low oil pressure NISSAN GT-R 1998 User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: GT-R, Model: NISSAN GT-R 1998Pages: 230, PDF Size: 12.66 MB

Page 40 of 230

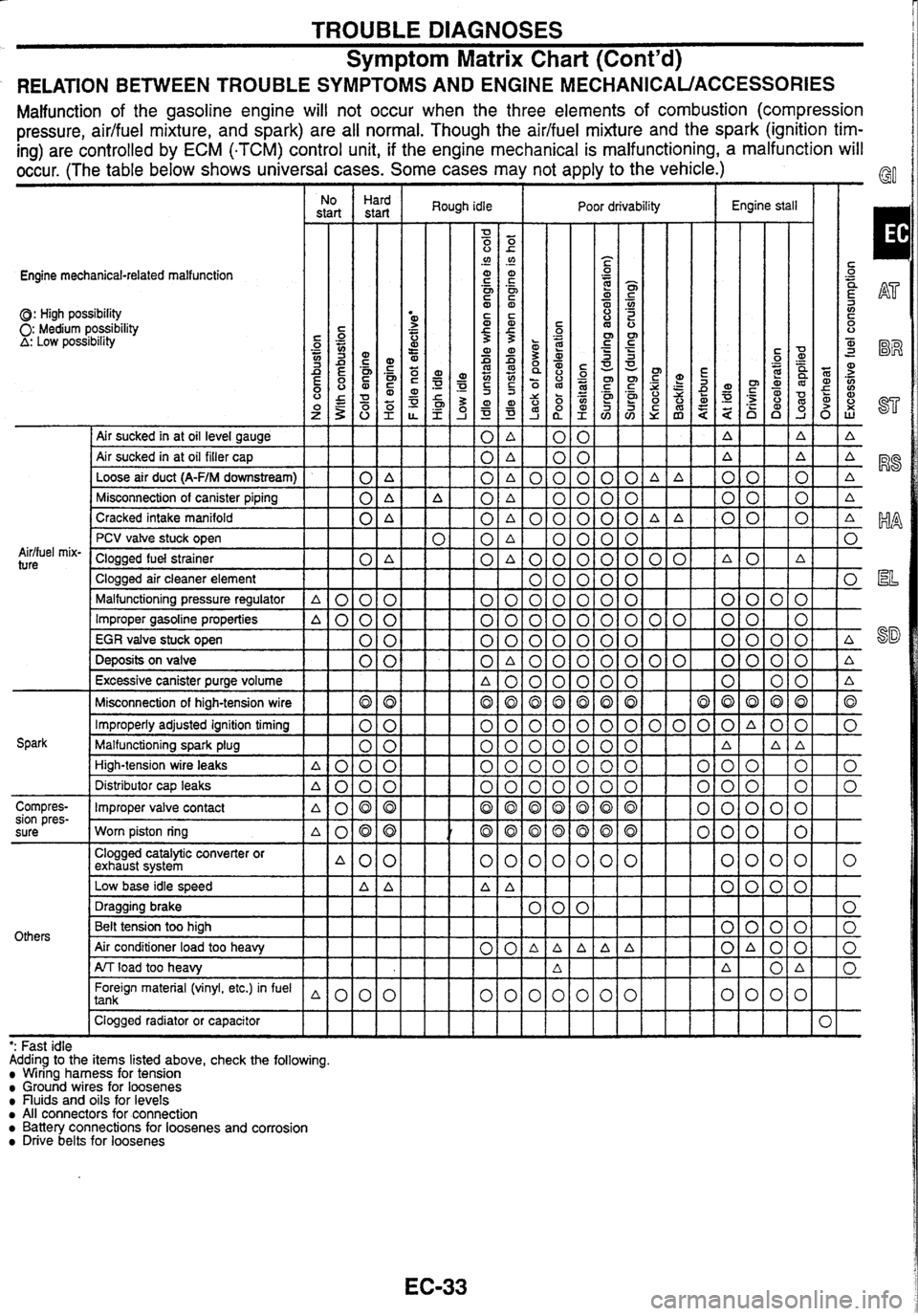

TROUBLE DIAGNOSES

Symptom Matrix Chart (Cont'd)

RELATION BETWEEN TROUBLE SYMPTOMS AND ENGINE MECHANICAUACCESSORIES

Malfunction of the gasoline engine will not occur when the three elements of combustion (compression

pressure, aidfuel mixture, and spark) are all normal. Though the

aidfuel mixture and the spark (ignition tim-

ing) are controlled by ECM

(.TCM) control unit, if the engine mechanical is malfunctioning,

a malfunction will

occur. (The table below shows universal cases. Some cases may not apply to the vehicle.)

