oil filter NISSAN ALMERA N16 2003 Electronic Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2003Pages: 3189, PDF Size: 54.76 MB

Page 1688 of 3189

![NISSAN ALMERA N16 2003 Electronic Service Manual AT-232

[EURO-OBD]

TROUBLE DIAGNOSES FOR SYMPTOMS

5. DETECT MALFUNCTIONING ITEM

1. Remove control valve assembly. Refer to AT- 4 0 6 , "

Control Valve Assembly and Accumulators" .

2. Check th NISSAN ALMERA N16 2003 Electronic Service Manual AT-232

[EURO-OBD]

TROUBLE DIAGNOSES FOR SYMPTOMS

5. DETECT MALFUNCTIONING ITEM

1. Remove control valve assembly. Refer to AT- 4 0 6 , "

Control Valve Assembly and Accumulators" .

2. Check th](/img/5/57350/w960_57350-1687.png)

AT-232

[EURO-OBD]

TROUBLE DIAGNOSES FOR SYMPTOMS

5. DETECT MALFUNCTIONING ITEM

1. Remove control valve assembly. Refer to AT- 4 0 6 , "

Control Valve Assembly and Accumulators" .

2. Check the following items:

–Torque converter clutch control valve

–Pilot valve

–Pilot filter

3. Disassemble A/T.

4. Check torque converter and oil pump assembly.

OK or NG

OK >> GO TO 4

NG >> Repair or replace damaged parts.

14. Lock-up Is Not ReleasedECS007QF

SYMPTOM:

Lock-up is not released when accelerator pedal is released.

1. CHECK THROTTLE POSITION SENSOR* CIRCUIT

*: This sensor means accelerator pedal position (APP) sensor.

With CONSULT-II

Does “TCM INPUT SIGNALS” in “DATA MONITOR” show damage throttle position sensor circuit?

Without CONSULT-II

Does self-diagnosis show damage to throttle position sensor circuit?

Ye s o r N o

Yes >> Check throttle position sensor circuit. Refer to AT- 2 3 7 ,

"21. TCM Self-diagnosis Does Not Activate (PNP &

Overdrive Control Switches, and Throttle Position Sen-

sor Circuit Checks)" .

No >> GO TO 2

2. CHECK SYMPTOM

Check again.

OK or NG

OK >>INSPECTION END

NG >> 1. Perform TCM input/output signal inspection.

2. If NG, recheck TCM pin terminals for damage or loose connection with harness connector.

SCIA0706E

Page 1775 of 3189

![NISSAN ALMERA N16 2003 Electronic Service Manual TROUBLE DIAGNOSES FOR SYMPTOMS

AT-319

[EXC.F/EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

6.DETECT MALFUNCTIONING ITEM

1. Remove control valve assembly. Refer to AT- 4 0 6 , "

Control Valve Assembly and NISSAN ALMERA N16 2003 Electronic Service Manual TROUBLE DIAGNOSES FOR SYMPTOMS

AT-319

[EXC.F/EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

6.DETECT MALFUNCTIONING ITEM

1. Remove control valve assembly. Refer to AT- 4 0 6 , "

Control Valve Assembly and](/img/5/57350/w960_57350-1774.png)

TROUBLE DIAGNOSES FOR SYMPTOMS

AT-319

[EXC.F/EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

6.DETECT MALFUNCTIONING ITEM

1. Remove control valve assembly. Refer to AT- 4 0 6 , "

Control Valve Assembly and Accumulators" .

2. Check the following items:

–Shift valve A

–Shift valve B

–Shift solenoid valve A

–Shift solenoid valve B

–Pilot valve

–Pilot filter

OK or NG

OK >> GO TO 7

NG >> Repair or replace damaged parts.

7.CHECK SYMPTOM

Check again.

OK or NG

OK >>INSPECTION END

NG >> 1. Perform TCM input/output signal inspection.

