position sensor NISSAN ALMERA N16 2003 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2003, Model line: ALMERA N16, Model: NISSAN ALMERA N16 2003Pages: 3189, PDF Size: 54.76 MB

Page 5 of 3189

PrecautionsNJGI0001Observe the following precautions to ensure safe and proper

servicing. These precautions are not described in each indi-

vidual section.

SGI646

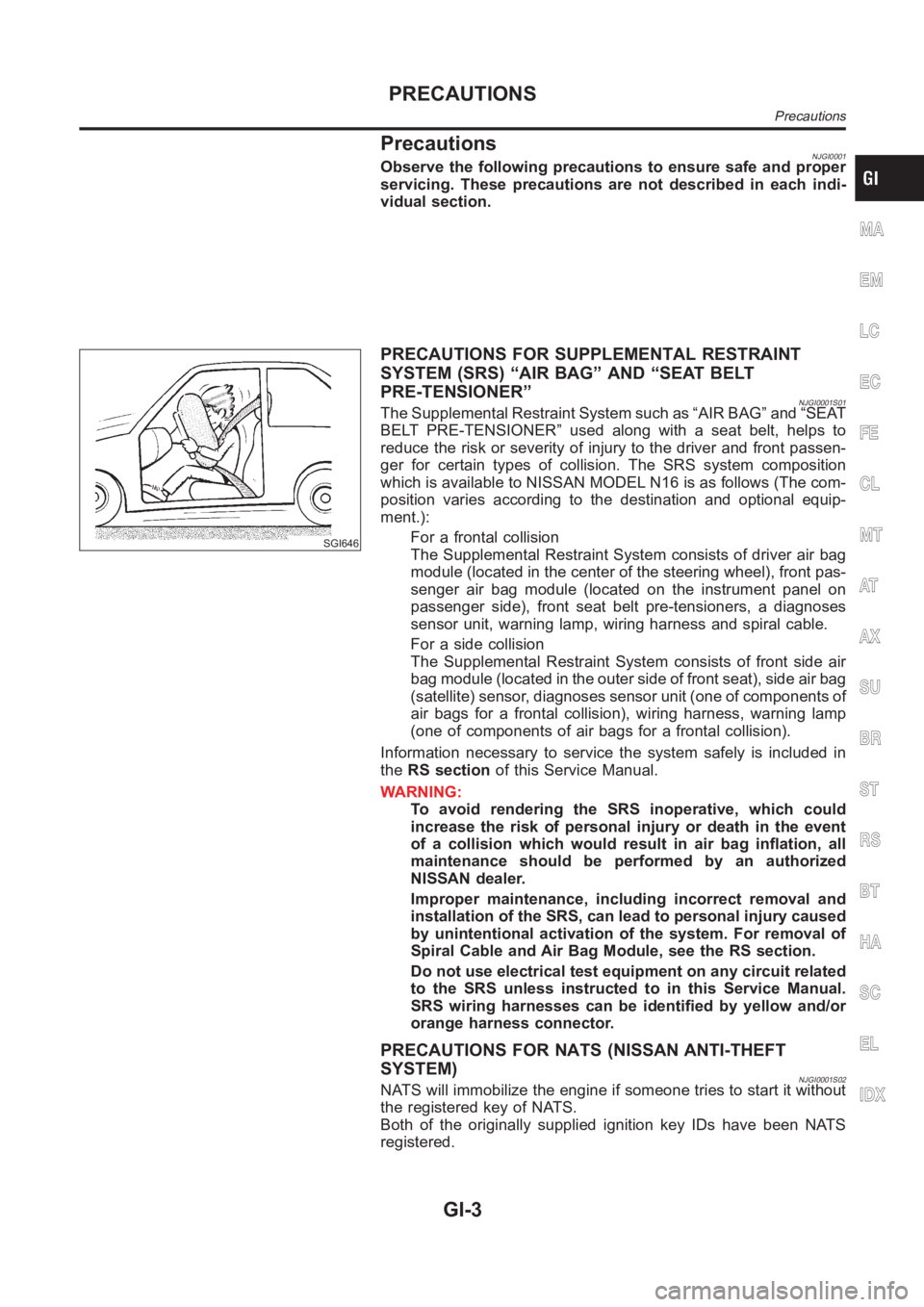

PRECAUTIONS FOR SUPPLEMENTAL RESTRAINT

SYSTEM (SRS) “AIR BAG” AND “SEAT BELT

PRE-TENSIONER”

NJGI0001S01The Supplemental Restraint System such as “AIR BAG” and “SEAT

BELT PRE-TENSIONER” used along with a seat belt, helps to

reduce the risk or severity of injury to the driver and front passen-

ger for certain types of collision. The SRS system composition

which is available to NISSAN MODEL N16 is as follows (The com-

position varies according to the destination and optional equip-

ment.):

For a frontal collision

The Supplemental Restraint System consists of driver air bag

module (located in the center of the steering wheel), front pas-

senger air bag module (located on the instrument panel on

passenger side), front seat belt pre-tensioners, a diagnoses

sensor unit, warning lamp, wiring harness and spiral cable.

