change time NISSAN GT-R 1998 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: GT-R, Model: NISSAN GT-R 1998Pages: 230, PDF Size: 12.66 MB

Page 2 of 230

NISSAN

MODEL R34 SERIES

FOREWORD

This Sewice Manual contains infor-

mation concerning necessary ser-

vice procedures and relevant data

for the model

R34 series.

All information, illustrations and

specifications contained in this Ser-

vice Manual are based on the latest

product information available at the

time of publication. If your NISSAN

model differs from the specifications

contained in this

Sewice Manual,

consult your NISSAN distributor for

information.

The right is resewed to make

changes in specifications and meth-

ods at any time without notice.

QUICK REFERENCE INDEX I

0 1998 KISSAN MOTOR CO., LTD. Printed in Japan

A11 rights reserved. No part of this Service Manual may be reproduced or stored in a retrieval system, or transmitted in any form, or by any means, electronic, mechanical, photocopying, recording or otherwise, without the prior written permission of Nissan Motor Company Ltd.. Tokyo, Japan.

Page 31 of 230

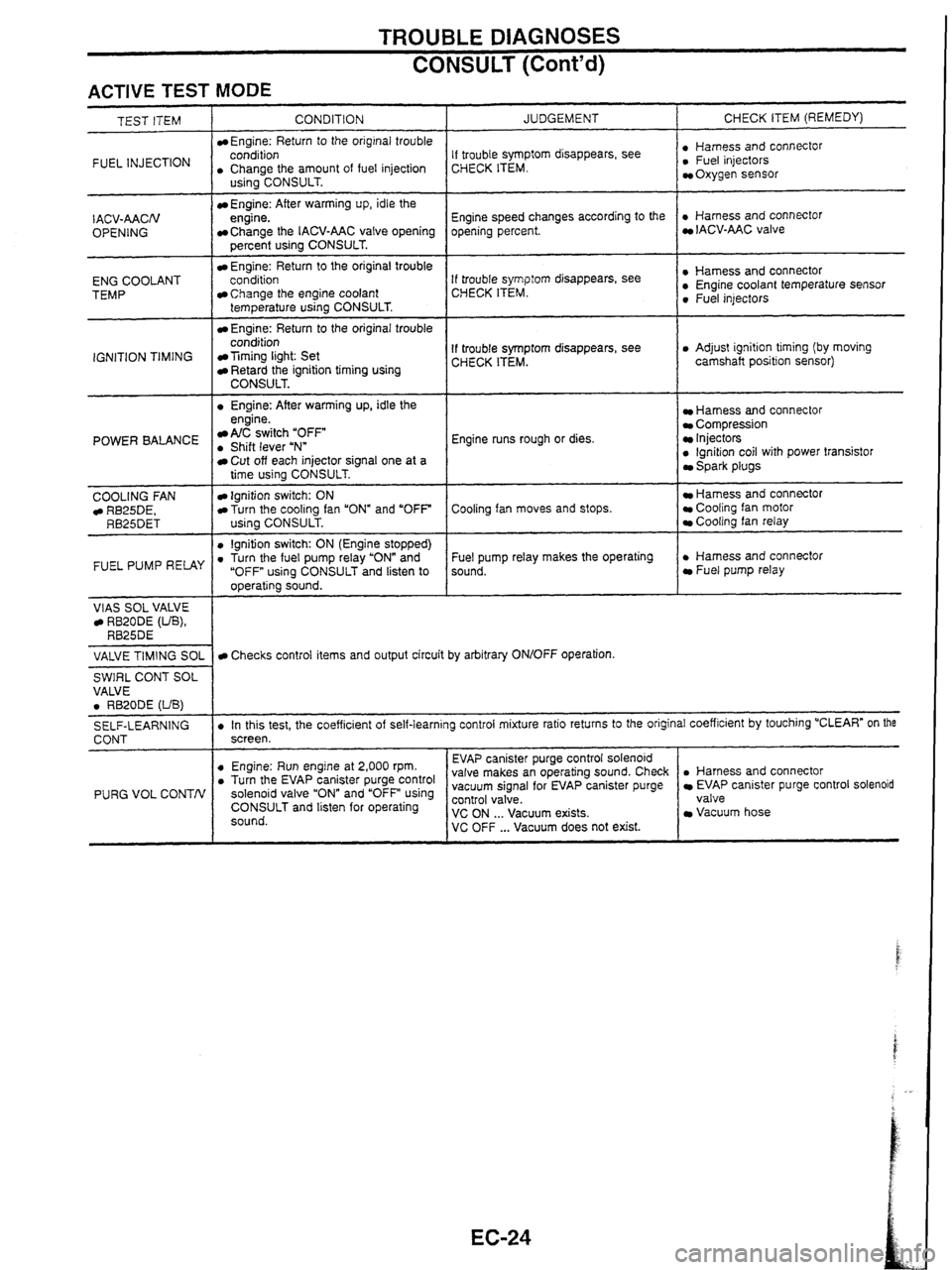

TROUBLE DIAGNOSES

CONSULT (Cont'd)

ACTIVE TEST MODE

INJECTION I . CCohArthe amount of fuel injection

TEST ITEM

CONDITION

Engine: Return

to the original trouble

- I . Engine: After warming up, idle the

IACV-AACN

OPENING

ENG COOLANT

TEMP

IGNITION TIMING

US~~~CONSULT.

Engine: After warming up, idle the

engine.

Change the IACV-AAC valve opening

percent using CONSULT.

Engine: Return to the original trouble

conditioo

Change the engine coolant

temperature using CONSULT.

Engine: Return to the original trouble

condition

Timing light: Set Retard the ignition timing using CONSULT.

