brake NISSAN ALMERA TINO 2001 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA TINO, Model: NISSAN ALMERA TINO 2001Pages: 3051, PDF Size: 46.38 MB

Page 44 of 3051

Diagnostic Worksheet=NLAT0023S0102

1.NRead the Fail-safe and listen to customer complaints. AT-7

2.NCHECK CVT FLUIDAT-51

NLeakage (Follow specified procedure)

NFluid condition

NFluid level

3.NPerform STALL TEST and LINE PRESSURE TEST. AT-51, 52

NStall test Ð Mark possible damaged components/others.

NForward clutchNReverse brake

NEngine

NLine pressure is low.

NLine Pressure test Ð Suspected parts:

4.NPerform all ROAD TEST and mark required procedures. AT-53

4-1. Check before engine is started.AT-54

NSELF-DIAGNOSTIC PROCEDURE Ð Mark detected items.

NPNP switch, AT-66.

NCVT fluid temperature sensor circuit, AT-73.

NVehicle speed sensor (Output pulley speed signal), AT-84.

NEngine speed signal, AT-90.

NTorque converter clutch solenoid valve, AT-94.

NLine pressure solenoid valve, AT-99.

NStep motor, AT-112, 117.

NLine pressure sensor, AT-119.

NThrottle position sensor, AT-104.

NPrimary speed sensor, AT-79.

NCVT SAFE FUNCTION, AT-125.

NCONTROL UNIT (RAM) CONTROL UNIT (ROM), AT-180.

NCONTROL UNIT (EEP ROM), AT-182.

NPNP switch, stop lamp switch, throttle position switch, AT-184.

NBattery

NOthers

5.NFor self-diagnosis NG items, inspect each component. Repair or replace the damaged parts. AT-22

6.NPerform all ROAD TEST and re-mark required procedures. AT-53

7.NPerform the Diagnostic Procedures for all remaining items marked NG. Repair or replace the damaged

parts.AT-58

AT-70

8.NErase DTC from TCM and ECM memories. AT-19

TROUBLE DIAGNOSIS Ð INTRODUCTIONEURO-OBD

Introduction (Cont'd)

AT-43

Page 49 of 3051

Diagnostic Worksheet=NLAT0247S0102

1.NRead the Fail-safe and listen to customer complaints. AT-7

2.NCHECK CVT FLUIDAT-51

NLeakage (Follow specified procedure)

NFluid condition

NFluid level

3.NPerform STALL TEST and LINE PRESSURE TEST. AT-51, 52

NStall test Ð Mark possible damaged components/others.

NForward clutchNReverse brake

NEngine

NLine pressure is low.

NLine Pressure test Ð Suspected parts:

4.NPerform all ROAD TEST and mark required procedures. AT-53

4-1. Check before engine is started.AT-54

NSELF-DIAGNOSTIC PROCEDURE Ð Mark detected items.

NCVT fluid temperature sensor, AT-170.

NVehicle speed sensor (Output pulley speed signal), AT-126.

NEngine speed signal, AT-176.

NTorque converter clutch solenoid valve, AT-164.

NLine pressure solenoid valve, AT-157.

NStep motor, AT-146, 150.

NLine pressure sensor, AT-151.

NThrottle position sensor, AT-137.

NPrimary speed sensor, AT-132.

NCVT save function, AT-125

NControl unit (RAM), control unit (ROM), AT-180

NControl unit (EEP ROM), AT-182

NBattery

NOthers

5.NFor self-diagnosis NG items, inspect each component. Repair or replace the damaged parts. AT-31

6.NPerform all ROAD TEST and re-mark required procedures. AT-53

7.NPerform the Diagnostic Procedures for all remaining items marked NG. Repair or replace the damaged

parts.AT-58

AT-130

8.NErase self-diagnosis code from TCM memories. AT-34

TROUBLE DIAGNOSIS Ð

INTRODUCTION

EXCEPT FOR EURO-OBD

Introduction (Cont'd)

