fuse box NISSAN ALMERA N16 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2003Pages: 3189, PDF Size: 54.76 MB

Page 16 of 3189

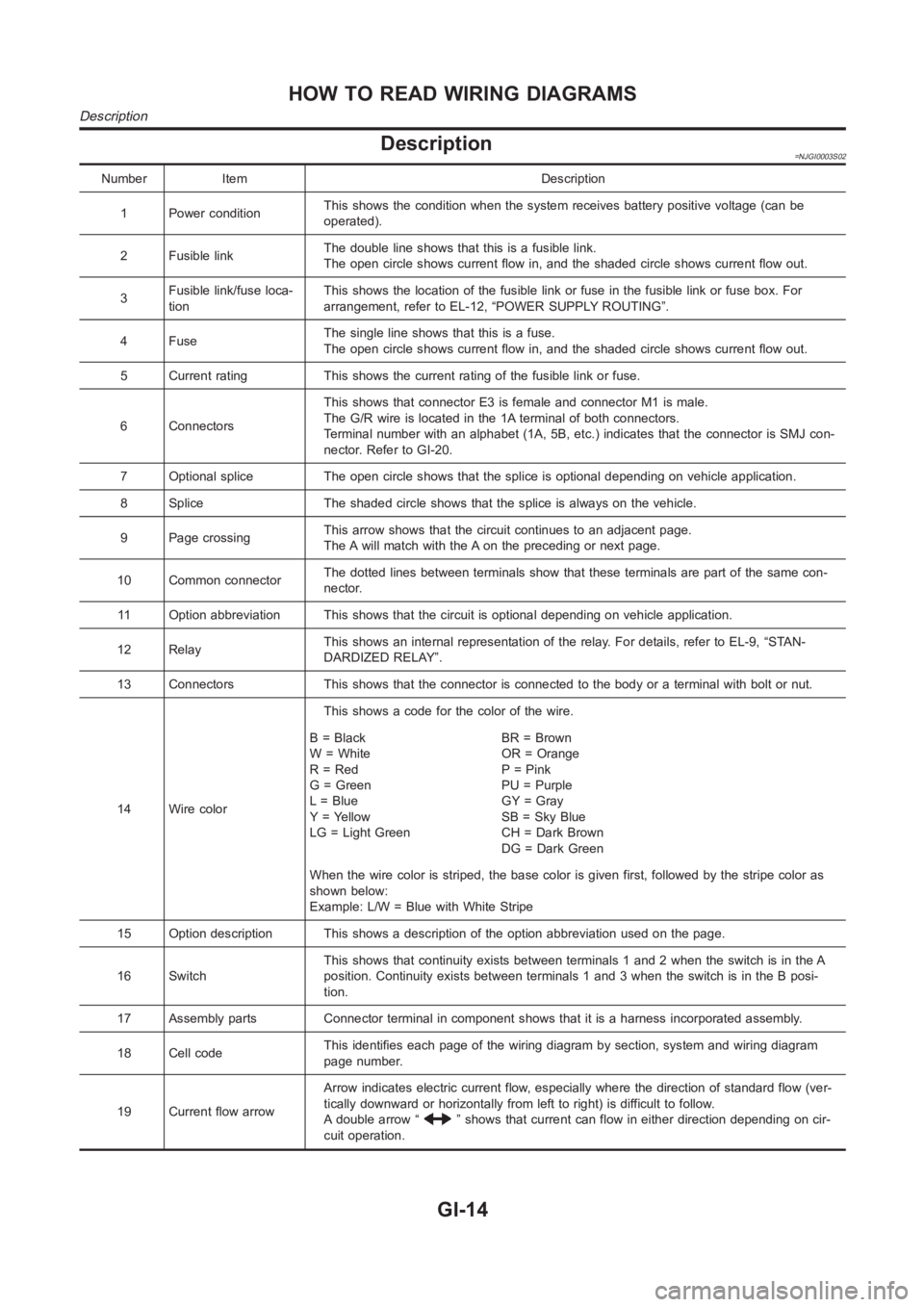

Description=NJGI0003S02

Number Item Description

1 Power conditionThis shows the condition when the system receives battery positive voltage (can be

operated).

2 Fusible linkThe double line shows that this is a fusible link.

The open circle shows current flow in, and the shaded circle shows current flow out.

3Fusible link/fuse loca-

tionThis shows the location of the fusible link or fuse in the fusible link or fusebox.For

arrangement, refer to EL-12, “POWER SUPPLY ROUTING”.

4FuseThe single line shows that this is a fuse.

The open circle shows current flow in, and the shaded circle shows current flow out.

5 Current rating This shows the current rating of the fusible link or fuse.

6 ConnectorsThis shows that connector E3 is female and connector M1 is male.

The G/R wire is located in the 1A terminal of both connectors.

Terminal number with an alphabet (1A, 5B, etc.) indicates that the connector is SMJ con-

nector. Refer to GI-20.

7 Optional splice The open circle shows that the splice is optional depending on vehicle application.

8 Splice The shaded circle shows that the splice is always on the vehicle.

9 Page crossingThis arrow shows that the circuit continues to an adjacent page.

The A will match with the A on the preceding or next page.

10 Common connectorThe dotted lines between terminals show that these terminals are part of thesamecon-

nector.

11 Option abbreviation This shows that the circuit is optional depending on vehicle application.

12 RelayThis shows an internal representation of the relay. For details, refer to EL-9, “STAN-

DARDIZED RELAY”.