2. If NG, recheck TCM pin terminals for damage or loose connection with harness connector.

8.DETECT MALFUNCTIONING ITEM

1. Remove control valve assembly. Refer to AT- 4 0 6 , "

Control Valve Assembly and Accumulators" .

2. Check the following items:

–Shift valve A

–Shift valve B

–Shift solenoid valve A

–Shift solenoid valve B

–Pilot valve

–Pilot filter

3. Disassemble A/T.

4. Check the following items:

–Forward clutch assembly

–Forward one-way clutch

–Low one-way clutch

–High clutch assembly

–Torque converter

–Oil pump assembly

OK or NG

OK >> GO TO 7

NG >> Repair or replace damaged parts.

Page 1777 of 3189

![NISSAN ALMERA N16 2003 Electronic Service Manual TROUBLE DIAGNOSES FOR SYMPTOMS

AT-321

[EXC.F/EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

5.CHECK A/T FLUID CONIDITION

1. Remove oil pan, refer to AT- 4 0 6 , "

REMOVAL" .

2. Check A/T fluid conditio NISSAN ALMERA N16 2003 Electronic Service Manual TROUBLE DIAGNOSES FOR SYMPTOMS

AT-321

[EXC.F/EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

5.CHECK A/T FLUID CONIDITION

1. Remove oil pan, refer to AT- 4 0 6 , "

REMOVAL" .

2. Check A/T fluid conditio](/img/5/57350/w960_57350-1776.png)

TROUBLE DIAGNOSES FOR SYMPTOMS

AT-321

[EXC.F/EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

5.CHECK A/T FLUID CONIDITION

1. Remove oil pan, refer to AT- 4 0 6 , "

REMOVAL" .

2. Check A/T fluid condition.

OK or NG

OK >> GO TO 6

NG >> GO TO 8

6.DETECT MALFUNCTIONING ITEM

1. Remove control valve. Refer to AT-406, "

Control Valve Assembly and Accumulators" .

2. Check the following items:

–Shift valve A

–Shift solenoid valve A (AT- 3 5 7 , "SHIFT SOLENOID VALVE A" )

–Pilot valve

–Pilot filter

OK or NG

OK >> GO TO 7

NG >> Repair or replace damaged parts.

7.CHECK SYMPTOM

Check again.

OK or NG

OK >>INSPECTION END

NG >> 1. Perform TCM input/output signal inspection.

2. If NG, recheck TCM pin terminals for damage or loose connection with harness connector.

8.DETECT MALFUNCTIONING ITEM

1. Remove control valve. Refer to AT-406, "

Control Valve Assembly and Accumulators" .

2. Check the following items:

–Shift valve A

–Shift solenoid valve A (AT- 3 5 7 , "SHIFT SOLENOID VALVE A" )

–Pilot valve

–Pilot filter

3. Disassemble A/T.

4. Check the following items:

–Servo piston assembly

–Brake band

–Oil pump assembly

OK or NG

OK >> GO TO 7

NG >> Repair or replace damaged parts.

SAT171B

Page 1779 of 3189

![NISSAN ALMERA N16 2003 Electronic Service Manual TROUBLE DIAGNOSES FOR SYMPTOMS

AT-323

[EXC.F/EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

5.DETECT MALFUNCTIONING ITEM

1. Remove control valve assembly. Refer to AT- 4 0 6 , "

Control Valve Assembly and NISSAN ALMERA N16 2003 Electronic Service Manual TROUBLE DIAGNOSES FOR SYMPTOMS

AT-323

[EXC.F/EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

5.DETECT MALFUNCTIONING ITEM

1. Remove control valve assembly. Refer to AT- 4 0 6 , "

Control Valve Assembly and](/img/5/57350/w960_57350-1778.png)

TROUBLE DIAGNOSES FOR SYMPTOMS

AT-323

[EXC.F/EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

5.DETECT MALFUNCTIONING ITEM

1. Remove control valve assembly. Refer to AT- 4 0 6 , "

Control Valve Assembly and Accumulators" .