For a side collision

The Supplemental Restraint System consists of front side air

bag module (located in the outer side of front seat), side air bag

(satellite) sensor, diagnoses sensor unit (one of components of

air bags for a frontal collision), wiring harness, warning lamp

(one of components of air bags for a frontal collision).

Information necessary to service the system safely is included in

theRS sectionof this Service Manual.

WARNING:

To avoid rendering the SRS inoperative, which could

increase the risk of personal injury or death in the event

of a collision which would result in air bag inflation, all

maintenance should be performed by an authorized

NISSAN dealer.

Improper maintenance, including incorrect removal and

installation of the SRS, can lead to personal injury caused

by unintentional activation of the system. For removal of

Spiral Cable and Air Bag Module, see the RS section.

Do not use electrical test equipment on any circuit related

to the SRS unless instructed to in this Service Manual.

SRS wiring harnesses can be identified by yellow and/or

orange harness connector.

PRECAUTIONS FOR NATS (NISSAN ANTI-THEFT

SYSTEM)

NJGI0001S02NATS will immobilize the engine if someone tries to start it without

the registered key of NATS.

Both of the originally supplied ignition key IDs have been NATS

registered.

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

PRECAUTIONS

Precautions

GI-3

Page 8 of 3189

Do not attempt to top off the fuel tank after the fuel pump nozzle

shuts off automatically. Continued refueling may cause fuel

overflow, resulting in fuel spray and possibly a fire.

WARNING:

To prevent ECM from storing the diagnostic trouble codes, do

not carelessly disconnect the harness connectors which are

related to the engine control system and TCM (Transmission

Control Module) system. The connectors should be discon-

nected only when working according to the WORK FLOW of

TROUBLE DIAGNOSES in EC and AT sections.

SGI787

PRECAUTIONS FOR MULTIPORT FUEL INJECTION

SYSTEM OR ENGINE CONTROL SYSTEM

NJGI0001S04Before connecting or disconnecting any harness connector for

the multiport fuel injection system or ECM:

Turn ignition switch to “OFF” position.

Disconnect negative battery terminal.

Otherwise, there may be damage to ECM.

Before disconnecting pressurized fuel line from fuel pump to

injectors, be sure to release fuel pressure.

Be careful not to jar components such as ECM and mass air

flow sensor.

PRECAUTIONS FOR THREE WAY CATALYSTNJGI0001S05If a large amount of unburned fuel flows into the catalyst, the cata-

lyst temperature will be excessively high. To prevent this, follow the

instructions below:

Use unleaded gasoline only. Leaded gasoline will seriously

damage the three way catalyst.

When checking for ignition spark or measuring engine

compression, make tests quickly and only when necessary.

Do not run engine when the fuel tank level is low, otherwise the

engine may misfire, causing damage to the catalyst.

Do not place the vehicle on flammable material. Keep flammable

material off the exhaust pipe and the three way catalyst.

SMA019D

PRECAUTIONS FOR HOSESNJGI0001S06Hose Removal and InstallationNJGI0001S0601To prevent damage to rubber hose, do not pry off rubber hose

with tapered tool or screwdriver.

PRECAUTIONS

Precautions (Cont’d)

