ECO mode NISSAN GT-R 1998 User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: GT-R, Model: NISSAN GT-R 1998Pages: 230, PDF Size: 12.66 MB

Page 45 of 230

TROUBLE DIAGNOSES

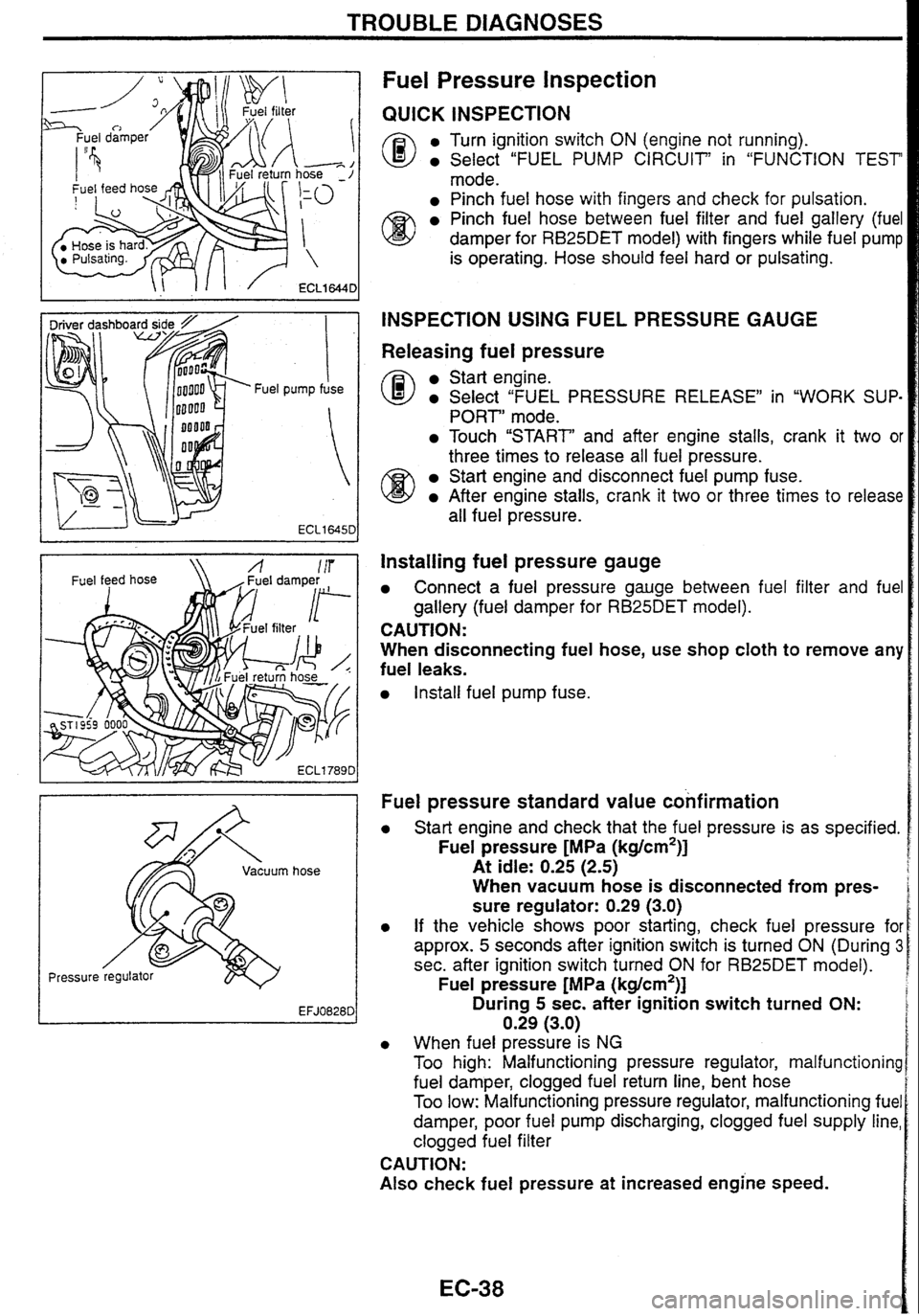

Fuel Pressure Inspection

Fuel pump fuse

Pressure hose

QUICK

INSPECTION

0 Turn ignition switch ON (engine not running).

Select "FUEL PUMP CIRCUIT' in "FUNCTION TEST

mode.

Pinch fuel hose with fingers and check for pulsation.

Pinch fuel hose between fuel filter and fuel gallery (fue

@ damper for RB2SDET model) with fingers while fuel puml

is operating. Hose should feel hard or pulsating.