POWER BALANCE engine. A/C switch "OFF . Shift lever uNn

COOLING

FAN RB25DE, RB25DET

FUEL PUMP RELAY

VlAS SOL VALVE RB20DE (UB), RB25DE

JUDGEMENT

Cut off each injector signal one at a

time using CONSULT.

Ignition switch: ON Turn the cooling fan "ON" and "OFF

using CONSULT.

0 lgnition switch: ON (Engine stopped) . Turn the fuel pump relay "ON" and

"OFF using CONSULT and listen to

operating sound. CHECK

ITEM (REMEDY)

If trouble symptom disappears, see

CHECK ITEM. : ~,"~~,,,~scOnnectOr Oxygen sensor

Engine speed changes according to the

opening percent.

. Harness and connector IACV-AAC valve

If trouble

symp:orn disappears, see

CHECK ITEM. : Sensor 0 Fuel injectors

If trouble symptom disappears, see

CHECK ITEM. 0 Adjust ignition timing (by moving

camshaft position sensor)

Engine runs rough or dies.

Harness and connector Compression Injectors 0 lgnition coil with power transistor Spark plugs

Cooling fan moves and stops.

Hamess and connector Cooling fan motor Cooling fan relay

Fuel pump relay makes the operating

sound.

. Harness and connector Fuel pump relay

VALVE

TIMING

SOL

SWIRL CONT SOL

VALVE

0 RB20DE (UB)

SELF-LEARNING

CONT

PURG VOL CONTN

Checks control items and output circuit by arbitrary ON/OFF operation.

. In this test, the coefficient of self-learning control mixture ratio returns to the original coefficient by touching "CLEAR" on the

screen.

. Harness and connector EVAP canister purge control solenoid

valve

Vacuum hose

0 Engine: Run engine at 2,000 rpm. . Turn the EV~P canister purge control solenoid valve and using CONSULT and listen for operating

sound. EVAP

canister purge control solenoid

valve makes an operating sound. Check

vacuum signal for EVAP canister purge ~~~~~~a'cuum exists. VC OFF ... Vacuum does not exist.

