sensor NISSAN GT-R 1998 Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: GT-R, Model: NISSAN GT-R 1998Pages: 230, PDF Size: 12.66 MB

Page 34 of 230

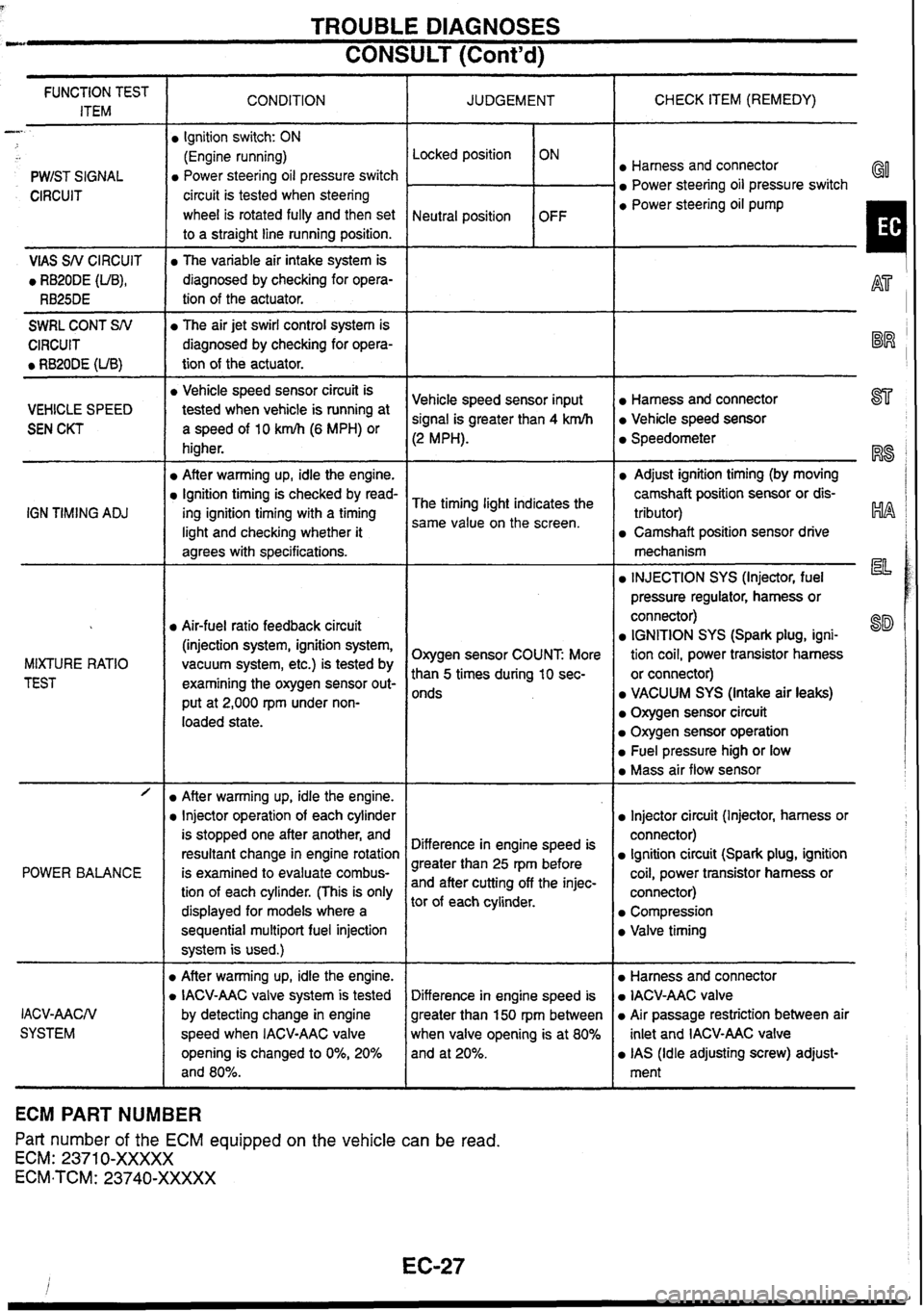

TROUBLE DIAGNOSES

CONSULT (Cont'd) --

CHECK ITEM (REMEDY)

FUNCTION TEST

ITEM CONDITION

JUDGEMENT

-

PWIST SIGNAL Locked position

Neutral position

Ignition

switch: ON

(Engine running)

Power steering oil pressure switch

circuit is tested when steering

wheel is rotated fully and then set

to a straight line running position. ON

OFF Harness and connector

Power steering oil pressure switch GO

CIRCUIT a Power steering oil pump

I VlAS SN CIRCUIT

0 RB20DE (UB),

RB25DE

The variable air intake system is

diagnosed by checking for opera-

tion of the actuator.

