oil temperature NISSAN ALMERA TINO 2001 Service Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA TINO, Model: NISSAN ALMERA TINO 2001Pages: 3051, PDF Size: 46.38 MB

Page 2302 of 3051

Unit: mm (in)

For adjusting For checking

HotCold* (reference

data)Hot

Intake0.32 - 0.40

(0.013 - 0.016)0.25 - 0.33

(0.010 - 0.013)0.21 - 0.49

(0.008 - 0.019)

Exhaust0.37 - 0.45

(0.015 - 0.018)0.32 - 0.40

(0.013 - 0.016)0.30 - 0.58

(0.012 - 0.023)

*: At a temperature of approximately 20ÉC (68ÉF)

Whenever valve clearances are adjusted to cold specifications, check that

the clearances satisfy hot specifications and adjust again if necessary.

AEM293

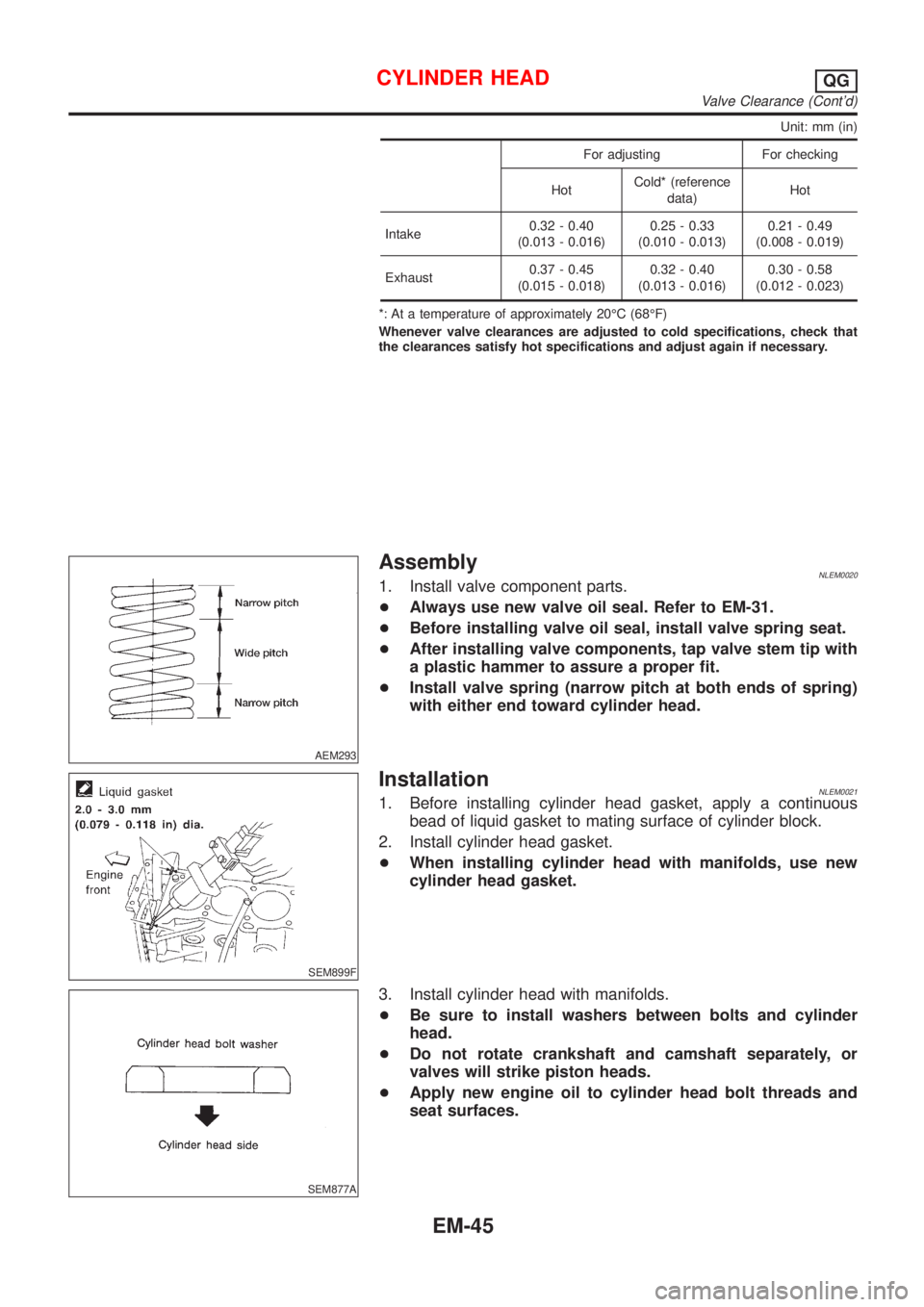

AssemblyNLEM00201. Install valve component parts.

+Always use new valve oil seal. Refer to EM-31.

+Before installing valve oil seal, install valve spring seat.

+After installing valve components, tap valve stem tip with

a plastic hammer to assure a proper fit.

+Install valve spring (narrow pitch at both ends of spring)

with either end toward cylinder head.

