oil temperature NISSAN ALMERA TINO 2001 Service Manual PDF

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2001, Model line: ALMERA TINO, Model: NISSAN ALMERA TINO 2001Pages: 3051, PDF Size: 46.38 MB

Page 2700 of 3051

Headlamp .................................................. EL-69

Headlining - See Roof trim ........................ BT-35

Heated oxygen sensor (HO2S)

(front) . EC-184, 192, 198, 204, 214, 414, 709,

717, 723, 729, 739, 944

Heated oxygen sensor (HO2S) heater

(front) .......................... EC-221, 421, 746, 951

Heated oxygen sensor (HO2S) heater

(rear) ........................... EC-263, 433, 786, 963

Heated oxygen sensor (rear) . EC-227, 237, 246,

256, 426, 752, 761, 770, 779, 956

Heated seat ............................................. EL-234

Height (Dimensions) ................................... GI-41

Hood ............................................................ BT-7

Horn ......................................................... EL-193

How to erase DTC for OBD system .. EC-69, 71,

594, 596, 1096

I

IACV-AAC valve ............. EC-343, 466, 863, 995

IATS - Wiring diagram .... EC-163, 409, 689, 939

IGN/SG - Wiring diagram ................ EC-501, 903

ILL - Wiring diagram ................................ EL-109

INJECT - Wiring diagram .............. EC-495, 1022

IVC - Wiring diagram ...................... EC-362, 476

Identification plate ...................................... GI-39

Idle air control (IAC) system .......... EC-343, 466,

863, 995

Idle air control valve (IACV) ........... EC-343, 466,

863, 995

Idle speed ........................................ EC-46,1111

Ignition coil .................................... EC-907, 1010

Ignition control system ............................ EC-500

Ignition timing ............................................ EC-46

Ignition wire inspection ........................... EC-814

Illumination ............................................... EL-107

Injection nozzle ..................................... EC-1083

Injector removal and installation ....... EC-44, 578

Input shaft (FF M/T) ..................... MT-34, 63, 68

Instrument panel ........................................ BT-22

Intake air temperature sensor ........ EC-161, 407,

687, 937

Intake valve timing control solenoid

valve ............................................ EC-360, 475

Interior lamp on-off control ....................... EL-117

Interior lamp ............................................. EL-116

Interior ........................................................ BT-28

J

Jacking points ............................................ GI-43

Joint connector (J/C) ............................... EL-531

Junction box (J/B) .................................... EL-527

K

KS - Wiring diagram ............................... EC-292

Keyless entry system - See Multi-re-

mote control system ............................. EL-314

Knock sensor (KS) ................. EC-291, 815, 816

Knuckle spindle ........................................... AX-5

L

LOAD - Wiring diagram ................ EC-536, 1051

Length (Dimensions) .................................. GI-41

License lamp ............................................. EL-87

Lifting points ............................................... GI-44

Line pressure test (A/T) ............................. AT-52

Liquid gasket application .............. EM-5, 76, 158

Location of electrical units ....................... EL-442

Lock, door .................................................. BT-18

Lubricant (R134a) A/C .............................. HA-87

Lubricants ................................................. MA-20

Lubrication circuit (engine) .............. LC-4, 24, 43

M

M/T major overhaul ............................. MT-24, 62

M/T removal and installation ..................... MT-18

MAFS - Wiring diagram ........ EC-156, 682, 1143

MAIN - Wiring diagram ......... EC-146, 671, 1136

MIL & Data link connectors circuit ......... EC-545,

1060

MIL/DL - Wiring diagram .... EC-545, 1060, 1303

MIRROR - Wiring diagram ...................... EL-241

Magnet clutch ............................................ HA-90

Mainshaft (M/T) ............................ MT-39, 63, 73

Malfunction indicator lamp (MIL) .............. EC-73,

598, 1097

Manual air conditioner - Wiring

diagram .................................................. HA-27

Manual transaxle number .......................... GI-40

Mass air flow sensor (MAFS) ................ EC-154,

679, 1143

Master cylinder (clutch) ............................. CL-11

Meter ........................................................ EL-130

Mirror defogger ........................................ EL-198

Mirror, door ................................................ BT-63

Misfire ............................................. EC-285, 808

Mode door control linkage

adjustment ............................................. HA-48

Model variation ........................................... GI-37

Molding - See Exterior ............................... BT-38

Multi-remote control system .................... EL-314

Multiport fuel injection (MFI) system . EC-35, 569

Multiport fuel injection precautions ............... GI-6

ALPHABETICAL INDEX

IDX-5

Page 2708 of 3051

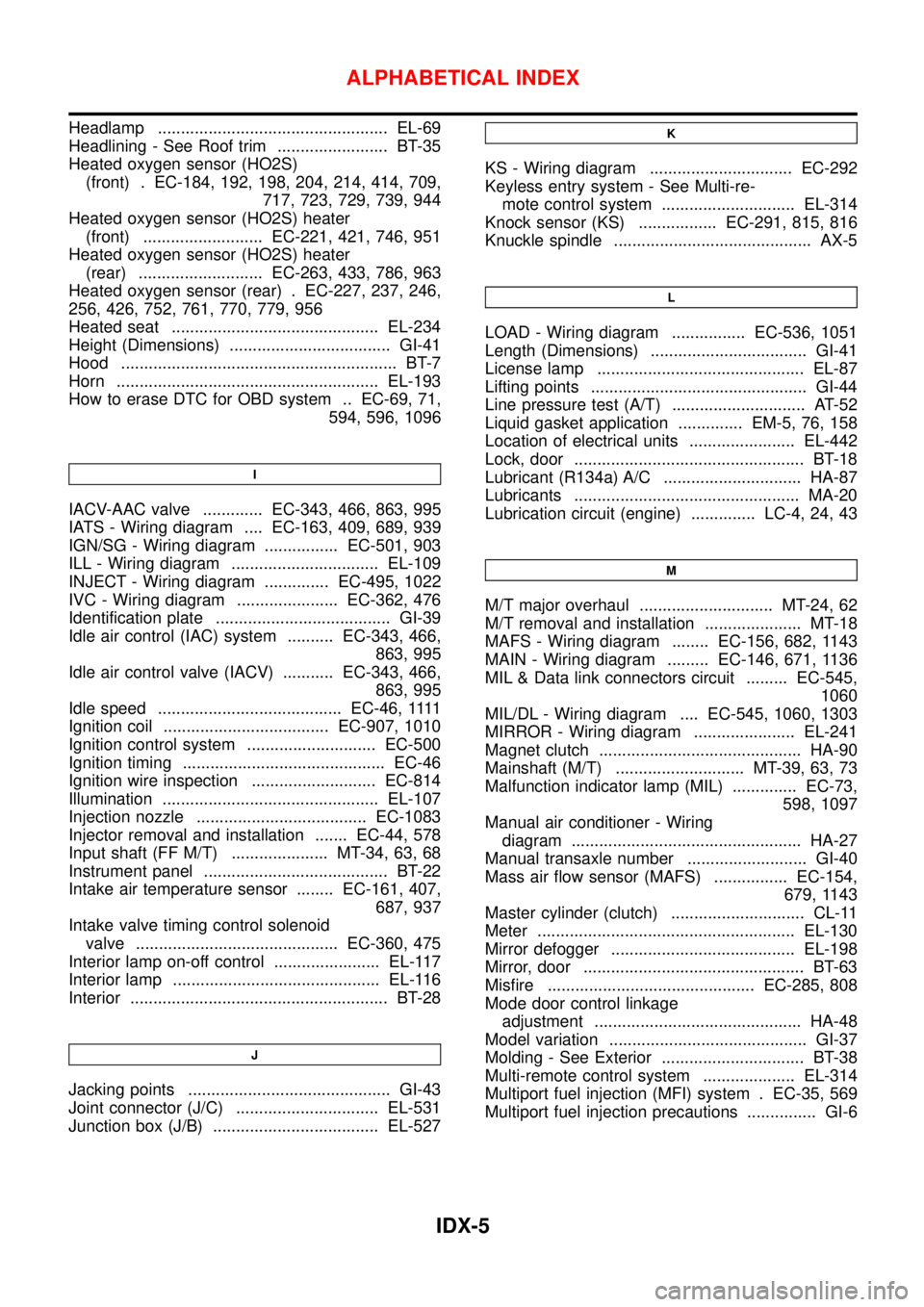

SEM853F

Oil Pressure CheckNLLC0004WARNING:

+Be careful not to burn yourself, as the engine and oil may

be hot.

+For M/T models, put gearshift lever in Neutral ªNº posi-

tion.

1. Check oil level.

2. Remove oil pressure switch.

SLC926-A

3. Install pressure gauge.

4. Start engine and warm it up to normal operating temperature.

5. Check oil pressure with engine running under no-load.

Engine speed

rpmApproximate discharge pressure

kPa (bar, kg/cm2, psi)

600 More than 98 (0.98, 1.0, 14)

2,000 More than 294 (2.94, 3.0, 43)

6,000 More than 392 (3.92, 4.0, 57)

+If difference is extreme, check oil passage and oil pump

for oil leaks.

6. Install oil pressure switch with sealant.

: 13 - 17 N´m (1.25 - 1.75 kg-m,9-12ft-lb)

Oil Pump

REMOVAL AND INSTALLATIONNLLC0005+Make sure that O-ring is fitted properly.