-

SWRL CONT SN

CIRCUIT

0 RB20DE (UB)

The air jet swirl control system is

diagnosed by checking for opera-

tion of the actuator.

-- -- -

a Vehicle speed sensor circuit is

tested when vehicle

is running at

a speed of 10 km/h (6 MPH) or

higher.

After warming up, idle the engine.

Ignition timing is checked by read-

ing ignition timing with a timing

light and checking whether it

agrees with specifications.

Harness and connector 877

Vehicle speed sensor

Vehicle

speed sensor input

signal is greater than 4 krnlh

(2 MPH).

VEHICLE SPEED

SEN CKT Speedometer

RS

Adjust ignition timing (by moving

camshaft position sensor or dis-

tributor)

HA

Camshaft position sensor drive

The

timing light indicates the

same value on the screen.

IGN

TIMING

ADJ

mechanism

la INJECTION SYS (Injector, fuel

pressure regulator, harness or

connector)

IGNITION SYS (Spark plug, igni-

tion coil, power transistor harness

or connector)

VACUUM SYS (Intake air leaks)

Oxygen sensor circuit

Oxygen sensor operation

Fuel pressure high or low

Mass air flow sensor

Air-fuel ratio feedback circuit

(injection system, ignition system,

vacuum system, etc.) is tested by

examining the oxygen sensor out-

put at 2,000

rpm under non-

loaded state. Oxygen sensor COUNT

More

than

5 times during 10 sec-

onds

MIXTURE

RATIO

TEST

- -- /

POWER BALANCE

Injector circuit (Injector, harness or

connector)

Ignition circuit (Spark plug, ignition

coil, power transistor harness or

connector)

Compression

Valve timing

After warming up, idle the engine.

Injector operation of each cylinder

is stopped one after another, and

resultant change in engine rotation

is examined to evaluate combus-

tion of each cylinder. (This is only

displayed for models where a

sequential

multipart fuel injection

system is used.)

D After warming up, idle the engine.

D IACV-AAC valve system is tested

by detecting change in engine

speed when IACV-AAC valve

opening is changed to

0%, 20%

and 80%. Difference

in engine speed is

greater than 25 rpm before

and after cutting off the injec-

tor of each cylinder.

Harness and connector

IACV-AAC valve

Air passage restriction between air

inlet and IACV-AAC valve

IAS (Idle adjusting screw) adjust-

ment

Difference

in engine speed is

greater than 150

rpm

between

when valve opening is at 80%

and at 20%.

IACV-AACN

SYSTEM

ECM PART NUMBER

Part number of the ECM equipped on the vehicle

can be read.

ECM: 2371 0-XXXXX

ECM-TCM: 23740-XXXXX

Page 35 of 230

TROUBLE DIAGNOSES

Symptom Matrix Chart

RELATION BETWEEN CONTROL ITEMS AND SENSORSfACTUATORS

@: High possibility to control damage 0: Low possibility to control damage

Sensors and actuators

1$1$1$ r I I

Crankshaft position sensor 1@1@1@

Ring gear crankshaft position sensor

[RB20DE (UB)] @

Mass air flow sensor

I Engine coolant temperature sensor I 0 I @ I 0 i I

Heated oxygen sensor 0

Knock sensor

Vehicle speed sensor

e? - 01 0

Throttle position sensor 000 C. $ Turbo pressure sensor (TIC) 0 0

Refrigerant pressure sensor

START

lgnition switch

@ 0

IGN 000

Air conditioner switch

Parklneutral position switch

Power steering oil pressure switch

Electrical load switch

Battery

voltage

0

injector @GO I

I power transistor I I I Ignition system I I I lgnition coil I I I I

AAC valve

Fuel DumD relav

. . I I I

2 o ECM & IGN coil relay I@l@l@ 1 I I % Auxiliary electric fan relay 3 - 2 Air conditioner relay

Canister purge control valve

0

Variable valve timing control solenoid valve

Variable air intake control solenoid valve

, (NA) Air jet swirl control solenoid valve

[RB20DE (UB)] 0

Turbo pressure control solenoid valve

(TW

FPCM (TIC)

%' Dropping resistor (TIC) 2. I I 5 Air regulator

Canister 0

Page 36 of 230

TROUBLE DIAGNOSES

Symptom Matrix Chart (Cont'd)

-RELATION BETWEEN TROUBLE SYMPTOMS AND SENSORS

-. - Sensors No I Hard

start start Rough

idle

Poor derivability Engine

stall

Symptom

@: High possibility 0: Low possibility

Crankshaft position

sensor (POS,

REF) Instantaneous

xeak

Ring gear crankshaft

position sensor

[RB20DE

(UB)]

s 1 Signal iigh output

,ow output

"