AT-48

Page 52 of 3051

SAT767B

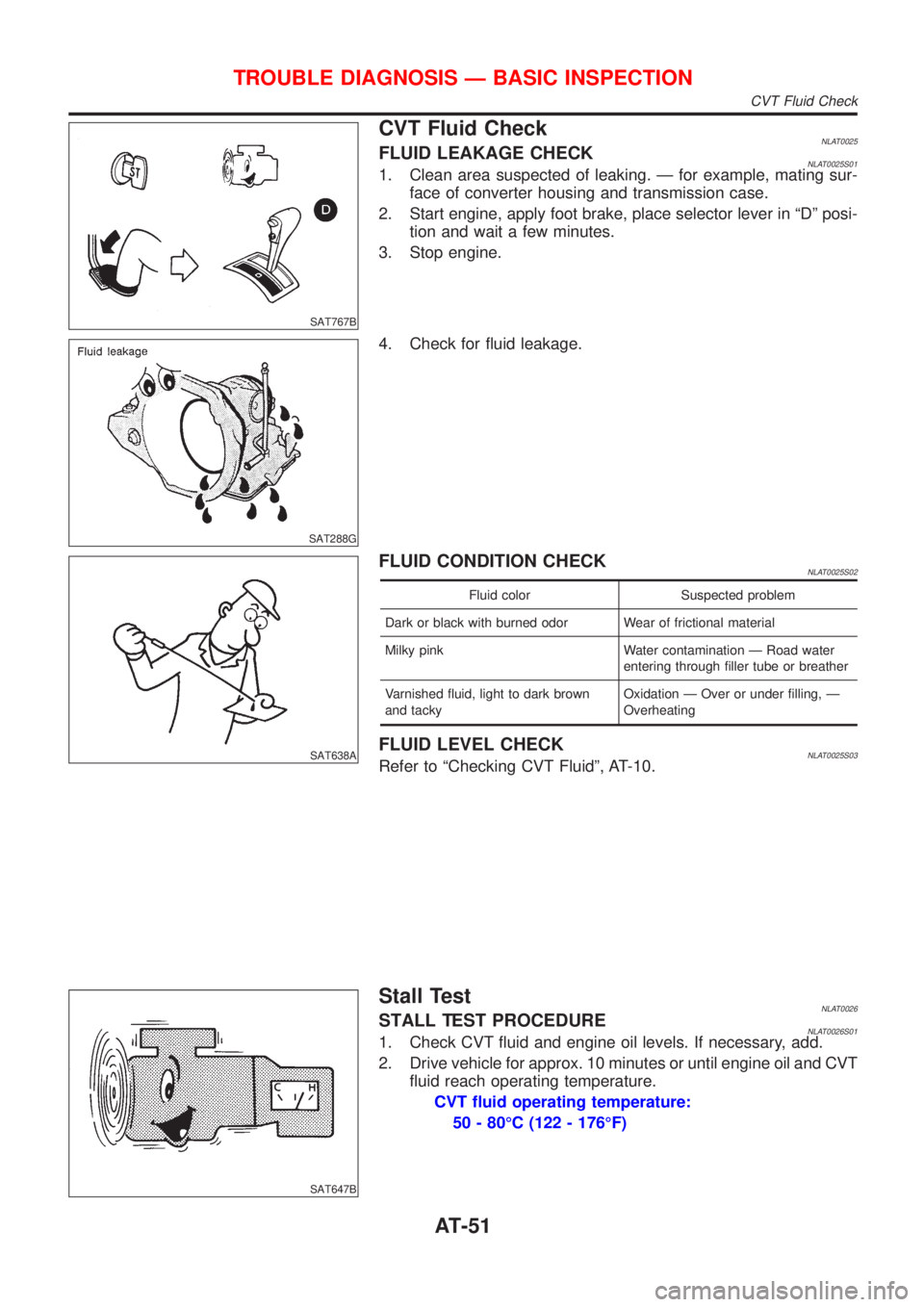

CVT Fluid CheckNLAT0025FLUID LEAKAGE CHECKNLAT0025S011. Clean area suspected of leaking. Ð for example, mating sur-

face of converter housing and transmission case.

2. Start engine, apply foot brake, place selector lever in ªDº posi-

tion and wait a few minutes.

3. Stop engine.

SAT288G

4. Check for fluid leakage.

SAT638A

FLUID CONDITION CHECKNLAT0025S02

Fluid color Suspected problem

Dark or black with burned odor Wear of frictional material

Milky pink Water contamination Ð Road water

entering through filler tube or breather

Varnished fluid, light to dark brown

and tackyOxidation Ð Over or under filling, Ð

Overheating

FLUID LEVEL CHECKNLAT0025S03Refer to ªChecking CVT Fluidº, AT-10.

SAT647B

Stall TestNLAT0026STALL TEST PROCEDURENLAT0026S011. Check CVT fluid and engine oil levels. If necessary, add.

2. Drive vehicle for approx. 10 minutes or until engine oil and CVT

fluid reach operating temperature.

CVT fluid operating temperature:

50 - 80ÉC (122 - 176ÉF)

