door lock NISSAN GT-R 1998 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: GT-R, Model: NISSAN GT-R 1998Pages: 230, PDF Size: 12.66 MB

Page 150 of 230

FULLY AUTOMATIC AIR CONDlTlONER

Component Parts Location

Intake door actua:or

,

Sunload sensor

Controller

B&wer temperature sensor

fan motor

@ Radiator core lower support I

Front defros!er grille (left)

1 ,?efros:er gnlie (left) t I

0 Blower fan motor relay

Engine room, right relay box I / Air conditioner relay I

Blower and cooling unit

I Blower fan motor

? Ar condlboner relay

@ Refrigerant

pressure sensor @ Compressor @ Ambtent sensor

a Liquid tank I @ Englne room. front left

I

Blower and cooling unit

lnta Instrument panel, center I

7 IJj Cluster

lid A 0 Fuse block, rear face 1

Page 157 of 230

FULLY AUTOMATIC AIR CONDITIONER

Trouble Diagnosis by Self-diagnosis Function

There are 5 steps in the self-diagnosis: to check for any sensor failure, and to check that a given control sig-

nal is transmitted to each output device.

Diagnosis

content

- - -

Diagnostic

item

i Step I I Step 2 - - - - - - - --

Each sensor check

Indicator lamp check

Display segments Ambient sensor

0 Indicator lamp In-vehicle sensor

lntake air tempera-

ture sensor

Sunload sensor Step

3

Each

actuator check

and reset check display for each

sen-

lntake door actuator

Air mix door actua-

tor Mode door actuator

lntake door actuator

Air mix door actua-

tor

Mode door actuator

Blower fan motor

Compressor

Air purifier (only

when connected)

Ambient sensor

In-vehicle sensor

lntake air tempera-

ture sensor

SELF-DIAGNOSIS OPERATION PROCEDURE R8

Switching to self-diagnosis mode

Turn the temperature adjustment dial all the way to the left.

Start the engine with the ignition switch from OFF position. Within 10 seconds, press and hold the OFF

switch for more than approx. 5 seconds, to start the self-diagnosis step 1.

Self-diagnosis completion EL

a Turn the ignition switch OFF.

Turn the AUTO switch ON.

Switching between self-diagnosis steps

Use the temperature adjustment dial to switch between self-diagnosis steps 1 to 5.

Temperature adjustment dial (turn clockwise): Step

1-5

Temperature adjustment dial (turn counterclockwise): Step

5- 1

a Refer to "SELF-DIAGNOSIS DISPLAY ITEM" for the diagnosis contents of each step.

Page 158 of 230

FULLY AUTOMATIC AIR CONDITIONER

Trouble Diagnosis

by Self-diagnosis Function

(Cont'd)

Step 3 AUTO SW: ON +

I

Step 1

(CW) Tum the temperature (CCW) Turn the temperature

adjustment dial. adjustment dial. I

IGN SW: OFF

AUTO SW: ON *

T

I Step 4 I AUTO SW: ON *

4 (CW) Turn the temperature (CCW) Turn the temperature

adjustment dial. adjustment dial. I

Step 2 IGN SW: OFF

AUTO SW: ON *

I

CW: Clockwise I CCW: Counterclockwise

Step 5 Detected temperature d~splay for each sensor IGN SW: OFF AUTO SW: ON

C : Each switch indicator lamp HAK0725D

SELF-DIAGNOSIS DISPLAY ITEM

Step 1 - Display segments and indicator lamp check

Check the controller switch indicator lamp and display segments.

Normal: The switch indicator lamp and display segments are illu-

minated.

Abnormal: Malfunctioning area will not be illuminated.

lllum~nated when a short- (T"e last digir ") circuit is detected.

the display code

the corresponding codes

Step 2 - Each sensor check

Display shows "2 in the step 2 mode, and then shows the judge-

ment result.

Check the data of each sensor inputted into the automatic ampli-

fier.

Normal: Display shows

"20.

