p1251 NISSAN ALMERA N16 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2003Pages: 3189, PDF Size: 54.76 MB

Page 1056 of 3189

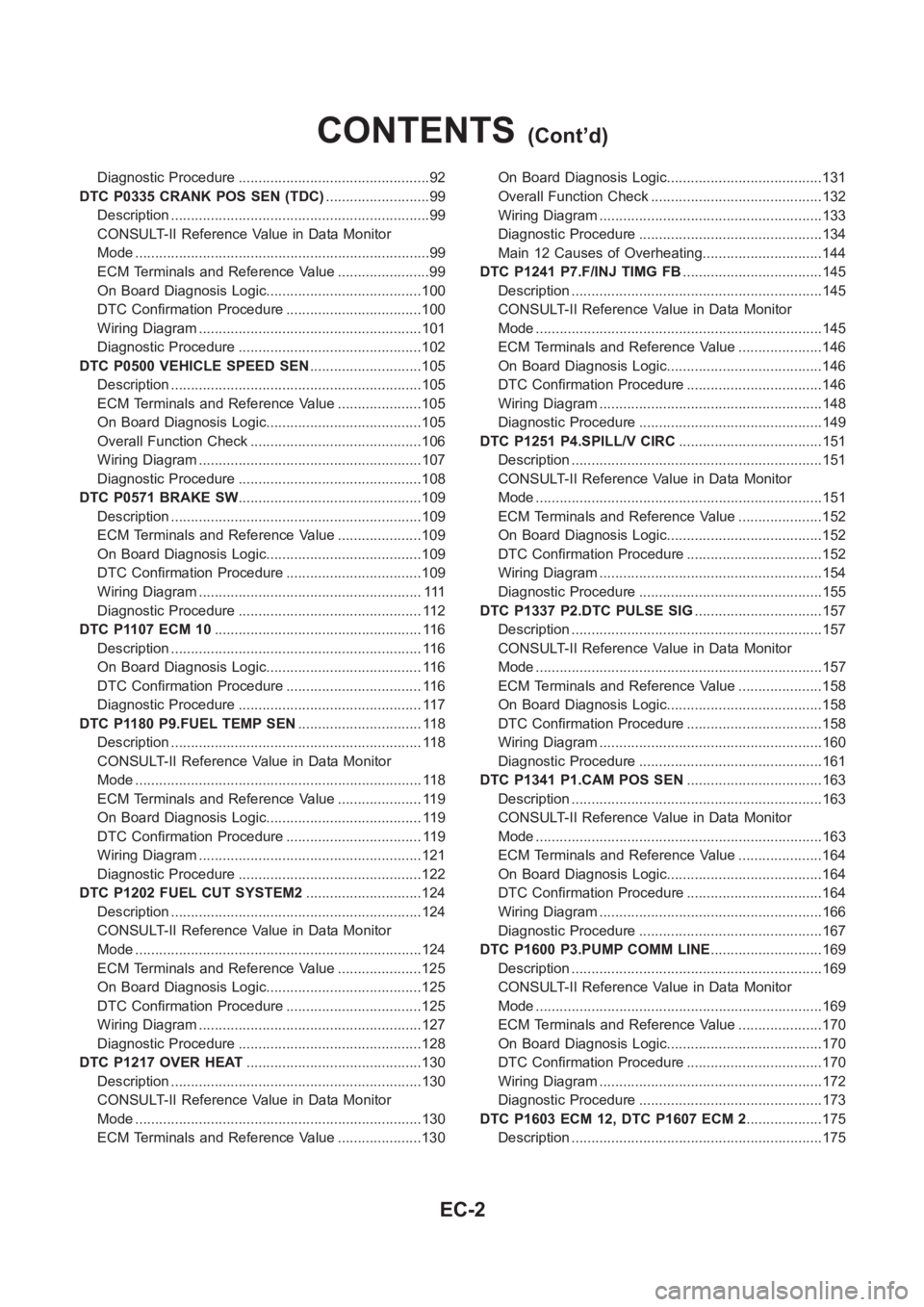

Diagnostic Procedure ................................................92

DTC P0335 CRANK POS SEN (TDC)..........................99

Description <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

110011[.............99

CONSULT-II Reference Value in Data Monitor

Mode <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

1100110011001100110011001100110011[...............99

ECM Terminals and Reference Value .......................99

On Board Diagnosis Logic.......................................100

DTC Confirmation Procedure ..................................100

Wiring Diagram ........................................................101

Diagnostic Procedure ..............................................102

DTC P0500 VEHICLE SPEED SEN............................105

Description <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

110011[...........105

ECM Terminals and Reference Value .....................105

On Board Diagnosis Logic.......................................105

Overall Function Check ...........................................106

Wiring Diagram ........................................................107

Diagnostic Procedure ..............................................108

DTC P0571 BRAKE SW..............................................109

Description <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

110011[...........109

ECM Terminals and Reference Value .....................109

On Board Diagnosis Logic.......................................109

DTC Confirmation Procedure ..................................109

Wiring Diagram ........................................................ 111

Diagnostic Procedure .............................................. 112

DTC P1107 ECM 10<0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

110011[ 116

Description <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

110011[........... 116

On Board Diagnosis Logic....................................... 116

DTC Confirmation Procedure .................................. 116

Diagnostic Procedure .............................................. 117

DTC P1180 P9.FUEL TEMP SEN............................... 118

Description <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

110011[........... 118

CONSULT-II Reference Value in Data Monitor

Mode <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

1100110011001100110011001100110011[............. 118

ECM Terminals and Reference Value ..................... 119

On Board Diagnosis Logic....................................... 119

DTC Confirmation Procedure .................................. 119

Wiring Diagram ........................................................121

Diagnostic Procedure ..............................................122

DTC P1202 FUEL CUT SYSTEM2.............................124

Description <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

110011[...........124

CONSULT-II Reference Value in Data Monitor

Mode <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

1100110011001100110011001100110011[.............124

ECM Terminals and Reference Value .....................125

On Board Diagnosis Logic.......................................125

DTC Confirmation Procedure ..................................125

Wiring Diagram ........................................................127

Diagnostic Procedure ..............................................128

DTC P1217 OVER HEAT............................................130

Description <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

110011[...........130

CONSULT-II Reference Value in Data Monitor

Mode <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

1100110011001100110011001100110011[.............130