SEM899F

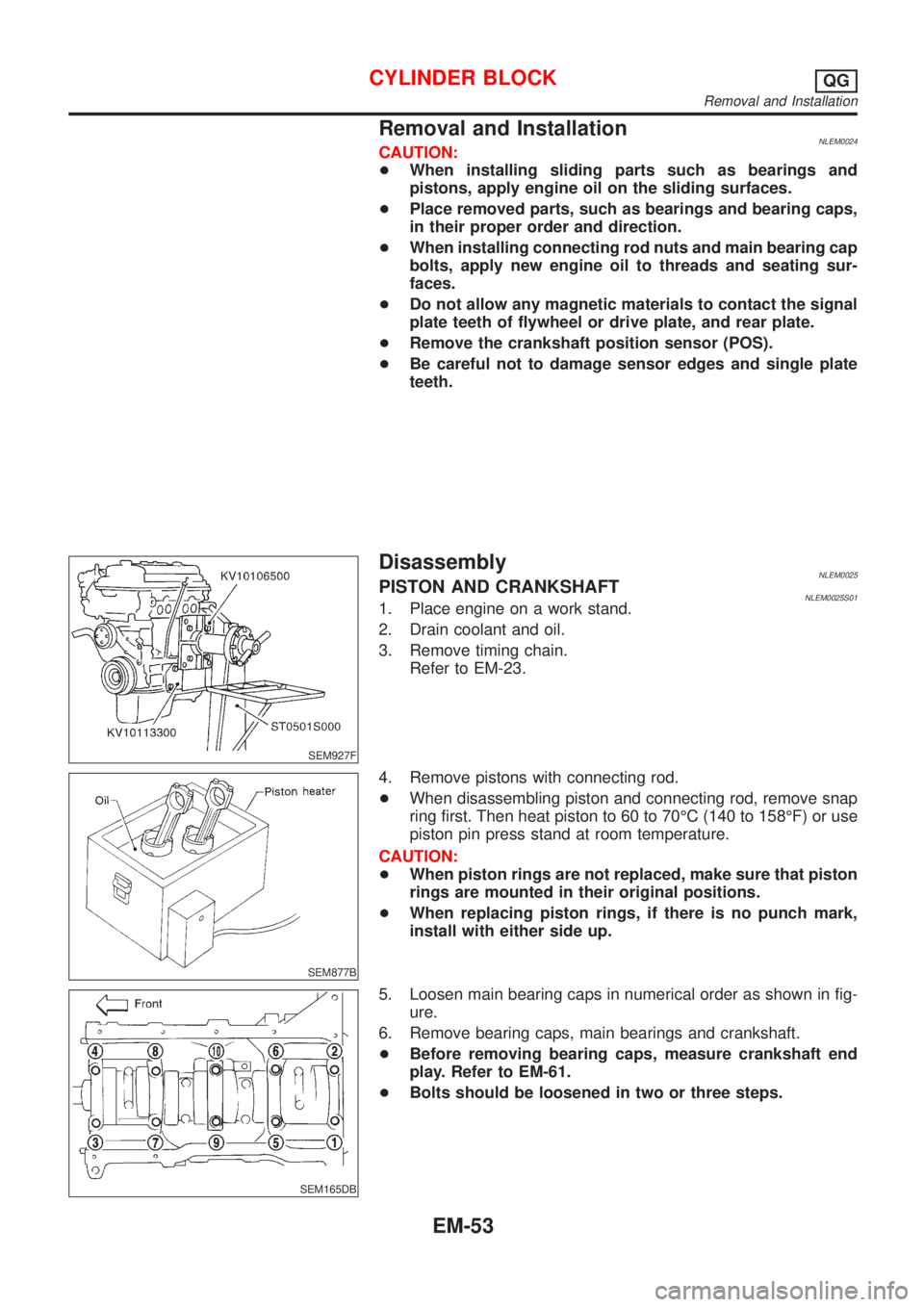

InstallationNLEM00211. Before installing cylinder head gasket, apply a continuous

bead of liquid gasket to mating surface of cylinder block.

2. Install cylinder head gasket.

+When installing cylinder head with manifolds, use new

cylinder head gasket.

SEM877A

3. Install cylinder head with manifolds.

+Be sure to install washers between bolts and cylinder

head.

+Do not rotate crankshaft and camshaft separately, or

valves will strike piston heads.

+Apply new engine oil to cylinder head bolt threads and

seat surfaces.

CYLINDER HEADQG

Valve Clearance (Cont'd)

EM-45

Page 2310 of 3051

Removal and InstallationNLEM0024CAUTION:

+When installing sliding parts such as bearings and

pistons, apply engine oil on the sliding surfaces.

+Place removed parts, such as bearings and bearing caps,

in their proper order and direction.

+When installing connecting rod nuts and main bearing cap

bolts, apply new engine oil to threads and seating sur-

faces.

+Do not allow any magnetic materials to contact the signal

plate teeth of flywheel or drive plate, and rear plate.

+Remove the crankshaft position sensor (POS).

+Be careful not to damage sensor edges and single plate

teeth.

