button NISSAN ALMERA N16 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2003Pages: 3189, PDF Size: 54.76 MB

Page 7 of 3189

SEF289H

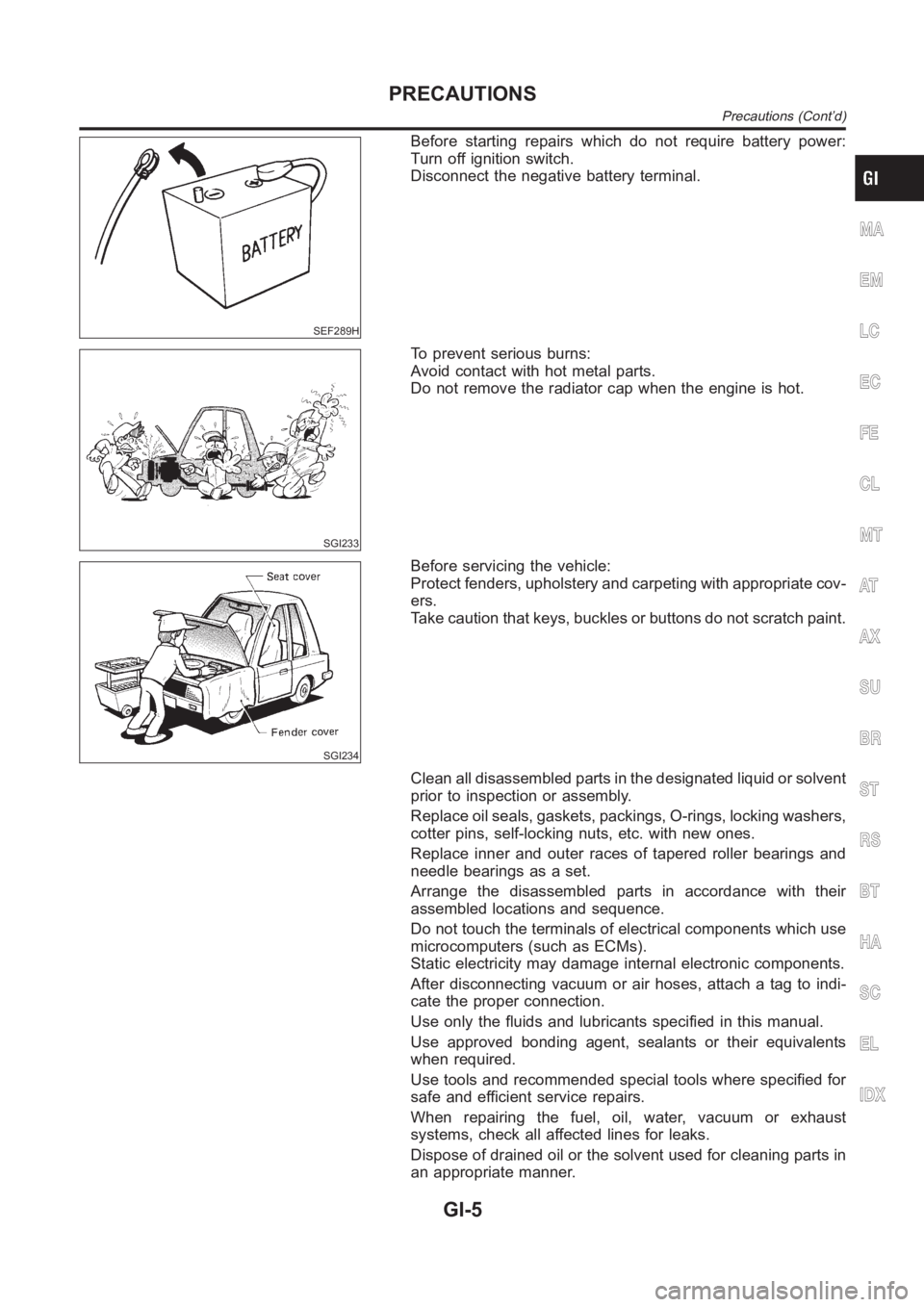

Before starting repairs which do not require battery power:

Turn off ignition switch.

Disconnect the negative battery terminal.

SGI233

To prevent serious burns:

Avoid contact with hot metal parts.

Do not remove the radiator cap when the engine is hot.

SGI234

Before servicing the vehicle:

Protect fenders, upholstery and carpeting with appropriate cov-

ers.

Take caution that keys, buckles or buttons do not scratch paint.

Clean all disassembled parts in the designated liquid or solvent

prior to inspection or assembly.

Replace oil seals, gaskets, packings, O-rings, locking washers,

cotter pins, self-locking nuts, etc. with new ones.

Replace inner and outer races of tapered roller bearings and

needle bearings as a set.

Arrange the disassembled parts in accordance with their

assembled locations and sequence.

Do not touch the terminals of electrical components which use

microcomputers (such as ECMs).

Static electricity may damage internal electronic components.

After disconnecting vacuum or air hoses, attach a tag to indi-

cate the proper connection.

Use only the fluids and lubricants specified in this manual.

Use approved bonding agent, sealants or their equivalents

when required.

Use tools and recommended special tools where specified for

safe and efficient service repairs.

When repairing the fuel, oil, water, vacuum or exhaust

systems, check all affected lines for leaks.

Dispose of drained oil or the solvent used for cleaning parts in

an appropriate manner.