TROUBLE DIAGNOSIS Ð BASIC INSPECTION

CVT Fluid Check

AT-51

Page 53 of 3051

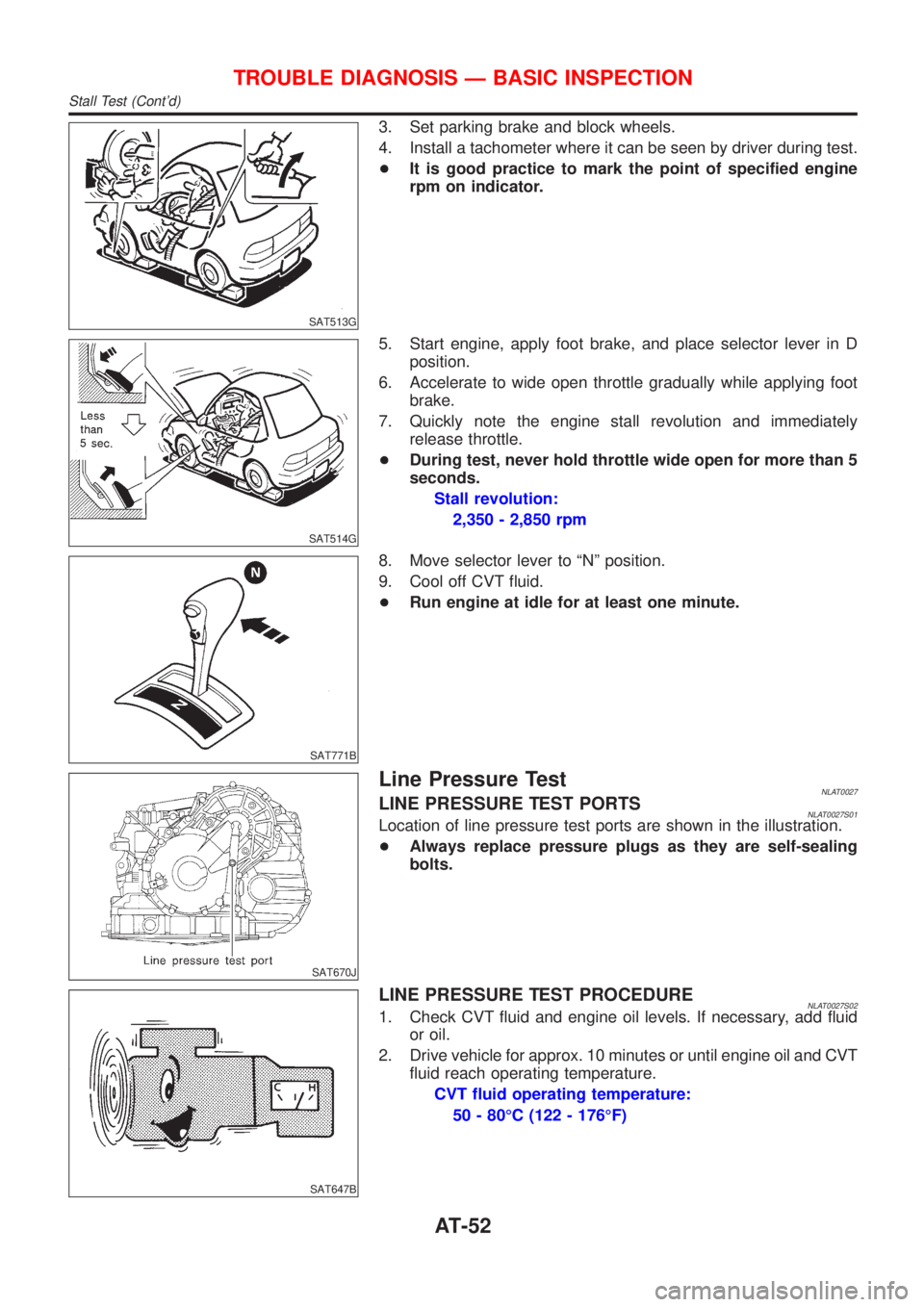

SAT513G

3. Set parking brake and block wheels.

4. Install a tachometer where it can be seen by driver during test.

+It is good practice to mark the point of specified engine

rpm on indicator.

SAT514G

5. Start engine, apply foot brake, and place selector lever in D

position.

6. Accelerate to wide open throttle gradually while applying foot

brake.

7. Quickly note the engine stall revolution and immediately

release throttle.

+During test, never hold throttle wide open for more than 5

seconds.

Stall revolution:

2,350 - 2,850 rpm

SAT771B

8. Move selector lever to ªNº position.

9. Cool off CVT fluid.

+Run engine at idle for at least one minute.

SAT670J

Line Pressure TestNLAT0027LINE PRESSURE TEST PORTSNLAT0027S01Location of line pressure test ports are shown in the illustration.

+Always replace pressure plugs as they are self-sealing

bolts.

SAT647B

LINE PRESSURE TEST PROCEDURENLAT0027S021. Check CVT fluid and engine oil levels. If necessary, add fluid

or oil.

2. Drive vehicle for approx. 10 minutes or until engine oil and CVT

fluid reach operating temperature.

CVT fluid operating temperature:

50 - 80ÉC (122 - 176ÉF)

TROUBLE DIAGNOSIS Ð BASIC INSPECTION

Stall Test (Cont'd)

AT-52

Page 54 of 3051

3. Install pressure gauge to corresponding line pressure port.

SAT513G

4. Set parking brake and block wheels.

+Continue to depress brake pedal fully while line pressure

test is being performed at stall speed.

SAT493G

5. Start engine and measure line pressure at idle and stall speed.

+When measuring line pressure at stall speed, follow the

stall test procedure.

Line pressure: Refer to SDS, AT-210.

SAT692J

Road TestNLAT0028DESCRIPTIONNLAT0028S01+The purpose of the test is to determine overall performance of

CVT and analyze causes of problems.

+The road test consists of the following three parts:

1. Check before engine is started

2. Cruise test

SAT496G

+Before road test, familiarize yourself with all test procedures

and items to check.

+Conduct tests on all items until specified symptom is found.

Troubleshoot items which check out No Good after road test.