GI-6

Page 53 of 3189

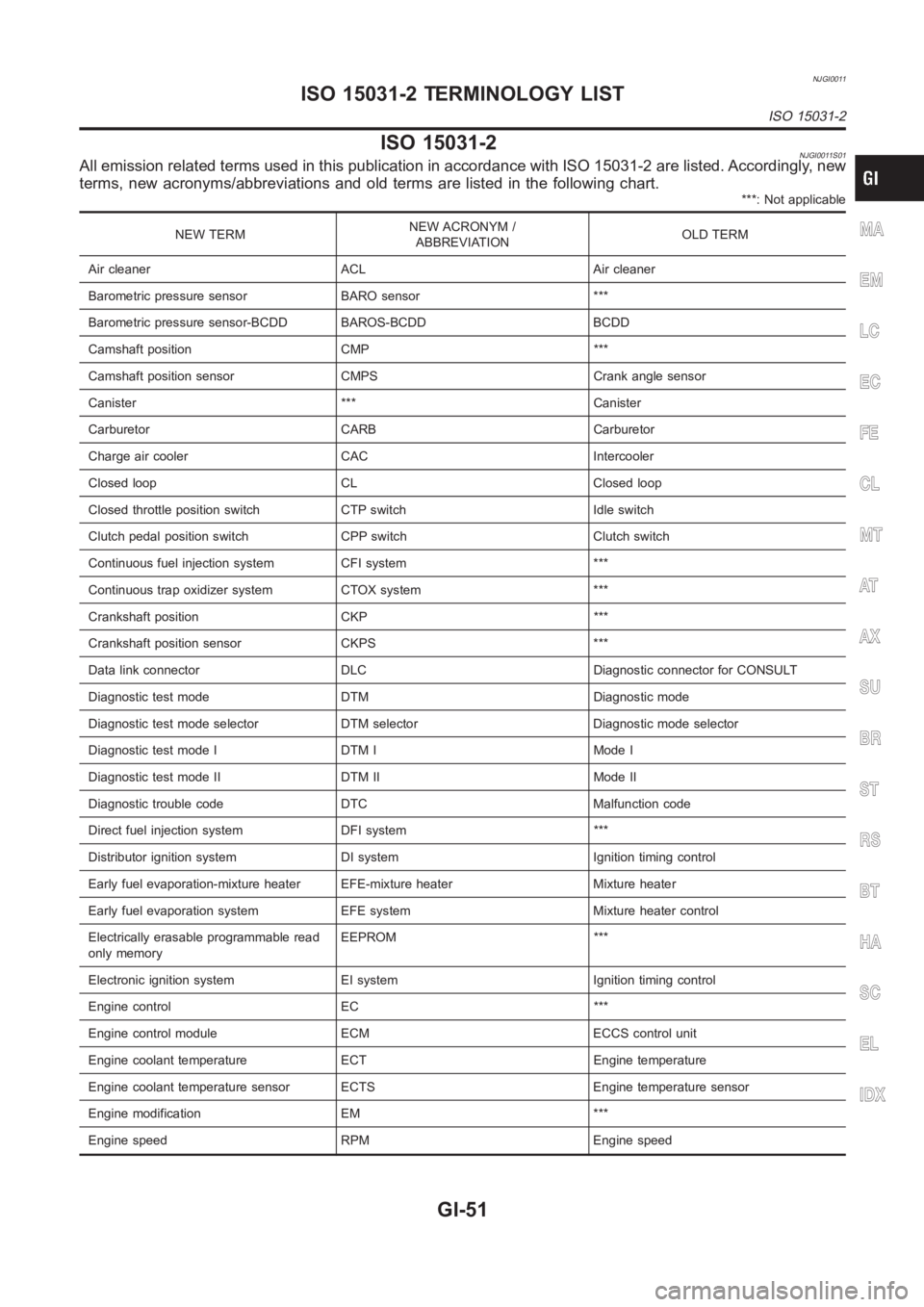

NJGI0011

ISO 15031-2NJGI0011S01All emission related terms used in this publication in accordance with ISO15031-2 are listed. Accordingly, new

terms, new acronyms/abbreviations and old terms are listed in the following chart.

***: Not applicable

NEW TERMNEW ACRONYM /

ABBREVIATIONOLD TERM

Air cleaner ACL Air cleaner

Barometric pressure sensor BARO sensor ***

Barometric pressure sensor-BCDD BAROS-BCDD BCDD

Camshaft position CMP ***

Camshaft position sensor CMPS Crank angle sensor

Canister *** Canister

Carburetor CARB Carburetor

Charge air cooler CAC Intercooler

Closed loop CL Closed loop

Closed throttle position switch CTP switch Idle switch

Clutch pedal position switch CPP switch Clutch switch

Continuous fuel injection system CFI system ***

Continuous trap oxidizer system CTOX system ***

Crankshaft position CKP ***

Crankshaft position sensor CKPS ***

Data link connector DLC Diagnostic connector for CONSULT

Diagnostic test mode DTM Diagnostic mode

Diagnostic test mode selector DTM selector Diagnostic mode selector

Diagnostic test mode I DTM I Mode I

Diagnostic test mode II DTM II Mode II

Diagnostic trouble code DTC Malfunction code

Direct fuel injection system DFI system ***

Distributor ignition system DI system Ignition timing control

Early fuel evaporation-mixture heater EFE-mixture heater Mixture heater

Early fuel evaporation system EFE system Mixture heater control

Electrically erasable programmable read

only memoryEEPROM ***

Electronic ignition system EI system Ignition timing control

Engine control EC ***

Engine control module ECM ECCS control unit

Engine coolant temperature ECT Engine temperature

Engine coolant temperature sensor ECTS Engine temperature sensor

Engine modification EM ***

Engine speed RPM Engine speedMA

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ISO 15031-2 TERMINOLOGY LIST