2 Power supply

Engine coolant tem-

perature sensor

iigh resistance

-ow resistance

- -- Heated oxygen sen-

sor

Knock sensor

iigh output

.ow output

Ipedshort

Vehicle s~eed sensor

Throttle position sen-

sor Jnstable output

'oar adjustment

Turbo pressure sen-

sor

(TIC)

Refrigerant pressure

sensor

Ignition switch (IGN)

k$n;pRnT)sw

i tch

Air conditioner switch

ParWneutral position

switch

Power steering oil

pressure switch

Electrical load switch

Multiplex communica-

tion line

Control unit power

supply

Sensor ground

Control unif and con-

nector

*: Fast idle

'oor contact

Vater intrusion

Page 37 of 230

TROUBLE DIAGNOSES

Symptom Matrix Chart (Cont'd)

Sensor-related problems I Symptom characteristics and ins~ection hints

Open Engine

will not start when either REF signal circuit or POS signal circuit is open.

Neither fuel system nor ignition system outputs control signals.

Crankshaft position sensor

(POS, REF) Instanta-

neous break Symptoms

vary with the break time and the vehicle's driving conditions. Light

shock or surging will occur while the vehicle is being driven, and the engine will

stall at idle speed.

Ring gear crankshaft position

sensor

[RB20DE

(UB)]

Signal

Mass air flow sensor Open

Open

High output

Low output I Aidfuel

ratio becomes lean. Dirty hot wire or air entering the system could be the

cause. No

airfluel ratio compensation

is carried out during lean bum status. Drivability

may be affected.

Enters fail-safe mode. Driving under

2,400 rpm is allowed.

Airlfuel

ratio becomes rich. Black smoke may be noted. Poor contact at the

ground could be the cause.

Engine coolant temperature sen-

sor Open

Open

Opedshort

High resis-

tance

Low resis-

tance

Opedshort

Heated oxygen sensor

I

Airlfuel ratio becomes over-rich.

Same symptom as when signal wire is open.

Enters fail-safe mode. Malfunction indicator lamp comes ON. Ordinary driving is

allowed. Problems tend to occur when engine is cold or engine coolant tempera-

ture

is high.

Detects low engine coolant temperature. Problems tend to occur after engine

warm-up.

Detects high engine coolant temperature. Problems tend to occur when engine is

cold.

Base

aidfuel ratio is used.

lgnition timing is retarded within the knock control range. Lack of power may be

OpedShort

I noted.

Knock sensor lgnition

timing is retarded within the knock control range. Lack of power may be

High

Output

(noted.

Low output

1 lgnition timing may not be retarded when knock is detected.

Vehicle speed sensor

Throttle position sensor

Opedshort

Opedshort

Unstable out-

put

Poor adjust-

ment

Open

Turbo pressure sensor

(TE) Fuel

cut time becomes-shorter, or no fuel cut is observed.

Base idle speed is used. Fuel injection is not increased during acceleration.

AIT shift point changes for AfF vehicles.

Unnecessary cut-in fuel injection could be the cause. Poor contact at the ground

or control unit could be the cause.

ldle judgment is "OFF while idling. Condition returns

normal by turning the igni-

tion switch ON and OFF repeatedly.

Turbo pressure is judged zero. No remarkable malfunction will be detected.

Refrigerant pressure is judged high. ldle speed remains high while the air condi-

tioner is ON.

Refrigerant pressure sensor

Short Refrigerant pressure

is judged low. ldle speed remains low while the air condi-

tioner is ON.

lgnition switch (IGN)

lgnition switch (START)

Air conditioner switch Open

Engine

will not start because neither fuel system nor ignition system outputs con-

trol signals.

Engine starts in normal condition. Engine may not start when temperature is

extremefy

low.

Air conditioner will not operate. No other malfunction will be noted.

Park/neutral

position switch is judged "OFF. Target engine speed for cold engine

in

N or P position is reduced.

ParWneutral position switch is judged

"0N"I Fast Jdle is effective when the engine

is cold and the gear is in other than N and P posrtlons. Vehrcle excessrvely

creeps.

Open

Open

Parklneutral

position

switch

Short

Power steering oil pressure

switch Open

Engine may

stall when the steering wheel is turned while the vehicle is standstill

and the accelerator pedal is lightly pressed, or when the steering wheel is turned

Electrical load switch Short

Open

Open/short

Multiplex communication line

- -- during deceleration. '

Power steering switch is judged 'ON." Value will be compensated constantly.

Idle speed drops so that the engine can stall when electrical load is applied.

Torque reduction control is not performed. Therefore,

shift shock becomes

greater.

- -- -- -- -- Engine will not start because neither fuel system nor ignition system outputs con-

trol signals.

Open

Control unit power supply

- -- - - --- - - - - - O~edshort I Same symptoms as when sensor harness is open.

