brake NISSAN ALMERA TINO 2001 Service Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA TINO, Model: NISSAN ALMERA TINO 2001Pages: 3051, PDF Size: 46.38 MB

Page 239 of 3051

CALIPER.................................................................38

ROTOR...................................................................39

Installation ..................................................................39

PARKING BRAKE CONTROL......................................40

Components...............................................................40

Removal and Installation ...........................................40

Inspection...................................................................40

Adjustment .................................................................41

ABS

DESCRIPTION...............................................................42

Purpose......................................................................42

ABS (Anti-Lock Brake System) Operation ................42

ABS Hydraulic Circuit ................................................42

System Components .................................................43

System Description ....................................................43

SENSOR.................................................................43

CONTROL UNIT......................................................43

ABS ACTUATOR AND ELECTRIC UNIT....................43

Component Parts and Harness Connector

Location .....................................................................45

Schematic ..................................................................46

MODELS WITH SELF-DIAGNOSIS FUNCTION

(DATA LINK CONNECTOR TERMINAL NO. 9)

...........46

MODELS WITHOUT SELF-DIAGNOSIS

FUNCTION (DATA LINK CONNECTOR TERMINAL

NO. 9)

.....................................................................47

Wiring Diagram - ABS - .............................................48

MODELS WITH SELF-DIAGNOSIS FUNCTION

(DATA LINK CONNECTOR TERMINAL NO. 9)

...........48

MODELS WITHOUT SELF-DIAGNOSIS

FUNCTION (DATA LINK CONNECTOR TERMINAL

NO. 9)

.....................................................................52

ON BOARD DIAGNOSTIC SYSTEM

DESCRIPTION...............................................................56

Self-diagnosis (Only models with data link

connector terminal No. 9) ..........................................56

FUNCTION..............................................................56

SELF-DIAGNOSIS PROCEDURE..............................56

HOW TO READ SELF-DIAGNOSTIC RESULTS

(MALFUNCTION CODES)

........................................57

HOW TO ERASE SELF-DIAGNOSTIC RESULTS

(MALFUNCTION CODES)

........................................57

CONSULT-II ...............................................................58

CONSULT-II APPLICATION TO ABS..........................58

ECU (ABS CONTROL UNIT) PART NUMBER

MODE

.....................................................................58

CONSULT-II Inspection Procedure............................58

SELF-DIAGNOSIS PROCEDURE..............................58

SELF-DIAGNOSTIC RESULTS MODE.......................60

DATA MONITOR PROCEDURE................................61

ACTIVE TEST PROCEDURE....................................62

DATA MONITOR MODE...........................................63

ACTIVE TEST MODE...............................................63

TROUBLE DIAGNOSIS - INTRODUCTION..................64

How to Perform Trouble Diagnoses for Quick

and Accurate Repair ..................................................64

INTRODUCTION......................................................64

TROUBLE DIAGNOSIS - BASIC INSPECTION...........65

Preliminary Check......................................................65

Ground Circuit Check ................................................68

ABS ACTUATOR AND ELECTRIC UNIT GROUND.....68

TROUBLE DIAGNOSIS - GENERAL

DESCRIPTION...............................................................69

Malfunction Code/Symptom Chart.............................69

MODELS WITH SELF-DIAGNOSIS FUNCTION

(DATA LINK CONNECTOR TERMINAL NO. 9)

...........69

TROUBLE DIAGNOSES FOR SELF-DIAGNOSTIC

ITEMS.............................................................................71

Wheel Sensor or Rotor ..............................................71

DIAGNOSTIC PROCEDURE.....................................71

ABS Actuator Solenoid Valve or Solenoid Valve

Relay ..........................................................................74

DIAGNOSTIC PROCEDURE.....................................74

Motor Relay or Motor.................................................77

DIAGNOSTIC PROCEDURE.....................................77

Low Voltage ...............................................................79

DIAGNOSTIC PROCEDURE.....................................79

Control Unit ................................................................81

DIAGNOSTIC PROCEDURE.....................................81

TROUBLE DIAGNOSES FOR SYMPTOMS.................82

1. ABS Works Frequently ..........................................82

2. Unexpected Pedal Action ......................................82

3. Long Stopping Distance ........................................83

4. ABS Does Not Work ..............................................84

5. Pedal Vibration and Noise.....................................85

6. ABS Warning Lamp Does Not Come On

When Ignition Switch Is Turned On...........................86

7. ABS Warning Lamp Stays On When Ignition

Switch Is Turned On ..................................................88

REMOVAL AND INSTALLATION.................................90

Wheel Sensors ..........................................................90

ABS Actuator and Electric Unit..................................91

REMOVAL...............................................................91

INSTALLATION........................................................91

Sensor Rotor..............................................................92

REMOVAL...............................................................92

INSTALLATION........................................................92

SERVICE DATA AND SPECIFICATIONS (SDS).........93

General Specifications ...............................................93

Disc Brake .................................................................93

Brake Pedal ...............................................................93

Parking Brake ............................................................93

CONTENTS(Cont’d)

BR-2

Page 240 of 3051

Supplemental Restraint System (SRS)“AIR

BAG”and“SEAT BELT PRE-TENSIONER”

NLBR0081The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER” used along with

a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain types of

collision. The SRS system composition which is available to NISSAN MODEL V10 is as follows (The compo-

sition varies according to the destination and optional equipment.):

+For a frontal collision

The Supplemental Restraint System consists of driver air bag module (located in the center of the steer-

ing wheel), front passenger air bag module (located on the instrument panel on passenger side), front seat

belt pre-tensioners, a diagnosis sensor unit, warning lamp, wiring harness and spiral cable.