Abnormal: The last digit of the display code flashes for a malfunc-

tioning sensor. At this time, if a short-circuit

is detected,

"AUTO is displayed. Furthermore, when there are more

than one malfunctioning sensor, the corresponding dis-

play codes flash twice starting with the smaller code.

The sunload sensor will judge an abnormality when there is

insufficient lighting (less than 5,000 lx) such as while being

placed indoor or during the evening.

Page 163 of 230

FULLY AUTOMATIC AIR CONDITIONER

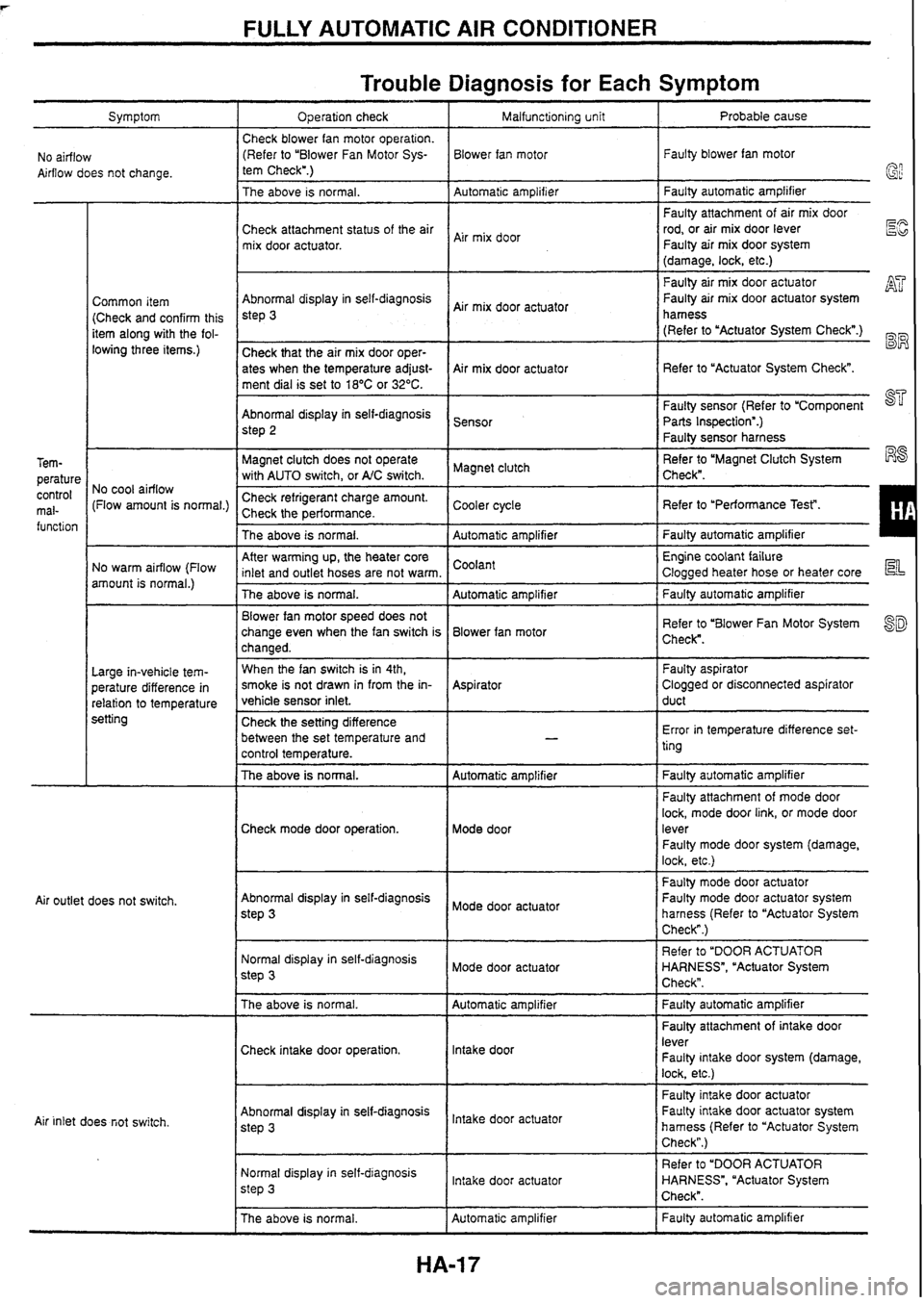

Symptom

Trouble Diagnosis for Each Symptom

No airflow

Airflow does not change. Operation check

Check blower fan motor operation. (Refer to "Blower Fan Motor Sys-

tem Check".)

The above is normal.

I Automatic amolifier 1 Faultv automatic amplifier

Faulty attachment of air mix door

rod, or air mix door lever

Faulty air mix door system

ElG

(damage, lock, etc.)

Malfunctioning unit

Blower fan motor Probable cause

Faulty blower fan motor

Check attachment status of the air

mix door actuator.

Common item (Check and confirm this

item along with the fol-

lowing three items.)

Air mix door

Abnormal display in self-diagnosis

step

3

Check that the air mix door oper-

ates when the temperature

adjust-

ment dial is set to

18OC or 32°C.

Faulty sensor (Refer to 'Component a

Parts Inspection".)

Faulty sensor harness

Air

mix door actuator

Air mix door actuator

Abnormal display in self-diagnosis

step 2

Magnet clutch does not operate

Magnet clutch Refer

to 'Magnet Clutch System R8

with AUTO switch, or A/C switch. Check".

I Faulty

air mix door actuator

Faulty air mix door actuator system AT

hamess

(Refer to "Actuator System Check".)

BW

Refer to "Actuator System Check".

@'i?

Sensor

Tem- perature

control mal-

function No

cool airflow

(Flow amount is normal.)

ngeranr

cnarge

amounr.

( Cooler cycle 2 ~erformance. I Refer to 'Performance Test". I

