check engine NISSAN GT-R 1998 Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: GT-R, Model: NISSAN GT-R 1998Pages: 230, PDF Size: 12.66 MB

Page 104 of 230

![NISSAN GT-R 1998 Owners Guide

TCS/ABS SYSTEM

Control Unit Input/Output Signal Specifications

(Contd)

THRTL OPENING TAR-

GET

[%]

Display Monitor item

Motor throttle angle con-

dition

TCS

MODET3

TCS OFF LAMP Dat NISSAN GT-R 1998 Owners Guide

TCS/ABS SYSTEM

Control Unit Input/Output Signal Specifications

(Contd)

THRTL OPENING TAR-

GET

[%]

Display Monitor item

Motor throttle angle con-

dition

TCS

MODET3

TCS OFF LAMP Dat](/img/5/57354/w960_57354-103.png)

TCS/ABS SYSTEM

Control Unit Input/Output Signal Specifications

(Cont'd)

THRTL OPENING TAR-

GET

[%]

Display Monitor item

Motor throttle angle con-

dition

TCS

MODET3

TCS OFF LAMP Data monitor I Condition

Specifications

TCS is inoperative.

TCS is operational.

Communication line

cir-

TCS is inoperative.

Number of cylinders to cuit between

TCS/ABS

which fuel is cut off control unit and

I.z /LT TCS is operational.

ECM-TCM or ECM

GEAR

TCS

SW

TCS OFF indicator lamp

TCS OFF indicator lamp

status

1 1 lEi3FF indicator amp

TCS OFF indicator lamp

@

Check item (Reference)

SLlP LAMP

0%

0 - 100%

Gear selection

TCS OFF switch status (ONIOFF)

P/N POSITION SIGNAL Communication line cir-

@

cuit

between TCSIABS

control unit and throttle

control unit

lzc

SLlP indicator lamp is / ow

TCS OFF switch circuit ST

I

1: 1st gear 2: 2nd gear 3: 3rd gear

4: 4th gear 5: 5th gear

SLIP

indicator lamp

sta-

cuit

TCS switch ON

TCS switch OFF

PNP switch signal or

neutral position switch

signal status (ONIOFF) ON

OFF

SLlP indicator lamp is

ON.

( A/T selector position: I I

I %~hift position: I ON

ON

SLIP indicator lamp cir-

1 Other than Neutral I 1

Neutral

A/T selector position:

Other than N and P

MA' shift position:

A/T PNP switch or neu-

tral position switch circuit

OFF

'1: Tire pressure must be in accordance with specification.

'2: ABS warning lamp ON: When the ignition switch is turned ON (before starting the engine) or a malfunction is detected ABS warning lamp OFF: When the engine has started (with the system in normal condition) '3: TCS mode: 0 - 24, number of cylinders to which fuel is cut off x 4

Throttle control unit

THRTL POS SEN

Display

TH MOTOR VOLT Monitor item I Sensor

voltage (V)

Sensor voltage

(V)

Throttle valve is fully

I Approx. 0.5V closed.

Engine is idling.

I

Data monitor

Approx. 3.4V

Condition

TH OPEN CONT Specifications

Motor throttle target

angle signal (ms)

NEUT

POSl

SW

START

SIGNAL

ONIOFF TCS

is inoperative

Shift (selector) lever is in

parkheutral

position. Approx.

9 ms Check

item (Reference)

ON

1

Throttle position sensor

circuit

ONIOFF Throttle motor sensor

circuit

Communication line cir-

cuit between

TCS/ABS

control unit and throttle

control unit

Start signal circuit

ParWneutral position

switch circuit

Ignition switch

ON

I

Page 105 of 230

TCSlABS SYSTEM

Precautions for Trouble

Diagnosis

After performing trouble diagnosis, be sure to erase trouble stored in memory.

Refer to "CONSULT for

TCS/ABS Control Unit Control System"

(BR-27), "Self-diagnosis for TCSIABS

Control Unit Control System"

(BR-34), "CONSULT for Throttle Control Unit Control System" (BR-37) or

"Self-diagnosis for Throttle Control Unit Control System"

(BR-41).

The concerns that are difficult to duplicate may be caused by faulty electrical connections. Move harnesses

or harness connectors by hand to check if there is any poor mating of connector halves or faulty connec-

tion. Do not force to open a connector terminal when using a circuit tester for inspection.

