NISSAN ALMERA TINO 2001 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA TINO, Model: NISSAN ALMERA TINO 2001Pages: 3051, PDF Size: 46.38 MB

Page 421 of 3051

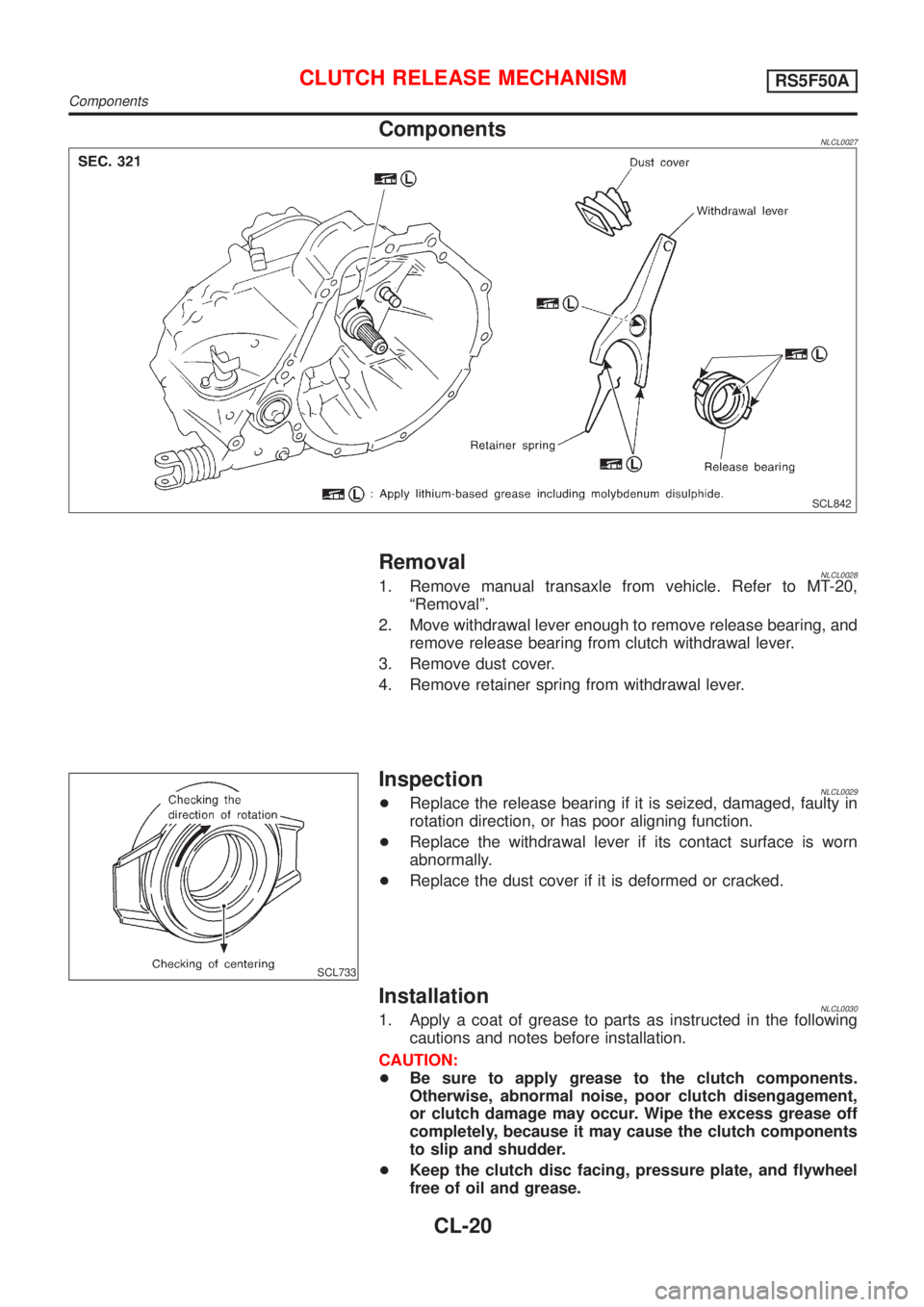

ComponentsNLCL0027

SCL842

RemovalNLCL00281. Remove manual transaxle from vehicle. Refer to MT-20,

ªRemovalº.

2. Move withdrawal lever enough to remove release bearing, and

remove release bearing from clutch withdrawal lever.