INSPECTION USING FUEL PRESSURE GAUGE

Releasing fuel pressure

Start engine.

Select "FUEL PRESSURE RELEASE" in "WORK SUP

PORT' mode.

Touch "START' and after engine stalls, crank it two o

three times to release all fuel pressure.

Start engine and disconnect fuel pump fuse.

After engine stalls, crank it two or three times to releas

all fuel pressure.

Installing fuel pressure gauge

Connect a fuel pressure gauge between fuel filter and fue

gallery (fuel damper for

RB25DET model).

CAUTION:

When disconnecting fuel hose, use shop cloth to remove an!

fuel leaks.

Install fuel pump fuse.

Fuel pressure standard value confirmation

Start engine and check that the fuel pressure is as specified.

Fuel pressure [MPa (kg/cm2)]

At idle: 0.25 (2.5)

When vacuum hose is disconnected from pres-

sure regulator:

0.29 (3.0)

If the vehicle shows poor starting, check fuel pressure fo

approx.

5 seconds after ignition switch is turned ON (During :

sec. after ignition switch turned ON for RB25DET model).

Fuel pressure [MPa (kg/cm2)]

During 5 sec. after ignition switch turned ON:

0.29 (3.0)

When fuel pressure is NG

Too high: Malfunctioning pressure regulator, malfunction in^

fuel damper, clogged fuel return line, bent hose

Too low: Malfunctioning pressure regulator, malfunctioning fue

damper, poor fuel pump discharging, clogged fuel supply line

clogged fuel filter

CAUTION:

Also check fuel pressure at increased engine speed.

Page 75 of 230

TROUBLE DIAGNOSES

Self-diagnosis

DESCRIPTION

If malfunction should occur in electrical systems, turning ignition switch ON lights M mode switch POWER

indicator lamp

(M-AT Dual matic AfT warning lamp) for 2 seconds, and then flashes the indicator lamp for 8 Gc

seconds. If malfunction does not occur, A/T mode switch POWER indicator lamp (M-AT Dual matic A/T warn-

ing lamp) is turned on for

2 seconds upon turning ignition switch ON. To locate and display the malfunction-

ing part, output the trouble information memory and flash

A/T mode switch POWER indicator lamp (M-AT Dual

matic

A/T warning lamp) by inputting self-diagnostic startup signal.

SELF-DIAGNOSIS PROCEDURE

1. Warm up engine.

2. Repeat ON-OFF cycles of ignition switch for more than once, and turn it OFF at last.

3. Move A/T mode switch to AUTO, and turn overdrive control switch to O/D ON.

4. Turn ignition switch ON with selector lever in "Pn position, and ensure POWER indicator lamp is turned on

for

2 seconds.

5. Turn ignition switch OFF.

6. Move selector lever to "D" position.

7. Turn overdrive control switch O/D OFF.

8. Turn ignition switch ON.

9. Move selector lever to "2" position.

10. Turn overdrive control switch OID ON.

11. Move selector lever to "I" position.

12. Turn overdrive control switch O/D OFF.

13. Depress accelerator pedal fully, and release it.

14. Read flashing status of POWER indicator lamp to complete self-diagnosis procedures.

M-AT

1. Warm up engine.

2. Repeat ON-OFF cycles of ignition switch for more than once, and turn it OFF at last.

3. Turn ignition switch ON with selector lever in "P" position, and ensure dual matic PJT warning lamp is turned

on for

2 seconds.

4. Turn ignition switch OFF.

5. Depress brake pedal, release accelerator pedal, and then move selector lever to "D" position.

6. Turn ignition switch ON.

7. Release brake pedal, and move selector lever to "3" position.

8. While depressing brake pedal with left foot, depress accelerator pedal fully with right foot, and move

selector lever to

"2" position.