Engine mechanical-related malfunction

0: High possibility 0: Medium possibility A: Low posstbility

I No I Hard

start start

I Air sucked in at oil level gauge

Air sucked in at oil filler cap

Loose air duct

(A-F/M downstream) 0 A

Misconnection of canister piping

0 A

Cracked intake manifold

0 A

Aidfuel

mix-

ture

PCV valve stuck open

Clogged fuel strainer

0 A

Clogged air cleaner element

Malfunctioning pressure regulator

A 0 0 0

Improper gasoline properties A000

EGR valve stuck open 0 0

Deposits on valve 0 0

Excessive canister purge volume

Misconnection of high-tension wire

Improperly adjusted ignition timing

Malfunctioning spark plug

High-tension wire leaks

A000

Spark Distributor cap leaks

A000

Compres-

Improper valve contact

sion pres-

. a080

sure Worn piston ring ~080

Others

Clogged catalytic converter or

exhaust system A00

Low base idle speed A

A

Foreign material (vinyl, etc.) in fuel 1 tank

Clogged radiator or capacitor

IIII

Rough idle I Poor drivability Engine stall

- - - - - - -- ': Fast

idle

Adding to the items listed above, check the following.

Wiring harness for tension Ground wires for loosenes nuids and oils for levels All connectors for connection Battery connections for loosenes and corrosion Drive belts for loosenes

