sensor NISSAN GT-R 1998 Owners Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: GT-R, Model: NISSAN GT-R 1998Pages: 230, PDF Size: 12.66 MB

Page 150 of 230

FULLY AUTOMATIC AIR CONDlTlONER

Component Parts Location

Intake door actua:or

,

Sunload sensor

Controller

B&wer temperature sensor

fan motor

@ Radiator core lower support I

Front defros!er grille (left)

1 ,?efros:er gnlie (left) t I

0 Blower fan motor relay

Engine room, right relay box I / Air conditioner relay I

Blower and cooling unit

I Blower fan motor

? Ar condlboner relay

@ Refrigerant

pressure sensor @ Compressor @ Ambtent sensor

a Liquid tank I @ Englne room. front left

I

Blower and cooling unit

lnta Instrument panel, center I

7 IJj Cluster

lid A 0 Fuse block, rear face 1

Page 151 of 230

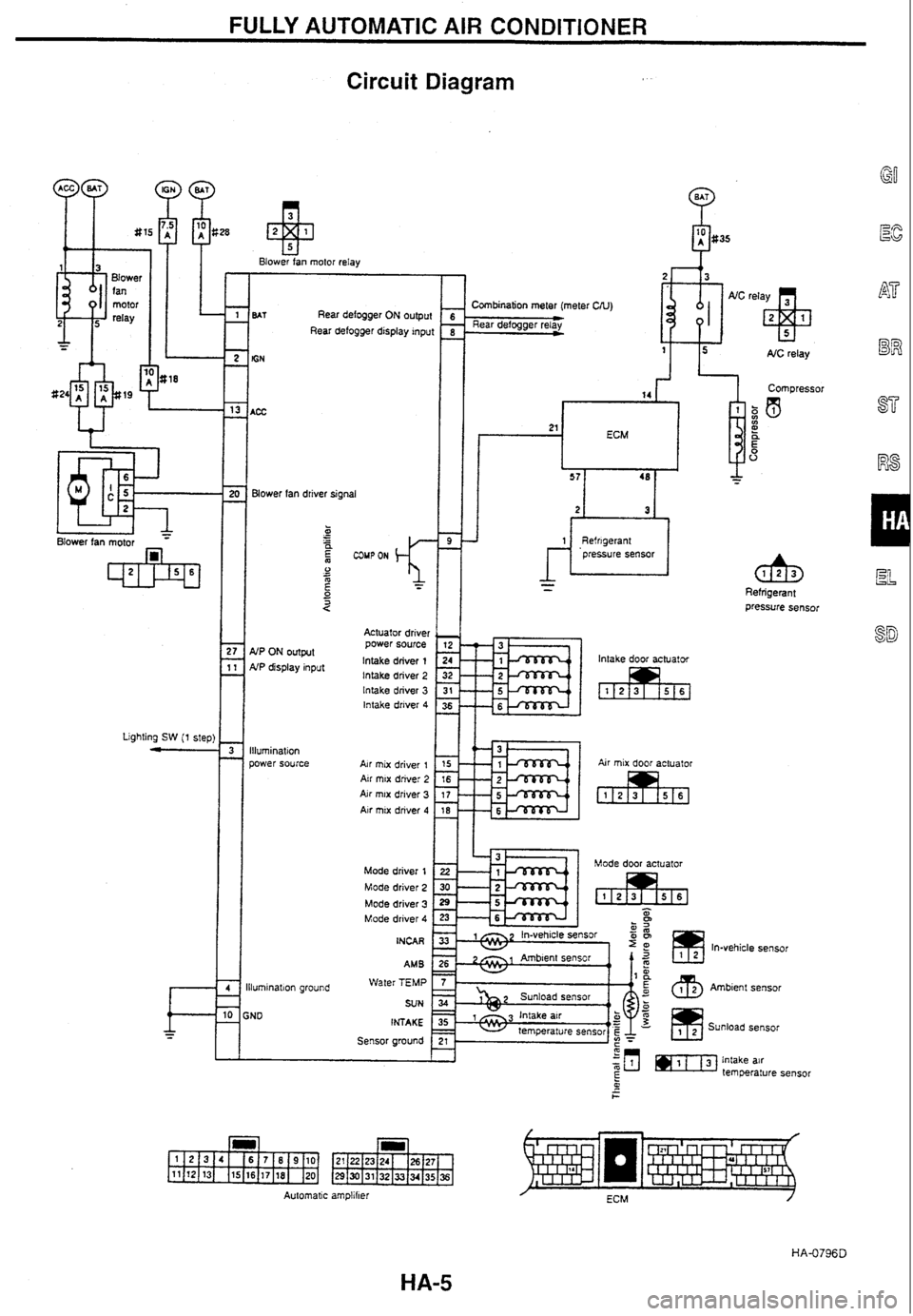

FULLY AUTOMATIC AIR CONDITIONER

Circuit

Diagram

Blower tan motor relay

Rear defogger

A Combination meter (meter UU) output * I Rear defogger relay - Rear defogger display inpui

I Compressor

Blower

fan driver signal Refrigerant Pressure sensor

Actuator driver power source

lntake driver

1 lntake driver 2 lntake driver 3 lntake driver 4

lntake door actuator NP ON output NP display input

Lighting

SW (1 step)

Y-lkEka Air mix door actuator

Illumination

power

source

Air mix driver 1 Air mrx drive: 2 Air mix driver 3 Air mix driver 4

Mode driver 1 1 Mode driver 2 Mode driver 3 Mode driver 4

INCAR In-vehicle sensor

Ambienl sensor

Sunload sensor

AM B

Water TEMP

SUN

INTAKE

Sensor around

lluminatron

groun:!

