check engine NISSAN GT-R 1998 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: GT-R, Model: NISSAN GT-R 1998Pages: 230, PDF Size: 12.66 MB

Page 5 of 230

CONSULT CHECKING SYSTEM

Function and System Application

Diagnostic test mode

Work support

Self-diagnostic results

Trouble diagnostic record Function

This mode enables a technician to adjust some devices faster

and more accurately by following the indications on CONSULT.

ECU discriminated

No.

Data monitor

I I whether each system is "OK" or 'NG". lxH-1-

Conducted by CONSULT instead of a technician to determine

Function test Self-diagnostic

results can be read and erased quickly.

Current self-diagnostic results and all trouble diagnostic records

previously stored can be read.

Active test

ECM part number

L x: Applicable ENGINE

x

Classification

number of a replacement ECU can be read to pre-

vent an incorrect ECU from being installed.

InputIOutput data in the ECM can be read.

Lithium Battery Replacement

x

Diagnostic Test Mode in which CONSULT drives some actuators

apart from the

ECMs and also shifts some parameters

in a

specified range.

ECM part number can be read.

CONSULT contains a lithium battery. When replacing the battery obey the following:

WARNING:

Replace the lithium battery with SANYO Electric Co., Ltd.,

CR2032 only. Use of another battery may

present

a risk of fire or explosion. The battery may present a fire or chemical burn hazard if mistreated.

Do not recharge, disassemble or dispose of in fire.

Keep the battery out of reach of children and discard used battery conforming to the local regulations.

AfT

-

-

x

Checking Equipment

x

-

x

x

When ordering the below equipment, contact your NlSSAN distributor. Air

bag

-

-

-

x

!

Tool name ABS

-

x

X

-

x

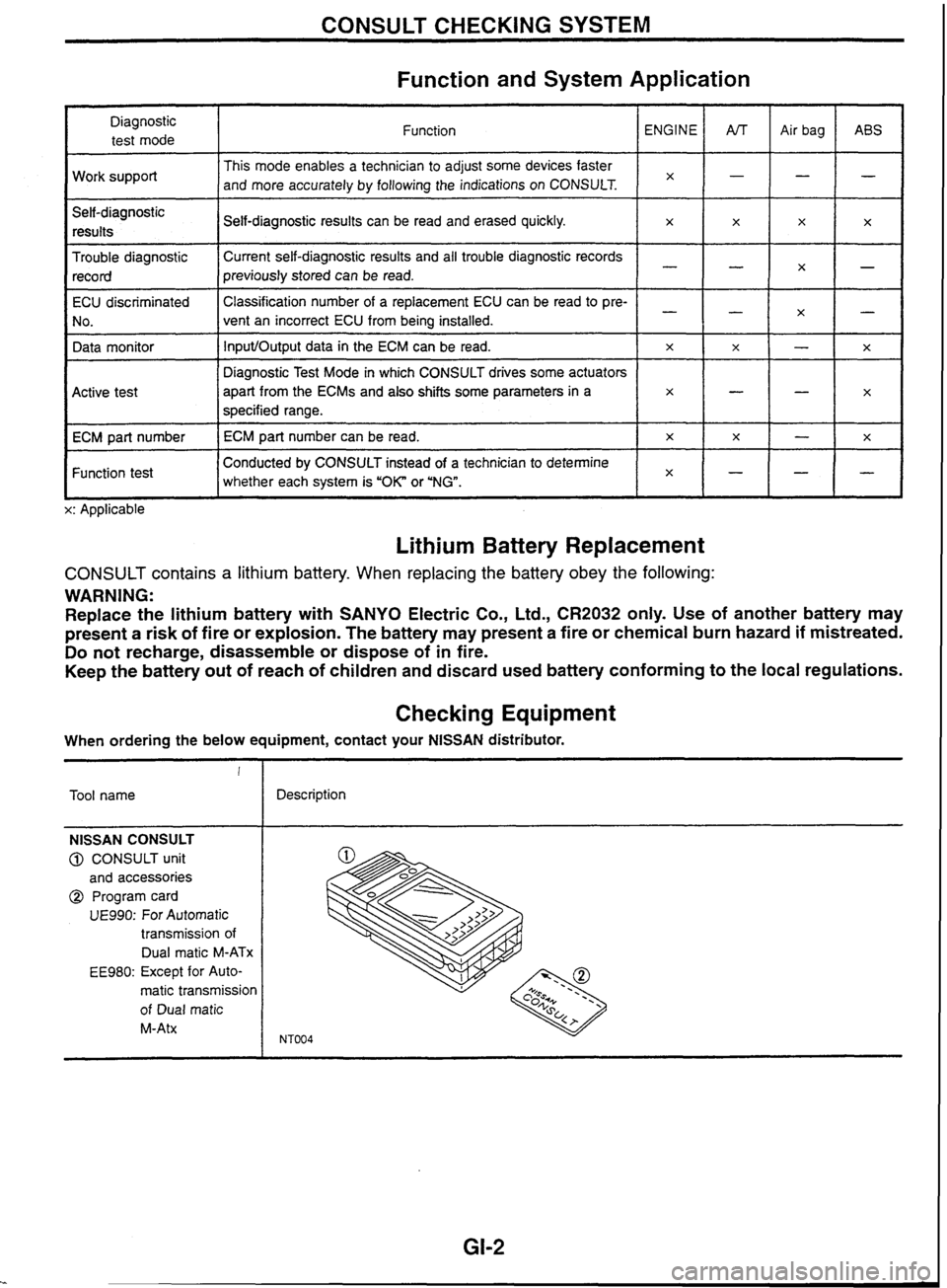

NISSAN CONSULT

@ CONSULT unit

and accessories

@ Program card

UE990: For Automatic

transmission of

Dual

rnatic M-ATx

EE980: Except for Auto-

matic transmission

of Dual

matic

M-Atx

x

-

--

X

-

Description

-

x

-

-

x

x

Page 18 of 230

ENGINE AND EMISSION CONTROL OVERALL SYSTEM

Circuit Diagram

RB20DE (UB).MTT, RB25DE, RB25DET.MTT MODELS

Fan motor

Auxtliary

electric

Ian

relay

-

Alr cmdll~oner compressor

Arr

conduoner

relay

14

Y Mallunct~on indcator lamp A 17

26 $7 = Power steenng 011

pressure sw~icr.

I

23

43 Engine Want

temwrature sensor B.