ECM Terminals and Reference Value .....................130On Board Diagnosis Logic.......................................131

Overall Function Check ...........................................132

Wiring Diagram ........................................................133

Diagnostic Procedure ..............................................134

Main 12 Causes of Overheating..............................144

DTC P1241 P7.F/INJ TIMG FB...................................145

Description <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

110011[...........145

CONSULT-II Reference Value in Data Monitor

Mode <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

1100110011001100110011001100110011[.............145

ECM Terminals and Reference Value .....................146

On Board Diagnosis Logic.......................................146

DTC Confirmation Procedure ..................................146

Wiring Diagram ........................................................148

Diagnostic Procedure ..............................................149

DTC P1251 P4.SPILL/V CIRC....................................151

Description <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

110011[

...........151

CONSULT-II Reference Value in Data Monitor

Mode <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

1100110011001100110011001100110011[.............151

ECM Terminals and Reference Value .....................152

On Board Diagnosis Logic.......................................152

DTC Confirmation Procedure ..................................152

Wiring Diagram ........................................................154

Diagnostic Procedure ..............................................155

DTC P1337 P2.DTC PULSE SIG................................157

Description <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

110011[...........157

CONSULT-II Reference Value in Data Monitor

Mode <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

1100110011001100110011001100110011[.............157

ECM Terminals and Reference Value .....................158

On Board Diagnosis Logic.......................................158

DTC Confirmation Procedure ..................................158

Wiring Diagram ........................................................160

Diagnostic Procedure ..............................................161

DTC P1341 P1.CAM POS SEN..................................163

Description <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

110011[...........163

CONSULT-II Reference Value in Data Monitor

Mode <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

1100110011001100110011001100110011[.............163

ECM Terminals and Reference Value .....................164

On Board Diagnosis Logic.......................................164

DTC Confirmation Procedure ..................................164

Wiring Diagram ........................................................166

Diagnostic Procedure ..............................................167

DTC P1600 P3.PUMP COMM LINE............................169

Description <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

110011[...........169

CONSULT-II Reference Value in Data Monitor

Mode <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

1100110011001100110011001100110011[.............169

ECM Terminals and Reference Value .....................170

On Board Diagnosis Logic.......................................170

DTC Confirmation Procedure ..................................170

Wiring Diagram ........................................................172

Diagnostic Procedure ..............................................173

DTC P1603 ECM 12, DTC P1607 ECM 2...................175

Description <0011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100110011001100

110011[...........175

CONTENTS(Cont’d)

