ESP NISSAN ALMERA N16 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2003Pages: 3189, PDF Size: 54.76 MB

Page 2 of 3189

FOREWORD

This manual contains maintenance and repair procedures for NISSAN

ALMERA, model N16 series.

In order to assure your safety and the efficient functioning of the vehicle,

this manual should be read thoroughly. It is especially important that the

PRECAUTIONS in the GI section be completely understood before starting

any repair task.

All information in this manual is based on the latest product information

at the time of publication. The right is reserved to make changes in speci-

fications and methods at any time without notice.

IMPORTANT SAFETY NOTICE

The proper performance of service is essential for both the safety of the

technician and the efficient functioning of the vehicle.

The service methods in this Service Manual are described in such a man-

ner that the service may be performed safely and accurately.

Service varies with the procedures used, the skills of the technician and the

tools and parts available. Accordingly, anyone using service procedures,

tools or parts which are not specifically recommended by NISSAN must

first completely satisfy himself that neither his safety nor the vehicle’s

safety will be jeopardized by the service method selected.

NISSAN EUROPE S.A.S.

Service Engineering Section

Paris, France

Page 6 of 3189

The security indicator is located on the combi meter. The indicator

blinks when the ignition switch is in “OFF” or “ACC” position.

Therefore, NATS warns outsiders that the vehicle is equipped with

the anti-theft system.

When NATS detects trouble, the security indicator lamp lights

up while ignition switch is in “ON” position.

This lighting up indicates that the anti-theft is not functioning,

so prompt service is required.

When servicing NATS (trouble diagnoses, system initialization

and additional registration of other NATS ignition key IDs),

CONSULT-II hardware and CONSULT-II NATS software is

necessary.

Regarding the procedures of NATS initialization and NATS

ignition key ID registration, refer to CONSULT-II operation

manual, NATS.

Therefore, CONSULT-II NATS software (program card and

operation manual) must be kept strictly confidential to main-

tain the integrity of the anti-theft function.

When servicing NATS (trouble diagnoses, system initialization

and additional registration of other NATS ignition key IDs), it

may be necessary to re-register original key identification.

Therefore, be sure to receive all keys from vehicle owner. A

maximum of five key IDs can be registered into NATS.

When failing to start the engine first time using the key of

NATS, start as follows.

a) Leave the ignition key in “ON” position for approximately 5

seconds.

b) Turn ignition key to “OFF” or “LOCK” position and wait approxi-

mately 5 seconds.

c) Repeat step 1 and 2 again.

d) Restart the engine while keeping the key separate from any

others on key-chain.

SGI285

GENERAL PRECAUTIONSNJGI0001S03Do not operate the engine for an extended period of time

without proper exhaust ventilation.

Keep the work area well ventilated and free of any inflammable

materials. Special care should be taken when handling any

inflammable or poisonous materials, such as gasoline, refrig-

erant gas, etc. When working in a pit or other enclosed area,

be sure to properly ventilate the area before working with haz-

ardous materials.

Do not smoke while working on the vehicle.

SGI231

Before jacking up the vehicle, apply wheel chocks or other tire

blocks to the wheels to prevent the vehicle from moving. After

jacking up the vehicle, support the vehicle weight with safety

stands at the points designated for proper lifting before work-

ing on the vehicle.

These operations should be done on a level surface.

When removing a heavy component such as the engine or

transaxle, be careful not to lose your balance and drop them.

Also, do not allow them to strike adjacent parts, especially the

brake tubes and master cylinder.