Tachometer drive signal Check connmr

To rear defogger relay

/ [RB2MWD TO starter motor *'""L'*" - > TO PNP switch

I TO Starter relay

[Except lor ' - RB25DE.4WDI

Page 20 of 230

ENGINE AND EMISSION CONTROL OVERALL SYSTEM

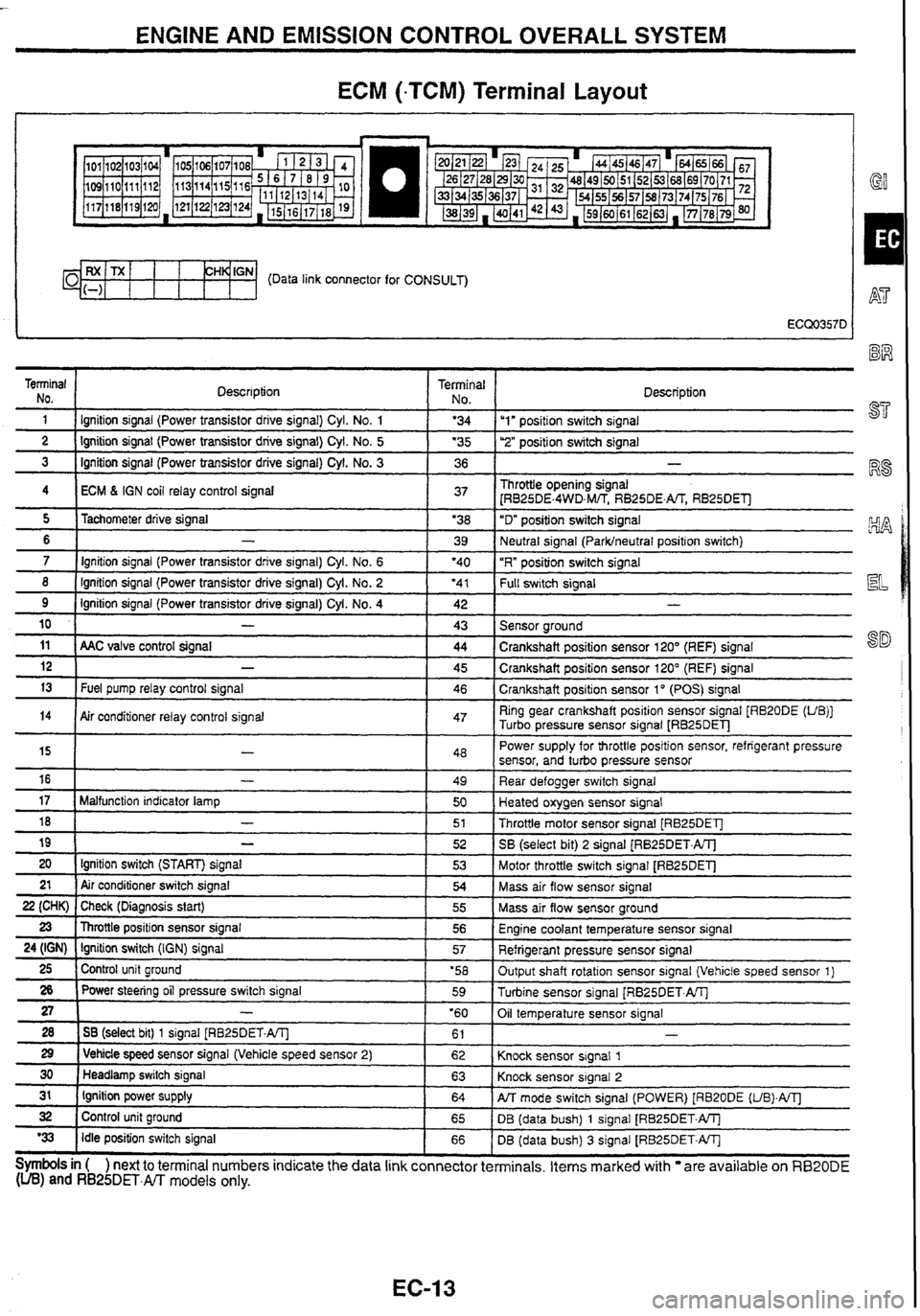

ECM (-TCM) Terminal Layout

I GY

CH~'GN- (Data link connector for CONSULT)

Terminal NO.

1 Description Terminal 1 No I Description - - 1 I lgnition

signal (Power transistor drrve signal) Cyl. No. 1 1 '34 Iu1" positron switch signal -- ---- 2 1 Ignition signal (Power transistor drive signal) Cyl. No. 5 1 '35 1 ''2" posifion switch signal - - 3 1 Ignition signal (Power transistor drive signal) Cyl. No. 3 1 36 1 -

4 I ECM 6 IGN coil relay control signal 1 37 1 Throttle opening signal

[RB25DE.4WD,M/TS RB25DE.m RB25DEll

- - - -- - - - - 8 ( Ignition signal (Power transistor drive signal) Cyl. No. 2 ( '41 1 f-k swltch signal

5

6

7

11 ( AAC valve control signal ( 44 1 Crankshaft position sensor 120' (REF) signal

Tachometer

drive signal

-

Ignition signal (Power transistor drive signal) Cyl. No. 6

9

10

'38

39

'40

Ignition signal (Power transistor drive signal)

Cyl.

No. 4

-

12

13

"D" position switch signal

Neutral signal

(Parklneutral position switch)

"R" position switch signal

14

Symbols in ( ) next to terminal numbers indicate the data link connector terminals. Items marked with are available on RB20DE (UB) and RB25DET.m models only.

42

43

-

Fuel pump relay control signal

15

16

17

18

19

20 21

22 (CHK)

23

24 (IGN)

25

26

27

28

29

30

31

32

'33

- -

Sensor around

Air conditioner relay control signal 45

46

-

-

Malfunction indicator lamp

-

-

Ignition switch (START) signal

Air conditioner switch signal

Check (Diagnosis start)

Throttle position sensor signal

Ignition switch

(IGN) signal

Control unit ground

Power steering oil pressure switch signal

-

1 SB (select bit) 1 signal [RB25DET.A/Tl

1 Vehicle speed sensor signal (Vehicle speed sensor 2)

Headlamp switch signal

Ignition power supply

Control unit ground

Idle position switch signal Crankshaft

position sensor 120" (REF) signal

Crankshaft position sensor 1

" (POS) signal

47 Ring gear crankshaft position sensor signal [RB20DE (UB)]

Turbo pressure sensor signal

LRB25DEl-J

48

49

50

51

52

53

54

55

56

57

'58 59

'60 61

62

63

64

65

66 Power

supply for throttle position sensor, refrigerant pressure

sensor, and turbo pressure sensor

Rear defogger switch signal

Heated oxygen sensor signal

Throttle motor sensor signal [RB25DET]

SB

(select bit)

2 signal (RB25DET.ATJ

Motor throttle switch signal

[RB25DET]

Mass air flow sensor signal

Mass air flow sensor ground

Engine coolant temperature sensor signal

Refrigerant pressure sensor signal

Output shaft rotation sensor signal (Vehicle speed sensor 1)

Turbine sensor signal

[RB25DET.AlTj

Oil temperature sensor signal

Knock sensor signal

1

Knock sensor signal 2

PJT mode switch signal (POWER) [RB20DE (UB).A/Tl

DB (data bush) 1 signal [RB25DET.W

DB (data bush)

3 signal [RB25DET.W

Page 24 of 230

TROUBLE DIAGNOSES

Self-diagnosis (Cont'd)