3. Remove dust cover.

4. Remove retainer spring from withdrawal lever.

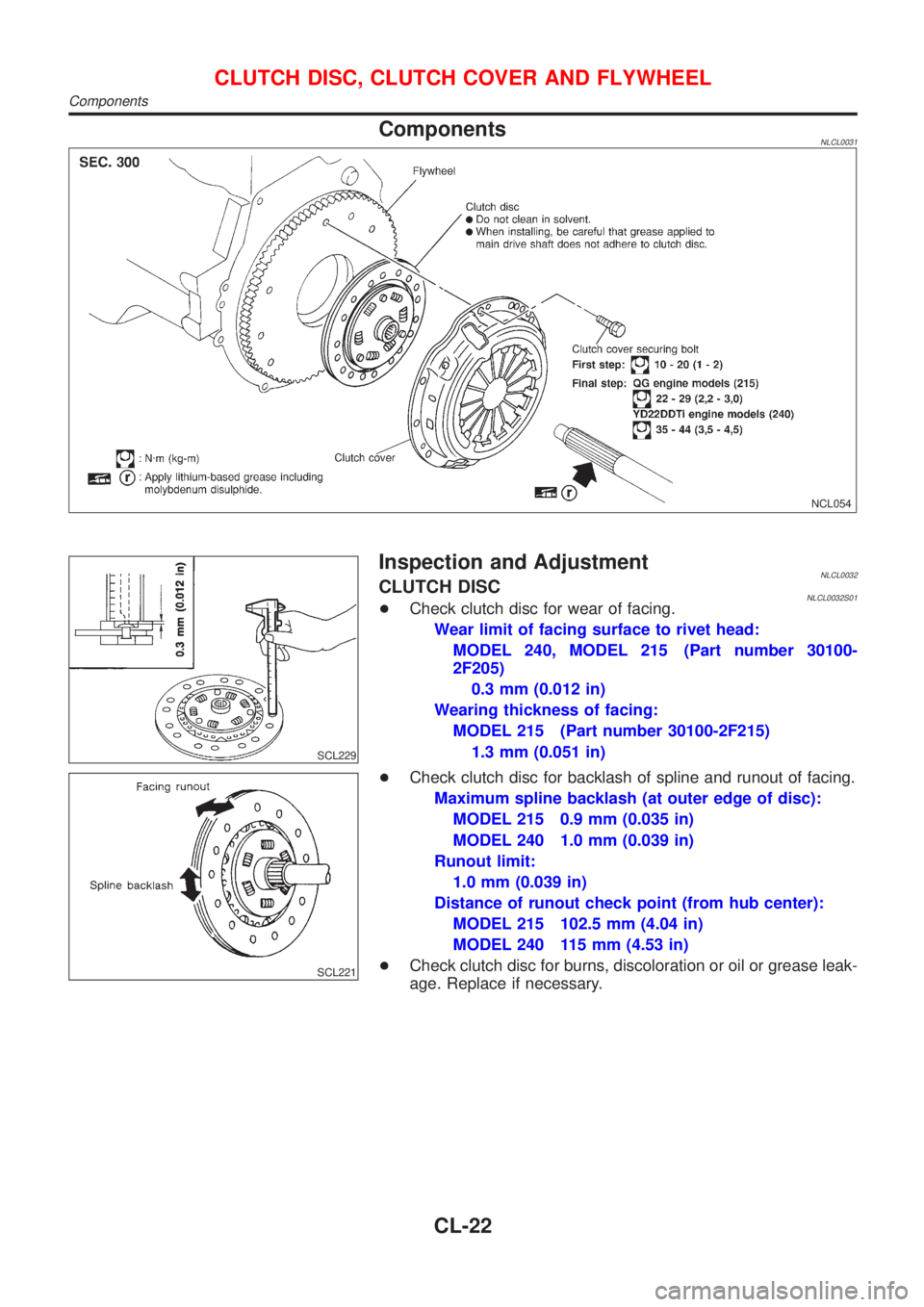

SCL733

InspectionNLCL0029+Replace the release bearing if it is seized, damaged, faulty in

rotation direction, or has poor aligning function.

+Replace the withdrawal lever if its contact surface is worn

abnormally.

+Replace the dust cover if it is deformed or cracked.

InstallationNLCL00301. Apply a coat of grease to parts as instructed in the following

cautions and notes before installation.

CAUTION:

+Be sure to apply grease to the clutch components.

Otherwise, abnormal noise, poor clutch disengagement,

or clutch damage may occur. Wipe the excess grease off

completely, because it may cause the clutch components

to slip and shudder.

+Keep the clutch disc facing, pressure plate, and flywheel

free of oil and grease.

CLUTCH RELEASE MECHANISMRS5F50A

Components

CL-20

Page 422 of 3051

![NISSAN ALMERA TINO 2001 Service Repair Manual +Clean old grease and abrasive materials off the grease

application area.

SCL815

NOTE:

+Equally apply a coat [approximately 1 mm (0.04 in) thick] of

clutch sleeve grease to withdrawal lever and holder NISSAN ALMERA TINO 2001 Service Repair Manual +Clean old grease and abrasive materials off the grease

application area.

SCL815

NOTE:

+Equally apply a coat [approximately 1 mm (0.04 in) thick] of

clutch sleeve grease to withdrawal lever and holder](/img/5/57352/w960_57352-421.png)

+Clean old grease and abrasive materials off the grease

application area.

SCL815

NOTE:

+Equally apply a coat [approximately 1 mm (0.04 in) thick] of

clutch sleeve grease to withdrawal lever and holder spring

frictional surfaces.

+Apply a coat of clutch sleeve grease to the grooves on contact

surfaces of the withdrawal lever ball pin and inner surface of

release bearing so that grease application, make sure that

grease is flush with grooves.

+Equally apply a thin coat of clutch sleeve grease to release

bearing frictional surface. After grease application, install

release bearing. Wipe off excess grease forced out during

bearing installation. Remove release bearing.