ISO 15031-2

GI-51

Page 55 of 3189

NEW TERMNEW ACRONYM /

ABBREVIATIONOLD TERM

Malfunction indicator MI Check engine light

Manifold absolute pressure MAP ***

Manifold absolute pressure sensor MAPS ***

Manifold differential pressure MDP ***

Manifold differential pressure sensor MDPS ***

Manifold surface temperature MST ***

Manifold surface temperature sensor MSTS ***

Manifold vacuum zone MVZ ***

Manifold vacuum zone sensor MVZS ***

Mass air flow sensor MAFS Air flow meter

Mixture control solenoid valve MC solenoid valve Air-fuel ratio control solenoid valve

Multiport fuel injection system MFI system Fuel injection control

Nonvolatile random access memory NVRAM ***

On board diagnostic system OBD system Self-diagnoses

Open loop OL Open loop

Oxidation catalyst OC Catalyst

Oxidation catalytic converter system OC system ***

Oxygen sensor O2S Exhaust gas sensor

Park position switch *** Park switch

Park/neutral position switch PNP switch Park/neutral switch

Inhibitor switch

Neutral position switch

Periodic trap oxidizer system PTOX system ***

Positive crankcase ventilation PCV Positive crankcase ventilation

Positive crankcase ventilation valve PCV valve PCV valve

Powertrain control module PCM ***

Programmable read only memory PROM ***

Pulsed secondary air injection control

solenoid valvePAIRC solenoid valve AIV control solenoid valve

Pulsed secondary air injection system PAIR system Air induction valve (AIV) control

Pulsed secondary air injection valve PAIR valve Air induction valve

Random access memory RAM ***

Read only memory ROM ***

Scan tool ST ***

Secondary air injection pump AIR pump ***

Secondary air injection system AIR system ***

Sequential multiport fuel injection system SFI system Sequential fuel injection

Service reminder indicator SRI ***

MA

EM

LC

EC

FE

CL

MT

AT

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

ISO 15031-2 TERMINOLOGY LIST

ISO 15031-2 (Cont’d)