PRECAUTIONS

Precautions (Cont’d)

GI-4

Page 16 of 3189

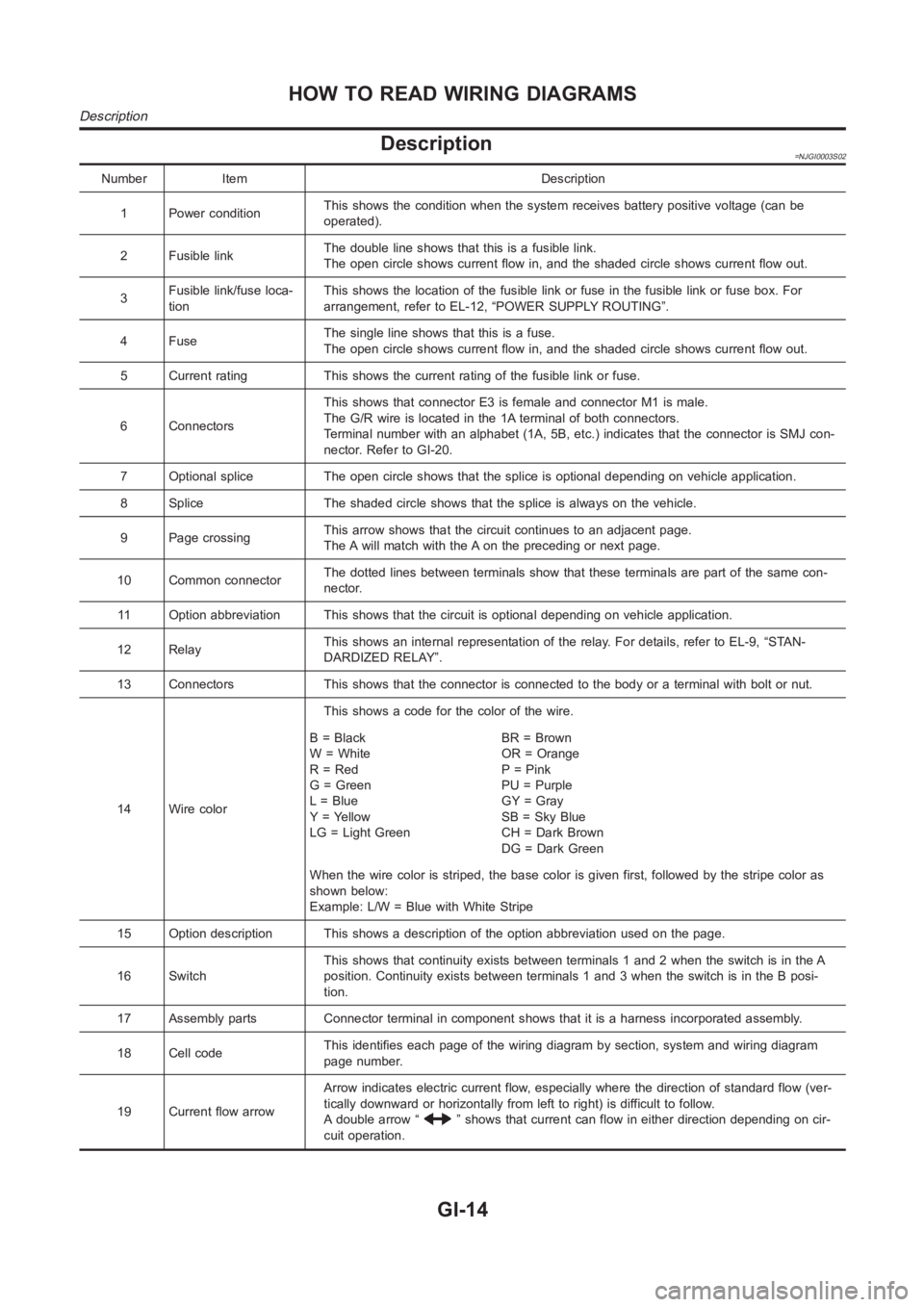

Description=NJGI0003S02

Number Item Description

1 Power conditionThis shows the condition when the system receives battery positive voltage (can be

operated).

2 Fusible linkThe double line shows that this is a fusible link.

The open circle shows current flow in, and the shaded circle shows current flow out.

3Fusible link/fuse loca-

tionThis shows the location of the fusible link or fuse in the fusible link or fusebox.For

arrangement, refer to EL-12, “POWER SUPPLY ROUTING”.

4FuseThe single line shows that this is a fuse.

The open circle shows current flow in, and the shaded circle shows current flow out.