1. Drain engine oil.

2. Remove drive belts.

3. Remove oil pan. Refer to EM-20, ªOIL PANº.

4. Remove oil strainer.

5. Remove front cover. Refer to EM-22, ªTIMING CHAINº.

6. Install front cover.

7. Reinstall parts in reverse order of removal.

ENGINE LUBRICATION SYSTEMQG

Oil Pressure Check

LC-5

Page 2728 of 3051

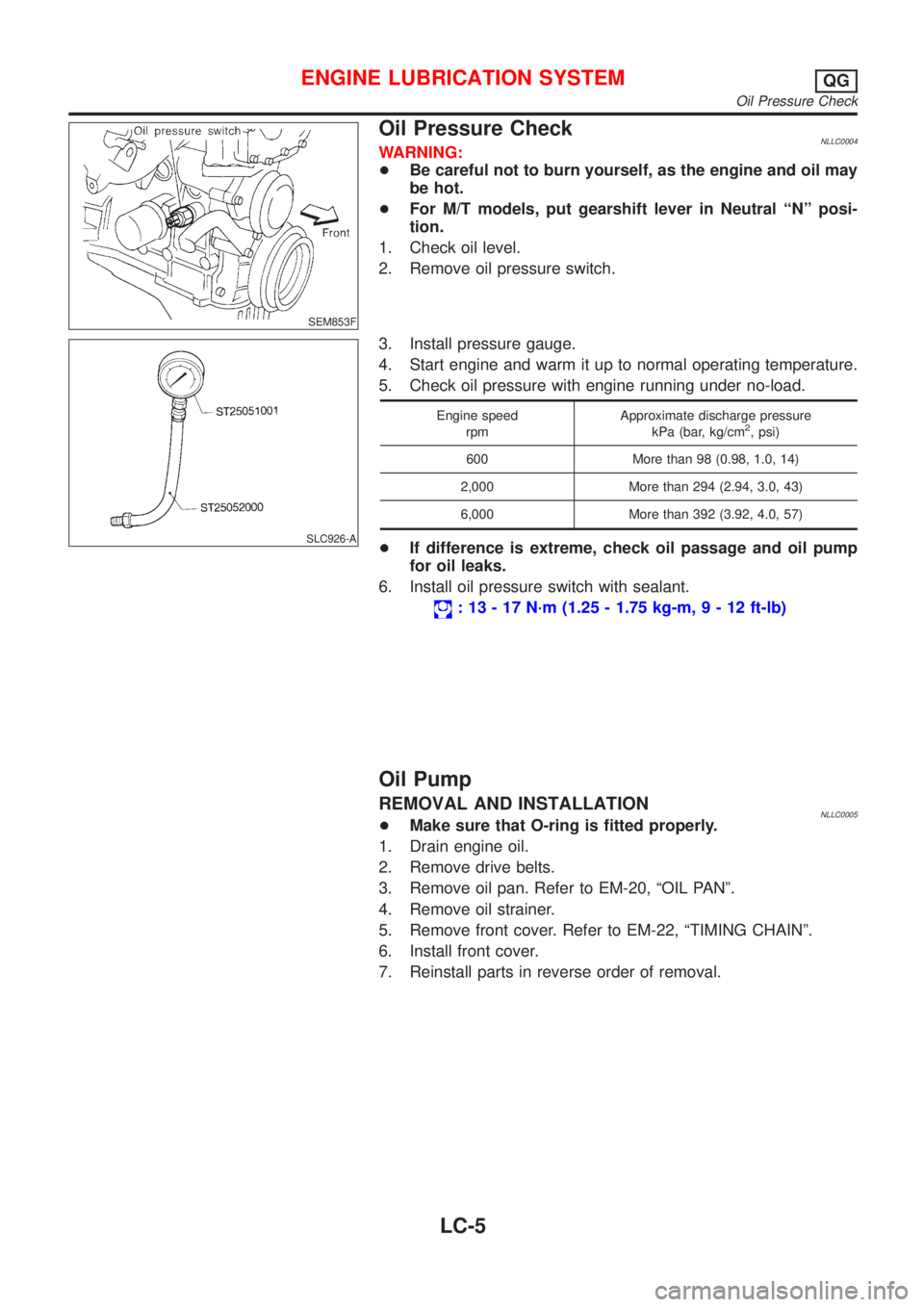

NLC045

Oil Pressure CheckNLLC0116WARNING:

+Be careful not to burn yourself, as the engine and oil may

be hot.

+For A/T models, put selector lever in Park ªPº position.

1. Check oil level.

2. Remove oil pressure switch.

SLC717A

3. Install pressure gauge.

4. Start engine and warm it up to normal operating temperature.

5. Check oil pressure with engine running under no-load.

Engine speed

rpmApproximate discharge pressure

kPa (kg/cm2, psi)

Idle speed More than 78 (0.8, 11)

3,200 314 - 392 (3.2 - 4.0, 46 - 57)

+If difference is extreme, check oil passage and oil pump

for oil leaks.

6. Install oil pressure switch with sealant.

Oil Pump

REMOVAL AND INSTALLATIONNLLC01171. Remove drive belts.

2. Remove oil pans. Refer to EM-91, ªOil panº.

3. Remove oil strainer and baffle plate.

4. Remove front cover assembly. Refer to EM-96, ªTiming Chainº.

SLC491A

+Always replace oil seal and O-ring with new ones.

Refer to EM-105, ªOIL SEAL REPLACEMENTº.

+When installing oil pump, apply engine oil to gears.

+Be sure that O-rings are properly fitted.

+Use a scraper to remove old liquid gasket from mating

surface of front cover.

+Also remove traces of liquid gasket from mating surface

of cylinder block.