Refer to ªON BOARD DIAGNOSTIC SYSTEM

DESCRIPTIONº, AT-18 to AT-28 (EURO-OBD)/AT-31 to AT-38

(Except for EURO-OBD).

TROUBLE DIAGNOSIS Ð BASIC INSPECTION

Line Pressure Test (Cont'd)

AT-53

Page 159 of 3051

SAT250K

SAT815HA

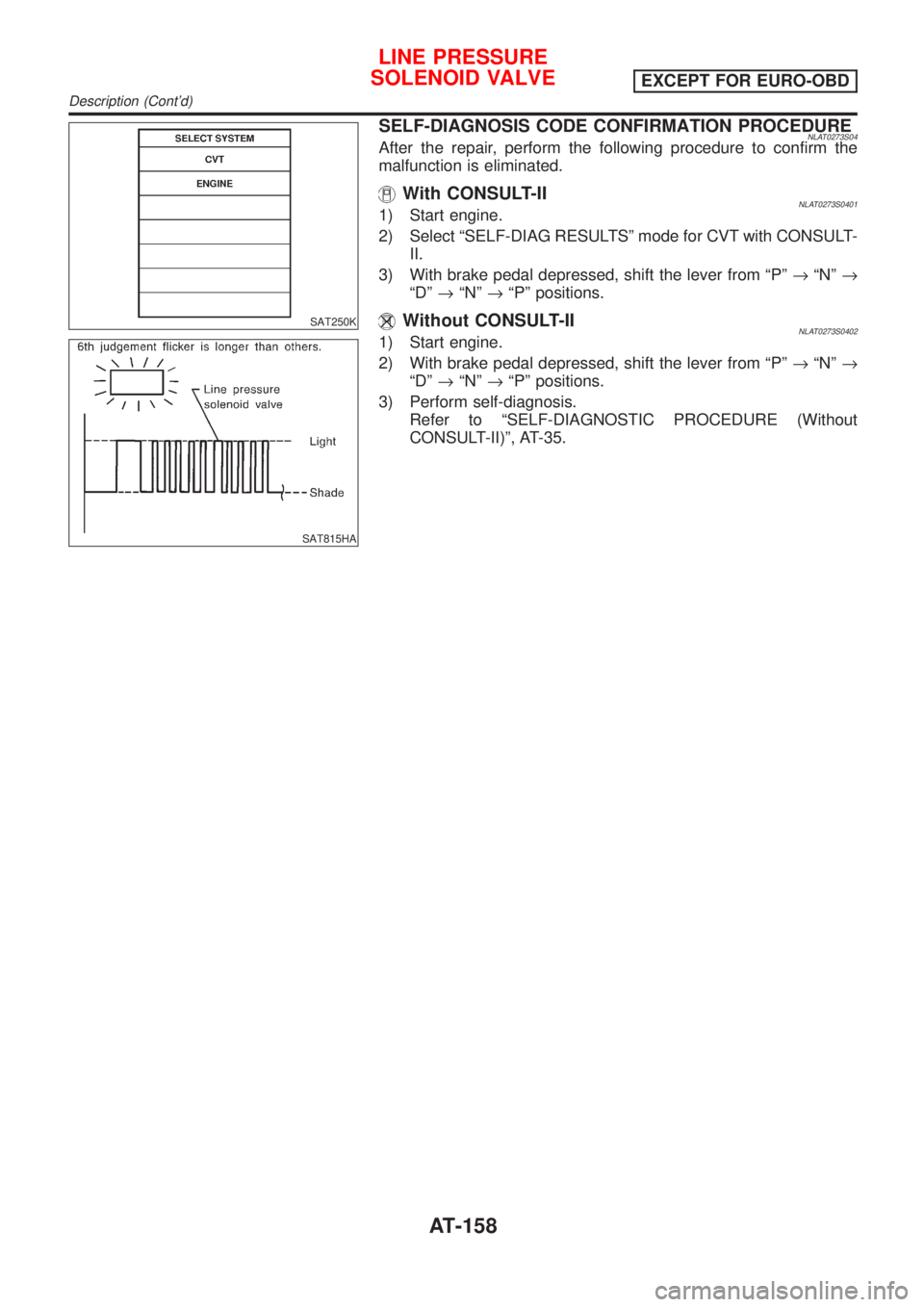

SELF-DIAGNOSIS CODE CONFIRMATION PROCEDURENLAT0273S04After the repair, perform the following procedure to confirm the

malfunction is eliminated.

With CONSULT-IINLAT0273S04011) Start engine.

2) Select ªSELF-DIAG RESULTSº mode for CVT with CONSULT-

II.

3) With brake pedal depressed, shift the lever from ªPº®ªNº®

ªDº®ªNº®ªPº positions.

Without CONSULT-IINLAT0273S04021) Start engine.

2) With brake pedal depressed, shift the lever from ªPº®ªNº®

ªDº®ªNº®ªPº positions.

3) Perform self-diagnosis.

Refer to ªSELF-DIAGNOSTIC PROCEDURE (Without

CONSULT-II)º, AT-35.