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

PRECAUTIONS

Precautions (Cont’d)

GI-5

Page 1274 of 3189

PBIC0648E

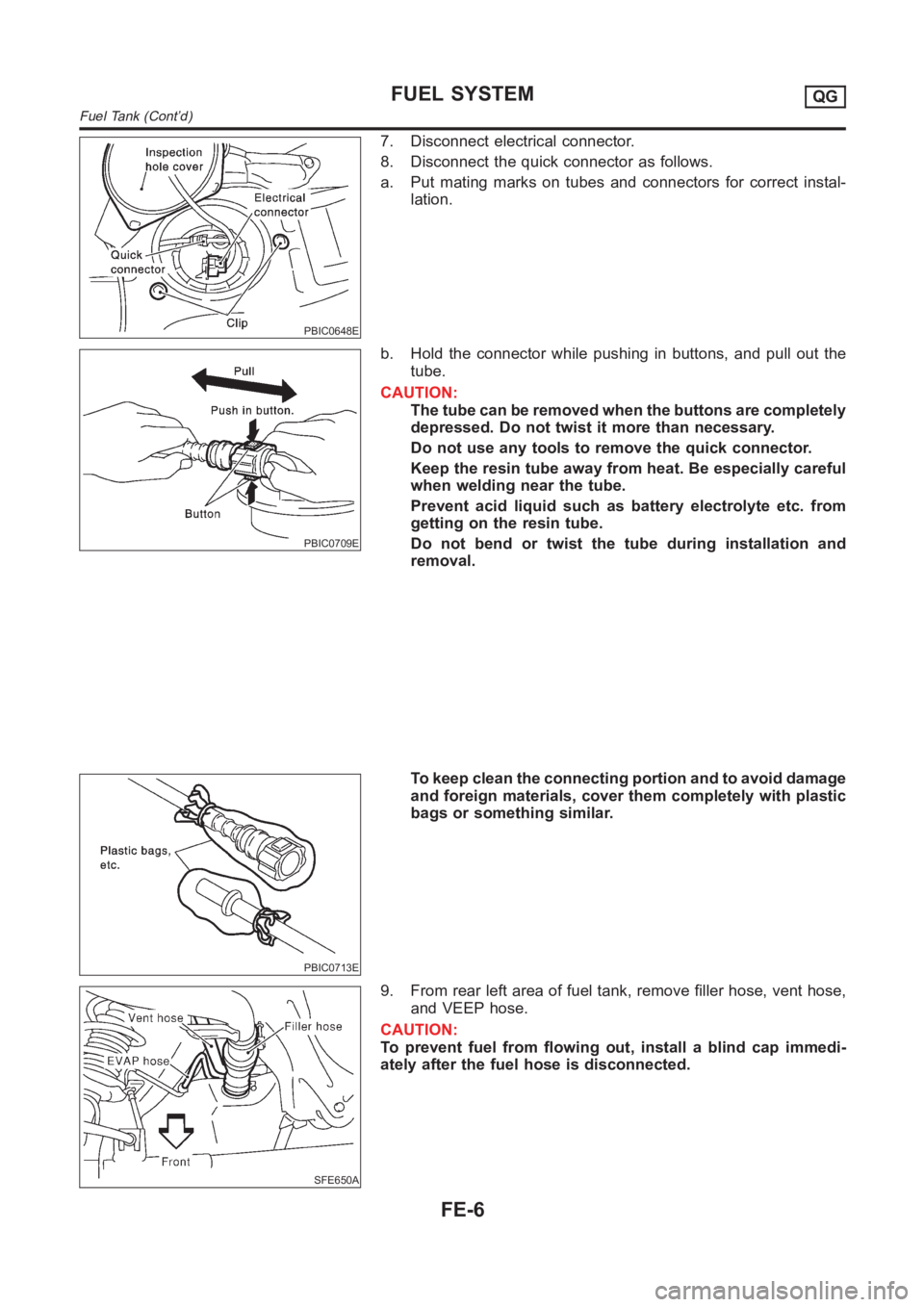

7. Disconnect electrical connector.

8. Disconnect the quick connector as follows.

a. Put mating marks on tubes and connectors for correct instal-

lation.

PBIC0709E

b. Hold the connector while pushing in buttons, and pull out the

tube.

CAUTION:

The tube can be removed when the buttons are completely

depressed. Do not twist it more than necessary.

Do not use any tools to remove the quick connector.

Keep the resin tube away from heat. Be especially careful

when welding near the tube.

Prevent acid liquid such as battery electrolyte etc. from

getting on the resin tube.

Do not bend or twist the tube during installation and

removal.

PBIC0713E

To keep clean the connecting portion and to avoid damage

and foreign materials, cover them completely with plastic

bags or something similar.

SFE650A

9. From rear left area of fuel tank, remove filler hose, vent hose,

and VEEP hose.

CAUTION:

To prevent fuel from flowing out, install a blind cap immedi-

ately after the fuel hose is disconnected.

FUEL SYSTEMQG

Fuel Tank (Cont’d)

FE-6

Page 1859 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual A/T SHIFT LOCK SYSTEM

AT-403

[ALL]

D

E

F

G

H

I

J

K

L

MA

B

AT

A/T DEVICE CHECK

1. Shift Lock Solenoid

●Check operation sound.

When ignition switch is turned to “ON” position and selector lever is NISSAN ALMERA N16 2003 Electronic Repair Manual A/T SHIFT LOCK SYSTEM

AT-403

[ALL]

D

E

F

G

H

I

J

K

L

MA

B

AT

A/T DEVICE CHECK

1. Shift Lock Solenoid

●Check operation sound.