EC-2

Page 1058 of 3189

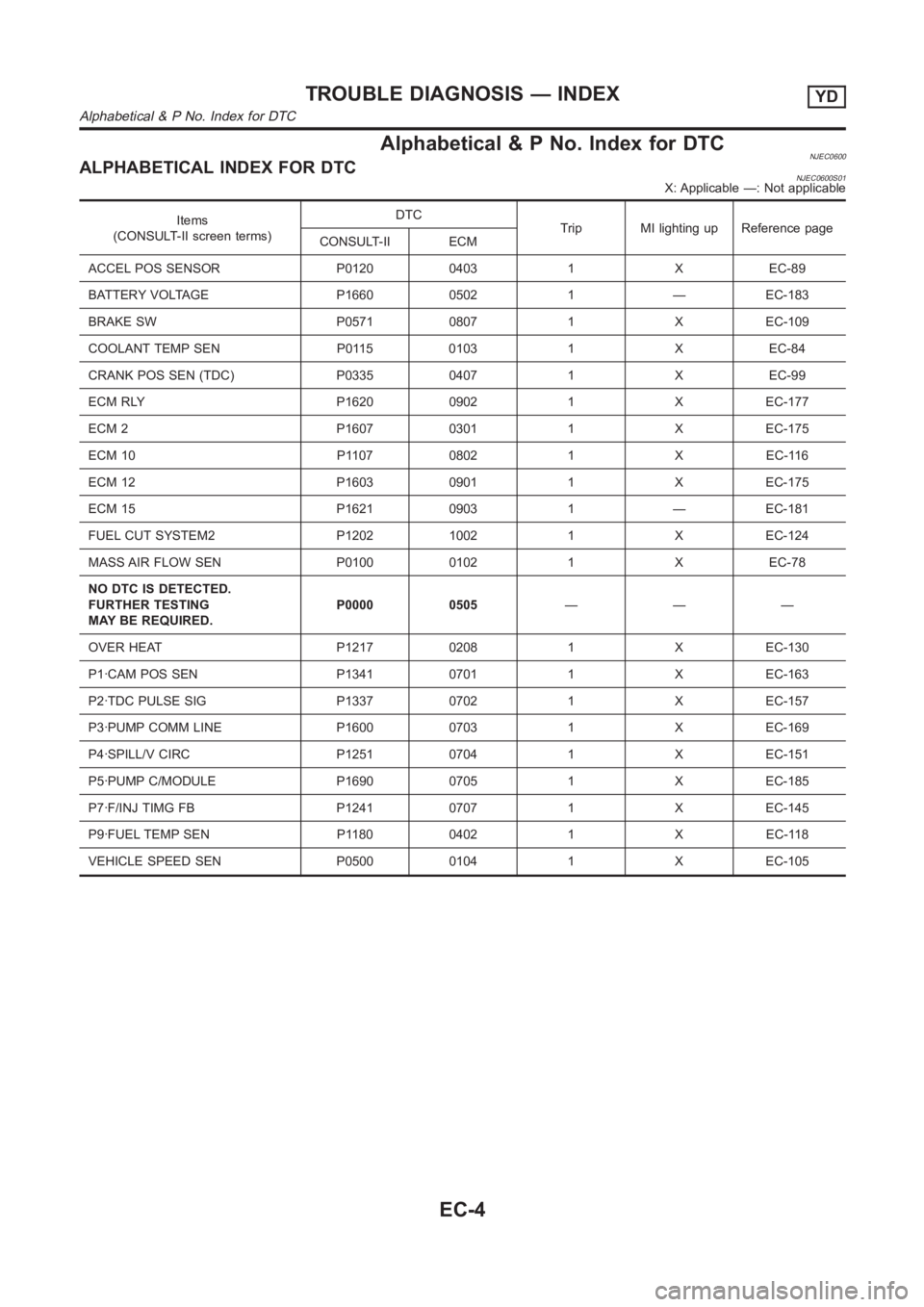

Alphabetical & P No. Index for DTCNJEC0600ALPHABETICAL INDEX FOR DTCNJEC0600S01X: Applicable —: Not applicable

Items

(CONSULT-II screen terms)DTC

Trip MI lighting up Reference page

CONSULT-II ECM

ACCEL POS SENSOR P0120 0403 1 X EC-89

BATTERY VOLTAGE P1660 0502 1 — EC-183

BRAKE SW P0571 0807 1 X EC-109

COOLANT TEMP SEN P0115 0103 1 X EC-84

CRANK POS SEN (TDC) P0335 0407 1 X EC-99

ECM RLY P1620 0902 1 X EC-177

ECM 2 P1607 0301 1 X EC-175

ECM 10 P1107 0802 1 X EC-116

ECM 12 P1603 0901 1 X EC-175

ECM 15 P1621 0903 1 — EC-181

FUEL CUT SYSTEM2 P1202 1002 1 X EC-124

MASS AIR FLOW SEN P0100 0102 1 X EC-78

NO DTC IS DETECTED.