9. Read dual matic A/T warning lamp indication to complete self-diagnosis procedures.

Page 84 of 230

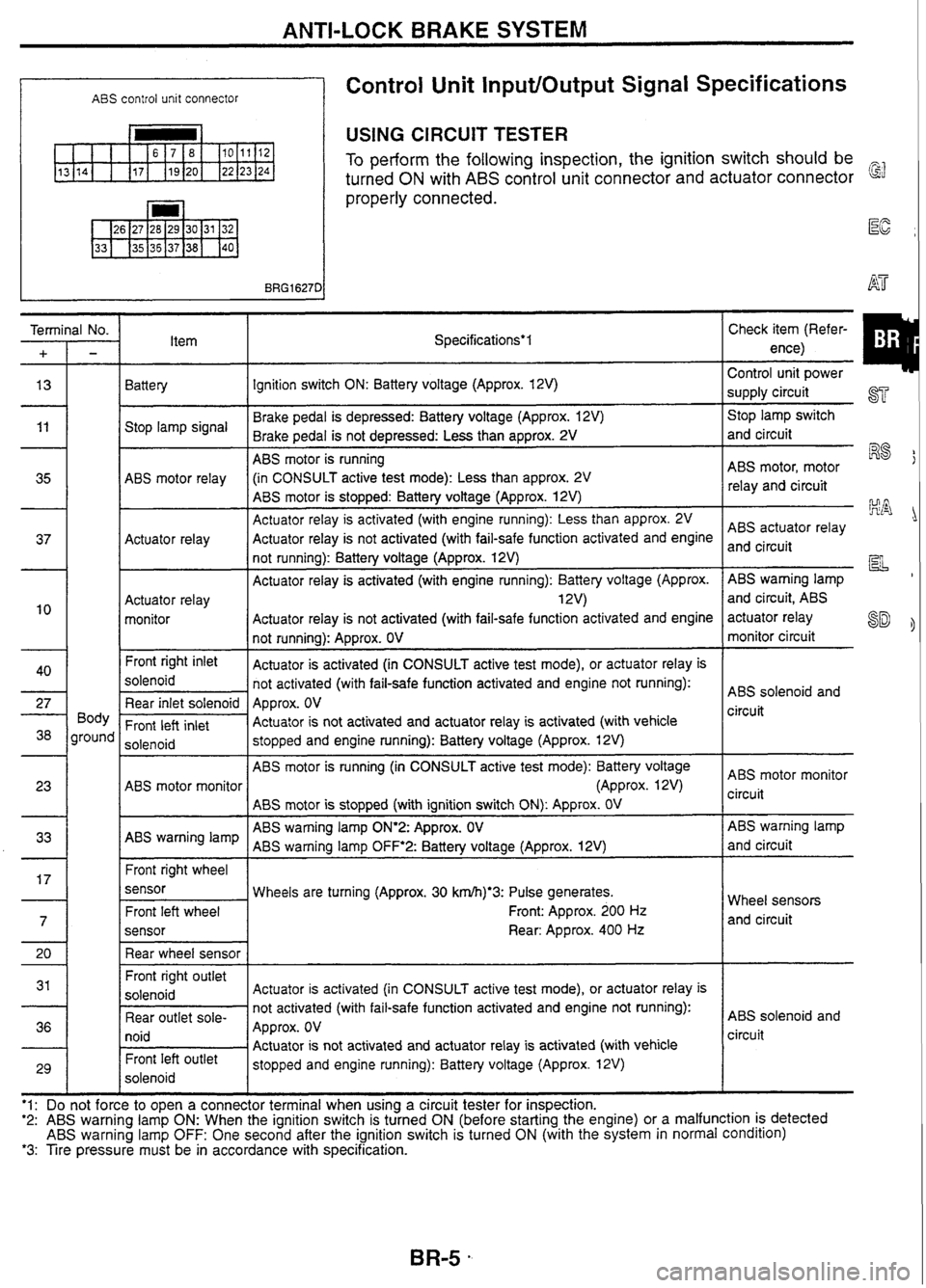

ANTI-LOCK BRAKE SYSTEM

ABS control unit connector

Terminal No.

Control Unit InputlOutput Signal Specifications

USING CIRCUIT TESTER

To perform the following inspection, the ignition switch should be

turned

ON with ABS control unit connector and actuator connector

properly connected.

Item Specifications*l

Battery Ignition switch ON: Battery voltage (Approx. 12V)

Brake pedal is depressed: Battery voltage (Approx. 12V)

Stop lamp signal

Brake pedal is not depressed: Less than approx.

2V

ABS motor is running

ABS motor relay (in

CONSULT active test mode): Less than approx.

2V

ABS motor is stopped: Battery voltage (Approx.

12V)

Actuator relay is activated (with engine running): Less than approx. 2V

Actuator relay Actuator

relay is not activated (with fail-safe function activated and engine

not running): Battery voltage (Approx. 12V)

Actuator relay is activated (with engine running): Battery voltage (Approx.