Page 41 of 230

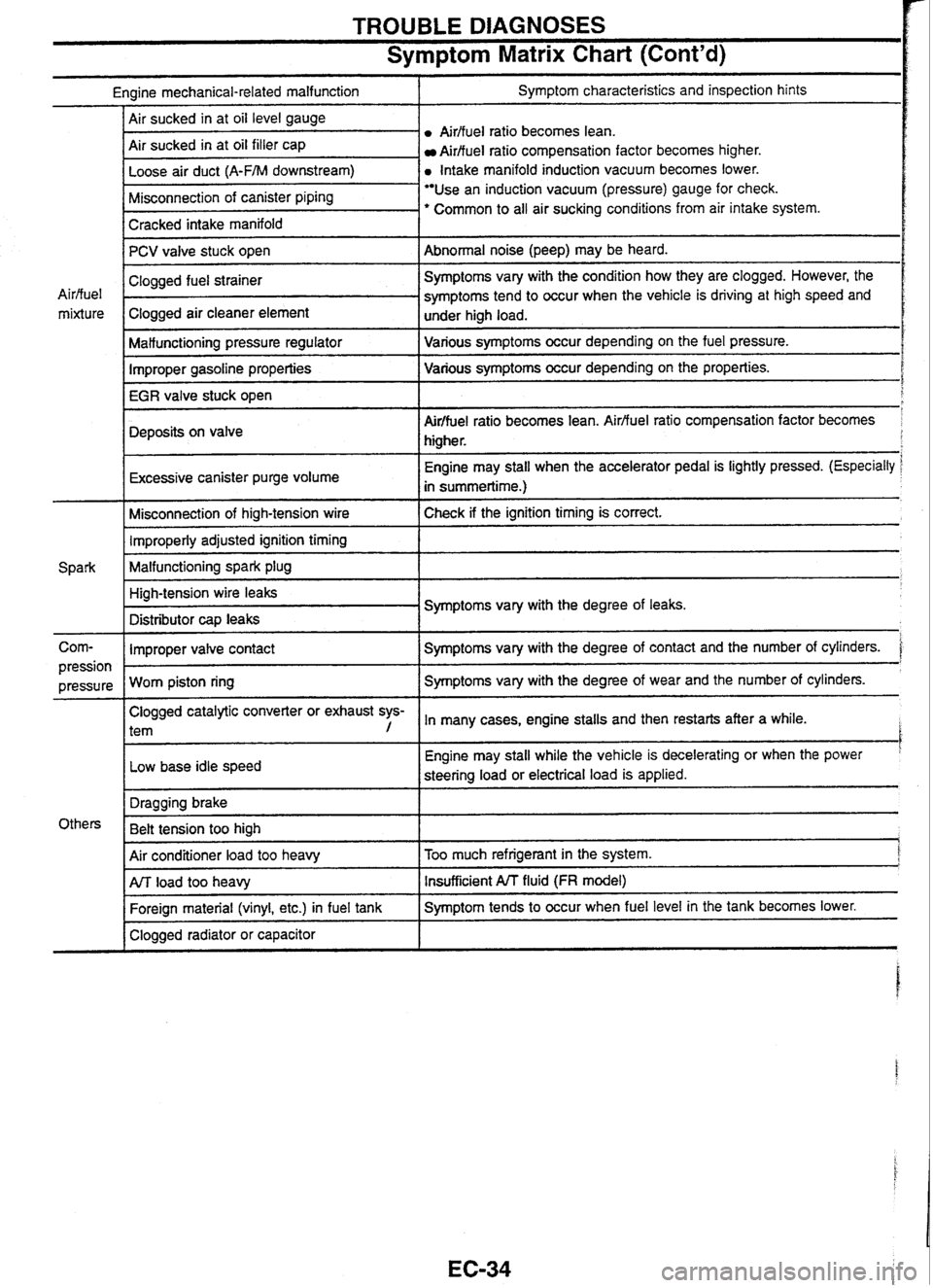

TROUBLE DIAGNOSES

Symptom Matrix Chart (Cont'd)

Engine mechanical-related malfunction I Symptom characteristics and inspection hints

Airffuel

ratio becomes lean.

Air sucked in at oil filler cap

Aidfuel ratio compensation factor becomes higher.

a Intake manifold induction vacuum becomes lower.

I Cracked intake manifold I

Misconnection of canister piping Use an induction vacuum (pressure) gauge for check.

' Common to all air sucking conditions from air intake system.

-

PCV valve stuck open

I Malfunctioning pressure regulator I Various symptoms occur depending on the fuel pressure.

Abnormal noise (peep) may

be heard.

Air/fuel

mixture

Improper gasoline properties Various

symptoms occur depending on the properties.

IEGRiale

stuck open

I

Clogged fuel strainer .

Clogged air cleaner element

Deposits on valve

r

Symptoms vary with the condition how they are clogged. However, the

symptoms tend to occur when the vehicle is driving at high speed and

under high load.

I

Air/fuel ratio becomes lean. Airfluel ratio compensation factor becomes

higher.

Excessive canister purge volume

I

Engine may stall when the accelerator pedal is lightly pressed. (Especially

in summertime.)

Misconnection of high-tension wire Check if the ignition timing

is correct. 1 Improperly adjusted ignition timing 1

Malfunctioning spark plug 1

Corn- I Improper valve contact I Symptoms vary with the degree of contact and the number of cylinders. '

High-tension wire leaks

Distributor

cap leaks Symptoms

vary with the degree of leaks.

Clogged catalytic converter or exhaust sys-

l tem , In many cases, engine stalls and then restarts after a while. I

pression I

Low base idle speed

pressure

Worn piston ring I

Engine may

stall while the vehicle is decelerating or when the power '

steering load or electrical load is applied.

Symptoms vary

with the degree of wear and the number of cylinders.

I

Air conditioner load too heavy I Too much refrigerant in the system. j

Others Dragging

brake

Belt tension too high

1

I Clogged radiator or capacitor I

ArJ load too heavy

Foreign material (vinyl, etc.) in fuel tank Insufficient A/T fluid (FR model)

Symptom tends to occur when fuel level in the tank becomes lower.

Page 55 of 230

TROUBLE DIAGNOSES

System Description

Vehicle with RB20DE and RB25DET engine has TCM integrated into ECM. Vehicle with RB25DE engine has

TCM and ECM separately.

Fail-safe Function @ When malfunction occurs in each sensor and solenoid, the fail-safe functions below enable vehicle to be

driven.