I Malfunction indicator lamp

MALFUNCTiON INDICATOR LAMP (MIL) INDICATION

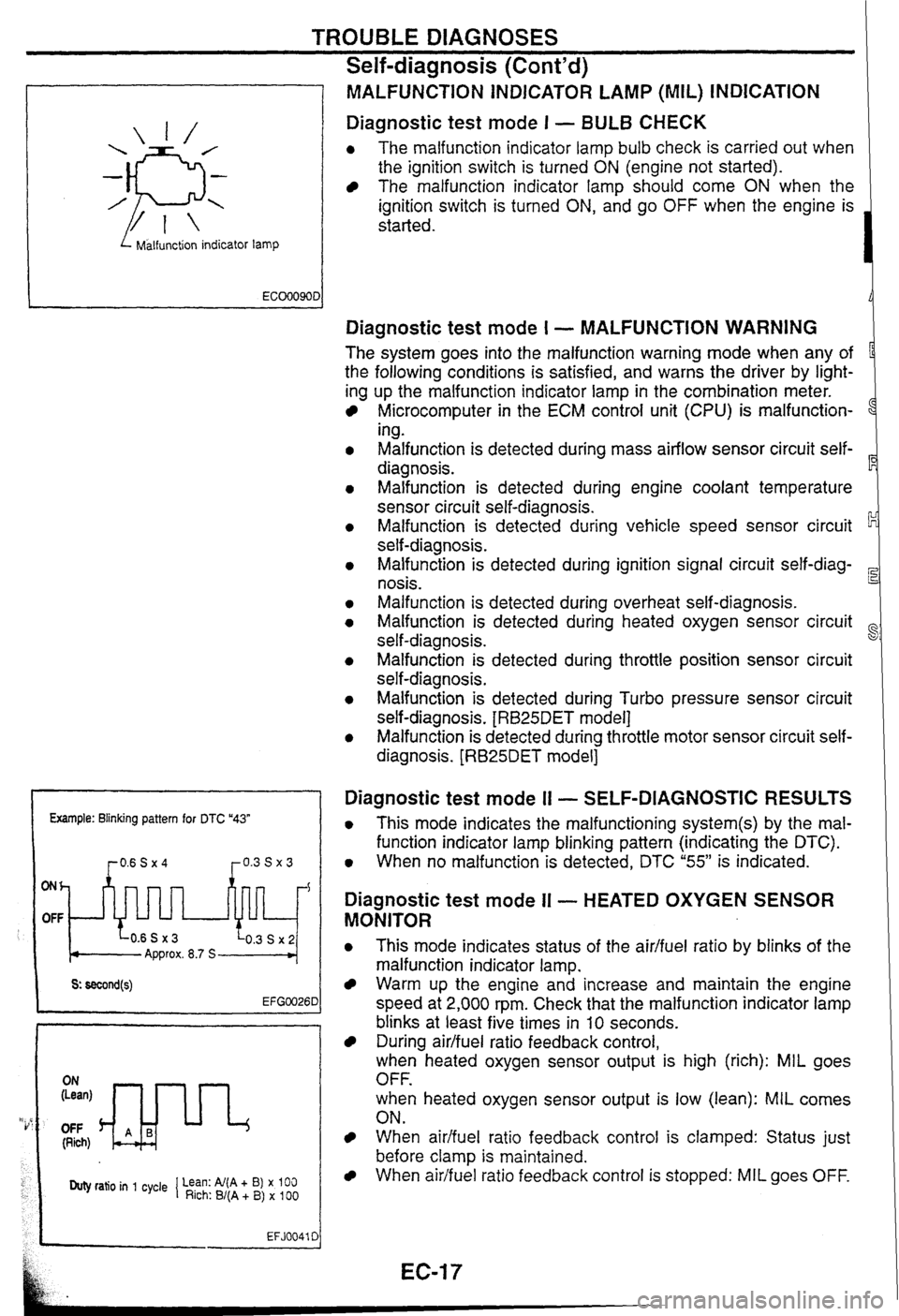

Diagnostic test mode I - BULB CHECK

0 The malfunction indicator lamp bulb check is carried out when

the ignition switch is turned

ON (engine not started).

The malfunction indicator lamp should come ON when the

ignition switch is turned

ON, and go OFF when the engine is

started.

Example: Blinking pattern for DTC "43"

ONh

OFF

Approx. 8.7 S

OFF (Rich)

Duty ratio in 1 cycle 1 Lean: Al(A + B) x 100 Rich: B/(A + B) x 100

EFJ0041 C

Diagnostic test mode I - MALFUNCTION WARNING

The system goes into the malfunction warning mode when any of

the following conditions is satisfied, and warns the driver by light-

ing up the malfunction indicator lamp in the combination meter.

Microcomputer in the ECM control unit (CPU) is malfunction-

1

ing.

Malfunction is detected during mass airflow sensor circuit self-

diagnosis.

Malfunction is detected during engine coolant temperature

sensor circuit self-diagnosis.

Malfunction is detected during vehicle speed sensor circuit

self-diagnosis.

Malfunction is detected during ignition signal circuit

self-diag-

nosis.

Malfunction is detected during overheat self-diagnosis.

Malfunction is detected during heated oxygen sensor circuit

self-diagnosis.

~alfunsion is detected during throttle position sensor circuit

self-diagnosis.

Malfunction is detected during Turbo pressure sensor circuit

self-diagnosis.

[RB25DET model]

Malfunction is detected during throttle motor sensor circuit self-

diagnosis.

[RB25DET model]

Diagnostic test mode I1 - SELF-DIAGNOSTIC RESULTS

0 This mode indicates the malfunctioning system(s) by the mal-

function indicator lamp blinking pattern (indicating the DTC).

0 When no malfunction is detected, DTC "55" is indicated.

Diagnostic test mode II - HEATED OXYGEN SENSOR

MONITOR

0 This mode indicates status of the aidfuel ratio by blinks of the

malfunction indicator lamp.

Warm up the engine and increase and maintain the engine

speed at 2,000 rpm. Check that the malfunction indicator lamp

blinks at least five times in

10 seconds.

During airlfuel ratio feedback control,

when heated oxygen sensor output is high (rich): MIL goes

OFF.

when heated oxygen sensor output is low (lean):

MIL comes

ON.

When aidfuel ratio feedback control is clamped: Status just

before clamp

is maintained.

When airifuel ratio feedback control is stopped: MIL goes OFF.

Page 25 of 230

TROUBLE DIAGNOSES

Self-diagnosis

(Cont'd)

