drain bolt NISSAN ALMERA N16 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2003Pages: 3189, PDF Size: 54.76 MB

Page 100 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual EM-22

[QG]

OIL PAN AND OIL STRAINER

OIL PAN AND OIL STRAINER

P F P : 1111 0

Removal and InstallationEBS00LQ6

REMOVAL

WARNING:

To avoid the danger of being scalded, never drain the engine oil when the NISSAN ALMERA N16 2003 Electronic Repair Manual EM-22

[QG]

OIL PAN AND OIL STRAINER

OIL PAN AND OIL STRAINER

P F P : 1111 0

Removal and InstallationEBS00LQ6

REMOVAL

WARNING:

To avoid the danger of being scalded, never drain the engine oil when the](/img/5/57350/w960_57350-99.png)

EM-22

[QG]

OIL PAN AND OIL STRAINER

OIL PAN AND OIL STRAINER

P F P : 1111 0

Removal and InstallationEBS00LQ6

REMOVAL

WARNING:

To avoid the danger of being scalded, never drain the engine oil when the engine is hot.

1. Remove undercover.

2. Drain engine oil. Refer to LC-8, "Changing Engine Oil".

3. Remove exhaust front tube. Refer to FE-10, "Removal and Installation".

4. Using a transmission jack, be sure to support the bottom of tran-

saxle oil pan, and remove center member.

5. Remove gusset and engine rear plate (lower) [A/T vehicle].

6. Loosen and remove mounting nuts and bolts in reverse order

shown in figure.

PBIC0548E

1. Oil strainer 2. Washer 3. Drain plug

4. Oil pan

SEM067F

SEM072F

Page 101 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual OIL PAN AND OIL STRAINER

EM-23

[QG]

C

D

E

F

G

H

I

J

K

L

MA

EM

7. Insert Tool (Seal cutter) between oil pan and cylinder block.

Slide tool by tapping on the side of the tool with a hammer.

NISSAN ALMERA N16 2003 Electronic Repair Manual OIL PAN AND OIL STRAINER

EM-23

[QG]

C

D

E

F

G

H

I

J

K

L

MA

EM

7. Insert Tool (Seal cutter) between oil pan and cylinder block.

Slide tool by tapping on the side of the tool with a hammer.](/img/5/57350/w960_57350-100.png)

OIL PAN AND OIL STRAINER

EM-23

[QG]

C

D

E

F

G

H

I

J

K

L

MA

EM

7. Insert Tool (Seal cutter) between oil pan and cylinder block.

Slide tool by tapping on the side of the tool with a hammer.

Remove oil pan.

8. Remove oil strainer.

INSTALLATION

1. Install oil strainer.

NOTE:

Gasket and O-ring are not used for sealed area with oil pump.

2. Install oil pan drain plug.

●Referring to “Components”, install drain plug washer.

3. Apply a continuous bead of liquid gasket to position shown in figure.

Use Genuine Liquid Gasket or equivalent.

4. Tighten mounting nuts and bolts in order shown in figure.

●Install mounting nuts and bolts as follows.

5. Install center member.

Refer to ENGINE ASSEMBLY, EM-67, "

Removal and Installa-

tion" .

6. Install remaining parts in the reverse order of removal.

INSPECTION AFTER INSTALLATION

●Check for leakage of engine oil when engine is warmed.

●Pour engine oil or start engine at least 30 minutes after oil pan is installed.