VEHICLE SPEED SENSOR 1 (Output shaft speed sensor)

Inputs a signal from vehicle speed sensor in speedometer. EG

THROTTLE POSITION SENSOR

Detects throttle opening by idle switch and full switch, and controls line pressure as follows. I 1 I Idle switch

-

--

I

--

ON OFF I Minimum oil pressure I 0/8 ST

I

OFF OFF

Full switch

ON Maximum oil pressure

PNP SWITCH

When the multiple PNP switch signals are input to TCM and ECM-TCM, the priority of selector lever position I28

becomes as follows by internal TCM determination.

4AT D, N, R, 2, 1 I%$ M-AT D, N, R, 3, 2

Because the hydraulic circuit of the control valve is switched by manual valve according to the selector lever

position, however, actual operating condition of vehicle becomes as follows.

EL

I N I "N" and other position signals I N

Line pressure

218

P

R

- - -- pp - pp - -

4AT I D I "D" and other position signals I Dl*DP*Dd

Throttle opening I

418 BR

Running status

Actual lever position

1 "2 and other position signals I 21 ~22

PNP switch input signal

"P and other position signals

"R" and other position signals

--

r"2 and "1" 21 ~22

P 83

R

I 2 1 "2" and other position signals / 21 42

M -AT

3

L

1

P

R

N

D

"1" and other position signals

"P" and other position signals

"R" and other position signals

"N" and other position signals

"D" and other position signals

I

l,++l2

P

R

N

D1t;.D2c*D3

"3 and other position signals

"3" and "2" position signals

3, -3,-3-3,

3, +3, +3,

Page 56 of 230

TROUBLE DIAGNOSES

Fail-safe Function (Cont'd)

SHIFT SOLENOID A, B

When a malfunctioning signal of solenoid is input to TCM and ECM-TCM, the gear is shifted as follows.

Normal Abnormal solenoid A Abnormal solenoid B Abnormal solenoid A/B Shift positions A B Gears A B Gears A I3 Gears A 8 Gears

0 0 1 st o-+x 03x - - - -

-- 0: Solenoid ON X: Solenoid OFF -: Abnormal

LINE PRESSURE SOLENOID

When a malfunctioning signal of solenoid is input to TCM and ECM-TCM, the line pressure solenoid is turned

OFF, and the line pressure is set to maximum oil pressure.

LOCK-UP SOLENOID

When a malfunctioning signal of solenoid is input to TCM and ECM.TCM, the lock-up solenoid is turned OFF,

and the lock-up

is released.

OVERRUN CLUTCH SOLENOID

When a malfunctioning signal of solenoid is input to TCM and ECM-TCM, the overrun clutch solenoid is turned

OFF, and the overrun clutch is engaged to apply the engine brake during deceleration.

MANUAL MODE SWITCH (M-AT)

When a malfunctioning signal of manual mode switch is input to TCM and ECM.TCM, the gear is controlled

with normal "D" position.

SHIFT CONTROL UNIT (Except RB20DE)

When a malfunction occurs in the shift control unit, the shift solenoid NB are turned OFF, and the gear posi-

tion

is controlled with 3rd speed.

TURBINE SENSOR (Except RB20DE)

Controlled by vehicle speed sensor 1 in the same way without turbine sensor

Page 58 of 230

TROUBLE DIAGNOSES

Clutch and Band Chart

U0.C

(Low one-

way

clutchl L&R/B

(Low and

reverse

brake)

F/O C

(Forward

clutch)

.

Remarks

PARK POSI-

TION

REVERSE POSITION

O/C

(Overrun

clutch)

*I@

'I@

'18

@

NEUTRAL

POSITION

*"

c'utch)

0

0

WC

clutch)

(Reverse

0

P

R

N

Automatic shift

0

0

FIC

(For-

ward

clutch)

0

0

0

69

0

Band servo

'4

2 Automatic shift

1 st

2nd

-3rd 4th

1 st

1. Locked in 1st

-

4th apply

0

2nd apply

0

'263

*3@

2nd

I st

2nd

0

0

0

DUAL MATIC M-ATx

3rd release

0

8

0

0

0

--

fi In Band servo I FI0.C / UOC I L&WB I

(Reverse clutch) FIC (For- WC (High

ward

clutch) clutch)