Page 34 of 230

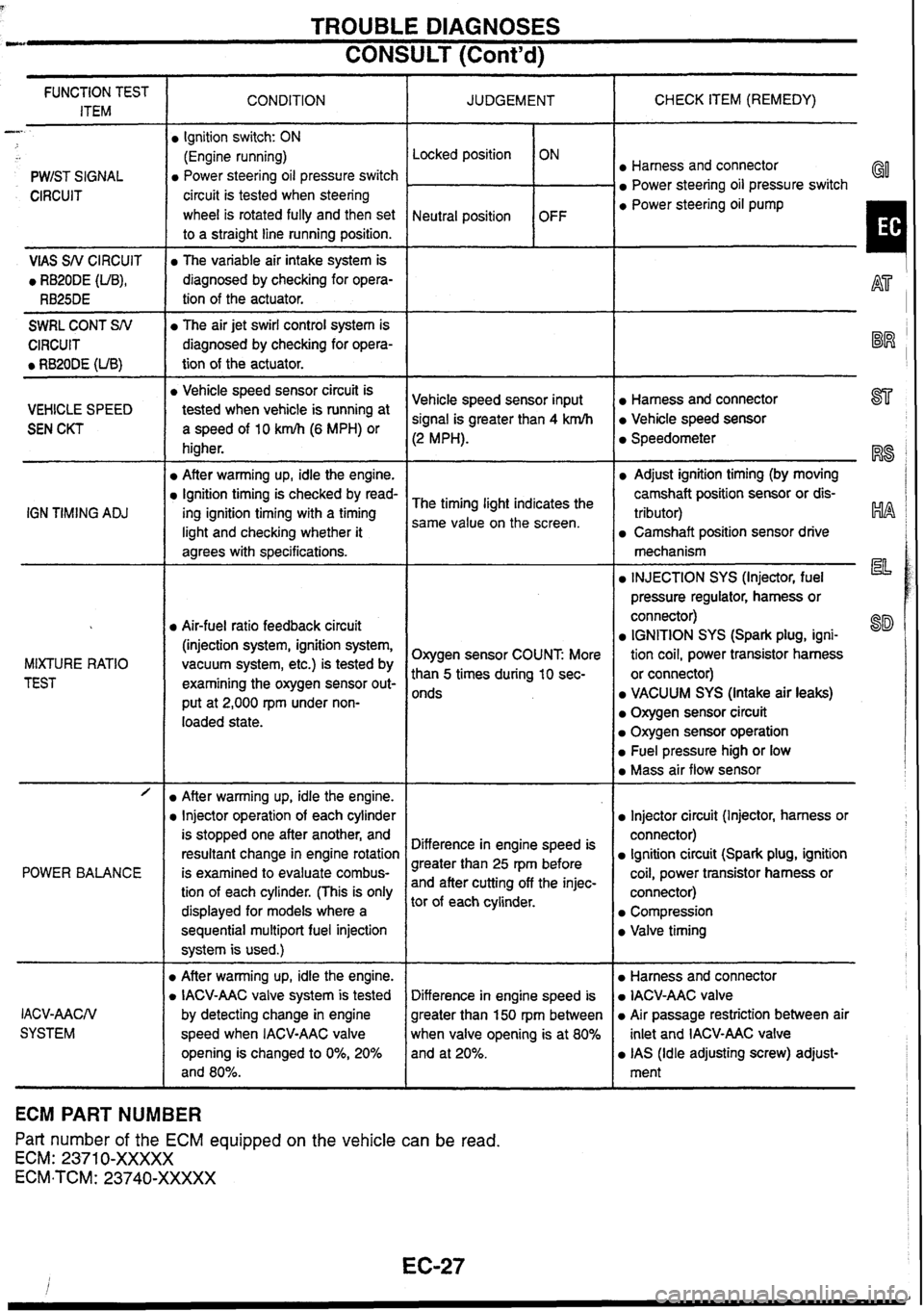

TROUBLE DIAGNOSES

CONSULT (Cont'd) --

CHECK ITEM (REMEDY)

FUNCTION TEST

ITEM CONDITION

JUDGEMENT

-

PWIST SIGNAL Locked position

Neutral position

Ignition

switch: ON

(Engine running)

Power steering oil pressure switch

circuit is tested when steering

wheel is rotated fully and then set

to a straight line running position. ON

OFF Harness and connector

Power steering oil pressure switch GO

CIRCUIT a Power steering oil pump

I VlAS SN CIRCUIT

0 RB20DE (UB),

RB25DE

The variable air intake system is

diagnosed by checking for opera-

tion of the actuator.