2. Installation is in the reverse order of removal.

CLUTCH RELEASE MECHANISMRS5F50A

Installation (Cont'd)

CL-21

Page 423 of 3051

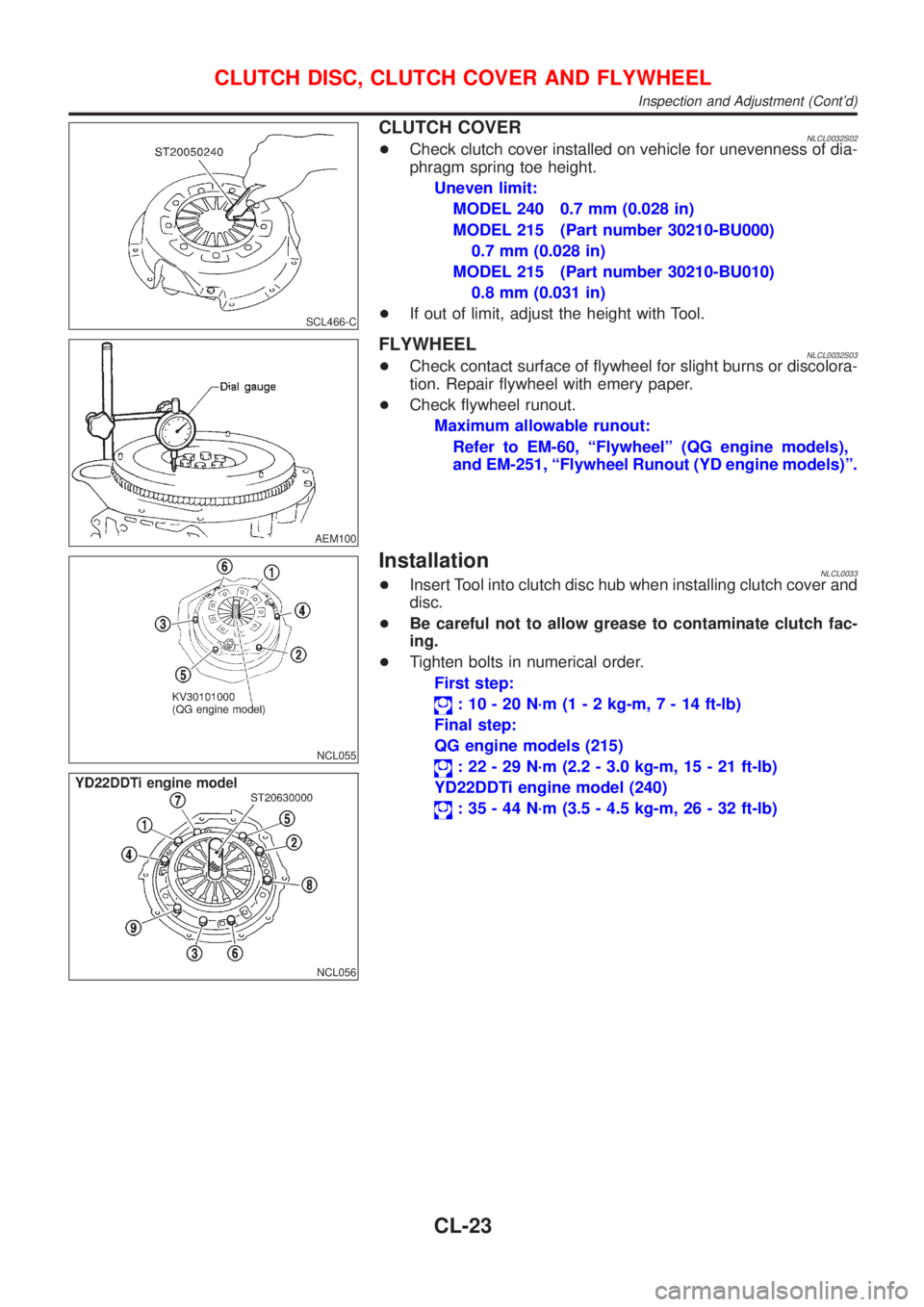

ComponentsNLCL0031

NCL054

SCL229

Inspection and AdjustmentNLCL0032CLUTCH DISCNLCL0032S01+Check clutch disc for wear of facing.

Wear limit of facing surface to rivet head:

MODEL 240, MODEL 215 (Part number 30100-

2F205)

0.3 mm (0.012 in)

Wearing thickness of facing:

MODEL 215 (Part number 30100-2F215)

1.3 mm (0.051 in)

SCL221

+Check clutch disc for backlash of spline and runout of facing.

Maximum spline backlash (at outer edge of disc):

MODEL 215 0.9 mm (0.035 in)

MODEL 240 1.0 mm (0.039 in)

Runout limit:

1.0 mm (0.039 in)

Distance of runout check point (from hub center):

MODEL 215 102.5 mm (4.04 in)

MODEL 240 115 mm (4.53 in)

+Check clutch disc for burns, discoloration or oil or grease leak-

age. Replace if necessary.

