ABS NISSAN GT-R 1998 Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: GT-R, Model: NISSAN GT-R 1998Pages: 230, PDF Size: 12.66 MB

Page 93 of 230

ANTI-LOCK BRAKE SYSTEM

Self-diagnosis

DESCRIPTION

When a problem occurs in the ABS, the ABS warning lamp on the

instrument panel comes on. To actuate the self-diagnostic results

mode, ground the self-diagnostic check terminal

4 located on the

data

link

connector for

CONSULT. The ABS warning lamp, then,

flashes and indicates the location of the malfunction.

SELF-DIAGNOSIS PROCEDURE

1. Collect information on the concern from the customer, and then

perform basic inspections.

2. Drive vehicle at approx. 30 km/h for approx. 1 minute.

3. Stop vehicle and start diagnosis.

4. Turn ignition switch "OFF'.

5. Ground the self-diagnostic check terminal 4.

6. Turn ignition switch "ON" to start the self-diagnostic results

mode.

CAUTION:

Keep terminal 4 grounded during self-diagnosis.

Do not depress brake pedal. (Self-diagnosis would not

start.)

Do not start engine. (Self-diagnosis would not start.)

7. After 3 or 4 seconds, ABS warning lamp starts blinking to indi-

cate the malfunction code No.

The indication terminates after 5 minutes. Turning the ignition

switch from

"OFF" to "ON" resumes blinking the indication.

8. Verify the location of the malfunction with "MALFUNCTION

CODUSYMPTOM CHART", BR-16. Then make the necessary

repairs.

9. After the malfunctions are repaired, erase the malfunction

codes stored in the control unit. Refer to "HOW

TO ERASE

SELF-DIAGNOSTIC RESULTS" on the next page.

10. Rerun the self-diagnostic results mode to verify that the mal-

function codes have been erased.

11. Disconnect the check terminal from the ground. The self-diag-

nostic results mode is now complete.

12. Drive vehicle at approx. 30 km/h for approx. I minute, and then

check that the ABS warning lamp is off.

HOW TO READ SELF-DIAGNOSTIC RESULTS

(Malfunction codes)

Determine the code No. by observing the time and the fre-

quency that the

ABS warning lamp blinks ON and OFF.

When multiple malfunctions occur at a time, up to three code

numbers can be stored; the latest malfunction will be indicated

first.

The indication begins with the start code No. 12. A maximum

of three code numbers appear in the order of the latest one

first. The indication then returns to the start code No.

12 to

repeat.

The start code No. 12 is only indicated repeatedly when there

is no malfunction.

Page 94 of 230

ANTI-LOCK BRAKE SYSTEM

Self-diagnosis (Cont'd)

Example: Code No. 25 Front left wheel sensor (open-ccrcuit)

lnd~cat~on

s:arl

Start code No. i2

Unit: seconds BRG1185D

ABS warnq lamp ON -

A9S warnrng lamp OFF

Self-d~agnosis complete , C ABS warning lamp !

I i I I I

................ &. j(j(?.:e~o"dd~i!~?!!f!!. . -----... .-.---.--. iiii rase 1 12.5 seconds I mode

Malfunct~on

memory Malfunction memory is Nn. erase mode starts. Is erased BRG0057C

Tens d~g~ts Un~ts digits Code No 25 I I - I

HOW TO ERASE SELF-DIAGNOSTIC RESULTS

(Malfunction codes)

r--------- -T---t----t-l-T-l-

1. Turn the ignition switch "ON" and start the engine.

-.

---------- -I--I--t--l-i-"I

2. Drive the vehicle at approx. 30 kmh for approx. 1 minute to

check that there is no other malfunction.

ST

3. Stop the vehicle.

4. Turn the ignition switch "OFF'.

5. Ground the self-diagnostic check terminal. RS'

6. Turn the ignition switch "ON" to start the self-diagnostic results

-

-.

3 06 0.9 03C303 3.3 06 0.6 0.6 09 050303030305030303

-----

mode.