When ignition switch is turned to “ON” position and selector lever is](/img/5/57350/w960_57350-1858.png)

A/T SHIFT LOCK SYSTEM

AT-403

[ALL]

D

E

F

G

H

I

J

K

L

MA

B

AT

A/T DEVICE CHECK

1. Shift Lock Solenoid

●Check operation sound.

When ignition switch is turned to “ON” position and selector lever is set in “P” position.

2. Park Position Switch

●Check resistance between A/T device harness terminal 6 and 7.

STOP LAMP SWITCH

●Check continuity between terminals 1 and 2.

Check stop lamp switch after adjusting brake pedal — refer to

BR-12.

Brake pedal Operation sound

Depressed Yes

Released No

Condition Resistance

When selector lever is set in “P” position and selector

lever button is released111Ω

When selector lever is not set in “P” position and selector

lever button is released0Ω

SAT011K

Condition Continuity

When brake pedal is depressed Yes

When brake pedal is released No

SAT861JA

Page 2032 of 3189

ATC-52

TROUBLE DIAGNOSIS

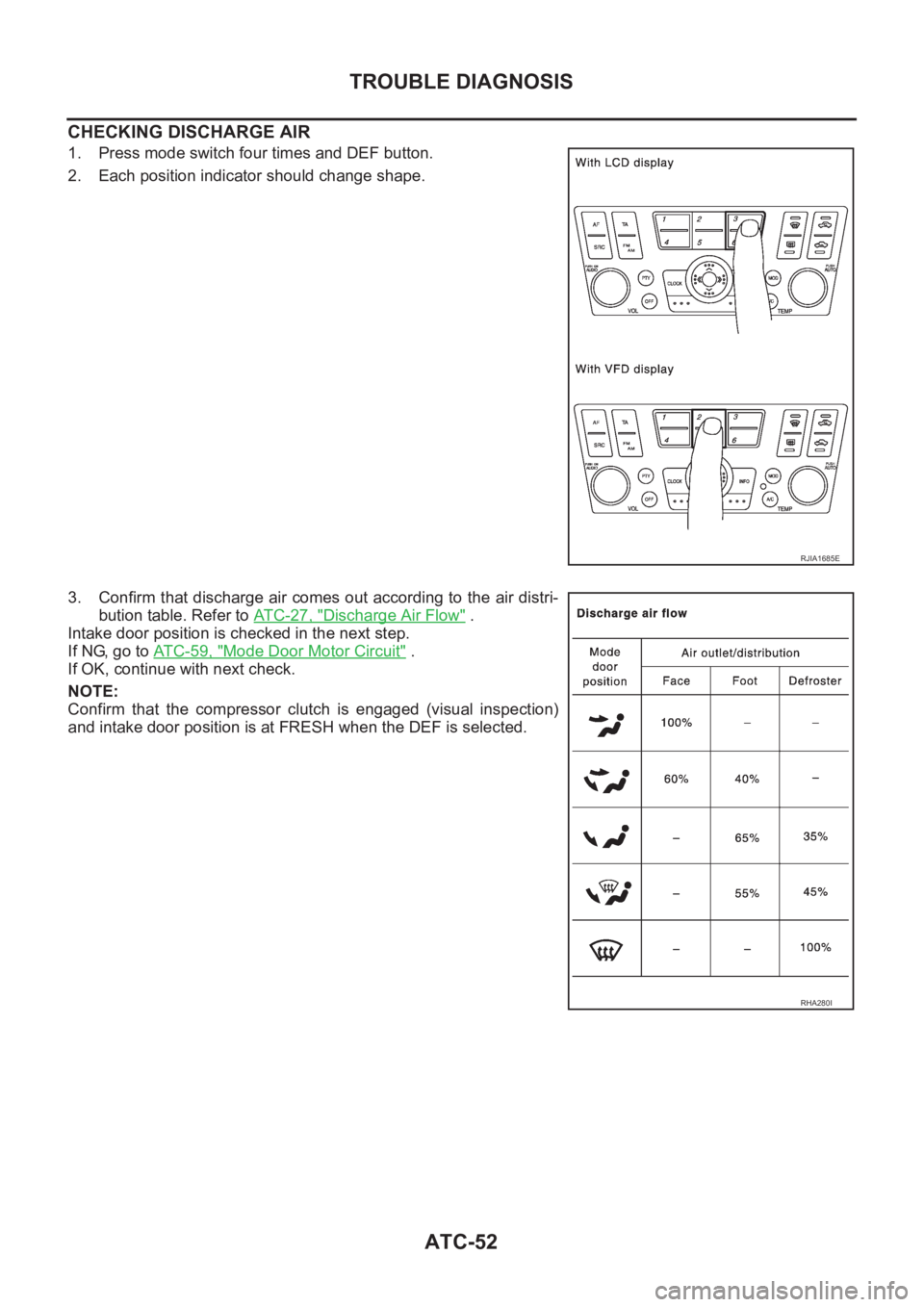

CHECKING DISCHARGE AIR

1. Press mode switch four times and DEF button.

2. Each position indicator should change shape.

3. Confirm that discharge air comes out according to the air distri-

bution table. Refer to ATC-27, "

Discharge Air Flow" .

Intake door position is checked in the next step.

If NG, go to AT C - 5 9 , "

Mode Door Motor Circuit" .

If OK, continue with next check.

NOTE:

Confirm that the compressor clutch is engaged (visual inspection)

and intake door position is at FRESH when the DEF is selected.