The above is normal. I Automatic amolifier 1 Faulty automatic amplifier I

After warming up, the heater core

inlet and outlet hoses are not warm. 1 Coolant I

Engine coolant failure

Clogged heater hose or heater core

No warm airflow

(Flow

amount is normal.)

The above is normal. Automatic amplifier

1 Faulty automatic amplifier

Blower fan motor speed does not

change even when the fan switch is Blower fan motor

changed. Refer

to "Blower Fan Motor System

Check".

I

When the fan switch is in 4th, Faulty aspirator

smoke is not drawn in from the

in-

Aspirator Clogged

or disconnected aspirator

vehicle sensor inlet. duct

Large

in-vehicle tem-

perature difference in

relation to temperature

setting Check the setting difference

between the set temperature and

control temperature. Error

in temperature difference set-

ting

- The above isnormal.- Automatic amplifier Faulty automatic amplifier

Faulty attachment of mode door

lock, mode door link, or mode door

Check mode door operation. Mode door lever

Faulty mode door system (damage,

lock, etc.)

Faulty mode door actuator

Abnormal display in self-diagnosis Faulty mode door actuator system

step

3 Mode door actuator

harness (Refer to "Actuator System

Check".)

Air

outlet does not switch.

Normal display in self-diagnosis

Mode door actuator

step

3

Refer to "DOOR ACTUATOR

HARNESS", "Actuator System

Check".

The above is normal.

I Automatic amplifier I Faulty automatic amplifier - - I I Faulty attachment of intake door

Check intake door operation. lntake

door lever

Faulty intake door system (damage,

lock, etc.)

~aulG intake door actuator

Faulty intake door actuator system

hamess (Refer to "Actuator System

Check".)

Abnormal

display in self-diagnosis

door step 3 Air inlet does fiot switch.

Normal display in self-diagnosis

lntake door actuator

step

3

Refer to "DOOR ACTUATOR

HARNESS", "Actuator System

Check".