PARK POSI-

TION

REVERSE POSITION

NEUTRAL POSITION

@ 0 . . Automatic shift

0 '269 8 - -

-38 8 0

@

G3 0 Automatic shift

10 I I Automatic shift

I I I I I I I

:ch is being set in "OFF position. (D, shift is inhibited.) '2: oil pressure is applied to both 2nd "apply" side and 3rd "releasen side of band servo piston. However, brake band does not contract because oil pressure area on the "releasen side is greater than that on the "apply" side. '3: Oil pressure is applied to 4th "apply" side in condition '2 above, and brake band contracts. '4: A/T will not shift to 4th when overdrive control switch is set in "OFF position.

* 1 : O~erate when control

swil

0: Operates. a: Operates

during "progressive" acceleration.

@: Operates but does not affect power transmission. @: Operates when throttle opening is less than specification, but does not affect engine brake. fi: O~erates when throttle opening is less than specification, activating engine brake.

Page 69 of 230

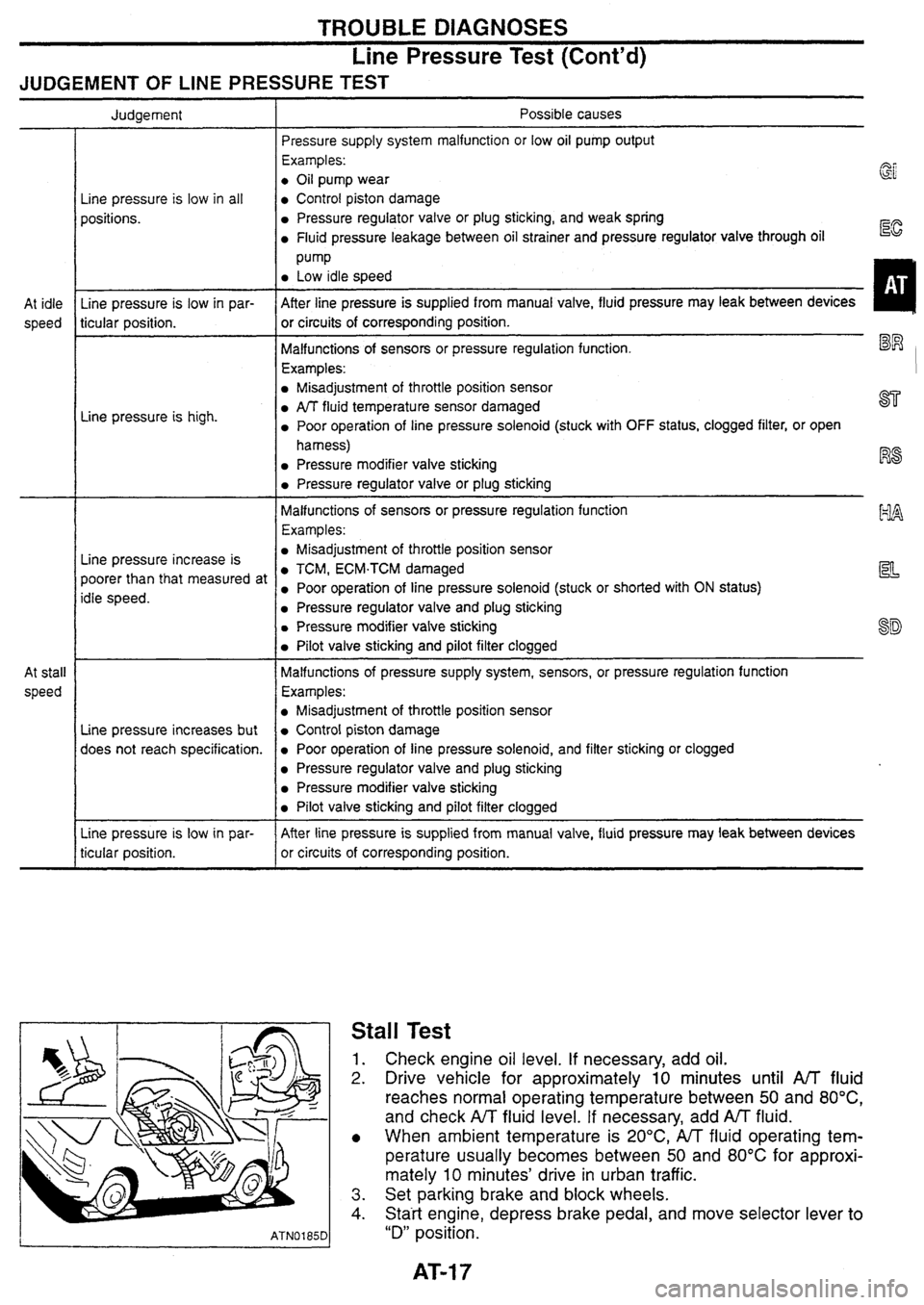

TROUBLE DIAGNOSES

Line Pressure Test (Cont'd)

JUDGEMENT OF LINE PRESSURE TEST

At idle

speed

At stall

speed Judgement

Line pressure is low in all

positions.

Line pressure is low in par-

ticular position.

Line pressure is

high.

Line pressure increase is

poorer than that measured at

idle speed.

Line pressure increases but

does not reach specification.

Line pressure is low in par-

ticular position. Possible

causes

Pressure supply system malfunction or low oil pump output

Examples:

0 Oil pump wear

Control piston damage

Pressure regulator valve or plug sticking, and weak spring

Fluid pressure leakage between oil strainer and pressure regulator valve through oil Eg

Pump

Low idle speed

After line pressure is supplied from manual valve, fluid pressure may leak between devices

or circuits of corresponding position.

1

Malfunctions of sensors or pressure regulation function. El

Examples:

Misadjustment of throttle position sensor

PJT fluid temperature sensor damaged ST

Poor operation of line pressure solenoid (stuck with OFF status, clogged filter, or open

harness)