Actuator relay 1 2V)

monitor Actuator

relay is not activated (with fail-safe function activated and engine

not running): Approx. OV

Front

right inlet

Actuator is activated (in CONSULT active test mode), or actuator relay is

solenoid not activated (with fail-safe function activated and engine not running):

Rear inlet solenoid Approx. OV

Front

left inlet Actuator

is not activated and actuator relay is activated (with vehicle

solenoid stopped

and engine running): Battery voltage (Approx. 12V)

ABS motor is running (in CONSULT active test mode): Battery voltage

ABS motor monitor (Approx. 12V)

ABS motor is stopped (with ignition switch

ON): Approx. OV

ABS warning lamp

ON'2:

Approx. OV

ABS warning lamp

ABS warning lamp

OFF'2:

Battery voltage (Approx. 12V)

Front right wheel

sensor Wheels are turning (Approx. 30

krn/h)*3: Pulse generates.

Front: Approx. 200

Hz

sensor

Rear: Approx. 400 Hz

Front right outlet

Actuator is activated (in CONSULT active test mode), or actuator relay is

not activated (with fail-safe function activated and engine not running):

Rear outlet

sole-

Approx. OV

I lUlU / Actuator is not activated and actuator relay is activated (with vehicle Front left Outlet stopped and engine running): Battery voltage (Approx. 12V)

solenoid

'1:e

to

tooen

a connector terminal when

using a circuit tester for inspection. Control

I

unit

power

supply circuit

ST

Stop lamp switch

and circuit

ABS motor, motor

R8

relay and circuit

ABS actuator relay

and circuit

pL

ABS warning lamp

and circuit, ABS

actuator relay

SD monitor circuit

ABS solenoid and

circuit

ABS motor monitor

circuit

ABS warning lamp

and circuit

Wheel sensors and circuit

ABS solenoid and

circuit

'2: ABS warning lamp ON: When the ignition switch is turned ON (before starting the engine) or a malfunction is detected ABS warning lamp OFF: One second after the ignition switch is turned ON (with the system in normal condition) *3: Tire pressure must be in accordance with specification.

Page 89 of 230

![NISSAN GT-R 1998 User Guide

ANTI-LOCK BRAKE SYSTEM

CONSULT (Contd) - -

Diagnostic item

CONTROL UNIT --

BAnERY "OLTAGE

[VB-HIGH]

"OLTAGE

[VB- LO

W]

Function of calculation in ABS control unit has failed.

Diagnost NISSAN GT-R 1998 User Guide

ANTI-LOCK BRAKE SYSTEM

CONSULT (Contd) - -

Diagnostic item

CONTROL UNIT --

BAnERY "OLTAGE

[VB-HIGH]

"OLTAGE

[VB- LO

W]

Function of calculation in ABS control unit has failed.

Diagnost](/img/5/57354/w960_57354-88.png)

ANTI-LOCK BRAKE SYSTEM

CONSULT (Cont'd) - -

Diagnostic item

CONTROL UNIT --

BAnERY "OLTAGE

[VB-HIGH]

"OLTAGE

[VB- LO

W]

Function of calculation in ABS control unit has failed.

Diagnostic

item is detected when

...

Control unit,

control

unit

power supply

and ground

circuit

Check item

ABS control unit battery voltage

is abnormally high.

ABS control unit battery voltage is abnormally low.

. ABS MOTOR

[LOCK FAILURE] Control

unit

power supply

circuit ABS motor speed is abnormally low. AES motor,

motor relay

and circuit

1 I

'1 : ABS warning lamp turns on if a wheel or wheels spin for I0 to 80 seconds (depending on the wheel speed) with the vehicle

stuck in snow. ice, or mud. This is a normal condition.

'2: After repairing short-circuited sensor, turning ignition switch ON lights up ABS warning lamp. Check that ABS warning lamp

turns

off when the vehicle is driven at approx. 30 krnh for approx. 1 minute as shown in the self-diagnosis procedure. NOTE: If "ABSn is not displayed on "SELECT SYSTEM" screen, check ABS control unit and data link connector circuit, and make sure

of the CONSULT card number.

DATA MONITOR PROCEDURE

Refer to CONSULT Instruction Manual for details on data

monitor function.

1. Turn ignition switch OFF.

2. Connect CONSULT connector to data link connector for CON-

SULT.

3. Turn ignition switch ON.

4. Touch "START' on CONSULT screen.

5. Touch "ABS" on CONSULT screen.

If "START" is touched immediately after engine is started

or ignition switch is turned on,

"ABS" may not be dis-

played on "SELECT SYSTEM" screen. To display "ABS",

repeat the data monitor procedure from the beginning.

6. Touch "DATA MONITORn.

7. Touch "SETTING" to set recording condition.

8. Touch "AUTO TRIG", "LONG TIME" and then "ENTER".

9. Return to "SELECT MONITOR ITEM" screen and touch "CIU

INPUT ITEM", "ALL SIGNALS" or 'SELECTION FROM

MENU". Refer to "DATA MONITOR MODE" on the next page.