LINE PRESSURE

SOLENOID VALVE

EXCEPT FOR EURO-OBD

Description (Cont'd)

AT-158

Page 186 of 3051

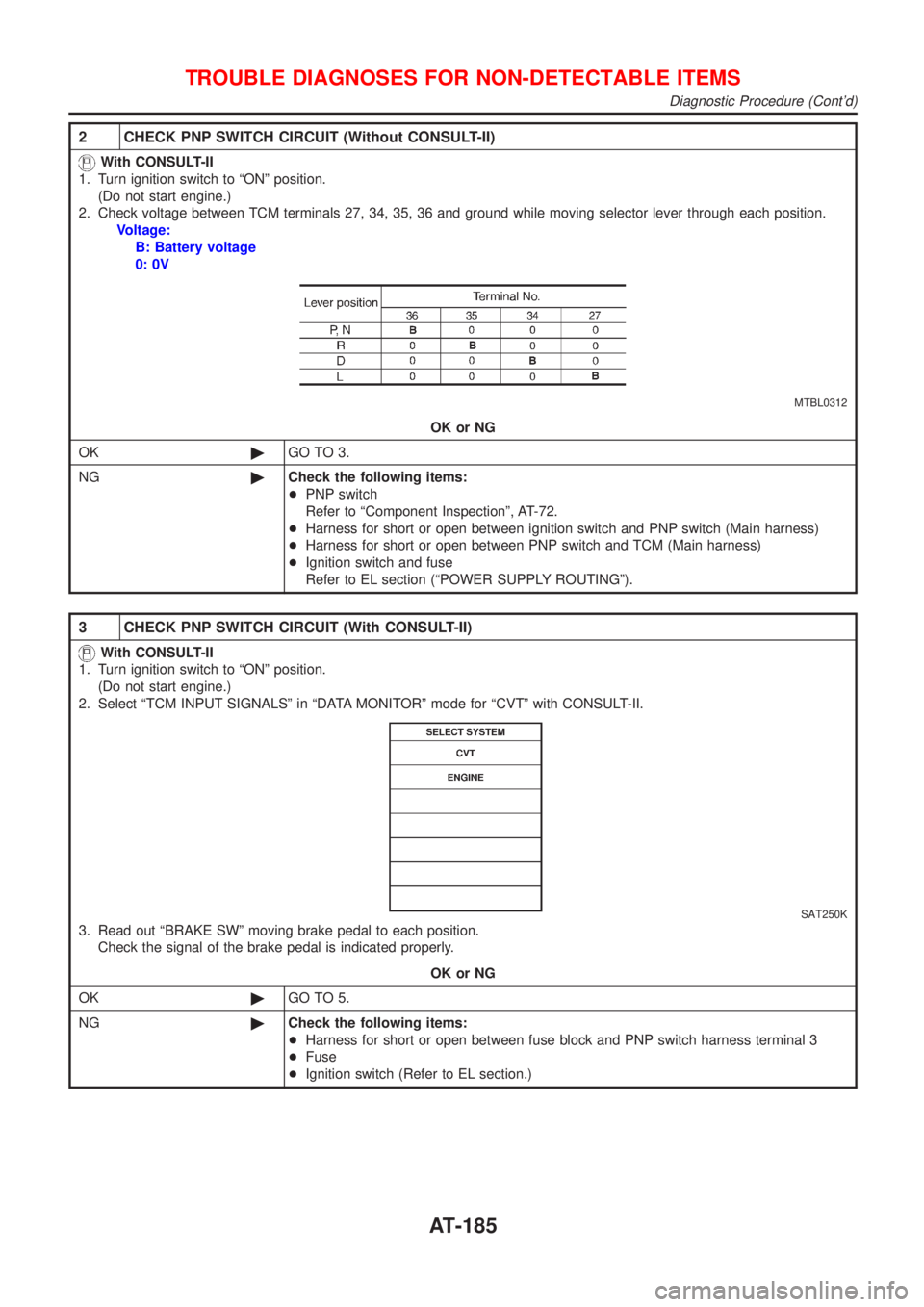

2 CHECK PNP SWITCH CIRCUIT (Without CONSULT-II)

With CONSULT-II

1. Turn ignition switch to ªONº position.

(Do not start engine.)

2. Check voltage between TCM terminals 27, 34, 35, 36 and ground while moving selector lever through each position.

Voltage:

B: Battery voltage

0: 0V

MTBL0312

OK or NG

OK©GO TO 3.

NG©Check the following items:

+PNP switch

Refer to ªComponent Inspectionº, AT-72.

+Harness for short or open between ignition switch and PNP switch (Main harness)

+Harness for short or open between PNP switch and TCM (Main harness)

+Ignition switch and fuse

Refer to EL section (ªPOWER SUPPLY ROUTINGº).

3 CHECK PNP SWITCH CIRCUIT (With CONSULT-II)

With CONSULT-II

1. Turn ignition switch to ªONº position.

(Do not start engine.)

2. Select ªTCM INPUT SIGNALSº in ªDATA MONITORº mode for ªCVTº with CONSULT-II.

SAT250K

3. Read out ªBRAKE SWº moving brake pedal to each position.

Check the signal of the brake pedal is indicated properly.

OK or NG

OK©GO TO 5.

