wheel NISSAN GT-R 1998 Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: GT-R, Model: NISSAN GT-R 1998Pages: 230, PDF Size: 12.66 MB

Page 133 of 230

ELECTRIC SUPER HICAS

Trouble Diagnosis

with CONSULT (Cont'd)

connector for

'@g SELECT DlAG MODE

SELF-DIAG RESULTS i

DATA MONITOR

ACTIVE TEST

ECM PART NUMBER

u

1 I lhil SELECT MONITOR ITEM I 1

SELECTION FROM MENU

I Il

I

START I

ACTIVE TEST PROCEDURE

After connecting CONSULT to data link connector, start the

engine.

Touch "START", "HICAS and "ACTIVE TEST".

Touch 'SIMULATE" and "SELECT MONITOR ITEM".

Turn the steering wheel right or left to make the rear actuator

operate.

Reference values in normal condition

-- -

0" (Neutral) I 2.4V I 2.4V I No (Approx OV)

Steering angle

sensor

ECM PART NUMBER

Rear steering

angle main sensor

--

R 90"

L 90"

After connecting CONSULT to data link connector, turn ignition

switch ON.

Touch "START', "HICAS" and "ECM PART NUMBER7'.

Part number printed on the control unit label and part number

shown on the CONSULT screen are as follows:

2-door model: 28505

AAI

00

4-door model: 28505 AAll 0

Trouble Diagnosis with Self-diagnosis

Rear steering

angle sub-sensor

4.4V

0.4V

DESCRIPTION

If the system detects some error while vehicle is running, it notifies

the driver of a malfunction

by turning ON the HICAS warning lamp,

and at the same time, it halts the normal control and enters the

fail-safe mode.

Motor current

SELF-DIAGNOSIS PROCEDURE

4.4V

0.4V

1. Start the engine.

2. Within 10 seconds after the engine has started, turn the steer-

ing wheel more than

20" right-to-left and repeat this

5 times or

more, and then depress the brake pedal

5 times or more.

Yes (Variable)

Page 134 of 230

ELECTRIC SUPER HICAS

Trouble

Diagnosis with Self-diagnosis (Cont'd)

DIAGNOSTIC ITEM INPUT

1. Move the vehicle one or two meters at a very low speed.

2. Turn the steering wheel more than 20" right-to-left once or

more.

Example: Motor power supply and steering

angle neutral signal are abnormal.

1s ,

2H z

ON

OFF

/ r Second / / I I display

Tens Units Tens

Units starts.

Example: Motor power supply and steering

angle neutral signal are abnormal.

1s- ,

0.8s A - ,2S , ,1.8S -

ON I-- '1 7, OFF- -.-- -

5s 55 1s 1.8s v".2S I_

/ -j- &lnd,

display

Tens Units Tens Units starts.

/

(12) (23) STE0109D

DISPLAY OF SELF-DIAGNOSTIC RESULTS

The results of self-diagnosis are shown by flash patterns of HlCAS BR

warning lamp.

Display when past data shows that fail-safe function

has been activated previously

Only an abnormal item is indicated by the pattern shown in the ~8 left figure. The pattern is repeated.

Display when past data shows that fail-safe function

has not been activated previously EL

If all items are normal, HlCAS warning lamp flashes at a fre-

quency of

4 Hz. sD

If system is in fail-safe mode, only an abnormal item is indi-

cated by the pattern shown in the left figure. The pattern

is

repeated.

MALFUNCTION CODE CHART

Malfunction code No. 1 Diagnostic item

11 I Control unit

2

1 [ ~ze speed signal

12

13

22 I Steering angle signal

Motor

power supply

Motor output --

23 ]Steering angle neutral signal

24 I Rear steering angle main sensor signal

2

5 I Rear steering angle sub-sensor signal

33

I Engine speed signal

HOW TO ERASE SELF-DIAGNOSTIC RESULTS

If past record shows that fail-safe function has been activated

previously, use CONSULT, or leave the battery disconnected for

more than

30 minutes to clear the memory.