RJIA1685E

RHA280I

Page 2051 of 3189

TROUBLE DIAGNOSIS

ATC-71

C

D

E

F

G

H

I

K

L

MA

B

AT C

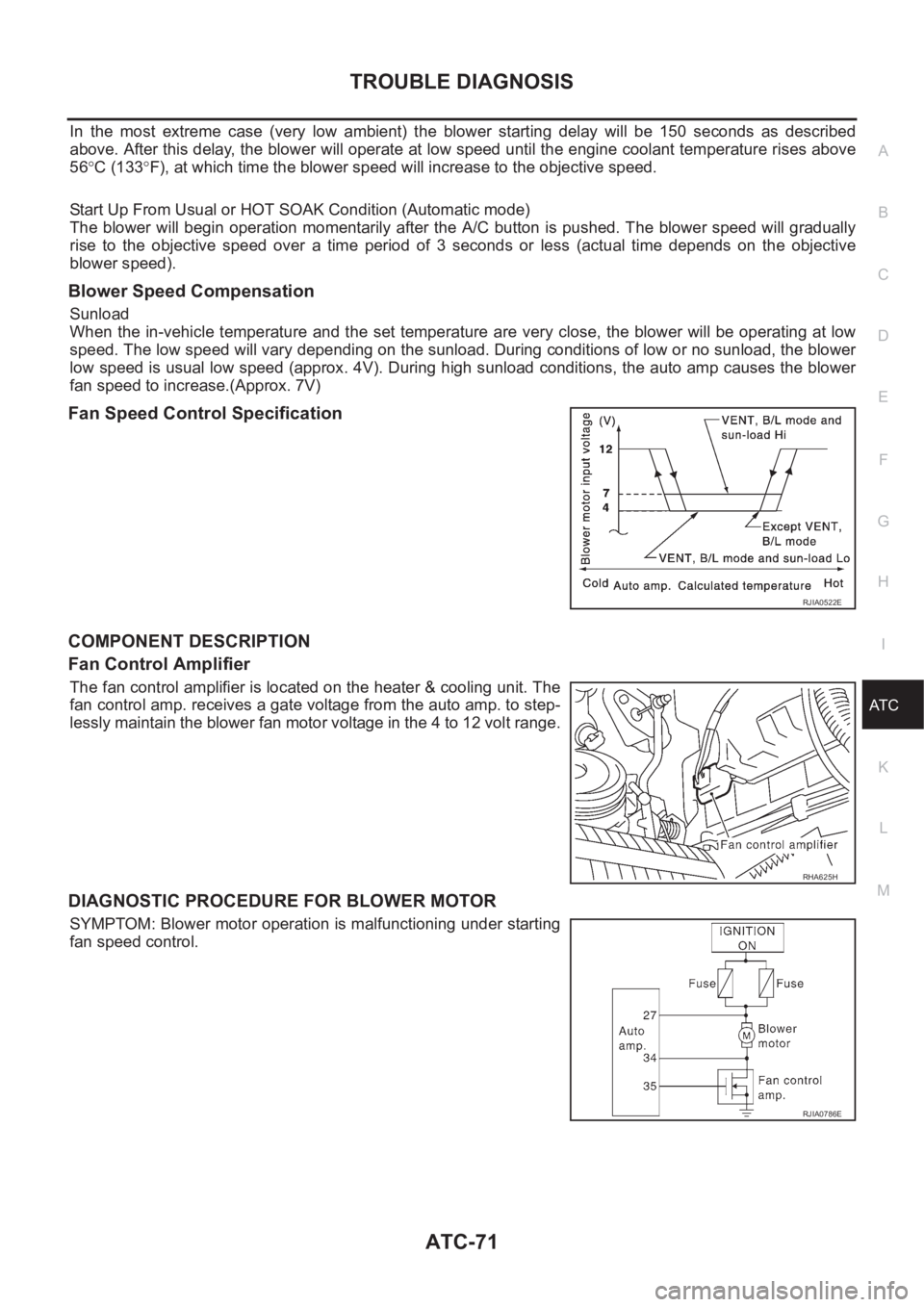

In the most extreme case (very low ambient) the blower starting delay will be 150 seconds as described

above. After this delay, the blower will operate at low speed until the engine coolant temperature rises above

56°C (133°F), at which time the blower speed will increase to the objective speed.

Start Up From Usual or HOT SOAK Condition (Automatic mode)

The blower will begin operation momentarily after the A/C button is pushed. The blower speed will gradually

rise to the objective speed over a time period of 3 seconds or less (actual time depends on the objective

blower speed).

Blower Speed Compensation

Sunload

When the in-vehicle temperature and the set temperature are very close, the blower will be operating at low

speed. The low speed will vary depending on the sunload. During conditions of low or no sunload, the blower

low speed is usual low speed (approx. 4V). During high sunload conditions, the auto amp causes the blower

fan speed to increase.(Approx. 7V)

Fan Speed Control Specification

COMPONENT DESCRIPTION

Fan Control Amplifier

The fan control amplifier is located on the heater & cooling unit. The

fan control amp. receives a gate voltage from the auto amp. to step-

lessly maintain the blower fan motor voltage in the 4 to 12 volt range.

DIAGNOSTIC PROCEDURE FOR BLOWER MOTOR

SYMPTOM: Blower motor operation is malfunctioning under starting

fan speed control.