FURTHER TESTING

MAY BE REQUIRED.P0000 0505———

OVER HEAT P1217 0208 1 X EC-130

P1·CAM POS SEN P1341 0701 1 X EC-163

P2·TDC PULSE SIG P1337 0702 1 X EC-157

P3·PUMP COMM LINE P1600 0703 1 X EC-169

P4·SPILL/V CIRC P1251 0704 1 X EC-151

P5·PUMP C/MODULE P1690 0705 1 X EC-185

P7·F/INJ TIMG FB P1241 0707 1 X EC-145

P9·FUEL TEMP SEN P1180 0402 1 X EC-118

VEHICLE SPEED SEN P0500 0104 1 X EC-105

TROUBLE DIAGNOSIS — INDEXYD

Alphabetical & P No. Index for DTC

EC-4

Page 1059 of 3189

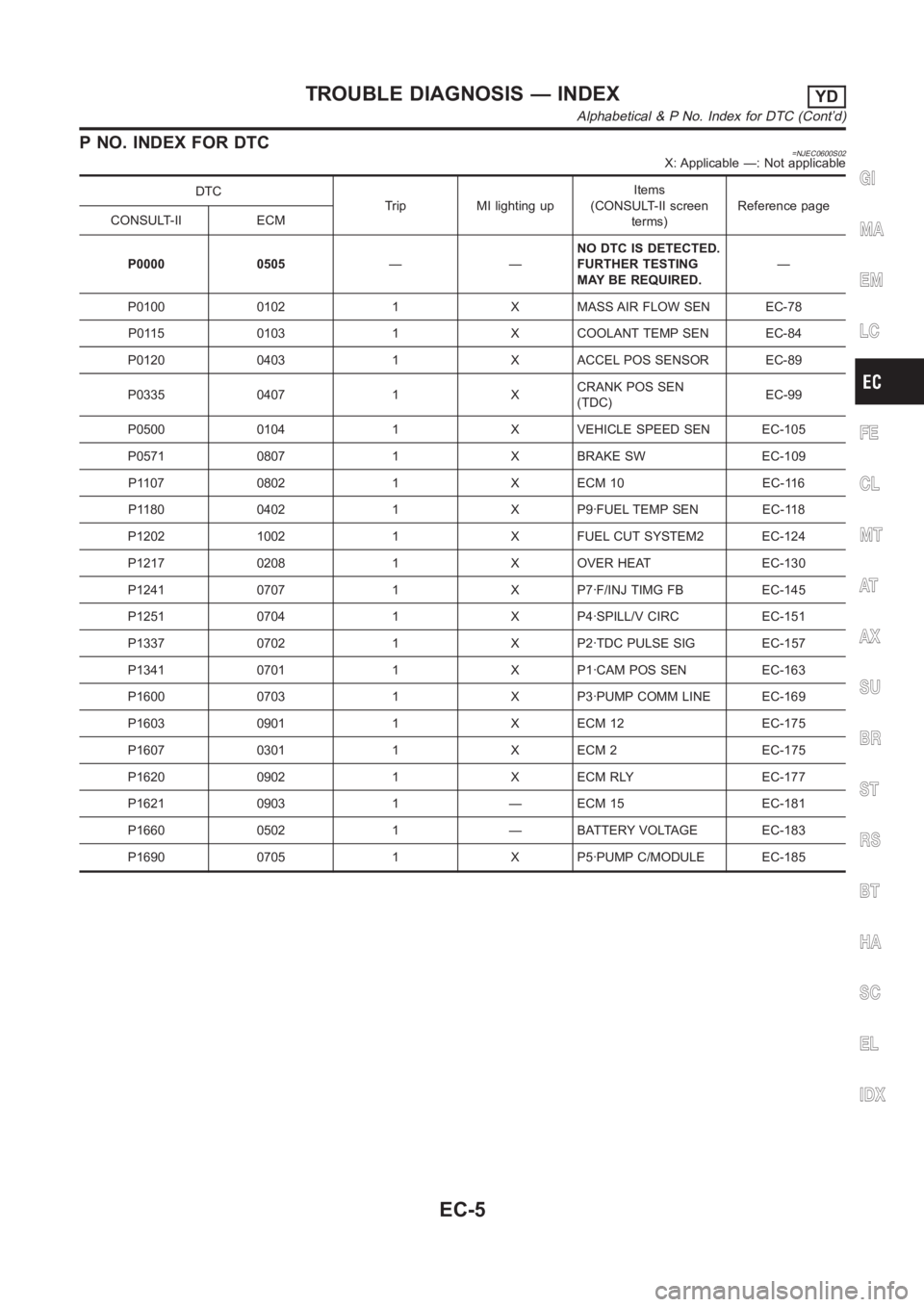

P NO. INDEX FOR DTC=NJEC0600S02X: Applicable —: Not applicable

DTC

Trip MI lighting upItems

(CONSULT-II screen

terms)Reference page

CONSULT-II ECM

P0000 0505——NO DTC IS DETECTED.

FURTHER TESTING

MAY BE REQUIRED.—

P0100 0102 1 X MASS AIR FLOW SEN EC-78

P0115 0103 1 X COOLANT TEMP SEN EC-84

P0120 0403 1 X ACCEL POS SENSOR EC-89

P0335 0407 1 XCRANK POS SEN

(TDC)EC-99

P0500 0104 1 X VEHICLE SPEED SEN EC-105

P0571 0807 1 X BRAKE SW EC-109

P1107 0802 1 X ECM 10 EC-116

P1180 0402 1 X P9·FUEL TEMP SEN EC-118

P1202 1002 1 X FUEL CUT SYSTEM2 EC-124

P1217 0208 1 X OVER HEAT EC-130

P1241 0707 1 X P7·F/INJ TIMG FB EC-145

P1251 0704 1 X P4·SPILL/V CIRC EC-151

P1337 0702 1 X P2·TDC PULSE SIG EC-157

P1341 0701 1 X P1·CAM POS SEN EC-163

P1600 0703 1 X P3·PUMP COMM LINE EC-169

P1603 0901 1 X ECM 12 EC-175

P1607 0301 1 X ECM 2 EC-175

P1620 0902 1 X ECM RLY EC-177

P1621 0903 1 — ECM 15 EC-181

P1660 0502 1 — BATTERY VOLTAGE EC-183

P1690 0705 1 X P5·PUMP C/MODULE EC-185GI

MA

EM

LC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

TROUBLE DIAGNOSIS — INDEXYD

Alphabetical & P No. Index for DTC (Cont’d)

EC-5

Page 1205 of 3189

SEF437Y

DescriptionNJEC0714SYSTEM DESCRIPTIONNJEC0714S01The ECM and the electronic control fuel injection pump control unit

(abbreviated as the injection pump control unit) perform the real

time communication (signal exchange).

The ECM transmits the signals of the target fuel injection amount,

target fuel injection timing, and engine speed, etc., and receives

the signals of the pump speed and fuel temperature, etc. from the

injection pump control unit.

By those signals, the injection pump controls the optimum fuel

injection amount and injection timing of the spill valve and timing

control valve.

Injection pump control unit has an on board diagnostic system,

which detects malfunctions related to sensors or actuators built-into

electronic control fuel injection pump. These malfunction informa-

tion are transferred through the line (circuit) from injection pump

control unit to ECM.

FUEL INJECTION AMOUNT CONTROLNJEC0714S02In accordance with the target fuel injection amount signal from the

ECM, the injection amount is controlled by controlling the spill valve

in the injection pump and by changing the needle opening time.

FUEL INJECTION TIMING CONTROLNJEC0714S03Based on the target fuel injection timing signal from the ECM, the

injection timing is controlled in accordance with the timer spring by

performing the duty control of the timing control valve in the injec-

tion pump and by adjusting the pressure of the timer piston high

pressure chamber.

FUEL TEMPERATURE SENSORNJEC0714S04The sensor detects the fuel temperature in the injection pump and

calibrates the injection amount change by the fuel temperature.