5 Current rating This shows the current rating of the fusible link or fuse.

6 ConnectorsThis shows that connector E3 is female and connector M1 is male.

The G/R wire is located in the 1A terminal of both connectors.

Terminal number with an alphabet (1A, 5B, etc.) indicates that the connector is SMJ con-

nector. Refer to GI-20.

7 Optional splice The open circle shows that the splice is optional depending on vehicle application.

8 Splice The shaded circle shows that the splice is always on the vehicle.

9 Page crossingThis arrow shows that the circuit continues to an adjacent page.

The A will match with the A on the preceding or next page.

10 Common connectorThe dotted lines between terminals show that these terminals are part of thesamecon-

nector.

11 Option abbreviation This shows that the circuit is optional depending on vehicle application.

12 RelayThis shows an internal representation of the relay. For details, refer to EL-9, “STAN-

DARDIZED RELAY”.

13 Connectors This shows that the connector is connected to the body or a terminal with bolt or nut.

14 Wire colorThis shows a code for the color of the wire.

B=Black

W = White

R = Red

G = Green

L = Blue

Y = Yellow

LG = Light GreenBR = Brown

OR = Orange

P = Pink

PU = Purple

GY = Gray

SB = Sky Blue

CH = Dark Brown

DG=DarkGreen

When the wire color is striped, the base color is given first, followed by the stripe color as

shown below:

Example: L/W = Blue with White Stripe

15 Option description This shows a description of the option abbreviationused on the page.

16 SwitchThis shows that continuity exists between terminals 1 and 2 when the switchis in the A

position. Continuity exists between terminals 1 and 3 when the switch is inthe B posi-

tion.

17 Assembly parts Connector terminal in component shows that it is a harness incorporated assembly.

18 Cell codeThis identifies each page of the wiring diagram by section, system and wiring diagram

page number.

19 Current flow arrowArrow indicates electric current flow, especially where the direction ofstandard flow (ver-

tically downward or horizontally from left to right) is difficult to follow.

A double arrow “

” shows that current can flow in either direction depending on cir-

cuit operation.