NG©Check the following items:

+Harness for short or open between fuse block and PNP switch harness terminal 3

+Fuse

+Ignition switch (Refer to EL section.)

TROUBLE DIAGNOSES FOR NON-DETECTABLE ITEMS

Diagnostic Procedure (Cont'd)

AT-185

Page 196 of 3051

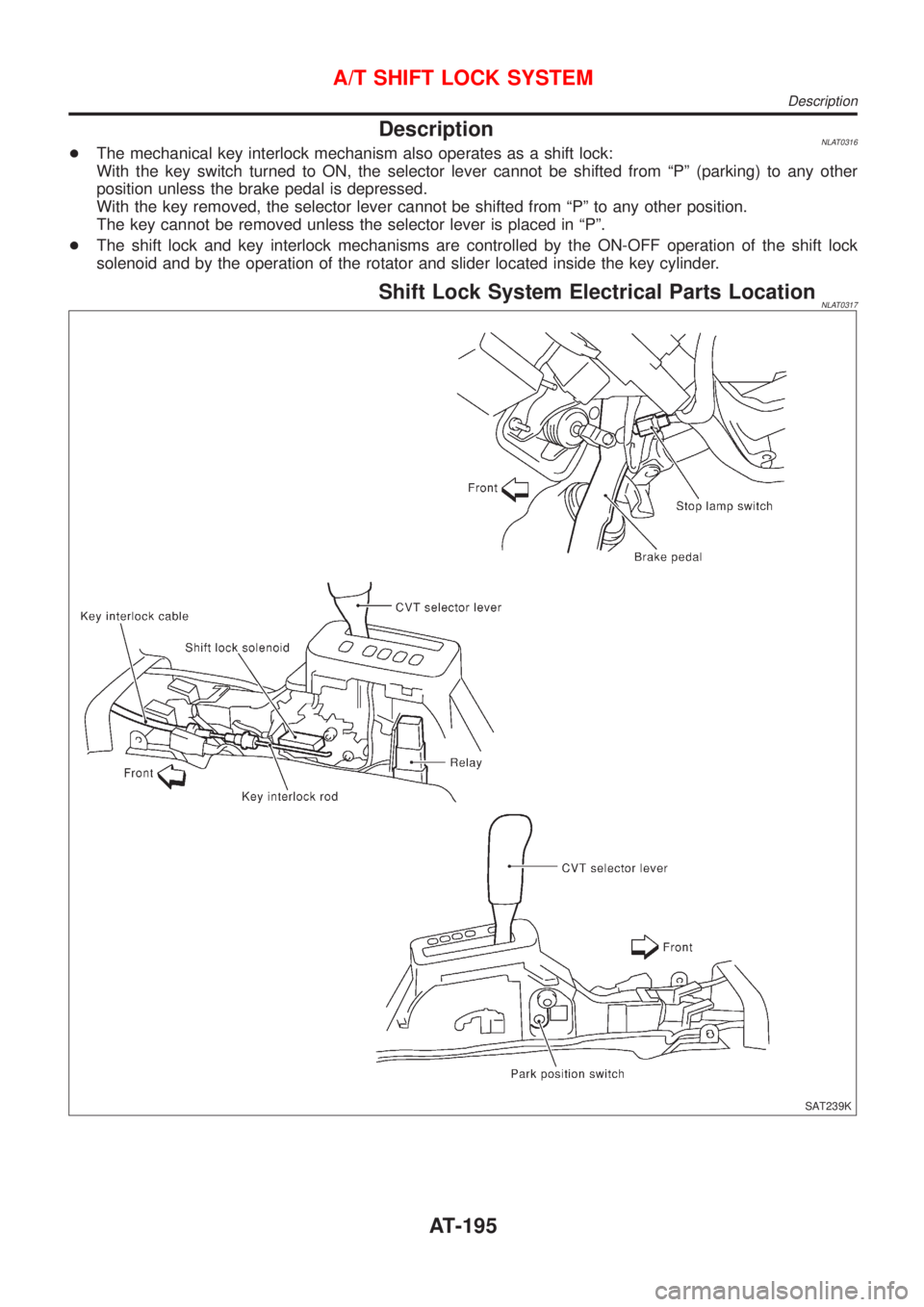

DescriptionNLAT0316+The mechanical key interlock mechanism also operates as a shift lock:

With the key switch turned to ON, the selector lever cannot be shifted from ªPº (parking) to any other

position unless the brake pedal is depressed.

With the key removed, the selector lever cannot be shifted from ªPº to any other position.

The key cannot be removed unless the selector lever is placed in ªPº.

+The shift lock and key interlock mechanisms are controlled by the ON-OFF operation of the shift lock

solenoid and by the operation of the rotator and slider located inside the key cylinder.

Shift Lock System Electrical Parts LocationNLAT0317

SAT239K

A/T SHIFT LOCK SYSTEM

Description

AT-195

Page 199 of 3051

Diagnostic ProcedureNLAT0319SYMPTOM 1:

+Selector lever cannot be moved from ªPº position with key

in ON position and brake pedal applied.