RJIA0522E

RHA625H

RJIA0786E

Page 2453 of 3189

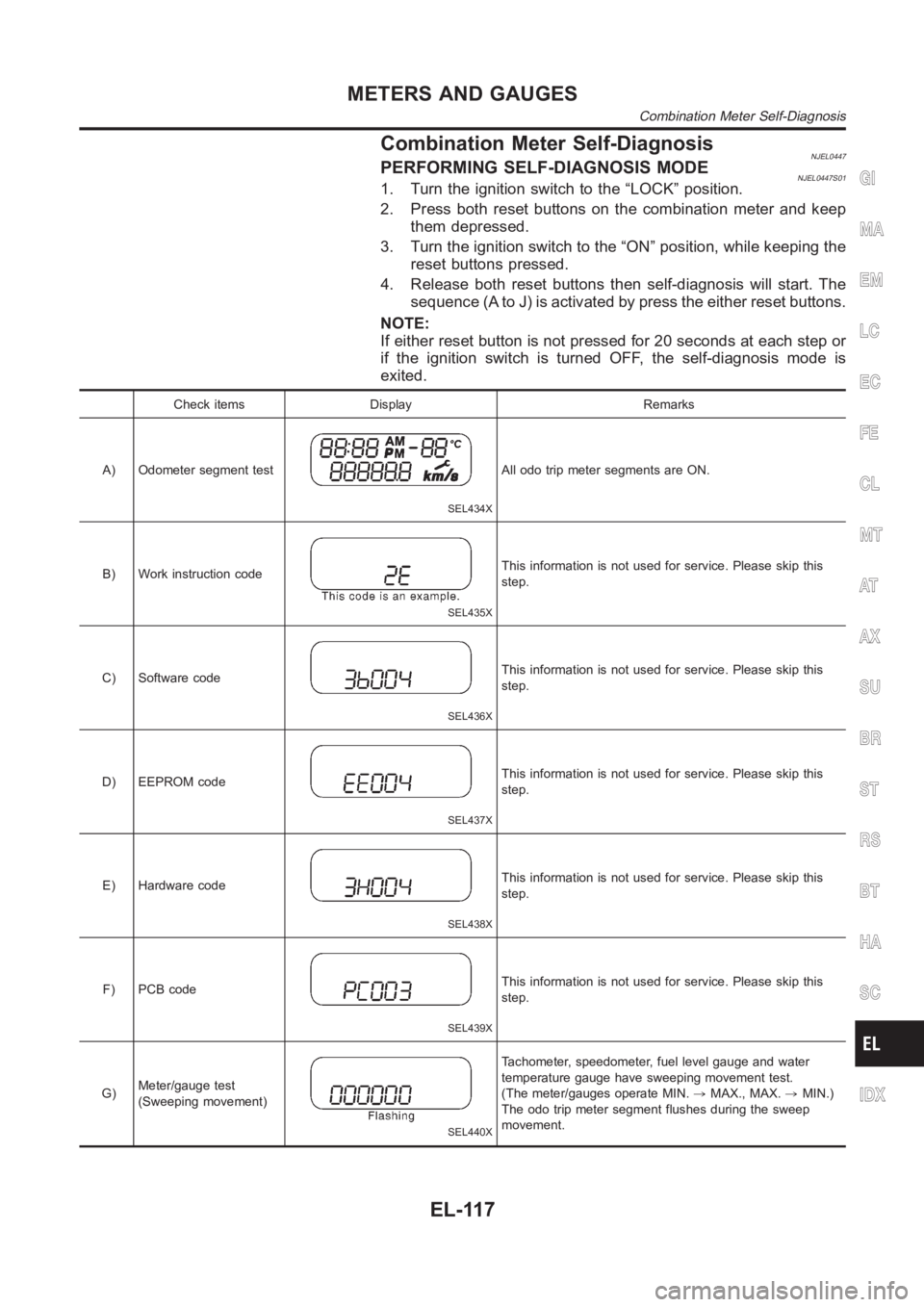

Combination Meter Self-DiagnosisNJEL0447PERFORMING SELF-DIAGNOSIS MODENJEL0447S011. Turn the ignition switch to the “LOCK” position.

2. Press both reset buttons on the combination meter and keep

them depressed.

3. Turn the ignition switch to the “ON” position, while keeping the

reset buttons pressed.

4. Release both reset buttons then self-diagnosis will start. The

sequence (A to J) is activated by press the either reset buttons.

NOTE:

If either reset button is not pressed for 20 seconds at each step or

if the ignition switch is turned OFF, the self-diagnosis mode is

exited.

Check items Display Remarks

A) Odometer segment test

SEL434X

All odo trip meter segments are ON.

B) Work instruction code

SEL435X

This information is not used for service. Please skip this

step.

C) Software code

SEL436X

This information is not used for service. Please skip this

step.

D) EEPROM code

SEL437X

This information is not used for service. Please skip this

step.

E) Hardware code

SEL438X

This information is not used for service. Please skip this

step.

F) PCB code

SEL439X

This information is not used for service. Please skip this

step.

G)Meter/gauge test

(Sweeping movement)

SEL440X

Tachometer, speedometer, fuel level gauge and water

temperature gauge have sweeping movement test.

(The meter/gauges operate MIN.,MAX., MAX.,MIN.)

The odo trip meter segment flushes during the sweep

movement.