iND

Automatic

amp!iher

Page 152 of 230

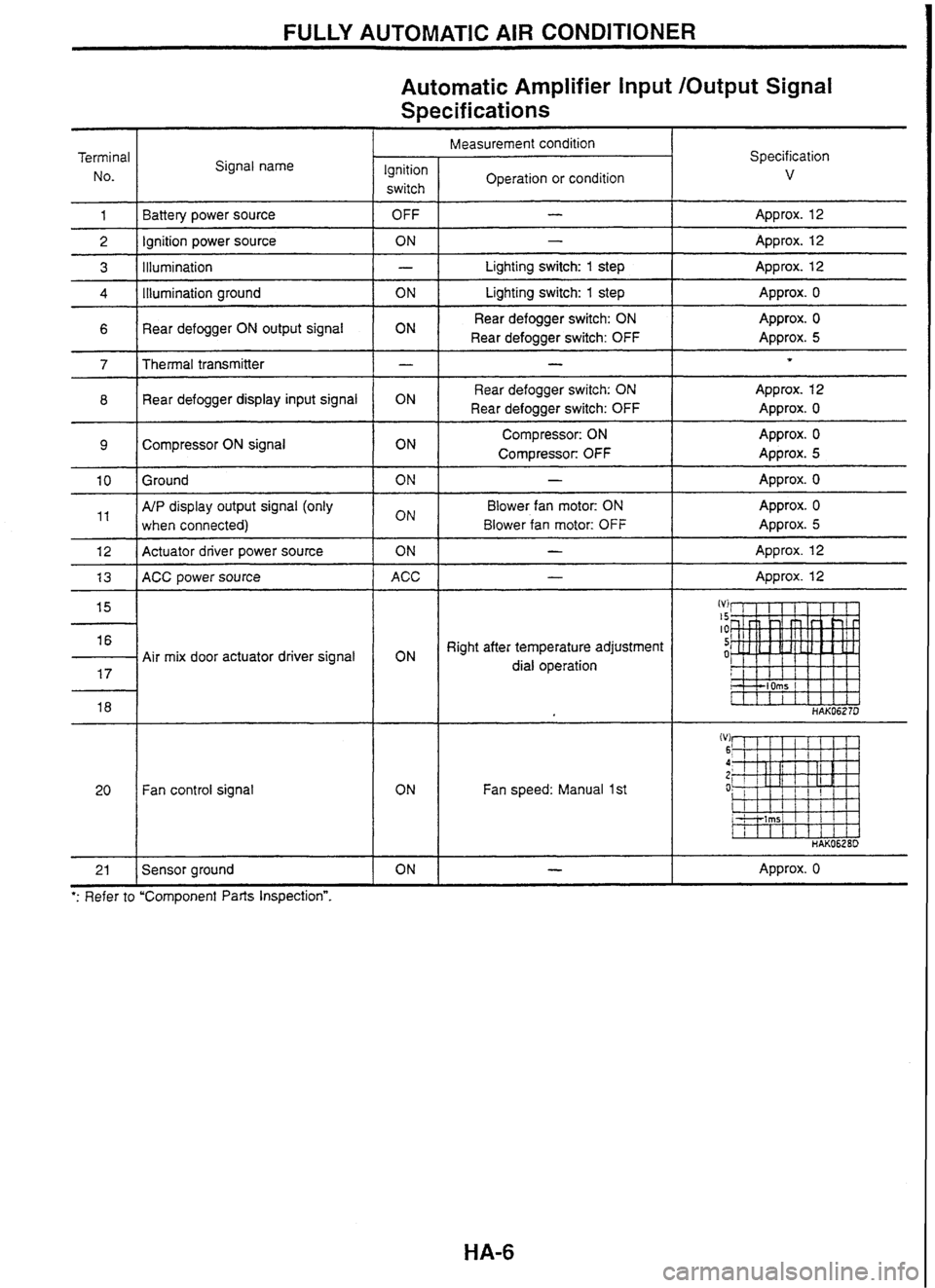

FULLY AUTOMATIC AIR CONDITIONER

Automatic Amplifier Input /Output Signal

Specifications

Measurement condition I Terminal

No. Specification

v Signal

name

Ignition

I Operation or condition

switch

OFF

I - I Approx. 12

Battery

power source

Ignition power source

lllumination

ON

I - I Approx. 12

- I Lighting switch: 1 step 1 Approx. 12

ON r Lighting switch: 1 step I Approx. o

6 1 Rear defogger ON output signal Rear

defogger switch: ON

Rear defogger switch: OFF 1

Approx. 0

Approx.

5

Rear defogger switch: ON

Rear defogger switch: OFF

1

7

Approx. 12

Approx. 0

Thermal transmitter 8 1 Rear defogger

display input signal

Compressor: ON

Compressor:

OFF

Approx. 0

Approx.

5 Compressor ON signal

ON

-I-- - - - I Approx. 0 10 1 Ground

AfP display output signal (only

when connected) Blower

fan motor: ON

Blower fan motor:

OFF

Approx. 0

Approx.

5

12 1 Actuator driver power source

ON I - 1 Approx. 12

1 3 1 ACC power source ACC I - I Approx. 12

Right after temperature adjustment

dial operation

Air mix

door actuator driver signal

Fan control signal

Fan speed: Manual

1st

ON I - I Approx. 0

21

': Refer to "Component

Parts Inspectionn.

Sensor ground

Page 153 of 230

FULLY AUTOMATIC AIR CONDITIONER

Automatic Amplifier Input /Output Signal

Terminal

No. Measurement condition

Specification V Signal name

Ignition

switch Operation

or condition

Right after mode switch (air outlet switch) operation

I

Mode door actuator driver signal

Right after

FRE switch or REC

switch operation 24

I

26 I Ambient sensor

lntake door actuator driver signal

Approx.

0

Approx. 5

A/P ON output (only when con-

'' / nected) Blower fan

motor: ON

Blower fan motor: OFF

Right after mode switch (air outlet

switch) operation

Mode door actuator driver signal

Right after

FRE switch or REC

switch operation -1 lntake door actuator driver signal

33 1 In-vehicle sensor

34 I Sunload sensor

35 1 lntake air temperature sensor

Right after FRE switch or REC

switch operation

36

*: Refer to "Component Parts Inspection".