GI-53

Page 56 of 3189

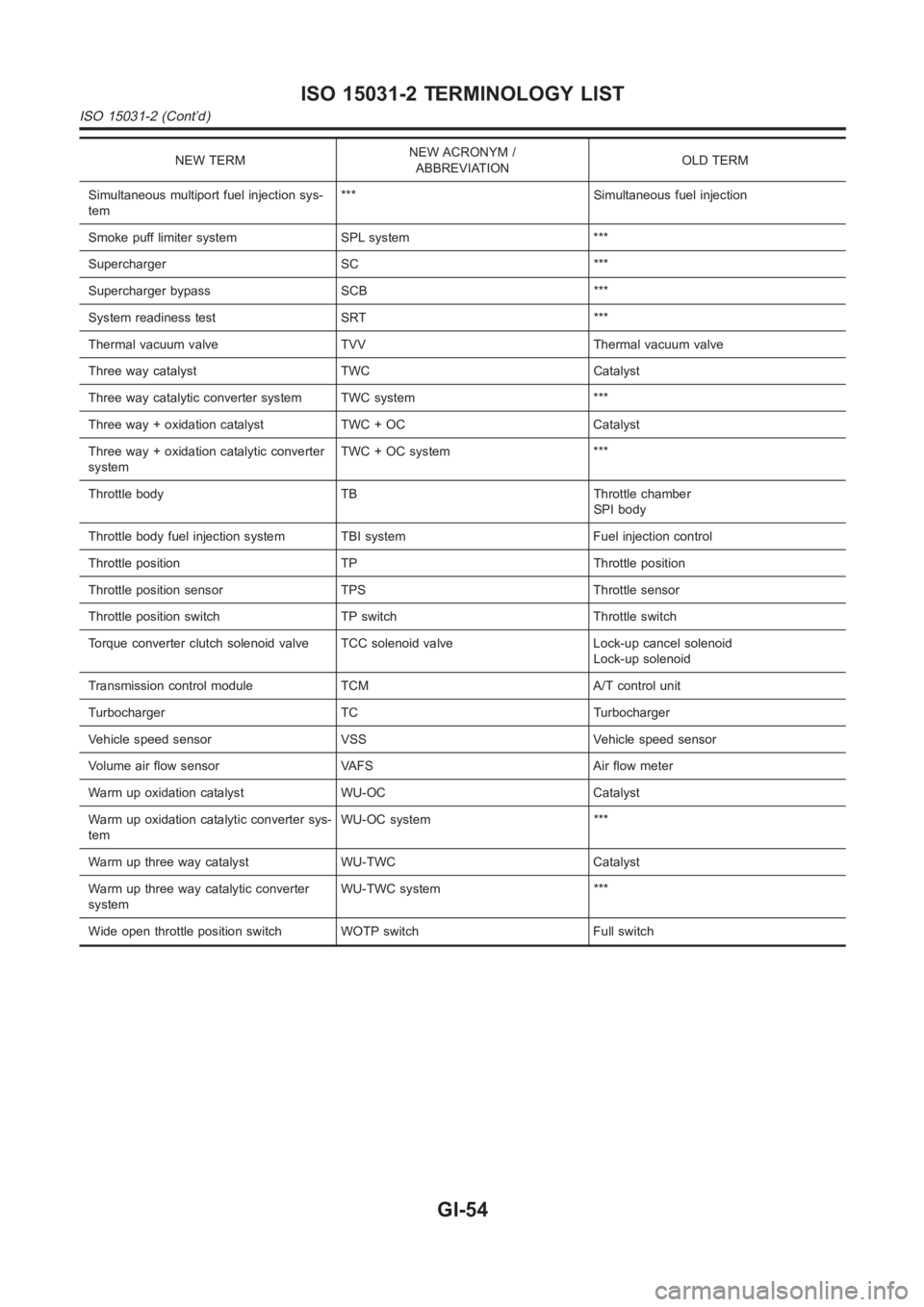

NEW TERMNEW ACRONYM /

ABBREVIATIONOLD TERM

Simultaneous multiport fuel injection sys-

tem*** Simultaneous fuel injection

Smoke puff limiter system SPL system ***

Supercharger SC ***

Supercharger bypass SCB ***

System readiness test SRT ***

Thermal vacuum valve TVV Thermal vacuum valve

Three way catalyst TWC Catalyst

Three way catalytic converter system TWC system ***

Three way + oxidation catalyst TWC + OC Catalyst

Three way + oxidation catalytic converter

systemTWC + OC system ***

Throttle body TB Throttle chamber

SPI body

Throttle body fuel injection system TBI system Fuel injection control

Throttle position TP Throttle position

Throttle position sensor TPS Throttle sensor

Throttle position switch TP switch Throttle switch

Torque converter clutch solenoid valve TCC solenoid valve Lock-up cancelsolenoid

Lock-up solenoid

Transmission control module TCM A/T control unit

Turbocharger TC Turbocharger

Vehicle speed sensor VSS Vehicle speed sensor

Volume air flow sensor VAFS Air flow meter

Warm up oxidation catalyst WU-OC Catalyst

Warm up oxidation catalytic converter sys-

temWU-OC system ***

Warm up three way catalyst WU-TWC Catalyst

Warm up three way catalytic converter

systemWU-TWC system ***

Wide open throttle position switch WOTP switch Full switch

ISO 15031-2 TERMINOLOGY LIST

ISO 15031-2 (Cont’d)

GI-54

Page 107 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual ROCKER COVER

EM-29

[QG]

C

D

E

F

G

H

I

J

K

L

MA

EM

ROCKER COVERPFP:13264

Removal and InstallationEBS00LQA

CAUTION:

Apply new engine oil when installing the parts that specified to do so in the figure.

NISSAN ALMERA N16 2003 Electronic Repair Manual ROCKER COVER

EM-29

[QG]

C

D

E

F

G

H

I

J

K

L

MA

EM

ROCKER COVERPFP:13264

Removal and InstallationEBS00LQA

CAUTION:

Apply new engine oil when installing the parts that specified to do so in the figure.](/img/5/57350/w960_57350-106.png)

ROCKER COVER

EM-29

[QG]

C

D

E

F

G

H

I

J

K

L

MA

EM

ROCKER COVERPFP:13264

Removal and InstallationEBS00LQA

CAUTION:

Apply new engine oil when installing the parts that specified to do so in the figure.