10. Touch "START'.

11. Display data monitor.

12. If necessary, sequentially touch "REC START, "REC STOP",

"DATA DISPLAY", "NUMBER PRINT' and "PRINT' to print out

the data.

Page 91 of 230

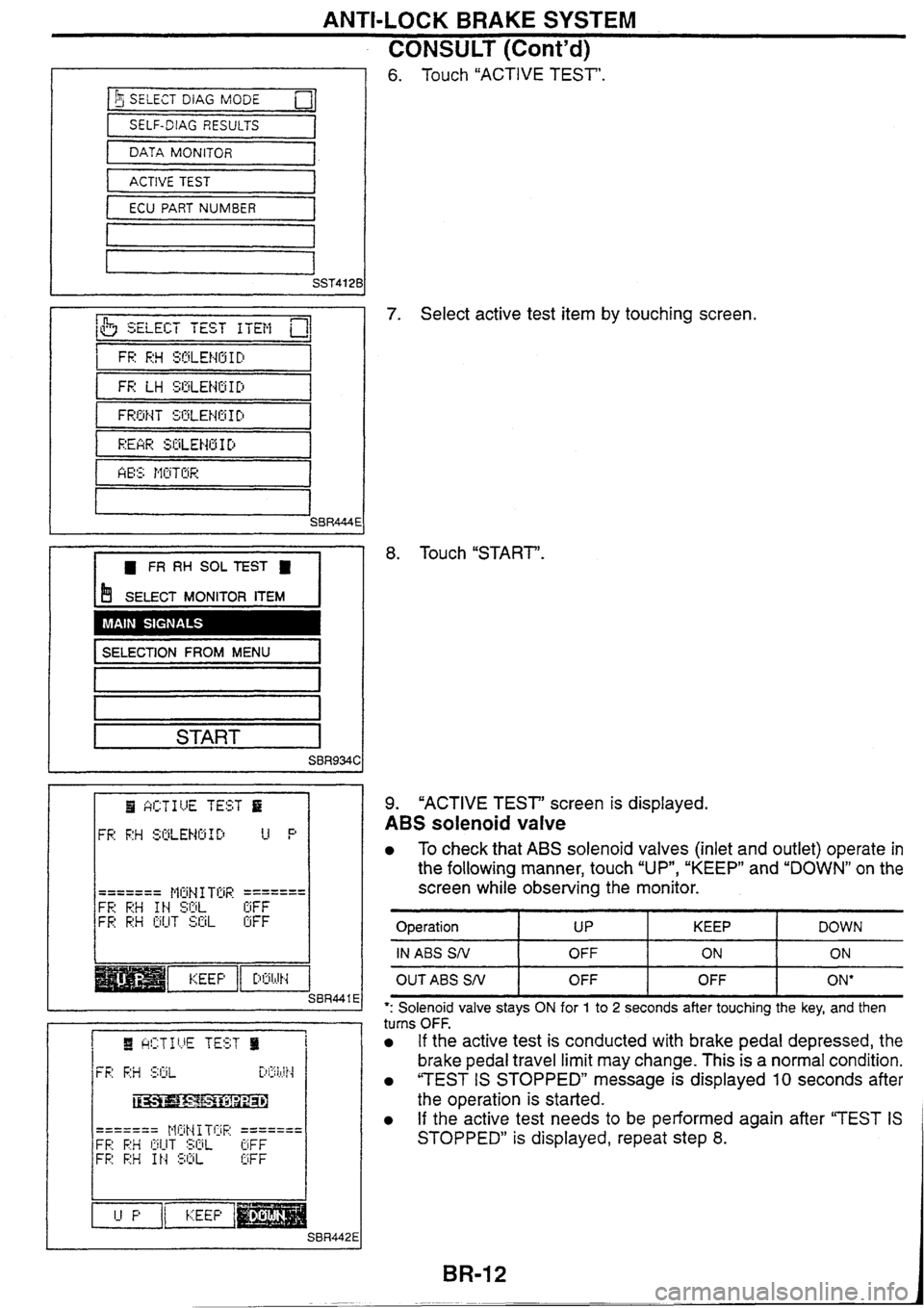

ANTI-LOCK BRAKE SYSTEM

CONSULT (Cont'd)

I b~ SELECT DiAG MODE 01 r SELF-DIAG RESULTS

DATA MONITOR

ACTIVE TEST

ECU

PART NUMBER I

FR RH SOL TEST

I 1 !!! SELECT MONITOR ITEM I I

I I SELECTION FROM MENU I I

I I START 1

6. Touch "ACTIVE TEST'.

7. Select active test item by touching screen.

8. Touch "START'.

9. "ACTIVE TEST" screen is displayed.