SEM365EA

PBIC0549E

Mounting bolt:

[Shank length under

head 10 mm (0.39 in)]: Nos. 1 - 10, 13, 14

[Shank length under

head 12 mm (0.47 in)]: Nos. 11, 12

SEM072F

Page 104 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual EM-26

[QG]

FUEL INJECTOR AND FUEL TUBE

FUEL INJECTOR AND FUEL TUBE

PFP:16600

Removal and InstallationEBS00LQ9

CAUTION:

●Apply new engine oil when installing the parts that specified to do so in the NISSAN ALMERA N16 2003 Electronic Repair Manual EM-26

[QG]

FUEL INJECTOR AND FUEL TUBE

FUEL INJECTOR AND FUEL TUBE

PFP:16600

Removal and InstallationEBS00LQ9

CAUTION:

●Apply new engine oil when installing the parts that specified to do so in the](/img/5/57350/w960_57350-103.png)

EM-26

[QG]

FUEL INJECTOR AND FUEL TUBE

FUEL INJECTOR AND FUEL TUBE

PFP:16600

Removal and InstallationEBS00LQ9

CAUTION:

●Apply new engine oil when installing the parts that specified to do so in the figure.

●Do not remove or disassembly parts unless instructed as shown in the figure.

REMOVAL

1. Release fuel pressure. Refer to EC-34, "FUEL PRESSURE RELEASE" (WITH EURO-OBD), EC-427,

"FUEL PRESSURE RELEASE" (WITHOUT EURO-OBD).

2. Disconnect harness for fuel injector, and move it aside.

3. Remove fuel hose.

CAUTION:

After removal, install blind plug to fuel hose to prevent the fuel from draining.

4. Remove fuel tube and injector assembly with the following pro-

cedure:

a. Loosen mounting bolts in reverse order shown in figure.

b. Pull out fuel injector/fuel tube assembly toward engine rear side.

YEM051

1. Fuel tube 2. Fuel feed hose 3. O-ring

4. Clip 5. Fuel injector 6. Intake manifold

PBIC0617E

Page 126 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual EM-48

[QG]

TIMING CHAIN

2. Disconnect battery ground cable.

3. Remove undercover, front RH wheel and RH splash cover.

4. Drain engine coolant from radiator and cylinder block. Refer to LC-17, "Cha NISSAN ALMERA N16 2003 Electronic Repair Manual EM-48

[QG]

TIMING CHAIN

2. Disconnect battery ground cable.

3. Remove undercover, front RH wheel and RH splash cover.

4. Drain engine coolant from radiator and cylinder block. Refer to LC-17, "Cha](/img/5/57350/w960_57350-125.png)

EM-48

[QG]

TIMING CHAIN

2. Disconnect battery ground cable.

3. Remove undercover, front RH wheel and RH splash cover.

4. Drain engine coolant from radiator and cylinder block. Refer to LC-17, "Changing Engine Coolant".

5. Drain engine oil from oil pan.

6. Remove drive belt. Refer to EM-13, "

Removal and Installation" .

7. Remove power steering pump from adjusting bar.

8. Remove alternator. SC-33, "Removal and Installation".

9. Remove ignition coils. Refer to EM-24, "

IGNITION COIL" .

10. Remove rocker cover. Refer to EM-29, "

Removal and Installation" .

11. Remove oil level gauge.

12. Remove exhaust front tube. Refer to FE-10, "Removal and Installation".

13. Remove center member.

14. Remove gusset.

15. Remove rear plate (lower) (A/T models).

16. Remove oil pan and oil strainer. Refer to EM-22, "

Removal and Installation" .

17. For safe operation, and to reduce load to mount insulator, install removed center member again.

18. Remove engine front-side (right side of vehicle) engine mount. Refer to EM-67, "

ENGINE ASSEMBLY" .

a. Remove any parts that cause difficulties for operation around mount, or perform transfer.

b. Support cylinder block bottom surface with a transmission jack.

CAUTION:

●When applying jack, use a wooden block to avoid damage to oil pan mounting surface.

●While performing following operations, support engine front-side with jack.

c. Separate engine mounting insulator and bracket.

d. Remove engine mounting bracket.

19. Remove cylinder head front cover.

●Move harness which was previously fixed on front surface.

20. Remove auxiliary bolts of cylinder head.

21. Set the No. 1 cylinder to the compression TDC.

a. Turn the crankshaft pulley clockwise, and align the timing indica-

tor of the gear case to the timing mark of the crankshaft pulley.