lntake door actuator driver signal

Page 156 of 230

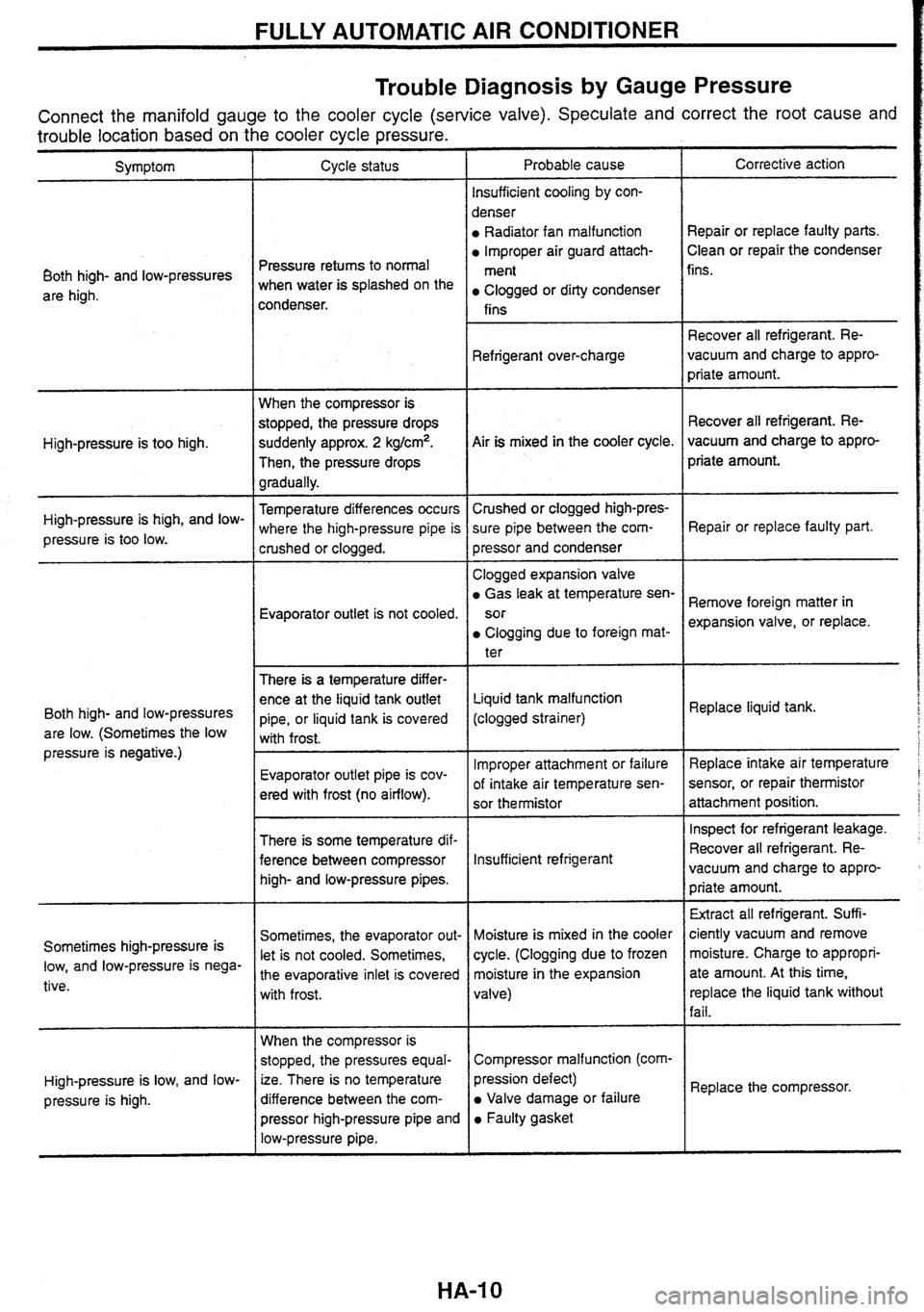

FULLY AUTOMATIC AIR CONDITIONER

Trouble Diagnosis

by Gauge Pressure

Connect the manifold gauge to the cooler cycle (service valve). Speculate and correct the root cause and

trouble location based on the cooler cycle pressure.

Probable cause

lnsufficient cooling

by con-

denser

Radiator fan malfunction

lmproper air guard attach-

ment

Clogged or dirty condenser

fins Corrective action

Symptom Cycle status

Repair or replace faulty parts.