Page 201 of 230

![NISSAN GT-R 1998 Owners Guide

SERVICE DATA

SECTION SD

CONTENTS

L ] RB20DE (UB) [I 17 FS5R30A 1-

ENGINE MECHANICAL ............................................... 2 MANUAL TRANSMISSION ........................................ NISSAN GT-R 1998 Owners Guide

SERVICE DATA

SECTION SD

CONTENTS

L ] RB20DE (UB) [I 17 FS5R30A 1-

ENGINE MECHANICAL ............................................... 2 MANUAL TRANSMISSION ........................................](/img/5/57354/w960_57354-200.png)

SERVICE DATA

SECTION SD

CONTENTS

L ] RB20DE (UB) [I 17 FS5R30A 1-

ENGINE MECHANICAL ............................................... 2 MANUAL TRANSMISSION ........................................... 10

-1 RB25DE /I

ENGINE MECHANICAL .................................................. 4

17 RB25DET I]

ENGINE MECHANICAL .................................................. 6

CLUTCH.. . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . .. . . . . . . . . . . . . .. . . . .+.. . . . . . . . . . -8

71 FS5W71C

MANUAL TRANSMISSION

.................... ......................... 9

AUTOMATIC TRANSMISSION ........................... .......... 12

TRANSFER .............. ......... ..... .. ... ........ . . ............. 18

PROPELLER SHAFT ................................................. 19

FRONT FINAL DRIVE ................................................. 20

REAR FINAL DRIVE ..................................................... 22

DRIVE SHAFT ............................................................... 24

AXLE & SUSPENSION ................................................. 25

ROAD WHEEL AND TIRE ............................................. 27

BRAKE. ... ...... . .. ... . .... . . . . . .... . .. .. . . .. . . .. . . . .. . . .. ... .. .. . . . . . . . . .. .... . -28