PBIC0557E

PBIC0750E

Page 136 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual EM-58

[QG]

CYLINDER HEAD

8. Install spark plug, ignition coil and harness connectors.

Removal and InstallationEBS00LQI

REMOVAL

1. Release fuel pressure. Refer to EC-34, "FUEL PRESSURE RELEA NISSAN ALMERA N16 2003 Electronic Repair Manual EM-58

[QG]

CYLINDER HEAD

8. Install spark plug, ignition coil and harness connectors.

Removal and InstallationEBS00LQI

REMOVAL

1. Release fuel pressure. Refer to EC-34, "FUEL PRESSURE RELEA](/img/5/57350/w960_57350-135.png)

EM-58

[QG]

CYLINDER HEAD

8. Install spark plug, ignition coil and harness connectors.

Removal and InstallationEBS00LQI

REMOVAL

1. Release fuel pressure. Refer to EC-34, "FUEL PRESSURE RELEASE" (WITH EURO-OBD), EC-427,

"FUEL PRESSURE RELEASE" (WITHOUT EURO-OBD).

2. Remove undercover.

3. Drain engine coolant. Refer to LC-17, "Changing Engine Coolant".

4. Remove the following components and related parts:

●Intake manifold and intake manifold collector. Refer to EM-16, "INTAKE MANIFOLD" .

●Exhaust manifold and catalytic converter. Refer to EM-19, "EXHAUST MANIFOLD AND CATALYTIC

CONVERTER" .

●Ignition coil. Refer to EM-24, "IGNITION COIL" .

●Rocker cover. Refer to EM-29, "ROCKER COVER" .

●Camshaft. Refer to EM-32, "CAMSHAFT" .

●Alternator bracket. Refer to SC-33, "Removal and Installation".

PBIC0972E

1. Rear engine slinger 2. Cylinder head bolt 3. Washer

4. Auxiliary bolt of cylinder head 5. Cylinder head gasket 6. Cylinder head assembly

Page 146 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual EM-68

[QG]

ENGINE ASSEMBLY

WARNING:

●Position vehicle on a flat and solid surface.

●Place chocks at front and back of rear wheels.

●Do not remove engine until exhaust system has complete NISSAN ALMERA N16 2003 Electronic Repair Manual EM-68

[QG]

ENGINE ASSEMBLY

WARNING:

●Position vehicle on a flat and solid surface.

●Place chocks at front and back of rear wheels.

●Do not remove engine until exhaust system has complete](/img/5/57350/w960_57350-145.png)

EM-68

[QG]

ENGINE ASSEMBLY

WARNING:

●Position vehicle on a flat and solid surface.

●Place chocks at front and back of rear wheels.

●Do not remove engine until exhaust system has completely cooled off, otherwise, you may burn

yourself and/or fire may break out in fuel line.

●Before disconnecting fuel hose, release pressure.

Refer to EC-34 (WITH EURO-OBD), EC-428 (WITHOUT EURO-OBD).

●Be sure to lift engine and transaxle in a safe manner.

●For engines not equipped with engine slingers, attach proper slingers and bolts described in

PARTS CATALOG.

CAUTION:

●When lifting engine, be sure to clear surrounding parts. Use special care near accelerator wire

casing, brake lines and brake master cylinder.

●When lifting the engine, always use engine slingers in a safe manner.

●When removing drive shaft, be careful not to damage grease seal of transaxle.

●Before separating engine and transaxle, remove crankshaft position sensor (POS) from the cylin-

der block assembly.

●Always be extra careful not to damage edge of crankshaft position sensor (POS), or signal plate

teeth.

Engine cannot be removed separately from transaxle. Remove engine with transaxle as an assembly.