2. Check the following items:

–Shift valve B

–Shift solenoid valve B (AT- 3 6 2 , "SHIFT SOLENOID VALVE B" )

–Pilot valve

–Pilot filter

OK or NG

OK >> GO TO 6

NG >> Repair or replace damaged parts.

6.CHECK SYMPTOM

Check again.

OK or NG

OK >>INSPECTION END

NG >> 1. Perform TCM input/output signal inspection.

2. If NG, recheck TCM pin terminals for damage or loose connection with harness connector.

7.DETECT MALFUNCTIONING ITEM

1. Remove control valve assembly. Refer to AT- 4 0 6 , "

Control Valve Assembly and Accumulators" .

2. Check the following items:

–Shift valve B

–Shift solenoid valve B (AT- 3 6 2 , "SHIFT SOLENOID VALVE B" )

–Pilot valve

–Pilot filter

3. Disassemble A/T.

4. Check the following items:

–Servo piston assembly

–High clutch assembly

–Oil pump assembly

OK or NG

OK >> GO TO 6

NG >> Repair or replace damaged parts.

Page 1781 of 3189

![NISSAN ALMERA N16 2003 Electronic Service Manual TROUBLE DIAGNOSES FOR SYMPTOMS

AT-325

[EXC.F/EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

4.CHECK A/T FLUID CONDITION

1. Remove oil pan, refer to AT- 4 0 6 , "

REMOVAL" .

2. Check A/T fluid condition NISSAN ALMERA N16 2003 Electronic Service Manual TROUBLE DIAGNOSES FOR SYMPTOMS

AT-325

[EXC.F/EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

4.CHECK A/T FLUID CONDITION

1. Remove oil pan, refer to AT- 4 0 6 , "

REMOVAL" .

2. Check A/T fluid condition](/img/5/57350/w960_57350-1780.png)

TROUBLE DIAGNOSES FOR SYMPTOMS

AT-325

[EXC.F/EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

4.CHECK A/T FLUID CONDITION

1. Remove oil pan, refer to AT- 4 0 6 , "

REMOVAL" .

2. Check A/T fluid condition.

OK or NG

OK >> GO TO 5

NG >> GO TO 7

5.DETECT MALFUNCTIONING ITEM

1. Remove control valve assembly. Refer to AT- 4 0 6 , "

Control Valve Assembly and Accumulators" .

2. Check the following items:

–Shift valve B

–Overrun clutch control valve

–Shift solenoid valve B

–Pilot valve

–Pilot filter

OK or NG

OK >> GO TO 6

NG >> Repair or replace damaged parts.

6.CHECK SYMPTOM

Check again.

OK or NG

OK >>INSPECTION END

NG >> 1. Perform TCM input/output signal inspection.

2. If NG, recheck TCM pin terminals for damage or loose connection with harness connector.

7.DETECT MALFUNCTIONING ITEM

1. Remove control valve assembly. Refer to AT- 4 0 6 , "

Control Valve Assembly and Accumulators" .

2. Check the following items:

–Shift valve B

–Overrun clutch control valve

–Shift solenoid valve B

–Pilot valve

–Pilot filter

3. Disassemble A/T.

4. Check the following items:

–Servo piston assembly

–Brake band

–Torque converter

–Oil pump assembly

OK or NG

OK >> GO TO 6

NG >> Repair or replace damaged parts.

SAT171B

Page 1783 of 3189

![NISSAN ALMERA N16 2003 Electronic Service Manual TROUBLE DIAGNOSES FOR SYMPTOMS

AT-327

[EXC.F/EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

1.CHECK DIAGNOSTIC RESULTS

Does self-diagnosis show damage to engine speed signal circuit

after cruise test?