-

SWRL CONT SN

CIRCUIT

0 RB20DE (UB)

The air jet swirl control system is

diagnosed by checking for opera-

tion of the actuator.

-- -- -

a Vehicle speed sensor circuit is

tested when vehicle

is running at

a speed of 10 km/h (6 MPH) or

higher.

After warming up, idle the engine.

Ignition timing is checked by read-

ing ignition timing with a timing

light and checking whether it

agrees with specifications.

Harness and connector 877

Vehicle speed sensor

Vehicle

speed sensor input

signal is greater than 4 krnlh

(2 MPH).

VEHICLE SPEED

SEN CKT Speedometer

RS

Adjust ignition timing (by moving

camshaft position sensor or dis-

tributor)

HA

Camshaft position sensor drive

The

timing light indicates the

same value on the screen.

IGN

TIMING

ADJ

mechanism

la INJECTION SYS (Injector, fuel

pressure regulator, harness or

connector)

IGNITION SYS (Spark plug, igni-

tion coil, power transistor harness

or connector)

VACUUM SYS (Intake air leaks)

Oxygen sensor circuit

Oxygen sensor operation

Fuel pressure high or low

Mass air flow sensor

Air-fuel ratio feedback circuit

(injection system, ignition system,

vacuum system, etc.) is tested by

examining the oxygen sensor out-

put at 2,000

rpm under non-

loaded state. Oxygen sensor COUNT

More

than

5 times during 10 sec-

onds

MIXTURE

RATIO

TEST

- -- /

POWER BALANCE

Injector circuit (Injector, harness or

connector)

Ignition circuit (Spark plug, ignition

coil, power transistor harness or

connector)

Compression

Valve timing

After warming up, idle the engine.

Injector operation of each cylinder

is stopped one after another, and

resultant change in engine rotation

is examined to evaluate combus-

tion of each cylinder. (This is only

displayed for models where a

sequential

multipart fuel injection

system is used.)

D After warming up, idle the engine.

D IACV-AAC valve system is tested

by detecting change in engine

speed when IACV-AAC valve

opening is changed to

0%, 20%

and 80%. Difference

in engine speed is

greater than 25 rpm before

and after cutting off the injec-

tor of each cylinder.

Harness and connector

IACV-AAC valve

Air passage restriction between air

inlet and IACV-AAC valve

IAS (Idle adjusting screw) adjust-

ment

Difference

in engine speed is

greater than 150

rpm

between

when valve opening is at 80%

and at 20%.

IACV-AACN

SYSTEM

ECM PART NUMBER

Part number of the ECM equipped on the vehicle

can be read.

ECM: 2371 0-XXXXX

ECM-TCM: 23740-XXXXX

Page 37 of 230

TROUBLE DIAGNOSES

Symptom Matrix Chart (Cont'd)

Sensor-related problems I Symptom characteristics and ins~ection hints

Open Engine

will not start when either REF signal circuit or POS signal circuit is open.

Neither fuel system nor ignition system outputs control signals.

Crankshaft position sensor

(POS, REF) Instanta-

neous break Symptoms

vary with the break time and the vehicle's driving conditions. Light

shock or surging will occur while the vehicle is being driven, and the engine will

stall at idle speed.

Ring gear crankshaft position

sensor

[RB20DE

(UB)]

Signal

Mass air flow sensor Open

Open

High output

Low output I Aidfuel

ratio becomes lean. Dirty hot wire or air entering the system could be the

cause. No

airfluel ratio compensation

is carried out during lean bum status. Drivability

may be affected.

Enters fail-safe mode. Driving under

2,400 rpm is allowed.