CAUTION:

c--

Do not depress the brake pedal during self-diagnosis. Do not

start the engine. (The self-diagnosis

would not start.)

7. The ABS warning lamp starts to blink 3 or 4 seconds after the EL

self-diagnostic results mode is started.

8. Under the self-diagnostic results mode, the malfunction $jD

memory erase mode starts when the check terminal is discon-

nected from the ground.

9. Ground the check terminal 3 times or more in succession

within 12.5 seconds after the erase mode starts. (Each ground-

ing must

be 1 second or longer.)

10. Disconnect the grounding cable from the check terminal to

erase the malfunction memory and complete the

self-diagno-

sis. The ABS warning lamp

, then, turns off.

11. Turn the ignition switch

"OFF'.

Page 95 of 230

ANTI-LOCK BRAKE SYSTEM

Self-diagnosis (Cont'd)

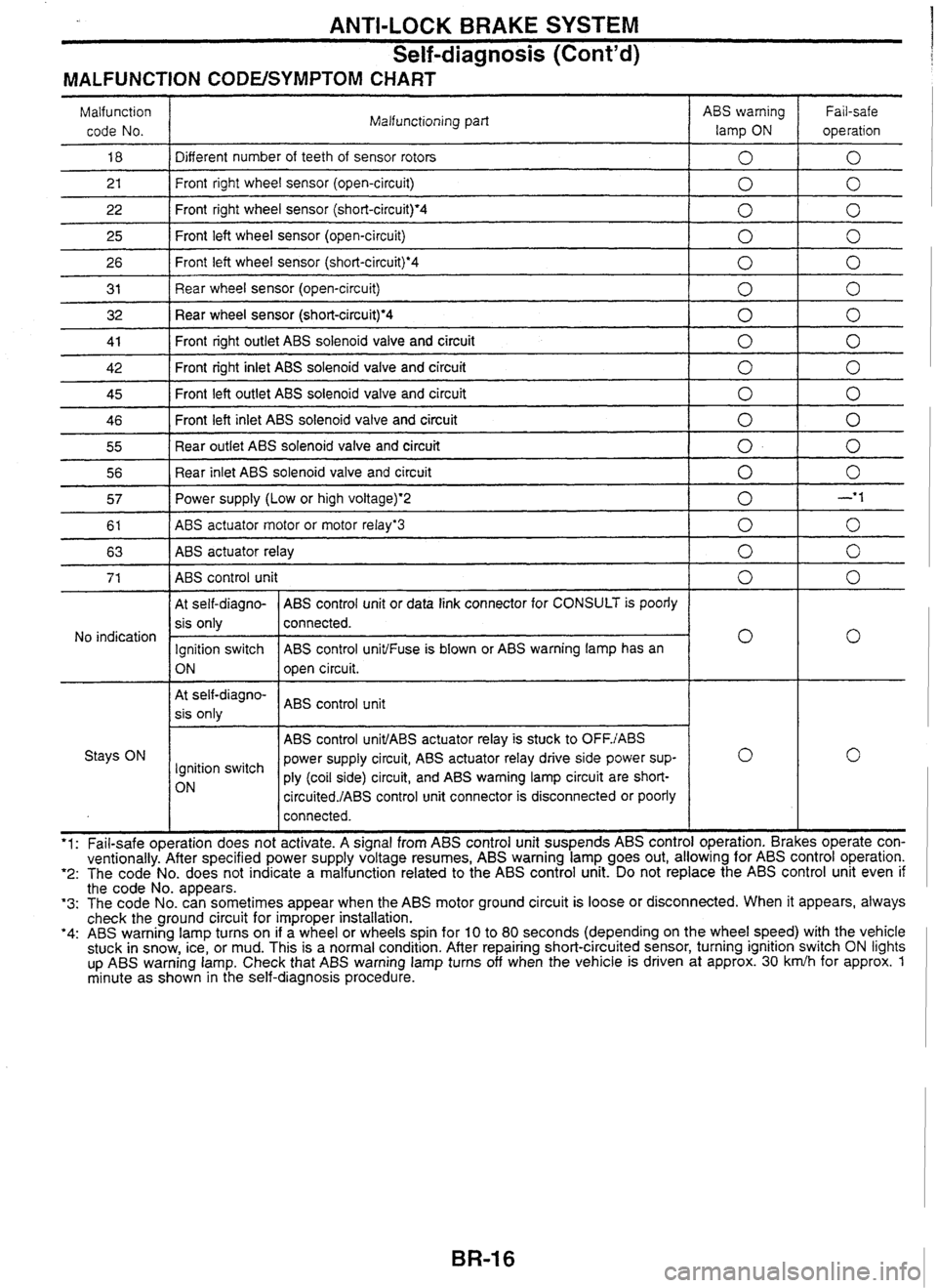

MALFUNCTION CODEISYMPTOM CHART

Malfunction code No. Malfunctioning

part ABS warning

lamp

ON

Fail-safe

operation

18 1 Different number of teeth of sensor rotors 1010

2 1

26 I Front left wheel sensor (short-circuiQ.4 1010

- --

22

25

3 1 I Rear wheel sensor (open-circuit) 1010

Front right wheel sensor (open-circuit)

32 Rear wheel sensor (short-circuit)'4 1 0 1 0

Front right wheel sensor (short-circuit)'4

Front left wheel sensor (open-circuit)

41

I Front right outlet ABS solenoid valve and circuit 1010

0 0

0

0

0

0

- -

42

-- - -

46 Front left inlet ABS solenoid valve and circuit 0 1 0

45 Front

left outlet ABS solenoid valve and circuit

55

1 Rear outlet ABS solenoid valve and circuit 1010

Front right inlet ABS solenoid valve and circuit

56

1 Rear inlet ABS solenoid valve and circuit 1010

0

57 1 Power supply (Low or high voltage)*2 I 0 I -'I

0

0

0

I At self-diagno- ( ABS control unit or data link connector for CONSULT is poorly 1 I

61

63

At self-diagno-

I ABS control unit

sis only

ABS

actuator motor or motor relayg3