ENGINE LUBRICATION SYSTEMSR

Oil Pressure Check

LC-25

Page 2731 of 3051

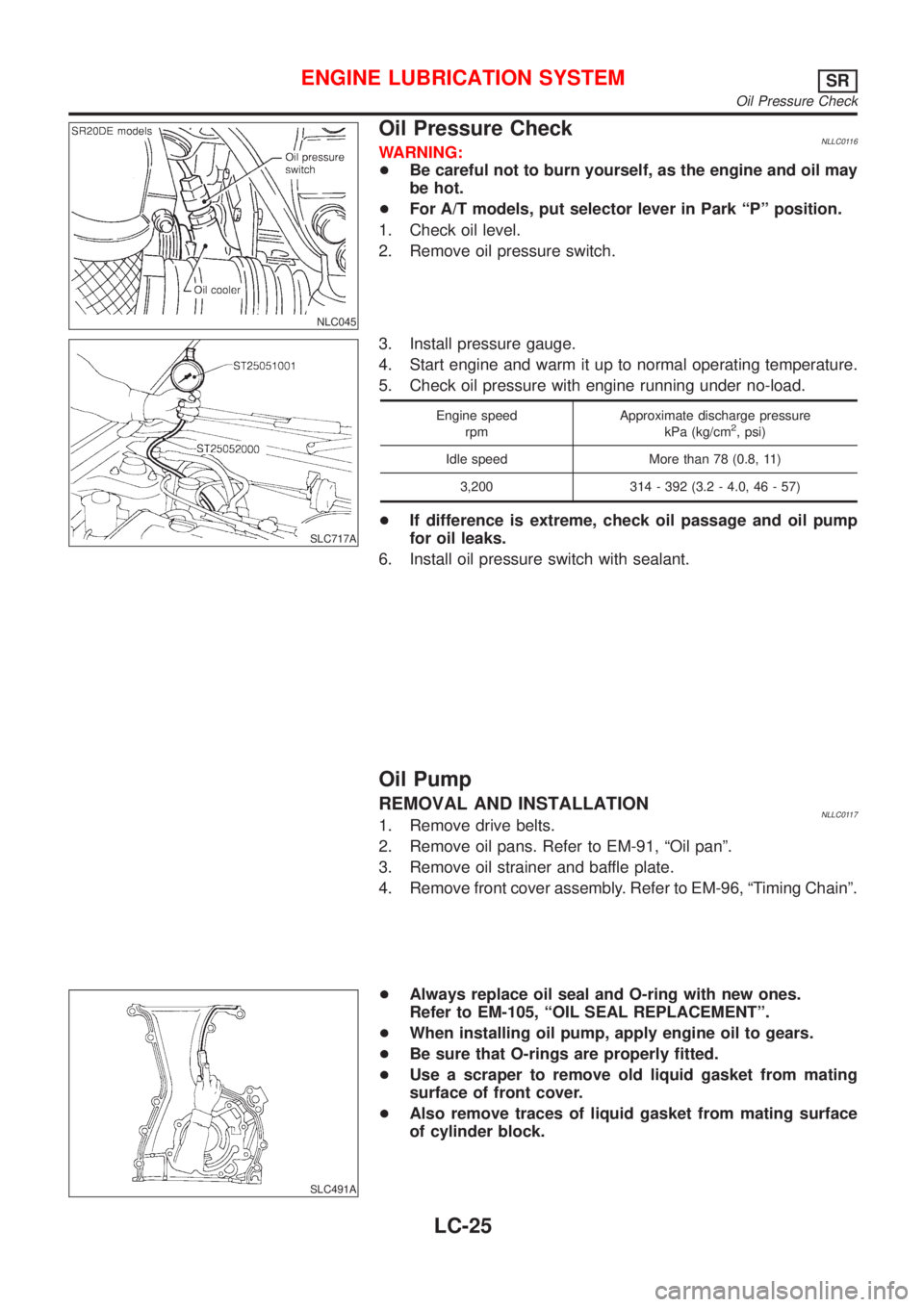

NMA039

Changing Engine OilNLLC0125WARNING:

+Be careful not to burn yourself, as the engine oil is hot.

+Prolonged and repeated contact with used engine oil may

cause skin cancer; try to avoid direct skin contact with

used oil. If skin contact is made, wash thoroughly with

soap or hand cleaner as soon as possible.

1. Warm up engine, and check for oil leakage from engine com-

ponents.

2. Stop engine.

3. Remove drain plug and oil filler cap.

4. Drain oil and refill with new engine oil.

Oil grade: API SH or ACEA grade A1-98, A3-98

Viscosity: See ªRECOMMENDED FLUIDS AND

LUBRICANTSº, MA-20.

Refill oil capacity (Approximate):

Unit:!(Imp pts)

Drain and refill

With oil filter change 3.7 (6-1/2)

Without oil filter change 3.5 (6-1/8)

Dry engine (engine overhaul) 3.9 (6-7/8)

CAUTION:

+Be sure to clean drain plug and install with new washer.

Drain plug:

: 29 - 39 N´m (3.0 - 4.0 kg-m, 22 - 29 ft-lb)

+The refill oil capacity depends on oil temperature and

drain time. Use these specifications as a reference only.

Always use the dipstick to determine when the proper

amount of oil is in the engine.

NDI021

5. Start engine and check area around drain plug and oil filter oil

leakage.

6. Run engine for a few minutes, then turn it off. After several

minutes, check oil level.

NMA041

Changing Engine Oil FilterNLLC01261. Remove oil filter with Tool.

WARNING:

Be careful not to burn yourself, as the engine and the engine

oil are hot.