+For a side collision

The Supplemental Restraint System consists of front side air bag module (located in the outer side of front

seat), side air bag (satellite) sensor, diagnosis sensor unit (one of components of air bags for a frontal

collision), wiring harness, warning lamp (one of components of air bags for a frontal collision).

Information necessary to service the system safely is included in theRS sectionof this Service Manual.

WARNING:

+To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance should be per-

formed by an authorized NISSAN dealer.

+Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the RS section.

+Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. Spiral cable and wiring harnesses covered with yellow insulation tape either just

before the harness connectors or for the complete harness are related to the SRS.

SBR686C

Precautions for Brake SystemNLBR0002+Recommended fluid is brake fluid“DOT 4”.

+Never reuse drained brake fluid.

+Be careful not to splash brake fluid on painted areas.

+To clean or wash all parts of master cylinder, disc brake

caliper and wheel cylinder, use clean brake fluid.

+Never use mineral oils such as gasoline or kerosene. They

will ruin rubber parts of the hydraulic system.

+Use flare nut wrench when removing and installing brake

tube.

+Always torque brake lines when installing.

+Burnish the brake contact surfaces after refinishing or

replacing rotors, after replacing pads, or if a soft pedal

occurs at very low mileage.

Refer to“Brake Burnishing Procedure”,“ON-VEHICLE

SERVICE”, BR-7.

WARNING:

+Clean brake pads with a waste cloth, then wipe with a dust

collector.

PRECAUTIONS

Supplemental Restraint System (SRS) “AIR BAG” and “SEAT BELT PRE-TENSIONER”

BR-3

Page 241 of 3051

Precautions When Working On ABSNLBR0149+Use recommended tyres in combination with ABS.

+Please fit tyres or studded tyres, etc. with the same size.

+If different sizes of tyres, or tyres other than the ones rec-

ommended for use with the ABS, are fitted, stopping dis-

tance will increase and control and stability could deterio-

rate.

+When changing brake pads, please use Nissan genuine

parts.

+When fitting radios etc, do not position the radio itself,

antenna, or antenna cables within an area of about 100

mm (3.94 in) of the control unit.

+When doing any work that requires electro-welding, first

remove the control unit.

+Please take care when taking a power supply for the

audio, lamps etc., not to take this from any ABS-related

harness. (Please refer to the electrical wiring diagrams for

ABS-related harnesses)

Wiring Diagrams and Trouble DiagnosisNLBR0003When you read wiring diagrams, refer to the following:

+GI-11,“HOW TO READ WIRING DIAGRAMS”

+EL-10,“POWER SUPPLY ROUTING”

When you perform trouble diagnosis, refer to the following:

+GI-32,“HOW TO FOLLOW TEST GROUPS IN TROUBLE DIAGNOSIS”

+GI-21,“HOW TO PERFORM EFFICIENT DIAGNOSES FOR AN ELECTRICAL INCIDENT”