STEERING ........... ............. ..... ... ............... ...... ................ 29

SUPER HICAS ............................................................ 30

Page 203 of 230

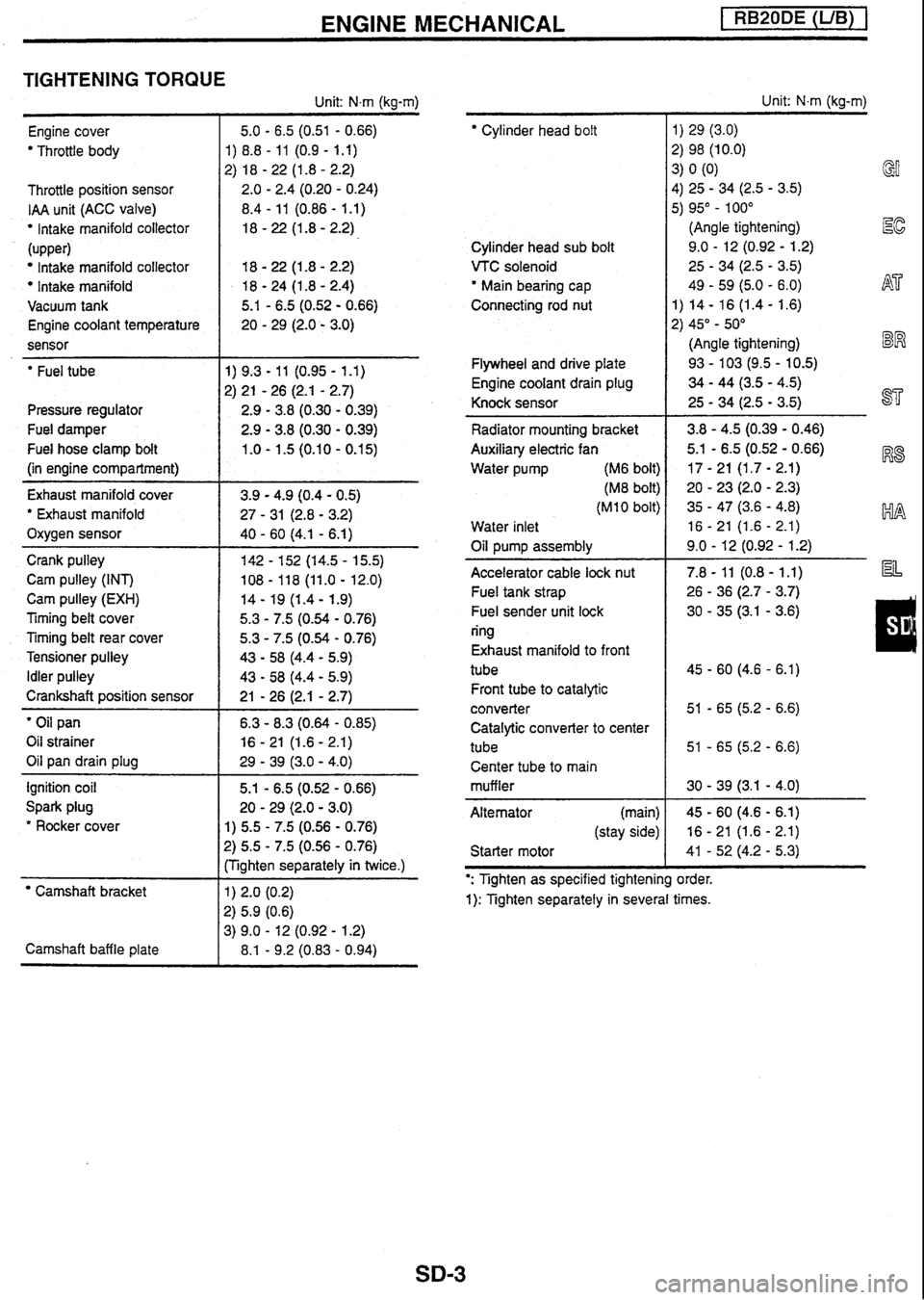

ENGINE MECHANICAL [ RB20DE (UB) 1

TIGHTENING TORQUE

Unit: N.m (kg-m)

Engine cover

Throttle body

Throttle position sensor

IAA unit (ACC valve)

lntake manifold collector

(upper)

Intake manifold collector

Intake manifold

Vacuum tank

Engine coolant temperature

sensor

- --

' Fuel tube

Pressure regulator

Fuel damper

Fuel hose clamp bolt

(in engine compartment)

Exhaust manifold cover

' Exhaust manifold

Oxygen sensor

Crank pulley

Cam pulley (INT)

Cam pulley

(EXH)

Timing belt cover

Timing belt rear cover

Tensioner pulley

Idler pulley

Crankshaft position sensor

' Oil pan

Oil strainer

Oil pan drain plug

ignition coil

Spark plug

* Rocker cover

Camshaft bracket

Camshaft baffle plate 5.1

- 6.5 (0.52 - 0.66)

20

- 29 (2.0 - 3.0)

1) 5.5 - 7.5 (0.56 - 0.76)

?) 5.5 - 7.5 (0.56 - 0.76)

:Tighten separately in twice.)

Cylinder head bolt

Cylinder head sub bolt

VTC solenoid

' Main bearing cap

Connecting rod nut

Flywheel and drive plate

Engine coolant drain plug

Knock sensor

Radiator mounting bracket

Auxiliary electric fan

Water pump (M6 bolt)

(M8 bolt)

(MI 0 bolt)

Water inlet

Oil pump assembly

Accelerator cable

lock nut

Fuel tank strap

Fuel sender unit lock

ring

Exhaust manifold to front

tube Front tube to catalytic

converter Catalytic converter to cent

tube Center tube to main

muffler

Alternator (main)

(stay side)

Starter motor Unit:

N-m (kg-m)

1)

29 (3.0)

2) 98 (10.0)

3)

0

(0)

4) 25

- 34 (2.5 - 3.5) GI

5) 95" - 100"

(Angle tightening)

Ec

9.0 - 12 (0.92 - 1.2)

25

- 34 (2.5 - 3.5)

49

- 59 (5.0 - 6.0) h$7'

1) 14 - 16 (1.4 - 1.6)

2) 45"

- 50"

(Angle tightening)

BW

93 - 103 (9.5 - 10.5)

34 - 44 (3.5 - 4.5)

25

- 34 (2.5 - 3.5) ST

': Tighten as specified tightening order.

1): Tighten separately in several times.