Airlfuel

ratio becomes rich. Black smoke may be noted. Poor contact at the

ground could be the cause.

Engine coolant temperature sen-

sor Open

Open

Opedshort

High resis-

tance

Low resis-

tance

Opedshort

Heated oxygen sensor

I

Airlfuel ratio becomes over-rich.

Same symptom as when signal wire is open.

Enters fail-safe mode. Malfunction indicator lamp comes ON. Ordinary driving is

allowed. Problems tend to occur when engine is cold or engine coolant tempera-

ture

is high.

Detects low engine coolant temperature. Problems tend to occur after engine

warm-up.

Detects high engine coolant temperature. Problems tend to occur when engine is

cold.

Base

aidfuel ratio is used.

lgnition timing is retarded within the knock control range. Lack of power may be

OpedShort

I noted.

Knock sensor lgnition

timing is retarded within the knock control range. Lack of power may be

High

Output

(noted.

Low output

1 lgnition timing may not be retarded when knock is detected.

Vehicle speed sensor

Throttle position sensor

Opedshort

Opedshort

Unstable out-

put

Poor adjust-

ment

Open

Turbo pressure sensor

(TE) Fuel

cut time becomes-shorter, or no fuel cut is observed.

Base idle speed is used. Fuel injection is not increased during acceleration.

AIT shift point changes for AfF vehicles.

Unnecessary cut-in fuel injection could be the cause. Poor contact at the ground

or control unit could be the cause.

ldle judgment is "OFF while idling. Condition returns

normal by turning the igni-

tion switch ON and OFF repeatedly.

Turbo pressure is judged zero. No remarkable malfunction will be detected.

Refrigerant pressure is judged high. ldle speed remains high while the air condi-

tioner is ON.

Refrigerant pressure sensor

Short Refrigerant pressure

is judged low. ldle speed remains low while the air condi-

tioner is ON.

lgnition switch (IGN)

lgnition switch (START)

Air conditioner switch Open

Engine

will not start because neither fuel system nor ignition system outputs con-

trol signals.

Engine starts in normal condition. Engine may not start when temperature is

extremefy

low.

Air conditioner will not operate. No other malfunction will be noted.

Park/neutral

position switch is judged "OFF. Target engine speed for cold engine

in

N or P position is reduced.

ParWneutral position switch is judged

"0N"I Fast Jdle is effective when the engine

is cold and the gear is in other than N and P posrtlons. Vehrcle excessrvely

creeps.

Open

Open

Parklneutral

position

switch

Short

Power steering oil pressure

switch Open

Engine may

stall when the steering wheel is turned while the vehicle is standstill

and the accelerator pedal is lightly pressed, or when the steering wheel is turned

Electrical load switch Short

Open

Open/short

Multiplex communication line

- -- during deceleration. '

Power steering switch is judged 'ON." Value will be compensated constantly.

Idle speed drops so that the engine can stall when electrical load is applied.

Torque reduction control is not performed. Therefore,

shift shock becomes

greater.

- -- -- -- -- Engine will not start because neither fuel system nor ignition system outputs con-

trol signals.

Open

Control unit power supply

- -- - - --- - - - - - O~edshort I Same symptoms as when sensor harness is open.

Sensor ground -- - Poor contact

Water intru-

sion - -- - - - - - -- -- In case of poor contact, the connector fitting may be loose. In case of water

intrusion, the engine stalls and become inoperative for a while. The engine may restart soon in some cases.