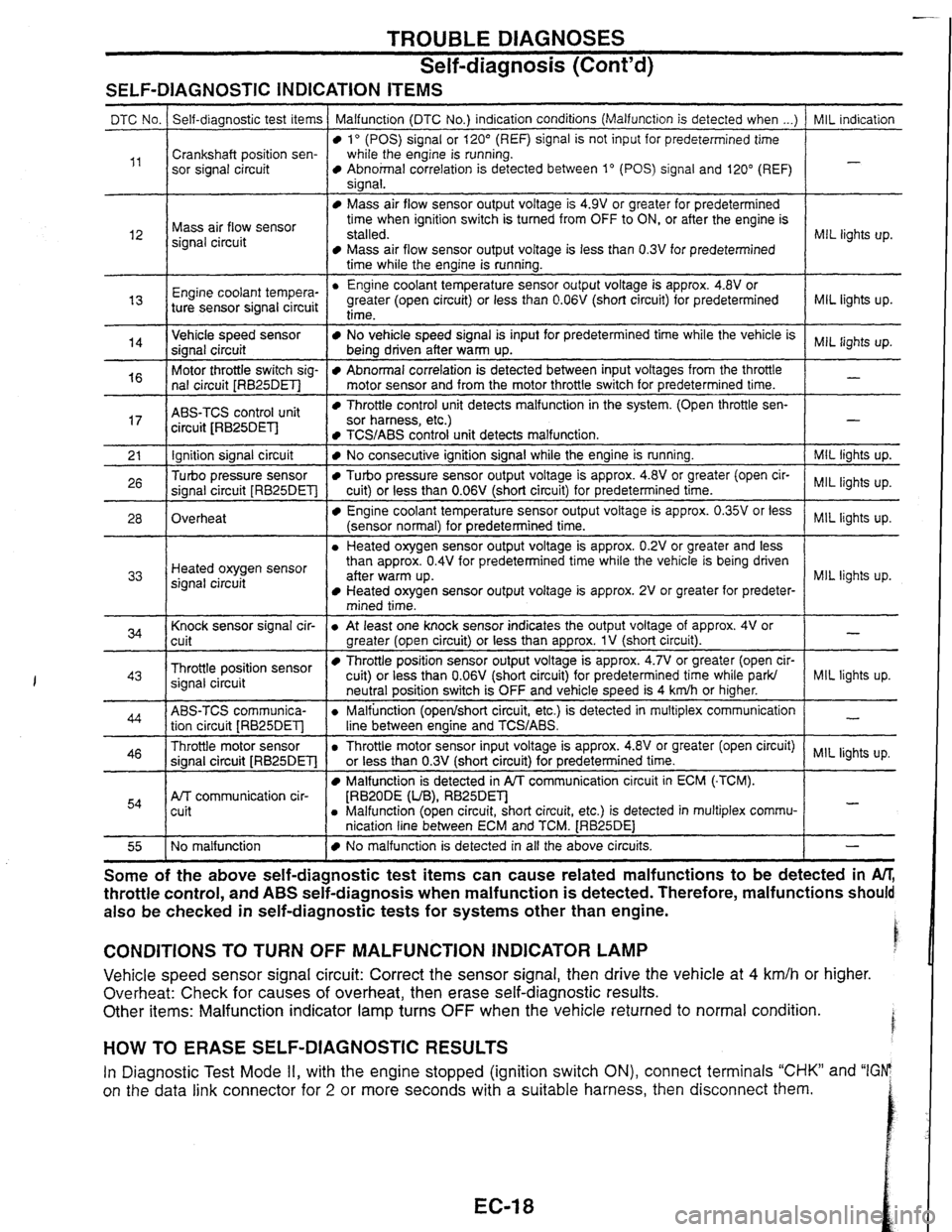

SELF-DIAGNOSTIC INDICATION ITEMS

I time while the engine is running. I

MIL indication

-

DTC No.

,,

MIL lights up. l2

Self-diagnostic test items

Crankshaft position sen-

sor signal circuit Malfunction (DTC No.)

indication conditions (Malfunction is detected when ...)

lo (POS) signal or 120" (REF) signal is not input for predetermined time

while the engine is running.

Abnohal correlation is detected between 1" (POS) signal and 120" (REF)

sianal.

Mass air flow sensor

signal circuit

MIL lights up.

Engine coo'ant tempera-

"

Mass air flow sensor output voltage is 4.9V or greater for predetermined

time when ignition switch is turned from OFF to ON, or after the engine is

stalled.

Mass air flow sensor output voltage is less than 0.3V for predetermined

Engine coolant temperature sensor output voltage is approx.

4.8V or

greater (open circuit) or less than

0.06V (short circuit) for predetermined

MIL lights up.

-

14

ABS-TCS control unit

circuit JRB25DEl-l

ture sensor signal circuit Throttle control unit detects malfunction

in the system. (Open throttle sen- sor harness, etc.)

Ignition signal circuit

Turbo pressure sensor

signal circuit

[RB25DET]

Overheat

I 1 mined time. I

time-

Vehicle speed sensor

signal circuit

Motor throttle switch sig-

nal circuit

[RB25DET]

TCS/ABS control unit detects malfunction. 1 -

I Knock sensor signal cir-

cuit

- --

No vehicle speed signal is input for predetermined time while the vehicle is

being driven after warm up.

Abnormal correlation is detected between input voltages from the throttle

motor sensor and from the motor throttle switch for predetermined time.

I

MIL lights up. Heated oxygen sensor

signal circuit

Throttle position sensor

signal circuit

No consecutive ignition signal while the engine is running.

Turbo pressure sensor output voltage is approx. 4.8V or greater (open cir-

cuit) or less than

0.06V (short circuit) for predetermined time.

Engine coolant temperature sensor output voltage is approx. 0.35V or less

(sensor normal) for predetermined time.

a Heated oxygen sensor output voltage is approx. 0.2V or greater and less

than approx.

0.4V for predetermined time while the vehicle is being driven

aner warm up. Heated oxygen sensor output voltage is approx. 2V or greater for predeter-

ABS-TCS communica- tion circuit

[RB25DET]

Throttle motor sensor

signal circuit

[RB25DET]

Afr communication cir-

cuit

MIL lights up.

lights

up.

MIL lights up.

NQ malfunction

I a At least one knock sensor indicates the output voltage of approx. 4V or

greater (open circuit) or less than approx.

1V (short circuit).

Throttle position sensor output voltage is approx. 4.7V or greater (open cir-

cuit) or less than

0.06V

(short circuit) for predetermined time while ark/

a Throttle motor sensor input voltage is approx. 418~or greater (open circuit) MIL lights up.

or less than

0.3V

(short circuit) for predetermined time. I

-

MIL liqhts up. neutral position switch is OFF and vehicle speed is 4 kdh or higher.

a Malfunction (openlshort circuit, etc.) is detected in multiplex communication

line between enaine and

TCWABS.

Malfunction is detected in PA communication circuit in ECM (-TCM).

[RBZODE (UB), RB25Dm a Malfunction (open circuit, short circuit, etc.) is detected in multiplex commu-

nication line between ECM and TCM.

[RB25DE1

-

-

No malfunction is detected in all the above circuits. I - - --

Some of the above ~elfaia~nostic test items can cause related malfunctions to be detected in M,

throttle control, and ABS seif-diagnosis when malfunction is detected. Therefore, malfunctions should

also be checked in self-diagnostic tests for systems other than engine.

CONDITIONS TO TURN OFF MALFUNCTION INDICATOR LAMP

Vehicle speed sensor signal circuit: Correct the sensor signal, then drive the vehicle at 4 km/h or higher.

Overheat: Check

for causes of overheat, then erase self-diagnostic results.

Other items: Malfunction indicator lamp turns

OFF when the vehicle returned to normal condition.

HOW TO ERASE SELF-DIAGNOSTIC RESULTS

In Diagnostic Test Mode II, with the engine stopped (ignition switch ON), connect terminals "CHK" and "IGFP

on the data link connector for

2 or more seconds with a suitable harness, then disconnect them.