Read GI section thoroughly in advance and make sure of all the general precautions.

Basic Inspection

BASIC INSPECTION 1 - Brake fluid level and leakage

1. Check brake fluid level in reservoir tank. Replenish brake fluid if necessary.

2. Check for leakage at or around brake piping and ABS actuator. If leakage or seepage is noted, proceed

as follows:

If ABS actuator connectors are loose, tighten to specified torque. Recheck to ensure that leakage is no

longer present.

If flare nut threads at piping connectors or actuator threads are damaged, replace faulty parts with new

ones. Recheck to ensure that leakage is no longer present.

If brake fluid leaks through areas other than actuator connectors, wipe off using a clean cloth. Recheck

for leakage or seepage. If necessary, replace faulty parts with new ones.

If brake fluid leaks at or seeps through ABS actuator, wipe off using a clean cloth.

Recheck for leakage or seepage. If necessary, replace ABS actuator with new one.

CAUTION:

ABS actuator cannot be disassembled. Do not attempt to disassemble it.

3. Check brake disc rotors and pads for proper operation.

BASIC INSPECTION 2 - Loose power line terminal

Check battery terminals (positive and negative) and battery mounting (ground) for looseness. If necessary,

tighten to specified torque. Check the battery for lower voltage.

BASIC INSPECTION 3 - SLlP indicator lamp, TCS OFF indicator lamp and ABS warning

lamp

Turn ignition switch "ON" to ensure that TCS OFF indicator lamp lights up. If TCS OFF indicator lamp does

not light, check TCS OFF indicator lamp circuit.

Turn ignition switch

"ON" to ensure that SLlP indicator lamp lights

up. If SLlP indicator lamp does not light,

check SLlP indicator lamp circuit.

Turn ignition switch "ON" to ensure that ABS warning lamp lights up. If ABS warning lamp does not light,

check ABS warning lamp circuit.

Check that the SLlP indicator lamp and the ABS warning lamp go off approx.

1 second after the engine

has started. If either of the lamps still remains on, perform the self-diagnosis for TCSIABS control unit

control system and the self-diagnosis for throttle control unit control system.

After driving vehicle at approx. 30

km/h

for approx.

1 minute, check to ensure that the SLlP indicator lamp

and the ABS warning lamp are off. If either of the lamps still remains on, perform the self-diagnosis for

TCS/ABS

control unit control system and the self-diagnosis for throttle control unit control system.

Check that the TCS OFF indicator lamp turns ON and OFF when the TCS OFF switch is turned to

ON

and OFF respectively, with the engine running. If the lamp status does not correspond to the switch

position, check the TCS OFF switch circuit.

Check that the TCS OFF indicator lamp goes off when the engine has started with the TCS OFF switch

OFF. If the TCS

OFF indicator lamp does not go off even 10 seconds after the engine has started, per-

form the self-diagnosis for TCSIABS control unit control system and the self-diagnosis for throttle control

unit control system.

After driving vehicle at approx.

30 kmlh for approx. 1 minute with the TCS OFF switch OFF, check to ensure

that the TCS OFF indicator lamp is off. If the TCS OFF indicator lamp lights up, perform the

self-diagno-

sis for

TCS/ABS

control unit control system and the self-diagnosis for throttle control unit control system.

After performing self-diagnosis procedures, be sure to erase trouble stored in memory.

Page 106 of 230

TCS/ABS SYSTEM

CONSULT for TCS/ABS Control Unit Control

System

CONTROL UNIT PART NUMBER

The part number that is shown on the control unit label and CON-

SULT

A/T model: 47850 AA310

M/T model: 47850 AA110

SELF-DIAGNOSIS PROCEDURE rn

Collect information on the concern from the customer, and then

perform basic inspections.

Turn ignition switch OFF and connect CONSULT connector to

data link connector for CONSULT on the vehicle.

ST

Start engine and drive vehicle at approx. 30 km/h for approx.

1 minute.

Stop vehicle with engine running and touch "START", "ABS"

38

and "SELF-DIAG RESULTS" sequentially on the CONSULT

screen.

If "START" is touched immediately after engine is started y;rjn

or ignition switch is turned on, "ABS" may not be dis-

played on "SELECT SYSTEM" screen. To display "ABS", E~

repeat the self-diagnosis procedure from the beginning.