Control unit

and connector

Page 119 of 230

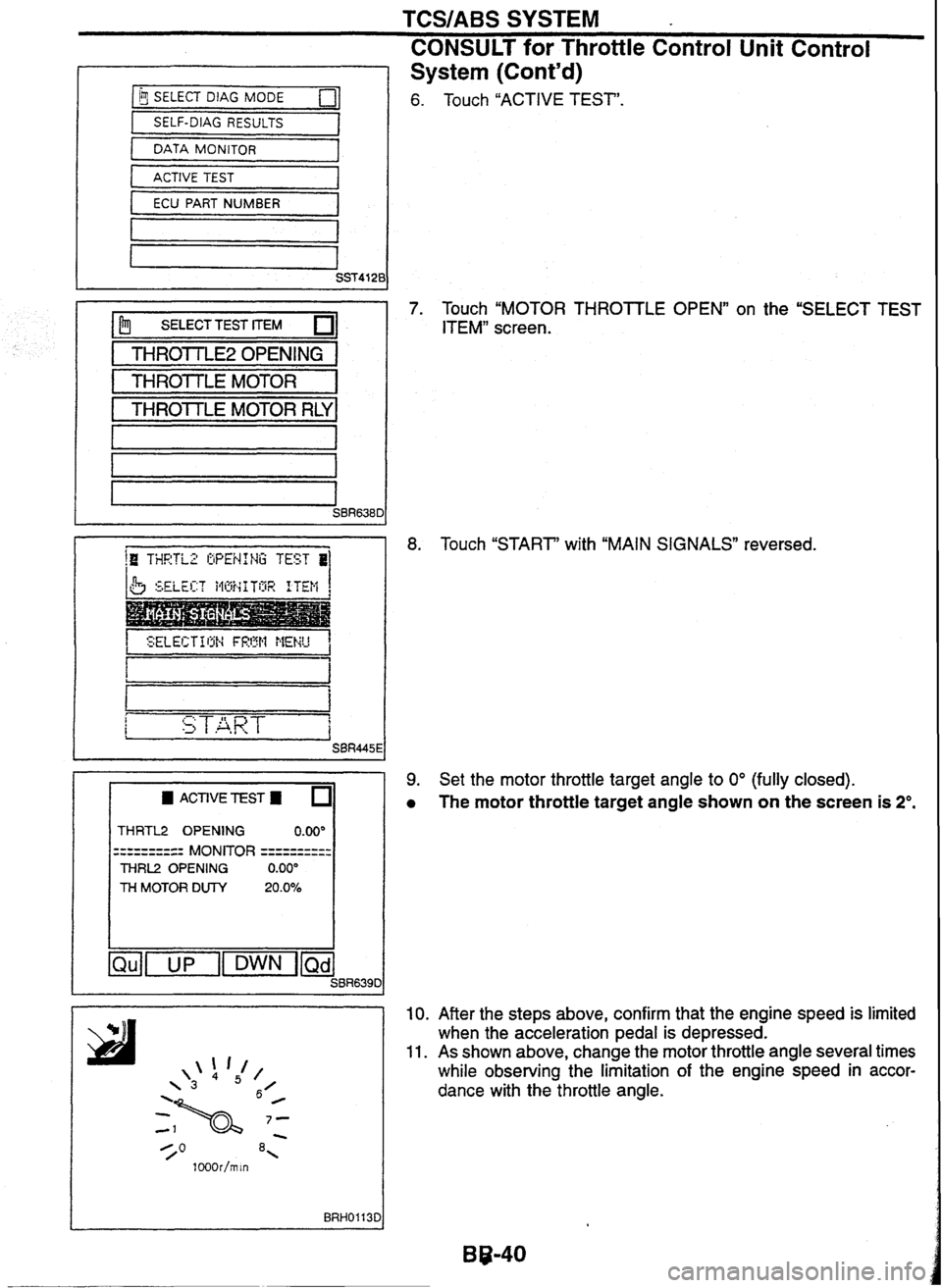

TCSIABS SYSTEM

CONSULT

for Throttle Control Unit Control

bJ SELECT DIAG MODE

SELF-DIAG RESULTS & I

DATA MONITOR 1

ACTIVE TEST I

ECU PART NUMBER I

I P?j SELECTTEST ITEM

I THROTIIEZ OPENING a

I THROTTLE MOTOR I

1 THROTLE MOTOR RLY 1

w ACTIVE TEST

THRTL2 OPENlNG 0.00" ---------- ---------- MONITOR ==========

THRL2 OPENING 0.00"

THMOTORDUTY 20.0°/0

System (Cont'd)

Touch "ACTIVE TEST".