ABS solenoid valve

To check that ABS solenoid valves (inlet and outlet) operate in

the following manner, touch

"UP*, "KEEP" and "DOWN" on the

screen while observing the monitor.

Operation I UP I KEEP ( DOWN

IN ABS SN I OFF 1 ON I ON

OUTABS SN I OFF I OFF I ON*

*: Solenoid valve stays ON for 1 to 2 seconds after touching the key, and then

turns OFF.

If the active test is conducted with brake pedal depressed, the

brake pedal travel limit may change. This is a normal condition.

"TEST IS STOPPED" message is displayed 10 seconds after

the operation is started.

If the active test needs to be performed again after "TEST IS

STOPPED" is displayed, repeat step 8.

Page 93 of 230

ANTI-LOCK BRAKE SYSTEM

Self-diagnosis

DESCRIPTION

When a problem occurs in the ABS, the ABS warning lamp on the

instrument panel comes on. To actuate the self-diagnostic results

mode, ground the self-diagnostic check terminal

4 located on the

data

link

connector for

CONSULT. The ABS warning lamp, then,

flashes and indicates the location of the malfunction.

SELF-DIAGNOSIS PROCEDURE

1. Collect information on the concern from the customer, and then

perform basic inspections.

2. Drive vehicle at approx. 30 km/h for approx. 1 minute.

3. Stop vehicle and start diagnosis.

4. Turn ignition switch "OFF'.

5. Ground the self-diagnostic check terminal 4.

6. Turn ignition switch "ON" to start the self-diagnostic results

mode.

CAUTION:

Keep terminal 4 grounded during self-diagnosis.

Do not depress brake pedal. (Self-diagnosis would not

start.)

Do not start engine. (Self-diagnosis would not start.)

7. After 3 or 4 seconds, ABS warning lamp starts blinking to indi-

cate the malfunction code No.

The indication terminates after 5 minutes. Turning the ignition

switch from

"OFF" to "ON" resumes blinking the indication.

8. Verify the location of the malfunction with "MALFUNCTION

CODUSYMPTOM CHART", BR-16. Then make the necessary

repairs.

9. After the malfunctions are repaired, erase the malfunction

codes stored in the control unit. Refer to "HOW

TO ERASE

SELF-DIAGNOSTIC RESULTS" on the next page.

10. Rerun the self-diagnostic results mode to verify that the mal-

function codes have been erased.

11. Disconnect the check terminal from the ground. The self-diag-

nostic results mode is now complete.

12. Drive vehicle at approx. 30 km/h for approx. I minute, and then

check that the ABS warning lamp is off.

HOW TO READ SELF-DIAGNOSTIC RESULTS

(Malfunction codes)

Determine the code No. by observing the time and the fre-

quency that the

ABS warning lamp blinks ON and OFF.

When multiple malfunctions occur at a time, up to three code

numbers can be stored; the latest malfunction will be indicated

first.

The indication begins with the start code No. 12. A maximum

of three code numbers appear in the order of the latest one

first. The indication then returns to the start code No.

12 to

repeat.

The start code No. 12 is only indicated repeatedly when there

is no malfunction.

Page 94 of 230

ANTI-LOCK BRAKE SYSTEM

Self-diagnosis (Cont'd)

Example: Code No. 25 Front left wheel sensor (open-ccrcuit)

lnd~cat~on

s:arl

Start code No. i2

Unit: seconds BRG1185D

ABS warnq lamp ON -

A9S warnrng lamp OFF

Self-d~agnosis complete , C ABS warning lamp !

I i I I I

................ &. j(j(?.:e~o"dd~i!~?!!f!!. . -----... .-.---.--. iiii rase 1 12.5 seconds I mode

Malfunct~on

memory Malfunction memory is Nn. erase mode starts. Is erased BRG0057C

Tens d~g~ts Un~ts digits Code No 25 I I - I

HOW TO ERASE SELF-DIAGNOSTIC RESULTS

(Malfunction codes)

r--------- -T---t----t-l-T-l-

1. Turn the ignition switch "ON" and start the engine.

-.

---------- -I--I--t--l-i-"I

2. Drive the vehicle at approx. 30 kmh for approx. 1 minute to

check that there is no other malfunction.

ST

3. Stop the vehicle.

4. Turn the ignition switch "OFF'.

5. Ground the self-diagnostic check terminal. RS'

6. Turn the ignition switch "ON" to start the self-diagnostic results

-

-.