13 Connectors This shows that the connector is connected to the body or a terminal with bolt or nut.

14 Wire colorThis shows a code for the color of the wire.

B=Black

W = White

R = Red

G = Green

L = Blue

Y = Yellow

LG = Light GreenBR = Brown

OR = Orange

P = Pink

PU = Purple

GY = Gray

SB = Sky Blue

CH = Dark Brown

DG=DarkGreen

When the wire color is striped, the base color is given first, followed by the stripe color as

shown below:

Example: L/W = Blue with White Stripe

15 Option description This shows a description of the option abbreviationused on the page.

16 SwitchThis shows that continuity exists between terminals 1 and 2 when the switchis in the A

position. Continuity exists between terminals 1 and 3 when the switch is inthe B posi-

tion.

17 Assembly parts Connector terminal in component shows that it is a harness incorporated assembly.

18 Cell codeThis identifies each page of the wiring diagram by section, system and wiring diagram

page number.

19 Current flow arrowArrow indicates electric current flow, especially where the direction ofstandard flow (ver-

tically downward or horizontally from left to right) is difficult to follow.

A double arrow “

” shows that current can flow in either direction depending on cir-

cuit operation.

HOW TO READ WIRING DIAGRAMS

Description

GI-14

Page 17 of 3189

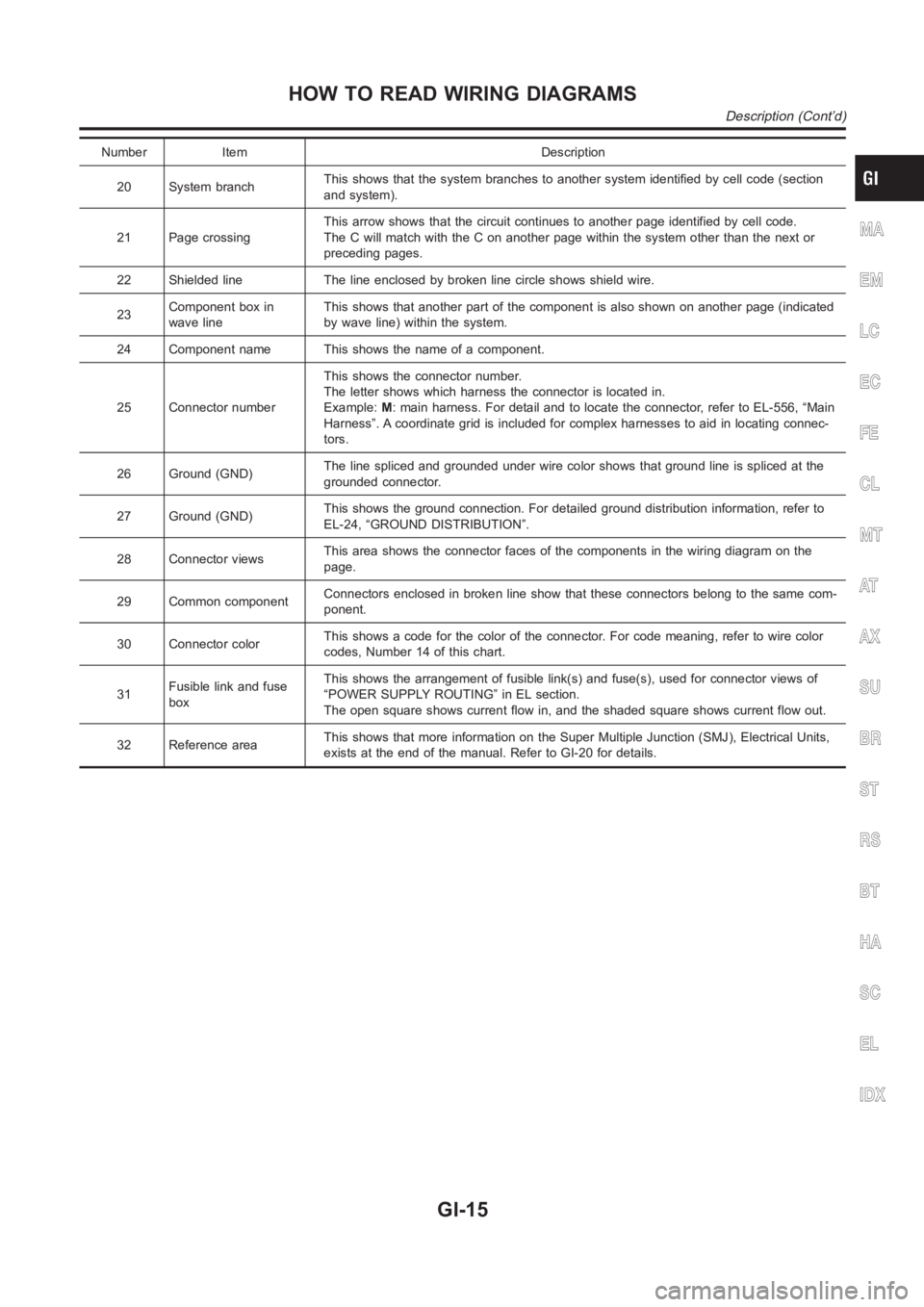

Number Item Description

20 System branchThis shows that the system branches to another system identified by cell code (section

and system).

21 Page crossingThis arrow shows that the circuit continues to another page identified by cell code.

The C will match with the C on another page within the system other than the next or

preceding pages.

22 Shielded line The line enclosed by broken line circle shows shield wire.

23Component box in

wave lineThis shows that another part of the component is also shown on another page (indicated

by wave line) within the system.

24 Component name This shows the name of a component.

25 Connector numberThis shows the connector number.

The letter shows which harness the connector is located in.

Example:M: main harness. For detail and to locate the connector, refer to EL-556, “Main

Harness”. A coordinate grid is included for complex harnesses to aid in locating connec-

tors.

