NISSAN ALTIMA 1996 U13 / 1.G Owners Manual

Manufacturer: NISSAN, Model Year: 1996, Model line: ALTIMA, Model: NISSAN ALTIMA 1996 U13 / 1.GPages: 183, PDF Size: 1.38 MB

Page 131 of 183

WARNING

Operating the engine with the air

cleaner off can cause you or others to

be burned. The air cleaner not only

cleans the air, it stops flame if the

engine backfires. If it isn't there, and

the engine backfires, you could be

burned. Don't drive with it off, and be

careful working on the engine with the

air cleaner off.

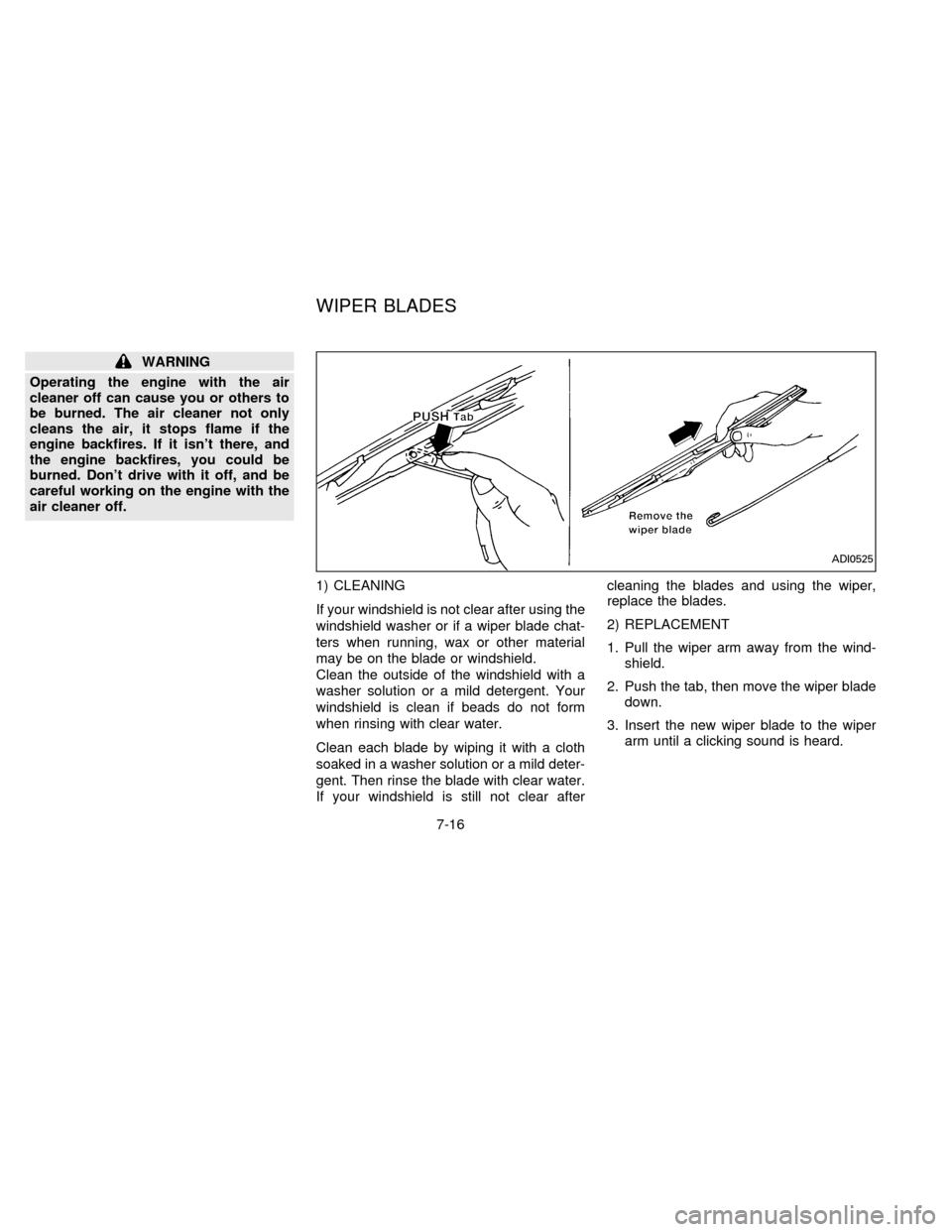

1) CLEANING

If your windshield is not clear after using the

windshield washer or if a wiper blade chat-

ters when running, wax or other material

may be on the blade or windshield.

Clean the outside of the windshield with a

washer solution or a mild detergent. Your

windshield is clean if beads do not form

when rinsing with clear water.

Clean each blade by wiping it with a cloth

soaked in a washer solution or a mild deter-

gent. Then rinse the blade with clear water.

If your windshield is still not clear aftercleaning the blades and using the wiper,

replace the blades.

2) REPLACEMENT

1. Pull the wiper arm away from the wind-

shield.

2. Push the tab, then move the wiper blade

down.

3. Insert the new wiper blade to the wiper

arm until a clicking sound is heard.

ADI0525

WIPER BLADES

7-16

ZX

Page 132 of 183

CAUTION

After wiper blade replacement, return

the wiper arm to its original position.

Otherwise it may be damaged when the

engine hood is opened.

Make sure the wiper blade contacts the

glass; otherwise the arm may be dam-

aged from wind pressure.