ENGINE LUBRICATION SYSTEMSR

Changing Engine Oil

LC-28

Page 2747 of 3051

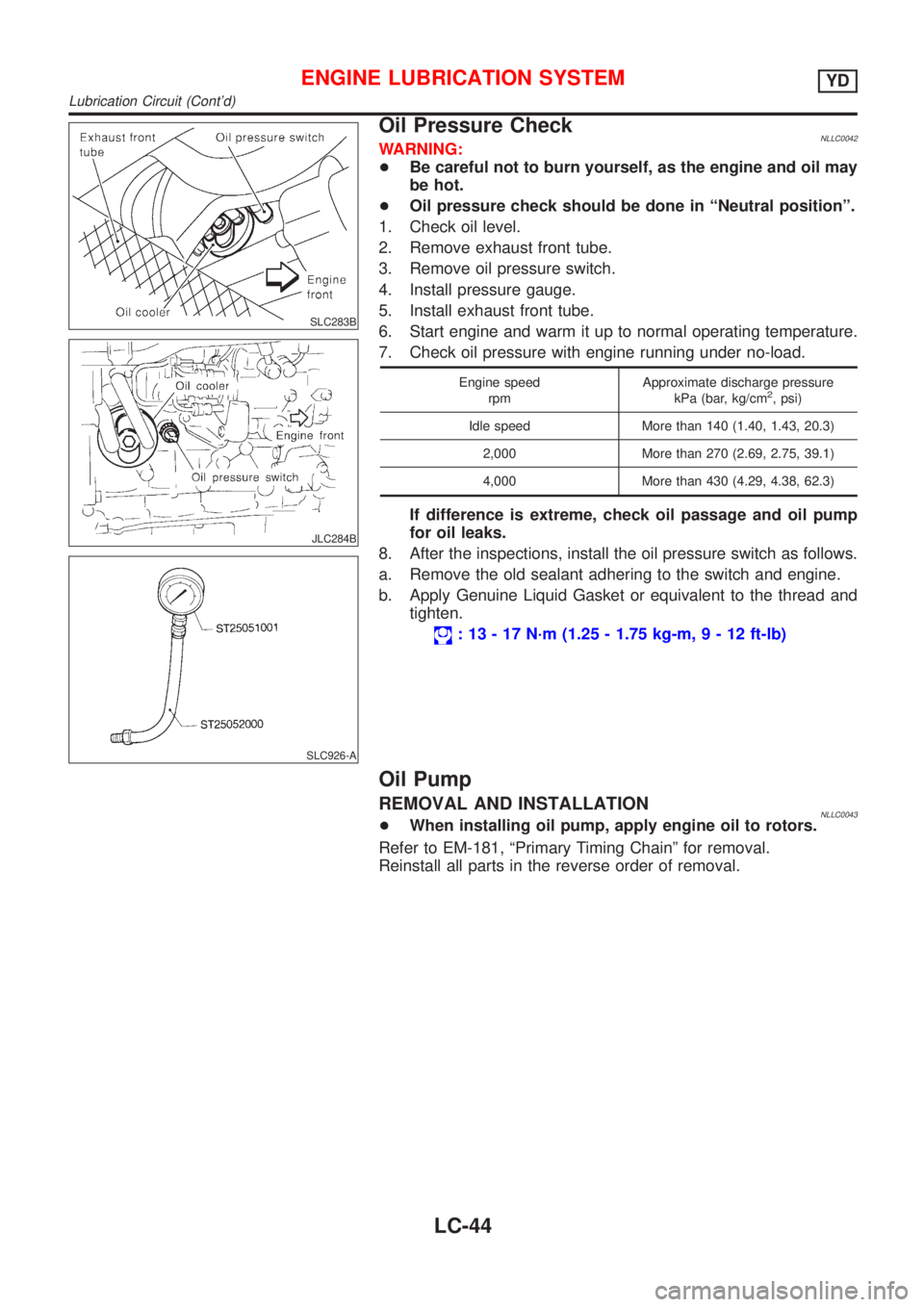

SLC283B

JLC284B

SLC926-A

Oil Pressure CheckNLLC0042WARNING:

+Be careful not to burn yourself, as the engine and oil may

be hot.

+Oil pressure check should be done in ªNeutral positionº.

1. Check oil level.

2. Remove exhaust front tube.

3. Remove oil pressure switch.

4. Install pressure gauge.

5. Install exhaust front tube.

6. Start engine and warm it up to normal operating temperature.

7. Check oil pressure with engine running under no-load.

Engine speed

rpmApproximate discharge pressure

kPa (bar, kg/cm2, psi)

Idle speed More than 140 (1.40, 1.43, 20.3)

2,000 More than 270 (2.69, 2.75, 39.1)

4,000 More than 430 (4.29, 4.38, 62.3)