26 Ground (GND)The line spliced and grounded under wire color shows that ground line is spliced at the

grounded connector.

27 Ground (GND)This shows the ground connection. For detailed ground distribution information, refer to

EL-24, “GROUND DISTRIBUTION”.

28 Connector viewsThis area shows the connector faces of the components in the wiring diagramon the

page.

29 Common componentConnectors enclosed in broken line show that these connectors belong to thesamecom-

ponent.

30 Connector colorThis shows a code for the color of the connector. For code meaning, refer to wire color

codes, Number 14 of this chart.

31Fusible link and fuse

boxThis shows the arrangement of fusible link(s) and fuse(s), used for connector views of

“POWER SUPPLY ROUTING” in EL section.

The open square shows current flow in, and the shaded square shows current flow out.

32 Reference areaThis shows that more information on the Super Multiple Junction (SMJ), Electrical Units,

exists at the end of the manual. Refer to GI-20 for details.

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

HOW TO READ WIRING DIAGRAMS

Description (Cont’d)

GI-15

Page 23 of 3189

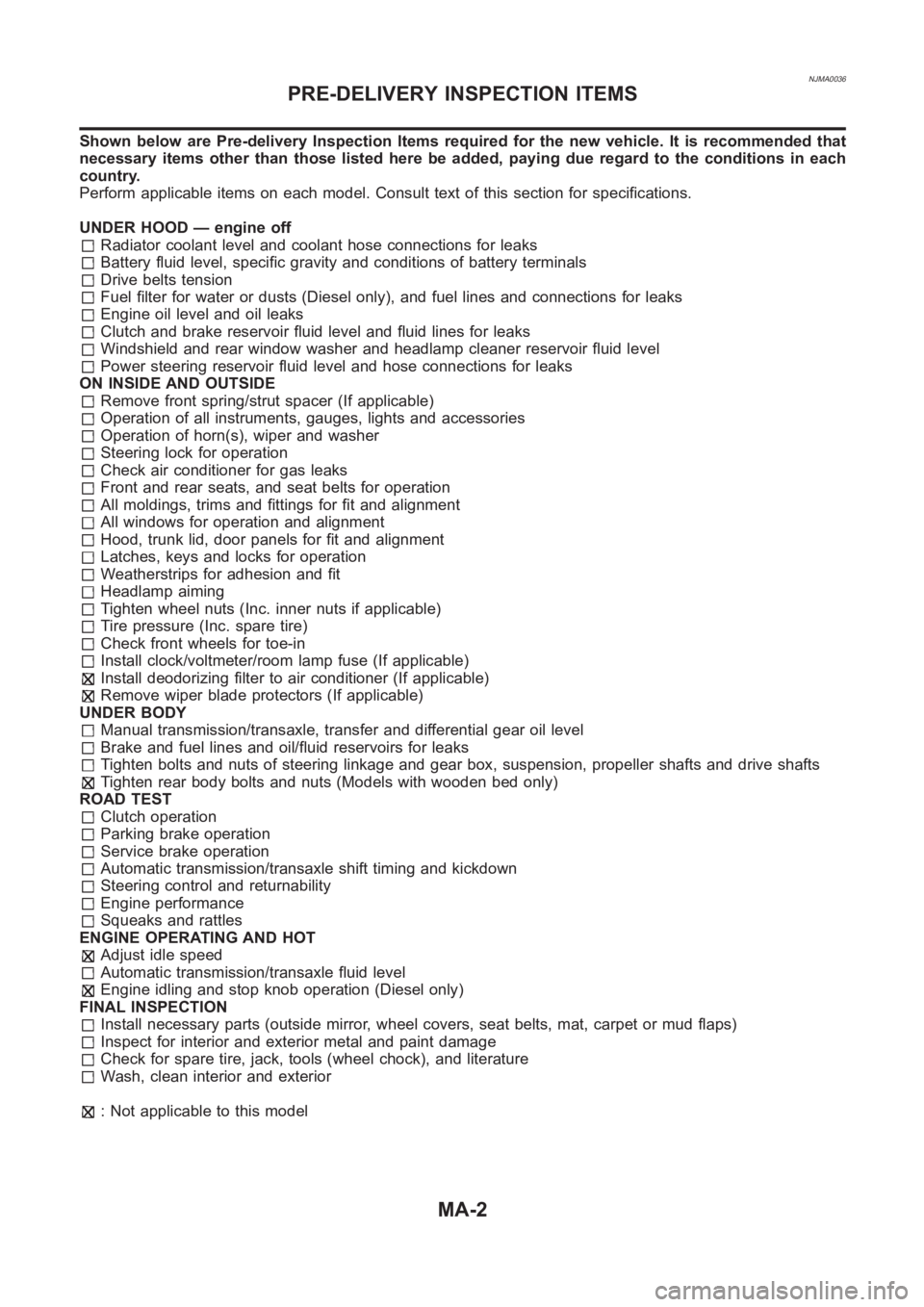

manual.

Fuse block — Junction box (J/B)

Fuse block — Junction box (J/B) connector number is shown in the

Reference Area of the wiring diagram. For connector terminal and

fuse arrangement, refer to the “FUSE BLOCK — Junction Box

(J/B)” electrical reference page at the end of the manual.

Fuse and fusible link box

For fuse arrangement in the fuse and fusible link box, refer to the

“FUSE AND FUSIBLE LINK BOX” electrical reference page at the

end of the manual.

Electrical units

Electrical unit connector symbols are shown in the Connector Area

of the wiring diagram.