ABS

actuator relay

No indication

I I ABS control unit1ABS actuator relay is stuck to OFFJABS I Stays ON power supply circuit, ABS actuator relay drive side power sup-

lgnition switch

ply (coil side) circuit, and ABS warning lamp circuit are

short-

circuited./ABS control unit connector is disconnected or poorly

0

0

I

sis only

Ignition switch

ON

I I connected. I I

0

0

connected.

ABS control

unit1Fuse is blown or ABS warning lamp has an

open circuit.

- -- '1: Fail-safe operation does not activate. A signal from ABS control unit suspends ABS control operation. Brakes operate con-

ventionally. After specified power supply voltage resumes, ABS warning lamp goes out, allowing for ABS control operation. '2: The code No. does not indicate a malfunction related to the ABS control unit. Do not replace the ABS control unit even if the code No. appears. '3: The code No. can sometimes appear when the ABS motor ground circuit is loose or disconnected. When it appears, always

check the ground circuit for improper installation.

'4: ABS warning lamp turns on if a wheel or wheels spin for 10 to 80 seconds (depending on the wheel speed) with the vehicle

stuck in snow, ice, or mud. This is a normal condition. After repairing short-circuited sensor, turning ignition switch ON lights

up

ABS warning lamp. Check that ABS warning lamp turns off when the vehicle is driven at approx. 30 krnlh for approx. 1 minute as shown in the self-diagnosis procedure.

Page 96 of 230

TCSIABS SYSTEM

System

Description

ABS FUNCTION

During ABS operation, the brake pedal pulsates along with a mechanical noise. This ensures that the ABS

is working properly. mP

When starting up the engine or immediately after the vehicle starts to run, the brake pedal pulsates and G'

a motor noise from the engine compartment can be heard. They are caused by the ABS operation check

and should not be considered abnormal.