SEM927F

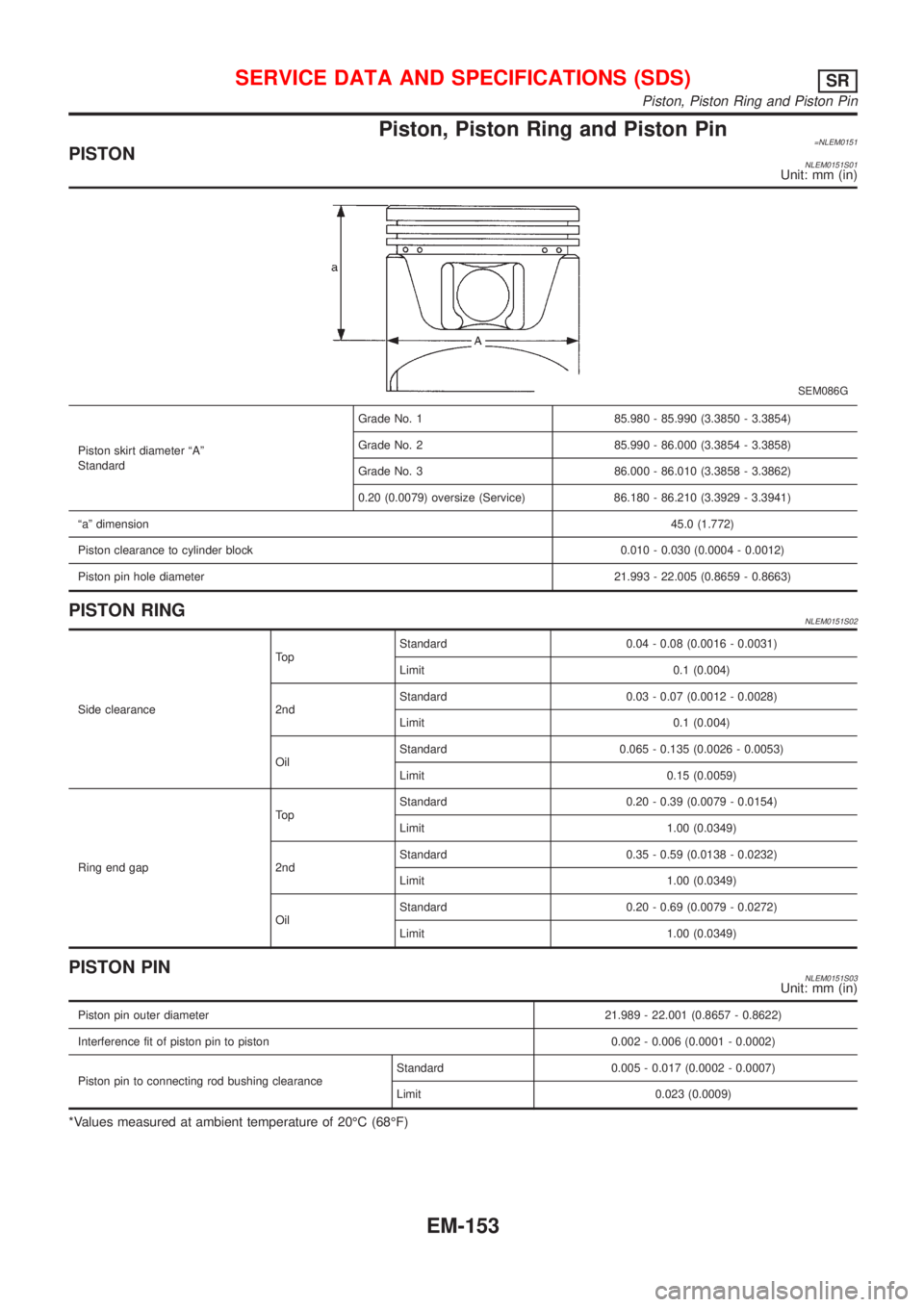

DisassemblyNLEM0025PISTON AND CRANKSHAFTNLEM0025S011. Place engine on a work stand.

2. Drain coolant and oil.

3. Remove timing chain.

Refer to EM-23.

SEM877B

4. Remove pistons with connecting rod.

+When disassembling piston and connecting rod, remove snap

ring first. Then heat piston to 60 to 70ÉC (140 to 158ÉF) or use

piston pin press stand at room temperature.

CAUTION:

+When piston rings are not replaced, make sure that piston

rings are mounted in their original positions.

+When replacing piston rings, if there is no punch mark,

install with either side up.

SEM165DB

5. Loosen main bearing caps in numerical order as shown in fig-

ure.

6. Remove bearing caps, main bearings and crankshaft.

+Before removing bearing caps, measure crankshaft end

play. Refer to EM-61.

+Bolts should be loosened in two or three steps.

CYLINDER BLOCKQG

Removal and Installation

EM-53

Page 2410 of 3051

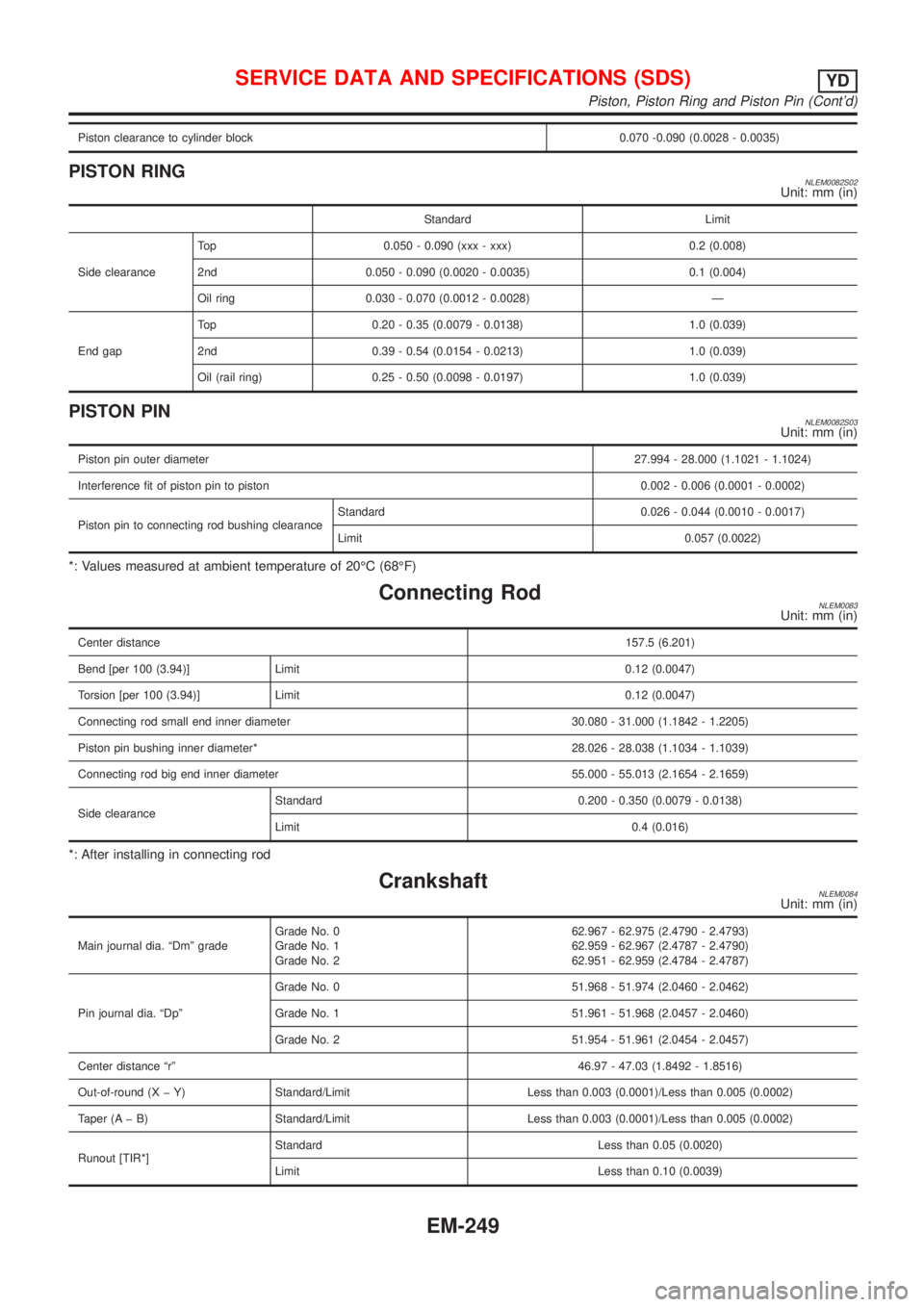

Piston, Piston Ring and Piston Pin=NLEM0151PISTONNLEM0151S01Unit: mm (in)

