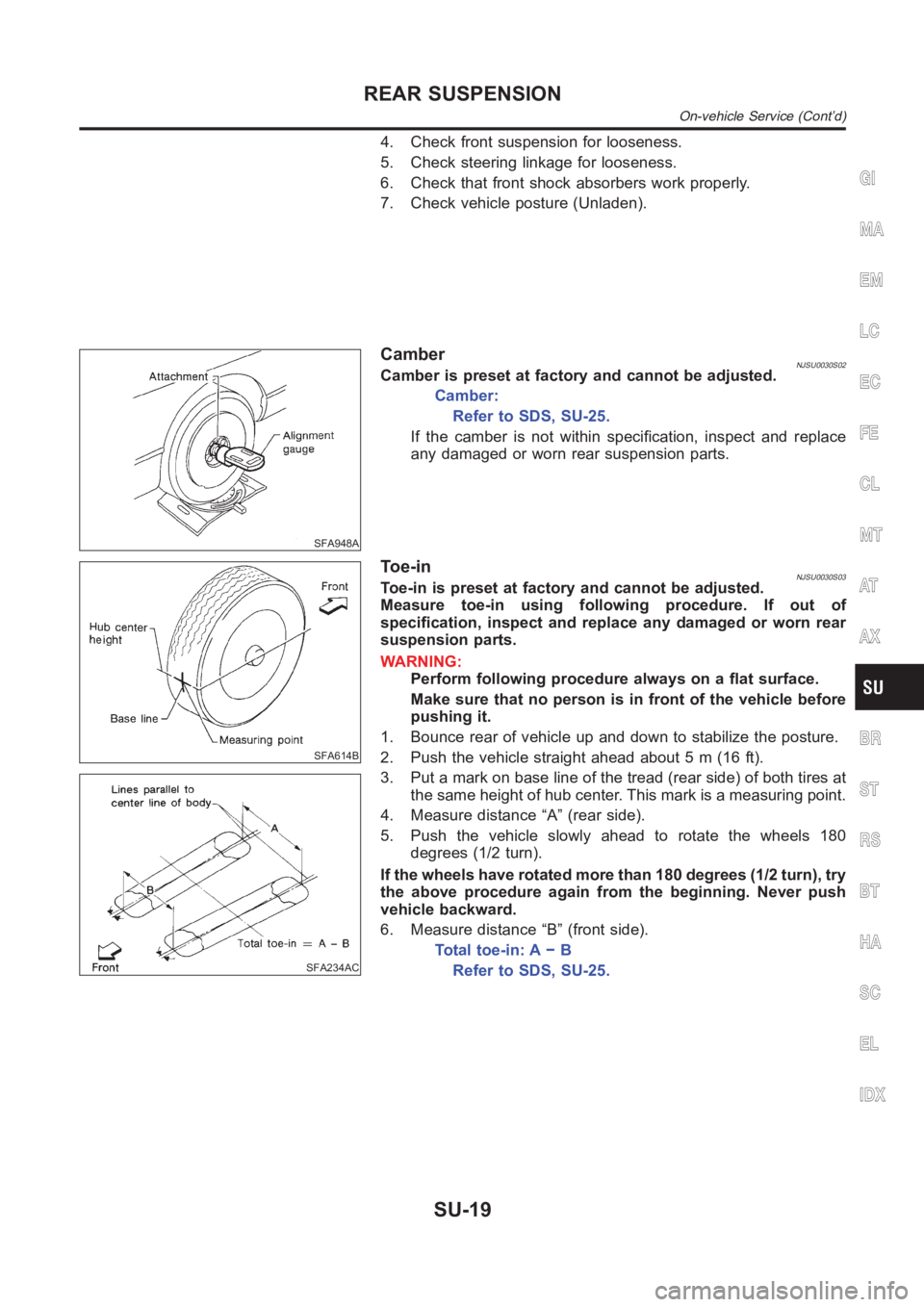

4. Check front suspension for looseness.

5. Check steering linkage for looseness.

6. Check that front shock absorbers work properly.

7. Check vehicle posture (Unladen).

SFA948A

CamberNJSU0030S02Camber is preset at factory and cannot be adjusted.

Camber:

Refer to SDS, SU-25.