A vehicle with the ABS may stop in a longer distance than a vehicle without the ABS when the brake is

EC

applied on a bad road, gravel road, or deep fresh snow.

TCS FUNCTION

TCS/ABS control unit monitors the speed of the driving wheels through 4 wheel speed sensors. If driving

wheel slip is detected, fuel to the engine is cut

ol

and the throttle valve is adjusted so that the engine

a

torque is reduced. On vehicles with automatic transmission, transmission shift schedule is also changed

to control the rear wheel driving torque, which results

in the reduction of wheel slip. This system enables

the throttle valve to be controlled so that optimum engine torque can be achieved in accordance with the

driver's acceleration request.

The driver may not feel satisfied with acceleration on some road surfaces. This poor acceleration occurs

because the operating TCS gives priority to maintaining optimum traction. Therefore, this condition should

R8

be considered normal.

When shiftdown is made or the acceleration pedal is depressed while the vehicle is driven on the road

surface that has different friction coefficients, the TCS may operate temporarily.

r-- 4 Lrd[-i

On vehicles with manual transmission, the SLlP indicator lamp and the TCS OFF indicator lamp may light

up when the engine is about to stall in the conditions shown below.

If the lamps go off when engine speed

increases, there is no problem in the system.

At start, the engine almost stalls and the engine speed is much lower than the idle speed.

The vehicle is driven at an extremely low speed with a high-speed gear engaged.

The clutch has been engaged until the vehicle almost stops. 8D

FAIL-SAFE FUNCTION

ABS system

If any malfunction is detected in the system, the ABS warning lamp, the TCS OFF indicator lamp and the SLlP

indicator lamp in the instrument panel is turned on with the TCSIABS deactivated and the vehicle's brake sys-

tem reverts to normal operation.

TCS system

If any malfunction is detected in the system, both the SLlP indicator lamp and the TCS indicator lamp on the

instrument panel light up and the TCS is shut down. The vehicle operates in the same manner as a vehicle

without the

TCS, while the ABS is operational.

If there is a malfunction in the throttle control system, the TCS becomes inoperative while the ABS

remains functional.

When fail-safe operation is activated, perform the self-diagnosis procedure for the TCSIABS first.

Refer to

BR-27 for details.

Page 97 of 230

TCSIABS SYSTEM

System Description (Cont'd)

Parts that make throttle control inoperative

Malfunction code No.

11

12

13

91

32 I

Throttle motor return spring (Return spring is bro-

ken.) Malfunctioning part

Throttle position sensor circuit

Throttle motor sensor circuit Circuit for

the communication line

(DKR line)

between

TCSIABS control unit and throttle control

unit

Actuator system (Motor circuit is open or throttle

L I

22

23

24

Parts that make throttle control operative

motor intermittently works.)

Throttle motor drive system (overcurrent)

Throttle motor relay circuit (shorted)

Throttle motor relay circuit (open)

System Diagram

Secondary throttle posrt~on sensor value - - C; Front nght C CI) - ul wheel sensor , Throttle control unrt 0 - CI, -

$ Rear ngh:

g 5 wheel sensor c 0 m E

000000

Total control stgnal for engrne, AIT and TCS/ABS (multrpie communication)

TCSlABS control unrt

Rear lett

whee! sensor

TCS OFF swtch

Front left

wheei sensor

-+ SLIP 1ndrca:or Lamp '

----c TCS OFF rndcator lamp

c A9S warnlns lamp BR-0227D

Malfunction code No.