Sensor ground -- - Poor contact

Water intru-

sion - -- - - - - - -- -- In case of poor contact, the connector fitting may be loose. In case of water

intrusion, the engine stalls and become inoperative for a while. The engine may restart soon in some cases.

Control unit

and connector

Page 39 of 230

TROUBLE DIAGNOSES

Symptom Matrix Chart (Cont'd)

An open circuit causes no fuel injection to the corresponding cylinder, and the heated oxygen sensor output becomes lean. When the open circuits are

observed at all cylinders, the engine will not start.

Actuator-related malfunction

Injector Symptom

characteristics and inspection hints

Drive

circuit

lgnition signal

(POW&

transistor

drive

siqnal)

(open

Injection Open

Short

Fuel pump relay

1 Open 1 Engine will not start. In case of instantaneous break, surging may occur.

A

short circuit causes continuous fuel injection to the corresponding cylinder, and

over-rich airlfuel ratio and misfire will be noted. When the short circuits are

observed at all cylinders, the engine will not start.

Foreign

material

Clogs

L

Foreign

material causes continuous fuel injection to the corresponding cylinder.

Symptoms vary with the condition how the injection port is clogged.

Aidfuel ratio

compensation factor becomes larger.

(1 10 to 125%)

Canister purge control valve Ignition primary

signal (Power

transistor ground)

Auxiliary electric fan relay

[RB25DE, RB25DETI

1 Short

Open

Open -

Open

Open

Leaks

Open

Open

lgnition coil

AAC valve

The valve purges constantly. In summertime, engine may stall at idle speed due

i to rich aidfuel ratio. In wintertime, various malfunctions may occur due to lean

airlfuel ratio.

An open circuit causes no fuel injection to the corresponding cylinder, and the '

heated oxygen sensor output becomes lean. When the open circuits are observed at all cylinders, the engine will not start. In case of instantaneous break, symptoms vary with the break time and the

vehicle's driving conditions. Light shock or surging will occur while the vehicle

is being driven.

The engine will stall when break time is long.

AAC valve is fully closed. Symptoms vary with the base engine speed. When it is

too low, engine may stall while the vehicle is decelerating or when the power

steering load or electrical load is applied.

Power

supply

s~de

primary

Second-

arY side

Power

supply

Drive

circuit

Open Open Auxiliary

electric fan will not operate even after warm-up is completed.

The valve

will not purge. Gasoline smell may be noted when the weather is hot.

Variable valve timing control

solenoid valve

Variable air intake control sole-

noid valve (NA)

Air jet swirl control solenoid

valve

[RB20DE

(UB)]

Injector ground (Total ground) lnstanta- Symptoms vary

with the break time and the vehicle's driving conditions. Surging neous break or engine stall may occur when the instantaneous break occurred during fuel

I I injection. I

Open

, Open

Short

Turbo pressure control solenoid

valve (TIC) Valve

timing not switched.

Variable air intake valve opens, and torque in low speed range is reduced.

Variable air intake valve closes, and torque in high speed range is reduced.

Open

Short Air jet

swirl control valve remains closed.

Air jet swirl control valve remains open.

Open

Open Swing valve opens earlier, and

maximum turbo pressure is reduced.

Engine will not start

because the injectors do not operate.