SEM086G

Piston skirt diameter ªAº

StandardGrade No. 1 85.980 - 85.990 (3.3850 - 3.3854)

Grade No. 2 85.990 - 86.000 (3.3854 - 3.3858)

Grade No. 3 86.000 - 86.010 (3.3858 - 3.3862)

0.20 (0.0079) oversize (Service) 86.180 - 86.210 (3.3929 - 3.3941)

ªaº dimension45.0 (1.772)

Piston clearance to cylinder block 0.010 - 0.030 (0.0004 - 0.0012)

Piston pin hole diameter21.993 - 22.005 (0.8659 - 0.8663)

PISTON RINGNLEM0151S02

Side clearanceTo pStandard 0.04 - 0.08 (0.0016 - 0.0031)

Limit 0.1 (0.004)

2ndStandard 0.03 - 0.07 (0.0012 - 0.0028)

Limit 0.1 (0.004)

OilStandard 0.065 - 0.135 (0.0026 - 0.0053)

Limit 0.15 (0.0059)

Ring end gapTo pStandard 0.20 - 0.39 (0.0079 - 0.0154)

Limit 1.00 (0.0349)

2ndStandard 0.35 - 0.59 (0.0138 - 0.0232)

Limit 1.00 (0.0349)

OilStandard 0.20 - 0.69 (0.0079 - 0.0272)

Limit 1.00 (0.0349)

PISTON PINNLEM0151S03Unit: mm (in)

Piston pin outer diameter21.989 - 22.001 (0.8657 - 0.8622)

Interference fit of piston pin to piston 0.002 - 0.006 (0.0001 - 0.0002)

Piston pin to connecting rod bushing clearanceStandard 0.005 - 0.017 (0.0002 - 0.0007)

Limit 0.023 (0.0009)

*Values measured at ambient temperature of 20ÉC (68ÉF)

SERVICE DATA AND SPECIFICATIONS (SDS)SR

Piston, Piston Ring and Piston Pin

EM-153

Page 2506 of 3051

Piston clearance to cylinder block 0.070 -0.090 (0.0028 - 0.0035)

PISTON RINGNLEM0082S02Unit: mm (in)

Standard Limit

Side clearanceTop 0.050 - 0.090 (xxx - xxx) 0.2 (0.008)

2nd 0.050 - 0.090 (0.0020 - 0.0035) 0.1 (0.004)

Oil ring 0.030 - 0.070 (0.0012 - 0.0028) Ð

End gapTop 0.20 - 0.35 (0.0079 - 0.0138) 1.0 (0.039)

2nd 0.39 - 0.54 (0.0154 - 0.0213) 1.0 (0.039)

Oil (rail ring) 0.25 - 0.50 (0.0098 - 0.0197) 1.0 (0.039)

PISTON PINNLEM0082S03Unit: mm (in)

Piston pin outer diameter27.994 - 28.000 (1.1021 - 1.1024)

Interference fit of piston pin to piston 0.002 - 0.006 (0.0001 - 0.0002)

Piston pin to connecting rod bushing clearanceStandard 0.026 - 0.044 (0.0010 - 0.0017)

Limit 0.057 (0.0022)

*: Values measured at ambient temperature of 20ÉC (68ÉF)

Connecting RodNLEM0083Unit: mm (in)

Center distance157.5 (6.201)

Bend [per 100 (3.94)] Limit 0.12 (0.0047)

Torsion [per 100 (3.94)] Limit 0.12 (0.0047)

Connecting rod small end inner diameter 30.080 - 31.000 (1.1842 - 1.2205)

Piston pin bushing inner diameter* 28.026 - 28.038 (1.1034 - 1.1039)

Connecting rod big end inner diameter 55.000 - 55.013 (2.1654 - 2.1659)

Side clearanceStandard 0.200 - 0.350 (0.0079 - 0.0138)

Limit 0.4 (0.016)

*: After installing in connecting rod

CrankshaftNLEM0084Unit: mm (in)

Main journal dia. ªDmº gradeGrade No. 0

Grade No. 1

Grade No. 262.967 - 62.975 (2.4790 - 2.4793)

62.959 - 62.967 (2.4787 - 2.4790)

62.951 - 62.959 (2.4784 - 2.4787)

Pin journal dia. ªDpºGrade No. 0 51.968 - 51.974 (2.0460 - 2.0462)

Grade No. 1 51.961 - 51.968 (2.0457 - 2.0460)

Grade No. 2 51.954 - 51.961 (2.0454 - 2.0457)

Center distance ªrº46.97 - 47.03 (1.8492 - 1.8516)

Out-of-round (X þ Y) Standard/Limit Less than 0.003 (0.0001)/Less than 0.005 (0.0002)

Taper (A þ B) Standard/Limit Less than 0.003 (0.0001)/Less than 0.005 (0.0002)

Runout [TIR*]Standard Less than 0.05 (0.0020)

Limit Less than 0.10 (0.0039)

SERVICE DATA AND SPECIFICATIONS (SDS)YD

Piston, Piston Ring and Piston Pin (Cont'd)

EM-249

Page 2547 of 3051

+Do not use gasoline, kerosine, diesel fuel, gas oil, thinners or

solvents for cleaning skin.

+If skin disorders develop, obtain medical advice without delay.

+Where practicable, degrease components prior to handling.

+Where there is a risk of eye contact, eye protection should be

worn, for example, chemical goggles or face shields; in addi-

tion an eye wash facility should be provided.

Environmental Protection PrecautionsNLGI0001S0702Burning used engine oil in small space heaters or boilers can be

recommended only for units of approved design. The heating sys-

tem must meet the requirements of HM Inspectorate of Pollution for

small burners of less than 0.4 MW. If in doubt, check with the

appropriate local authority and/or manufacturer of the approved

appliance.

Dispose of used oil and used oil filters through authorized waste

disposal contractors to licensed waste disposal sites, or to the

waste oil reclamation trade. If in doubt, contact the local authority

for advice on disposal facilities.