31

33

Malfunctioning parts

Starter signal circuit (shorted)

Paridneutral

position switch circuit (open or

shorted)

Page 98 of 230

TCSfABS SYSTEM

Component Parts

Location

[El TCSIABS

Rear wheel sensor

Throttle motor relay

Front right wheel

senso

Throttle control unit

Front left wheel sensor

@ RH side of engine compartment

// /LA~A~~~~

RH side of rear suspension t%ernb&- /

I Rear wheel sensor connector

Engine compartment control unit

-- -- -- -

- - LH side of engine compartment

Behind LH side lower fi

Page 99 of 230

10 SLIP indicator lamp IOA~ I

Throttle

motor relay ABS warnina lam. 1 I Throlllo

motor sensor

Throtlle

~osition sensor ,----------- --- - 7 I I I Actuator motor I

1 L

TCS OFF indicator

Throlllo motor

I angle signal ECM TCM

37 or ECM

TCS switch signal

5 3

4

2

7 6

7

Throttle ClU 20

10

Stop lamp SW u22 & FR OUT 1 1

j To data link

,connector TXL I for {W- l CONSULT I I I I I I

Rear IN

Throllle molor

1 I

& 5 6 7 8 @JgT$@

- - - - - - - - - DKV (Throlllo angle output) 2

ECM.TCM or ECM 2

109 3 Meter CIU (NT model only) 111 3

--------- -- DKR (Ttirotllo niolor (argot : angle signal) ' TO data link I 1 4 connector for I

To Meler CIU (Engine speed signal) 4 1 115

Dala link connector

for CONSULT

Ttlrottle CIU

Page 100 of 230

TCSIABS SYSTEM

Control Unit

InputlOutput Signal Specifications

USING CIRCUIT TESTER

TCS/ABS control unit - -

To perform the following inspection, the ignition switch should be turned ON with TCS/ABS control unit con-

nector and actuator connector properly connected.

I

TCS/ABS contro! unit connector

Terminal No.

P Front right wheel I

Item

sensor

I

Specifications'l

Rear right wheel Wheels are turning (Approx.

30 km/h)'3: Pulse generates.

Front: Approx. 200

Hz

Rear: ADDrox. 200 Hz I . , sensor

Rear left wheel

sensor

I

I

Brake pedal is depressed: Battery voltage (Approx. 12V)

Stop lamp signal Brake pedal is not depressed: Less than approx. 2V

Actuator relay is activated (with engine running): Less than approx.

2V

Actuator relay Actuator relay

is not activated (with fail-safe function activated and engine

not running): Battery voltage (Approx.

12V)

ABS motor is running (in CONSULT active test mode): Battery voltage

ABS motor monitor (Approx. 12V)

ABS motor is stopped (with ignition switch ON): Approx. OV

SLIP

indicator

SLIP

indicator lamp

ON'S: OV

lamp

SLIP

indicator lamp

OFF'5: Battery voltage (Approx. 12V)

TCS OFF indicator TCS OFF indicator lamp

ON'4: OV

lamp TCS OFF indicator lamp

OFF'4: Battery voltage (Approx. 12V)

TCS OFF switch TCS OFF switch is pressed: Approx. OV

signal TCS OFF switch is not pressed: Approx. 4

- 5V

Engine speed sig-

nal Pulse generates.

Refer to EC section

("ECM.TCM Input/Outout Reference Value")

Total control signal

(Multiple communi-

cation) for engine,

A/T and TCSIABS Check item (Refer-

ence)