PRECAUTIONS

Precautions When Working On ABS

BR-4

Page 242 of 3051

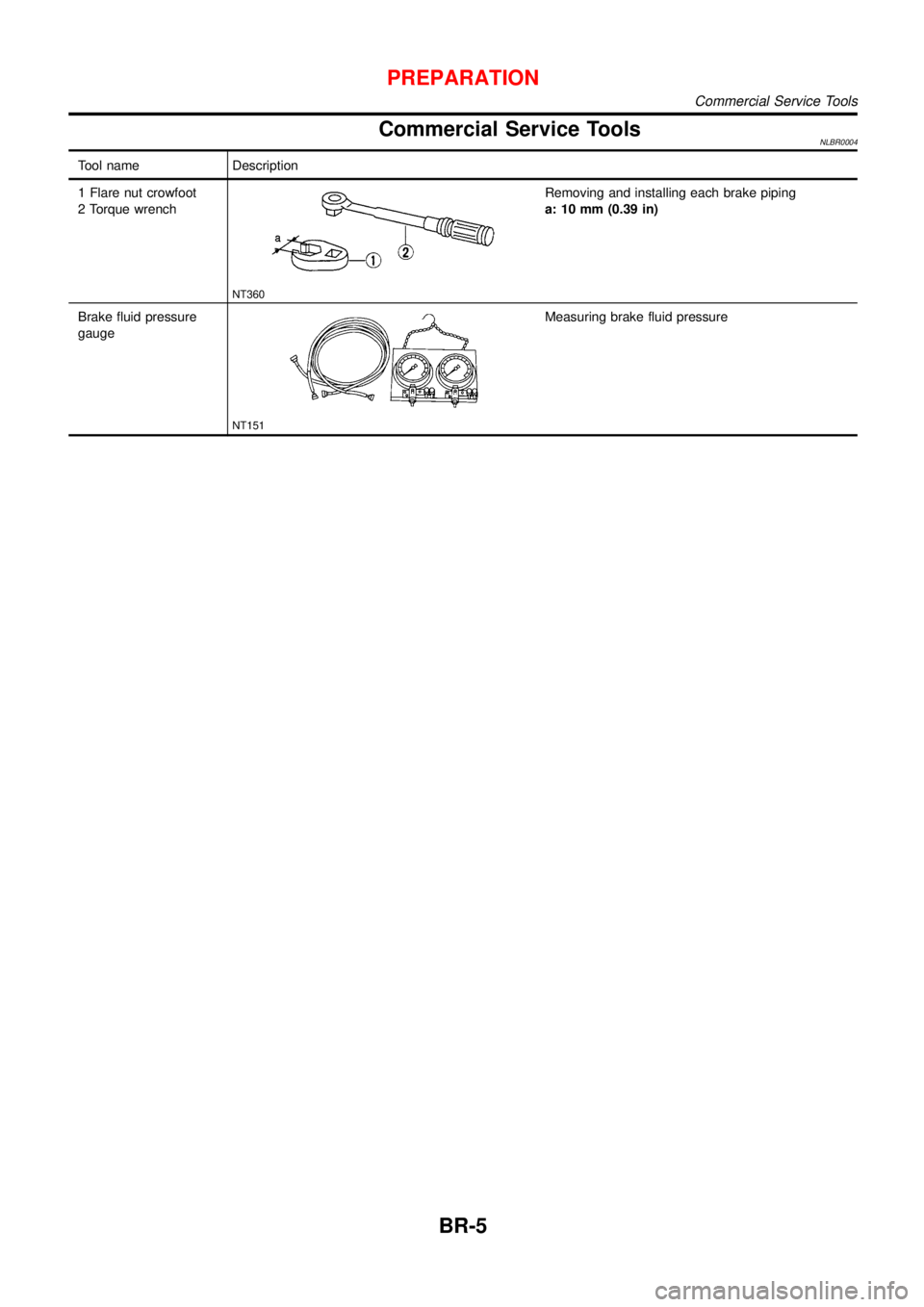

Commercial Service ToolsNLBR0004

Tool name Description

1 Flare nut crowfoot

2 Torque wrench

NT360

Removing and installing each brake piping

a: 10 mm (0.39 in)