It is illegal to pour used oil on to the ground, down sewers or drains,

or into water courses.

The regulations concerning the pollution vary between

regions.

PRECAUTIONS FOR FUELNLGI0001S08Gasoline EngineNLGI0001S0804Models with three way catalyst

Unleaded premium gasoline of at least 95 octane (RON)

If premium gasoline is not available, unleaded regular gaso-

line with an octane rating of 91 (RON) may be temporarily

used, but only under the following precautions:

+Have the fuel tank filled only partially with unleaded regu-

lar gasoline, and fill up with premium unleaded gasoline

as soon as possible.

+Avoid full throttle driving and abrupt acceleration.

CAUTION:

Do not use leaded gasoline. Using leaded gasoline will dam-

age the three way catalyst.

Diesel Engine*:NLGI0001S0805Diesel fuel of at least 50 cetane

* If two types of diesel fuel are available, use summer or winter

fuel properly according to the following temperature conditions.

+Above �7°C (20°F) ... Summer type diesel fuel.

+Below �7°C (20°F) ... Winter type diesel fuel.

CAUTION:

+Do not use home heating oil, gasoline, or other alternate

fuels in your diesel engine. The use of those can cause

engine damage.

+Do not use summer fuel at temperatures below �7°C

(20°F). The cold temperatures will cause wax to form in the

fuel. As a result, it may prevent the engine from running

smoothly.

+Do not add gasoline or other alternate fuels to diesel fuel.

PRECAUTIONS FOR AIR CONDITIONINGNLGI0001S09Use an approved refrigerant recovery unit any time the air condi-

tioning system must be discharged. Refer to HA-85, “HFC-134a

(R-134a) Service Procedure” for specific instructions.

PRECAUTIONS

Precautions (Cont’d)

GI-8

Page 2596 of 3051

+When installing an air conditioner in the vehicle, connect the pipes as the final stage of the opera-

tion. Do not remove the seal caps of pipes and other components until just before required for

connection.

+Allow components stored in cool areas to warm to working area temperature before removing seal

caps. This prevents condensation from forming inside A/C components.

+Thoroughly remove moisture from the refrigeration system before charging the refrigerant.

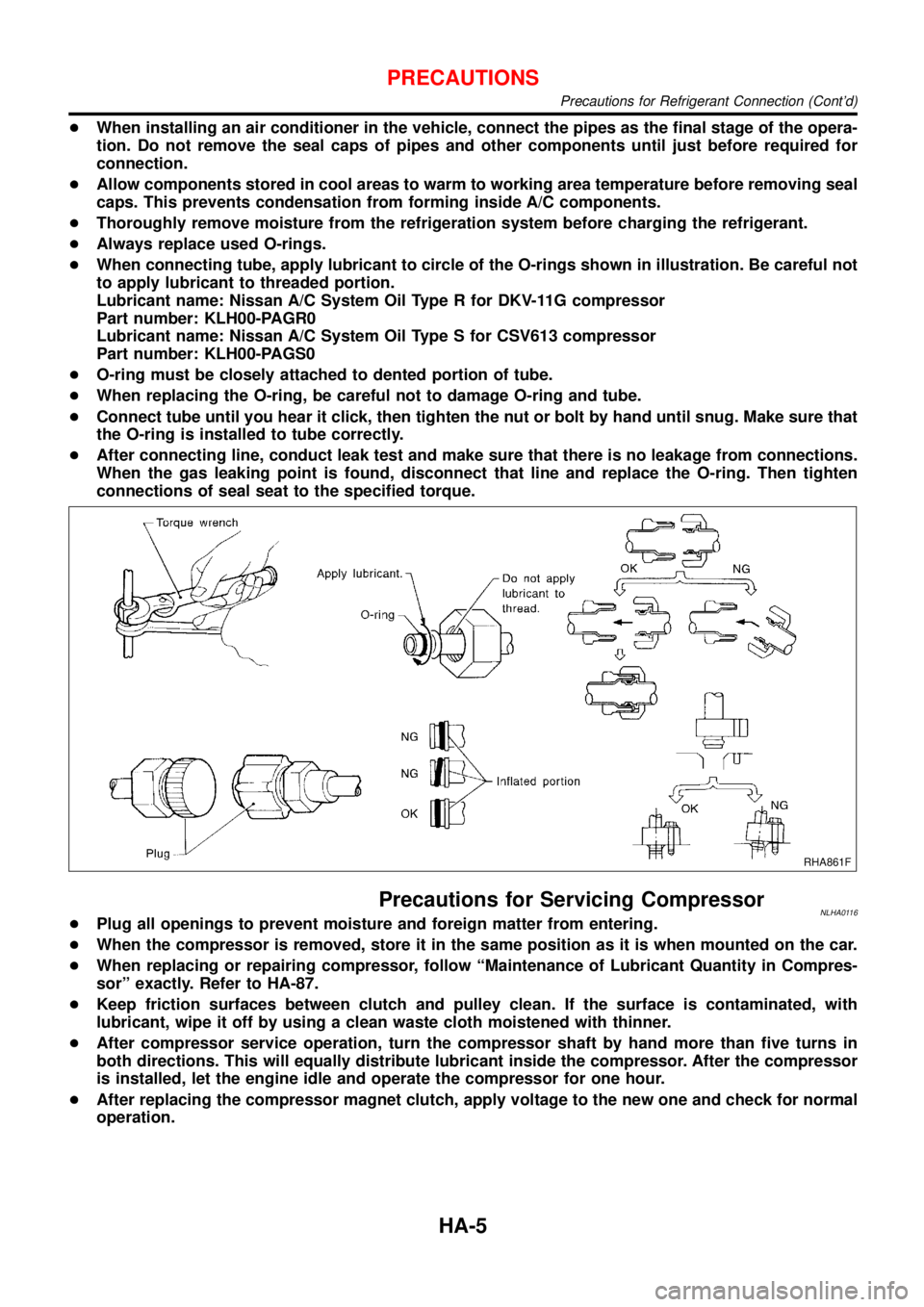

+Always replace used O-rings.

+When connecting tube, apply lubricant to circle of the O-rings shown in illustration. Be careful not

to apply lubricant to threaded portion.