If the camber is not within specification, inspect and replace

any damaged or worn rear suspension parts.

SFA614B

SFA234AC

To e - i nNJSU0030S03Toe-in is preset at factory and cannot be adjusted.

Measure toe-in using following procedure. If out of

specification, inspect and replace any damaged or worn rear

suspension parts.

WARNING:

Perform following procedure always on a flat surface.

Make sure that no person is in front of the vehicle before

pushing it.

1. Bounce rear of vehicle up and down to stabilize the posture.

2. Push the vehicle straight ahead about 5 m (16 ft).

3. Put a mark on base line of the tread (rear side) of both tires at

the same height of hub center. This mark is a measuring point.

4. Measure distance “A” (rear side).

5. Push the vehicle slowly ahead to rotate the wheels 180

degrees (1/2 turn).

If the wheels have rotated more than 180 degrees (1/2 turn), try

the above procedure again from the beginning. Never push

vehicle backward.

6. Measure distance “B” (front side).

Total toe-in: A − B

Refer to SDS, SU-25.

GI

MA

EM

LC

EC

FE

CL

MT

AT

AX

BR

ST

RS

BT

HA

SC

EL

IDX

REAR SUSPENSION

On-vehicle Service (Cont’d)

SU-19

Page 2178 of 3189

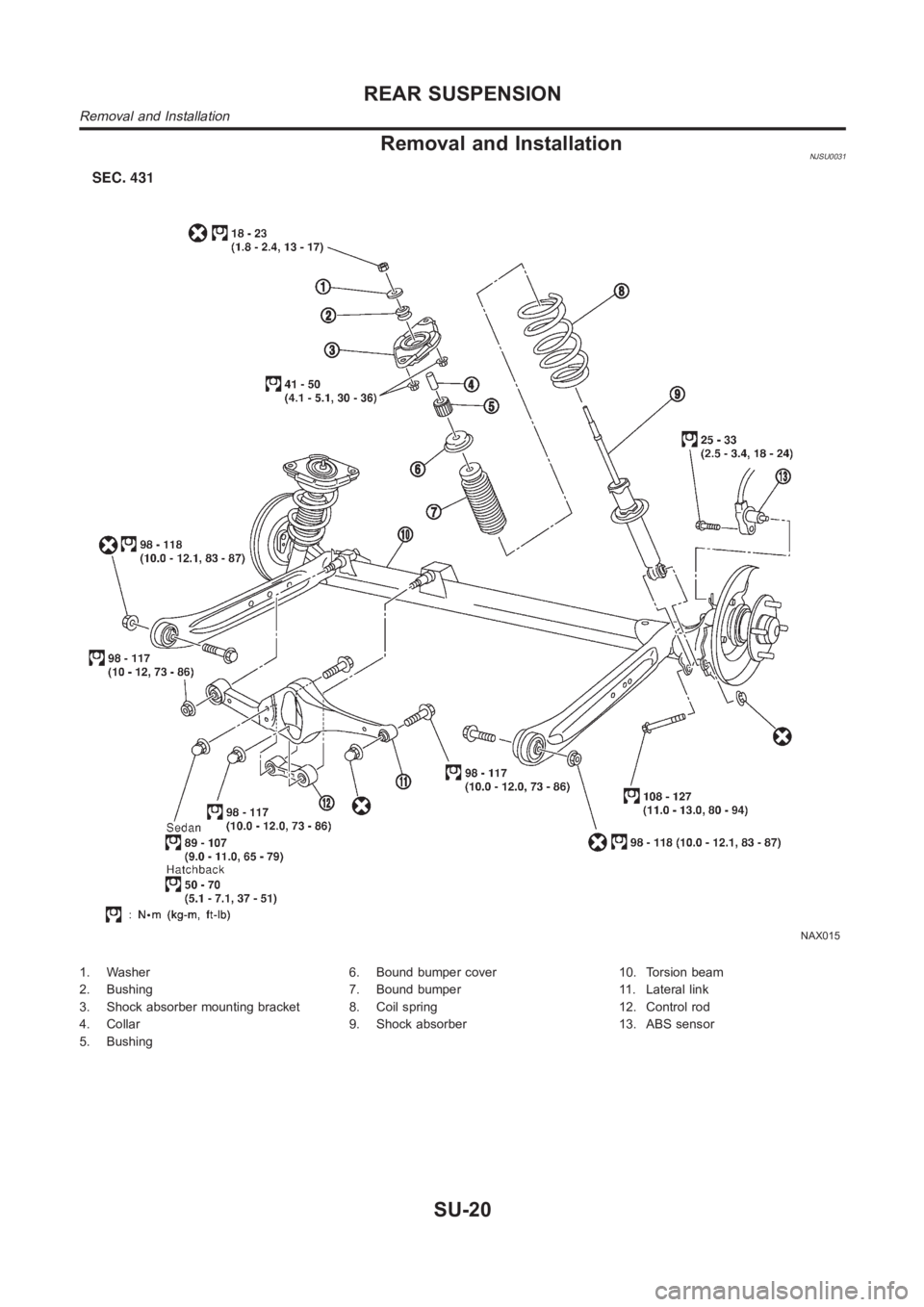

Removal and InstallationNJSU0031

NAX015

1. Washer

2. Bushing

3. Shock absorber mounting bracket

4. Collar

5. Bushing6. Bound bumper cover

7. Bound bumper

8. Coil spring

9. Shock absorber10. Torsion beam

11. Lateral link

12. Control rod

13. ABS sensor

REAR SUSPENSION

Removal and Installation

SU-20

Page 2179 of 3189

SRA695A

SSU038

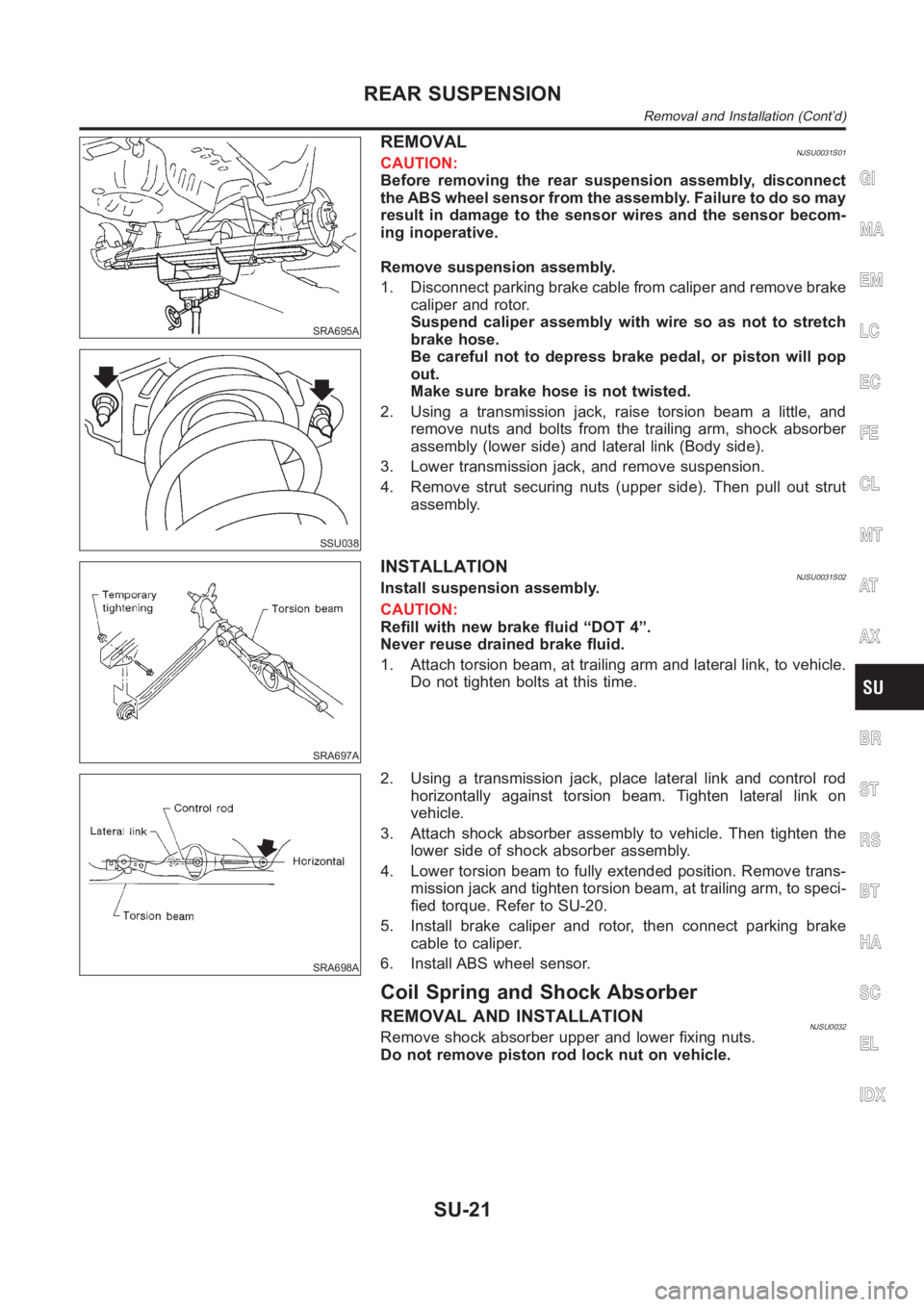

REMOVALNJSU0031S01CAUTION:

Before removing the rear suspension assembly, disconnect

the ABS wheel sensor from the assembly. Failure to do so may

result in damage to the sensor wires and the sensor becom-

ing inoperative.

Remove suspension assembly.

1. Disconnect parking brake cable from caliper and remove brake

caliper and rotor.

Suspend caliper assembly with wire so as not to stretch

brake hose.

Be careful not to depress brake pedal, or piston will pop

out.

Make sure brake hose is not twisted.

2. Using a transmission jack, raise torsion beam a little, and

remove nuts and bolts from the trailing arm, shock absorber

assembly (lower side) and lateral link (Body side).