I I The above is normal. I Automatic amplifier I Faulty automatic amplifier

Page 165 of 230

ELECTRICAL SYSTEM

SECTION EL

CONTENTS

CENTRAL DOOR LOCK SYSTEM ................................. 2

Component Parts Location .......................................... 2

Circuit Diagram ............................................................ 2

Combination Meter (meter control unit) Input/

Output Signal Specifications

........................................ 2

Inspection before Trouble Diagnoses ......................... -3

Trouble Diagnoses ....................................................... 3

REMOTE CONTROL ENTRY SYSTEM .......................... 4

Component Parts Location .......................................... 4

Circuit Diagram ............................................................ 4

Remote Control Entry Control Unit Input/Output

Signal Specifications

.................................................... 5

System Check ............................................................. -5

Inspection before Trouble Diagnoses .......................... 6

Trouble Diagnoses ....................................................... 6

Component Parts inspection ....................................... 6

ID Code Entry Procedure ............................................ 7

POWER WINDOW SYSTEM ........................................... 8

System Description ..................................................... -8

Precautions ................................................................. -8

Component Parts Location .......................................... 8

Circuit Diagram ............................................................ 9

Power Window Main Switch Input/Output Signal

Specifications

............................................................... 9

Inspection before Trouble Diagnoses ........................ 11

Trouble Diagnoses .................................................... 11

SUNROOF SYSTEM ...................................................... 12

Component Parts Location ........................................ 12

Circuit Diagram .......................................................... 12

Sunroof Switch and Sunroof Motor Assembly

lnputiOutput Signal Specifications

............................. 12

AUTO LIGHT SYSTEM ................................................. 1 3

Component Parts Location ........................................ 13

Auto Light Control Unit Input/Output Signal

Specifications

............................................................. 13

Circuit Diagram ........................................................ 14

Trouble Diagnoses .................................................. I 4

..................................... XENON HEADLAMP SYSTEM 15

Trouble Diagnoses ..................................................... 15

IGNITION KEY-OPERATED ILLUMINATION

SYSTEM

................................................................... 7

Component Parts Location ........................................ 17

.......................................................... Circuit Diagram 17

Meter Control Unit InputlOutput Signal

....................................................... Specifications 1 7

METER ........................................................................\

18

Corn bination Meter .................................................... 18

Triple Meter ................................................................ 20

................................................ COMBINATION METER 21

.................................................... System Description 21

........................................ Component Parts Location 21

Diagnosis Function .................................................... 21

................................... Meter-related Circuit Diagram 22

..................................................... Trouble Diagnoses 23

Combination Meter InpuVOutput Signal

Specifications

............................................................ -25

..................................... Component Parts Inspection 26

TRIPLE METER ............................................................. 29

Special Service Tool ................................................... 29

........................................ Component Parts Location 29

Circuit Diagram .......................................................... 29

Triple Meter InputfOutput Signal Specifications ........ 30

Component Parts Inspection ..................................... 30

IGNITION KEY WARNING BUZZER AND LIGHT

WARNING BUZZER

...................................................... 31

Component Parts Location ........................................ 31

Circuit Diagram .......................................................... 31

Meter Control Unit InpuVOutput Signal

Specifications

............................................................. 31

FRONT WIPER .............................................................. 32

Component Parts Location ........................................ 32

Circuit Diagram .......................................................... 32

Front Wiper Input/Output Signal Specifications ........ 32

Page 167 of 230

CENTRAL DOOR LOCK SYSTEM

Component

Parts Location

Door lock relay

LOCK -

Door lock relay

connector

1 LOCK 1

TK20 I I 5\41 1 (Brown) 1 11el j I 1

Combination meter

(Meter C/U) connector

I

Circuit Diagram

Driver door lock

Remote control entry

SW signal C/U connector

Lock signal

18. Unlock sign311 5 T 1

PMI main SW

(Central door lock SW)

----- I . RH door1

actuator 1 I I I Rear LH door I lock actuator I I I,,,,,,,------J

Driver door lock

actuator SW

P/'W main SW connector PNV main SW connector

(2-door Coupe) 1 (4-door Sedan) OCC3324 C

Combination Meter (meter control unit) Input/

Output Signal Specifications

-

I

. . 4 1 Driver door lock switch signal I

Specification

Approx. OV

Locked (OFF)

5

18

55

56

60

Operation or condition

Unlocked (ON1

Terminal No.