Pressure modifier valve sticking F%

Pressure regulator valve or plug sticking

Malfunctions of sensors or pressure regulation function

Examples:

EILA

Misadjustment of throttle position sensor

TCM, ECM.TCM damaged la

Poor operation of line pressure solenoid (stuck or shorted with ON status)

Pressure regulator valve and plug sticking

Pressure modifier valve sticking

sf$

Pilot valve sticking and pilot filter clogged

Malfunctions of pressure supply system, sensors, or pressure regulation function

Examples:

Misadjustment of throttle position sensor

Control piston damage

Poor operation of line pressure solenoid, and filter sticking or clogged

Pressure regulator valve and plug sticking

Pressure modifier valve sticking

Pilot valve sticking and pilot filter clogged

After line pressure is supplied from manual valve, fluid pressure

may leak between devices

or circuits of corresponding position.

Stall Test

1. Check engine oil level. If necessary, add oil.

2. Drive vehicle for approximately 10 minutes until A/T fluid

reaches normal operating temperature between

50 and 80°C,

and check A/T fluid level. If necessary, add AfT fluid.

When ambient temperature is

20°C,

A/T fluid operating tem-

perature usually becomes between 50 and

80°C for approxi-

mately

10 minutes' drive in urban traffic.

3. Set parking brake and block wheels.

4. Statt engine, depress brake pedal, and move selector lever to

"D" position.

Page 77 of 230

TROUBLE DIAGNOSES

Symptom Chart

Sharp shock in Engine brake

applied

Shifting

Malfunctions

Slip

(Racing)

hifting

.- erator pedal

Shifting

Shifting

inspection item

Fluid level and status

Control linkage

PNP switch (short/open circuit)

Throttle ~osition sensor (installed)

I Vehicle weed sensor

I Enaine meed sensor

A/T fluid temperature sensor

Engine idle speed

Line

Dressure

Control valve assembly

Shift solenoid

A

Shift solenoid B

Line pressure solenoid

Lock-up solenoid

Overrun clutch solenoid

Accumulator N-D

Accumulator

1-2

Accumulator 2-3

Accumulator 3-4 (N-R) Ignition coil and starter motor

Overdrive control switch

I AfT mode switch (AUTO)