CAM RING POSITION SENSORNJEC0714S05The sensor detects the passing of the protrusion on the sensor

wheel in the injection pump by the semiconductor magnetic resis-

tance element sensor. The cam ring position sensor synchronizes

with the cam ring, and detects the actual advance amount. The

injection pump control unit measures the injection pump revolution

by the signal of the cam ring position sensor.

CONSULT-II Reference Value in Data Monitor

Mode

NJEC0715Remarks: Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

FUEL TEMP SEN Engine: After warming up More than 40°C (104°F)

SPILL/V Engine: After warming up, idle the engine. Approx. 12 - 13°CA

INT/A VOLUME Engine: After warming up, idle the engine. Approx. 150 - 450 mg/st

F/CUT SIGNAL Engine: After warming up Idle ON

GI

MA

EM

LC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

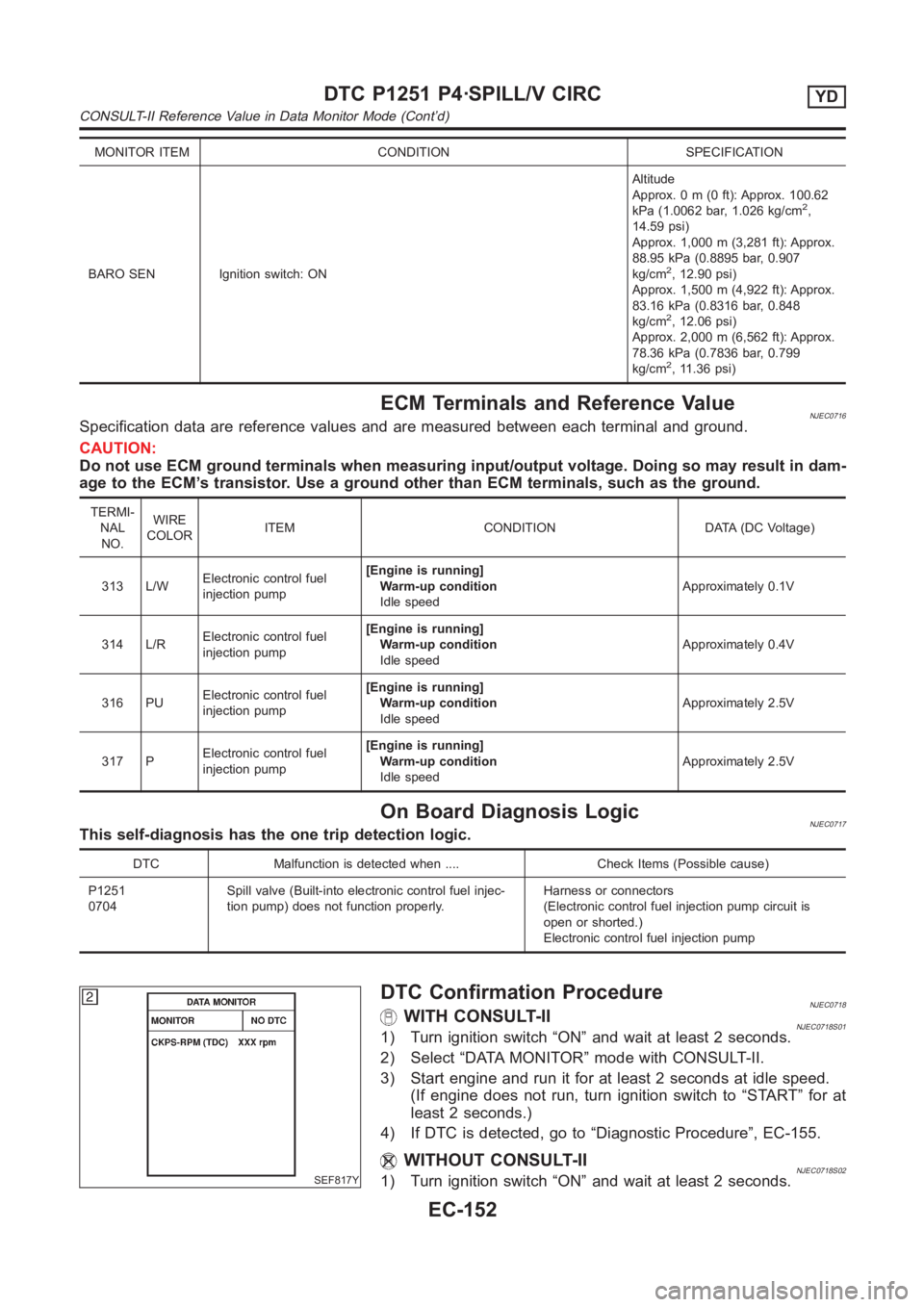

DTC P1251 P4·SPILL/V CIRCYD

Description

EC-151

Page 1206 of 3189

MONITOR ITEM CONDITION SPECIFICATION

BARO SEN Ignition switch: ONAltitude

Approx. 0 m (0 ft): Approx. 100.62

kPa (1.0062 bar, 1.026 kg/cm

2,

14.59 psi)

Approx. 1,000 m (3,281 ft): Approx.

88.95 kPa (0.8895 bar, 0.907

kg/cm

2, 12.90 psi)

Approx. 1,500 m (4,922 ft): Approx.

83.16 kPa (0.8316 bar, 0.848

kg/cm

2, 12.06 psi)

Approx. 2,000 m (6,562 ft): Approx.