3. Lower transmission jack, and remove suspension.

4. Remove strut securing nuts (upper side). Then pull out strut

assembly.

SRA697A

INSTALLATIONNJSU0031S02Install suspension assembly.

CAUTION:

Refill with new brake fluid “DOT 4”.

Never reuse drained brake fluid.

1. Attach torsion beam, at trailing arm and lateral link, to vehicle.

Do not tighten bolts at this time.

SRA698A

2. Using a transmission jack, place lateral link and control rod

horizontally against torsion beam. Tighten lateral link on

vehicle.

3. Attach shock absorber assembly to vehicle. Then tighten the

lower side of shock absorber assembly.

4. Lower torsion beam to fully extended position. Remove trans-

mission jack and tighten torsion beam, at trailing arm, to speci-

fied torque. Refer to SU-20.

5. Install brake caliper and rotor, then connect parking brake

cable to caliper.

6. Install ABS wheel sensor.

Coil Spring and Shock Absorber

REMOVAL AND INSTALLATIONNJSU0032Remove shock absorber upper and lower fixing nuts.

Do not remove piston rod lock nut on vehicle.

GI

MA

EM

LC

EC

FE

CL

MT

AT

AX

BR

ST

RS

BT

HA

SC

EL

IDX

REAR SUSPENSION

Removal and Installation (Cont’d)