CLUTCH DISC, CLUTCH COVER AND FLYWHEEL

Components

CL-22

Page 424 of 3051

SCL466-C

AEM100

NCL055

NCL056

:10 -20 N´ m (1- 2kg-m ,7-14 ft-lb)

:22 -29 N´ m (2.2- 3.0 kg-m ,15 -21 ft-lb)

:35 -44 N´ m (3.5- 4.5 kg-m ,26 -32 ft-lb)

Inspection and Adjustment (Cont'd)

Page 425 of 3051

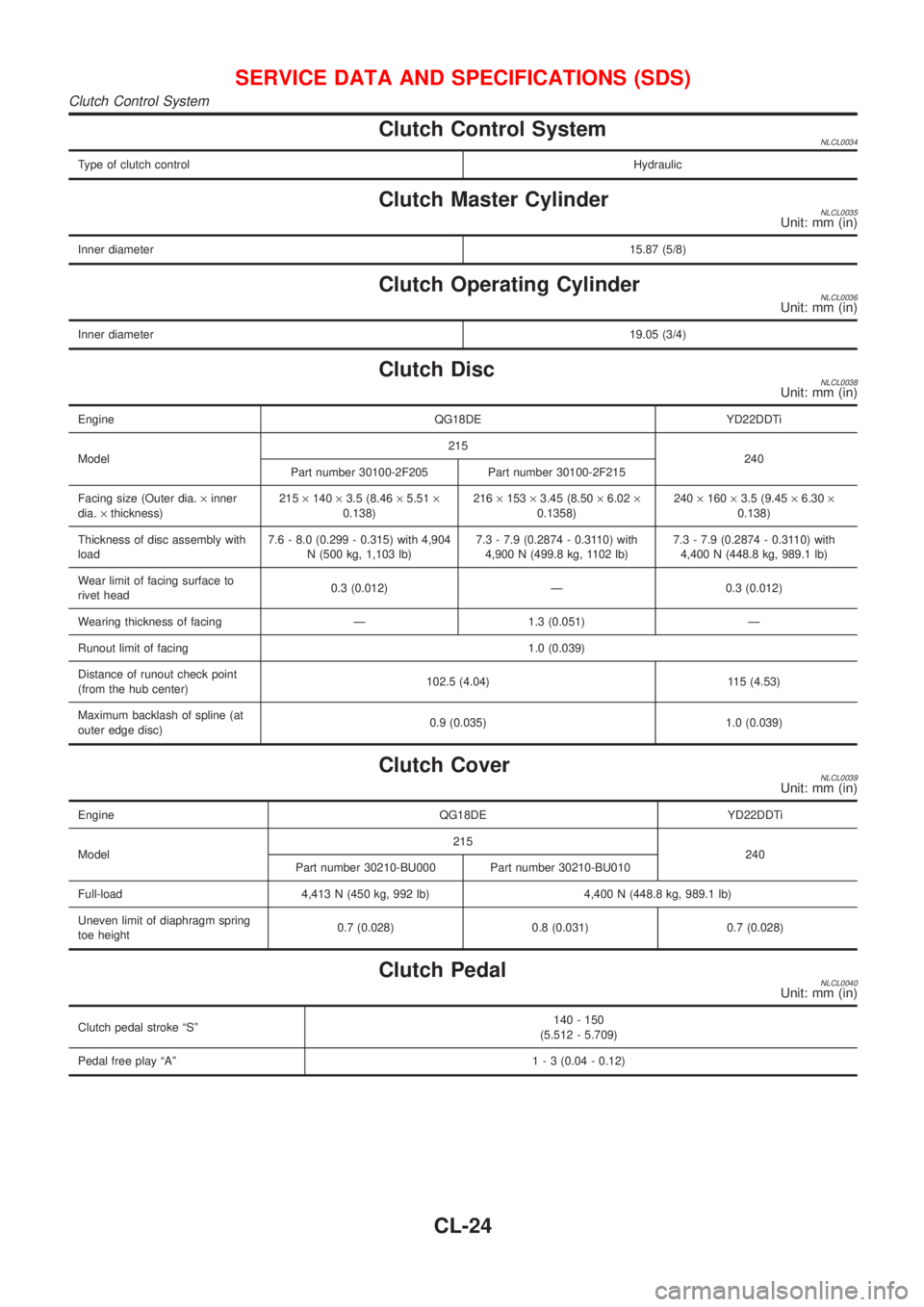

Clutch Control SystemNLCL0034

Type of clutch controlHydraulic

Clutch Master CylinderNLCL0035Unit: mm (in)

Inner diameter15.87 (5/8)

Clutch Operating CylinderNLCL0036Unit: mm (in)

Inner diameter19.05 (3/4)

Clutch DiscNLCL0038Unit: mm (in)

Engine QG18DE YD22DDTi

Model215

240

Part number 30100-2F205 Part number 30100-2F215

Facing size (Outer dia.´inner

dia.´thickness)215´140´3.5 (8.46´5.51´

0.138)216´153´3.45 (8.50´6.02´

0.1358)240´160´3.5 (9.45´6.30´

0.138)