However, when there is not enough space to show the connector

terminal arrangement in the Connector Area of the wiring diagram,

the electrical unit connector number is shown in the Reference

Area of the wiring diagram. For electrical unit connector terminal

arrangement, refer to the “ELECTRICAL UNITS” electrical refer-

ence page at the end of the manual. Most of the electrical unit

connectors on this page are shown from the harness side of the

connector.

Joint connector

Joint connector symbols are shown in the connector area of the

wiring diagram. For connector internal wiring layout and joint con-

nector terminal arrangement, refer to the “JOINT CONNECTOR

(J/C)” electrical reference page at the end of the manual.

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

HOW TO READ WIRING DIAGRAMS

Description (Cont’d)

GI-21

Page 58 of 3189

NJMA0036

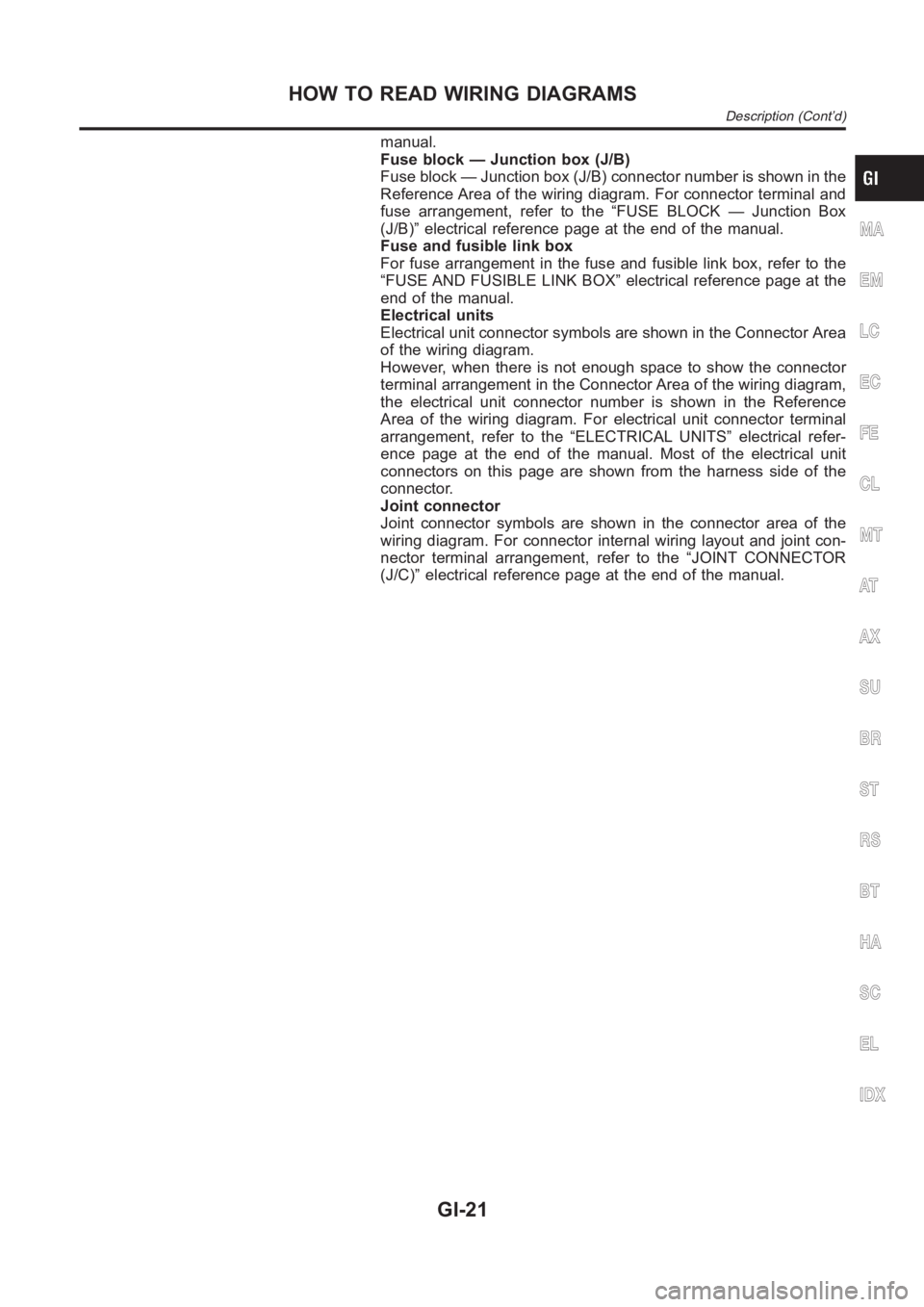

Shown below are Pre-delivery Inspection Items required for the new vehicle. It is recommended that

necessary items other than those listed here be added, paying due regard tothe conditions in each

country.

Perform applicable items on each model. Consult text of this section for specifications.

UNDER HOOD — engine off

Radiator coolant level and coolant hose connections for leaks

Battery fluid level, specific gravity and conditions of battery terminals

Drive belts tension

Fuel filter for water or dusts (Diesel only), and fuel lines and connections for leaks

Engine oil level and oil leaks

Clutch and brake reservoir fluid level and fluid lines for leaks

Windshield and rear window washer and headlamp cleaner reservoir fluid level

Power steering reservoir fluid level and hose connections for leaks

ON INSIDE AND OUTSIDE

Remove front spring/strut spacer (If applicable)

Operation of all instruments, gauges, lights and accessories

Operation of horn(s), wiper and washer

Steering lock for operation

Check air conditioner for gas leaks

Front and rear seats, and seat belts for operation

All moldings, trims and fittings for fit and alignment

All windows for operation and alignment

Hood, trunk lid, door panels for fit and alignment

Latches, keys and locks for operation

Weatherstrips for adhesion and fit

Headlamp aiming

Tighten wheel nuts (Inc. inner nuts if applicable)