Page 205 of 230

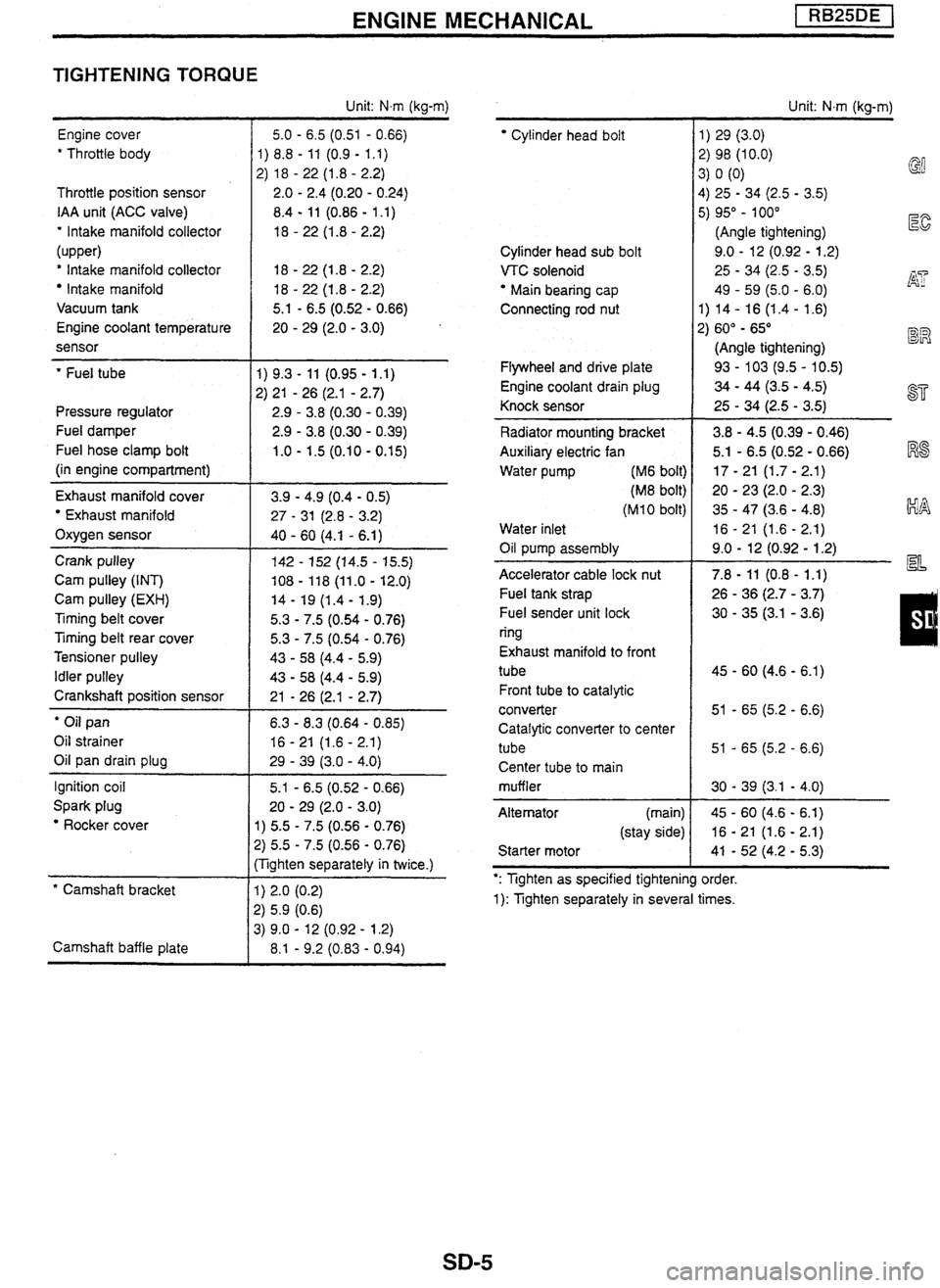

ENGINE MECHANICAL

TIGHTENING TORQUE

Engine cover

' Throttle body

Throttle position sensor

IAA unit (ACC valve)