If you wax the surface of the hood, be

careful not to let wax get into the washer

nozzle. This may cause clogging or im-

proper windshield washer operation. If wax

gets into the nozzle, remove it with a needle

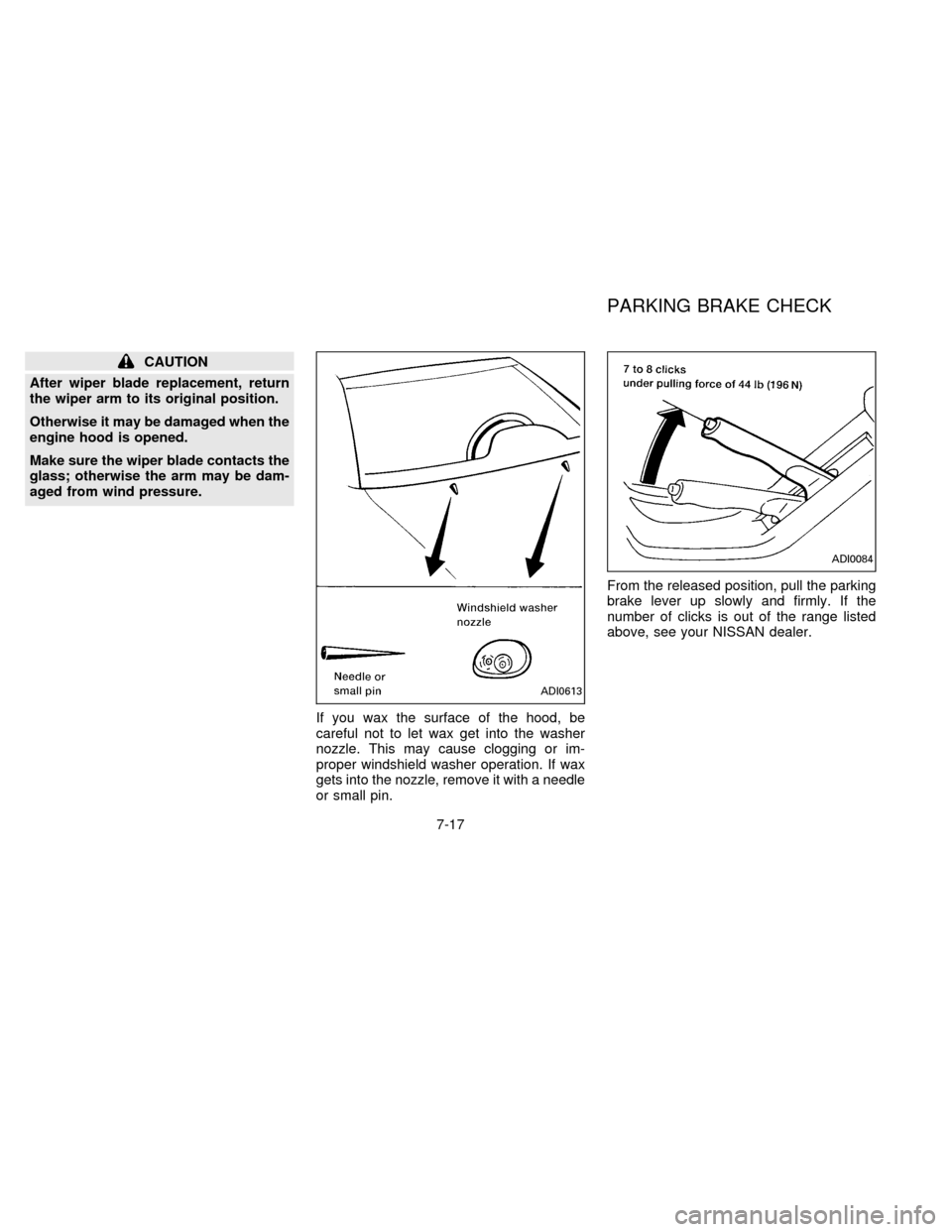

or small pin.From the released position, pull the parking

brake lever up slowly and firmly. If the

number of clicks is out of the range listed

above, see your NISSAN dealer.