Ye NISSAN ALMERA N16 2003 Electronic Service Manual TROUBLE DIAGNOSES FOR SYMPTOMS

AT-327

[EXC.F/EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

1.CHECK DIAGNOSTIC RESULTS

Does self-diagnosis show damage to engine speed signal circuit

after cruise test?

Ye](/img/5/57350/w960_57350-1782.png)

TROUBLE DIAGNOSES FOR SYMPTOMS

AT-327

[EXC.F/EURO-OBD]

D

E

F

G

H

I

J

K

L

MA

B

AT

1.CHECK DIAGNOSTIC RESULTS

Does self-diagnosis show damage to engine speed signal circuit

after cruise test?

Ye s o r N o

Yes >> Check engine speed signal circuit. Refer to AT- 3 8 3 ,

"ENGINE SPEED SIGNAL" .

No >> GO TO 2

2.CHECK A/T FLUID CONDITION

1. Remove oil pan, refer to AT- 4 0 6 , "

REMOVAL" .

2. Check A/T fluid condition.

OK or NG

OK >> GO TO 3

NG >> GO TO 5

3.DETECT MALFUNCTIONING ITEM

1. Remove control valve assembly. Refer to AT- 4 0 6 , "

Control Valve Assembly and Accumulators" .

2. Check the following items:

–Torque converter clutch control valve

–Pilot valve

–Pilot filter

OK or NG

OK >> GO TO 4

NG >> Repair or replace damaged parts.

4.CHECK SYMPTOM

Check again.

OK or NG

OK >>INSPECTION END

NG >> 1. Perform TCM input/output signal inspection.

2. If NG, recheck TCM pin terminals for damage or loose connection with harness connector.

SCIA0773E

SAT171B

Page 1784 of 3189

![NISSAN ALMERA N16 2003 Electronic Service Manual AT-328

[EXC.F/EURO-OBD]

TROUBLE DIAGNOSES FOR SYMPTOMS

5. DETECT MALFUNCTIONING ITEM

1. Remove control valve assembly. Refer to AT- 4 0 6 , "

Control Valve Assembly and Accumulators" .

2. Ch NISSAN ALMERA N16 2003 Electronic Service Manual AT-328

[EXC.F/EURO-OBD]

TROUBLE DIAGNOSES FOR SYMPTOMS

5. DETECT MALFUNCTIONING ITEM

1. Remove control valve assembly. Refer to AT- 4 0 6 , "

Control Valve Assembly and Accumulators" .

2. Ch](/img/5/57350/w960_57350-1783.png)

AT-328

[EXC.F/EURO-OBD]

TROUBLE DIAGNOSES FOR SYMPTOMS

5. DETECT MALFUNCTIONING ITEM

1. Remove control valve assembly. Refer to AT- 4 0 6 , "

Control Valve Assembly and Accumulators" .

2. Check the following items:

–Torque converter clutch control valve

–Pilot valve

–Pilot filter

3. Disassemble A/T.

4. Check torque converter and oil pump assembly.

OK or NG

OK >> GO TO 4

NG >> Repair or replace damaged parts.

14. Lock-up Is Not ReleasedECS007RD

SYMPTOM:

Lock-up is not released when accelerator pedal is released.

1. CHECK THROTTLE POSITION SENSOR* CIRCUIT

*: This sensor means accelerator pedal position (APP) sensor.

With CONSULT-II

Does “TCM INPUT SIGNALS” in “DATA MONITOR” show damage throttle position sensor circuit?

Without CONSULT-II

Does self-diagnosis show damage to throttle position sensor circuit?

Ye s o r N o

Yes >> Check throttle position sensor circuit. Refer to AT- 3 3 3 ,

"21. TCM Self-diagnosis Does Not Activate (PNP &

Overdrive Control Switches, and Throttle Position Sen-

sor Circuit Checks)" .

No >> GO TO 2

2. CHECK SYMPTOM

Check again.

OK or NG

OK >>INSPECTION END

NG >> 1. Perform TCM input/output signal inspection.