Page 42 of 230

TROUBLE DIAGNOSES

ldle speed adjusting screw

ECL1641 C

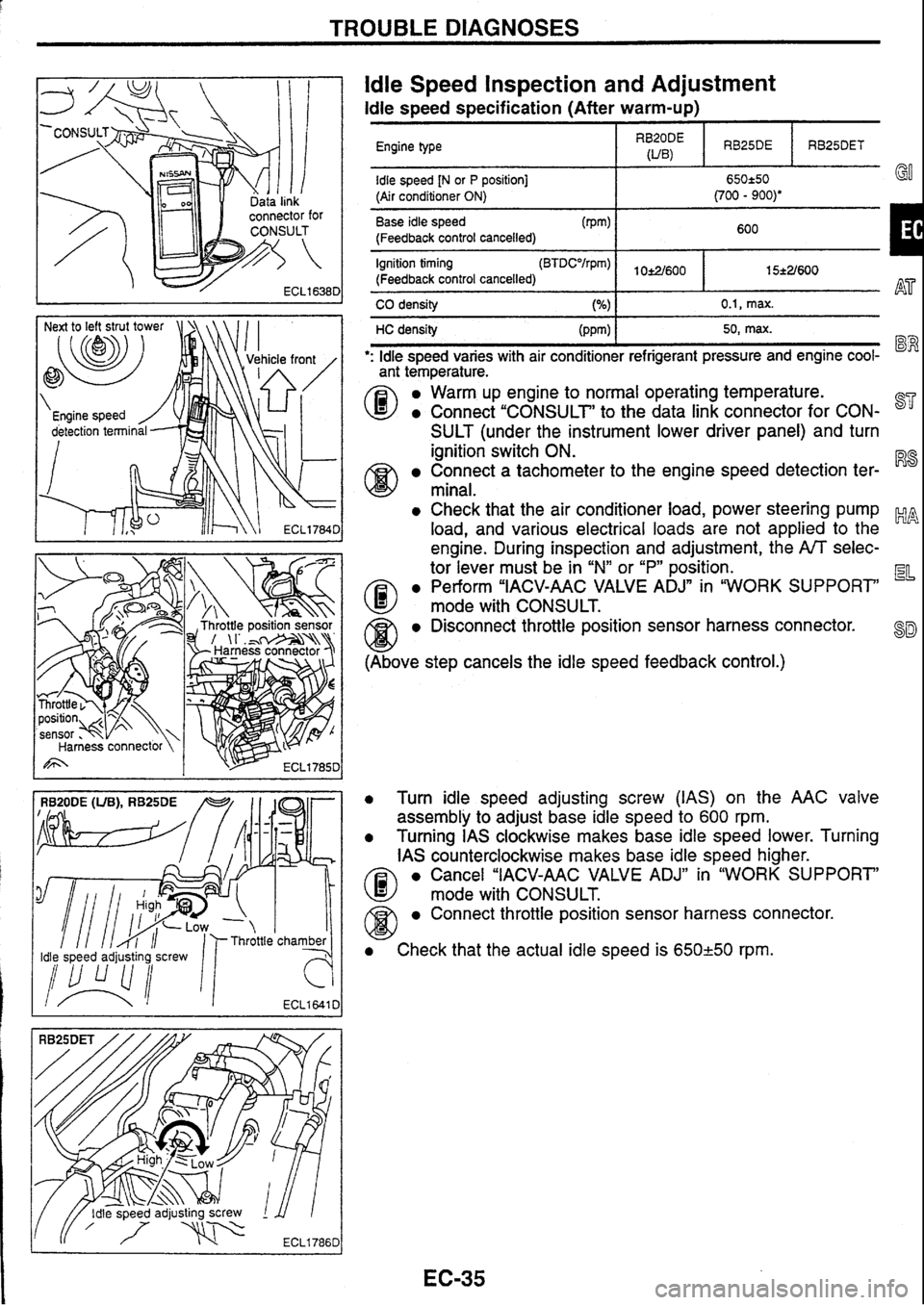

ldle Speed Inspection and Adjustment

ldle speed specification (After warm-up)

Engine type I RygE I RB25DE I RB25DET

Base idle speed (Pm)

(Feedback control cancelled) 600

I 1

idle speed [N or P position] (Air conditioner ON)

Ignition timing

(Feedback control cancelled) I 15*2/600

. . I I

650250 Go (700 - 900)'

CO density 0.1, max.

HC density 50, max.

': ldle speed varies with air conditioner refrigerant pressure and engine cool- "" "

ant temperature.

0

a Warm up engine to normal operating temperature.

a Connect "CONSULT' to the data link connector for CON- 87'

SULT (under the instrument lower driver panel) and turn

ignition switch ON.

Connect a tachometer to the engine speed detection ter- R8

minal.

a Check that the air conditioner load, power steering pump ~p, -4 load, and various electrical loads are not applied to the

engine. During inspection and adjustment, the

A/T selec-

tor lever must be in

"N"

or

"P"

position.

a Perform "IACV-AAC VALVE ADJn in "WORK SUPPORT EL

@ mode with CONSULS.

@ a Disconnect throttle position sensor harness connector. 8~

(Above step cancels the idle speed feedback control.)

0 Turn idle speed adjusting screw (IAS) on the AAC valve

assembly to adjust base idle speed to

600 rpm.

a Turning IAS clockwise makes base idle speed lower. Turning

IAS counterclockwise makes base idle speed higher.

a Cancel "IACV-AAC VALVE ADJ" in "WORK SUPPORT'

@ mode with CONSULT.

a Connect throttle position sensor harness connector.

a Check that the actual idle speed is 650-1-50 rpm.