ADI0613

ADI0084

PARKING BRAKE CHECK

7-17

ZX

Page 133 of 183

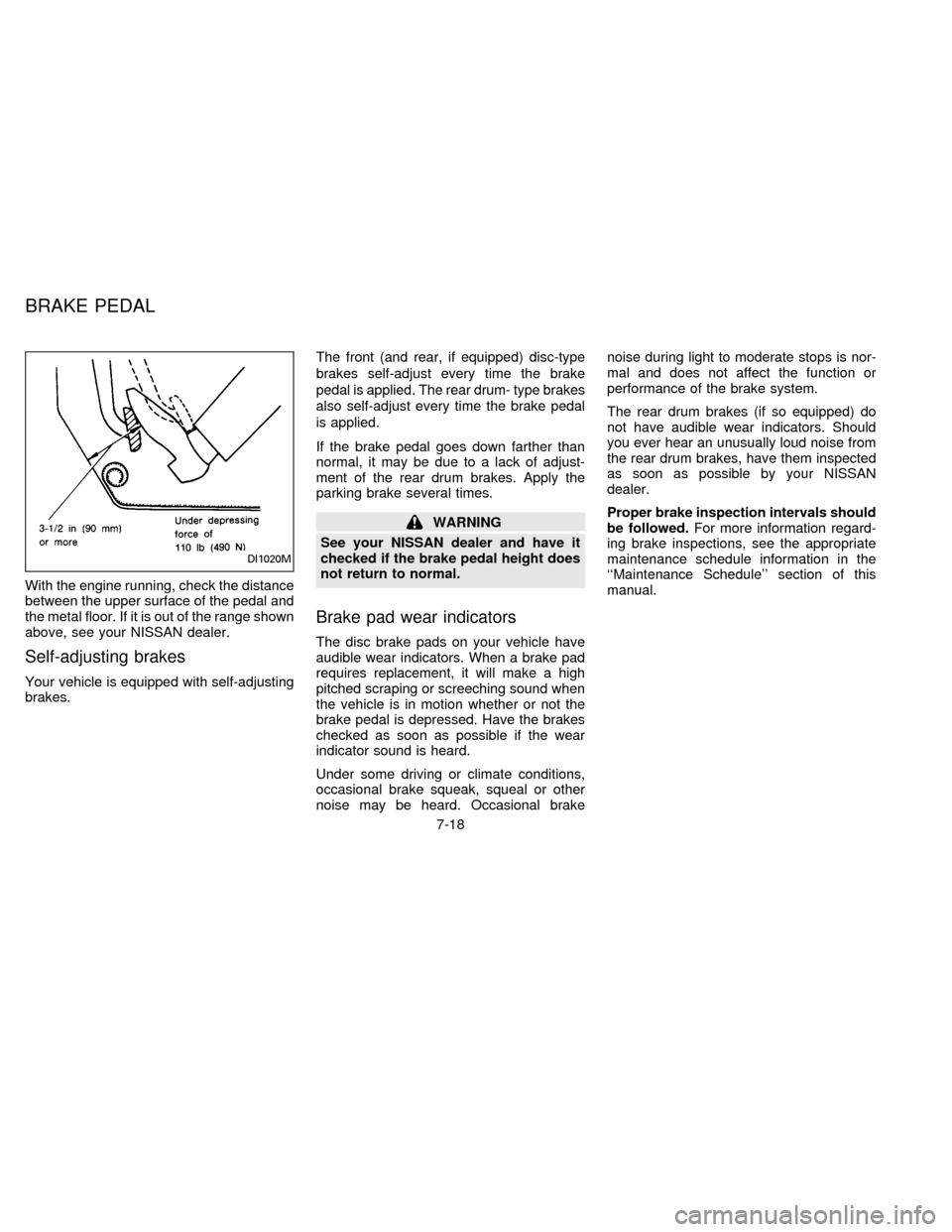

With the engine running, check the distance

between the upper surface of the pedal and

the metal floor. If it is out of the range shown

above, see your NISSAN dealer.

Self-adjusting brakes

Your vehicle is equipped with self-adjusting

brakes.The front (and rear, if equipped) disc-type

brakes self-adjust every time the brake

pedal is applied. The rear drum- type brakes

also self-adjust every time the brake pedal

is applied.

If the brake pedal goes down farther than

normal, it may be due to a lack of adjust-

ment of the rear drum brakes. Apply the

parking brake several times.

WARNING

See your NISSAN dealer and have it

checked if the brake pedal height does

not return to normal.

Brake pad wear indicators

The disc brake pads on your vehicle have

audible wear indicators. When a brake pad

requires replacement, it will make a high

pitched scraping or screeching sound when

the vehicle is in motion whether or not the

brake pedal is depressed. Have the brakes

checked as soon as possible if the wear

indicator sound is heard.

Under some driving or climate conditions,

occasional brake squeak, squeal or other

noise may be heard. Occasional brakenoise during light to moderate stops is nor-

mal and does not affect the function or

performance of the brake system.

The rear drum brakes (if so equipped) do

not have audible wear indicators. Should

you ever hear an unusually loud noise from

the rear drum brakes, have them inspected

as soon as possible by your NISSAN

dealer.

Proper brake inspection intervals should

be followed.For more information regard-

ing brake inspections, see the appropriate

maintenance schedule information in the

``Maintenance Schedule'' section of this

manual.

DI1020M

BRAKE PEDAL

7-18

ZX

Page 134 of 183

Check the brake booster function as fol-

lows:

1. With the engine off, press and release

the brake pedal several times. When

brake pedal movement (distance of

travel) remains the same from one pedal

application to the next, continue on to

next step.

2. While depressing the brake pedal, start

the engine. The pedal height should drop

a little.

3. With the brake pedal depressed, stop the

engine. Keep the pedal depressed for

about 30 seconds. The pedal height

should not change.

4. Run the engine for one minute without

depressing the brake pedal, then turn it

off. Depress the brake pedal several

times. The pedal travel distance will de-

crease gradually with each depression

as the vacuum is released from the

booster.