' Intake manifold collector

(upper)

' Intake manifold collector

Intake manifold

Vacuum tank

Engine coolant temperature

sensor

' Fuel tube

Pressure regulator

Fuel damper

Fuel hose clamp bolt

(in engine compartment)

Exhaust manifold cover

Exhaust manifold

Oxygen sensor

Crank pulley

Cam pulley (INT)

Cam pulley

(EXH)

Timing belt cover

Ttming belt rear cover

Tensioner pulley

Idler pulley

Crankshaft position sensor

' Oil pan

Oil strainer

Oil pan drain plug

Ignition coil

Spark plug

Rocker cover

* Camshaft bracket

Camshaft baffle plate Unit:

Nm (kg-m)

5.0

- 6.5 (0.51 - 0.66)

1) 8.8

- 11 (0.9 - 1.1)

2) 18

- 22 (1.8 - 2.2)

2.0

- 2.4 (0.20 - 0.24)

8.4

- 11 (0.86 - 1 .I)

18

- 22 (1.8 - 2.2)

5.1

- 6.5 (0.52 - 0.66)

20

- 29 (2.0 - 3.0)

1) 5.5 - 7.5 (0.56 - 0.76)

2) 5.5 - 7.5 (0.56 - 0.76)

:Tighten separately in twice.)

Cylinder head bolt

Cylinder head sub bolt

VTC solenoid

Main bearing cap

Connecting rod nut

Flywheel and drive plate

Engine coolant drain plug

Knock sensor

Radiator mounting bracket

Auxiliary electric fan

Water pump

(M6 bolt)

(M8 bolt)

(M 1 0 bolt)

Water inlet

Oil pump assembly

-

Accelerator cable lock nut

Fuel tank strap

Fuel sender unit lock

ring

Exhaust manifold to front

tube

Front tube to catalytic

converter

Catalytic converter to center

tube Center tube to main

muffler

Alternator (main)

(stay side)

Starter motor Unit:

N.m (kg-m)

1) 29 (3.0)

2) 98 (10.0) 3) 0 (0)

@

4)

25 - 34 (2.5 - 3.5)

5) 95" - 100"

(Angle tightening)

E

9.0 - 12 (0.92 - 1.2)

25

- 34 (2.5 - 3.5) j$? 49 - 59 (5.0 - 6.0)

1) 14- 16

(1.4- 1.6)

2) 60"

- 65" BR

(Angle tightening)

93

- 103 (9.5 - 10.5)

34 - 44 (3.5 - 4.5)

25

- 34 (2.5 - 3.5) a=

': Tighten as specified tightening order.

1): Tighten separately in several times.

Page 207 of 230

ENGINE MECHANICAL pEZBq

TIGHTENING TORQUE

Engine cover

' Throttle body

Throttle position sensor

IAA unit

(ACC valve)

' Intake manifold collector

* Intake manifold

Engine coolant temperature

sensor

' Fuel tube

Pressure regulator

Fuel damper

Fuel hose clamp bolt

(in engine compartment)

Turbocharger Oil tube

Water tube (block side)

(turbocharger side)

Oxygen sensor

Exhaust manifold cover

' Exhaust manifold

Crank pulley

Cam pulley (INT)

Cam pulley

(EXH)

Timing belt cover

Timing belt rear cover

Tensioner pulley

Idler pulley

Crankshaft position sensor

' Oil pan

Oil strainer

Oil pan drain plug

Ignition coil

Spark plug

' Rocker cover

' Camshaft bracket

Camshaft baffle plate Unit:

N.m (kg-m)

5.0

- 6.5 (0.51 - 0.66)

1)

8.8

- 11 (0.9 - 1.1)

2)

18

- 22 (1 -8 - 2.2)

2.0

- 2.4 (0.20 - 0.24)

8.4

- 11 (0.86 - 1.1)

18

- 22 (1.8 - 2.2)

18

- 22 (1 -8 - 2.2)

20

- 29 (2.0 - 3.0)

5.1

- 6.5 (0.52 - 0.66)

20

- 29 (2.0 - 3.0)

1) 5.5

- 7.5 (0.56 - 0.76)

2) 5.5 - 7.5 (0.56 - 0.76)

(Tighten separately in twice.)