Tire pressure (Inc. spare tire)

Check front wheels for toe-in

Install clock/voltmeter/room lamp fuse (If applicable)

Install deodorizing filter to air conditioner (If applicable)

Remove wiper blade protectors (If applicable)

UNDER BODY

Manual transmission/transaxle, transfer and differential gear oil level

Brake and fuel lines and oil/fluid reservoirs for leaks

Tighten bolts and nuts of steering linkage and gear box, suspension, propeller shafts and drive shafts

Tighten rear body bolts and nuts (Models with wooden bed only)

ROAD TEST

Clutch operation

Parking brake operation

Service brake operation

Automatic transmission/transaxle shift timing and kickdown

Steering control and returnability

Engine performance

Squeaks and rattles

ENGINE OPERATING AND HOT

Adjust idle speed

Automatic transmission/transaxle fluid level

Engine idling and stop knob operation (Diesel only)

FINAL INSPECTION

Install necessary parts (outside mirror, wheel covers, seat belts, mat, carpet or mud flaps)

Inspect for interior and exterior metal and paint damage

Check for spare tire, jack, tools (wheel chock), and literature

Wash, clean interior and exterior

: Not applicable to this model

PRE-DELIVERY INSPECTION ITEMS

MA-2

Page 193 of 3189

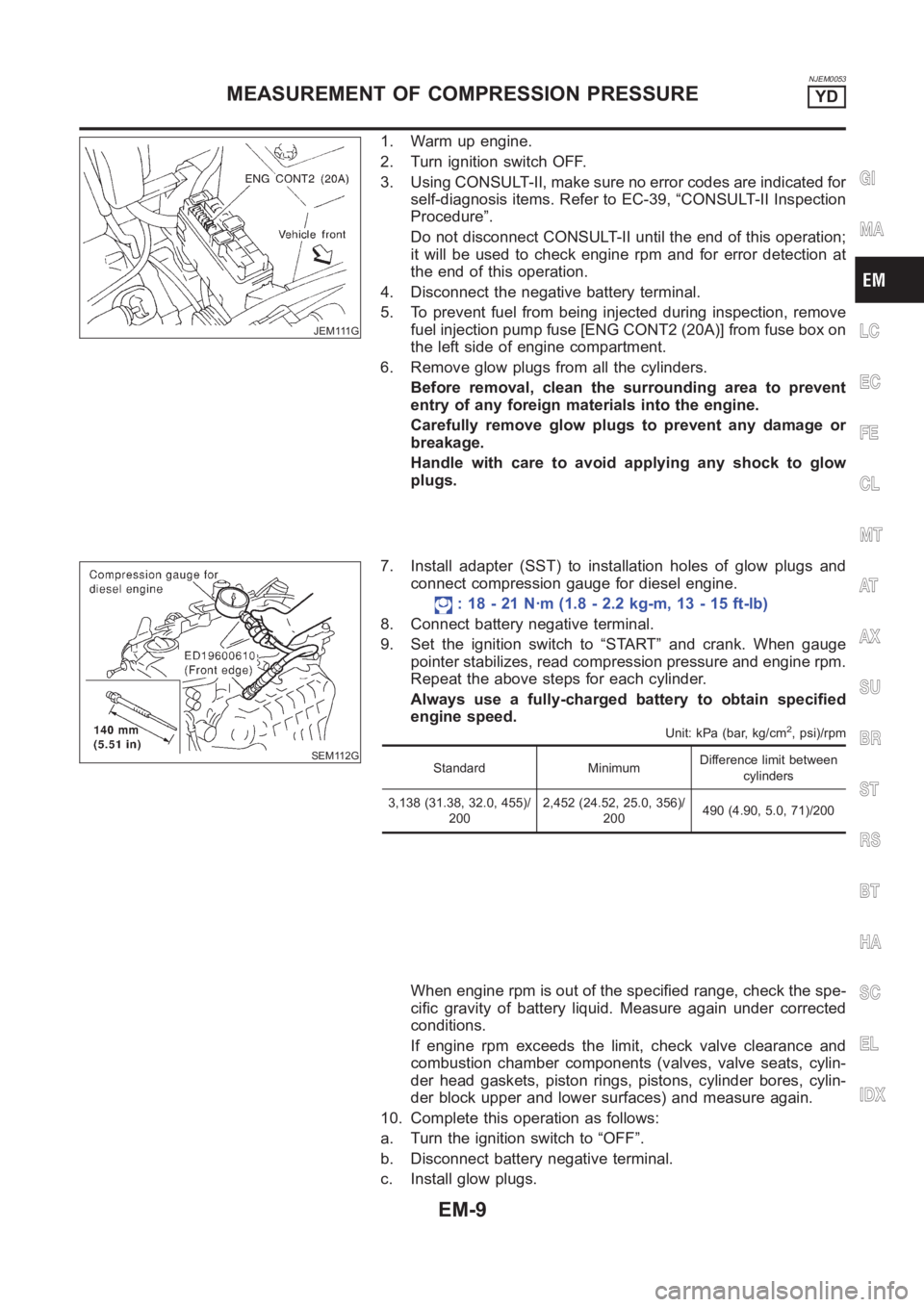

NJEM0053

JEM111G

1. Warm up engine.

2. Turn ignition switch OFF.

3. Using CONSULT-II, make sure no error codes are indicated for

self-diagnosis items. Refer to EC-39, “CONSULT-II Inspection

Procedure”.

Do not disconnect CONSULT-II until the end of this operation;

it will be used to check engine rpm and for error detection at

the end of this operation.