SU-21

Page 2180 of 3189

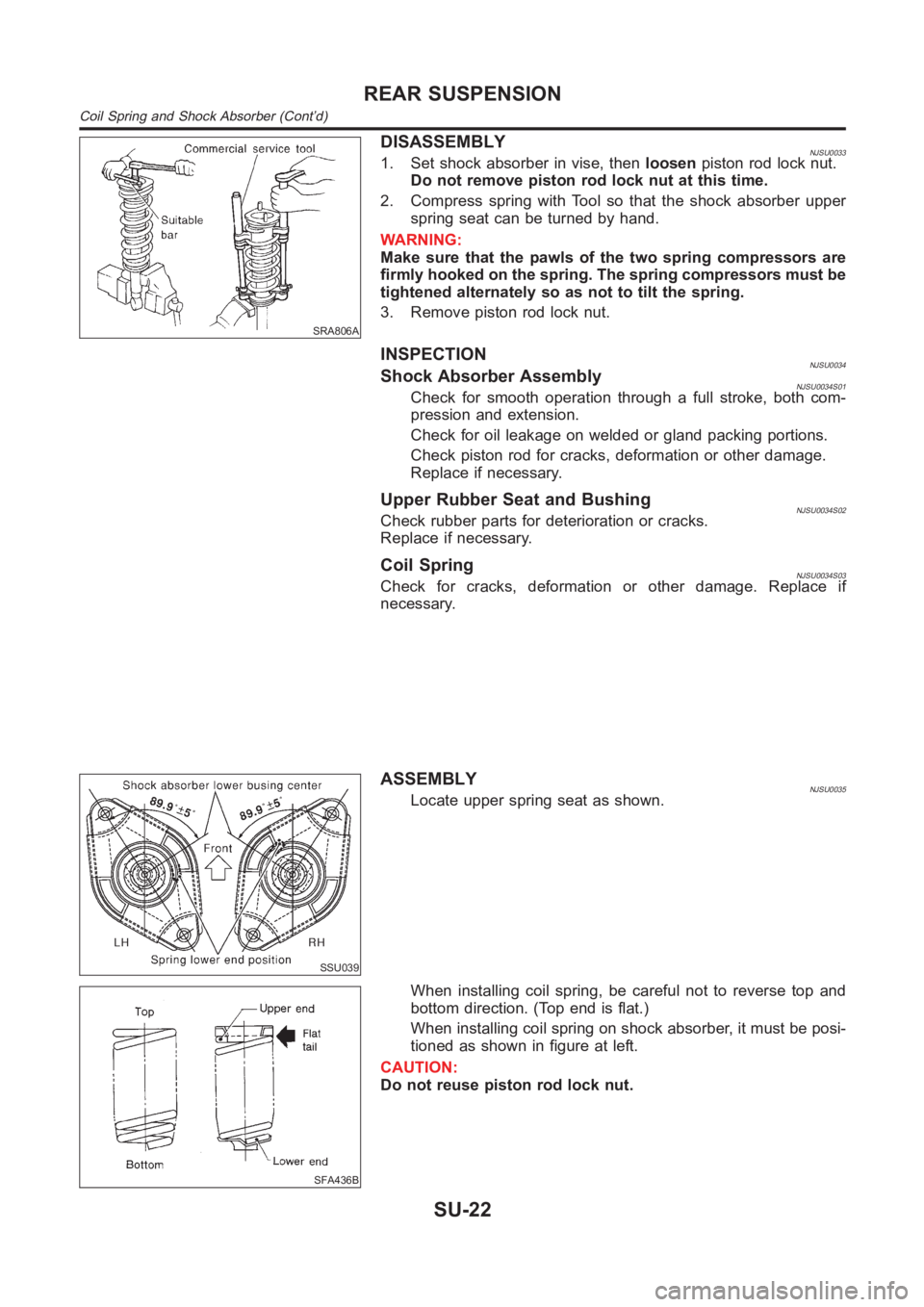

SRA806A

DISASSEMBLYNJSU00331. Set shock absorber in vise, thenloosenpiston rod lock nut.

Do not remove piston rod lock nut at this time.

2. Compress spring with Tool so that the shock absorber upper

spring seat can be turned by hand.

WARNING:

Make sure that the pawls of the two spring compressors are

firmly hooked on the spring. The spring compressors must be

tightened alternately so as not to tilt the spring.

3. Remove piston rod lock nut.

INSPECTIONNJSU0034Shock Absorber AssemblyNJSU0034S01Check for smooth operation through a full stroke, both com-

pression and extension.

Check for oil leakage on welded or gland packing portions.

Check piston rod for cracks, deformation or other damage.

Replace if necessary.

Upper Rubber Seat and BushingNJSU0034S02Check rubber parts for deterioration or cracks.

Replace if necessary.

Coil SpringNJSU0034S03Check for cracks, deformation or other damage. Replace if

necessary.

SSU039

ASSEMBLYNJSU0035Locate upper spring seat as shown.

SFA436B

When installing coil spring, be careful not to reverse top and

bottom direction. (Top end is flat.)

When installing coil spring on shock absorber, it must be posi-

tioned as shown in figure at left.

CAUTION:

Do not reuse piston rod lock nut.

REAR SUSPENSION

Coil Spring and Shock Absorber (Cont’d)

SU-22