Wheel sensors

and circuit Stop lamp switch

and circuit

ABS actuator relay

and circuit

ABS motor monitor

circuit

SLlP indicator

lamp and circuit

TCS OFF indicator

lamp and circuit

TCS OFF switch

and circuit

Engine speed sig-

nal circuit

Circuit for total

control signal (Mul-

tiple communica-

tion) for engine, A/T and TCSIABS

Page 101 of 230

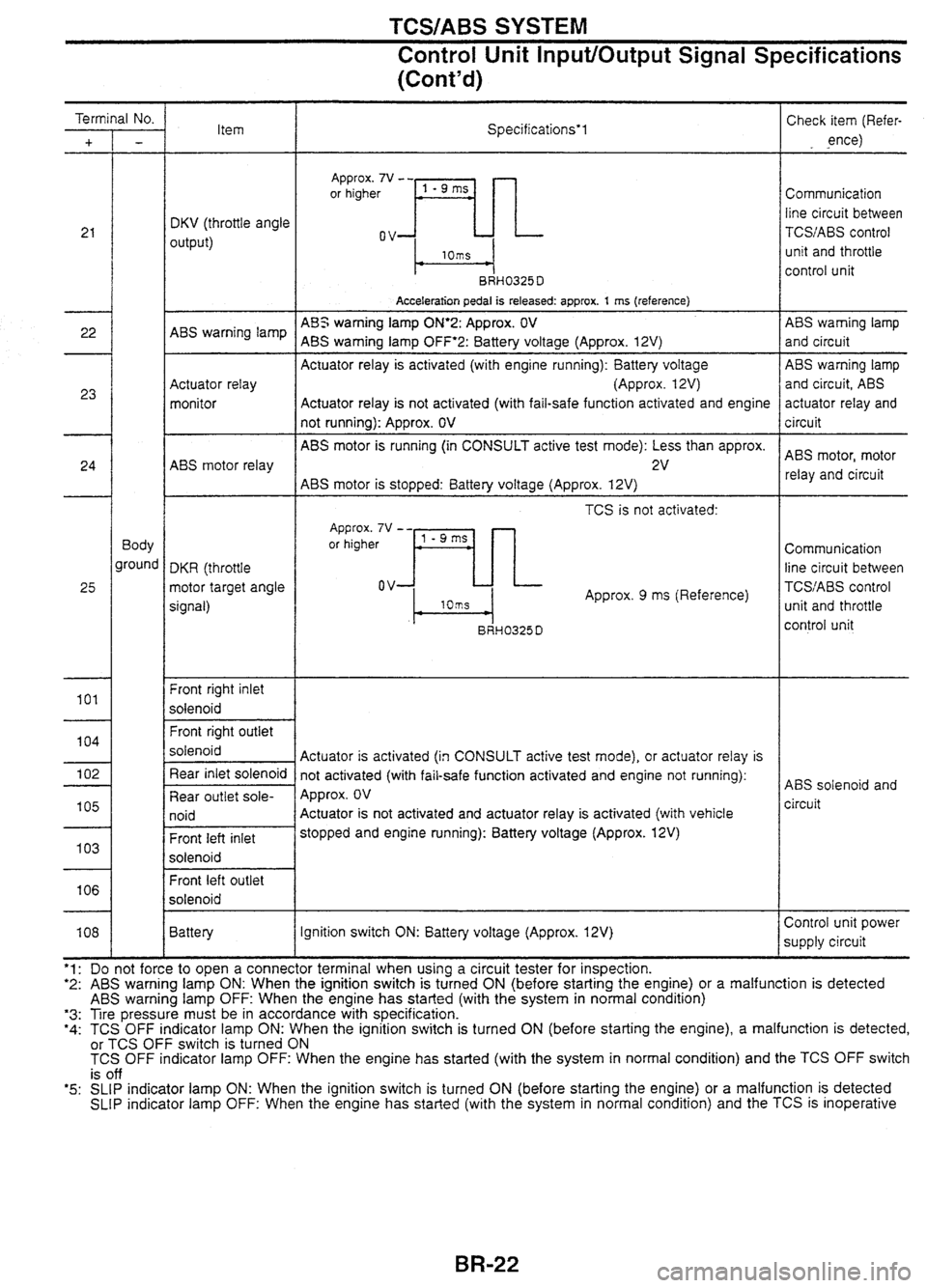

TCS/ABS SYSTEM

Control Unit InputlOutput Signal Specifications

(Cont'd)

Terminal No.

Specifications'l

- - --

Check item (Refer-

ence)

- - -

Body

ground

-

Approx. 7V - - or higher Communication

line circuit between

TCSIABS control

unit and throttle

control unit

DKV

(throttle angle

output)

Acceleration pedal is released: approx. 1 ms (reference)

ABS warning lamp ABS warning

lamp

and circuit 4B3 warning lamp 0Nr2: Approx. OV

4BS

warning lamp 0FF72: Battery voltage (Approx. 12V)

cictuator

relay is activated (with engine running): Battery voltage

(Approx.