Touch

"MOTOR THROSTLE OPEN" on the "SELECT TEST

ITEMn screen.

Touch "START' with "MAIN SIGNALS" reversed.

Set the motor throttle target angle to

0° (fully closed).

The motor throttle target angle shown on the screen is 2".

After the steps above, confirm that the engine speed is limited

when the acceleration pedal is depressed.

As shown above, change the motor throttle angle several times

while observing the limitation of the engine speed in accor-

dance with the throttle angle.

Page 129 of 230

ELECTRIC SUPER HICAS

Trouble

Diagnosis with CONSULT (Cont'd)

SELF-DIAGNOSTIC RESULTS MOI -- - - -

Diagnostic item

Diagnostic item is detected when ...

Vehicle speed signal changes rapidly during

running.

I Remarks

VEHICLE SPEED SEN

[SIGNAL

TURN](.b)

I This code appears also when

engine is idling at

1,500 rpm

or faster for more than 10

, seconds; in this case, it does

not indicate abnormality.

Vehicle speed signal is not sensed for more

than

10 seconds while the vehicle is running

at

1,500 rpm of engine speed.

CODE

54

STEERING

ANGLE SEN

[NO ANG

SIG](.a) Steering angle does not change for a while

when vehicle is running at 60

km,h or faster.

Steering angle from neutral position is kept at

60" degrees or more for a certain time when

vehicle is running

at 50 km/h or faster.

Steering angle from neutral position is kept at

30" degrees or more while vehicle travels a

certain distance.

STEERING

ANGLE SEN

[ANG SIG

FIX](.e)

STEERING ANGLE

SEN

[ANG

F1X3O0](-g)

STEERING ANGLE SEN

[NO NEUT

SIG](.b)

No neutral signal (ON signal) is sensed while

vehicle travels a certain distance.

No neutral signal (ON signal) is sensed while

steering wheel is turned more than

360'.

No neutral signal (OFF signal) is sensed while

steering wheel is turned more than

50"

degrees.

STEERING ANGLE

SEN

[NEU SIG

OFF](.c)

STEERING

ANGLE SEN

[NEUT SIG

ON](.d) - - --

a When steering wheel

is turned 360" after the

detection of neutral signal, the neutral signal is

sensed for

a certain period of time.

STEERING ANGLE

SEN

[OFFSET

NEUTJ(.f)

For a certain

period of time, input signal from

main sensor shows abnormality against sensor

power supply voltage.

a When input signal from main sefisor shows

2.5+1 V, input signal from sub-sensor shows

abnormality against sensor power supply volt-

age for a certain period of time.

RR

ST ANGLE SENSOR

[MAIN

SIGNAL](.a)

RR ST ANGLE SENSOR

[SUB

SIGNALJ(.b)

- -

Input signals from main sensor and sub-sen-

sor show more than a certain amount of differ-

ence from each other.

The voltage is higher or lower than the stan-

dard value.

RR

ST ANGLE SENSOR

[OFFSET SIG](-C)

RR ST ANGLE SENSOR

[ABNORMAL

VOL](.d)

r

a Engine speed shows an abnormally low value

for a certain period of time when vehicle is

running at

2 krnlh or faster.

ENG

REV SIGNAL

[ABNORMAL SIGNAL]

a When HlCAS motor relay is ON, motor power

supply voltage shows an abnormally lower

value than ignition power supply voltage.

When control unit keeps motor power OFF, the

motor power voltage shows a non-zero value

for a certain period of time.

MOTOR VOLTAGE

[LOW VOLTAGE](-a)

MOTOR VOLTAGE

[BAD

OBSTRCT](.b)

When a motor current is more than IOA, the

actual output of the motor shows an abnor-

mally low value for a certain period of time.

MOTOR

OUTPUT

[ABNORML

SIG](.a)

- -

MOTOR OUTPUT

[REV CURRENTJ(-C) When motor output is kept ON, a reverse cur-

rent is flowing.