HOW TO READ WIRING DIAGRAMS

Description

GI-14

Page 18 of 3189

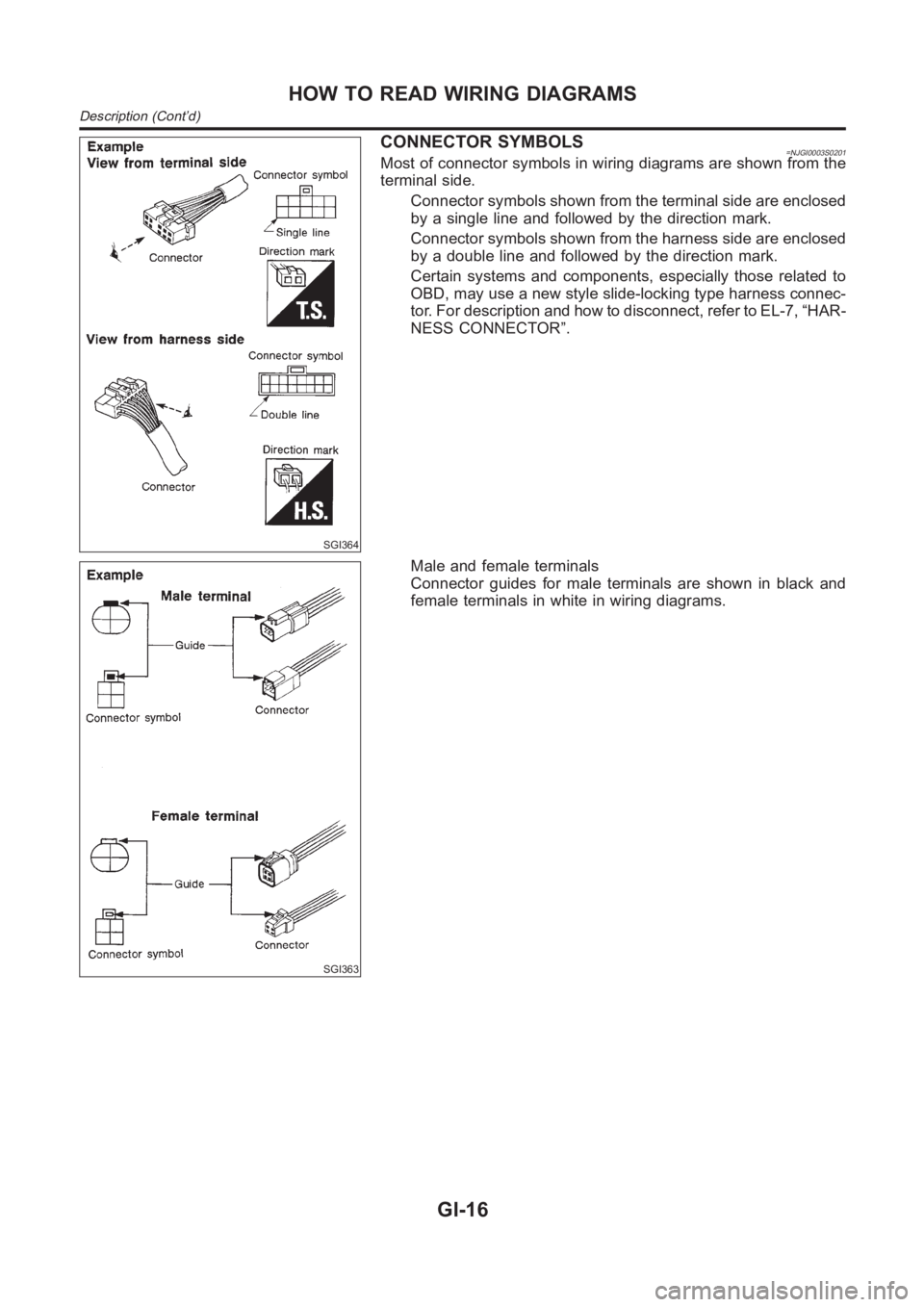

SGI364

CONNECTOR SYMBOLS=NJGI0003S0201Most of connector symbols in wiring diagrams are shown from the

terminal side.

Connector symbols shown from the terminal side are enclosed

by a single line and followed by the direction mark.

Connector symbols shown from the harness side are enclosed

by a double line and followed by the direction mark.

Certain systems and components, especially those related to

OBD, may use a new style slide-locking type harness connec-

tor. For description and how to disconnect, refer to EL-7, “HAR-

NESS CONNECTOR”.

SGI363

Male and female terminals

Connector guides for male terminals are shown in black and

female terminals in white in wiring diagrams.

HOW TO READ WIRING DIAGRAMS

Description (Cont’d)

GI-16

Page 130 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual EM-52

[QG]

TIMING CHAIN

2. Install front oil seal to front cover.

●Install it so that identification letters on oil seal will face toward

front side of the engine.

●Using an oil seal drift (commer NISSAN ALMERA N16 2003 Electronic Repair Manual EM-52

[QG]

TIMING CHAIN

2. Install front oil seal to front cover.

●Install it so that identification letters on oil seal will face toward

front side of the engine.

●Using an oil seal drift (commer](/img/5/57350/w960_57350-129.png)

EM-52

[QG]

TIMING CHAIN

2. Install front oil seal to front cover.

●Install it so that identification letters on oil seal will face toward

front side of the engine.

●Using an oil seal drift (commercial service tool), press oil seal

in until it is flush with end surface of mounting position.

●Make sure that oil seal outer circumference is free from dam-

age and burr.

3. Install front cover with the following procedure:

a. Install O-ring to cylinder block.

b. Using a flat-bladed screwdriver, apply a continuous bead of liq-

uid gasket to contact surface between cylinder head gasket

lower surface and cylinder block (2 locations shown in figure).

Use Genuine Liquid Gasket or equivalent.

c. Apply a continuous bead of liquid gasket to back surface of front

cover (location shown in figure).

CAUTION:

●Do not apply liquid gasket to groove A shown in figure.

●Especially for locations indicated by * mark in figure,

strictly observe application range of liquid gasket.

d. Apply liquid gasket to top surface of front cover lightly and

evenly.