Thickness of disc assembly with

load7.6 - 8.0 (0.299 - 0.315) with 4,904

N (500 kg, 1,103 lb)7.3 - 7.9 (0.2874 - 0.3110) with

4,900 N (499.8 kg, 1102 lb)7.3 - 7.9 (0.2874 - 0.3110) with

4,400 N (448.8 kg, 989.1 lb)

Wear limit of facing surface to

rivet head0.3 (0.012) Ð 0.3 (0.012)

Wearing thickness of facing Ð 1.3 (0.051) Ð

Runout limit of facing 1.0 (0.039)

Distance of runout check point

(from the hub center)102.5 (4.04) 115 (4.53)

Maximum backlash of spline (at

outer edge disc)0.9 (0.035) 1.0 (0.039)

Clutch CoverNLCL0039Unit: mm (in)

Engine QG18DE YD22DDTi

Model215

240

Part number 30210-BU000 Part number 30210-BU010

Full-load 4,413 N (450 kg, 992 lb) 4,400 N (448.8 kg, 989.1 lb)

Uneven limit of diaphragm spring

toe height0.7 (0.028) 0.8 (0.031) 0.7 (0.028)

Clutch PedalNLCL0040Unit: mm (in)

Clutch pedal stroke ªSº140 - 150

(5.512 - 5.709)

Pedal free play ªAº1 - 3 (0.04 - 0.12)

SERVICE DATA AND SPECIFICATIONS (SDS)

Clutch Control System

CL-24

Page 426 of 3051

ENGINE CONTROL SYSTEM

SECTION

EC

CONTENTS

QG18DE

TROUBLE DIAGNOSIS - INDEX..................................16

Alphabetical & P No. Index for DTC .........................16

PRECAUTIONS.............................................................21

Precautions for Supplemental Restraint System

(SRS)²AIR BAG²and²SEAT BELT

PRE-TENSIONER²....................................................21

Precautions for On Board Diagnostic (OBD)

System of Engine ......................................................21

Engine Fuel & Emission Control System ..................22

Wiring Diagrams and Trouble Diagnosis ...................24

PREPARATION.............................................................25

Special Service Tools ................................................25

Commercial Service Tools .........................................25

ENGINE AND EMISSION CONTROL OVERALL

SYSTEM.........................................................................26

Engine Control Component Parts Location ...............26

Circuit Diagram ..........................................................30

System Diagram ........................................................32

Vacuum Hose Drawing ..............................................33

System Chart .............................................................34

ENGINE AND EMISSION BASIC CONTROL

SYSTEM DESCRIPTION...............................................35

Multiport Fuel Injection (MFI) System .......................35

Electronic Ignition (EI) System ..................................37

Air Conditioning Cut Control ......................................38

Fuel Cut Control (at no load & high engine

speed) ........................................................................39

Evaporative Emission System ...................................39

Positive Crankcase Ventilation ..................................42

BASIC SERVICE PROCEDURE...................................43

Fuel Pressure Release ..............................................43

Fuel Pressure Check .................................................43

Fuel Pressure Regulator Check ................................44

Injector .......................................................................44

How to Check Idle Speed and Ignition Timing ..........46

Preparation ................................................................47

Inspection Procedure .................................................49Idle Air Volume Learning ...........................................57