REMOVAL

1. Move harnesses on top surface and right side of rocker cover, and move them aside.

2. Remove ignition coil. Refer to EM-24, "

Removal and Installation" .

3. Disconnect PCV hoses on rocker cover side.

4. If necessary, remove PCV control valve.

5. If necessary, remove intake valve timing control solenoid valve and camshaft position sensor (PHASE).

CAUTION:

●Do not shock it.

●Do not disassemble it.

●Tip of camshaft position sensor (PHASE) generates strong magnetic fields. Keep it away from

metal particles or objects affected by magnetic fields.

KBIA1375E

1. PCV hose 2. Rocker cover 3. Grommet

4. PCV control valve 5. PCV hose 6.Intake valve timing control solenoid

valve

7. O-ring 8. Oil filter cap 9. Gasket

10. Gasket 11. Rocker cover oil seal 12. Gasket

13. O-ring 14. Camshaft position sensor (PHASE)

Page 109 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual ROCKER COVER

EM-31

[QG]

C

D

E

F

G

H

I

J

K

L

MA

EM

d. Tighten mounting screws to specified torque in 2 or more steps

in numerical order shown in figure.

3. Install intake valve timing control NISSAN ALMERA N16 2003 Electronic Repair Manual ROCKER COVER

EM-31

[QG]

C

D

E

F

G

H

I

J

K

L

MA

EM

d. Tighten mounting screws to specified torque in 2 or more steps

in numerical order shown in figure.

3. Install intake valve timing control](/img/5/57350/w960_57350-108.png)

ROCKER COVER

EM-31

[QG]

C

D

E

F

G

H

I

J

K

L

MA

EM

d. Tighten mounting screws to specified torque in 2 or more steps

in numerical order shown in figure.

3. Install intake valve timing control solenoid valve and camshaft position sensor (PHASE).

●Tighten bolt after fully inserting it into rocker cover.

4. Install PCV valve.

●Insert until flange contacts grommet tightly.

5. Install remaining parts in the reverse order of removal.Bolt length: Bolt position

25 mm (0.98 in) : 1

65 mm (2.56 in) : 2

20 mm (0.79 in) : Except the above (all circumference)

KBIA1376E

Page 146 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual EM-68

[QG]

ENGINE ASSEMBLY

WARNING:

●Position vehicle on a flat and solid surface.

●Place chocks at front and back of rear wheels.

●Do not remove engine until exhaust system has complete NISSAN ALMERA N16 2003 Electronic Repair Manual EM-68

[QG]

ENGINE ASSEMBLY

WARNING:

●Position vehicle on a flat and solid surface.

●Place chocks at front and back of rear wheels.

●Do not remove engine until exhaust system has complete](/img/5/57350/w960_57350-145.png)

EM-68

[QG]

ENGINE ASSEMBLY

WARNING:

●Position vehicle on a flat and solid surface.

●Place chocks at front and back of rear wheels.

●Do not remove engine until exhaust system has completely cooled off, otherwise, you may burn

yourself and/or fire may break out in fuel line.

●Before disconnecting fuel hose, release pressure.

Refer to EC-34 (WITH EURO-OBD), EC-428 (WITHOUT EURO-OBD).

●Be sure to lift engine and transaxle in a safe manner.

●For engines not equipped with engine slingers, attach proper slingers and bolts described in

PARTS CATALOG.

CAUTION:

●When lifting engine, be sure to clear surrounding parts. Use special care near accelerator wire

casing, brake lines and brake master cylinder.

●When lifting the engine, always use engine slingers in a safe manner.

●When removing drive shaft, be careful not to damage grease seal of transaxle.

●Before separating engine and transaxle, remove crankshaft position sensor (POS) from the cylin-

der block assembly.

●Always be extra careful not to damage edge of crankshaft position sensor (POS), or signal plate

teeth.

Engine cannot be removed separately from transaxle. Remove engine with transaxle as an assembly.

REMOVAL

1. Drain coolant from radiator and cylinder block. Refer to LC-17, "Chacking Engine Coolant".

2. Remove coolant reservoir tank and bracket.

3. Drain engine oil.

4. Remove battery and battery tray.

5. Remove air cleaner and air duct.

6. Remove drive belts.

7. Remove alternator and air conditioner compressor from engine.

8. Remove power steering oil pump from engine and position aside.

Power steering oil pump does not need to be disconnected from power steering tubes.

9. Remove the following parts:

●RH and LH front tires

●Splash covers

●RH and LH brake caliper assemblies

Refer to BR-28,"Removal".