Brake fluid pressure

gauge

NT151

Measuring brake fluid pressure

PREPARATION

Commercial Service Tools

BR-5

Page 243 of 3051

NLBR0005

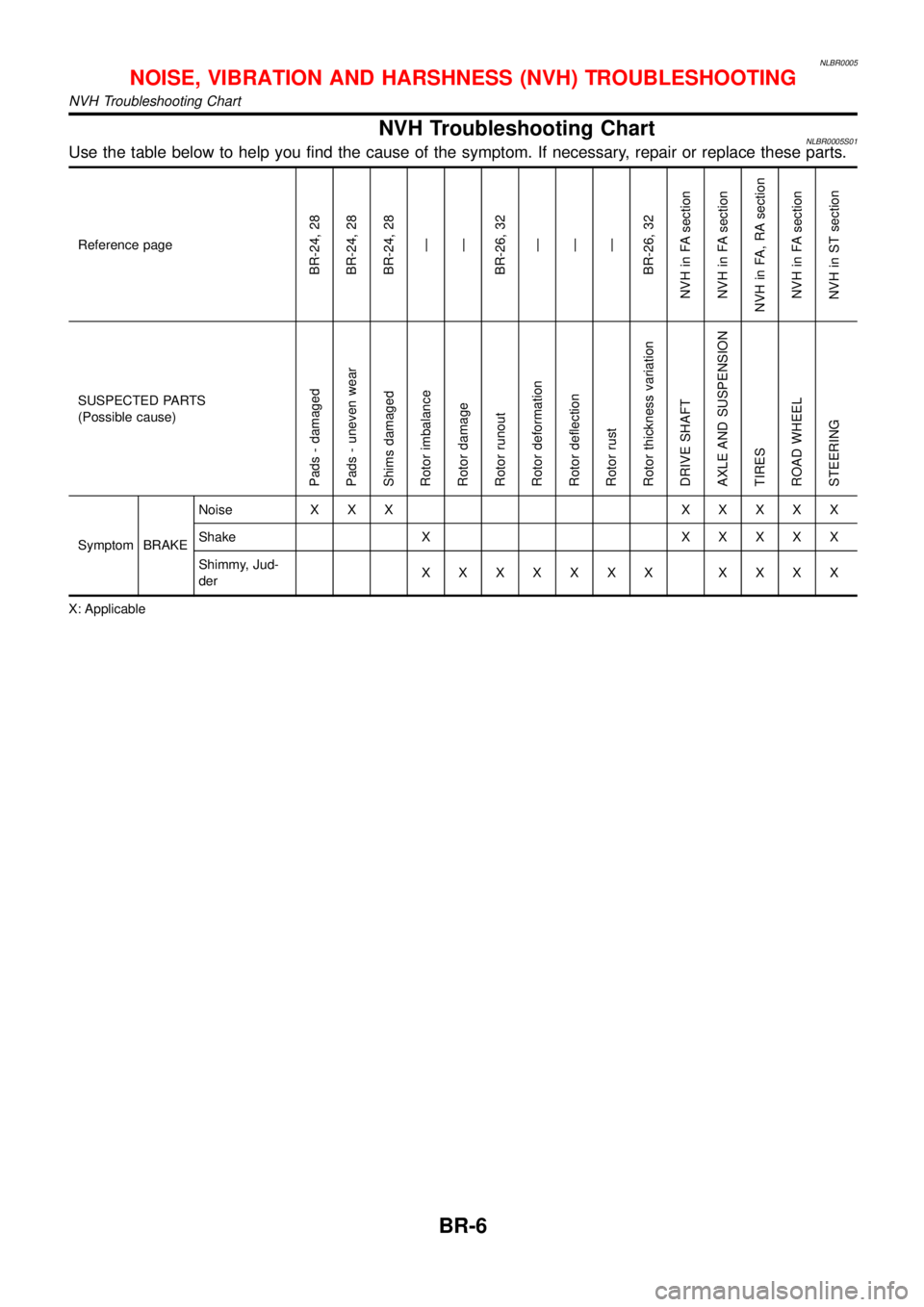

NVH Troubleshooting ChartNLBR0005S01Use the table below to help you find the cause of the symptom. If necessary, repair or replace these parts.

Reference page

BR-24, 28

BR-24, 28

BR-24, 28

—

—

BR-26, 32

—

—

—

BR-26, 32

NVH in FA section

NVH in FA section

NVH in FA, RA section

NVH in FA section

NVH in ST section

SUSPECTED PARTS

(Possible cause)