3 06 0.9 03C303 3.3 06 0.6 0.6 09 050303030305030303

-----

mode.

CAUTION:

c--

Do not depress the brake pedal during self-diagnosis. Do not

start the engine. (The self-diagnosis

would not start.)

7. The ABS warning lamp starts to blink 3 or 4 seconds after the EL

self-diagnostic results mode is started.

8. Under the self-diagnostic results mode, the malfunction $jD

memory erase mode starts when the check terminal is discon-

nected from the ground.

9. Ground the check terminal 3 times or more in succession

within 12.5 seconds after the erase mode starts. (Each ground-

ing must

be 1 second or longer.)

10. Disconnect the grounding cable from the check terminal to

erase the malfunction memory and complete the

self-diagno-

sis. The ABS warning lamp

, then, turns off.

11. Turn the ignition switch

"OFF'.

Page 109 of 230

TCSfABS SYSTEM

CONSULT for

TCSfABS Control

Unit Control

System (Cont'd)

Diagnostic item

LAN CIRCUIT

1

LAN CIRCUIT 2

Diagnostic item is detected when ... I Check item

NOTE:

If "NO FAILn is displayed as a result of the CONSULT self-diagnosis when the ABS warning lamp is lit, inspect the engine speed

signal circuit.

If "ABSn is not displayed on "SELECT SYSTEM" screen, check ABS control unit and data link connector circuit, and make sure of the CONSULT card number. If "ENGINE SYSTEM", "LAN SIGNAL 1". "LAN SIGNAL 2", "LAN SIGNAL 3, "LAN CIRCUIT 1" or "LAN CIRCUIT 2" is displayed

on the screen, perform the self-diagnosis for the

ECM.TCM

or ECM.

If "THROlTLE CONTROLLER COMMUNICATIONn is displayed on the screen, perform the self-diagnosis for throttle control unit.

Total control signal (multiple signal) for engine, All and TCSIABS is abnormal (open or

shorted communication harness,-faulty connections, abnormal TCSIABS control unit or

ECM.TCM

or ECM).

ECM.TCM

or ECM power is cut

off or decreased for 2 seconds or longer.

Total control signal (multiple signal) for engine,

ArT and TCSIABS is suspected to be

interrupted (open or shorted communication harness, faulty connections, abnormal

TCS/ABS

control unit or ECM TCM or ECM).

ECM.TCM or ECM power is cut off or decreased for 2 seconds or longer.

DATA

a

1.

2.

3.

4.

5.

a

signal 1, 2

(multiple sig-

nal) for

and

TCSI

ABS

MONITOR PROCEDURE

Refer to CONSULT Instruction Manual for details on data

monitor function.

Turn ignition switch OFF.

Connect CONSULT connector to data link connector for

CON-

SU LT.

Turn ignition switch

ON.

Touch "START" on CONSULT screen.

Touch "ABS" on CONSULT screen.

If "START" is touched immediately after engine is started

or ignition switch is turned ON, "ABS" may not be dis-

played on "SELECT SYSTEM" screen. To display "ABS",

repeat the data monitor procedure from the beginning.

Touch "DATA MONITOR".

Touch "SETTING" to set recording condition.

Touch "AUTO TRIG", "LONG TIME" and then

"ENTER".

Return to "SELECT MONITOR ITEM" screen and touch "C/U

INPUT ITEM",

"ALL SIGNALS" or "SELECTION FROM

MENU". Refer to "DATA MONITOR MODE" on the next page.

10. Touch "START".

11. Display data monitor.

12. If necessary, sequentially touch "REC START, "REC STOP",

"DATA DISPLAY", "NUMBER PRINT" and "PRINT" to print out

the data.

Page 113 of 230

TCS/ABS SYSTEM

Self-diagnostic check ter (Terminal 4 of data link c

Data link connector for CONSULT

Self-diagnosis for TCSfABS Control Unit

Control System

SELF-DIAGNOSIS PROCEDURE

1. Collect information on the concern from the customer, and then

perform basic inspections.

2. Drive vehicle at approx. 30 km/h for approx. 1 minute.

3. Stop vehicle and start diagnosis.

4. Turn ignition switch "OFF.

5. Ground the self-diagnostic check terminal 4 on the data link

connector for CONSULT.

6. Turn ignition switch "ON" to start the self-diagnostic results

mode.

CAUTION:

Keep terminal 4 grounded during self-diagnosis. Do not

depress brake pedal. Do not start engine. (Self-diagnosis

would

not start.)

When SLlP indicator lamp does not start blinking, check

TCSfABS

control unit power supply circuit and ground

circuit.