Self-diagnosis results are displayed on the screen. (Touch

"PRINT' to print out the self-diagnosis results,

if necessary.) 8~ If "NO FAIL" is displayed, inspect the SLlP indicator lamp, the

TCS OFF indicator lamp and the ABS warning lamp. Refer to

the previous page.

Perform appropriate inspection from the self-diagnostic results

mode and repair or replace faulty parts.

Start engine and drive vehicle at approx.

30 km/h for approx.

1 minute.

Recheck to ensure that there is no other malfunction.

Turn ignition switch OFF to prepare for erasing the trouble

stored in memory.

Start engine and touch "START",

"ABS", "SELF-DIAG

RESULTS" and "ERASE" sequentially on the CONSULT

screen to erase the trouble stored in memory.

If the trouble stored in memory is not erased, repeat step

6.

Drive vehicle at approx. 30 krn/h for approx. 1 minute and then

confirm that the TCS OFF indicator lamp, the

SLlP indicator

lamp, and the ABS warning lamp are OFF.

TCS OFF switch is not in cancel condition.

Page 108 of 230

![NISSAN GT-R 1998 Owners Guide

TCS/ABS SYSTEM

CONSULT

for TCSlABS Control Unit Control

System

(Contd)

Diagnostic item Check item

Diagnostic

item is detected when ...

ABS ACTUATOR RELAY

b~ FAILURE] ABS

actuator rel NISSAN GT-R 1998 Owners Guide

TCS/ABS SYSTEM

CONSULT

for TCSlABS Control Unit Control

System

(Contd)

Diagnostic item Check item

Diagnostic

item is detected when ...

ABS ACTUATOR RELAY

b~ FAILURE] ABS

actuator rel](/img/5/57354/w960_57354-107.png)

TCS/ABS SYSTEM

CONSULT

for TCSlABS Control Unit Control

System

(Cont'd)

Diagnostic item Check item

Diagnostic

item is detected when ...

ABS ACTUATOR RELAY

b~ FAILURE] ABS

actuator relay turns ON when control unit sends OFF signal. Actuator relay is short-

circuited to ground. ABS

actuator

relay and

circuit

ABS

ACTUATOR RELAY

[OFF FAILURE] ABS

actuator relay turns OFF when control unit sends ON signal. Relay control wire is

broken.

BAlTERY VOLTAGE

[VB-IiIGH] TCSIABS

control unit

power supply

and ground

circuit

TCSIABS

control unit battery voltage is abnormally high.

BAlTERY VOLTAGE

[VB-LOW TCSIABS control unit battery voltage is abnormally low.

- -

Function of calculation in TCS/ABS control unit has failed. TCSIABS

control unit

CONTROL

UNIT

ABS motor,

motor relay and circuit

ABS

MOTOR

[LOCK FAILURE] ABS

motor speed is abnormally low.

Engine speed signal is interrupted or signal wire is suspected to be broken.

TCSIABS control unit connector or ECM-TCM or ECM connector is poorly connected. Engine

speed signal circuit

ENGINE

SPEED SIG

Circuit for

the commu-

nication line

between

TCSIABS

control unit

and throttle control unit

The communication line between TCSIABS control unit and throttle control unit is open

or shorted.

Throttle control system (throttle control unit, peripheral harness, and throttle actuator)

is abnormal.

TCSIABS control unit or throttle control unit battery voltage is low.

THROTLE

POSl

SIG

Engine main components (crankshaft position sensor, mass air flow sensor, engine cool-

ant temperature sensor, ignition primary signal, throttle position sensor, and motor throttle

position sensor) are abnormal. Engine sys-

tem

ENGINE SYSTEM

Total control

signal

1

(multiple sig- nal) for

engine,

A/l

and TCSI

ABS

Total control signal (multiple signal) for engine, AIT and TCS/ABS is abnormal (open or

shorted communication harness, faulty connections, abnormal

TCS/ABS control unit or

ECM-TCM or ECM).

TCSIABS control unit power is momentarily cut off or decreased.

LAN

SIGNAL

1

Total control signal (multiple signal) for engine,

and TCS/ABS is abnormal (open or

shorted communication harness, faulty connections, abnormal

TCS/ABS control unit or

ECM.TCM or ECM).

ECM.TCM or ECM starter switch is stuck to ON.

The starter switch is ON for 10 seconds or longer even after the engine has started.

(This is not

a malfunction.)