Page 43 of 230

TROUBLE DlAGNOSES

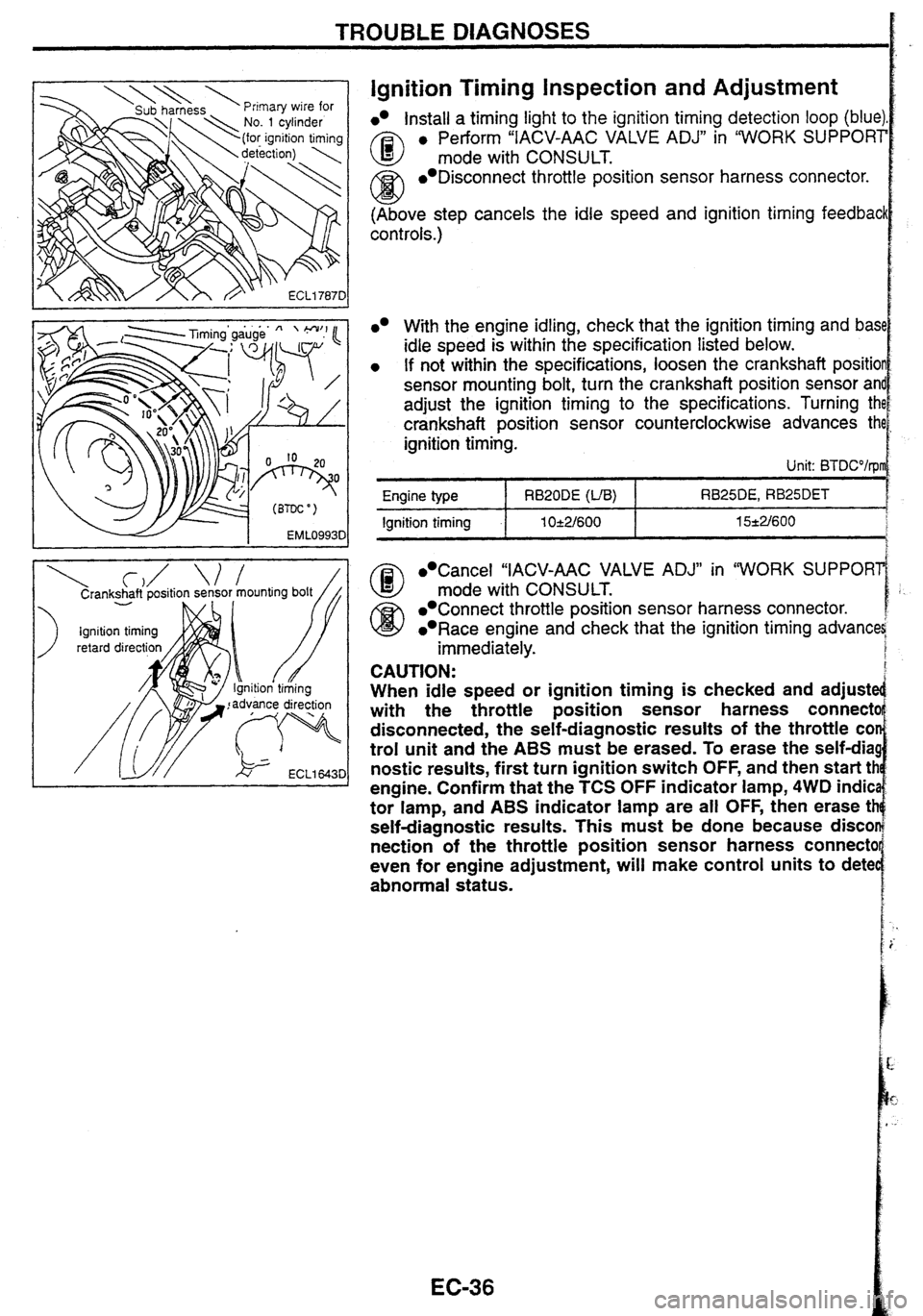

Ignition Timing inspection and Adjustment

lnstall a timing light to the ignition timing detection loop (blue)

A3 e Perform "IACV-AAC VALVE ADJ" in "WORK SUPPORT

mode with CONSULT.

/Ci3 Disconnect throttle position sensor harness connector.

w (Above step cancels the idle speed and ignition timing feedbacl

cont rots.)

Cancel "IACV-AAC VALVE ADJ" in "WORK SUPPORl

@ mode with CONSULT.

Connect throttle position sensor harness connector.

Race engine and check that the ignition timing advana

immediately.

With the engine idling, check that the ignition timing and bas1

idle speed is within the specification listed below.

If not within the specifications, loosen the crankshaft positio

sensor mounting bolt, turn the crankshaft position sensor

an

adjust the ignition timing to the specifications. Turning th

crankshaft position sensor counterclockwise advances th

ignition timing.

Unit: BTDCO/rpl

CAUTION:

When idle speed or ignition timing is checked and adjuste

with the throttle position sensor harness

connectc

disconnected, the self-diagnostic results of the throttle

COI

trol unit and the ABS must be erased. To erase the self-dia!

nostic

results, first turn ignition switch OFF, and then start tt

engine. Confirm that the

TCS OFF indicator lamp, 4WD indic

tor lamp, and

ABS indicator lamp are all OFF, then erase tt

self-diagnostic results. This must be done because disco

nection

of the throttle position sensor harness connectc

even for engine adjustment,

will make control units to dete

abnormal status.