' Cylinder head boit

Cylinder head sub bolt

VTC solenoid

" Main bearing cap

Connecting rod

nut

Oil jet

Flywheel and drive plate

Engine coolant drain plug

Knock sensor

Radiator mounting bracket

Auxiliary electric fan

Water pump (M6 bolt)

(M8 bolt)

(MI

0 bolt)

Water inlet

Oil pump assembly

Accelerator cable lock nut

Fuel tank strap

Fuel sender unit lock

ring

Exhaust manifold to front

tube

Front tube to catalytic

converter

Catalytic converter to center

tube

Center tube to main

muffler

Alternator (main)

(stay side)

Starter motor Unit:

N.m (kg-m)

1) 29 (3.0)

2) 98 (10.0)

3) 0 (0)

4) 25 - 34 (2.5 - 3.5)

5) 95"

- 100"

(Angle tightening)

I%

9.0 - 12 (0.92 - 1.2)

25

- 34 (2.5 - 3.5)

49

- 59 (5.0 - 6.0) AT

1) 14 - 16 (1.4 - 1.6)

2) 60" - 65"

(Angle tightening) BR

30 - 40 (3.1 - 4.1)

93

- 103 (9.5 - 10.5)

34 - 44 (3.5 - 4.5) ST

25 - 34 (2.5 - 3.5)

3.8

- 4.5 (0.39 - 0.46) I%$

5.1 - 6.5 (0.52 - 0.66)

17

- 21 (1.7 - 2.1)

20

- 23 (2.0 - 2.3) kIA

35 - 47 (3.6 - 4.8)

16

- 21 (1.6 - 2.1)

9.0

- 12 (0.92 - 1.2) a=

': Tighten as specified tightening order.

1): Tighten separately in several times.

Page 224 of 230

DRIVE SHAFT

FRONT REAR

Z80T70C

Spider 1 00 1 39720 51E00 I

Joint type

Amount of grease

Boot length at installed mm

I I

I

'lamped number

assembly (final drive side) 0 1

39720

51 EO1 T7fP

Parts number

Final drive side

Wheel side

Final drive side

Wheel side

Final drive side

Wheel side T70C

Z80

11 0

- 120

75

- 85

95.5

- 97.5

90.5

- 92.5

T82CT82F

assembly 39720 lOVl0

(final drive and

wheel sides) 39720

1OV11 T82C

T82F

39720 10V12 Joint type

Amount of grease

Boot length at installed mm

Spider

Joint type Final drive side

Wheel side Final

drive side

Wheel side

Final drive side 'wheel side

Final drive side

. Wheel side

Stamped number

Amount of grease T82F

T82C

102

- 107

115

- 125

95

- 97

Wheel side 75 - 85 Parts number

Boot length at installed

Wheel side 90.5

- 92.5 TYP~

I Stamped 1 Parts

number I Type

number Joint

type

Wheel side

Amount of grease g

Spider

assembly

(final drive side) Boot length

at

installed

mm

00

01

I Drive shaft nut

Front

TIGHTENING

TORQUE

Unit: N-m (ka-m)

Final drive side

Wheel side

39720lOVlO

39720 1

OV11

Drive shaft nut 92.9 - 94.9

96.0

- 98.0

T82

F Drive

shaft

to side flange (left side)

;

Rear 28

- 37

(2.8 - 3.8)

T82CT82F

35

- 44

Drive shaft to side

flange

Z100D90F

(6.5 - 8.0)

Page 225 of 230

AXLE & SUSPENSION

WHEEL ALIGNMENT -

1 Camber I -0°45'-t45'

[caster

1 6"35'+45'

I Amount of side slip (Reference)(Only for HICAS)

mm I In 5 to Out 5

WHEEL BEARING

- -

12"50'-t45' GI

0 to In 2

In

5 to Out 5

-0°55'&30' EG

0 to Out 5.2

Front

Rear

- -

Location T Front axle

r- King pin inclination

Toe-in mm

Amount of side slip (Reference)

mm

Camber

Toe-in rnm

Applied model

I 2WD

Rotating torque

N.m

(kg-m)