Lubricant name: Nissan A/C System Oil Type R for DKV-11G compressor

Part number: KLH00-PAGR0

Lubricant name: Nissan A/C System Oil Type S for CSV613 compressor

Part number: KLH00-PAGS0

+O-ring must be closely attached to dented portion of tube.

+When replacing the O-ring, be careful not to damage O-ring and tube.

+Connect tube until you hear it click, then tighten the nut or bolt by hand until snug. Make sure that

the O-ring is installed to tube correctly.

+After connecting line, conduct leak test and make sure that there is no leakage from connections.

When the gas leaking point is found, disconnect that line and replace the O-ring. Then tighten

connections of seal seat to the specified torque.

RHA861F

Precautions for Servicing CompressorNLHA0116+Plug all openings to prevent moisture and foreign matter from entering.

+When the compressor is removed, store it in the same position as it is when mounted on the car.

+When replacing or repairing compressor, follow“Maintenance of Lubricant Quantity in Compres-

sor”exactly. Refer to HA-87.

+Keep friction surfaces between clutch and pulley clean. If the surface is contaminated, with

lubricant, wipe it off by using a clean waste cloth moistened with thinner.

+After compressor service operation, turn the compressor shaft by hand more than five turns in

both directions. This will equally distribute lubricant inside the compressor. After the compressor

is installed, let the engine idle and operate the compressor for one hour.

+After replacing the compressor magnet clutch, apply voltage to the new one and check for normal

operation.

PRECAUTIONS

Precautions for Refrigerant Connection (Cont’d)

HA-5

Page 2603 of 3051

Refrigeration System

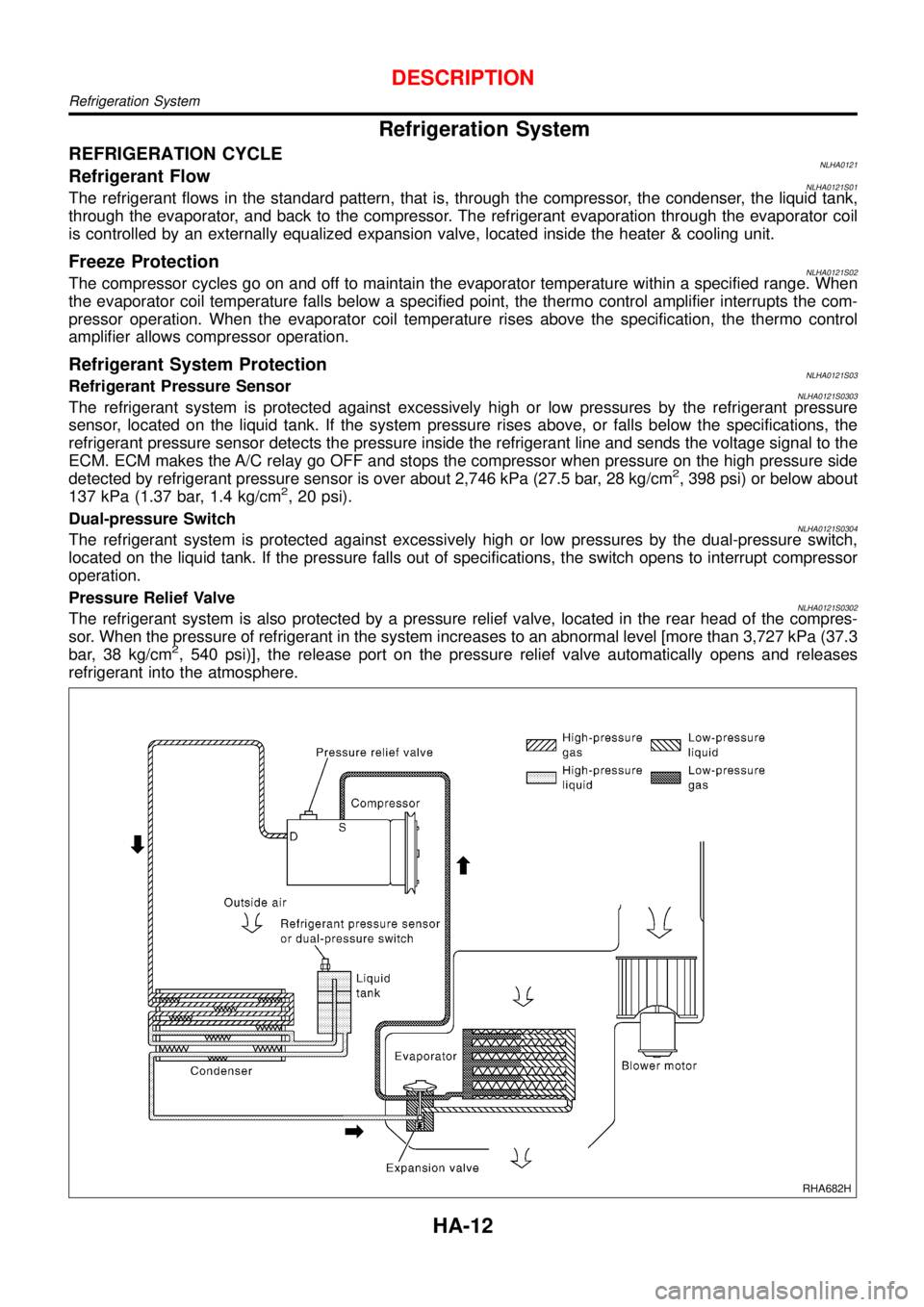

REFRIGERATION CYCLENLHA0121Refrigerant FlowNLHA0121S01The refrigerant flows in the standard pattern, that is, through the compressor, the condenser, the liquid tank,

through the evaporator, and back to the compressor. The refrigerant evaporation through the evaporator coil

is controlled by an externally equalized expansion valve, located inside the heater & cooling unit.

Freeze ProtectionNLHA0121S02The compressor cycles go on and off to maintain the evaporator temperature within a specified range. When

the evaporator coil temperature falls below a specified point, the thermo control amplifier interrupts the com-

pressor operation. When the evaporator coil temperature rises above the specification, the thermo control

amplifier allows compressor operation.