If the brakes do not operate properly, see

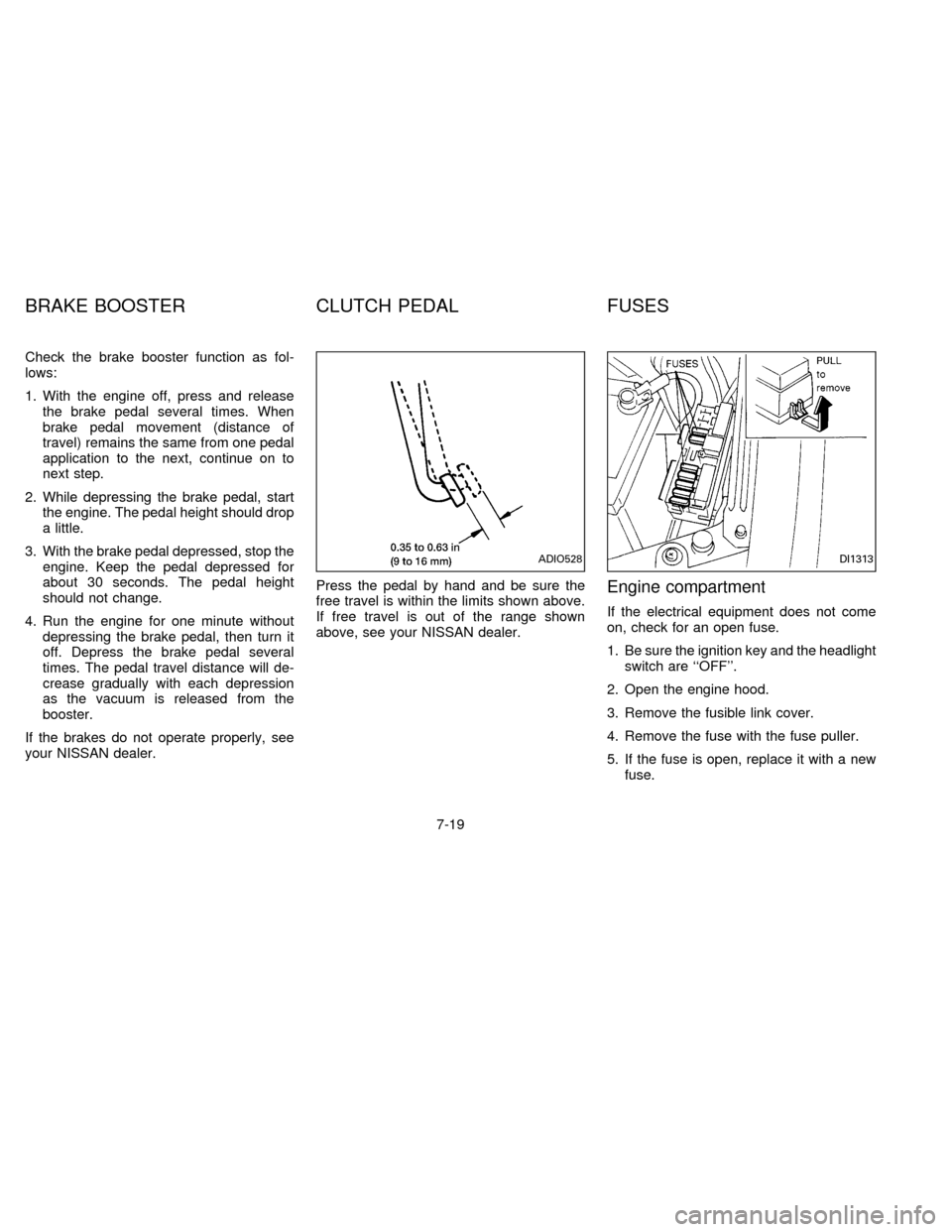

your NISSAN dealer.Press the pedal by hand and be sure the

free travel is within the limits shown above.

If free travel is out of the range shown

above, see your NISSAN dealer.

Engine compartment

If the electrical equipment does not come

on, check for an open fuse.

1. Be sure the ignition key and the headlight

switch are ``OFF''.

2. Open the engine hood.

3. Remove the fusible link cover.

4. Remove the fuse with the fuse puller.

5. If the fuse is open, replace it with a new

fuse.

ADIO528DI1313

BRAKE BOOSTER CLUTCH PEDAL FUSES

7-19

ZX

Page 135 of 183

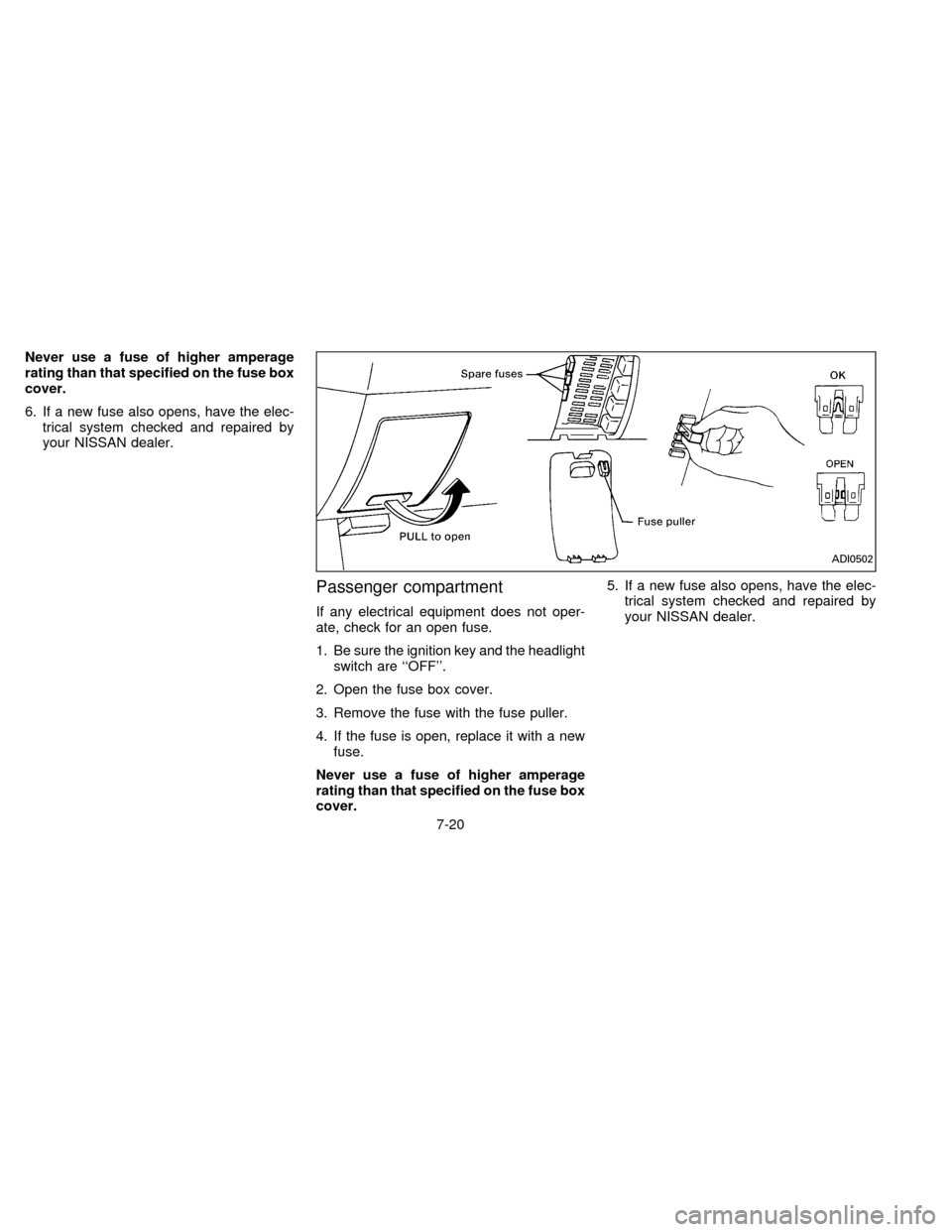

Never use a fuse of higher amperage

rating than that specified on the fuse box

cover.