ON BOARD DIAGNOSTIC SYSTEM

DESCRIPTION...............................................................59

Introduction ................................................................59

Two Trip Detection Logic ...........................................59

Emission-related Diagnostic Information ...................60

NATS (Nissan Anti-theft System) ..............................72

Malfunction Indicator (MI) ..........................................73

OBD System Operation Chart (With Euro-OBD

Models Only)..............................................................77

CONSULT-II ...............................................................82

Generic Scan Tool (GST) ..........................................93

TROUBLE DIAGNOSIS - INTRODUCTION..................95

Introduction ................................................................95

Work Flow ..................................................................97

TROUBLE DIAGNOSIS - BASIC INSPECTION...........99

Basic Inspection.........................................................99

TROUBLE DIAGNOSIS - GENERAL

DESCRIPTION.............................................................122

DTC Inspection Priority Chart..................................122

Fail-safe Chart .........................................................123

Symptom Matrix Chart .............................................124

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................128

Major Sensor Reference Graph in Data Monitor

Mode ........................................................................130

ECM Terminals and Reference Value .....................133

TROUBLE DIAGNOSIS - SPECIFICATION VALUE..141

Description ...............................................................141

Testing Condition .....................................................141

Inspection Procedure ...............................................141

Diagnostic Procedure ..............................................142

TROUBLE DIAGNOSIS FOR INTERMITTENT

INCIDENT.....................................................................145

Description ...............................................................145

Diagnostic Procedure ..............................................145

TROUBLE DIAGNOSIS FOR POWER SUPPLY........146

Main Power Supply and Ground Circuit ..................146

Page 427 of 3051

DTC P0100 MASS AIR FLOW SENSOR (MAFS)......154

Component Description ...........................................154

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................154

ECM Terminals and Reference Value .....................154

On Board Diagnosis Logic.......................................154

Fail-safe Mode .........................................................155

DTC Confirmation Procedure ..................................155

Wiring Diagram ........................................................156

Diagnostic Procedure ..............................................158

Component Inspection .............................................160

DTC P0110 INTAKE AIR TEMPERATURE

SENSOR......................................................................161

Component Description ...........................................161

On Board Diagnosis Logic.......................................162

DTC Confirmation Procedure ..................................162

Wiring Diagram ........................................................163

Diagnostic Procedure ..............................................165

Component Inspection .............................................167

DTC P0115 ENGINE COOLANT TEMPERATURE

SENSOR (ECTS) (CIRCUIT).......................................169

Component Description ...........................................169

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................169

On Board Diagnosis Logic.......................................169

Fail-safe Mode .........................................................170

DTC Confirmation Procedure ..................................170

Wiring Diagram ........................................................171

Diagnostic Procedure ..............................................173

Component Inspection .............................................174

DTC P0120 THROTTLE POSITION SENSOR...........175

Component Description ...........................................175

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................175

ECM Terminals and Reference Value .....................176

On Board Diagnosis Logic.......................................176

Fail-safe Mode .........................................................176

DTC Confirmation Procedure ..................................176

Wiring Diagram ........................................................178

Diagnostic Procedure ..............................................180

Component Inspection .............................................182

DTC P0130 HEATED OXYGEN SENSOR 1

(FRONT) (CIRCUIT).....................................................184

Component Description ...........................................184

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................184

ECM Terminals and Reference Value .....................184

On Board Diagnosis Logic.......................................185

DTC Confirmation Procedure ..................................185

Overall Function Check ...........................................186

Wiring Diagram ........................................................187

Diagnostic Procedure ..............................................189Component Inspection .............................................190

DTC P0131 HEATED OXYGEN SENSOR 1

(FRONT) (LEAN SHIFT MONITORING).....................192

Component Description ...........................................192

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................192

ECM Terminals and Reference Value .....................192

On Board Diagnosis Logic.......................................193

DTC Confirmation Procedure ..................................193

Overall Function Check ...........................................194

Diagnostic Procedure ..............................................194

Component Inspection .............................................196

DTC P0132 HEATED OXYGEN SENSOR 1

(FRONT) (RICH SHIFT MONITORING)......................198

Component Description ...........................................198

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................198

ECM Terminals and Reference Value .....................198

On Board Diagnosis Logic.......................................199

DTC Confirmation Procedure ..................................199

Overall Function Check ...........................................200

Diagnostic Procedure ..............................................200

Component Inspection .............................................202

DTC P0133 HEATED OXYGEN SENSOR 1

(FRONT) (RESPONSE MONITORING).......................204

Component Description ...........................................204

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................204

ECM Terminals and Reference Value .....................204

On Board Diagnosis Logic.......................................205

DTC Confirmation Procedure ..................................205

Overall Function Check ...........................................206

Wiring Diagram ........................................................207

Diagnostic Procedure ..............................................209

Component Inspection .............................................212

DTC P0134 HEATED OXYGEN SENSOR 1

(FRONT) (HIGH VOLTAGE)........................................214

Component Description ...........................................214

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................214

ECM Terminals and Reference Value .....................214

On Board Diagnosis Logic.......................................215

DTC Confirmation Procedure ..................................215

Wiring Diagram ........................................................216

Diagnostic Procedure ..............................................218

Component Inspection .............................................219

DTC P0135 HEATED OXYGEN SENSOR 1

(FRONT) HEATER.......................................................221

Description ...............................................................221

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................221

ECM Terminals and Reference Value .....................221

CONTENTS(Cont'd)

EC-2

Page 428 of 3051

On Board Diagnosis Logic.......................................221

DTC Confirmation Procedure ..................................222

Wiring Diagram ........................................................223

Diagnostic Procedure ..............................................225

Component Inspection .............................................226

DTC P0137 HEATED OXYGEN SENSOR 2

(REAR) (MIN. VOLTAGE MONITORING)...................227

Component Description ...........................................227

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................227

ECM Terminals and Reference Value .....................227

On Board Diagnosis Logic.......................................227

DTC Confirmation Procedure ..................................228

Overall Function Check ...........................................229

Wiring Diagram ........................................................230

Diagnostic Procedure ..............................................232

Component Inspection .............................................235

DTC P0138 HEATED OXYGEN SENSOR 2

(REAR) (MAX. VOLTAGE MONITORING).................237

Component Description ...........................................237

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................237

ECM Terminals and Reference Value .....................237

On Board Diagnosis Logic.......................................237

DTC Confirmation Procedure ..................................238

Overall Function Check ...........................................239

Wiring Diagram ........................................................240

Diagnostic Procedure ..............................................242

Component Inspection .............................................244

DTC P0139 HEATED OXYGEN SENSOR 2

(REAR) (RESPONSE MONITORING).........................246

Component Description ...........................................246

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................246

ECM Terminals and Reference Value .....................246

On Board Diagnosis Logic.......................................246

DTC Confirmation Procedure ..................................247

Overall Function Check ...........................................248

Wiring Diagram ........................................................249

Diagnostic Procedure ..............................................251

Component Inspection .............................................254

DTC P0140 HEATED OXYGEN SENSOR 2

(REAR) (HIGH VOLTAGE)..........................................256

Component Description ...........................................256

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................256

ECM Terminals and Reference Value .....................256

On Board Diagnosis Logic.......................................256

DTC Confirmation Procedure ..................................257

Overall Function Check ...........................................257

Wiring Diagram ........................................................258

Diagnostic Procedure ..............................................260Component Inspection .............................................261