If difference is extreme, check oil passage and oil pump

for oil leaks.

8. After the inspections, install the oil pressure switch as follows.

a. Remove the old sealant adhering to the switch and engine.

b. Apply Genuine Liquid Gasket or equivalent to the thread and

tighten.

: 13 - 17 N´m (1.25 - 1.75 kg-m,9-12ft-lb)

Oil Pump

REMOVAL AND INSTALLATIONNLLC0043+When installing oil pump, apply engine oil to rotors.

Refer to EM-181, ªPrimary Timing Chainº for removal.

Reinstall all parts in the reverse order of removal.

ENGINE LUBRICATION SYSTEMYD

Lubrication Circuit (Cont'd)

LC-44

Page 2750 of 3051

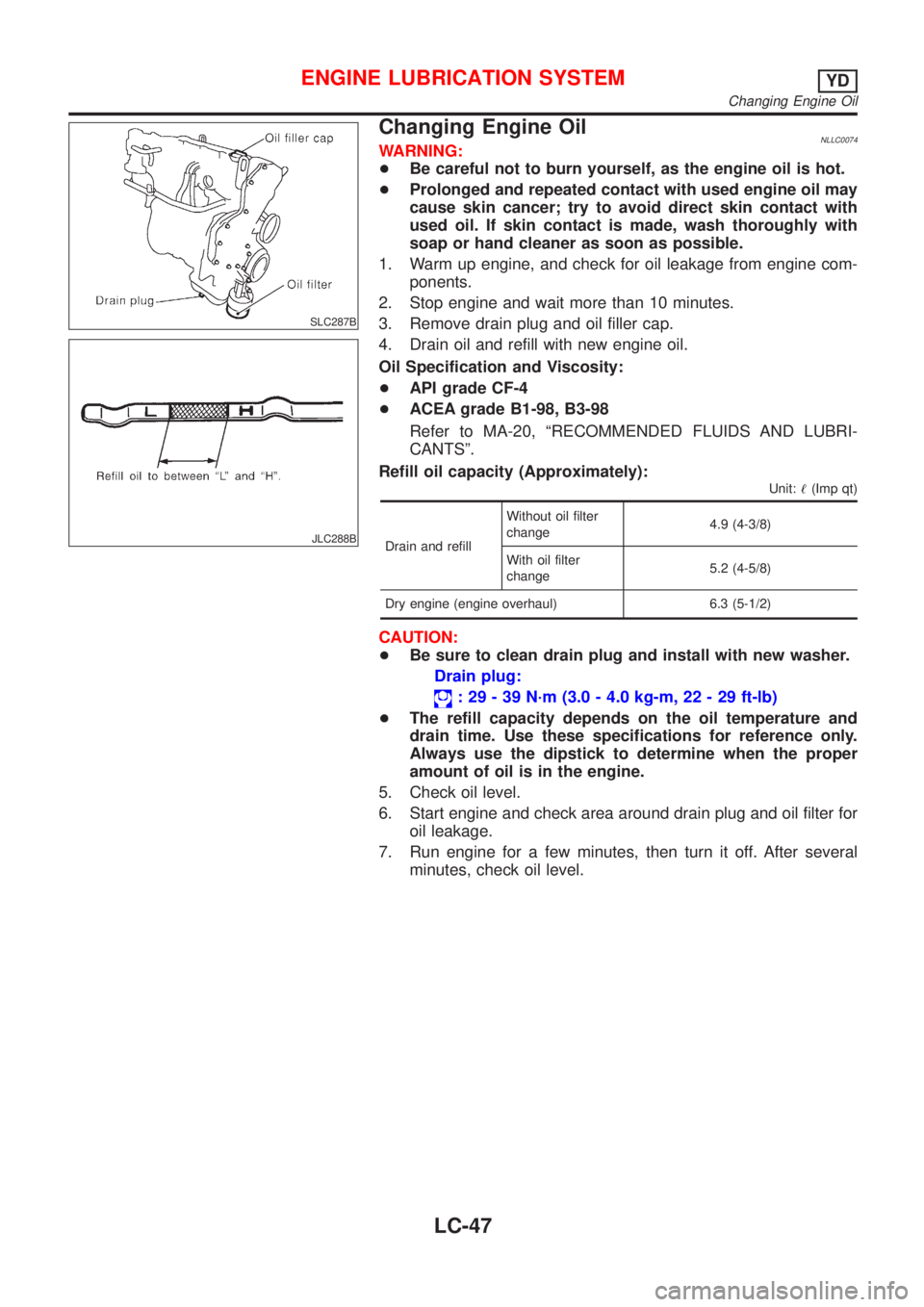

SLC287B

JLC288B

Changing Engine OilNLLC0074WARNING:

+Be careful not to burn yourself, as the engine oil is hot.