6. If a new fuse also opens, have the elec-

trical system checked and repaired by

your NISSAN dealer.

Passenger compartment

If any electrical equipment does not oper-

ate, check for an open fuse.

1. Be sure the ignition key and the headlight

switch are ``OFF''.

2. Open the fuse box cover.

3. Remove the fuse with the fuse puller.

4. If the fuse is open, replace it with a new

fuse.

Never use a fuse of higher amperage

rating than that specified on the fuse box

cover.5. If a new fuse also opens, have the elec-

trical system checked and repaired by

your NISSAN dealer.

ADI0502

7-20

ZX

Page 136 of 183

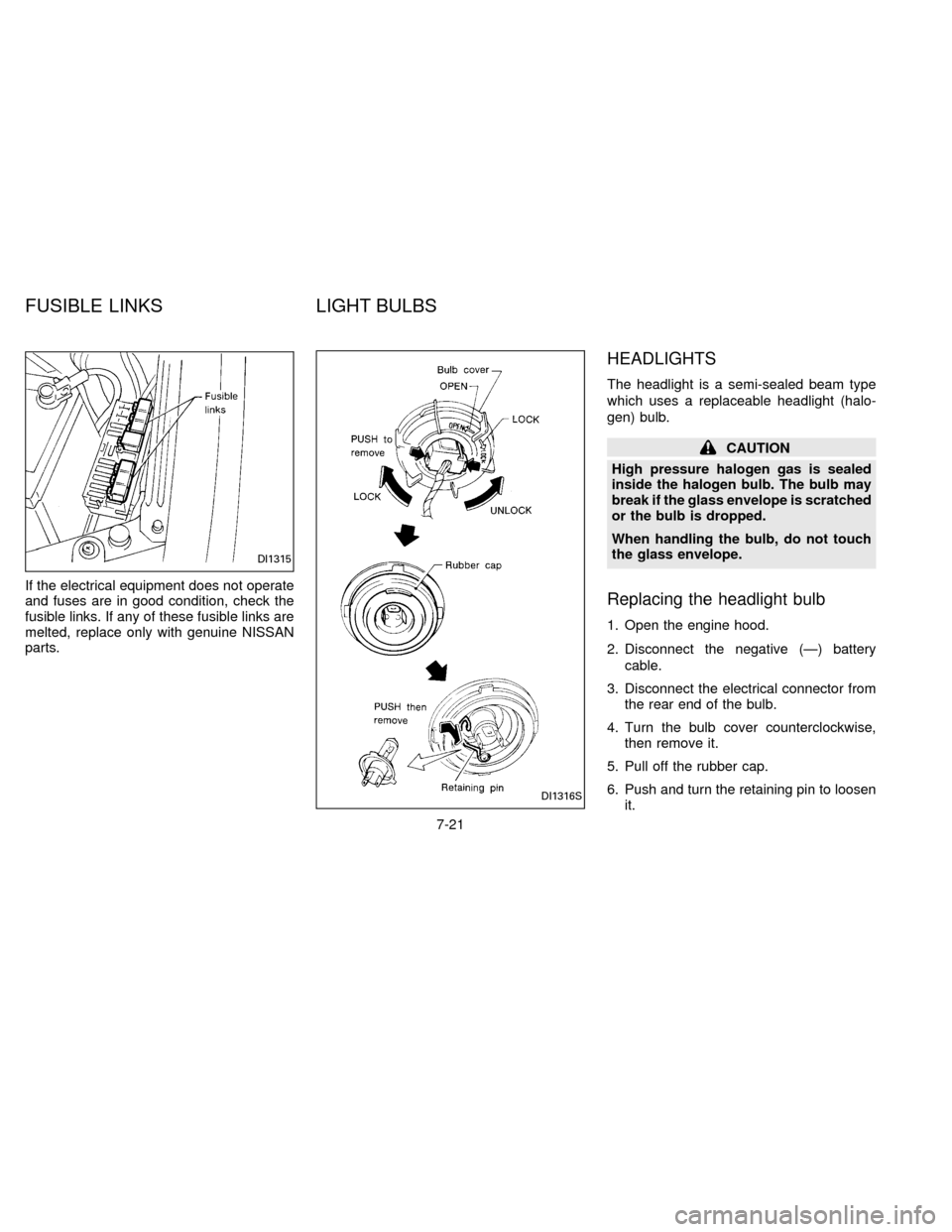

If the electrical equipment does not operate

and fuses are in good condition, check the

fusible links. If any of these fusible links are

melted, replace only with genuine NISSAN

parts.

HEADLIGHTS

The headlight is a semi-sealed beam type

which uses a replaceable headlight (halo-

gen) bulb.

CAUTION

High pressure halogen gas is sealed

inside the halogen bulb. The bulb may

break if the glass envelope is scratched

or the bulb is dropped.

When handling the bulb, do not touch

the glass envelope.

Replacing the headlight bulb

1. Open the engine hood.

2. Disconnect the negative (Ð) battery

cable.

3. Disconnect the electrical connector from

the rear end of the bulb.

4. Turn the bulb cover counterclockwise,

then remove it.

5. Pull off the rubber cap.

6. Push and turn the retaining pin to loosen

it.