Brake hose does not need to be disconnected from brake

caliper assembly. Never depress brake pedal.

●RH & LH drive shaft. Refer to AX-11, "Removal".

When removing drive shaft, be careful not to damage

transaxle side grease seal.

●Disconnect control rod and support rod from transaxle. (M/T

models.)

Refer to MT-26, "Removal".

●Disconnect control cable from transaxle. (A/T models.)

Refer to AT-411, "Removal".

SEM174D

SEM109G

Page 149 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual CYLINDER BLOCK

EM-71

[QG]

C

D

E

F

G

H

I

J

K

L

MA

EM

CAUTION:

Apply new engine oil to parts marked in illustration before installation.

DISASSEMBLY

1. Remove engine and transaxle assembly from vehicle, NISSAN ALMERA N16 2003 Electronic Repair Manual CYLINDER BLOCK

EM-71

[QG]

C

D

E

F

G

H

I

J

K

L

MA

EM

CAUTION:

Apply new engine oil to parts marked in illustration before installation.

DISASSEMBLY

1. Remove engine and transaxle assembly from vehicle,](/img/5/57350/w960_57350-148.png)

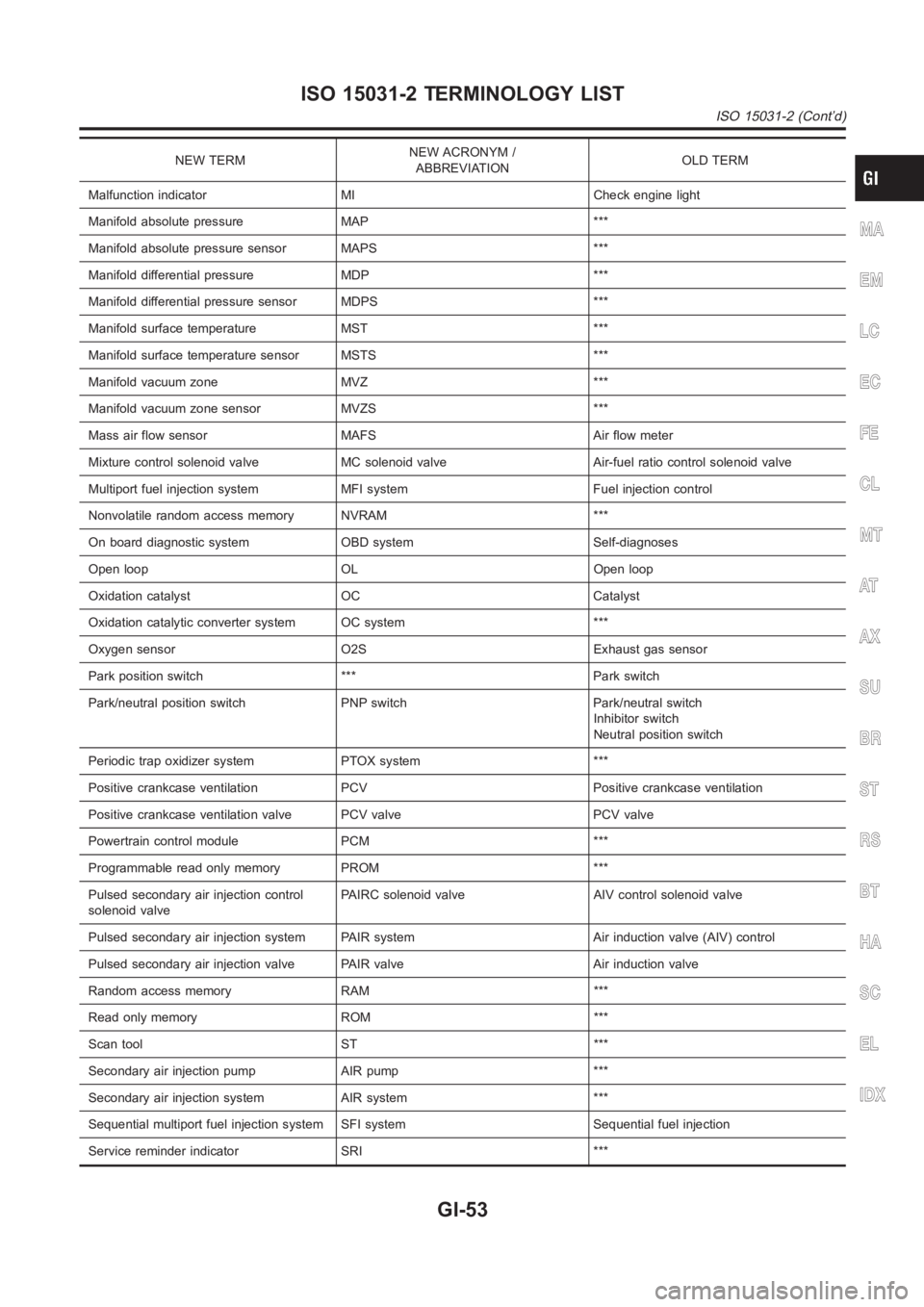

CYLINDER BLOCK

EM-71

[QG]