7. The SLlP indicator lamp starts blinking to indicate the malfunc-

tion code No.

3 or 4 seconds after the self-diagnostic results

mode is started.

The indication terminates after 5 minutes. Turning the igni-

tion switch from

"OFF" to "ON" resumes blinking the indi-

cation.

During the SLIP indicator lamp operation shown above,

TCS

OFF indicator lamp and ABS warning lamp are lit.

8. Vsrify the location of the malfunction with "MALFUNCTION

CODUSYMPTOM

CHART", BR-36. Then make the necessary

repairs.

9. After the malfunctions are repaired, erase the malfunction

codes stored

in the control unit. Refer to "HOW TO ERASE

SELF-DIAGNOSTIC RESULTS on the next page.

10. Rerun the self-diagnostic results mode to verify that the mal-

function codes have been erased.

When the malfunction codes have been erased, the start

code is only indicated.

11. Disconnect the check terminal from the ground. The self-diag-

nostic results mode is now complete.

12. Drive vehicle at approx. 30 km/h for approx. 1 minute, and then

check that the

TCS OFF indicator lamp, the SLlP indicator

lamp and the ABS warning lamp are OFF.

HOW TO READ SELF-DIAGNOSTIC RESULTS

(Malfunction codes)

Determine the code No. by observing the time and the fre-

quency that the SLlP indicator lamp flashes ON and OFF.

Refer to the next page.

When multiple malfunctions occur at a time, up to three code

numbers can

be stored; the latest malfunction will be indicated

first.

The indication begins with the start code No. 12. After that a

maximum of three code numbers appear in the order of the

latest one first. The indication then returns to the start code No.

12 to repeat.

The start code No.

12 is only indicated repeatedly when there

is no malfunction.

Page 114 of 230

TCS/ABS SYSTEM

Self-diagnosis for TCS/ABS Control Unit

control System (Cont'd)

Example: Code No. 25 Front left wheel sensor (open-circutt)

lnd~cat~on

start Start code No.

12

HOW TO ERASE SELF-DIAGNOSTIC RESULTS

(Malfunction codes)

1. Turn the ianition switch "ON" and start the engine.

ABS warnlng lamp - ON

ABS warning lamp

OFF

2. Drive the iehicle at approx. 30 km/h for appfox. 1 minute to

check that there

is no other malfunction.

3. Stop the vehicle and turn the ignition switch "OFF'. I88

4. Ground the self-diagnostic check terminal 4 on the data link

connector for CONSULT.

5. Turn the ignition switch "ONn to start the self-diagnostic results /,%@A

mode.

I---------- -------------- -?-I 3 06 0.9 03C303 3 3 06 3.6 06 09 030303030303030303

Unit: seconds BRG1185D

Tens drglts Units drgits Code No. 25

I -----l

7. Under the self-diagnostic results mode, the malfunction

memory erase mode starts when the check terminal

is discon-

nected from the ground.

8. Ground the check terminal 3 times or more in succession

-.

self-d~agnosts complete

SLlP ndicator lamp i

I ON r

f OFF - c 4 i

ground J Erase -- - - - - - - - - -i - - - - ---f2.i geconds-- - - - - - - .. t mode

Malfunct~on

memory

Malfunct~on

memory

IS erase mode starts. 1s erased. BRZOO~~D

within 12.5 seconds after the erase mode starts. (Each ground-

ing must be

2 seconds or longer.)

9. Disconnect the grounding cable from the check terminal to

erase the malfunction memory and complete the

self-diagno-

-----

CAUTION:

Keep terminal 4 grounded during self-diagnosis. Do not EL

depress the brake pedal during self-diagnosis. Do not start the

engine.

6. The SLIP indicator lamp starts blinking to indicate the malfunc- SD

tion code No. 3 or 4 seconds after the self-diagnostic results

mode is started.

The indication terminates after 5 minutes. Turning the igni-

tion switch from

"OFF" to "ON" resumes blinking the indi-

cation. During the SLlP indicator lamp operation shown

above,

TCS OFF indicator lamp and ABS warning lamp are

lit.

sis.

10. Rerun the self-diagnostic results mode to verify that the mal-

function codes have been erased.

0 When the malfunction codes have been erased, the start

code No.

12 is only indicated.

11. Disconnect the check terminal from the ground. The self-diag-

nostic results mode is now complete.

12. Drive vehicle at approx. 30 kdh for approx. 1 minute, and then

check that the

TCS OFF indicator lamp, the SLlP indicator

lamp

and the ABS warning lamp are OFF.

13. Turn the ignition switch "OFF.