4. Disconnect the negative battery terminal.

5. To prevent fuel from being injected during inspection, remove

fuel injection pump fuse [ENG CONT2 (20A)] from fuse box on

the left side of engine compartment.

6. Remove glow plugs from all the cylinders.

Before removal, clean the surrounding area to prevent

entry of any foreign materials into the engine.

Carefully remove glow plugs to prevent any damage or

breakage.

Handle with care to avoid applying any shock to glow

plugs.

SEM112G

7. Install adapter (SST) to installation holes of glow plugs and

connect compression gauge for diesel engine.

: 18 - 21 N·m (1.8 - 2.2 kg-m, 13 - 15 ft-lb)

8. Connect battery negative terminal.

9. Set the ignition switch to “START” and crank. When gauge

pointer stabilizes, read compression pressure and engine rpm.

Repeat the above steps for each cylinder.

Always use a fully-charged battery to obtain specified

engine speed.

Unit: kPa (bar, kg/cm2, psi)/rpm

Standard MinimumDifference limit between

cylinders

3,138 (31.38, 32.0, 455)/

2002,452 (24.52, 25.0, 356)/

200490 (4.90, 5.0, 71)/200

When engine rpm is out of the specified range, check the spe-

cific gravity of battery liquid. Measure again under corrected

conditions.

If engine rpm exceeds the limit, check valve clearance and

combustion chamber components (valves, valve seats, cylin-

der head gaskets, piston rings, pistons, cylinder bores, cylin-

der block upper and lower surfaces) and measure again.

10. Complete this operation as follows:

a. Turn the ignition switch to “OFF”.

b. Disconnect battery negative terminal.

c. Install glow plugs.

GI

MA

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

MEASUREMENT OF COMPRESSION PRESSUREYD

EM-9

Page 364 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual EC-34

[QG (WITH EURO-OBD)]

BASIC SERVICE PROCEDURE

DIAGNOSTIC PROCEDURE

If idle air volume learning cannot be performed successfully, proceed as follows:

1.Check that throttle valve is fully closed.

2 NISSAN ALMERA N16 2003 Electronic Repair Manual EC-34

[QG (WITH EURO-OBD)]

BASIC SERVICE PROCEDURE

DIAGNOSTIC PROCEDURE

If idle air volume learning cannot be performed successfully, proceed as follows:

1.Check that throttle valve is fully closed.

2](/img/5/57350/w960_57350-363.png)

EC-34

[QG (WITH EURO-OBD)]

BASIC SERVICE PROCEDURE

DIAGNOSTIC PROCEDURE

If idle air volume learning cannot be performed successfully, proceed as follows:

1.Check that throttle valve is fully closed.

2.Check PCV valve operation.

3.Check that downstream of throttle valve is free from air leakage.

4.When the above three items check out OK, engine component parts and their installation condi-

tion are questionable. Check and eliminate the cause of the incident.

It is useful to perform EC-105, "

TROUBLE DIAGNOSIS - SPECIFICATION VALUE" .

5.If any of the following conditions occur after the engine has started, eliminate the cause of the

incident and perform “Idle air volume learning” all over again:

–Engine stalls.

–Erroneous idle.

Fuel Pressure CheckEBS00K3E

FUEL PRESSURE RELEASE

Before disconnecting fuel line, release fuel pressure from fuel line to eliminate danger.

NOTE:

Prepare pans or saucers under the disconnected fuel line because the fuel may spill out. The fuel pres-

sure cannot be completely released because N16 models do not have fuel return system.

With CONSULT-II

1. Turn ignition switch “ON”.

2. Perform “FUEL PRESSURE RELEASE” in “WORK SUPPORT”

mode with CONSULT-II.

3. Start engine.

4. After engine stalls, crank it two or three times to release all fuel

pressure.

5. Turn ignition switch “OFF”.

Without CONSULT-II

1. Remove fuel pump fuse located in fuse box.

2. Start engine.

3. After engine stalls, crank it two or three times to release all fuel

pressure.

4. Turn ignition switch “OFF”.

5. Reinstall fuel pump fuse after servicing fuel system.

FUEL PRESSURE CHECK

NOTE:

●When reconnecting fuel line, always use new clamps.

●Make sure that clamp screw does not contact adjacent parts.

●Use a torque driver to tighten clamps.

●Use Pressure Gauge to check fuel pressure.

1. Release fuel pressure to zero. Refer to EC-34, "

FUEL PRESSURE RELEASE" .

SEF214Y

MBIB0262E

Page 428 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual EC-98

[QG (WITH EURO-OBD)]

TROUBLE DIAGNOSIS

FUNCTION

GST INSPECTION PROCEDURE

1. Turn ignition switch OFF.

2. Connect “GST” to data link connector, which is located under the

driver side dash pan NISSAN ALMERA N16 2003 Electronic Repair Manual EC-98

[QG (WITH EURO-OBD)]

TROUBLE DIAGNOSIS

FUNCTION

GST INSPECTION PROCEDURE

1. Turn ignition switch OFF.

2. Connect “GST” to data link connector, which is located under the

driver side dash pan](/img/5/57350/w960_57350-427.png)

EC-98

[QG (WITH EURO-OBD)]

TROUBLE DIAGNOSIS

FUNCTION

GST INSPECTION PROCEDURE

1. Turn ignition switch OFF.

2. Connect “GST” to data link connector, which is located under the

driver side dash panel near the fuse box cover.

3. Turn ignition switch ON.

4. Enter the program according to instruction on the screen or in

the operation manual.

(*: Regarding GST screens in this section, sample screens are

shown.)

Diagnostic test mode Function

MODE 1 READINESS TESTSThis mode gains access to current emission-related data values, including analog inputs

and outputs, digital inputs and outputs, and system status information.