78.36 kPa (0.7836 bar, 0.799

kg/cm

2, 11.36 psi)

ECM Terminals and Reference ValueNJEC0716Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may result in dam-

age to the ECM’s transistor. Use a ground other than ECM terminals, such as the ground.

TERMI-

NAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

313 L/WElectronic control fuel

injection pump[Engine is running]

Warm-up condition

Idle speedApproximately 0.1V

314 L/RElectronic control fuel

injection pump[Engine is running]

Warm-up condition

Idle speedApproximately 0.4V

316 PUElectronic control fuel

injection pump[Engine is running]

Warm-up condition

Idle speedApproximately 2.5V

317 PElectronic control fuel

injection pump[Engine is running]

Warm-up condition

Idle speedApproximately 2.5V

On Board Diagnosis LogicNJEC0717This self-diagnosis has the one trip detection logic.

DTC Malfunction is detected when .... Check Items (Possible cause)

P1251

0704Spill valve (Built-into electronic control fuel injec-

tion pump) does not function properly.Harness or connectors

(Electronic control fuel injection pump circuit is

open or shorted.)

Electronic control fuel injection pump

SEF817Y

DTC Confirmation ProcedureNJEC0718WITH CONSULT-IINJEC0718S011) Turn ignition switch “ON” and wait at least 2 seconds.

2) Select “DATA MONITOR” mode with CONSULT-II.

3) Start engine and run it for at least 2 seconds at idle speed.

(If engine does not run, turn ignition switch to “START” for at

least 2 seconds.)

4) If DTC is detected, go to “Diagnostic Procedure”, EC-155.

WITHOUT CONSULT-IINJEC0718S021) Turn ignition switch “ON” and wait at least 2 seconds.

DTC P1251 P4·SPILL/V CIRCYD

CONSULT-II Reference Value in Data Monitor Mode (Cont’d)

EC-152

Page 1207 of 3189

2) Start engine and run it for at least 2 seconds at idle speed.

(If engine does not run, turn ignition switch to “START” for at

least 2 seconds.)

3) Turn ignition switch “OFF”, wait at least 5 seconds and then

turn “ON”.

4) Perform “Diagnostic Test Mode II (Self-diagnostic results)” with

ECM.

5) If DTC is detected, go to “Diagnostic Procedure”, EC-155.

GI

MA

EM

LC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P1251 P4·SPILL/V CIRCYD

DTC Confirmation Procedure (Cont’d)