REMOVAL

1. Drain coolant from radiator and cylinder block. Refer to LC-17, "Chacking Engine Coolant".

2. Remove coolant reservoir tank and bracket.

3. Drain engine oil.

4. Remove battery and battery tray.

5. Remove air cleaner and air duct.

6. Remove drive belts.

7. Remove alternator and air conditioner compressor from engine.

8. Remove power steering oil pump from engine and position aside.

Power steering oil pump does not need to be disconnected from power steering tubes.

9. Remove the following parts:

●RH and LH front tires

●Splash covers

●RH and LH brake caliper assemblies

Refer to BR-28,"Removal".

Brake hose does not need to be disconnected from brake

caliper assembly. Never depress brake pedal.

●RH & LH drive shaft. Refer to AX-11, "Removal".

When removing drive shaft, be careful not to damage

transaxle side grease seal.

●Disconnect control rod and support rod from transaxle. (M/T

models.)

Refer to MT-26, "Removal".

●Disconnect control cable from transaxle. (A/T models.)

Refer to AT-411, "Removal".

SEM174D

SEM109G

Page 149 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual CYLINDER BLOCK

EM-71

[QG]

C

D

E

F

G

H

I

J

K

L

MA

EM

CAUTION:

Apply new engine oil to parts marked in illustration before installation.

DISASSEMBLY

1. Remove engine and transaxle assembly from vehicle, NISSAN ALMERA N16 2003 Electronic Repair Manual CYLINDER BLOCK

EM-71

[QG]

C

D

E

F

G

H

I

J

K

L

MA

EM

CAUTION:

Apply new engine oil to parts marked in illustration before installation.

DISASSEMBLY

1. Remove engine and transaxle assembly from vehicle,](/img/5/57350/w960_57350-148.png)

CYLINDER BLOCK

EM-71

[QG]

C

D

E

F

G

H

I

J

K

L

MA

EM

CAUTION:

Apply new engine oil to parts marked in illustration before installation.

DISASSEMBLY

1. Remove engine and transaxle assembly from vehicle, and separate transaxle from engine. Refer to EM-

67, "ENGINE ASSEMBLY" .

2. Mount engine on an engine stand with the following procedure.

a. Remove exhaust manifold and catalytic converter. Refer to EM-19, "

EXHAUST MANIFOLD AND CATA-

LYTIC CONVERTER" .

b. Remove engine front mounting bracket, alternator and air compressor bracket.

c. Install engine sub-attachment to left side of cylinder block.

d. Lift engine, and mount it onto the engine stand.

1. Rear oil seal 2. Rear oil seal retainer 3. Crankshaft position sensor (POS)

4. O-ring 5. Knock sensor 6. Oil level gauge guide

7. Cylinder block 8. Thrust bearing 9. Main bearing

10. Crankshaft 11. Key 12. Top ring

13. 2nd ring 14. Oil ring 15. Main bearing

16. Piston 17. Snap ring 18. Piston pin

19. Connecting rod 20. Connecting rod bearing 21. Connecting rod cap

22. Connecting rod nut 23. Main bearing cap bolt 24. Baffle plate

25. Main bearing cap 26. Signal plate 27. Rear plate

28. Coolant drain plug 29. Flywheel (M/T models) 30. Drive plate (A/T models)

PBIC0585E

PBIC1017E

Page 150 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual EM-72

[QG]

CYLINDER BLOCK

●A commercial engine stand can be used.

NOTE:

●This example is an engine stand for holding at transaxle

mounting side with the flywheel or drive plate removed.

3 NISSAN ALMERA N16 2003 Electronic Repair Manual EM-72

[QG]

CYLINDER BLOCK

●A commercial engine stand can be used.

NOTE:

●This example is an engine stand for holding at transaxle

mounting side with the flywheel or drive plate removed.

3](/img/5/57350/w960_57350-149.png)

EM-72

[QG]

CYLINDER BLOCK

●A commercial engine stand can be used.