Page 27 of 230

TROUBLE DIAGNOSES

CONSULT (Cont'd)

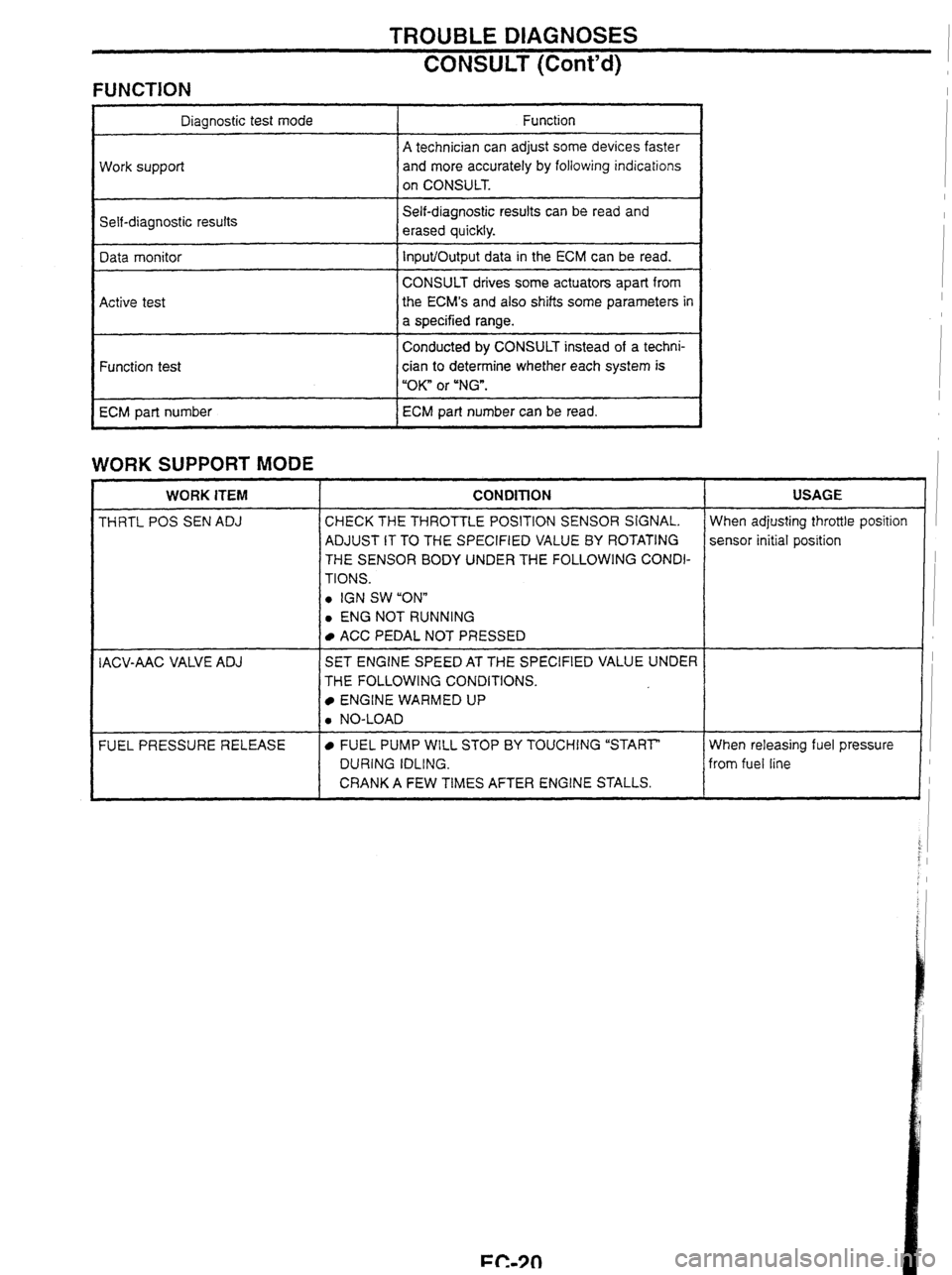

FUNCTION

Self-diagnostic results Diagnostic test mode

Work support

Self-diagnostic resuits can

be read and

erased quickly. Function

A technician can adjust some devices faster

and more accurately by following indications

on CONSULT.

Data monitor

Active test

WORK SUPPORT MODE

Input/Output data in the ECM can be read.

CONSULT drives some actuators apart from

the

ECM's and

also shifts some parameters in

a specified range.

Conducted

by CONSULT instead of a techni-

Function test

ECM part number

WORK ITEM I CONDITION I USAGE

cian to determine whether each system is

"OK" or

"NG".

ECM part number can be read.

THRTL

POS SEN ADJ CHECK THE THROTTLE POSITION SENSOR SIGNAL.

ADJUST IT TO THE SPECIFIED VALUE

BY ROTATING

THE SENSOR BODY UNDER THE FOLLOWING CONDI-

TIONS.

0 IGN SW "ONn

0 ENG NOT RUNNING When adjusting

throttle position

sensor initial position

I ACC PEDAL NOT PRESSED 1 I

IACV-AAC VALVE ADJ I SET ENGINE SPEED AT THE SPECIFIED VALUE UNDER I 1 THE FOLLOWING CONDITIONS.

ENGINE WARMED UP

When releasing fuel pressure I

from fuel line

FUEL

PRESSURE RELEASE

0 NO-LOAD

FUEL PUMP WILL STOP BY TOUCHING "START"

DURING IDLING.

CRANK A FEW TIMES AFTER ENGINE STALLS.

i J

Page 28 of 230

TROUBLE DIAGNOSES m

CONSULT (Cont'd)