2. If NG, recheck TCM pin terminals for damage or loose connection with harness connector.

15. Engine Speed Does Not Return To Idle (Light Braking D4→ D3 )ECS007RE

SYMPTOM:

●Engine speed does not smoothly return to idle when A/T shifts from D4 to D3 .

●Vehicle does not decelerate by engine brake when turning overdrive control switch OFF.

●Vehicle does not decelerate by engine brake when shifting A/T from “D” to “2” position.

SCIA0706E

Page 1895 of 3189

![NISSAN ALMERA N16 2003 Electronic Service Manual REPAIR FOR COMPONENT PARTS

AT-439

[ALL]

D

E

F

G

H

I

J

K

L

MA

B

AT

Control Valve AssemblyECS007TC

COMPONENTS

1. Solenoid valve assembly 2. O-ring 3. Clip

4. Terminal body 5. Control valve lower body 6. NISSAN ALMERA N16 2003 Electronic Service Manual REPAIR FOR COMPONENT PARTS

AT-439

[ALL]

D

E

F

G

H

I

J

K

L

MA

B

AT

Control Valve AssemblyECS007TC

COMPONENTS

1. Solenoid valve assembly 2. O-ring 3. Clip

4. Terminal body 5. Control valve lower body 6.](/img/5/57350/w960_57350-1894.png)

REPAIR FOR COMPONENT PARTS

AT-439

[ALL]