Use Genuine Liquid Gasket or equivalent.

e. Install O-ring to back surface of front cover.

f. With socket of oil pump inner rotor placed on crankshaft top sur-

face (clearance between front cover top surface and cylinder

head gasket lower surface is secured), move front cover close to

cylinder block. (Right side in figure)

g. Lift front cover at an angle and install it to mounting position so

that front cover will come in contact with both cylinder head gas-

ket lower surface and cylinder block front surface at the same

time. (Right side in figure)

CAUTION:

●During work, be sure not to damage cylinder head gas-

ket.

●When installing, avoid discontinuous bead of liquid gas-

ket caused by allowing it to adhere to an unnecessary area.

PBIC0530E

PBIC0561E

PBIC0562E

PBIC0563E

Page 135 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual CYLINDER HEAD

EM-57

[QG]

C

D

E

F

G

H

I

J

K

L

MA

EM

CYLINDER HEADPFP:11041

On-Vehicle ServiceEBS00LQH

CHECKING COMPRESSION PRESSURE

1. Warm up engine thoroughly. Then, stop it.

2. Release fuel pressu NISSAN ALMERA N16 2003 Electronic Repair Manual CYLINDER HEAD

EM-57

[QG]

C

D

E

F

G

H

I

J

K

L

MA

EM

CYLINDER HEADPFP:11041

On-Vehicle ServiceEBS00LQH

CHECKING COMPRESSION PRESSURE

1. Warm up engine thoroughly. Then, stop it.

2. Release fuel pressu](/img/5/57350/w960_57350-134.png)

CYLINDER HEAD

EM-57

[QG]

C

D

E

F

G

H

I

J

K

L

MA

EM

CYLINDER HEADPFP:11041

On-Vehicle ServiceEBS00LQH

CHECKING COMPRESSION PRESSURE

1. Warm up engine thoroughly. Then, stop it.

2. Release fuel pressure. Refer to EC-34, "

FUEL PRESSURE RELEASE" (WITH EURO-OBD), EC-427,

"FUEL PRESSURE RELEASE" (WITHOUT EURO-OBD).

3. Remove ignition coil and spark plug from each cylinder.

Refer to IGNITION COIL EM-24, "

Removal and Installation" and SPARK PLUG EM-25, "Removal and

Installation" .

4. Connect engine tachometer (not required in use of CONSULT-II).

5. Disconnect fuel injector harness connector so that no fuel is injected.

6. Install compression tester with adapter onto spark plug hole.

●Use compression gauge whose picking up end inserted to spark

plug hole is smaller than 20 mm (0.79 in) in diameter. Otherwise,

it may be caught by cylinder head during removal.

7. With accelerator pedal fully depressed, turn ignition switch to

“START” for cranking. When the gauge pointer stabilizes, read

the compression pressure and engine rpm. Perform these steps

to check each cylinder.

Compression pressure

[kPa (bar, kg/cm2 , psi)/rpm]

CAUTION:

Always use a fully changed battery to obtain specified engine speed.

●If the engine speed is out of specified range, check battery liquid for proper gravity. Check engine speed

again with normal battery gravity.

●If compression pressure is below minimum value, check valve clearances and parts associated with com-

bustion chamber (Valve, valve seat, piston, piston ring, cylinder bore, cylinder head, cylinder head gas-

ket). After the checking, measure compression pressure again.

●If some cylinders have low compression pressure, pour small amount of engine oil into the spark plug hole

of the cylinder to re-check it for compression.

–If the added engine oil improves the compression, the piston rings may be worn out or damaged. Check

the piston rings and replace if necessary.

–If the compression pressure remains at low level despite the addition of engine oil, the valves may be mal-

functioning. Check the valves for damage. Replace the valve or valve seat accordingly.

●If two adjacent cylinders have respectively low compression pressure and their compression remains low

even after the addition of engine oil, the gaskets are leaking. In such a case, replace the cylinder head

gaskets.