Pads - damaged

Pads - uneven wear

Shims damaged

Rotor imbalance

Rotor damage

Rotor runout

Rotor deformation

Rotor deflection

Rotor rust

Rotor thickness variation

DRIVE SHAFT

AXLE AND SUSPENSION

TIRES

ROAD WHEEL

STEERING

Symptom BRAKENoise X X XXXXXX

Shake XXXXXX

Shimmy, Jud-

derXXXXXXX XXXX

X: Applicable

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

NVH Troubleshooting Chart

BR-6

Page 244 of 3051

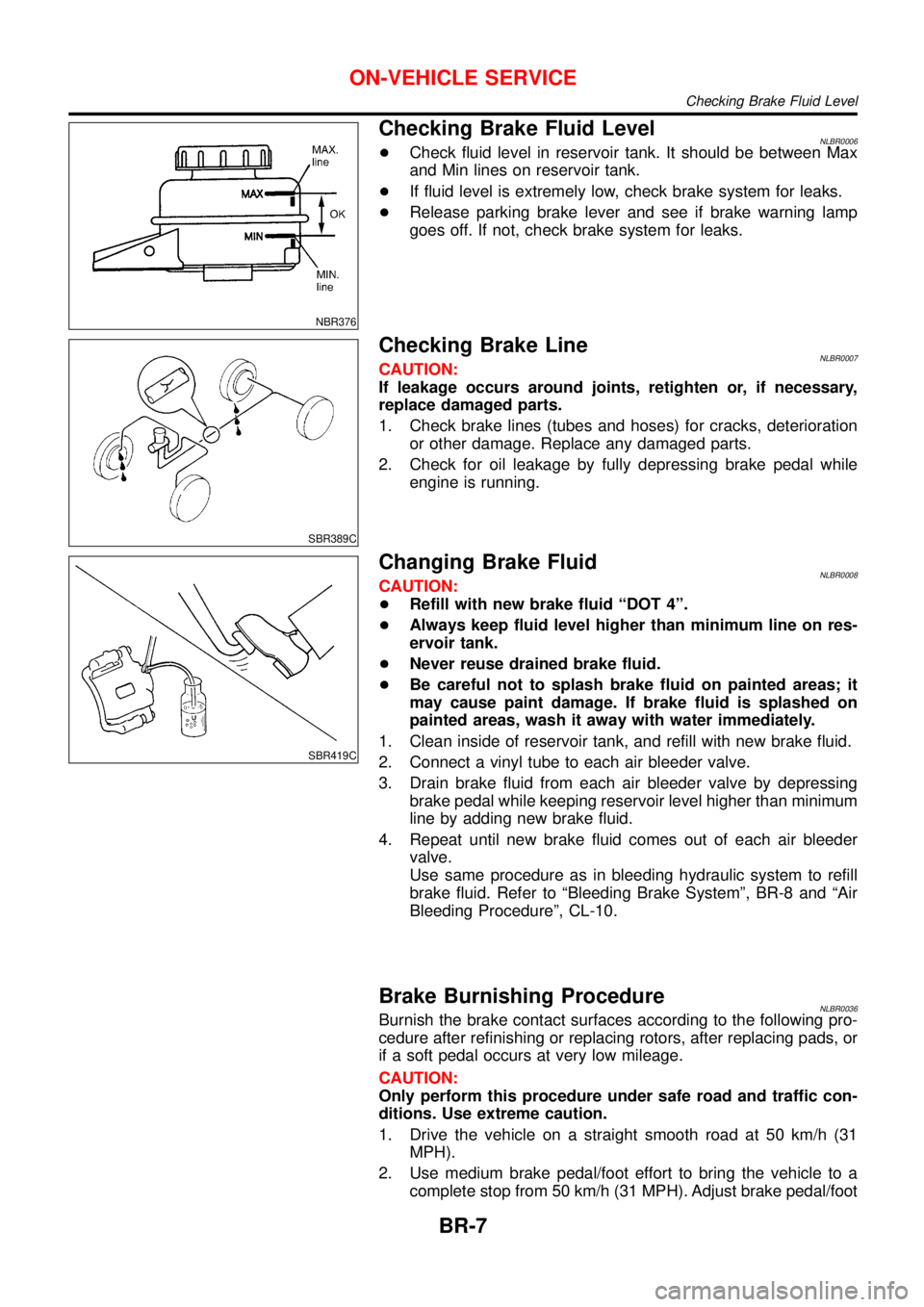

NBR376

Checking Brake Fluid LevelNLBR0006+Check fluid level in reservoir tank. It should be between Max

and Min lines on reservoir tank.

+If fluid level is extremely low, check brake system for leaks.

+Release parking brake lever and see if brake warning lamp

goes off. If not, check brake system for leaks.

SBR389C

Checking Brake LineNLBR0007CAUTION:

If leakage occurs around joints, retighten or, if necessary,

replace damaged parts.

1. Check brake lines (tubes and hoses) for cracks, deterioration

or other damage. Replace any damaged parts.

2. Check for oil leakage by fully depressing brake pedal while

engine is running.

SBR419C

Changing Brake FluidNLBR0008CAUTION:

+Refill with new brake fluid“DOT 4”.

+Always keep fluid level higher than minimum line on res-

ervoir tank.

+Never reuse drained brake fluid.

+Be careful not to splash brake fluid on painted areas; it

may cause paint damage. If brake fluid is splashed on

painted areas, wash it away with water immediately.

1. Clean inside of reservoir tank, and refill with new brake fluid.

2. Connect a vinyl tube to each air bleeder valve.

3. Drain brake fluid from each air bleeder valve by depressing

brake pedal while keeping reservoir level higher than minimum

line by adding new brake fluid.

4. Repeat until new brake fluid comes out of each air bleeder

valve.

Use same procedure as in bleeding hydraulic system to refill

brake fluid. Refer to“Bleeding Brake System”, BR-8 and“Air

Bleeding Procedure”, CL-10.

Brake Burnishing ProcedureNLBR0036Burnish the brake contact surfaces according to the following pro-

cedure after refinishing or replacing rotors, after replacing pads, or

if a soft pedal occurs at very low mileage.

CAUTION:

Only perform this procedure under safe road and traffic con-

ditions. Use extreme caution.

1. Drive the vehicle on a straight smooth road at 50 km/h (31

MPH).

2. Use medium brake pedal/foot effort to bring the vehicle to a

complete stop from 50 km/h (31 MPH). Adjust brake pedal/foot

ON-VEHICLE SERVICE

Checking Brake Fluid Level

BR-7

Page 245 of 3051

pressure such that vehicle stopping time equals 3 to 5 sec-

onds.

3. To cool the brake system, drive the vehicle at 50 km/h (31

MPH) for 1 minute without stopping.

4. Repeat steps 1 to 3, 10 times or more to complete the burnish-

ing procedure.