D

E

F

G

H

I

J

K

L

MA

B

AT

Control Valve AssemblyECS007TC

COMPONENTS

1. Solenoid valve assembly 2. O-ring 3. Clip

4. Terminal body 5. Control valve lower body 6. Oil strainer

7. Support plate 8. Lower inter separating gasket 9. Separating plate

10. Lower separating gasket 11. Steel ball 12. Control valve inter body

13. Pilot filter 14. Upper inter separating gasket 15. Separating plate

16. Upper separating gasket 17 Steel ball 18. Control valve upper body

19. Check ball 20. Fluid cooler relief valve spring 21. O-ring

22. T/C pressure holding spring 23. Check ball

SAT868J

Page 2198 of 3189

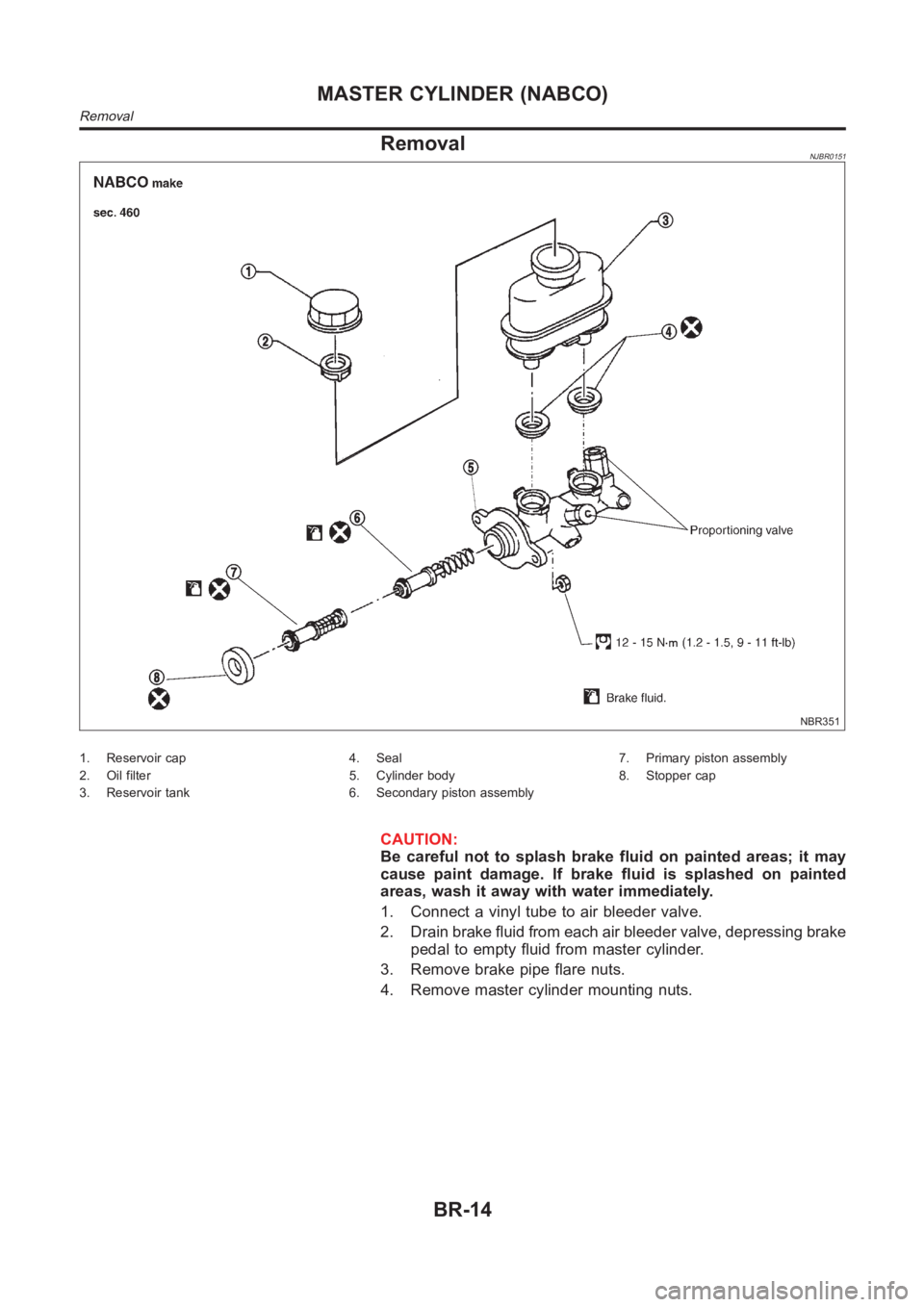

RemovalNJBR0151

NBR351

1. Reservoir cap

2. Oil filter

3. Reservoir tank4. Seal

5. Cylinder body

6. Secondary piston assembly7. Primary piston assembly

8. Stopper cap

CAUTION:

Be careful not to splash brake fluid on painted areas; it may

cause paint damage. If brake fluid is splashed on painted

areas, wash it away with water immediately.

1. Connect a vinyl tube to air bleeder valve.

2. Drain brake fluid from each air bleeder valve, depressing brake

pedal to empty fluid from master cylinder.

3. Remove brake pipe flare nuts.

4. Remove master cylinder mounting nuts.

MASTER CYLINDER (NABCO)