EC-153

Page 1208 of 3189

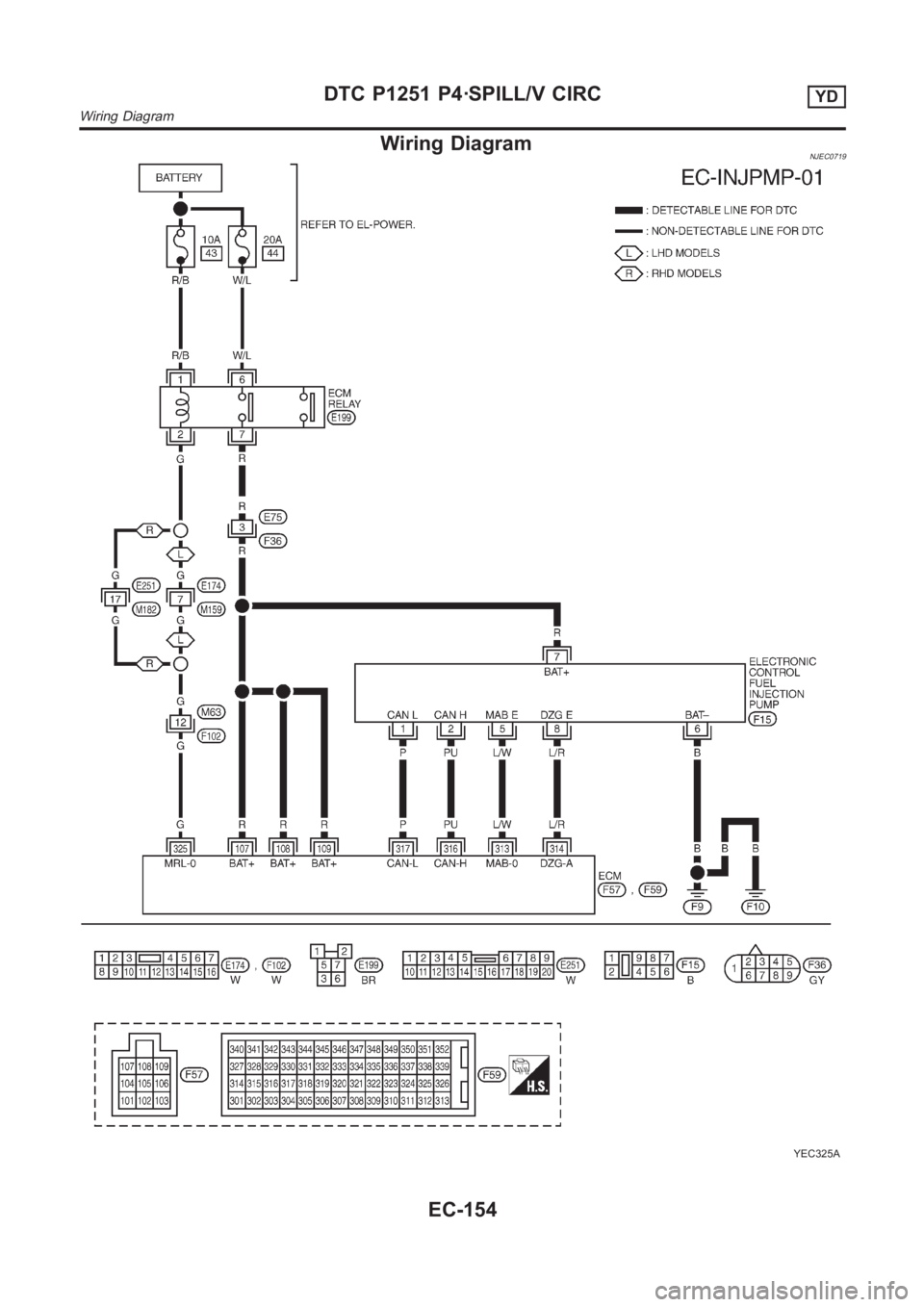

Wiring DiagramNJEC0719

YEC325A

DTC P1251 P4·SPILL/V CIRCYD

Wiring Diagram

EC-154

Page 1209 of 3189

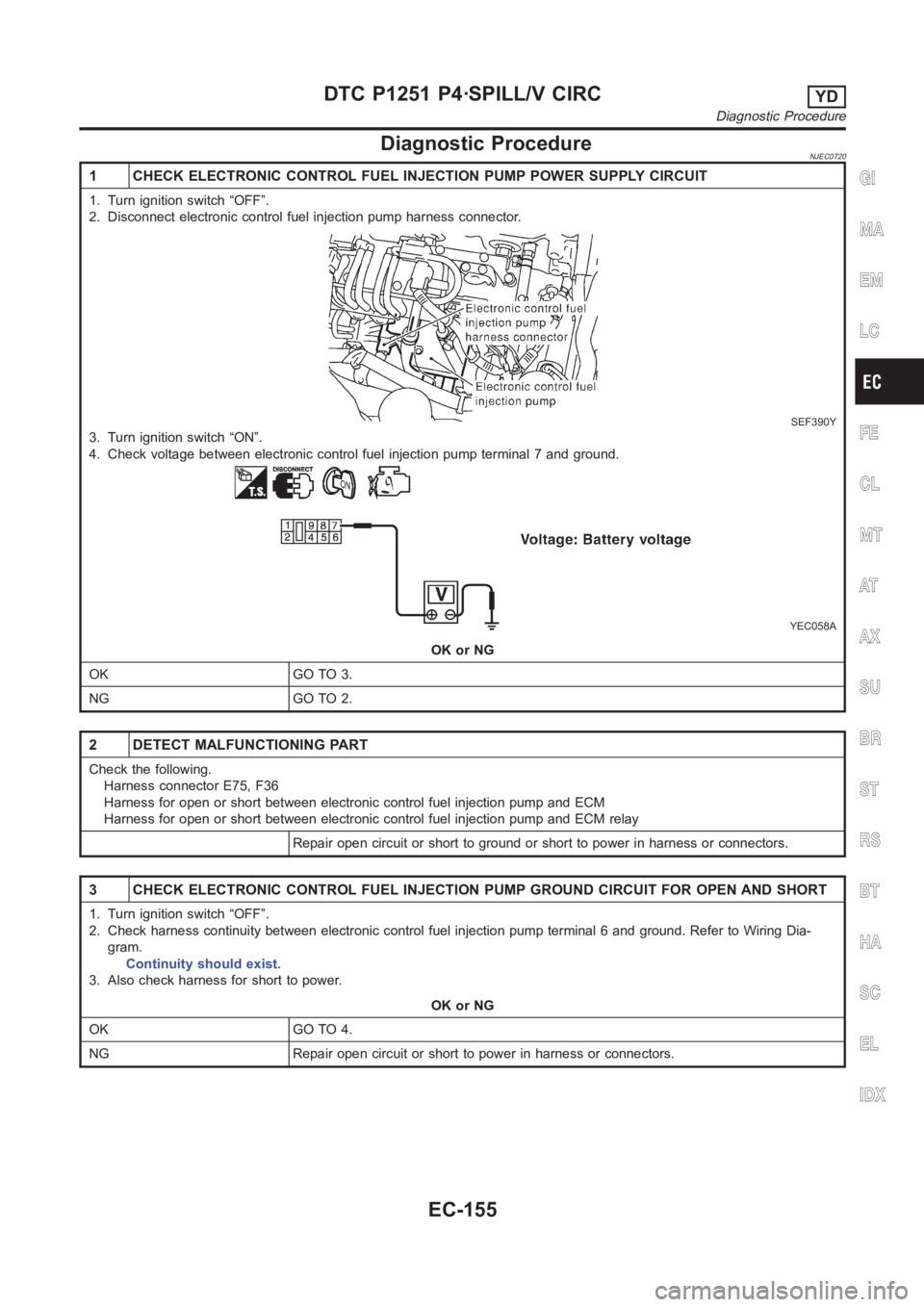

Diagnostic ProcedureNJEC0720

1 CHECK ELECTRONIC CONTROL FUEL INJECTION PUMP POWER SUPPLY CIRCUIT

1. Turn ignition switch “OFF”.

2. Disconnect electronic control fuel injection pump harness connector.

SEF390Y

3. Turn ignition switch “ON”.

4. Check voltage between electronic control fuel injection pump terminal7 and ground.

YEC058A

OK or NG

OK GO TO 3.

NG GO TO 2.