NOTE:

●This example is an engine stand for holding at transaxle

mounting side with the flywheel or drive plate removed.

3. Drain engine oil and coolant from inside of engine.

4. Remove the following components and associated parts.

●Fuel tube and injector assembly; Refer to EM-26, "Removal and Installation" .

●Intake manifold and intake manifold collector assembly; Refer to EM-16, "Removal and Installation" .

●Ignition coil; Refer to EM-24, "Removal and Installation" .

●Rocker cover; Refer to EM-29, "Removal and Installation" .

●Oil pan and oil strainer; Refer to EM-22, "Removal and Installation" .

●Front cover and timing chain; Refer to EM-47, "Removal and Installation" .

●Camshaft; Refer to EM-32, "Removal and Installation" .

●Cylinder head assembly; Refer to EM-58, "Removal and Installation" .

●Auxiliary brackets and oil filter

5. Remove knock sensor.

CAUTION:

Avoid impacts such as a dropping.

6. Remove crankshaft position sensor (POS).

CAUTION:

●Avoid impacts such as a dropping.

●Do not disassemble.

●Keep it away from metal particles.

●Do not place sensor close to magnetic materials.

7. Remove flywheel (M/T models) or drive plate (A/T models). Fix

crankshaft with a ring gear stopper (special service tool), and

remove mounting bolts.

8. Remove rear plate.

9. Remove rear oil seal retainer.

●Insert a flat-bladed screwdriver between main bearing cap

and rear oil seal retainer to remove retainer.

10. Remove rear oil seal from rear oil seal retainer.

●Punch out with a flat-bladed screwdriver.

CAUTION:

●Be careful not to damage rear oil seal retainer.