+Prolonged and repeated contact with used engine oil may

cause skin cancer; try to avoid direct skin contact with

used oil. If skin contact is made, wash thoroughly with

soap or hand cleaner as soon as possible.

1. Warm up engine, and check for oil leakage from engine com-

ponents.

2. Stop engine and wait more than 10 minutes.

3. Remove drain plug and oil filler cap.

4. Drain oil and refill with new engine oil.

Oil Specification and Viscosity:

+API grade CF-4

+ACEA grade B1-98, B3-98

Refer to MA-20, ªRECOMMENDED FLUIDS AND LUBRI-

CANTSº.

Refill oil capacity (Approximately):

Unit:!(Imp qt)

Drain and refillWithout oil filter

change4.9 (4-3/8)

With oil filter

change5.2 (4-5/8)

Dry engine (engine overhaul) 6.3 (5-1/2)

CAUTION:

+Be sure to clean drain plug and install with new washer.

Drain plug:

: 29 - 39 N´m (3.0 - 4.0 kg-m, 22 - 29 ft-lb)

+The refill capacity depends on the oil temperature and

drain time. Use these specifications for reference only.

Always use the dipstick to determine when the proper

amount of oil is in the engine.

5. Check oil level.

6. Start engine and check area around drain plug and oil filter for

oil leakage.

7. Run engine for a few minutes, then turn it off. After several

minutes, check oil level.

ENGINE LUBRICATION SYSTEMYD

Changing Engine Oil

LC-47

Page 2775 of 3051

Maintenance Under Severe Driving Conditions=NLMA0046S04The maintenance intervals shown on the preceding pages are for normal operating conditions. If the vehicle

is mainly operated under severe driving conditions as shown below, more frequent maintenance must be per-

formed on the following items as shown in the table.

SEVERE DRIVING CONDITIONSNLMA0046S0401A—Driving under dusty conditions

B—Driving repeatedly short distances

C—Towing a trailer or caravan

D—Extensive idling

E—Driving in extremely adverse weather conditions or in areas where ambient temperatures are either

extremely low or extremely high

F—Driving in high humidity areas or in mountainous areas

G—Driving in areas using salt or other corrosive materials

H—Driving on rough and/or muddy roads or in the desert

I—Driving with frequent use of braking or in mountainous areas

Driving condition Maintenance itemMaintenance

operationMaintenance

intervalRefer-

ence

page

A........Aircleaner filter Viscous paper type Replace More frequentlyEM-18,

EM-88,

EM-169

ABCD.....Engine oil & oil filter (QG18DE/SR20DE

engine)ReplaceEvery 5,000 km

(3,000 miles) or 3

monthsLC-8,

LC-28,

LC-9,

LC-28

ABCD.....Engine oil (YD22DDTi engine)

ReplaceMore frequently LC-47

Engine oil filter (YD22DDTi engine)Every 7,500 km

(4,500 miles) or 6

monthsLC-48

A...E....Fuel filter (YD22DDTi engine) ReplaceEvery 20,000 km

(12,000 miles) or

12 monthsFE-15

.....F...Brake fluid ReplaceEvery 20,000 km

(12,000 miles) or

12 monthsBR-7

..C....H.H·CVT fluid ReplaceEvery 20,000 km

(12,000 miles) or

12 monthsAT-11

......GH.Steering gear & linkage, axle & suspen-

sion parts & drive shaftsCheckEvery 10,000 km

(6,000 miles) or 6

monthsST-7,

SU-5,

SU-18

A.C...GHIBrake pads, rotors & other brake com-

ponentsCheckEvery 5,000 km

(3,000 miles) or 3

monthsBR-24,

BR-28

......G..Lock, hinges & hood latch LubricateEvery 5,000 km

(3,000 miles) or 3

monthsBT-7,

BT-13

A........Ventilation air filter Replace More frequently HA-103

PERIODIC MAINTENANCE (EXCEPT FOR EUROPE)