DI1316S

DI1315

FUSIBLE LINKS LIGHT BULBS

7-21

ZX

Page 137 of 183

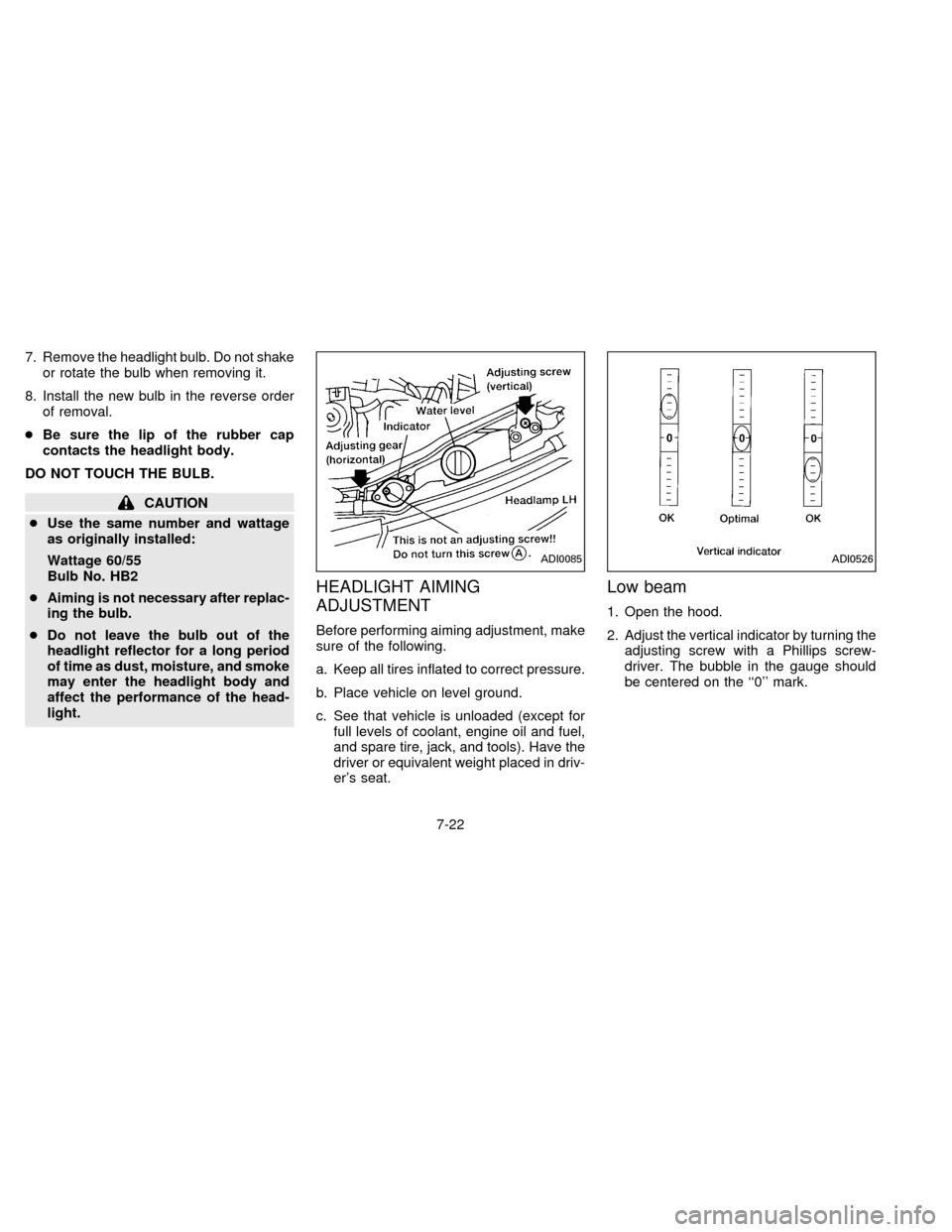

7. Remove the headlight bulb. Do not shake

or rotate the bulb when removing it.

8. Install the new bulb in the reverse order

of removal.

cBe sure the lip of the rubber cap

contacts the headlight body.

DO NOT TOUCH THE BULB.

CAUTION

cUse the same number and wattage

as originally installed:

Wattage 60/55

Bulb No. HB2

cAiming is not necessary after replac-

ing the bulb.

cDo not leave the bulb out of the

headlight reflector for a long period

of time as dust, moisture, and smoke

may enter the headlight body and

affect the performance of the head-

light.

HEADLIGHT AIMING

ADJUSTMENT

Before performing aiming adjustment, make

sure of the following.

a. Keep all tires inflated to correct pressure.

b. Place vehicle on level ground.

c. See that vehicle is unloaded (except for

full levels of coolant, engine oil and fuel,

and spare tire, jack, and tools). Have the

driver or equivalent weight placed in driv-

er's seat.

Low beam

1. Open the hood.

2. Adjust the vertical indicator by turning the

adjusting screw with a Phillips screw-

driver. The bubble in the gauge should

be centered on the ``0'' mark.