GI

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

IDX

METERS AND GAUGES

Combination Meter Self-Diagnosis

EL-117

Page 2455 of 3189

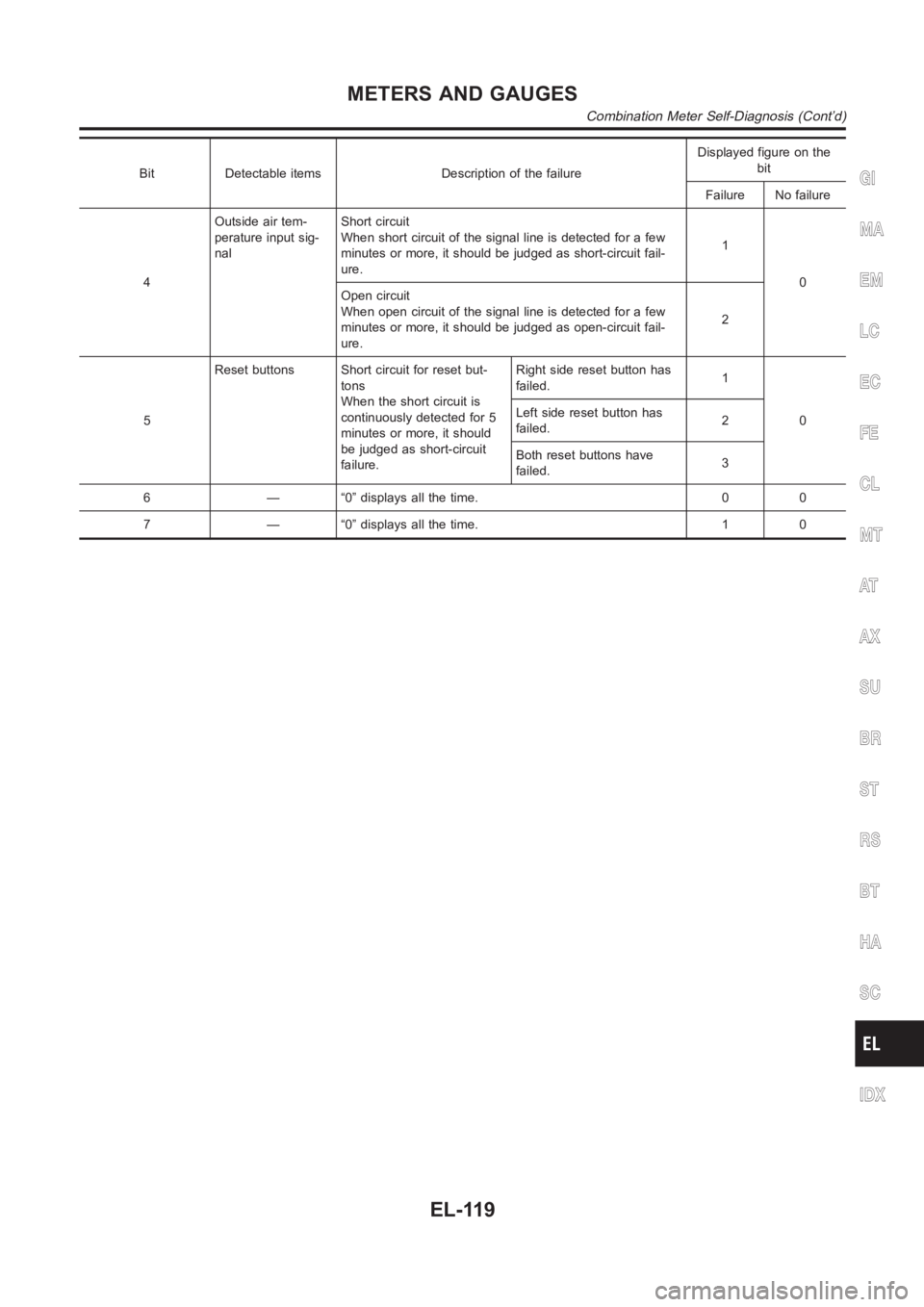

Bit Detectable items Description of the failureDisplayed figure on the

bit

Failure No failure

4Outside air tem-

perature input sig-

nalShort circuit

When short circuit of the signal line is detected for a few

minutes or more, it should be judged as short-circuit fail-

ure.1

0

Open circuit

When open circuit of the signal line is detected for a few

minutes or more, it should be judged as open-circuit fail-

ure.2

5Reset buttons Short circuit for reset but-

tons

When the short circuit is

continuously detected for 5

minutes or more, it should

be judged as short-circuit

failure.Right side reset button has

failed.1

0 Left side reset button has

failed.2

Both reset buttons have

failed.3

6 — “0” displays all the time. 0 0

7 — “0” displays all the time. 1 0GI

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

IDX

METERS AND GAUGES

Combination Meter Self-Diagnosis (Cont’d)