KBIA1402E

Engine type QG15DE QG18DE

Standard1,372 (13.72, 13.99,

198.9)1,324 (13.24, 13.5, 192)

Limit 1,176 (11.76, 12.0, 170.5) 1,128 (11.28, 11.5, 164)

Difference limit among

cylinders98 (0.98, 1.0, 14) 98 (0.98, 1.0, 14)SEM387C

Page 151 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual CYLINDER BLOCK

EM-73

[QG]

C

D

E

F

G

H

I

J

K

L

MA

EM

11. Remove the piston and connecting rod assembly.

●Before removing the piston and connecting rod assembly,

check the connecting rod si NISSAN ALMERA N16 2003 Electronic Repair Manual CYLINDER BLOCK

EM-73

[QG]

C

D

E

F

G

H

I

J

K

L

MA

EM

11. Remove the piston and connecting rod assembly.

●Before removing the piston and connecting rod assembly,

check the connecting rod si](/img/5/57350/w960_57350-150.png)

CYLINDER BLOCK

EM-73

[QG]

C

D

E

F

G

H

I

J

K

L

MA

EM

11. Remove the piston and connecting rod assembly.

●Before removing the piston and connecting rod assembly,

check the connecting rod side clearance. Refer to EM-84,

"CONNECTING ROD SIDE CLEARANCE" .

a. Position the crankshaft pin corresponding to the connecting rod

to be removed onto the bottom dead center.

b. Remove the connecting rod cap.

c. Using a hammer handle or similar tool, push the piston and con-

necting rod assembly out to the cylinder head side.

12. Remove the connecting rod bearings.

CAUTION:

●When removing them, note the installation position. Keep them in the correct order.

13. Remove the piston rings form the piston.

●Before removing the piston rings, check the piston ring side

clearance. Refer to EM-85, "

PISTON RING SIDE CLEAR-

ANCE" .

●Use a piston ring expander (commercial service tool).

CAUTION:

●When removing the piston rings, be careful not to dam-

age the piston.

●Be careful not to damage piston rings by expanding them

excessively.

14. Remove the piston from the connecting rod as follows:

a. Using a snap ring pliers, remove the snap ring.

b. Heat piston to 60 to 70°C (140 to 158°F) with drier or equivalent.

PBIC0259E

PBIC0087E

PBIC0088E

PBIC0089E

Page 155 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual CYLINDER BLOCK

EM-77

[QG]

C

D

E

F

G

H

I

J

K

L

MA

EM

10. Install piston rings with piston ring expander (commercial ser-

vice tool).

CAUTION:

●Be careful not to damage piston.

●When instal NISSAN ALMERA N16 2003 Electronic Repair Manual CYLINDER BLOCK

EM-77

[QG]

C

D

E

F

G

H

I

J

K

L

MA

EM

10. Install piston rings with piston ring expander (commercial ser-

vice tool).

CAUTION:

●Be careful not to damage piston.

●When instal](/img/5/57350/w960_57350-154.png)

CYLINDER BLOCK

EM-77

[QG]

C

D

E

F

G

H

I

J

K

L

MA

EM

10. Install piston rings with piston ring expander (commercial ser-

vice tool).

CAUTION:

●Be careful not to damage piston.

●When installing top ring, be careful not to break end gap

step.

●Position end gaps of each piston ring to piston front mark as

shown in figure, then install rings.

●Install top ring with stamp mark side facing upward.

11. Install the connecting rod bearings to the connecting rod and the

connecting rod cap.

●When installing the connecting rod bearings, apply engine oil

to the bearing surface (inside). Do not apply oil to the back

surface, but thoroughly clean it.

●When installing, align the connecting rod bearing stopper pro-

trusion with the notch of the connecting rod to install.

●Check the oil holes on the connecting rod and those on the

corresponding bearing are aligned.

12. Install the piston and connecting rod assembly to the crankshaft.

●Position the crankshaft pin corresponding to the connecting

rod to be installed onto the bottom dead center.

●Apply engine oil sufficiently to the cylinder bore, piston and

crankshaft pin.

●Match the cylinder position with the cylinder No. on the con-

necting rod to install.