Approx.

5V

Signal name

Central door lock switch unlock signal

Central door lock switch lock signal

Ground Passenger and rear

RH 8 LH door lock

actuator lock signal

Passenger and rear RH & LH door lock actuator unlock siqnal Unlocked

(ON)

Operation other than above (OFF)

Locked (ON)

Operation other than above (OFF)

-

Central door lock switch is locked.

Central door lock switch is unlocked. Approx.

OV

Approx. 5V

Approx.

OV

Approx. 5V

Approx.

OV

Changes from approx. 12 to OV and back

to approx. 12V.

Changes from approx.

12 to OV and back

to approx. 12V.

Page 168 of 230

CENTRAL DOOR LOCK SYSTEM

Symptom

Passenger door lock and rear

RH & LH door locks do not lock or unlock with the

central door lock switch.

Passenger door lock, rear

RH door lock,

or rear LH dooc lock do not lock or unlock

with the central door lock switch.

Passenger door lock and rear

RH & LH door locks do not lock or unlock with the

driver door lock knob. (They operate

properly with the central door lock switch.)

Inspection before Trouble Diagnoses

Check that components connectors are properly connected.

Trouble Diagnoses

SYMPTOM CHART

Malfunctioning item

Door lock relay circuit Possible

cause E8G Faulty power window main switch (central door lock switch)

Power window main switch circuit

Faulty door lock relay

Faulty door lock relay to combination meter (meter control unit)

BR harness

0 Faulty power window main switch (central door lock switch) to

combination meter (meter control unit) harness

Faulty power window main switch (central door lock switch) ground

circuit

I Faulty door lock relay to door lock actuator harness

Door lock actuator circuit

Combination meter

(meter control unit)

0 Faulty door lock actuator Faulty door lock actuator to door lock relay harness

0 Faulty combination meter (meter control unit) ST

Driver door lock switch circuit

0 Faulty driver door lock switch . Faulty driver door lock switch to combination meter (meter control

unit) harness

Combination meter (meter control unit)

Faulty driver door lock switch ground circuit

Faulty combination meter (meter control unit) m

Page 170 of 230

REMOTE CONTROL ENTRY SYSTEM

Remote Control Entry Control Unit

Terminal No.

InputIOutput Signal specifications

Signal name Operation or cond~t~on Specificatton

Close the driver door. (OFF) Approx.

12V Driver door

switch input signal . @ Open the driver door. (ON) Approx. OV

Close

all the doors. (OFF) Approx. 12V All door

switch input signal Ec Open one of the doors. (ON) Approx. OV

Driver door

lock actuator lock

output signal Lock with the remote control. Changes from

approx. 0 to 12V and back to approx. OV. t

Ground - Approx. OV BR Locked (OFF) Approx. 5V Driver door lock switch signal

Unlocked (ON) Approx. OV

Key-in detection switch input Insert (ON) Approx. 12V 87

signal

Ignition key Remove (OFF)

Approx. OV

ACC power supply Ignition switch to ACC Approx. 12V Rs

Passenger door and rear RH & Press the lock switch on the remote control. Changes

from approx. 5 to OV LH door lock output signal

and back to approx. 5V.

Passenger door and rear RH & Changes from approx. 5 to OV HA

LH door unlock output signal Press the unlock switch

on the remote control.

and back to approx. 5V.

Driver door lock actuator

Unlock with the remote control. Changes from approx. 0 to

unlock output signal 12V and back to approx. OV.

System Check

Easy way to confirm the func+ion of the remote control: Works

properly.

Program the remote control (A) to another vehicle

of the

same type and check if the remote control works properly. Does not work. is OK.