Maintenance Under Severe Driving Conditions

MA-8

Page 2780 of 3051

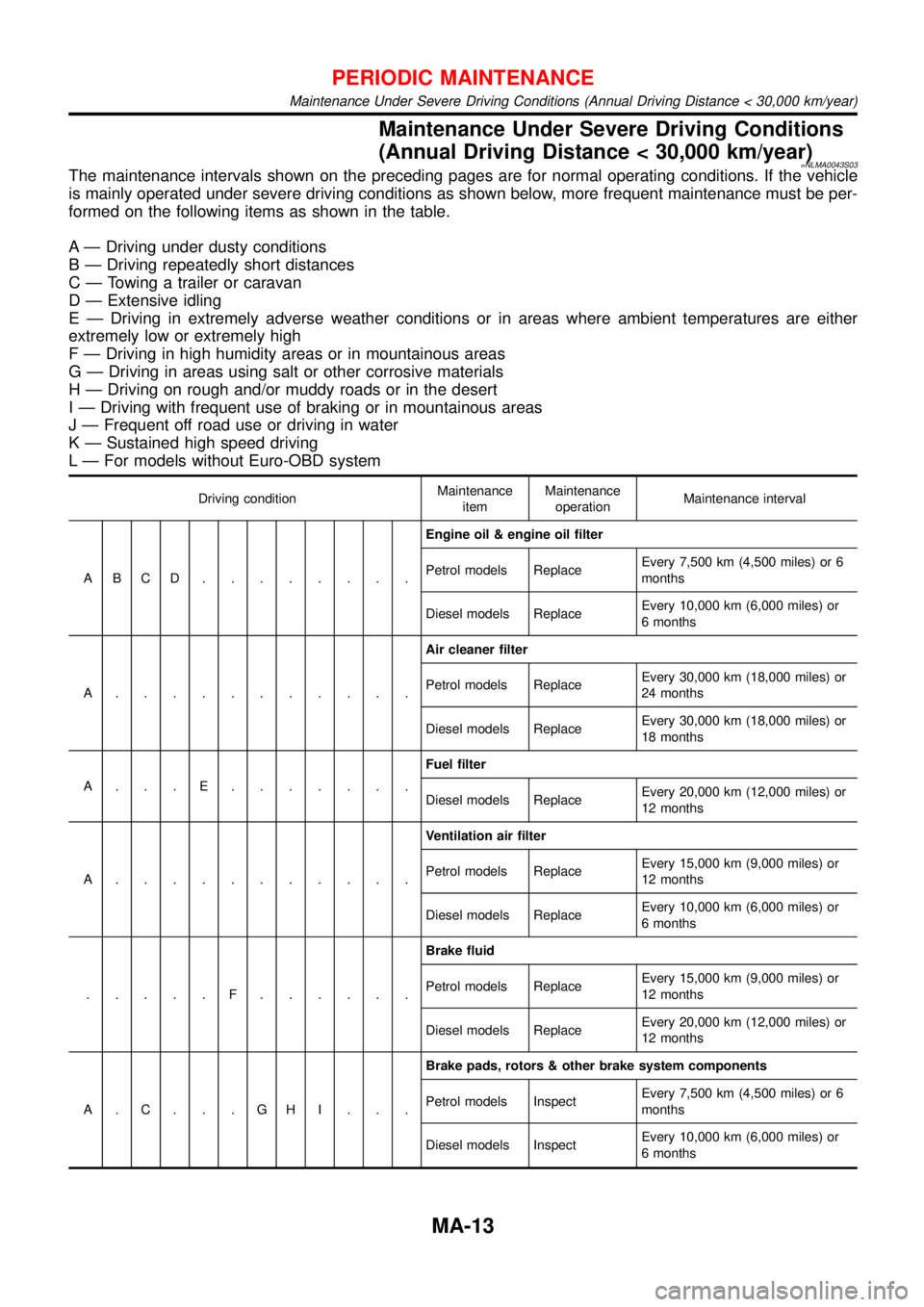

Maintenance Under Severe Driving Conditions

(Annual Driving Distance < 30,000 km/year)

=NLMA0043S03The maintenance intervals shown on the preceding pages are for normal operating conditions. If the vehicle

is mainly operated under severe driving conditions as shown below, more frequent maintenance must be per-

formed on the following items as shown in the table.

A—Driving under dusty conditions

B—Driving repeatedly short distances

C—Towing a trailer or caravan

D—Extensive idling

E—Driving in extremely adverse weather conditions or in areas where ambient temperatures are either

extremely low or extremely high

F—Driving in high humidity areas or in mountainous areas

G—Driving in areas using salt or other corrosive materials

H—Driving on rough and/or muddy roads or in the desert

I—Driving with frequent use of braking or in mountainous areas

J—Frequent off road use or driving in water

K—Sustained high speed driving

L—For models without Euro-OBD system

Driving conditionMaintenance

itemMaintenance

operationMaintenance interval

ABCD........Engine oil & engine oil filter

Petrol models ReplaceEvery 7,500 km (4,500 miles) or 6

months

Diesel models ReplaceEvery 10,000 km (6,000 miles) or

6 months

A...........Air cleaner filter

Petrol models ReplaceEvery 30,000 km (18,000 miles) or

24 months

Diesel models ReplaceEvery 30,000 km (18,000 miles) or

18 months

A...E.......Fuel filter

Diesel models ReplaceEvery 20,000 km (12,000 miles) or

12 months

A...........Ventilation air filter

Petrol models ReplaceEvery 15,000 km (9,000 miles) or

12 months

Diesel models ReplaceEvery 10,000 km (6,000 miles) or

6 months

.....F......Brake fluid

Petrol models ReplaceEvery 15,000 km (9,000 miles) or

12 months

Diesel models ReplaceEvery 20,000 km (12,000 miles) or

12 months

A.C...GHI...Brake pads, rotors & other brake system components

Petrol models InspectEvery 7,500 km (4,500 miles) or 6

months

Diesel models InspectEvery 10,000 km (6,000 miles) or

6 months

PERIODIC MAINTENANCE

Maintenance Under Severe Driving Conditions (Annual Driving Distance < 30,000 km/year)

MA-13

Page 2786 of 3051

Maintenance Under Severe Driving Conditions

(Annual Driving Distance > 30,000 km/year)

=NLMA0043S06The maintenance intervals shown on the preceding pages are for normal operating conditions. If the vehicle

is mainly operated under severe driving conditions as shown below, more frequent maintenance must be per-

formed on the following items as shown in the table.

A—Driving under dusty conditions

B—Driving repeatedly short distances

C—Towing a trailer or caravan

D—Extensive idling

E—Driving in extremely adverse weather conditions or in areas where ambient temperatures are either

extremely low or extremely high

F—Driving in high humidity areas or in mountainous areas

G—Driving in areas using salt or other corrosive materials

H—Driving on rough and/or muddy roads or in the desert

I—Driving with frequent use of braking or in mountainous areas

J—Frequent off road use or driving in water

K—Sustained high speed driving

L—For models without Euro-OBD system

Driving conditionMaintenance

itemMaintenance

operationMaintenance interval

ABCD........Engine oil & engine oil filter

Petrol models Replace Every 7,500 km (4,500 miles)

Diesel models Replace Every 10,000 km (6,000 miles)

A...........Air cleaner filter

Petrol models Replace Every 30,000 km (18,000 miles)

Diesel models Replace Every 30,000 km (18,000 miles)

A...E.......Fuel filter

Diesel models Replace Every 30,000 km (18,000 miles)

A...........Ventilation air filter

Petrol models Replace Every 15,000 km (9,000 miles)

Diesel models Replace Every 10,000 km (6,000 miles)