Clean or repair the condenser

Pressure retums to normal

when water is splashed on the

condenser. fins.

Both high- and low-pressures

are high.

Recover all refrigerant. Re-

vacuum and charge to appro-

priate amount.

Refrigerant

over-charge

When the compressor is

stopped, the pressure drops

suddenly approx.

2 kg/cm2.

Then, the pressure drops

gradually. Recover

all refrigerant. Re-

vacuum and charge to appro-

priate amount.

Air is mixed

in the cooler cycle.

High-pressure is too high.

Temperature differences occurs

where the high-pressure pipe is

crushed or clogged. Crushed

or clogged high-pres-

sure pipe between the com-

pressor and condenser

High-pressure

is high, and

low-

pressure is too low. Repair or replace

faulty part.

Evaporator outlet is not cooled. Clogged

expansion valve

Gas leak at temperature sen-

sor

Clogging due to foreign mat-

ter

There

is a temperature differ-

ence at the liquid tank outlet

pipe, or liquid tank is covered

with frost. Remove

foreign matter in

expansion valve, or replace.

Liquid tank malfunction

(clogged strainer) Replace

liquid tank.

Both high- and low-pressures

are low. (Sometimes the low

pressure is negative.)

lmproper attachment or failure

of intake air temperature sen-

sor thermistor Replace

intake air temperature

sensor, or repair

thermistor

attachment position.

Evaporator

outlet pipe is cov-

ered with frost (no airflow).

I Inspect for refrigerant leakage.

There is some temperature dif-

ference between compressor

high- and low-pressure pipes. Recover

all refrigerant.

Re-

lnsufficient refrigerant vacuum and charge to appro-

priate amount.

Extract all refrigerant. Suff

i-

ciently vacuum and remove

moisture. Charge to appropri-

ate amount. At this time,

replace the liquid tank without

fail.

Sometimes, the evaporator out-

let is not cooled. Sometimes,

the evaporative inlet is covered

with frost. Moisture

is mixed in the cooler

cycle. (Clogging due to frozen

moisture in the expansion

valve)

Sometimes

high-pressure is

low, and low-pressure is nega-

tive.

When the compressor is

stopped, the pressures equal-

ize. There is no temperature

difference between the com-

pressor high-pressure pipe and

low-pressure pipe. Compressor

malfunction

(com-

I

pression defect)

Valve damage or failure

Faulty gasket Replace

the compressor.

High-pressure

is low, and

low-

pressure

is high.

HA-I 0

Page 157 of 230

FULLY AUTOMATIC AIR CONDITIONER

Trouble Diagnosis by Self-diagnosis Function

There are 5 steps in the self-diagnosis: to check for any sensor failure, and to check that a given control sig-

nal is transmitted to each output device.

Diagnosis

content

- - -

Diagnostic

item

i Step I I Step 2 - - - - - - - --

Each sensor check

Indicator lamp check

Display segments Ambient sensor

0 Indicator lamp In-vehicle sensor

lntake air tempera-

ture sensor

Sunload sensor Step

3

Each

actuator check

and reset check display for each

sen-

lntake door actuator

Air mix door actua-

tor Mode door actuator

lntake door actuator

Air mix door actua-

tor

Mode door actuator

Blower fan motor

Compressor

Air purifier (only

when connected)

Ambient sensor

In-vehicle sensor

lntake air tempera-

ture sensor

SELF-DIAGNOSIS OPERATION PROCEDURE R8

Switching to self-diagnosis mode

Turn the temperature adjustment dial all the way to the left.

Start the engine with the ignition switch from OFF position. Within 10 seconds, press and hold the OFF

switch for more than approx. 5 seconds, to start the self-diagnosis step 1.

Self-diagnosis completion EL

a Turn the ignition switch OFF.

Turn the AUTO switch ON.

Switching between self-diagnosis steps

Use the temperature adjustment dial to switch between self-diagnosis steps 1 to 5.

Temperature adjustment dial (turn clockwise): Step

1-5

Temperature adjustment dial (turn counterclockwise): Step

5- 1

a Refer to "SELF-DIAGNOSIS DISPLAY ITEM" for the diagnosis contents of each step.