ADI0085ADI0526

7-22

ZX

Page 138 of 183

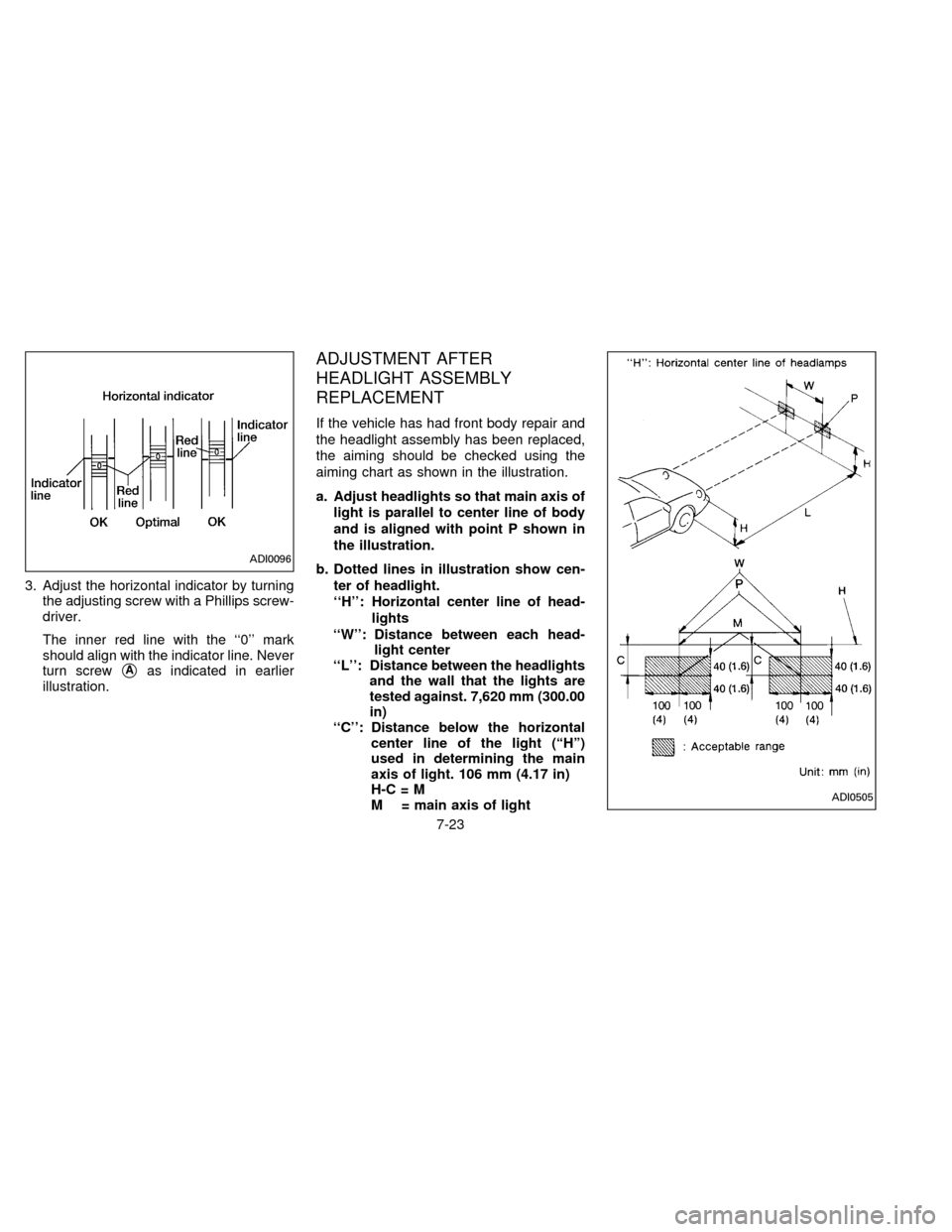

3. Adjust the horizontal indicator by turning

the adjusting screw with a Phillips screw-

driver.

The inner red line with the ``0'' mark

should align with the indicator line. Never

turn screw

sAas indicated in earlier

illustration.

ADJUSTMENT AFTER

HEADLIGHT ASSEMBLY

REPLACEMENT

If the vehicle has had front body repair and

the headlight assembly has been replaced,

the aiming should be checked using the

aiming chart as shown in the illustration.

a. Adjust headlights so that main axis of

light is parallel to center line of body

and is aligned with point P shown in

the illustration.

b. Dotted lines in illustration show cen-

ter of headlight.

``H'': Horizontal center line of head-

lights

``W'': Distance between each head-

light center

``L'': Distance between the headlights

and the wall that the lights are

tested against. 7,620 mm (300.00

in)

``C'': Distance below the horizontal

center line of the light (ªHº)

used in determining the main

axis of light. 106 mm (4.17 in)