Spring scale set position Less than

2.45 (0.25)

(NSK make)

Less than 3.33 (0.34)

(NTN make)

Spring scale measurement

N (kg) Without

SUPER HICAS

Less than

15.9 (1.63)

(NSK make)

Less than 21.6 (2.21)

(NTN make) Rear

axle

0.30

- 1 .I7 (0.03 - 0.12)

(NSK make)

0.520

- 1.882 (0.053 - 0.192)

(NTN make)

5.0

- 21 (0.5 - 2.2)

(NSK make)

2.95

- 10.5 (0.30 - 1 .O8)

(NTN make)

End play

mm l 0 With

SUPER HICAS

BALL JOINT

Oscillating torque N-m (kg-m)

Spring scale measurement (at cotter pin hole)

N (kg)

Sliding torque

N.m

(kg-m)

End play mm 0.50

- 3.40

(0.05 - 0.35)

7.95

- 55.3 (0.81 - 5.64)

0.50

- 3.40 (0.05 - 0.35)

0

Page 227 of 230

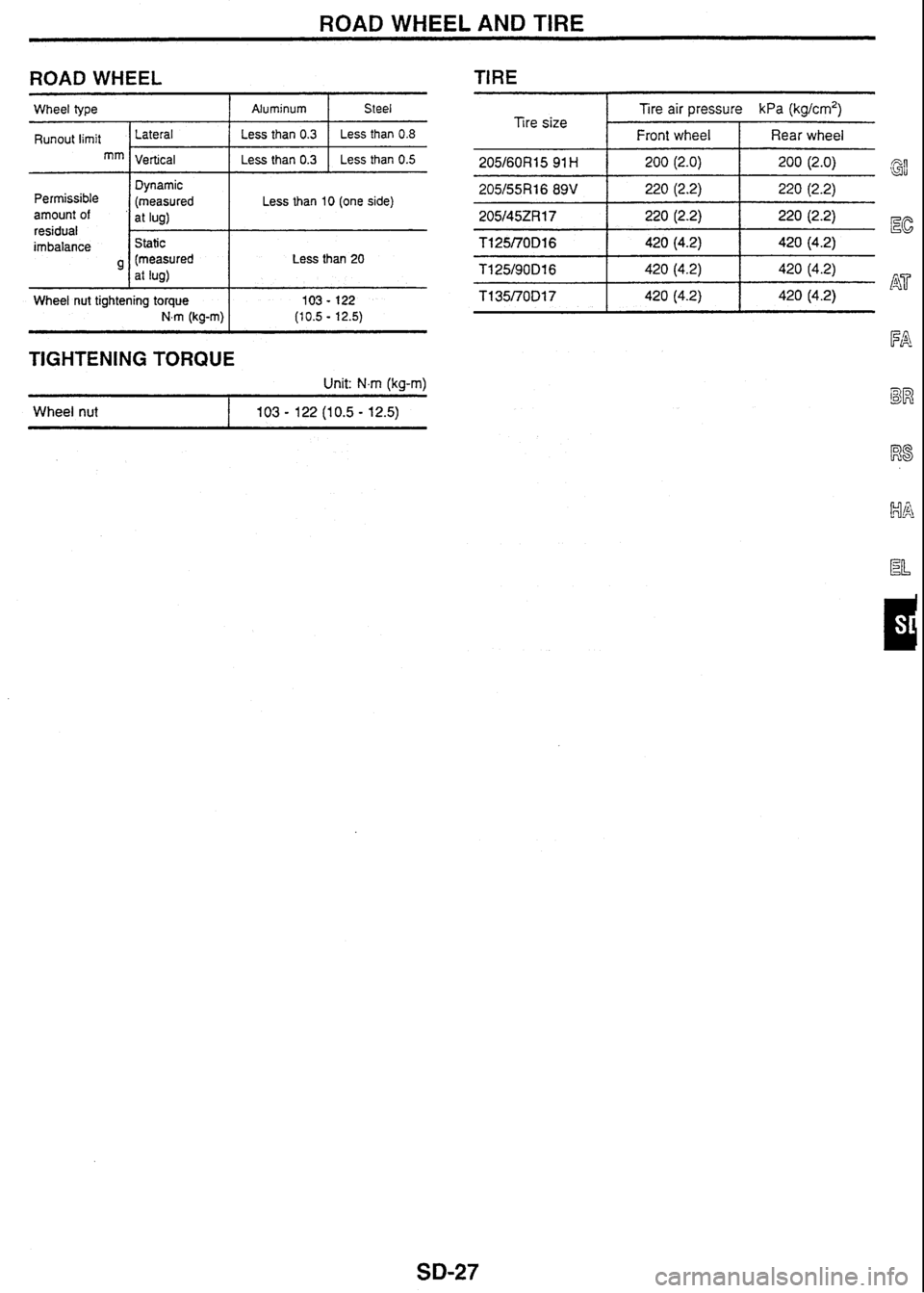

ROAD WHEEL AND TIRE

Dynamic Less than

10 (one side)

ROAD WHEEL

I G.JIUUOL imbalance

Less than 20

-- Wheel nut tightening torque

I

103 - 122

N.m

(kg-m)

(10.5 - 12.5) Steel

Less than 0.8

Less than

0.5

TIGHTENING TORQUE

Unit: N.m (kg-m)

Aluminum

Less than 0.3

Less than

0.3

Wheel type

Wheel nut 1 103 - 122 (10.5 - 12.5)

Runout limit mm

TIRE

Vertcal

Tire size Tire

air pressure kPa (kg/cm2) Front wheel 1 Rear

wheel

Page 228 of 230

BRAKE

BRAKING FORCE

More than 10% of axle

weight

REAR DlSC BRAKE

Total braking force of rear wheels

Variation between right and left of

each wheel Brake

type

Less than 8% of axle weight ADllVC

9.3

Brake

pad

Disc rotor

Total

braking force OPZ11V

11.5

Standard

thickness (New) mm

Wear limit of thickness mm

Standard thickness (New) mm

Wear limit of thickness mm

Runout limit mm

More than 50%

of vehicle