+Selector lever can be moved from ªPº position with key in

ON position and brake pedal released.

+Selector lever can be moved from ªPº position when key

is removed from key cylinder.

SYMPTOM 2:

Ignition key cannot be removed when selector lever is set to

ªPº position. It can be removed when selector lever is set to

any position except ªPº.

1 CHECK KEY INTERLOCK CABLE

Check key interlock cable for damage.

OK or NG

OK©GO TO 2.

NG©Repair key interlock cable. Refer to AT-202.

2 CHECK SELECTOR LEVER POSITION

Check selector lever position for damage.

OK or NG

OK©GO TO 3.

NG©Check selector lever. Refer to ªON-VEHICLE SERVICE Ð PNP Switch and Control

Cable Adjustmentº, AT-204.

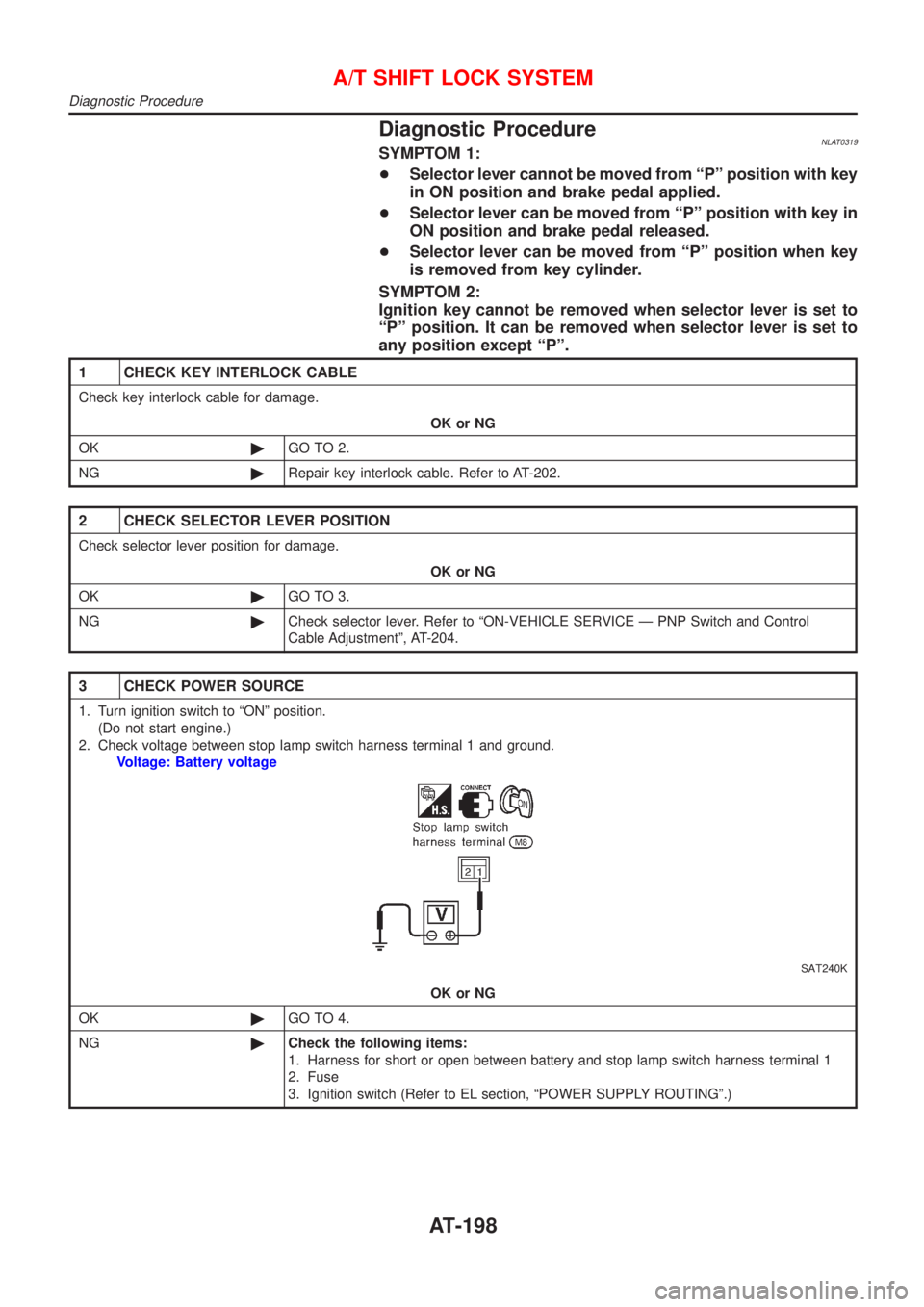

3 CHECK POWER SOURCE

1. Turn ignition switch to ªONº position.

(Do not start engine.)

2. Check voltage between stop lamp switch harness terminal 1 and ground.

Voltage: Battery voltage

SAT240K

OK or NG

OK©GO TO 4.