●Using a piston ring compressor, install the piston with the front

mark on the piston crown facing the front of the engine.

CAUTION:

Be careful not to damage the crankshaft pin, resulting from

an interference of the connecting rod big end.

13. Install the connecting rod cap.

●Match the stamped cylinder number marks on the connecting

rod with those on the cap to install.

PBIC0977E

PBIC0482E

PBIC0267E

PBIC0593E

Page 166 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual EM-88

[QG]

CYLINDER BLOCK

●If replacing the piston and piston pin assembly, refer to the “Piston Selection Table” to select the piston

corresponding to the applicable bore NISSAN ALMERA N16 2003 Electronic Repair Manual EM-88

[QG]

CYLINDER BLOCK

●If replacing the piston and piston pin assembly, refer to the “Piston Selection Table” to select the piston

corresponding to the applicable bore](/img/5/57350/w960_57350-165.png)

EM-88

[QG]

CYLINDER BLOCK

●If replacing the piston and piston pin assembly, refer to the “Piston Selection Table” to select the piston

corresponding to the applicable bore grade of the cylinder block to be used. Refer to EM-80, "

HOW TO

SELECT PISTON" .

Factory installed parts grading:

●Service parts apply only to grade 0.

Unit: mm (in)

CYLINDER BLOCK DISTORTION

●Using a scraper, remove gasket on the cylinder block surface,

and also remove oil, scale, carbon, or other contamination.

CAUTION:

Be careful not to allow gasket flakes to enter the oil or cool-

ant passages.

●Measure the distortion on the block upper face at some different

points in 6 directions.

●If out of the distortion limit, replace the cylinder block.

INNER DIAMETER OF MAIN BEARING HOUSING

●Install the main bearing caps with the main bearings removed,

and tighten the mounting bolts to the specified torque.

●Using a bore gauge, measure the inner diameter of the main

bearing housing.

●If out of the standard, replace the cylinder block and lower cylin-

der block assembly.

NOTE:

These components cannot be replaced as a single unit because

they were processed together.

PISTON TO CYLINDER BORE CLEARANCE

Inner Diameter of Cylinder Bore

●Using a bore gauge, measure cylinder bore for wear, out-of-

round and taper at 6 different points on each cylinder. (X and Y

directions at A, B and C) (Y is in longitudinal direction of engine)

Grade 0 1

Connecting rod small end inner diam-

eter19.000 - 19.006

(0.7480 - 0.7483)19.006 - 19.012

(0.7483 - 0.7485)

Piston pin outer diameter18.989 - 18.995

(0.7476 - 0.7478)18.995 - 19.001

(0.7478 - 0.7481)

Piston pin hole diameterQG15DE18.987 - 18.993

(0.7475 - 0.7478)18.993 - 18.999

(0.7478 - 0.7480)

QG18DE18.993 - 18.996

(0.7478- 0.7479)18.996 - 18.999

(0.7479 - 0.7480)

PBIC0591E

Limit : 0.1 mm (0.004 in)

PBIC0121E

Standard : 53.644 - 53.668 mm (2.1120 - 2.1129 in) dia.