Page 158 of 230

FULLY AUTOMATIC AIR CONDITIONER

Trouble Diagnosis

by Self-diagnosis Function

(Cont'd)

Step 3 AUTO SW: ON +

I

Step 1

(CW) Tum the temperature (CCW) Turn the temperature

adjustment dial. adjustment dial. I

IGN SW: OFF

AUTO SW: ON *

T

I Step 4 I AUTO SW: ON *

4 (CW) Turn the temperature (CCW) Turn the temperature

adjustment dial. adjustment dial. I

Step 2 IGN SW: OFF

AUTO SW: ON *

I

CW: Clockwise I CCW: Counterclockwise

Step 5 Detected temperature d~splay for each sensor IGN SW: OFF AUTO SW: ON

C : Each switch indicator lamp HAK0725D

SELF-DIAGNOSIS DISPLAY ITEM

Step 1 - Display segments and indicator lamp check

Check the controller switch indicator lamp and display segments.

Normal: The switch indicator lamp and display segments are illu-

minated.

Abnormal: Malfunctioning area will not be illuminated.

lllum~nated when a short- (T"e last digir ") circuit is detected.

the display code

the corresponding codes

Step 2 - Each sensor check

Display shows "2 in the step 2 mode, and then shows the judge-

ment result.

Check the data of each sensor inputted into the automatic ampli-

fier.

Normal: Display shows

"20.

Abnormal: The last digit of the display code flashes for a malfunc-

tioning sensor. At this time, if a short-circuit

is detected,

"AUTO is displayed. Furthermore, when there are more

than one malfunctioning sensor, the corresponding dis-

play codes flash twice starting with the smaller code.

The sunload sensor will judge an abnormality when there is

insufficient lighting (less than 5,000 lx) such as while being

placed indoor or during the evening.

Page 159 of 230

FULLY AUTOMATIC AIR CONDITIONER

Trouble Diagnosis by Self-diagnosis Function

(Cont'd)

Display code for malfunctioning sensor and identifying condition for automatic amplifier

I

The last digit of

Abnormal flashes for is detected.

Display code

21

22

24

25

a malfunctioning ( actuator terminal. I

When more than one

actuator terminal

are malfunctron~ng.

Ihe corresponding codes

flash twice starting

with the smaller code.

Sensor

Ambient sensor in-vehicle sensor

intake air temperature sensor

Sunload

sensor

Flashes twice

HAK0727C

Actuator display code

Identifying condition for automatic amplifier

Step 3 - Each actuator check and reset

Open circuit

Less than

41 .9"C

Less than -4 1 .g°C

Less than -4 1 .9"C

Less than 4 1.8 W/m2 (36.0 kcallm2. h)

Display shows "3" for approx. 1 second in the step 3 mode, and BB

then shows the judgement result.

Transmit an output signal to the intake door actuator, mode door

actuator, and air

mix door actuator; and check each actuator.

Furthermore, the actuator can be reset by pressing the front DEF

switch at this

time.

Normal: Display shows "30". I28

Abnormal: The display code flashes for a malfunctioning actuator.

At this time, if a short-circuit is detected, "AUTO is dis-

played. Furthermore, when there are more than one

malfunctioning sensor, the corresponding display codes

flash twice starting with the smaller code.

During reset: Display flashes

"30" and front DEF switch. (Approx.

P

EL

10 seconds)

Short-circuit

More than 100°C GI

More than 100°C

More than 100°C EG

More than 1729 W/m2 (1 487 kcal/m2.h)

Faulty harness display

SD

Display code

Actuator

Actuator

Terminal No. (actuator side)

Terminal

No. (automatic

amplifier side)

Open or short-circuit failure

display

31.0 - 32.5

Air mix door

': "AUTO" is displayed for a short-circuit.