PBIC0085E

PBIC0586E

SEM880F

Page 204 of 3189

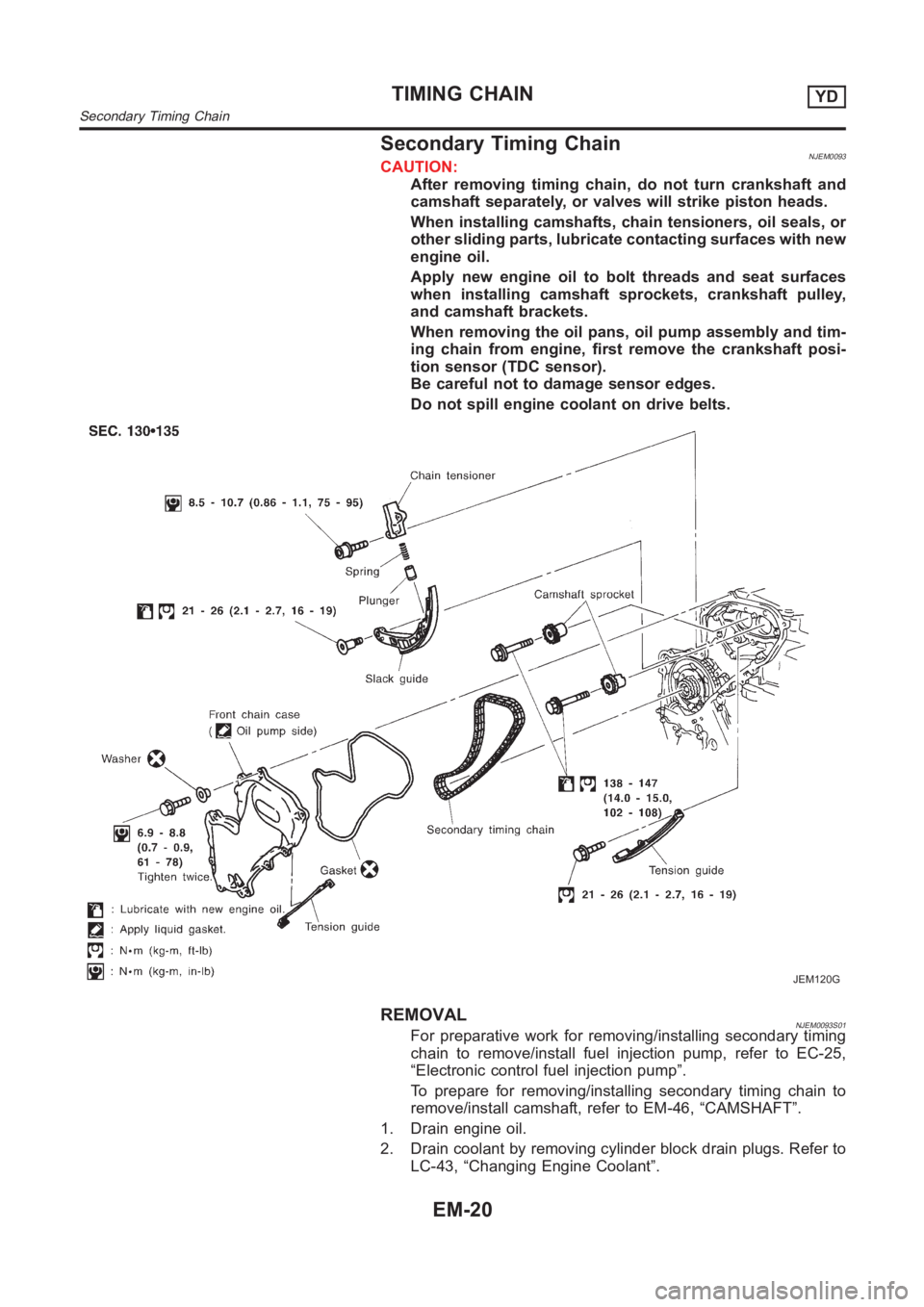

Secondary Timing ChainNJEM0093CAUTION:

After removing timing chain, do not turn crankshaft and

camshaft separately, or valves will strike piston heads.

When installing camshafts, chain tensioners, oil seals, or

other sliding parts, lubricate contacting surfaces with new

engine oil.

Apply new engine oil to bolt threads and seat surfaces

when installing camshaft sprockets, crankshaft pulley,

and camshaft brackets.

When removing the oil pans, oil pump assembly and tim-

ing chain from engine, first remove the crankshaft posi-

tion sensor (TDC sensor).

Be careful not to damage sensor edges.

Do not spill engine coolant on drive belts.

JEM120G

REMOVALNJEM0093S01For preparative work for removing/installing secondary timing

chain to remove/install fuel injection pump, refer to EC-25,

“Electronic control fuel injection pump”.

To prepare for removing/installing secondary timing chain to

remove/install camshaft, refer to EM-46, “CAMSHAFT”.

1. Drain engine oil.

2. Drain coolant by removing cylinder block drain plugs. Refer to

LC-43, “Changing Engine Coolant”.