Removal

BR-14

Page 2201 of 3189

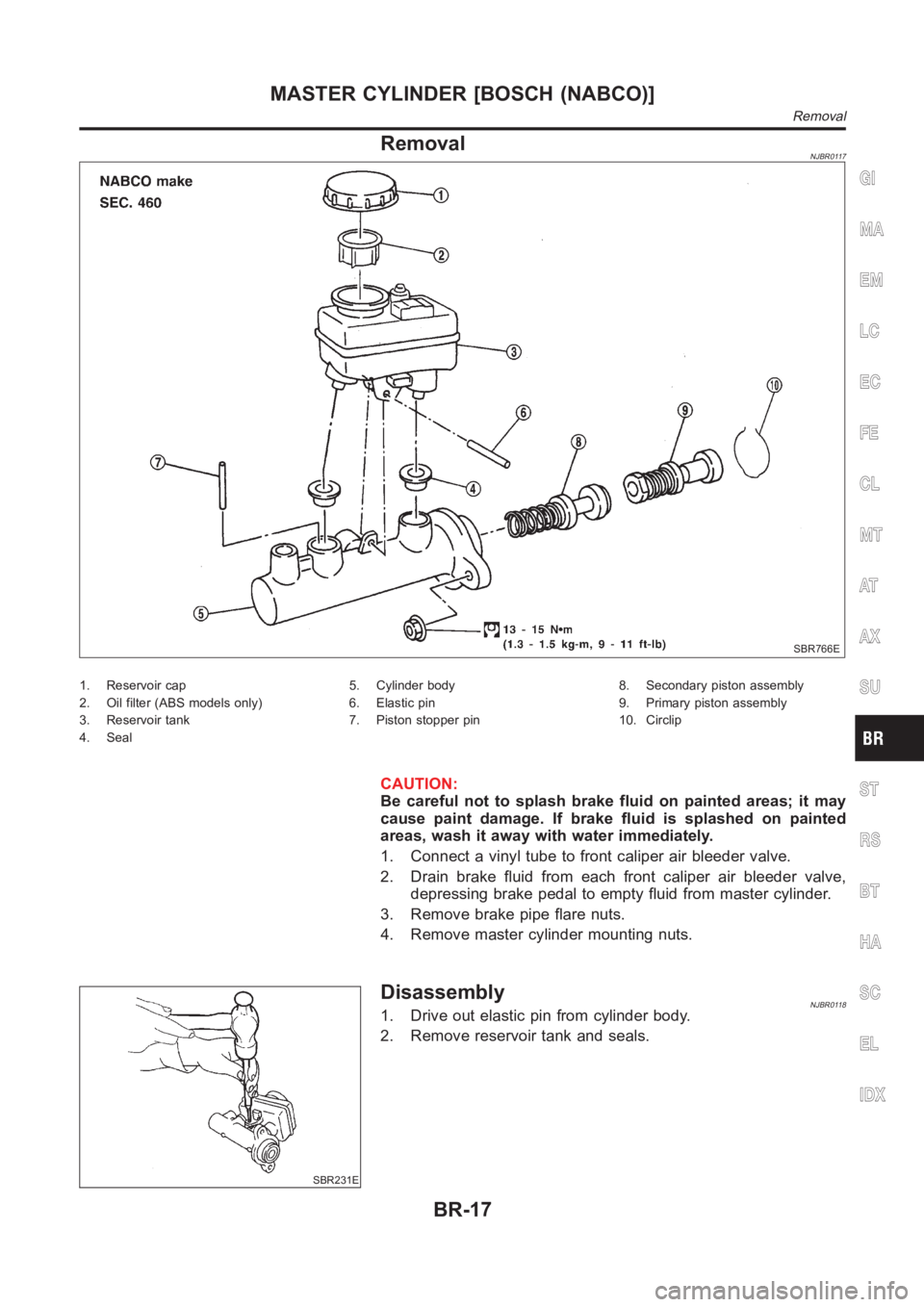

RemovalNJBR0117

SBR766E

1. Reservoir cap

2. Oil filter (ABS models only)

3. Reservoir tank

4. Seal5. Cylinder body

6. Elastic pin

7. Piston stopper pin8. Secondary piston assembly

9. Primary piston assembly

10. Circlip

CAUTION:

Be careful not to splash brake fluid on painted areas; it may

cause paint damage. If brake fluid is splashed on painted

areas, wash it away with water immediately.

1. Connect a vinyl tube to front caliper air bleeder valve.

2. Drain brake fluid from each front caliper air bleeder valve,

depressing brake pedal to empty fluid from master cylinder.

3. Remove brake pipe flare nuts.

4. Remove master cylinder mounting nuts.

SBR231E

DisassemblyNJBR01181. Drive out elastic pin from cylinder body.

2. Remove reservoir tank and seals.

GI

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

ST

RS

BT

HA

SC

EL

IDX

MASTER CYLINDER [BOSCH (NABCO)]

Removal

BR-17