PBIC0611E

PBIC0612E

Page 247 of 3189

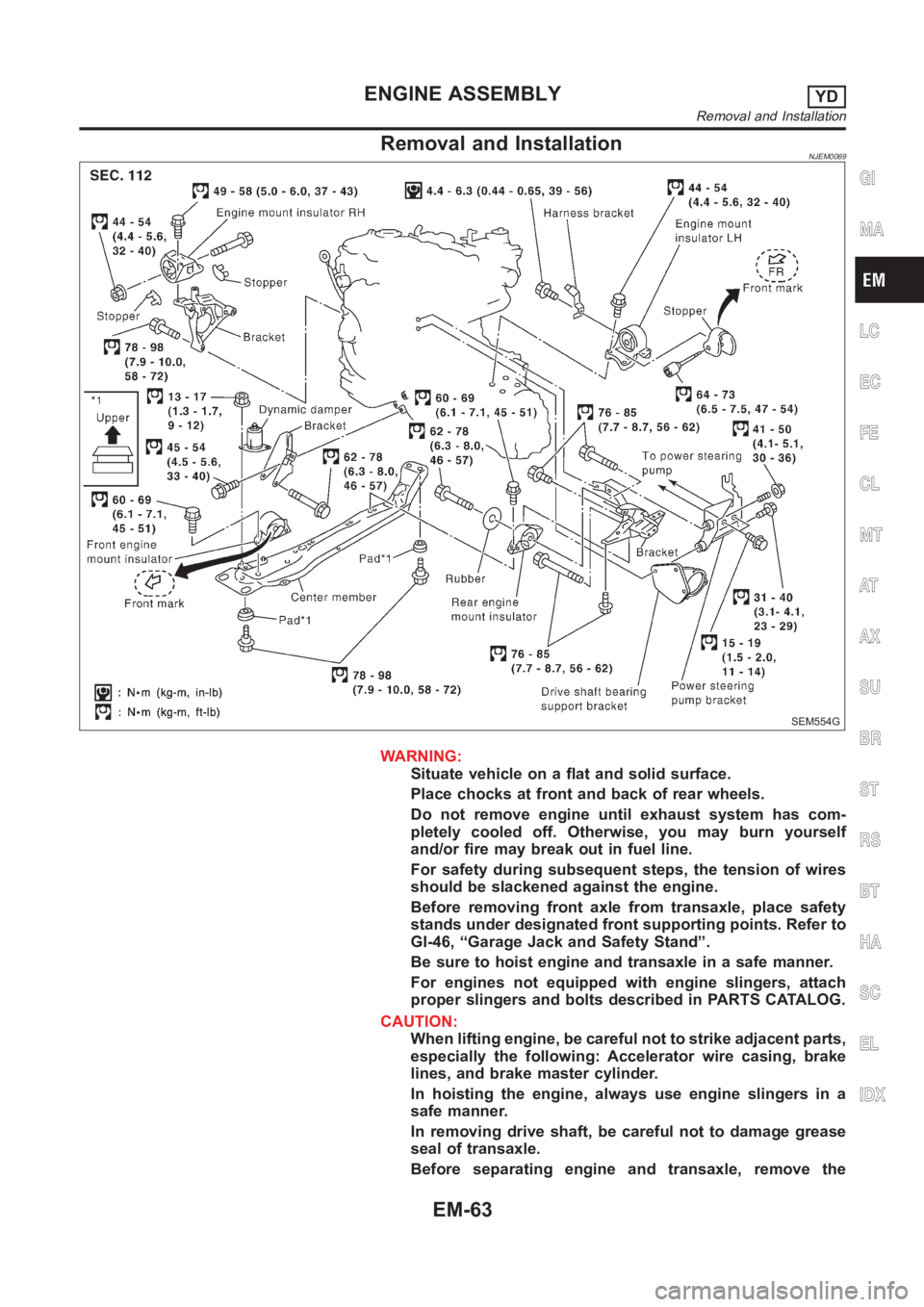

Removal and InstallationNJEM0069

SEM554G

WARNING:

Situate vehicle on a flat and solid surface.

Place chocks at front and back of rear wheels.

Do not remove engine until exhaust system has com-

pletely cooled off. Otherwise, you may burn yourself

and/or fire may break out in fuel line.

For safety during subsequent steps, the tension of wires

should be slackened against the engine.

Before removing front axle from transaxle, place safety

stands under designated front supporting points. Refer to

GI-46, “Garage Jack and Safety Stand”.

Be sure to hoist engine and transaxle in a safe manner.

For engines not equipped with engine slingers, attach

proper slingers and bolts described in PARTS CATALOG.

CAUTION:

When lifting engine, be careful not to strike adjacent parts,

especially the following: Accelerator wire casing, brake

lines, and brake master cylinder.

In hoisting the engine, always use engine slingers in a

safe manner.

In removing drive shaft, be careful not to damage grease

seal of transaxle.

Before separating engine and transaxle, remove the

GI

MA

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ENGINE ASSEMBLYYD

Removal and Installation

EM-63