TIMING CHAINYD

Secondary Timing Chain

EM-20

Page 220 of 3189

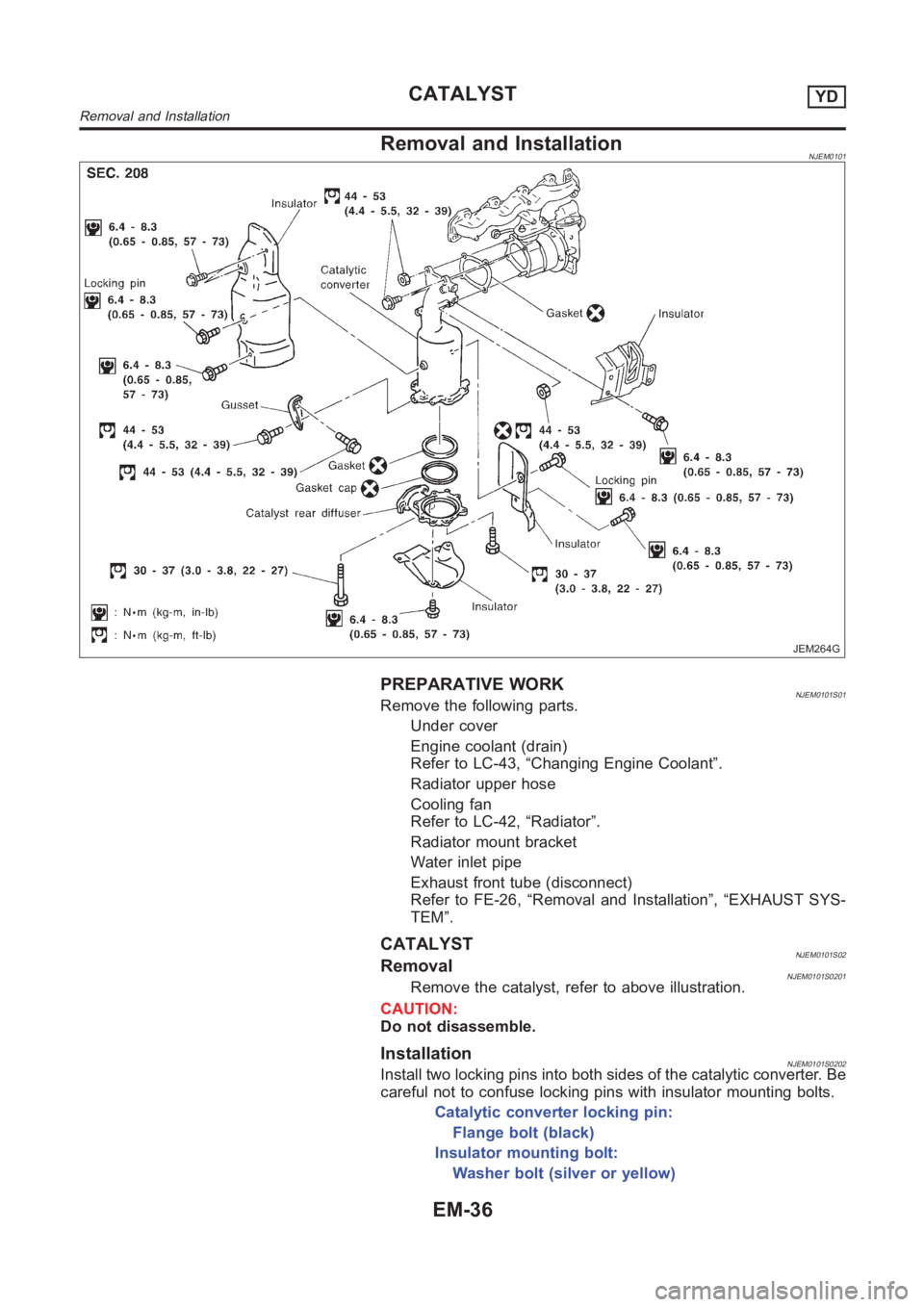

Removal and InstallationNJEM0101

JEM264G

PREPARATIVE WORKNJEM0101S01Remove the following parts.

Under cover

Engine coolant (drain)

Refer to LC-43, “Changing Engine Coolant”.

Radiator upper hose

Cooling fan

Refer to LC-42, “Radiator”.

Radiator mount bracket

Water inlet pipe

Exhaust front tube (disconnect)

Refer to FE-26, “Removal and Installation”, “EXHAUST SYS-

TEM”.

CATALYSTNJEM0101S02RemovalNJEM0101S0201Remove the catalyst, refer to above illustration.

CAUTION:

Do not disassemble.

InstallationNJEM0101S0202Install two locking pins into both sides of the catalytic converter. Be

careful not to confuse locking pins with insulator mounting bolts.

Catalytic converter locking pin:

Flange bolt (black)

Insulator mounting bolt:

Washer bolt (silver or yellow)

CATALYSTYD

Removal and Installation

EM-36