MODE 2 (FREEZE DATA)This mode gains access to emission-related data value which were stored by ECM during

the freeze frame. For details, refer to EC-40, "

FREEZE FRAME DATA AND 1ST TRIP

FREEZE FRAME DATA" .

MODE 3 DTCsThis mode gains access to emission-related power train trouble codes which were stored

by ECM.

MODE 4 CLEAR DIAG INFOThis mode can clear all emission-related diagnostic information. This includes:

●Clear number of diagnostic trouble codes (MODE 1)

●Clear diagnostic trouble codes (MODE 3)

●Clear trouble code for freeze frame data (MODE 1)

●Clear freeze frame data (MODE 2)

●Reset status of system monitoring test (MODE 1)

●Clear on board monitoring test results (MODE 6 and 7)

MODE 6 (ON BOARD TESTS)This mode accesses the results of on board diagnostic monitoring tests of specific com-

ponents/systems that are not continuously monitored.

MODE 7 (ON BOARD TESTS)This mode enables the off board test drive to obtain test results for emission-related pow-

ertrain components/systems that are continuously monitored during normal driving condi-

tions.

MODE 8 — This mode is not applicable on this vehicle.

MODE 9 (CALIBRATION ID)This mode enables the off-board test device to request specific vehicle information such

as Vehicle Identification Number (VIN) and Calibration IDs.

MBIB0251E

SEF398S

Page 758 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual EC-428

[QG (WITHOUT EURO-OBD)]

BASIC SERVICE PROCEDURE

2. Perform “FUEL PRESSURE RELEASE” in “WORK SUPPORT”

mode with CONSULT-II.

3. Start engine.

4. After engine stalls, crank it two or NISSAN ALMERA N16 2003 Electronic Repair Manual EC-428

[QG (WITHOUT EURO-OBD)]

BASIC SERVICE PROCEDURE

2. Perform “FUEL PRESSURE RELEASE” in “WORK SUPPORT”

mode with CONSULT-II.

3. Start engine.

4. After engine stalls, crank it two or](/img/5/57350/w960_57350-757.png)

EC-428

[QG (WITHOUT EURO-OBD)]

BASIC SERVICE PROCEDURE

2. Perform “FUEL PRESSURE RELEASE” in “WORK SUPPORT”

mode with CONSULT-II.

3. Start engine.

4. After engine stalls, crank it two or three times to release all fuel

pressure.

5. Turn ignition switch “OFF”.

Without CONSULT-II

1. Remove fuel pump fuse located in fuse box.

2. Start engine.

3. After engine stalls, crank it two or three times to release all fuel

pressure.

4. Turn ignition switch “OFF”.

5. Reinstall fuel pump fuse after servicing fuel system.

FUEL PRESSURE CHECK

NOTE:

●When reconnecting fuel line, always use new clamps.

●Make sure that clamp screw does not contact adjacent parts.

●Use a torque driver to tighten clamps.

●Use Pressure Gauge to check fuel pressure.

1. Release fuel pressure to zero. Refer to EC-427, "

FUEL PRESSURE RELEASE" .

2. Install the fuel pressure gauge with the fuel pressure check

adapter as shown in the figure.

3. Turn ignition switch “ON”, and check for fuel leakage.

4. Start engine and check for fuel leakage.

5. Read the indication of fuel pressure gauge.

6. If result is unsatisfactory, go to next step.

7. Check the following.

●Fuel hoses and fuel tubes for clogging

●Fuel filter for clogging

●Fuel pump

●Fuel pressure regulator for clogging

If OK, replace fuel pressure regulator.

If NG, repair or replace.

SEF214Y

MBIB0262E

At idling: Approximately 350 kPa

(3.5 bar, 3.57 kg/cm

2 , 51 psi)