RB25DE, RB25DET

15*2/600 Engine type

Ignition timing

RB20DE (VB)

1 O-e2/600

Page 47 of 230

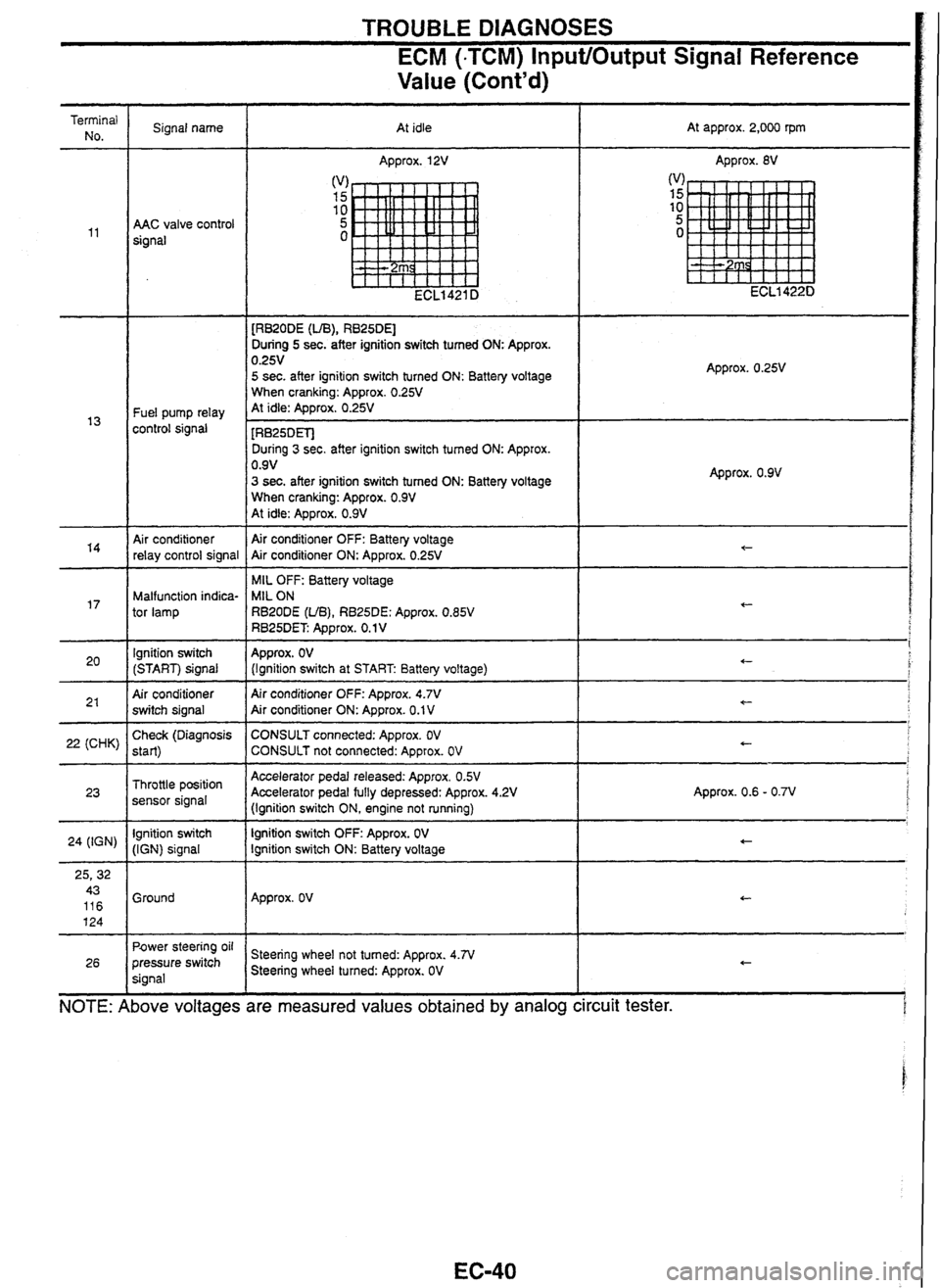

TROUBLE DIAGNOSES

ECM (-TCM) InputlOutput Signal Reference

Value (Cont'd)

d

voltages are

Terminal No. Signal name

At idle At

approx. 2,000 rpm

Approx.

12V Approx. 8V

AAC valve control

signal

[RB20DE

(UB), RB25DEl

During 5 sec. after ignition switch tumed ON: Approx. 0.25V 5 sec. after ignition switch turned ON: Battery voltage

When cranking: Approx. 0.25V At idle: Approx. 0.25V Fuel pump relay

control signal - - [RB25DETJ

During 3 sec. after ignition switch tumed ON: Approx.