Refrigerant System ProtectionNLHA0121S03Refrigerant Pressure SensorNLHA0121S0303The refrigerant system is protected against excessively high or low pressures by the refrigerant pressure

sensor, located on the liquid tank. If the system pressure rises above, or falls below the specifications, the

refrigerant pressure sensor detects the pressure inside the refrigerant line and sends the voltage signal to the

ECM. ECM makes the A/C relay go OFF and stops the compressor when pressure on the high pressure side

detected by refrigerant pressure sensor is over about 2,746 kPa (27.5 bar, 28 kg/cm

2, 398 psi) or below about

137 kPa (1.37 bar, 1.4 kg/cm2, 20 psi).

Dual-pressure Switch

NLHA0121S0304The refrigerant system is protected against excessively high or low pressures by the dual-pressure switch,

located on the liquid tank. If the pressure falls out of specifications, the switch opens to interrupt compressor

operation.

Pressure Relief Valve

NLHA0121S0302The refrigerant system is also protected by a pressure relief valve, located in the rear head of the compres-

sor. When the pressure of refrigerant in the system increases to an abnormal level [more than 3,727 kPa (37.3

bar, 38 kg/cm

2, 540 psi)], the release port on the pressure relief valve automatically opens and releases

refrigerant into the atmosphere.

RHA682H

DESCRIPTION

Refrigeration System

HA-12

Page 2678 of 3051

Maintenance of Lubricant Quantity in

Compressor

NLHA0160The lubricant in the compressor circulates through the system with

the refrigerant. Add lubricant to compressor when replacing any

component or after a large gas leakage occurred. It is important to

maintain the specified amount.

If lubricant quantity is not maintained properly, the following mal-

functions may result:

+Lack of lubricant: May lead to a seized compressor

+Excessive lubricant: Inadequate cooling (thermal exchange

interference)

LUBRICANTNLHA0160S01Name: Nissan A/C System Oil Type S for CSV613 compressor

Part number: KLH00-PAGS0

CHECKING AND ADJUSTINGNLHA0160S02Adjust the lubricant quantity according to the test group shown

below.

1 LUBRICANT RETURN OPERATION

Can lubricant return operation be performed?

+A/C system works properly.

+There is no evidence of a large amount of lubricant leakage.

YesorNo

Ye s©GO TO 2.

No©GO TO 3.

2 PERFORM LUBRICANT RETURN OPERATION, PROCEEDING AS FOLLOWS

1. Start engine, and set the following conditions:

+Test condition

Engine speed: Idling to 1,200 rpm

A/C or AUTO switch: ON

Blower speed: Max. position

Temp. control: Optional [Set so that intake air temperature is 25 to 30°C (77 to 86°F).]

2. Perform lubricant return operation for about 10 minutes.

3. Stop engine.

CAUTION:

If excessive lubricant leakage is noted, do not perform the lubricant return operation.

©GO TO 3.

3 CHECK COMPRESSOR

Should the compressor be replaced?

YesorNo

Ye s©GO TO HA-89.

No©GO TO 4.