DTC P0141 HEATED OXYGEN SENSOR 2

HEATER (REAR).........................................................263

Description ...............................................................263

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................263

ECM Terminals and Reference Value .....................263

On Board Diagnosis Logic.......................................264

DTC Confirmation Procedure ..................................264

Wiring Diagram ........................................................265

Diagnostic Procedure ..............................................267

Component Inspection .............................................268

DTC P0171 FUEL INJECTION SYSTEM

FUNCTION (LEAN SIDE)............................................269

On Board Diagnosis Logic.......................................269

DTC Confirmation Procedure ..................................269

Wiring Diagram ........................................................271

Diagnostic Procedure ..............................................273

DTC P0172 FUEL INJECTION SYSTEM

FUNCTION (RICH SIDE).............................................277

On Board Diagnosis Logic.......................................277

DTC Confirmation Procedure ..................................277

Wiring Diagram ........................................................279

Diagnostic Procedure ..............................................281

DTC P0300 - P0304 NO.4-1CYLINDER

MISFIRE, MULTIPLE CYLINDER MISFIRE...............285

On Board Diagnosis Logic.......................................285

DTC Confirmation Procedure ..................................285

Diagnostic Procedure ..............................................286

DTC P0325 KNOCK SENSOR (KS)...........................291

Component Description ...........................................291

ECM Terminals and Reference Value .....................291

On Board Diagnosis Logic.......................................291

DTC Confirmation Procedure ..................................291

Wiring Diagram ........................................................292

Diagnostic Procedure ..............................................293

Component Inspection .............................................294

DTC P0335 CRANKSHAFT POSITION SENSOR

(POS)............................................................................295

Component Description ...........................................295

ECM Terminals and Reference Value .....................295

On Board Diagnosis Logic.......................................296

DTC Confirmation Procedure ..................................296

Wiring Diagram ........................................................297

Diagnostic Procedure ..............................................299

Component Inspection .............................................301

DTC P0340 CAMSHAFT POSITION SENSOR

(CMPS) (PHASE).........................................................302

Component Description ...........................................302

ECM Terminals and Reference Value .....................302

On Board Diagnosis Logic.......................................303

DTC Confirmation Procedure ..................................303

CONTENTS(Cont'd)

EC-3

Page 429 of 3051

Wiring Diagram ........................................................304

Diagnostic Procedure ..............................................306

Component Inspection .............................................308

DTC P0400 EGR FUNCTION (CLOSED) (WHERE

FITTED)........................................................................310

Description ...............................................................310

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................ 311

ECM Terminals and Reference Value ..................... 311

On Board Diagnosis Logic....................................... 311

DTC Confirmation Procedure ..................................312

Wiring Diagram ........................................................314

Diagnostic Procedure ..............................................316

Component Inspection .............................................318

DTC P0403 EGR VOLUME CONTROL VALVE

(CIRCUIT) (WHERE FITTED)......................................319

Description ...............................................................319

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................320

ECM Terminals and Reference Value .....................320

On Board Diagnosis Logic.......................................320

DTC Confirmation Procedure ..................................320

Wiring Diagram ........................................................322

Diagnostic Procedure ..............................................324

Component Inspection .............................................326

DTC P0420 THREE WAY CATALYST FUNCTION...327

On Board Diagnosis Logic.......................................327

DTC Confirmation Procedure ..................................327

Overall Function Check ...........................................328

Diagnostic Procedure ..............................................328

DTC P0443 EVAP CANISTER PURGE VOLUME

CONTROL SOLENOID VALVE (CIRCUIT).................332

Description ...............................................................332

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................332

ECM Terminals and Reference Value .....................333

On Board Diagnosis Logic.......................................333

DTC Confirmation Procedure ..................................333

Wiring Diagram ........................................................334

Diagnostic Procedure ..............................................336

Component Inspection .............................................337

DTC P0500 VEHICLE SPEED SENSOR (VSS).........338

Component Description ...........................................338

ECM Terminals and Reference Value .....................338

On Board Diagnosis Logic.......................................338

DTC Confirmation Procedure ..................................338

Wiring Diagram ........................................................340

Diagnostic Procedure ..............................................342

DTC P0505 IDLE AIR CONTROL VALVE (IACV) -

AUXILIARY AIR CONTROL (AAC) VALVE...............343

Description ...............................................................343CONSULT-II Reference Value in Data Monitor