0.9V

3 sec. after ignition switch tumed ON: Battery voltage

When cranking: Approx. 0.9V At idle: Approx. 0.9V

Approx. 0.9V

Air conditioner

relay control signal Air conditioner

OFF: Battery voltage

Air conditioner ON: Approx. 0.25V

MIL OFF: Battery voltage

MIL ON

RBZODE

(UB), RB25DE: Approx. 0.85V RB25DET Approx. 0.1 V

Malfunction indica-

tor lamp

lgnition switch

(START) signal

Air conditioner

switch signal Approx.

OV (Ignition

switch at START Battery voltage)

Air conditioner OFF: Approx.

4.7V Air conditioner ON: Approx. 0.1 V -

22 (CHK) Check

(Diagnosis

start)

Throttle position

sensor signal

lgnition switch

(IGN) signal CONSULT

connected: Approx. OV CONSULT not connected: Approx. OV

Accelerator pedal released: Approx. OSV Accelerator pedal fully depressed: Approx. 4.2V

(Ignition switch ON, engine not running)

lgnition switch

OFF: Approx. OV lgnition switch ON: Battery voltage Approx.

0.6 - 0.7V

24

(IGN)

Ground Approx.

OV

Power

steering oil

pressure switch

signal Steering

wheel not tumed: Approx. 4.N Steering wheel turned: Approx. OV

26

NOTE: I bove measured values obtained by analog ircuit

tester.

Page 49 of 230

TROUBLE DIAGNOSES

ECM (-TCM) Input/Output Signal Reference

Terminal No. Signal name

At approx. 2,000 rprn At idle

When cranking: Approx.

1.3V

Approx.

1.4V

ECLl426D

Crankshaft position

sensor 120" (REF) sig-

nal At idle: Approx. 1.35 - 1.4V

When cranking: Approx.

2.6V

Approx.

2.6V

Crankshaft position sensor 1" (POS) signal jle: Approx. 2.6V

ECLl428C

When cranking (DC range): Approx. (AC range): Approx.

DC range: Approx.

0.1V

AC range: Approx. 3.2V

Ring gear crankshaft

position sensor signal

[RB20DE

(UB)]

At idle DC range - Approx. 0.1 V [Ac range]. /\ppmx. 1 .W (v: 15 10 5 0

t (When engine raced sirddenly: Approx. 2.7 - 3.1V)

Turbo

Dressure

sensor

signal ' [RB25DET]

Throttle position sensor,

refrigerant pressure

sensor, turbo pressure

sensor power supply

Rear defogger switch

signal

-

49

NOTE: ,

2ear defogger switch OFF: Approx. OV

Rear defogger switch ON: Battery voltage

C-

bove voltages are measured values obtained by analog circuit tester.

EC-42

Page 50 of 230

TROUBLE DIAGNOS

ECM (.TCM) lnpu

:s

3utput Signal Reference

Value (Cont'd)

.. No.

Fluctuates between approx. 0.1 to

0.4V and approx.

0.7 to

0.9V At

idle

- I I - I I -

I

I

- are measured

At approx. 2,000 rpm

:v: i .5 I .O 0.5 0

ECL 1 8645 11jllllllll ECL 1 8630

Throttle motor sensor

signal

[RB25DET'J Approx. 3.4V

I (Voltage becomes lower when TCS operates.)

Motor throttle switch

signal

[RB25DET]

Approx.

4.7V

Mass air flow sensor

signal

t

(When TCS is operating: Approx. OV)

Ignition switch ON: Approx.

0.2V

At idle: Approx.

1

.I - 1.2V Approx.

1.6 - 1.7V

Mass air flow sensor

ground Approx.

OV

I

Coolant temperature approx. 20°C: Approx. 3.5V

Coolant temperature approx.

80°C: Approx. 1.2V

Approx. 0.36V min.

(Voltage increases as the air conditioner refrigerant

pressure increases.)

Approx. 0.4

- 2V (') ': Voltage varies with measuring range (internal resis-

tame) of a circuit tester.

Battery voltage

C

+

+

+

56

-

62 1 Knock sensor signal 1

Engine coolant tem-

perature sensor signal

57

- -- -

63 1 Knock sensor signal 2

Refrigerant pressure

sensor

67 Control unit power

sup-

72

I PIY Receive (Data input to

control unit) 1

Transmit (Data output

from control unit) CONSULT

connected: Approx. 0.25V

CONSULT

not connected: Battery voltage

CONSULT connected: Approx.

9V max. CONSULT not connected: Approx. OV

C

Fan stopped: Battery voltage

Fan operating: Approx. 0.2 - 0.3V 78

NOTE: Above

Auxiliary electric fan

relay control signal

[RB25DE, RB25Dm

voltages values obtained

analog circuit

tester.