SERVICE PROCEDURE

Maintenance of Lubricant Quantity in Compressor

HA-87

Page 2698 of 3051

Canister - See EVAP canister .......... EC-39, 573

Charging system ....................................... SC-24

Cigarette lighter ....................................... EL-195

Circuit breaker ........................................... EL-32

Closed throttle position switch ....... EC-352, 872

Clutch cover .............................................. CL-22

Clutch disc ................................................. CL-22

Clutch master cylinder ............................... CL-11

Clutch operating cylinder ........................... CL-14

Clutch pedal .............................................. CL-10

Clutch release bearing ........................ CL-17, 20

Clutch release mechanism .................. CL-17, 20

Clutch withdrawal lever ....................... CL-17, 20

Coil spring (front) ...................................... SU-10

Coil spring (rear) ....................................... SU-23

Collision diagnosis .................................... RS-66

Combination lamp, rear, removal and

installation .............................................. BT-38

Combination meter removal and instal-

lation - See Instrument panel ................ BT-22

Combination meter .................................. EL-130

Combination switch ................................... EL-64

Compression pressure ........................... EM-164

Compressor clutch removal and

installation .............................................. HA-90

Compressor precaution ............................... HA-5

Compressor special service tool ................. HA-9

Connecting rod bearing clearance .. EM-58, 140,

232

Connecting rod bushing clearance .. EM-59, 141,

234

Connecting rod ......................... EM-55, 136, 227

Console box - See Instrument panel ......... BT-22

Control lever (M/T) .................................... MT-23

Converter housing installation ................. AT-207

Coolant mixture ratio ................................ MA-22

Cooling circuit (engine) ................. LC-12, 32, 53

Cooling fan control system ........................ LC-59

Cooling fan control ............... EC-373, 882, 1201

Cooling fan motor ........................... EC-385, 899

Cooling fan relay ............................. EC-384, 898

Coupling sleeve (M/T) ........................ MT-25, 63

Crank angle sensor built into distribu-

tor - See Camshaft position

sensor .................................................. EC-825

Crankcase emission control system -

See Positive crankcase ventilation ...... EC-42,

576, 1082

Crankcase ventilation system - See

Positive crankcase ventilation ...... EC-42, 576,

1082

Crankshaft position sensor (OBD) . EC-295, 439,

819, 969

Crankshaft position sensor (POS) .. EC-295, 439

Crankshaft position sensor (TDC) ......... EC-1166

Crankshaft ................................ EM-57, 138, 229

Cylinder block ........................... EM-52, 133, 221

Cylinder head ........................... EM-33, 108, 200D

DEF - Wiring diagram .............................. EL-199

DTC work support ............................. EC-91, 615

Data link connector for Consult ....... EC-43, 577,

1102

Daytime light system ................................. EL-73

Detonation sensor - See Knock

sensor .......................................... EC-291, 815

Diagnosis sensor unit ............................... RS-21

Diagnostic trouble code (DTC) for

OBD system ................... EC-16, 70, 550, 595,

1064, 1096

Diagnostic trouble code (DTC) inspec-

tion priority chart ......................... EC-122, 646

Differential gear (FF M/T) ............. MT-25, 63, 77

Dimensions ................................................. GI-41

Dome light - See Interior lamp ................ EL-116

Door glass ................................................. BT-14

Door lock ................................................... BT-18

Door mirror ................................................ BT-63

Door trim .................................................... BT-32

Door, front .................................................. BT-13

Door, rear ................................................... BT-13

Drive plate runout ..................... EM-60, 142, 235

Drive shaft (front) ...................................... AX-10

Dropping resistor (A/T) .................... AT-103, 163

Dual pressure switch ................................ HA-12

E

ECCS-D control module ... EC-1129, 1177, 1185,

1253, 1255, 1260, 1262

ECM input/output signal ........ EC-133, 657, 1129

ECTS - Wiring diagram ......... EC-171, 696, 1150

EGR control valve ................................... EC-400

EGR temperature sensor ................ EC-386, 915

EGR volume control valve ............ EC-319, 1277

EGR/TS - Wiring diagram ............... EC-389, 918

EGRC/V - Wiring diagram ....................... EC-322

EGRC1 - Wiring diagram ....... EC-314, 397, 449,

838, 925, 978, 1279

EVAP canister purge volume control

solenoid valve ............................... EC-40, 574

EVAP canister purge volume control

valve ............................ EC-332, 458, 852, 986

EVAP canister ................................... EC-40, 574

Electric sunroof ........................................ EL-238

Electrical diagnoses ................................... GI-21

Electrical ignition system .................. EC-37, 571

Electrical load signal circuit .......... EC-535, 1050

Electrical unit ........................................... EL-530

Electrical units location ............................ EL-442

Electronic fuel injection pump .... EC-1087, 1187,

1194, 1218, 1225, 1232, 1239, 1246, 1264

Engine compartment ................................. BT-66

Engine control circuit diagram ......... EC-30, 564,

1074

ALPHABETICAL INDEX

IDX-3

Page 2699 of 3051

Engine control component parts

location ................................ EC-26, 560, 1071

Engine control module (ECM) ........ EC-358, 880

Engine control system diagram and

chart .................................... EC-32, 566, 1076

Engine coolant temperature sensor

(ECTS) .............................. EC-169, 694, 1150

Engine fail-safe system .................. EC-123, 647

Engine oil precautions .................................. GI-7

Engine outer component parts ........... EM-12, 82

Engine removal ........................ EM-49, 130, 218

Engine room - See Engine

compartment .......................................... BT-66

Engine serial number ................................. GI-39

Evaporative emission (EVAP)

system ........................................... EC-39, 573

Exhaust gas recirculation (EGR)

valve ........... EC-310, 393, 446, 834, 921, 975

Exhaust system ................................... FE-11, 23

Exterior ...................................................... BT-38

F

F/PUMP - Wiring diagram ............. EC-518, 1034

FR02 - Wiring diagram .. EC-187, 207, 216, 415,

712, 732, 741, 945

FR02/H - Wiring diagram ............... EC-223, 422,

748, 952

FUEL - Wiring diagram ... EC-271, 279, 794, 802

Fan switch ................................................. HA-61

Final drive (FF M/T) ...................... MT-47, 63, 77

Finisher, interior - See Trim ....................... BT-28

Finisher, trunk lid ....................................... BT-31

Floor trim ................................................... BT-28

Fluids ........................................................ MA-20

Flywheel (clutch) ....................................... CL-22

Flywheel runout ........................ EM-60, 142, 235

Fog lamp, front, removal and

installation ................................................ BT-7

Fog lamp, front .......................................... EL-95

Fork rod (M/T) ..................................... MT-26, 64

Freeze frame data .............. EC-61, 71, 585, 596

Front axle .................................................... AX-2

Front bumper ............................................... BT-7

Front combination lamp removal and

installation ................................................ BT-7

Front disc brake ........................................ BR-24

Front door .................................................. BT-13

Front fog lamp removal and

installation ................................................ BT-7

Front fog lamp ........................................... EL-95

Front heated oxygen sensor (HO2S)

heater .......................... EC-221, 421, 746, 951

Front heated oxygen sensor (HO2S) ..... EC-184,

192, 198, 204, 214, 414, 709,

717, 723, 729, 739, 944Front seat belt ............................................. RS-5

Front seat .................................................. BT-46

Front suspension ........................................ SU-2

Front washer ............................................ EL-176

Front wiper ............................................... EL-176

Fuel cut control (at no load & high

engine speed) ..................... EC-39, 573, 1081

Fuel gauge ............................................... EL-130

Fuel injection system ............. EC-269, 277, 792,

800, 1079

Fuel injector .................................. EC-494, 1021

Fuel precautions ........................................... GI-8

Fuel pressure check ......................... EC-43, 577

Fuel pressure regulator .................... EC-44, 578

Fuel pressure release ....................... EC-43, 577

Fuel pump relay ............................ EC-516, 1032

Fuel pump ..................................... EC-516, 1032

Fuel system ........................................... FE-5, 15

Fuel tank vacuum relief valve ........... EC-40, 574

Fuse block ............................................... EL-527

Fuse ........................................................... EL-32

Fusible link ................................................. EL-32G

GLOW - Wiring diagram ....................... EC-1267

Garage jack and safety stand .................... GI-43

Gauges .................................................... EL-130

Gear components (M/T) ..................... MT-25, 63

Generator - See Alternator ....................... SC-28

Generic scan tool (GST) ................... EC-93, 617

Glass .......................................................... BT-14

Glow plug .............................................. EC-1267

Glow relay ............................................. EC-1267

Grease ...................................................... MA-20

Ground distribution .............................. EL-33, 48

H

H/LAMP - Wiring diagram .......................... EL-69

HEATER - Wiring diagram ........................ HA-23

HFC134a (R134a) system

precaution ................................................ HA-2

HFC134a (R134a) system service

procedure .............................................. HA-85

HFC134a (R134a) system service

tools ....................................................... HA-10

HFC134a system service equipment

precaution ................................................ HA-6

HORN - Wiring diagram .......................... EL-193

HSEAT - Wiring diagram ......................... EL-234

Harness connector ...................................... EL-5

Harness layout ......................................... EL-452

Hazard warning lamp .............................. EL-101

Headlamp removal and installation ............. BT-7

Headlamp washer .................................... EL-190

ALPHABETICAL INDEX

IDX-4