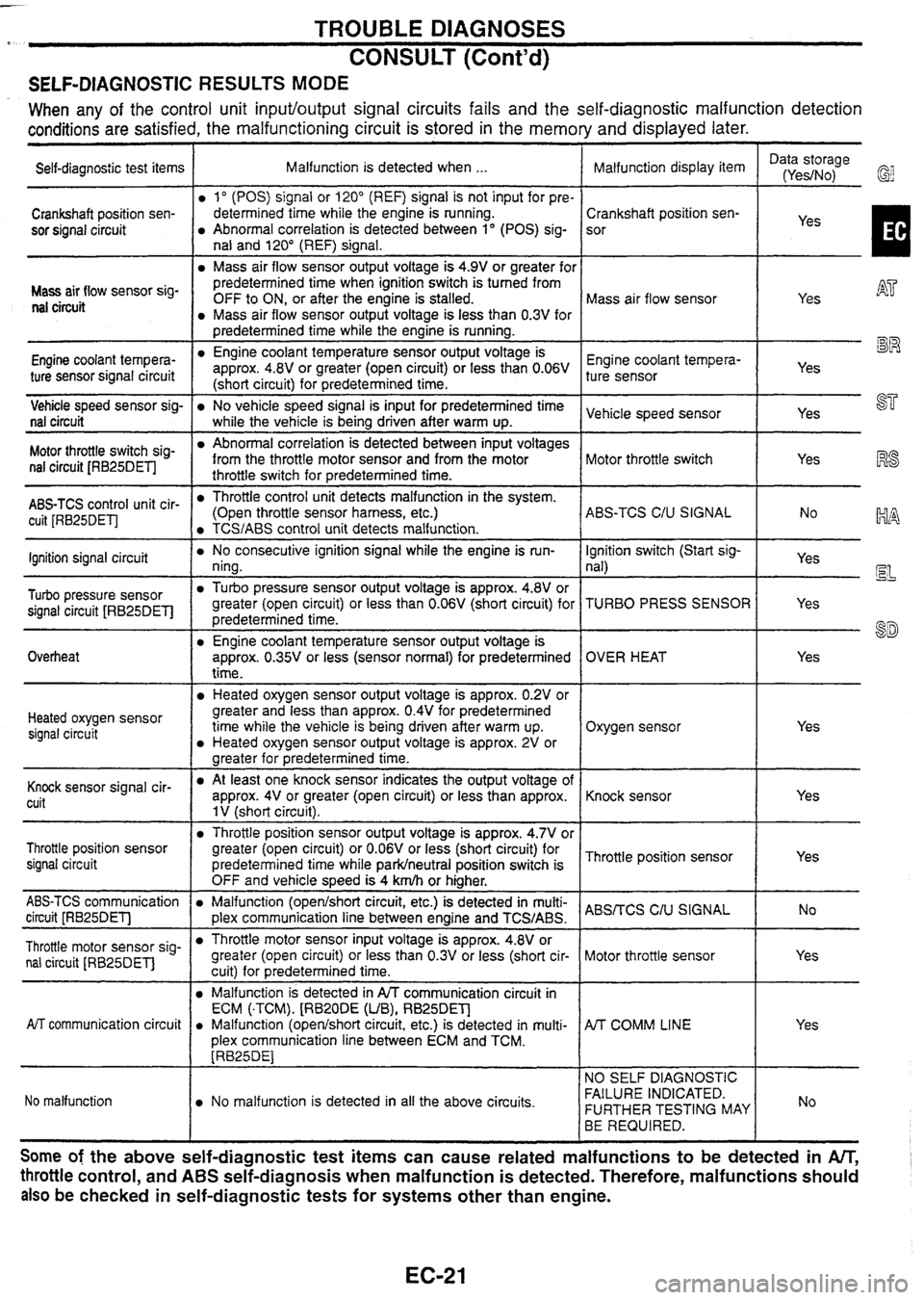

SELF-DIAGNOSTIC RESULTS MODE

When any of the control unit input/output signal circuits fails and the self-diagnostic malfunction detection

conditions

are satisfied, the malfunctioning circuit is stored in the memory and displayed later.

Self-diagnostic test items I Malfunction is detected when ... Data storage

Malfunction display item I (Yes/No,

Crankshaft position sen-

sor signal circuit

I predetermined time while the engine is running. 1 1 mm

Mass air 'low sensor sig- nal circuit

1" (POS) signal or 120" (REF) signal is not input for pre-

determined time while the engine is running.

Abnormal correlation is detected between 1" (POS) sig-

nal and 120" (REF) signal.

Mass air flow sensor output voltage is 4.9V or greater for

Vehicle speed sensor sig-

No vehicle speed signal is input for predetermined time Vehicle speed sensor I I Yes ST nal

circuit I while the vehicle is beina driven after warm UD.

predetermined time when ignition switch is turned from

OFF to ON, or after the engine is stalled.

Mass air flow sensor output voltage is less than 0.3V for

Engine coolant tempera-

ture sensor signal circuit

Crankshaft position sen-

sor

Mass air flow sensor

AT

Yes RS

-.

yes I

Engine coolant temperature sensor output voltage is

approx. 4.8V or greater (open circuit) or less than 0.06V

(short circuit) for predetermined time.

switch sig- nal circuit JRB25DETI

Engine coolant tempera- ture sensor

Abnormal correlation is detected between input voltages

from the throttle motor sensor and from the motor

throttle switch for predetermined time.

ABS-TCS control unit cir- cuit [RB25DETJ

19 L~J

Yes

--

Motor throttle switch

lgnition signal circuit

Turbo pressure sensor

signal circuit [RB25DETl

Overheat

Yes

Throttle control unit detects malfunction in the system.

(Open throttle sensor harness, etc.)

TCS/ABS control unit detects malfunction.

Heated oxygen sensor signal circuit ABS-TCS

C/U SIGNAL

No consecutive ignition

signal while the engine is run-

ning.

Turbo pressure sensor output voltage is approx. 4.8V or

greater (open circuit) or less than

0.06V (short circuit) for

predetermined time.

Engine coolant temperature sensor output voltage is

approx.

0.35V or less (sensor normal) for predetermined

time.

Yes

Heated oxygen sensor output voltage is approx. 0.2V or

greater and less than approx.

0.4V for predetermined

time while the vehicle is being driven after warm up.

Heated oxygen sensor output voltage is approx. 2V or

greater for medetermined time.

Knock cuit lgnition

switch (Start sig-

nal)

TURBO PRESS SENSOR

OVER HEAT

Oxygen sensor

Yes Yes

EL

Yes

8D

Yes

At

least one knock sensor indicates the output voltage of

approx. 4V or greater (open circuit) or less than approx.

1 V (short circuit).

Throttle position sensor

signal circuit

ABS-TCS communication

Malfunction (openlshort circuit, etc.) is detected in multi- ABSrrCS C,u circuit [RB25DETl 1 plex communication line between enaine and TCS/ABS. I

Knock sensor

Throttle position sensor output voltage is approx. 4.7V or

greater (open circuit) or

0.06V or less (short circuit) for

predetermined time while

parkheutral position switch is

OFF and vehicle

s~eed is 4

km/h or hiaher. Thronle

position sensor

Throttle motor sensor sig- nal circuit

[RB25DET] Yes

AiT communication

circuit

Yes

Throttle motor sensor input voltage is approx. 4.8V or

greater (open circuit) or less than

0.3V or less (short cir-

cuitl for

redetermined time.

No malfunction Motor

throttle sensor

Malfunction is detected in A/T communication circuit in

ECM

(.TCM).

(RB2ODE

(UB), RB25DET]

a Malfunction (opedshort circuit, etc.) is detected in multi-

plex communication line between ECM and TCM.

[RB25DE1

No malfunction is detected in all the above circuits.

A/T COMM LINE

NO SELF DIAGNOSTIC

FAILURE INDICATED.

FURTHER TESTING MAY

BE REQUIRED.

Some of the above self-diagnostic test items can cause related malfunctions to be detected in An;

throttle control, and ABS self-diagnosis when malfunction is detected. Therefore, malfunctions should

also

be checked in self-diagnostic tests for systems other than engine.

Page 31 of 230

TROUBLE DIAGNOSES

CONSULT (Cont'd)