2 DETECT MALFUNCTIONING PART

Check the following.

Harness connector E75, F36

Harness for open or short between electronic control fuel injection pump and ECM

Harness for open or short between electronic control fuel injection pump and ECM relay

Repair open circuit or short to ground or short to power in harness or connectors.

3 CHECK ELECTRONIC CONTROL FUEL INJECTION PUMP GROUND CIRCUIT FOR OPEN ANDSHORT

1. Turn ignition switch “OFF”.

2. Check harness continuity between electronic control fuel injection pump terminal 6 and ground. Refer to Wiring Dia-

gram.

Continuity should exist.

3. Also check harness for short to power.

OK or NG

OK GO TO 4.

NG Repair open circuit or short to power in harness or connectors.

GI

MA

EM

LC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

DTC P1251 P4·SPILL/V CIRCYD

Diagnostic Procedure

EC-155

Page 1210 of 3189

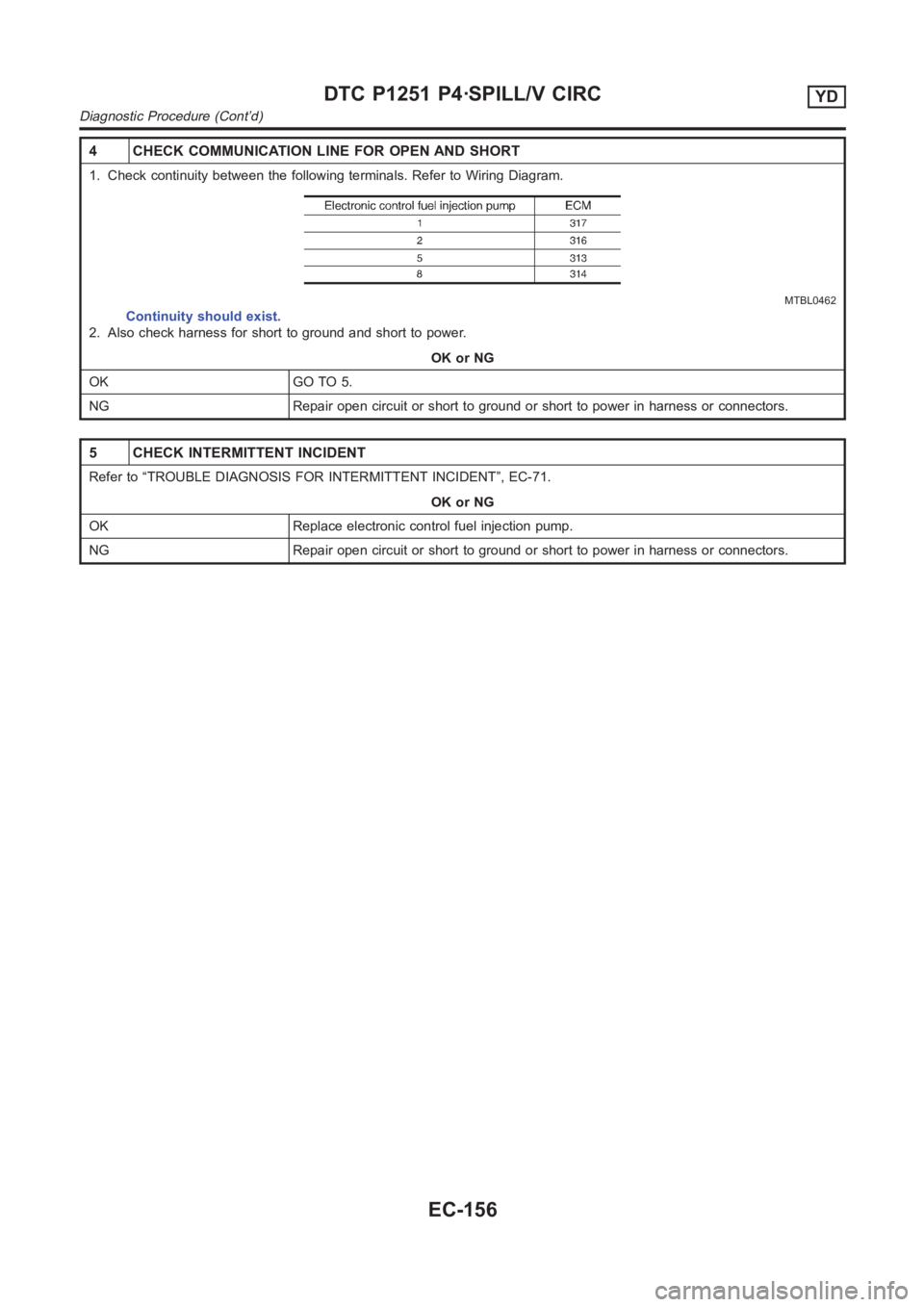

4 CHECK COMMUNICATION LINE FOR OPEN AND SHORT

1. Check continuity between the following terminals. Refer to Wiring Diagram.

MTBL0462

Continuity should exist.

2. Also check harness for short to ground and short to power.

OK or NG

OK GO TO 5.

NG Repair open circuit or short to ground or short to power in harness or connectors.

5 CHECK INTERMITTENT INCIDENT

Refer to “TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT”, EC-71.

OK or NG

OK Replace electronic control fuel injection pump.

NG Repair open circuit or short to ground or short to power in harness or connectors.

DTC P1251 P4·SPILL/V CIRCYD

Diagnostic Procedure (Cont’d)

EC-156