33.0 - 34.5

Mode door

Air mix door actuator

35.0 - 36.5

Intake door

1

15

31.0

Mode door actuator

2

16

31.5

1

22

33.0

Intake door actuator

1

24

35.0

5

17

32.0 2

30

33.5

6

18

32.5 2

32

35.5

5

29

34.0

6

23

34.5

5

31

36.0 6

36

36.5

Page 160 of 230

FULLY AUTOMATIC AIR CONDITIONER

Trouble Diagnosis

by Self-diagnosis Function -

When '32.5" 1s d~splayed d~rlng self-diagnos~s step 3 I I I (Cont'd)

Au;omafc amplifier

Actuator driver

powe: supply

Air mix driver

1

Air mix driver 2

Air mix driver 3

Air mix driver 4

1 1 Air mix door actuator 1

circuit

I I'

When a open-circuit failure is displayed for all four terminals of

each actuator, there is a possibility of a disconnected

connector, or broken harness of the actuator driver power

SOU rce.

The self-diagnosis cannot detect short-circuit between actua-

tor driver signals, but the actuators will vibrate when actuated.

Step 4 - Each output device check

Display shows "41" in the step 4 mode. When the DEF switch is

pushed it switches from

42-343+44+45-+46-,41. As indicated in

the following table, the automatic amplifier forcefully outputs to

each actuator, blower fan motor, and compressor in response

to

the display code. Confirm and check each output operation status

by observing, listening to the operating sound, placing hand at the

air outlet, or using other methods.

The operation status of each actuator, blower fan motor, and

1

compressor cannot be confirmed on the display.

Display code for output device and status

Display code

Output device / 11 1 42 1 43 I I I

Mode door

Intake door

Air mix door

Blower fan motor

Compressor

Air purifier (only when connected) VENT I B/L FOOT

Ambient

Recirculation

Full cold

BIL

Open 50%

61 0/e 35%

ON

ON

The blower fan motor revolution is controlled by the duty ratio

signal outputted from the automatic amplifier. (For duty ratio,

refer to "Blower Fan Motor System Check" on page

HA-15.)

Step 5 - Detected temperature display for each sensor

Display shows "5" in the step 5 mode. Every time the DEF switch

is pushed, the detected sensor temperature is displayed in

0.5"C

increments.

D/F

Ambient

Recirculation

Full cold

OFF

OFF

f' 7 Sensor display switches every tlme 2 )- z -2 - - ' the front DEF rwttch is pressed. C

X In al - - t 0 - D

A1 E ? < -

DEF

Ambient 20% ambient

Open

50% Full hot

61Yo 75%

ON

ON

Full hot

1 00% 61 %

ON

ON OFF

OFF ON

ON

Page 161 of 230

FULLY AUTOMATIC AIR CONDITIONER

Magnet Clutch System Check

MAGNET CLUTCH

Disconnect the compressor connector. Apply approx. 12V to the compressor to check the magnet clutch

operation.

/;sn

AIR CONDITIONER RELAY QJg

Remove the air conditioner relay. Apply approx. 12V between the air conditioner relay terminals No. 1 and

2. Check the relay operation sound. Ec Check the continuity between terminals No. 3 and 5.

REFRIGERANT CHARGE AMOUNT AT

Connect the manifold gauge to the vehicle side service valve.

Check that the lower pressure side (gauge pressure) is more than approx. 0.1 8 MPa (1.8 kg/cm2.G). BR

ECM

Start the engine, and short-circuit the ECM terminal No. 14 to the ground. Check the magnet clutch operation.

INTAKE AIR TEMPERATURE SENSOR

Start the engine, and short-circuit the intake air temperature sensor terminal No. 1 to the ground. Check the Rs

maanet clutch o~eration.

Blower Fan Motor System Check

BLOWER FAN MOTOR

Disconnect the blower fan motor connector. Short-circuit the blower fan motor terminals No. 2 and 5 to El!, (

the ground. Apply approx. 12V to the terminal No. 6, and check the motor operation.

Connect the blower fan motor connector. Turn the ignition switch to the ON position, and change the fan sD

switch from 1st to 4th. Check the blower fan motor terminal No. 5 with an oscilloscope. When the termi-

nal No.

5 is normal according to the following table and the fan airflow does not change, this indicates a

faulty blower fan motor.

When the terminal No.

5 results differ from the following table and the fan airflow does not change, this

indicates either a faulty harness between the blower fan motor and automatic amplifier, or a faulty auto-

matic amplifier.