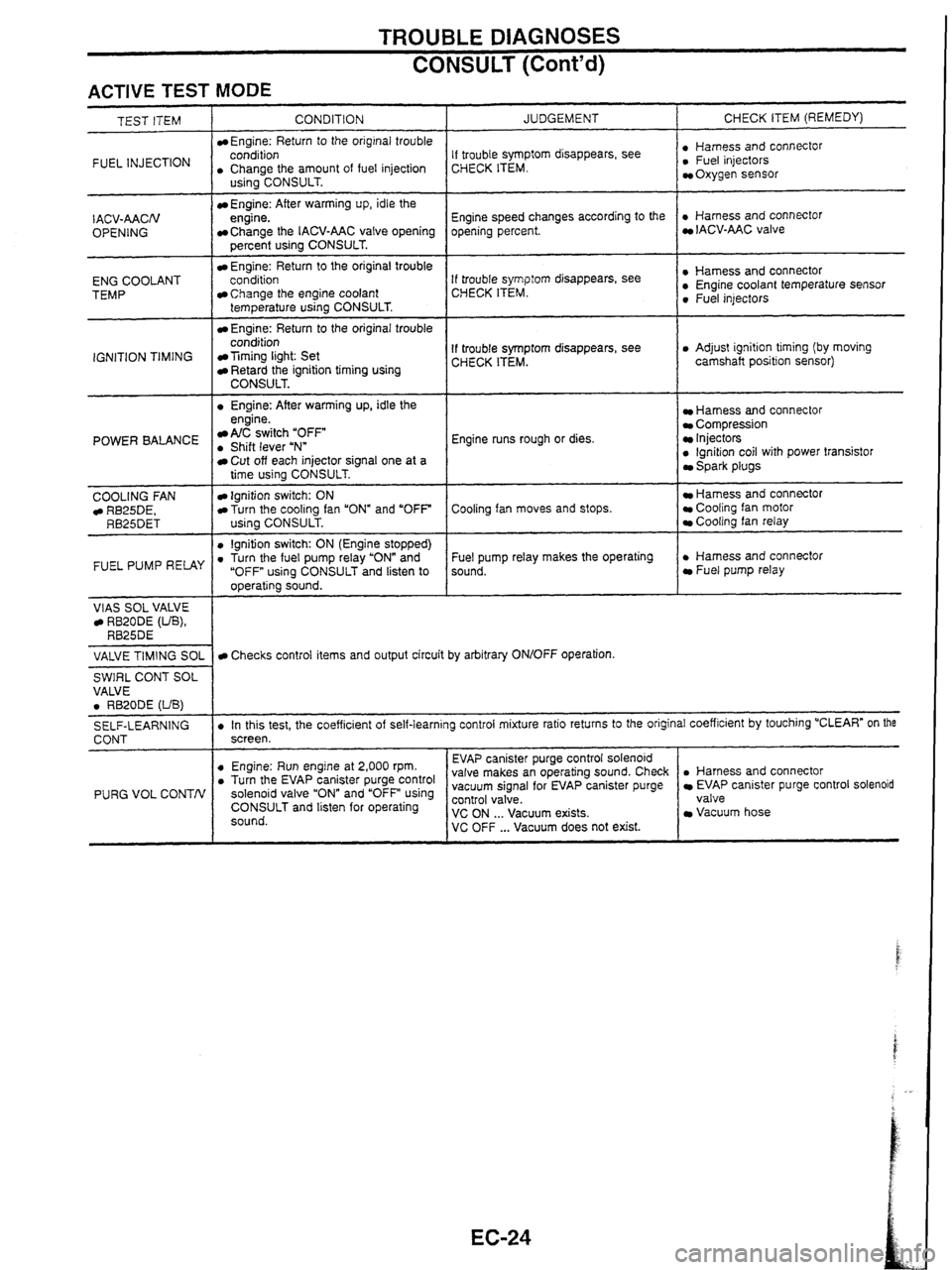

ACTIVE TEST MODE

INJECTION I . CCohArthe amount of fuel injection

TEST ITEM

CONDITION

Engine: Return

to the original trouble

- I . Engine: After warming up, idle the

IACV-AACN

OPENING

ENG COOLANT

TEMP

IGNITION TIMING

US~~~CONSULT.

Engine: After warming up, idle the

engine.

Change the IACV-AAC valve opening

percent using CONSULT.

Engine: Return to the original trouble

conditioo

Change the engine coolant

temperature using CONSULT.

Engine: Return to the original trouble

condition

Timing light: Set Retard the ignition timing using CONSULT.

POWER BALANCE engine. A/C switch "OFF . Shift lever uNn

COOLING

FAN RB25DE, RB25DET

FUEL PUMP RELAY

VlAS SOL VALVE RB20DE (UB), RB25DE

JUDGEMENT

Cut off each injector signal one at a

time using CONSULT.

Ignition switch: ON Turn the cooling fan "ON" and "OFF

using CONSULT.

0 lgnition switch: ON (Engine stopped) . Turn the fuel pump relay "ON" and

"OFF using CONSULT and listen to

operating sound. CHECK

ITEM (REMEDY)

If trouble symptom disappears, see

CHECK ITEM. : ~,"~~,,,~scOnnectOr Oxygen sensor

Engine speed changes according to the

opening percent.

. Harness and connector IACV-AAC valve

If trouble

symp:orn disappears, see

CHECK ITEM. : Sensor 0 Fuel injectors

If trouble symptom disappears, see

CHECK ITEM. 0 Adjust ignition timing (by moving

camshaft position sensor)

Engine runs rough or dies.

Harness and connector Compression Injectors 0 lgnition coil with power transistor Spark plugs

Cooling fan moves and stops.

Hamess and connector Cooling fan motor Cooling fan relay

Fuel pump relay makes the operating

sound.

. Harness and connector Fuel pump relay

VALVE

TIMING

SOL

SWIRL CONT SOL

VALVE

0 RB20DE (UB)

SELF-LEARNING

CONT

PURG VOL CONTN

Checks control items and output circuit by arbitrary ON/OFF operation.

. In this test, the coefficient of self-learning control mixture ratio returns to the original coefficient by touching "CLEAR" on the

screen.

. Harness and connector EVAP canister purge control solenoid

valve

Vacuum hose

0 Engine: Run engine at 2,000 rpm. . Turn the EV~P canister purge control solenoid valve and using CONSULT and listen for operating

sound. EVAP

canister purge control solenoid

valve makes an operating sound. Check

vacuum signal for EVAP canister purge ~~~~~~a'cuum exists. VC OFF ... Vacuum does not exist.