NBR357

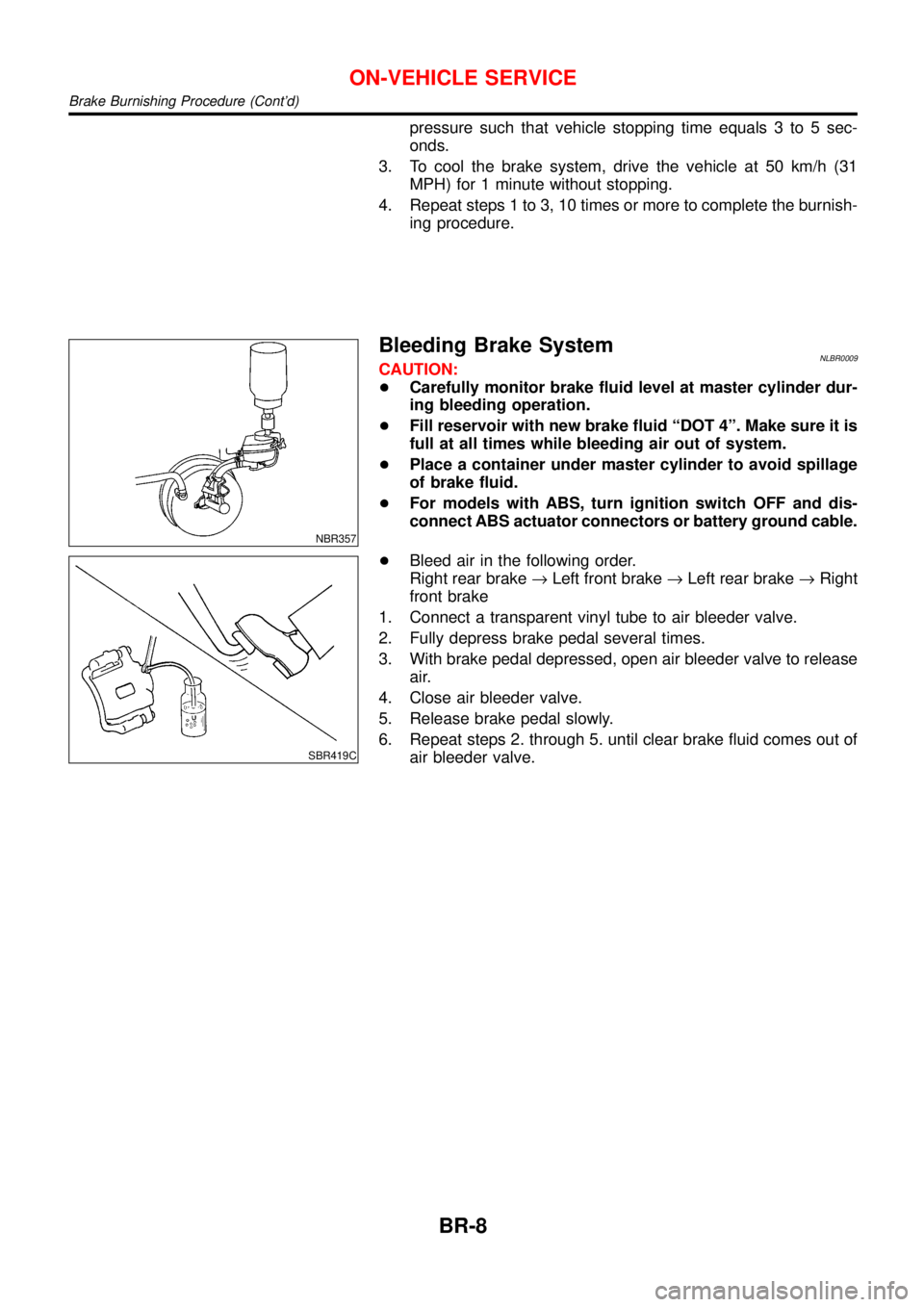

Bleeding Brake SystemNLBR0009CAUTION:

+Carefully monitor brake fluid level at master cylinder dur-

ing bleeding operation.

+Fill reservoir with new brake fluid“DOT 4”. Make sure it is

full at all times while bleeding air out of system.

+Place a container under master cylinder to avoid spillage

of brake fluid.

+For models with ABS, turn ignition switch OFF and dis-

connect ABS actuator connectors or battery ground cable.

SBR419C

+Bleed air in the following order.

Right rear brake→Left front brake→Left rear brake→Right

front brake

1. Connect a transparent vinyl tube to air bleeder valve.

2. Fully depress brake pedal several times.

3. With brake pedal depressed, open air bleeder valve to release

air.

4. Close air bleeder valve.

5. Release brake pedal slowly.

6. Repeat steps 2. through 5. until clear brake fluid comes out of

air bleeder valve.