C

D

E

F

G

H

I

J

K

L

MA

EM

CAUTION:

Apply new engine oil to parts marked in illustration before installation.

DISASSEMBLY

1. Remove engine and transaxle assembly from vehicle, and separate transaxle from engine. Refer to EM-

67, "ENGINE ASSEMBLY" .

2. Mount engine on an engine stand with the following procedure.

a. Remove exhaust manifold and catalytic converter. Refer to EM-19, "

EXHAUST MANIFOLD AND CATA-

LYTIC CONVERTER" .

b. Remove engine front mounting bracket, alternator and air compressor bracket.

c. Install engine sub-attachment to left side of cylinder block.

d. Lift engine, and mount it onto the engine stand.

1. Rear oil seal 2. Rear oil seal retainer 3. Crankshaft position sensor (POS)

4. O-ring 5. Knock sensor 6. Oil level gauge guide

7. Cylinder block 8. Thrust bearing 9. Main bearing

10. Crankshaft 11. Key 12. Top ring

13. 2nd ring 14. Oil ring 15. Main bearing

16. Piston 17. Snap ring 18. Piston pin

19. Connecting rod 20. Connecting rod bearing 21. Connecting rod cap

22. Connecting rod nut 23. Main bearing cap bolt 24. Baffle plate

25. Main bearing cap 26. Signal plate 27. Rear plate

28. Coolant drain plug 29. Flywheel (M/T models) 30. Drive plate (A/T models)

PBIC0585E

PBIC1017E

Page 150 of 3189

![NISSAN ALMERA N16 2003 Electronic Repair Manual EM-72

[QG]

CYLINDER BLOCK

●A commercial engine stand can be used.

NOTE:

●This example is an engine stand for holding at transaxle

mounting side with the flywheel or drive plate removed.

3 NISSAN ALMERA N16 2003 Electronic Repair Manual EM-72

[QG]

CYLINDER BLOCK

●A commercial engine stand can be used.

NOTE:

●This example is an engine stand for holding at transaxle

mounting side with the flywheel or drive plate removed.

3](/img/5/57350/w960_57350-149.png)

EM-72

[QG]

CYLINDER BLOCK

●A commercial engine stand can be used.

NOTE:

●This example is an engine stand for holding at transaxle

mounting side with the flywheel or drive plate removed.

3. Drain engine oil and coolant from inside of engine.

4. Remove the following components and associated parts.

●Fuel tube and injector assembly; Refer to EM-26, "Removal and Installation" .

●Intake manifold and intake manifold collector assembly; Refer to EM-16, "Removal and Installation" .

●Ignition coil; Refer to EM-24, "Removal and Installation" .

●Rocker cover; Refer to EM-29, "Removal and Installation" .

●Oil pan and oil strainer; Refer to EM-22, "Removal and Installation" .

●Front cover and timing chain; Refer to EM-47, "Removal and Installation" .

●Camshaft; Refer to EM-32, "Removal and Installation" .

●Cylinder head assembly; Refer to EM-58, "Removal and Installation" .

●Auxiliary brackets and oil filter

5. Remove knock sensor.

CAUTION:

Avoid impacts such as a dropping.

6. Remove crankshaft position sensor (POS).

CAUTION:

●Avoid impacts such as a dropping.

●Do not disassemble.

●Keep it away from metal particles.

●Do not place sensor close to magnetic materials.

7. Remove flywheel (M/T models) or drive plate (A/T models). Fix

crankshaft with a ring gear stopper (special service tool), and

remove mounting bolts.

8. Remove rear plate.

9. Remove rear oil seal retainer.

●Insert a flat-bladed screwdriver between main bearing cap

and rear oil seal retainer to remove retainer.

10. Remove rear oil seal from rear oil seal retainer.

●Punch out with a flat-bladed screwdriver.

CAUTION:

●Be careful not to damage rear oil seal retainer.

PBIC0085E

PBIC0586E

SEM880F