Turn

a radio ON. Touch the radio aerial with the remote

control (A). Press a switch on the remote control with . is heard.

the

remote

control on the aerial. Listen for noise.

(Radio frequency: around

78.6, 78.7, 78.8 MHz)

B f ' Works properly.

I

Program another remote control (6) to the vehicle

concerned and check if the remote control works properly. No noise

is heard. t The vehicle is OK.

Does not work.

Check item

Operation check

Remote control

(A) is OK. Remote control (A)

is

NG.

r The vehicle is NG. 0CC3078D

I

I System check A

Remote control

(A) is OK.

Remote control (A) is

NG.

System check B

The vehicle is OK.

Remote control (A) is NG. Program the remote control

(A) to the vehicle concerned again and check

for proper operation.

The vehicle is NG.

The vehicle is OK. Perform trouble diagnosis

to determine what causes the problem.

Check the remote control

(A) battery voltage.

The vehicle is NG. Check the

remote control (A) battery voltage and then perform trouble

diag- nosis to determine what causes the problem.

Page 171 of 230

REMOTE CONTROL ENTRY SYSTEM

lnspection before Trouble Diagnoses

Check system.

Check that other systems that use the following signals work

properly.

Check that component connectors are connected properly.

Trouble Diagnoses

SYMPTOM CHART

Symptom

None of the doors lock with the remote

control switch.

None of the doors unlock with the

remote control switch.

Door locks other than the driver door do

not operate with the remote control

switches.

Only the driver door lock does not oper-

ate with the remote control switch. Door

switch circuit Malfunctioning item

Faulty door switch to

remote control entry control unit

harness Possible cause

Key-in detection switch circuit

Faulty key-in detection switch to remote control entry control

unit harness

Remote control entry control unit

Key-in detection switch circuit

Faulty remote control entry control unit

Faulty key-in detection switch to remote control entry control

unit harness

Remote control entry control unit

Central door lock system circuit

Remote control entry control unit

Driver door lock actuator circuit

Remote control entry control unit

Faulty remote control entry control unit

Refer to

"CENTRAL DOOR LOCK SYSTEM", EL-2. Faulty combination meter (meter control unit) to remote

control entry control unit harness

Faulty remote control entry control unit

Faulty driver door lock actuator Faulty driver door lock actuator to remote control entry

control unit harness

Faulty remote control entry control unit

mA before

Use lithium

checking ihe battery.

photo battery (CRI 620

Component Parts lnspection

BATERY CHECK

Specification: Approx. 2.5 - 3.OV

CAUTION:

Connect resistance

(300Q) so that the current is approx. 10

or equivalent) for

replacement.

Page 172 of 230

REMOTE CONTROL ENTRY SYSTEM

ID Code Entry Procedure

Enter the identity (ID) code manually when:

remote controller or control unit is replaced.

an additional remote controller is activated.

To enter the ID code, follow the procedures below.

PROCEDURE

I Close all doors and lock driveis side door. I

Insert and remove the key from the ignition more than six times within 10 seconds.

(Power door lock will then unlock.)

Within

3 seconds after door lock is unlocked, turn ignition key switch to "ACCn posi-

tion and lock the driver's side door.

At this time, the original ID codes are erased.

Push any button on the new remote controller once. (Power door lock will then

unlock.)

At this time, the new ID code is entered. e

Lock driver's side door.

Do you

want to enter any additional remote controller ID codes?

A maximum four ID codes may be entered. Any attempt to enter more will be

ignored.

I Open driver's side door or turn the ignition key switch to 'OFF position. I

No

END.

After entering the identity (ID) code, check the operation of remote control

entry system.

Yes

NOTE

If you need to activate more than two additional new remote controllers, repeat the procedure

"Additional ID code entry" for each new remote controller.

If the same ID code that exists in the memory is input, the entry will be ignored.

Entry of maximum four ID codes is allowed and any attempt to enter more will be ignored.