H-C=M

M = main axis of light

ADI0505

ADI0096

7-23

ZX

Page 139 of 183

Even if the horizontal indicator does not

align with the indicator line or the bubble is

not centered in the water level after aiming

by the chart, it is acceptable if they are

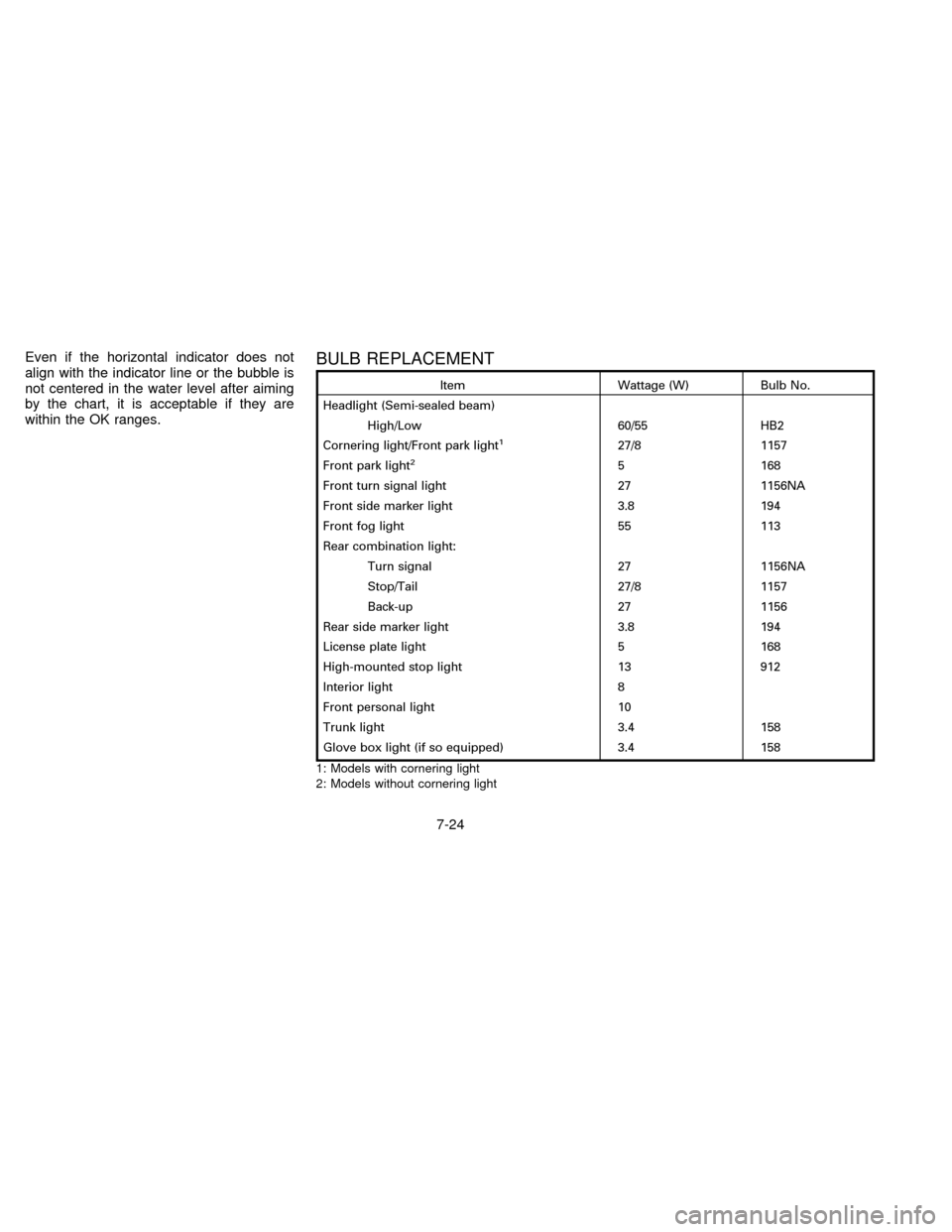

within the OK ranges.BULB REPLACEMENT

Item Wattage (W) Bulb No.

Headlight (Semi-sealed beam)

High/Low 60/55 HB2

Cornering light/Front park light

127/8 1157

Front park light25 168

Front turn signal light 27 1156NA

Front side marker light 3.8 194

Front fog light 55 113

Rear combination light:

Turn signal 27 1156NA

Stop/Tail 27/8 1157

Back-up 27 1156

Rear side marker light 3.8 194

License plate light 5 168

High-mounted stop light 13 912

Interior light 8

Front personal light 10

Trunk light 3.4 158

Glove box light (if so equipped) 3.4 158

1: Models with cornering light

2: Models without cornering light

7-24

ZX

Page 140 of 183

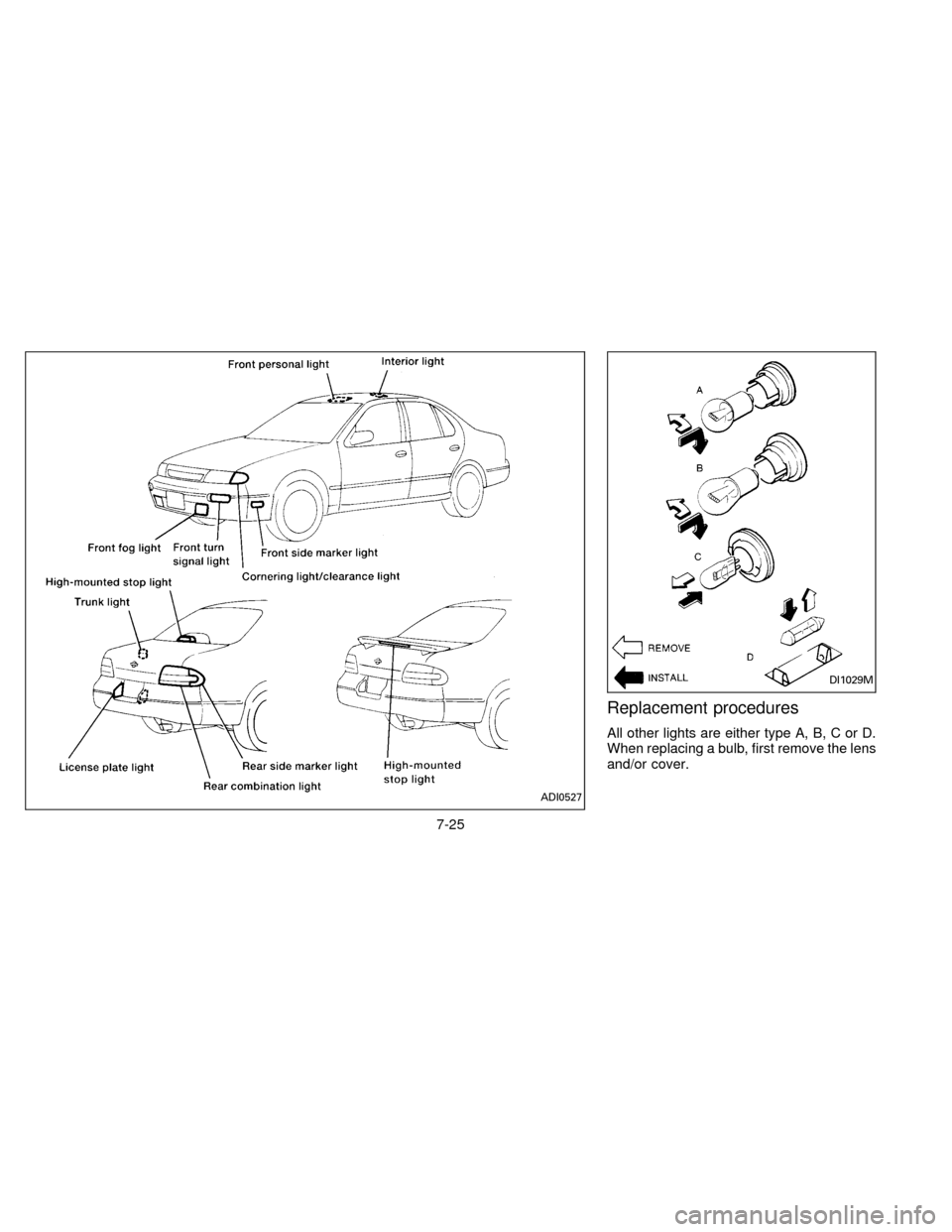

Replacement procedures

All other lights are either type A, B, C or D.

When replacing a bulb, first remove the lens

and/or cover.

ADI0527

DI1029M

7-25

ZX