Page 33 of 230

TROUBLE DIAGNOSES t i

CONSULT (Cont'd) i

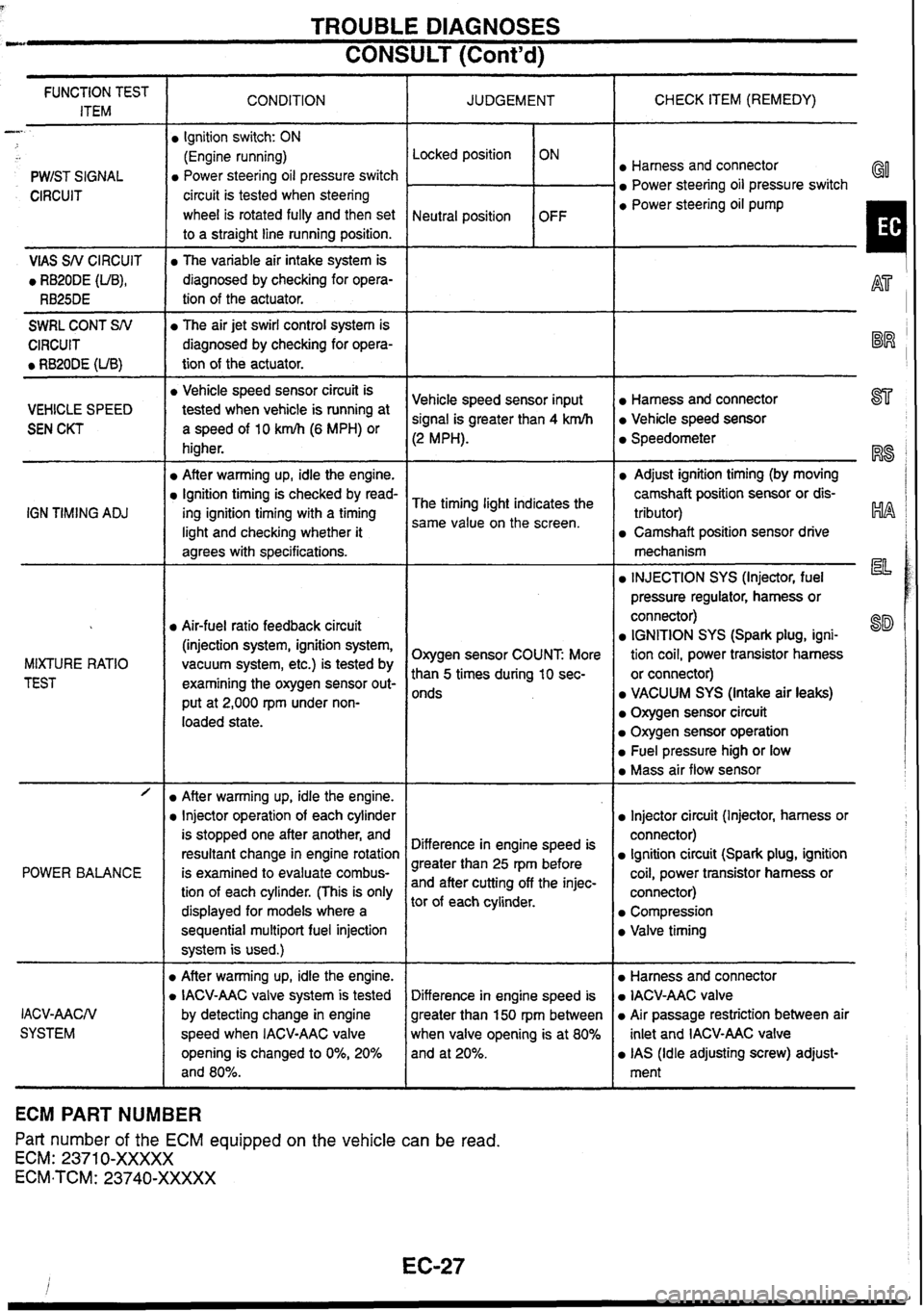

FUNCTION TEST MODE

CHECK ITEM (REMEDY)

FUNCTION

TEST

ITEM JUDGEMENT

CONDITION

lgnition switch: ON

(Engine stopped)

Displays the results of on board

diagnostic system.

SELF-DIAG

RESULTS Objective

system

--

ignition switch: ON

(Engine stopped)

Throttle position sensor circuit is

tested when throttle is opened and

closed fully. ("IDLE POSITION" is

the test item name for the vehicles

in which idle is selected by throttle

position sensor.) Harness and connector

Throttle position sensor (Closed

throttle position)

Throttle position sensor (Closed

throttle position) adjustment

Throttle linkage

Venfy operation in DATA

MONITOR mode.

Throttle

valve:

opened OFF

ON

CLOSED THROTTLE

POSl Throttle valve:

closed

lgnition switch: ON

(Engine stopped)

Throttle position sensor circuit is

tested when throttle is opened and

closed fully.

Harness and connector

Throttle position sensor

Throttle position sensor

adjustment

Throttle linkage

Verify operation in DATA

MONITOR mode.

Range

(Throttle

valve fully opened

- Throttle valve

fully closed) More

than 3.0V THROTTLE POSl

SEN CKT

lgnition switch: ON

(Engine stopped)

Neutral position switch circuit is

tested when shift lever is

manipulated.

lgnition switch: ON

(Engine stopped)

Fuel pump circuit is tested by

checking the pulsation in fuel

pressure when fuel tube is

pinched. Out of

N/P

positions OFF

Harness

and connector

Neutral position switch

Linkage adjustment

PARWNEUT POSl SW CKT

In

N/P positions

Harness and connector

Fuel pump

Fuel pump relay

Fuel filter clogging

Fuel level

There

is pressure pulsation on

the fuel feed hose.

FUEL PUMP

CIRCUIT

--

The valve timing control system is

diagnosed by checking for

operating sound of the solenoid

valve.

lgnition switch: ON

(Engine stopped)

Cooling fan circuit is tested when

cooling fan is rotated.

VALVE

TIMING

SN

CKT

Harness and connector

Cooling fan motor

Cooling fan relay

COOLING

FAN

CIRCUIT RB25DE, RB25DET

The cooling fan rotates and

stops every

3 seconds.

lgnition switch: ON -+ START

Start signal circuit is tested when

engine is started by operating the

starter. Battery voltage and water

temperature before cranking, and

average battery voltage, mass air

flow sensor output voltage and

cranking speed during cranking

are displayed.

Harness and connector

lgnition switch

START

SIGNAL

CIRCUIT Start

signal: OFF 3 ON

Page 34 of 230

TROUBLE DIAGNOSES

CONSULT (Cont'd) --

CHECK ITEM (REMEDY)

FUNCTION TEST

ITEM CONDITION

JUDGEMENT

-

PWIST SIGNAL Locked position

Neutral position

Ignition

switch: ON

(Engine running)

Power steering oil pressure switch

circuit is tested when steering

wheel is rotated fully and then set

to a straight line running position. ON

OFF Harness and connector

Power steering oil pressure switch GO

CIRCUIT a Power steering oil pump

I VlAS SN CIRCUIT

0 RB20DE (UB),

RB25DE

The variable air intake system is

diagnosed by checking for opera-

tion of the actuator.

-

SWRL CONT SN

CIRCUIT

0 RB20DE (UB)

The air jet swirl control system is

diagnosed by checking for opera-

tion of the actuator.

-- -- -

a Vehicle speed sensor circuit is

tested when vehicle

is running at

a speed of 10 km/h (6 MPH) or

higher.

After warming up, idle the engine.

Ignition timing is checked by read-

ing ignition timing with a timing

light and checking whether it

agrees with specifications.

Harness and connector 877

Vehicle speed sensor

Vehicle

speed sensor input

signal is greater than 4 krnlh

(2 MPH).

VEHICLE SPEED

SEN CKT Speedometer

RS

Adjust ignition timing (by moving

camshaft position sensor or dis-

tributor)

HA

Camshaft position sensor drive

The

timing light indicates the

same value on the screen.

IGN

TIMING

ADJ

mechanism

la INJECTION SYS (Injector, fuel

pressure regulator, harness or

connector)

IGNITION SYS (Spark plug, igni-

tion coil, power transistor harness

or connector)

VACUUM SYS (Intake air leaks)

Oxygen sensor circuit

Oxygen sensor operation

Fuel pressure high or low

Mass air flow sensor

Air-fuel ratio feedback circuit

(injection system, ignition system,

vacuum system, etc.) is tested by

examining the oxygen sensor out-

put at 2,000

rpm under non-

loaded state. Oxygen sensor COUNT

More

than

5 times during 10 sec-

onds

MIXTURE

RATIO

TEST

- -- /

POWER BALANCE

Injector circuit (Injector, harness or

connector)

Ignition circuit (Spark plug, ignition

coil, power transistor harness or

connector)

Compression

Valve timing

After warming up, idle the engine.

Injector operation of each cylinder

is stopped one after another, and

resultant change in engine rotation

is examined to evaluate combus-

tion of each cylinder. (This is only

displayed for models where a

sequential

multipart fuel injection

system is used.)

D After warming up, idle the engine.

D IACV-AAC valve system is tested

by detecting change in engine

speed when IACV-AAC valve

opening is changed to

0%, 20%

and 80%. Difference

in engine speed is

greater than 25 rpm before

and after cutting off the injec-

tor of each cylinder.

Harness and connector

IACV-AAC valve

Air passage restriction between air

inlet and IACV-AAC valve

IAS (Idle adjusting screw) adjust-

ment

Difference

in engine speed is

greater than 150

rpm

between

when valve opening is at 80%

and at 20%.

IACV-AACN

SYSTEM

ECM PART NUMBER

Part number of the ECM equipped on the vehicle

can be read.

ECM: 2371 0-XXXXX

ECM-TCM: 23740-XXXXX