Mode ........................................................................344

ECM Terminals and Reference Value .....................344

On Board Diagnosis Logic.......................................344

DTC Confirmation Procedure ..................................344

Wiring Diagram ........................................................345

Diagnostic Procedure ..............................................347

Component Inspection .............................................351

DTC P0510 CLOSED THROTTLE POSITION

SWITCH (WHERE FITTED).........................................352

Component Description ...........................................352

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................352

ECM Terminals and Reference Value .....................352

On Board Diagnosis Logic.......................................352

DTC Confirmation Procedure ..................................352

Overall Function Check ...........................................353

Wiring Diagram ........................................................354

Diagnostic Procedure ..............................................355

Component Inspection .............................................356

DTC P0605 ECM.........................................................358

Component Description ...........................................358

On Board Diagnosis Logic.......................................358

DTC Confirmation Procedure ..................................358

Diagnostic Procedure ..............................................359

D T C P 1111INTAKE VALVE TIMING CONTROL

SOLENOID VALVE......................................................360

Component Description ...........................................360

Operation .................................................................360

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................360

ECM Terminals and Reference Value .....................360

On Board Diagnosis Logic.......................................360

DTC Confirmation Procedure ..................................361

Wiring Diagram ........................................................362

Diagnostic Procedure ..............................................364

Component Inspection .............................................365

DTC P1131 SWIRL CONTROL VALVE SOLENOID

VALVE (CIRCUIT) (WHERE FITTED).........................366

Description ...............................................................366

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................366

ECM Terminals and Reference Value .....................367

Component Description ...........................................367

On Board Diagnosis Logic.......................................367

DTC Confirmation Procedure ..................................367

Wiring Diagram ........................................................369

Diagnostic Procedure ..............................................370

Component Inspection .............................................371

DTC P1217 OVERHEAT (COOLING SYSTEM).........373

System Description ..................................................373

CONTENTS(Cont'd)

EC-4

Page 430 of 3051

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................373

ECM Terminals and Reference Value .....................374

On Board Diagnosis Logic.......................................374

Overall Function Check ...........................................375

Wiring Diagram ........................................................376

Diagnostic Procedure ..............................................378

Main 12 Causes of Overheating..............................384

Component Inspection .............................................384

DTC P1401 EGR TEMPERATURE SENSOR

(WHERE FITTED)........................................................386

Component Description ...........................................386

On Board Diagnosis Logic.......................................386

DTC Confirmation Procedure ..................................386

Wiring Diagram ........................................................389

Diagnostic Procedure ..............................................391

Component Inspection .............................................392

DTC P1402 EGR FUNCTION (OPEN) (WHERE

FITTED)........................................................................393

Description ...............................................................393

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................394

ECM Terminals and Reference Value .....................394

On Board Diagnosis Logic.......................................394

DTC Confirmation Procedure ..................................395

Wiring Diagram ........................................................397

Diagnostic Procedure ..............................................399

Component Inspection .............................................400

DTC P1706 PARK/NEUTRAL POSITION (PNP)

SWITCH.......................................................................402

Component Description ...........................................402

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................402

ECM Terminals and Reference Value .....................402

On Board Diagnosis Logic.......................................402

DTC Confirmation Procedure ..................................402

Overall Function Check ...........................................403

Wiring Diagram ........................................................404

Diagnostic Procedure ..............................................405

INTAKE AIR TEMPERATURE SENSOR....................407

Component Description ...........................................407

Wiring Diagram ........................................................409

Diagnostic Procedure .............................................. 411

Component Inspection .............................................413

HEATED OXYGEN SENSOR 1 (FRONT)...................414

Component Description ...........................................414

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................414

ECM Terminals and Reference Value .....................414

Wiring Diagram ........................................................415

Diagnostic Procedure ..............................................417

Component Inspection .............................................419HEATED OXYGEN SENSOR 1 HEATER (FRONT)...421

Description ...............................................................421

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................421

ECM Terminals and Reference Value .....................421

Wiring Diagram ........................................................422

Diagnostic Procedure ..............................................424

Component Inspection .............................................425

HEATED OXYGEN SENSOR 2 (REAR).....................426

Component Description ...........................................426

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................426

ECM Terminals and Reference Value .....................426

Wiring Diagram ........................................................427

Diagnostic Procedure ..............................................429

Component Inspection .............................................431

HEATED OXYGEN SENSOR 2 HEATER (REAR).....433

Description ...............................................................433

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................433

ECM Terminals and Reference Value .....................433

Wiring Diagram ........................................................434

Diagnostic Procedure ..............................................436

Component Inspection .............................................438

CRANKSHAFT POSITION SENSOR (POS)...............439

Component Description ...........................................439

ECM Terminals and Reference Value .....................439

Wiring Diagram ........................................................440

Diagnostic Procedure ..............................................442

Component Inspection .............................................445

EGR VOLUME CONTROL SYSTEM (WHERE

FITTED)........................................................................446

Description ...............................................................446

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................447

ECM Terminals and Reference Value .....................448

Wiring Diagram ........................................................449

Diagnostic Procedure ..............................................451

Component Inspection .............................................456

EVAP CANISTER PURGE VOLUME CONTROL

SOLENOID VALVE......................................................458

Description ...............................................................458

CONSULT-II Reference Value in Data Monitor

Mode ........................................................................458

ECM Terminals and Reference Value .....................459

Wiring Diagram ........................................................460

Diagnostic Procedure ..............................................462

Component Inspection .............................................465

IDLE AIR CONTROL VALVE (IACV) - AUXILIARY

AIR CONTROL (AAC) VALVE....................................466

Description ...............................................................466

CONTENTS(Cont'd)

EC-5