ECM-TCM or ECM is abnormal. (Total control signal (multiple signal) for engine,

A/T

and TCSIABS is malfunctioning. Or the system is in the process of CPU back up.)

TCSIABS is abnormal. Total

control

signal

2

(multiple sig-

nal) for

engine,

PA

and TCSI

ABS

LAN

SIGNAL

2

LAN SIGNAL 3

Page 109 of 230

TCSfABS SYSTEM

CONSULT for

TCSfABS Control

Unit Control

System (Cont'd)

Diagnostic item

LAN CIRCUIT

1

LAN CIRCUIT 2

Diagnostic item is detected when ... I Check item

NOTE:

If "NO FAILn is displayed as a result of the CONSULT self-diagnosis when the ABS warning lamp is lit, inspect the engine speed

signal circuit.

If "ABSn is not displayed on "SELECT SYSTEM" screen, check ABS control unit and data link connector circuit, and make sure of the CONSULT card number. If "ENGINE SYSTEM", "LAN SIGNAL 1". "LAN SIGNAL 2", "LAN SIGNAL 3, "LAN CIRCUIT 1" or "LAN CIRCUIT 2" is displayed

on the screen, perform the self-diagnosis for the

ECM.TCM

or ECM.

If "THROlTLE CONTROLLER COMMUNICATIONn is displayed on the screen, perform the self-diagnosis for throttle control unit.

Total control signal (multiple signal) for engine, All and TCSIABS is abnormal (open or

shorted communication harness,-faulty connections, abnormal TCSIABS control unit or

ECM.TCM

or ECM).

ECM.TCM

or ECM power is cut

off or decreased for 2 seconds or longer.

Total control signal (multiple signal) for engine,

ArT and TCSIABS is suspected to be

interrupted (open or shorted communication harness, faulty connections, abnormal

TCS/ABS

control unit or ECM TCM or ECM).

ECM.TCM or ECM power is cut off or decreased for 2 seconds or longer.

DATA

a

1.

2.

3.

4.

5.

a

signal 1, 2

(multiple sig-

nal) for

and

TCSI

ABS

MONITOR PROCEDURE

Refer to CONSULT Instruction Manual for details on data

monitor function.

Turn ignition switch OFF.

Connect CONSULT connector to data link connector for

CON-

SU LT.

Turn ignition switch

ON.

Touch "START" on CONSULT screen.

Touch "ABS" on CONSULT screen.

If "START" is touched immediately after engine is started

or ignition switch is turned ON, "ABS" may not be dis-

played on "SELECT SYSTEM" screen. To display "ABS",

repeat the data monitor procedure from the beginning.

Touch "DATA MONITOR".

Touch "SETTING" to set recording condition.

Touch "AUTO TRIG", "LONG TIME" and then

"ENTER".

Return to "SELECT MONITOR ITEM" screen and touch "C/U

INPUT ITEM",

"ALL SIGNALS" or "SELECTION FROM

MENU". Refer to "DATA MONITOR MODE" on the next page.

10. Touch "START".

11. Display data monitor.

12. If necessary, sequentially touch "REC START, "REC STOP",

"DATA DISPLAY", "NUMBER PRINT" and "PRINT" to print out

the data.

Page 113 of 230

TCS/ABS SYSTEM

Self-diagnostic check ter (Terminal 4 of data link c

Data link connector for CONSULT

Self-diagnosis for TCSfABS Control Unit

Control System

SELF-DIAGNOSIS PROCEDURE

1. Collect information on the concern from the customer, and then

perform basic inspections.

2. Drive vehicle at approx. 30 km/h for approx. 1 minute.

3. Stop vehicle and start diagnosis.

4. Turn ignition switch "OFF.

5. Ground the self-diagnostic check terminal 4 on the data link

connector for CONSULT.

6. Turn ignition switch "ON" to start the self-diagnostic results

mode.

CAUTION:

Keep terminal 4 grounded during self-diagnosis. Do not

depress brake pedal. Do not start engine. (Self-diagnosis

would

not start.)

When SLlP indicator lamp does not start blinking, check

TCSfABS

control unit power supply circuit and ground

circuit.

7. The SLlP indicator lamp starts blinking to indicate the malfunc-

tion code No.

3 or 4 seconds after the self-diagnostic results

mode is started.

The indication terminates after 5 minutes. Turning the igni-

tion switch from

"OFF" to "ON" resumes blinking the indi-

cation.