EL-119

Page 2559 of 3189

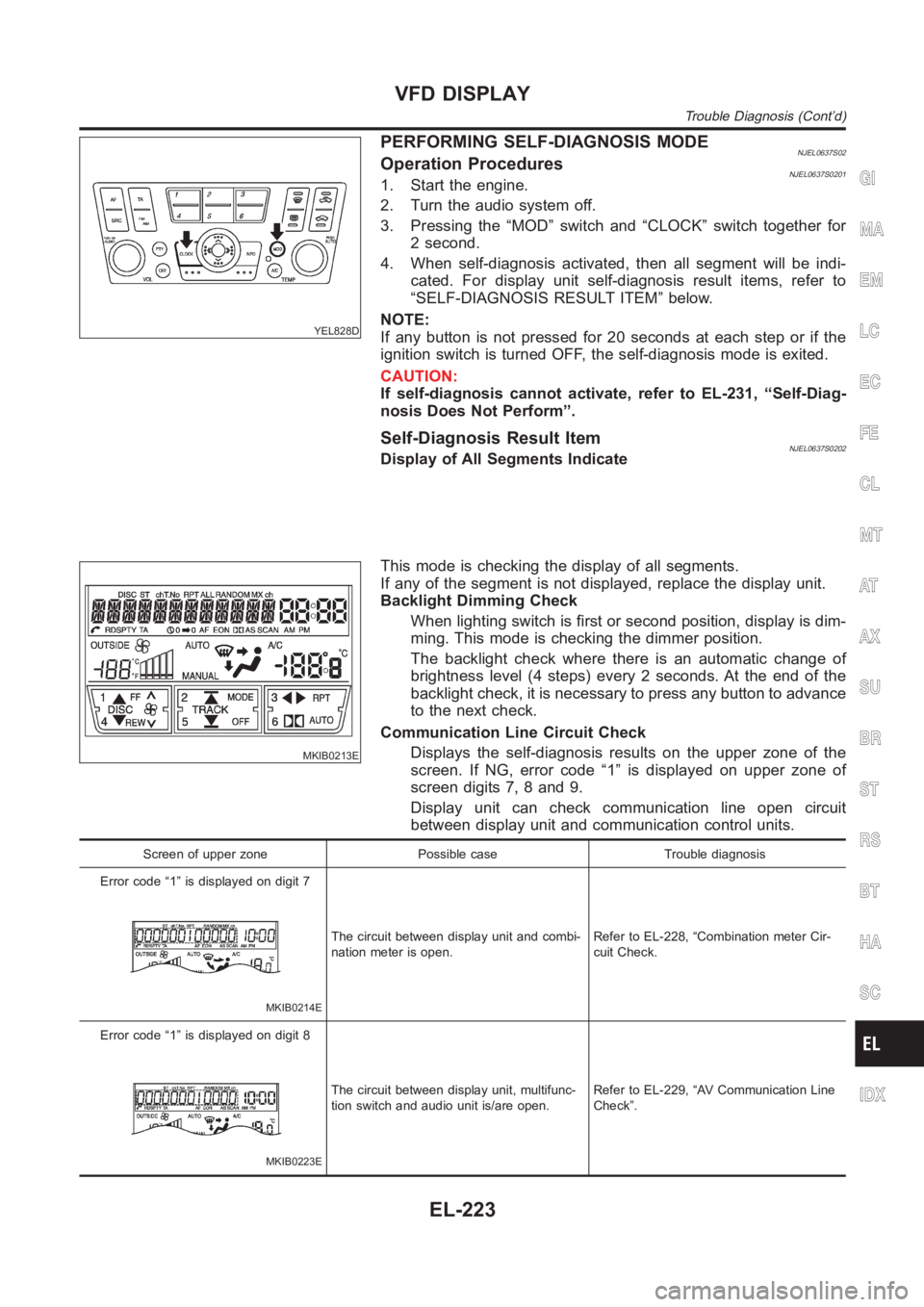

YEL828D

PERFORMING SELF-DIAGNOSIS MODENJEL0637S02Operation ProceduresNJEL0637S02011. Start the engine.

2. Turn the audio system off.

3. Pressing the “MOD” switch and “CLOCK” switch together for

2 second.

4. When self-diagnosis activated, then all segment will be indi-

cated. For display unit self-diagnosis result items, refer to

“SELF-DIAGNOSIS RESULT ITEM” below.

NOTE:

If any button is not pressed for 20 seconds at each step or if the

ignition switch is turned OFF, the self-diagnosis mode is exited.

CAUTION:

If self-diagnosis cannot activate, refer to EL-231, “Self-Diag-

nosis Does Not Perform”.

Self-Diagnosis Result ItemNJEL0637S0202Display of All Segments Indicate

MKIB0213E

This mode is checking the display of all segments.

If any of the segment is not displayed, replace the display unit.

Backlight Dimming Check

When lighting switch is first or second position, display is dim-

ming. This mode is checking the dimmer position.

The backlight check where there is an automatic change of

brightness level (4 steps) every 2 seconds. At the end of the

backlight check, it is necessary to press any button to advance

to the next check.

Communication Line Circuit Check

Displays the self-diagnosis results on the upper zone of the

screen. If NG, error code “1” is displayed on upper zone of

screen digits 7, 8 and 9.

Display unit can check communication line open circuit

between display unit and communication control units.

Screen of upper zone Possible case Trouble diagnosis

Error code “1” is displayed on digit 7

MKIB0214E

The circuit between display unit and combi-

nation meter is open.Refer to EL-228, “Combination meter Cir-

cuit Check.

Error code “1” is displayed on digit 8

MKIB0223E

The circuit between display unit, multifunc-

tion switch and audio unit is/are open.Refer to EL-229, “AV Communication Line

Check”.

GI

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

IDX

VFD DISPLAY

Trouble Diagnosis (Cont’d)

EL-223

Page 2597 of 3189

System Description=NJEL0502OPERATIONNJEL0502S02Power door lock/unlock operation by door key cylinder

With the key inserted into front door key cylinder, turning it to LOCK will lock all doors.

With the key inserted into front door key cylinder, turning it to UNLOCK will unlock all doors.

Power door lock/unlock operation by multi-remote controller (If equipped)

Pressing multi-remote controller LOCK button will lock all doors.

Pressing multi-remote controller UNLOCK button once will unlock driver door. Then, if an unlock signal is

sent from the remote controller again within 5 seconds, all other doors will be unlocked.

Power door lock/unlock operation by lock/unlock switch

With lock/unlock switch on driver door trim setting to LOCK will lock all doors.