MBIB0050E

Page 1346 of 3189

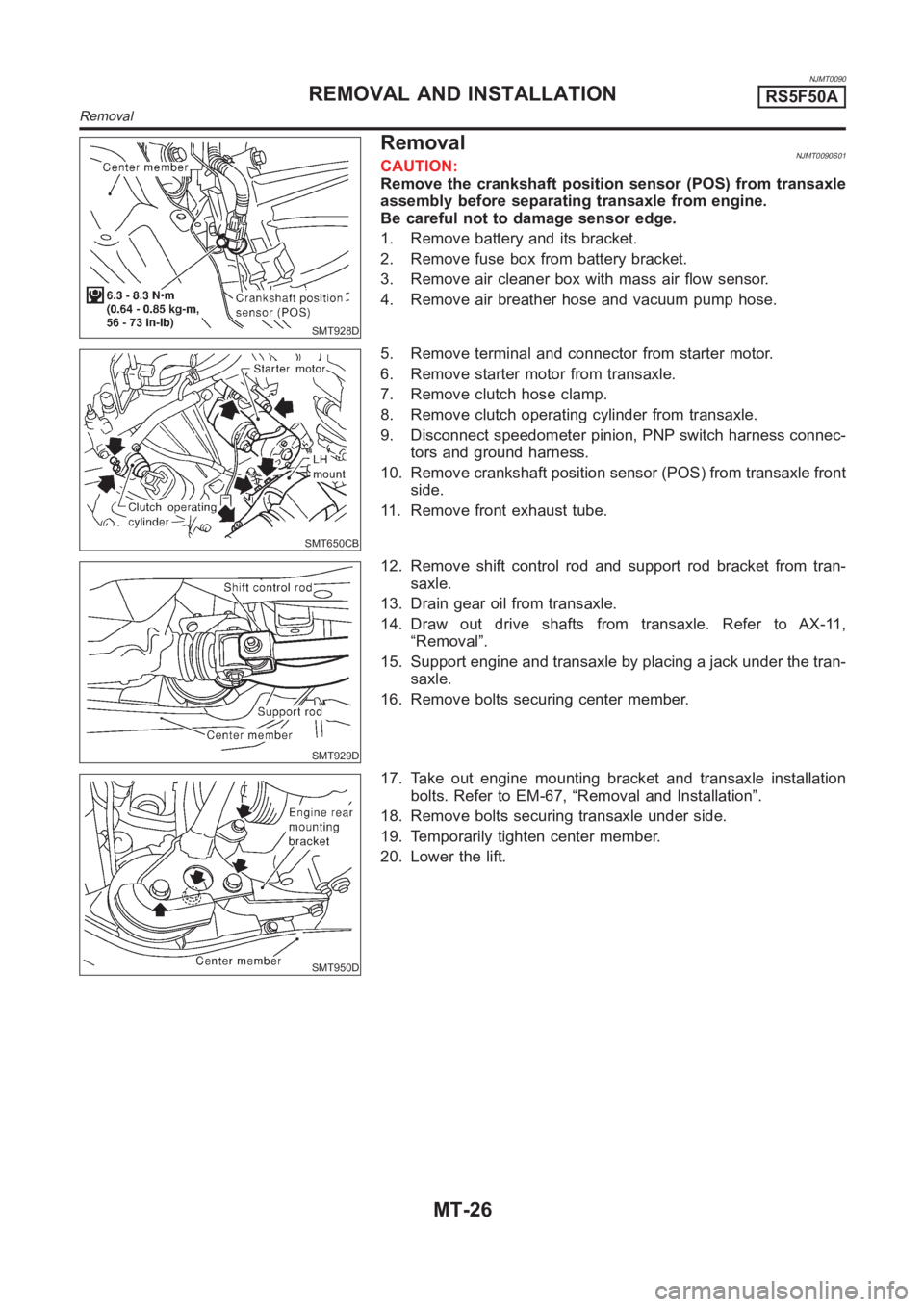

NJMT0090

SMT928D

RemovalNJMT0090S01CAUTION:

Remove the crankshaft position sensor (POS) from transaxle

assembly before separating transaxle from engine.

Be careful not to damage sensor edge.

1. Remove battery and its bracket.

2. Remove fuse box from battery bracket.

3. Remove air cleaner box with mass air flow sensor.

4. Remove air breather hose and vacuum pump hose.

SMT650CB

5. Remove terminal and connector from starter motor.

6. Remove starter motor from transaxle.

7. Remove clutch hose clamp.

8. Remove clutch operating cylinder from transaxle.

9. Disconnect speedometer pinion, PNP switch harness connec-

tors and ground harness.

10. Remove crankshaft position sensor (POS) from transaxle front

side.

11. Remove front exhaust tube.

SMT929D

12. Remove shift control rod and support rod bracket from tran-

saxle.

13. Drain gear oil from transaxle.

14. Draw out drive shafts from transaxle. Refer to AX-11,

“Removal”.

15. Support engine and transaxle by placing a jack under the tran-

saxle.

16. Remove bolts securing center member.

SMT950D

17. Take out engine mounting bracket and transaxle installation

bolts. Refer to EM-67, “Removal and Installation”.

18. Remove bolts securing transaxle under side.

19. Temporarily tighten center member.

20. Lower the lift.

REMOVAL AND INSTALLATIONRS5F50A

Removal

MT-26

Page 2379 of 3189

Trouble DiagnosesNJEL0202

Symptom Possible cause Repair order

Neither headlamp operates. 1. Lighting switch 1. Check Lighting switch.

LH headlamp (low and high beam)

does not operate, but RH head-

lamp (low and high beam) does

operate.1. 15A fuse

2. Headlamp LH ground circuit

3. Lighting switch1. Check 15A fuse (No. 35, located in fusible link and

fuse box). Verify battery positive voltage is present

at lighting switch terminal 8.

2. Check headlamp LH ground circuit.

3. Check lighting switch.

RH headlamp (low and high beam)

does not operate, but LH headlamp

(low and high beam) does operate.1. 15A fuse

2. Headlamp RH ground circuit

3. Lighting switch1. Check 15A fuse (No. 36, located in fusible link and

fuse box). Verify battery positive voltage is present

at lighting switch terminal 5.

2. Check headlamp RH ground circuit.

3. Check lighting switch.

LH high beam does not operate,

but LH low beam does operate.1. Bulb

2. Open in LH high beam circuit

3. Lighting switch1. Check bulb.

2. Check the harness between lighting switch and LH

high beam for an open circuit.

3. Check lighting switch.

LH low beam does not operate, but

LH high beam does operate.1. Bulb

2. Open in LH low beam circuit

3. Lighting switch1. Check bulb.

2. Check the harness between lighting switch and LH

low beam for an open circuit.

3. Check lighting switch.

RH high beam does not operate,

but RH low beam does operate.1. Bulb

2. Open in RH high beam circuit

3. Lighting switch1. Check bulb.

2. Check the harness between lighting switch and RH

high beam for an open circuit.

3. Check lighting switch.

RH low beam does not operate,

but RH high beam does operate.1. Bulb

2. Open in RH low beam circuit

3. Lighting switch1. Check bulb.

2. Check the harness between lighting switch and RH

low beam for an open circuit.

3. Check lighting switch.

High beam indicator does not work. 1. Bulb

2. Ground circuit

3. Open in high beam circuit1. Check bulb in combination meter.

2. Check harness between high beam indicator and

ground.

3. Check the harness between lighting switch and

combination meter for an open circuit.GI

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

IDX

HEADLAMP

Trouble Diagnoses

EL-43