ON-VEHICLE SERVICE

Brake Burnishing Procedure (Cont’d)

BR-8

Page 246 of 3051

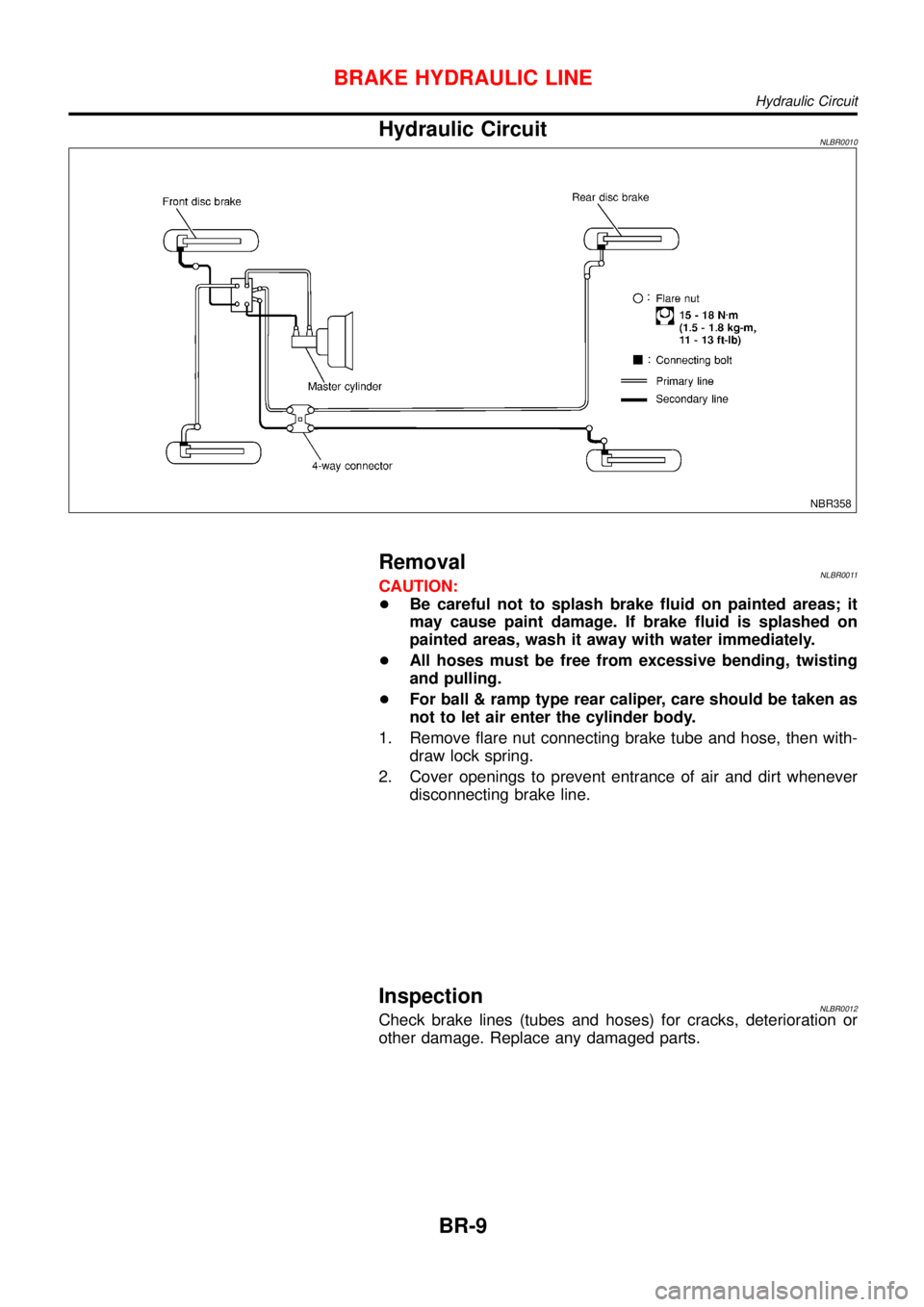

Hydraulic CircuitNLBR0010

NBR358

RemovalNLBR0011CAUTION:

+Be careful not to splash brake fluid on painted areas; it

may cause paint damage. If brake fluid is splashed on

painted areas, wash it away with water immediately.

+All hoses must be free from excessive bending, twisting

and pulling.

+For ball & ramp type rear caliper, care should be taken as

not to let air enter the cylinder body.

1. Remove flare nut connecting brake tube and hose, then with-

draw lock spring.

2. Cover openings to prevent entrance of air and dirt whenever

disconnecting brake line.

InspectionNLBR0012Check brake lines (tubes and hoses) for cracks, deterioration or

other damage. Replace any damaged parts.

BRAKE HYDRAULIC LINE

Hydraulic Circuit

BR-9

Page 247 of 3051

SBR686C

InstallationNLBR0013CAUTION:

+Refill with new brake fluid“DOT 4”.

+Never reuse drained brake fluid.

1. Tighten all flare nuts and connecting bolts.

Specification:

Flare nut

15-18N·m (1.5 - 1.8 kg-m, 11 - 13 ft-lb)

Connecting bolt

17-20N·m (1.7 - 2.0 kg-m, 12 - 14 ft-lb)

2. Refill until new brake fluid comes out of each air bleeder valve.

3. Bleed air. Refer to“Bleeding Brake System”, BR-8, and‘‘Air

Bleeding Procedure’’, CL-10.