With lock/unlock switch on driver door trim setting to UNLOCK will unlock all doors.GI

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

IDX

POWER DOOR LOCK

System Description

EL-261

Page 2637 of 3189

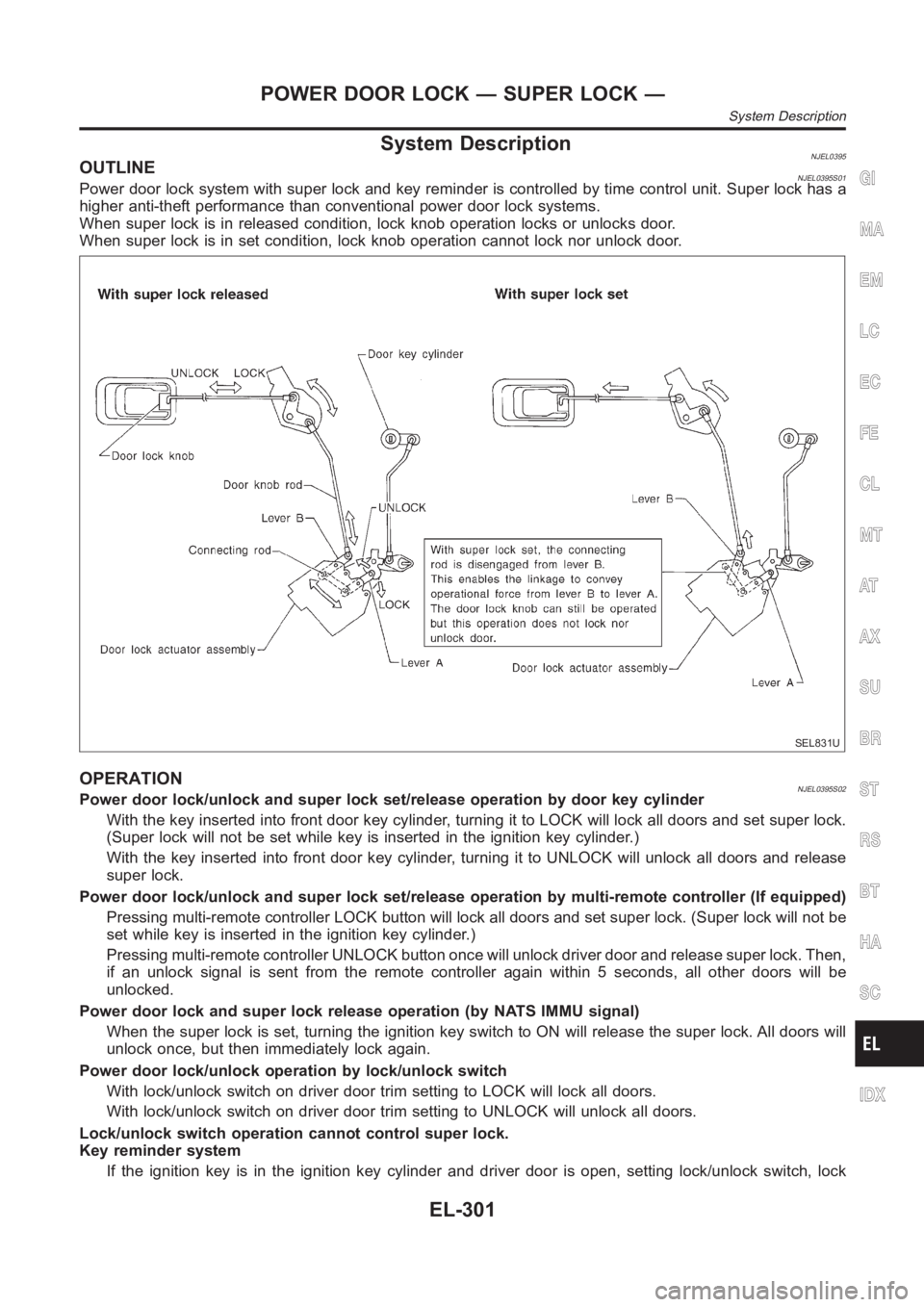

System DescriptionNJEL0395OUTLINENJEL0395S01Power door lock system with super lock and key reminder is controlled by time control unit. Super lock has a

higher anti-theft performance than conventional power door lock systems.

When super lock is in released condition, lock knob operation locks or unlocks door.

When super lock is in set condition, lock knob operation cannot lock nor unlock door.

SEL831U

OPERATIONNJEL0395S02Power door lock/unlock and super lock set/release operation by door key cylinder

With the key inserted into front door key cylinder, turning it to LOCK will lock all doors and set super lock.

(Super lock will not be set while key is inserted in the ignition key cylinder. )

With the key inserted into front door key cylinder, turning it to UNLOCK will unlock all doors and release

super lock.

Power door lock/unlock and super lock set/release operation by multi-remote controller (If equipped)

Pressing multi-remote controller LOCK button will lock all doors and set super lock. (Super lock will not be

set while key is inserted in the ignition key cylinder.)

Pressing multi-remote controller UNLOCK button once will unlock driver door and release super lock. Then,

if an unlock signal is sent from the remote controller again within 5 seconds, all other doors will be

unlocked.

Power door lock and super lock release operation (by NATS IMMU signal)

When the super lock is set, turning the ignition key switch to ON will release the super lock. All doors will

unlock once, but then immediately lock again.

Power door lock/unlock operation by lock/unlock switch

With lock/unlock switch on driver door trim setting to LOCK will lock all doors.

With lock/unlock switch on driver door trim setting to UNLOCK will unlock all doors.

Lock/unlock switch operation cannot control super lock.

Key reminder system

If the ignition key is in the ignition key cylinder and driver door is open, setting lock/unlock switch, lock

GI

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

IDX

POWER DOOR LOCK — SUPER LOCK —

System Description

EL-301