Torque converter

1 Oil pump

I Reverse clutch

I High clutch

I Forward clutch

I Forward one-wav clutch

I Overrun ciutch

1 Low one-wav clutch

I Low reverse brake

Brake. band (including servo)

Parking linkage

Page 78 of 230

Symptom Chart (Cont'd)

Greater noise

Malfunctions

Inspection item No shifting

I Shifting I

Fluid level

and status 11

Control linkage

-

(I) C 0 .- c. .- (I) 0 a

v

-CU

n - 1

PNP switch

(shortlopen

circuit)

Throttle position sensor (installed)

2 2

Vehicle speed sensor

I Engine speed sensor -

-T

L o 1 Control valve assembly .- - -- Shift solenoid A 4 3

. ' Shift solenoid 6 4 cut I1

--, Line pressure solenoid .- 5 -t Lock-up solenoid ?

6 Overrun clutch solenoid 3

Accumulator N-D

1 Accumulator 1-2 I 1-

Accumulator 2-3

Accumulator 3-4 (N-R)

Ignition coil and starter motor

I Overdrive control switch I 1-

A/T mode switch (AUTO)

A/T mode switch (POWER) I - I Ail mode switch (SNOW) I

I Torque converter I I

1 Oil pump I I -- - - Reverse clutch 0 -

'g High clutch a 4 6

%I Forward clutch I I - .- a Forward one-way clutch -

$ Overrun clutch a, 8

Low one-way clutch

O Low reverse brake 7

Brake band (including servo) 7

Parking linkage

Page 79 of 230

TROUBLE DIAGNOSES

Symptom Chart (Cont'd)

xi - - ([I C V) a, C .- cn C W

t 0 .- .L 2 a, - 8 0 ([I L 0 0 Q

& 0 a, a, Q V)

5 E .- X

i! L a

zl -I - 1 -

- 2 -

-

-

-

-

-

5 - 3 - 4 -

-

-

-

-

-

-

-

-

-

-

-

-

I1 - 0 - 6 - 7 -

-

-

-

-

9 - 8 -

-

vj c 0 .- - .- V) 0 n

Q 7J C ([I

t C .- r ([I c. V) c. 0 C V) a 0 7J 0, C .- 0 C W -

- 2 - 3 -

-

- -

-

1 -

-

-

-

- - a +- ([I a a, 2 0 c. 0 C V) a, 0 u a, - 0 2

8 - 1 -

-

-

-

-

-

-

-

2 - 3 -

-

-

-

-

-

-

-

-

-

-

- I

i

g

- 4 -

-

-

-

-

-

-

B- ; 2 to a =? - 0,

2 5.j c 2.z 2 a0 - 0- z & 5 0 gE V) V)o C 02 .s nu 5 ng %-([I C O c --t .- V) a V) r aa ([I z gz a, a- c 50 -6 s

6 $2

11

2

I

I

Malfunctions

Inspection item

I I I Fluid level and status I I Control linkage 2

PNP switch (shortfopen circuit) 1 I I I Throttle position sensor (installed) 111213

Vehicle speed sensor

214

Engine speed sensor L -

AIT fluid temperature sensor

Engine idle weed

Line pressure

Control valve assembly

Shift solenoid A 3

3

Shift solenoid B 4 4

Line pressure solenoid

Lock-up solenoid

Overrun clutch solenoid

u I I I -

Accumulator N-D I I 1 I Accumulator 1-2

Accumulator 2-3 I Accumulator 3-4 (N-R)

Ignition coil and starter motor

Overdrive control switch

Torque converter

tg Reverse clutch .- High clutch

2 Forward clutch C .- a Forward one-way clutch -.

$ Overrun clutch 0, 8

? Low one-way clutch 3= O Low reverse brake 9

Brake band (including servo)

Parking linkage

Page 187 of 230

COMBINATION METER

Diagnosis Function

(Cont'd)

METER CIRCUIT CHECK

After the segment check, press the odohrip meter switch to

verify that meters operate as shown below. (Low fuel warning

lamp goes off at this point.)

i

ELF0967D I It takes 1 minute for the meters to become stable.

DIAGNOSIS FUNCTION CANCELLATION

Turn the ignition switch ACC or OFF.

Meter-related Circuit Diagram

I I TO oil pressure W.L