NG©Check the following items:

1. Harness for short or open between battery and stop lamp switch harness terminal 1

2. Fuse

3. Ignition switch (Refer to EL section, ªPOWER SUPPLY ROUTINGº.)

A/T SHIFT LOCK SYSTEM

Diagnostic Procedure

AT-198

Page 200 of 3051

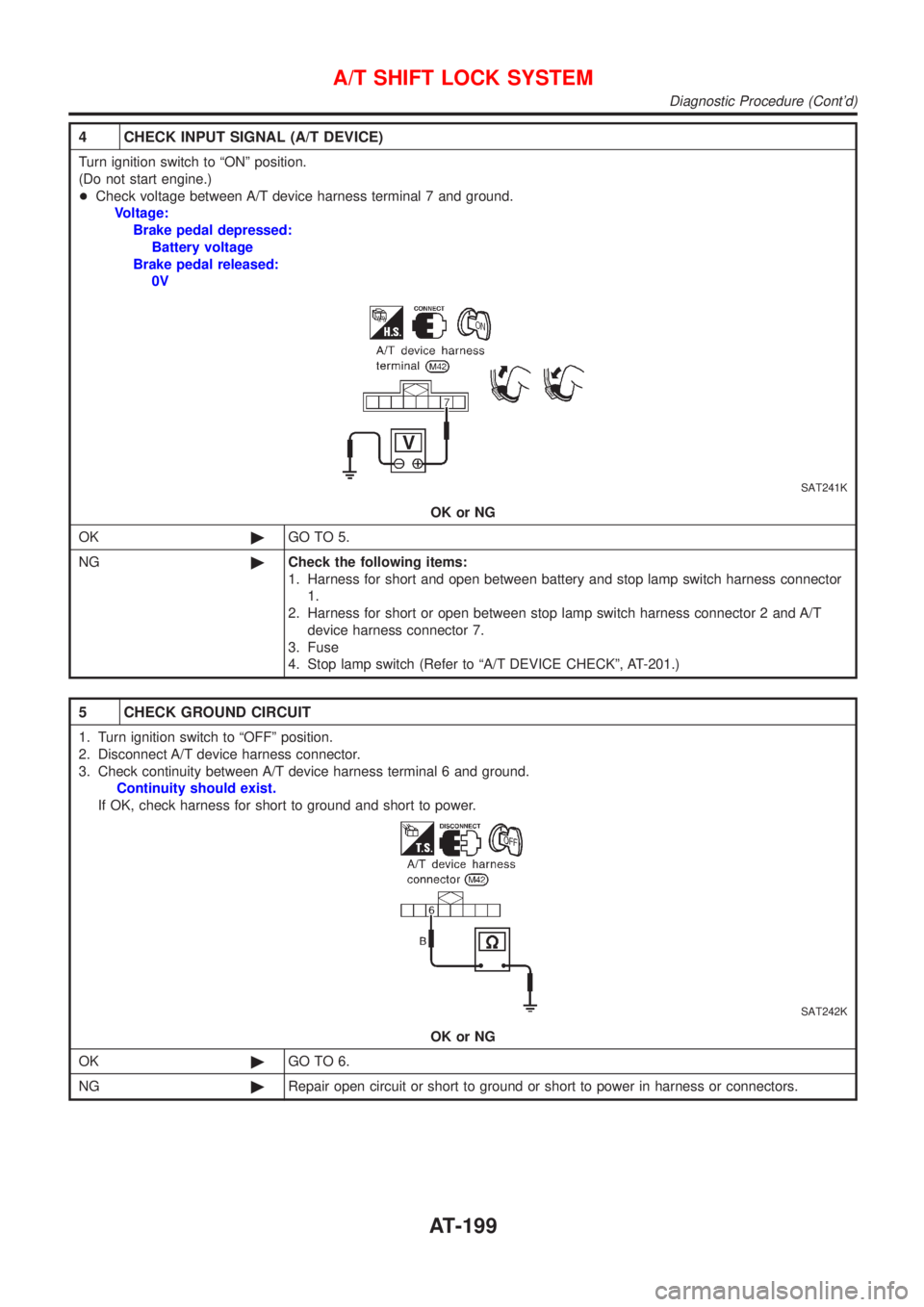

4 CHECK INPUT SIGNAL (A/T DEVICE)

Turn ignition switch to ªONº position.

(Do not start engine.)

+Check voltage between A/T device harness terminal 7 and ground.

Voltage:

Brake pedal depressed:

Battery voltage

Brake pedal released:

0V

SAT241K

OK or NG

OK©GO TO 5.

NG©Check the following items:

1. Harness for short and open between battery and stop lamp switch harness connector

1.

2. Harness for short or open between stop lamp switch harness connector 2 and A/T

device harness connector 7.

3. Fuse

4. Stop lamp switch (Refer to ªA/T DEVICE CHECKº, AT-201.)

5 CHECK GROUND CIRCUIT

1. Turn ignition switch to ªOFFº position.

2. Disconnect A/T device harness connector.

3. Check continuity between A/T device harness terminal 6 and ground.

Continuity should exist.

If OK, check harness for short to ground and short to power.

SAT242K

OK or NG

OK©GO TO 6.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

A/T SHIFT LOCK SYSTEM

Diagnostic Procedure (Cont'd)

AT-199