.....F......Brake fluid

Petrol models Replace Every 30,000 km (18,000 miles)

Diesel models Replace Every 30,000 km (18,000 miles)

..C....H....CVT fluid

Petrol models Replace Every 22,500 km (13,500 miles)

A.C...GHI...Brake pads, rotors & other brake system components

Petrol models Inspect Every 15,000 km (9,000 miles)

Diesel models Inspect Every 10,000 km (6,000 miles)

......GH....Steering gear & linkage, axle & suspension parts, drive shafts,

exhaust system

Petrol models Inspect Every 30,000 km (18,000 miles)

Diesel models Inspect Every 30,000 km (18,000 miles)

PERIODIC MAINTENANCE

Maintenance Under Severe Driving Conditions (Annual Driving Distance > 30,000 km/year)

MA-19

Page 2916 of 3051

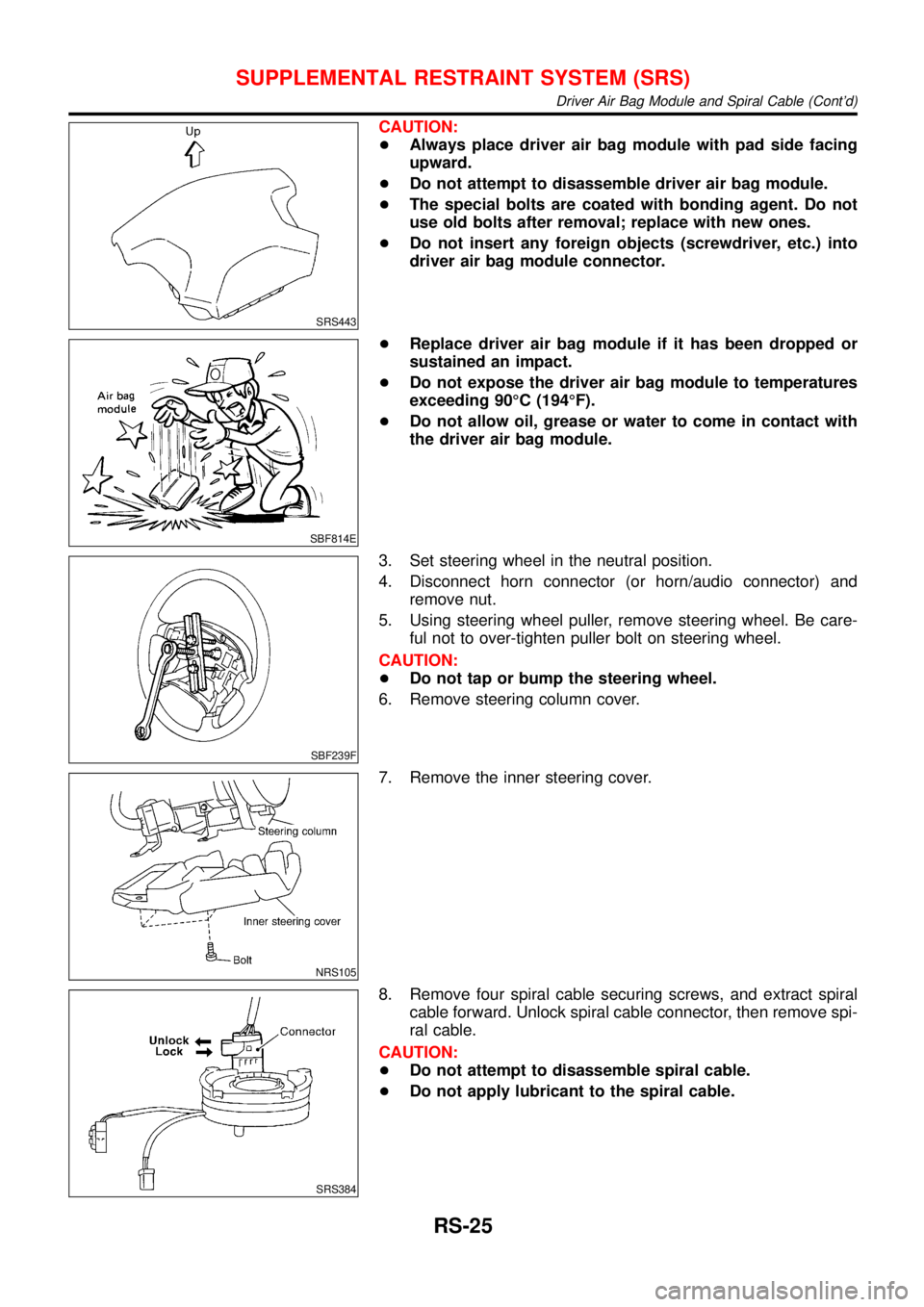

SRS443

CAUTION:

+Always place driver air bag module with pad side facing

upward.

+Do not attempt to disassemble driver air bag module.

+The special bolts are coated with bonding agent. Do not

use old bolts after removal; replace with new ones.

+Do not insert any foreign objects (screwdriver, etc.) into

driver air bag module connector.

SBF814E

+Replace driver air bag module if it has been dropped or

sustained an impact.

+Do not expose the driver air bag module to temperatures

exceeding 90°C (194°F).

+Do not allow oil, grease or water to come in contact with

the driver air bag module.

SBF239F

3. Set steering wheel in the neutral position.

4. Disconnect horn connector (or horn/audio connector) and

remove nut.

5. Using steering wheel puller, remove steering wheel. Be care-

ful not to over-tighten puller bolt on steering wheel.

CAUTION:

+Do not tap or bump the steering wheel.

6. Remove steering column cover.

NRS105

7. Remove the inner steering cover.

SRS384

8. Remove four spiral cable securing screws, and extract spiral

cable forward. Unlock spiral cable connector, then remove spi-

ral cable.

CAUTION:

+Do not attempt to disassemble spiral cable.

+Do not apply lubricant to the spiral cable.

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

Driver Air Bag Module and Spiral Cable (Cont’d)

RS-25