weight at inspected

Note: The braking force when both front wheels are locked up can be considered to meet the total braking force.

2.0

16

14

BRAKE PEDAL

18

16

PARKING BRAKE

Free play (at pedal top surface)

mm I 3 - 11 Less than

0.07 Type DS17HD I

Brake

lining

Depressed pedal height under force

of 490 N (50 kg)

(from dash panel top surface)

mm

Brake

pedal height

(from dash panel top surface)

mm

Standard inner diameter

I (New) mm I

Standard thickness (New) mrn

Wear limit of thickness

mm M/T: 163 - 173 IVT: 170 - 180

172 dia. 3.0 1.5

M/T: More

than 85 A. More than 90 . . Drum I

I

Wear limit of inner diameter

mm I 173 dia.

Clearance between the edge of stop

lamp switch screw and pedal stopper

mm Operating

stroke

[under force of 196 N (20

kg)] 5 - 7 notches

CHECK VALVE I

I

Maximum stroke

19 notches

Number of notches when brake warning

lamp turns on

TIGHTENING TORQUE

Unit: N.m (kg-m)

Within 1 notch

Vacuum leakage

[at

vacuum Of 66'7 kPa (-500 mmHg)]

BRAKE BOOSTER

Within 1.3 kPa (10 mmHg) of

vacuum for 15 seconds

Master cylinder fixing nut

I 12 - 14 (1.2 - 1.5)

Vacuum leakage

[at vacuum of 66.7

kPa

(-500

mmHg)l

Within 3.3

kPa

(25

mmHg)

of

vacuum for 15 seconds Front

caliper mounting bolt

Brake tube flare nut -- - 152 - 154 (15.5 - 15.8)

15

- 17 (1.5 - 1.8)

FRONT DlSC BRAKE

Input rod standard length at installed

mm

Brake type

I AD25VB I CUSVD [OPZ~~VC

140

Standard thickness

Wear limit of

thickness

Standard thickness

mm

1 22 1 26 1 30

Disc rotor Wear limit of

thickness

Runout

limit Less than 0.07