BRAKE HYDRAULIC LINE

Installation

BR-10

Page 248 of 3051

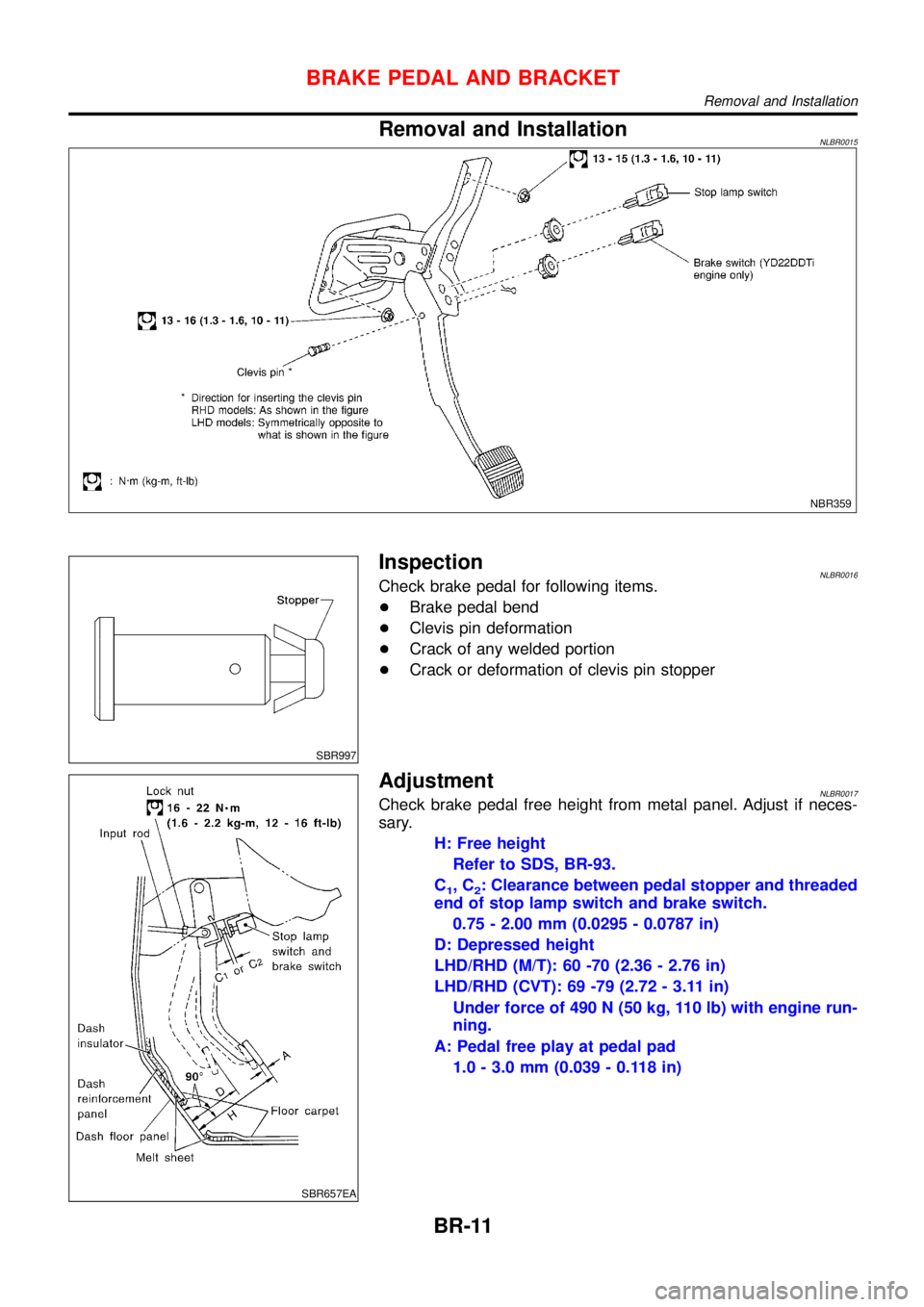

Removal and InstallationNLBR0015

NBR359

SBR997

InspectionNLBR0016Check brake pedal for following items.

+Brake pedal bend

+Clevis pin deformation

+Crack of any welded portion

+Crack or deformation of clevis pin stopper

SBR657EA

AdjustmentNLBR0017Check brake pedal free height from metal panel. Adjust if neces-

sary.

H: Free height

Refer to SDS, BR-93.

C

1,C2: Clearance between pedal stopper and threaded

end of stop lamp switch and brake switch.

0.75 - 2.00 mm (0.0295 - 0.0787 in)

D: Depressed height

LHD/RHD (M/T): 60 -70 (2.36 - 2.76 in)

LHD/RHD (CVT): 69 -79 (2.72 - 3.11 in)

Under force of 490 N (50 kg, 110 lb) with engine run-

ning.

A: Pedal free play at pedal pad

1.0 - 3.0 mm (0.039 - 0.118 in)

BRAKE PEDAL AND BRACKET

Removal and Installation

BR-11