Page 130 of 230

VEHICLE SP NISSAN GT-R 1998 Service Manual

ELECTRIC SUPER HlCAS

Trouble Diagnosis

with CONSULT (Contd)

Diagnostic item

MOTOR OUTPUT

[NO

CURRENTJ(.d)

MOTOR OUTPUT

[OVERCU

RRENTl(.e)

MOTOR OUTPUT

[MOTOR

LOCK](.

b)

VEHICLE SP](/img/5/57354/w960_57354-129.png)

ELECTRIC SUPER HlCAS

Trouble Diagnosis

with CONSULT (Cont'd)

Diagnostic item

MOTOR OUTPUT

[NO

CURRENTJ(.d)

MOTOR OUTPUT

[OVERCU

RRENTl(.e)

MOTOR OUTPUT

[MOTOR

LOCK](.

b)

VEHICLE SPEED SEN

[RAPD SIGN CHANGE21

VEHICLE SPEED SEN

[NO

SIGNAU]

VEHICLE SPEED SEN

[NO SIGNAL31

CONTROL UNIT

[ABNORMAL

1-61

Diagnostic item is detected when ... I Remarks

When motor output is kept OFF, a current is

flowing.

When motor output is kept ON, an overcurrent

is flowing.

Signal from rear steering angle sensor does

not change for a certain period of time while a

motor current of

17A or more is flowing.

When vehicle is running, vehicle speed signal

is not sensed for a certain period of time after

it has changed rapidly.

"VEHICLE SPEED SEN [RPD SIG CHG2J"

has occurred previously, and vehicle speed

signal is not sensed for a certain period of

time.

I

'VEHICLE SPEED SEN [RPD SIG CHG2]" I I

has not occurred previously, and vehicle

speed signal is not sensed for a certain period

of time while the vehicle is running at

1,500

rpm of engine speed.

Control unit is malfunctioning.

Page 141 of 230

TROUBLE DIAGNOSES - Supplemental Restraint System (SRS)

Trouble Diagnoses with CONSULT (Cont'd)

TROUBLE DIAGNOSIS RECORD

If a malfunction has occurred but is not recorded on seif-diagnosis,

it may be caused by some past malfunction. In such a case, past

malfunctions can be found

by selecting "TROUBLE DlAG

RECORD" in Diagnosis mode.

The "TROUBLE DlAG RECORD" can be selected for SRS air

bag system only.

Trouble Diagnoses without CONSULT

SRS AIR BAG SYSTEM

Self-diagnosis

The diagnosis modes are User mode and Diagnosis mode.

Switching between the two modes is accomplished by using

ignition switch

and driver door switch.

When lamp is not flashing (indicating no malfunction) in User mode, operating the door switch cannot change

the mode to Diagnosis mode.

When no malfunction is detected in Diagnosis mode, turning the ignition switch from "OFF" to "ON" changes

the mode to User mode. SRB0395D

User mode

Turn diver door switch 'ON" and 'OFF" at least 5 times within 7 seconds after sw~tching the

No malfunction is detected. (Lamp OFF)

IGN SW: ON

ON

OFF- 7 sec.

System is malfunctioning. (Lamp flashes)

Diagnosis

mode

User mode

ON

OFF

b A k Turn driver door switch "ON" and "OFF at

least 5, times

within 7 seconds after sw~tching

the ignition "ON".

IGN SW: OFF to ON IGN SW: OFF to ON

ignition

"ON".

-

- -

0.5 see. 0.5 sec.

Air bag is deployed or all of diagnosis sensor unit, air bag power supply circuit and AIR BAG warning lamp cir-

cuit are malfunctioning. (Lamp ON)

ON

OFF

Either air bag sensor unit or AIR BAG warning lamp circuit is malfunctioning. (Lamp OFF)

IGN SW: ON

OFF + SRB0412D

The display indicating a malfunction (flashes) keeps operation

until reset. If, however, the malfunction is a low battery volt-

age (less than 9V), the display changes from flashing to nor-

mal operation when the battery voltage has returned to normal

(more than

9V).