12V)

ktuator

relay is not activated (with fail-safe function activated and engine

70t

running): Approx.

OV

ABS warning lamp

and circuit,

ABS

actuator relay and

circuit

Actuator relay

monitor

48s

motor is running (in

CONSULT active test mode): Less than approx.

2V

4BS motor is stopped: Battery voltage (Approx. 12V)

TCS is not activated: ABS

motor, motor

relay and circuit

ABS

motor relay

Approx. 7V - -

OV I I Communication

line circuit between TCSfABS control

unit and throttle

control unit

DKR

(throttle

motor target angle

signal) Approx. 9 ms (Reference)

Front

right inlet

solenoid

Front right outlet

solenoid

4ctuator

is activated (in CONSULT active test mode), or actuator relay is

lot

activated (with fail-safe function activated and engine not running):

4pprox.

OV

4ctuator

is not activated and actuator relay is activated (with vehicle

stopped and engine running): Battery voltage (Approx.

12V)

Rear inlet solenoid

Rear outlet

sole- ABS solenoid and

circuit

Front left inlet

solenoid

Front left outlet

solenoid

Battery gnition switch

ON: Baitery voltage

(Approx. 12V) Control

unit power

supply circuit

'1: Do not force to oDen a connector terminal when usina a circuit tester for ins~ection. '2: ABS warning lamp ON: When the ignition switch is t6ned ON (before startirig the engine) or a malfunction is detected

ABS warning lamp OFF: When the engine has started (with the system in normal condition)

'3: Tire pressure must be in accordance with specification. '4: TCS OFF indicator lamp ON: When the ignition switch is turned ON (before starting the engine), a malfunction is detected,

or TCS OFF switch is turned ON TCS OFF indicator lamp OFF: When the engine has started (with the system in normal condition) and the TCS OFF switch

is off '5: SLlP indicator lamp ON: When the ignition switch is turned ON (before starting the engine) or a malfunction is detected

SLlP

indicator lamp OFF: When the engine has started (with the system in normal condition) and the TCS is inoperative

Page 102 of 230

TCS/ABS SYSTEM

Control

Unit InpuVOutput Signal Specifications

(Cont'd)

Throttle control unit

Terminal No.

Specifications*

item Check

item (Refer-

ence)

Throttle angle sig-

nal Ignition switch

ON

Throttle valve is fully closed: Approx.

0.5V

Throttle valve is fully open: Approx.

4.2V

Throttle motor sen-

sor

Throttle motor angle signal Throttle

position

sensor circuit and

ECM

I

Throttle motor sen-

sor and circuit R8 Engine is idling: Approx. 4.4V

I

I Throttle motor

TCS switch signal Engine

is idling: Approx.

3.4V

lgnition switch ON: Approx. 5V

Throttle control

unit power supply angle

signal and

MA

circuit

TCS switch signal

circuit

EL

Body

jround

- - -- -- - - - --

lgnition switch ON: Battery voltage (Approx. 12V)

Throttle control

unit power supply

Throttle motor relay

Sensor battery

voltage

Throttle control

unit power supply

Throttle motor relay Throttle

control

unit power circuit @J

1

Throttle control

unit power circuit

lgnition switch

ON: Battery voltage (Approx.

12V)

Throttle motor relay and circuit

lgnition

switch ON: Approx.

OV

Throttle position

sensor power cir-

cuit

lgnition

switch ON: Approx. 5V

lgnition switch ON: Battery voltage (Approx. 12V) Throttle control

unit power circuit

lgnition switch ON: Battery voltage (Approx. 12V)

I

Throttle motor

relay

and circuit

Start signal lgnition

switch START (Disconnect ECM-TCM connector or ECM connec-

tor.): Approx.

10V

*: Do not force to open a connector terminal when using a circuit tester for inspection. Start

signal circuit

and ECM