During the SLIP indicator lamp operation shown above,

TCS

OFF indicator lamp and ABS warning lamp are lit.

8. Vsrify the location of the malfunction with "MALFUNCTION

CODUSYMPTOM

CHART", BR-36. Then make the necessary

repairs.

9. After the malfunctions are repaired, erase the malfunction

codes stored

in the control unit. Refer to "HOW TO ERASE

SELF-DIAGNOSTIC RESULTS on the next page.

10. Rerun the self-diagnostic results mode to verify that the mal-

function codes have been erased.

When the malfunction codes have been erased, the start

code is only indicated.

11. Disconnect the check terminal from the ground. The self-diag-

nostic results mode is now complete.

12. Drive vehicle at approx. 30 km/h for approx. 1 minute, and then

check that the

TCS OFF indicator lamp, the SLlP indicator

lamp and the ABS warning lamp are OFF.

HOW TO READ SELF-DIAGNOSTIC RESULTS

(Malfunction codes)

Determine the code No. by observing the time and the fre-

quency that the SLlP indicator lamp flashes ON and OFF.

Refer to the next page.

When multiple malfunctions occur at a time, up to three code

numbers can

be stored; the latest malfunction will be indicated

first.

The indication begins with the start code No. 12. After that a

maximum of three code numbers appear in the order of the

latest one first. The indication then returns to the start code No.

12 to repeat.

The start code No.

12 is only indicated repeatedly when there

is no malfunction.

Page 114 of 230

TCS/ABS SYSTEM

Self-diagnosis for TCS/ABS Control Unit

control System (Cont'd)

Example: Code No. 25 Front left wheel sensor (open-circutt)

lnd~cat~on

start Start code No.

12

HOW TO ERASE SELF-DIAGNOSTIC RESULTS

(Malfunction codes)

1. Turn the ianition switch "ON" and start the engine.

ABS warnlng lamp - ON

ABS warning lamp

OFF

2. Drive the iehicle at approx. 30 km/h for appfox. 1 minute to

check that there

is no other malfunction.

3. Stop the vehicle and turn the ignition switch "OFF'. I88

4. Ground the self-diagnostic check terminal 4 on the data link

connector for CONSULT.

5. Turn the ignition switch "ONn to start the self-diagnostic results /,%@A

mode.

I---------- -------------- -?-I 3 06 0.9 03C303 3 3 06 3.6 06 09 030303030303030303

Unit: seconds BRG1185D

Tens drglts Units drgits Code No. 25

I -----l

7. Under the self-diagnostic results mode, the malfunction

memory erase mode starts when the check terminal

is discon-

nected from the ground.

8. Ground the check terminal 3 times or more in succession

-.

self-d~agnosts complete

SLlP ndicator lamp i

I ON r

f OFF - c 4 i

ground J Erase -- - - - - - - - - -i - - - - ---f2.i geconds-- - - - - - - .. t mode

Malfunct~on

memory

Malfunct~on

memory

IS erase mode starts. 1s erased. BRZOO~~D

within 12.5 seconds after the erase mode starts. (Each ground-

ing must be

2 seconds or longer.)

9. Disconnect the grounding cable from the check terminal to

erase the malfunction memory and complete the

self-diagno-

-----

CAUTION:

Keep terminal 4 grounded during self-diagnosis. Do not EL

depress the brake pedal during self-diagnosis. Do not start the

engine.

6. The SLIP indicator lamp starts blinking to indicate the malfunc- SD

tion code No. 3 or 4 seconds after the self-diagnostic results

mode is started.

The indication terminates after 5 minutes. Turning the igni-

tion switch from

"OFF" to "ON" resumes blinking the indi-

cation. During the SLlP indicator lamp operation shown

above,

TCS OFF indicator lamp and ABS warning lamp are

lit.

sis.

10. Rerun the self-diagnostic results mode to verify that the mal-

function codes have been erased.

0 When the malfunction codes have been erased, the start

code No.

12 is only indicated.

11. Disconnect the check terminal from the ground. The self-diag-

nostic results mode is now complete.

12. Drive vehicle at approx. 30 kdh for approx. 1 minute, and then

check that the

TCS OFF indicator lamp, the SLlP indicator

lamp

and the ABS warning lamp are OFF.

13. Turn the ignition switch "OFF.

Page 115 of 230

TCS/ABS SYSTEM

Self-diagnosis for TCSfABS Control Unit

Control System (Cont'd)

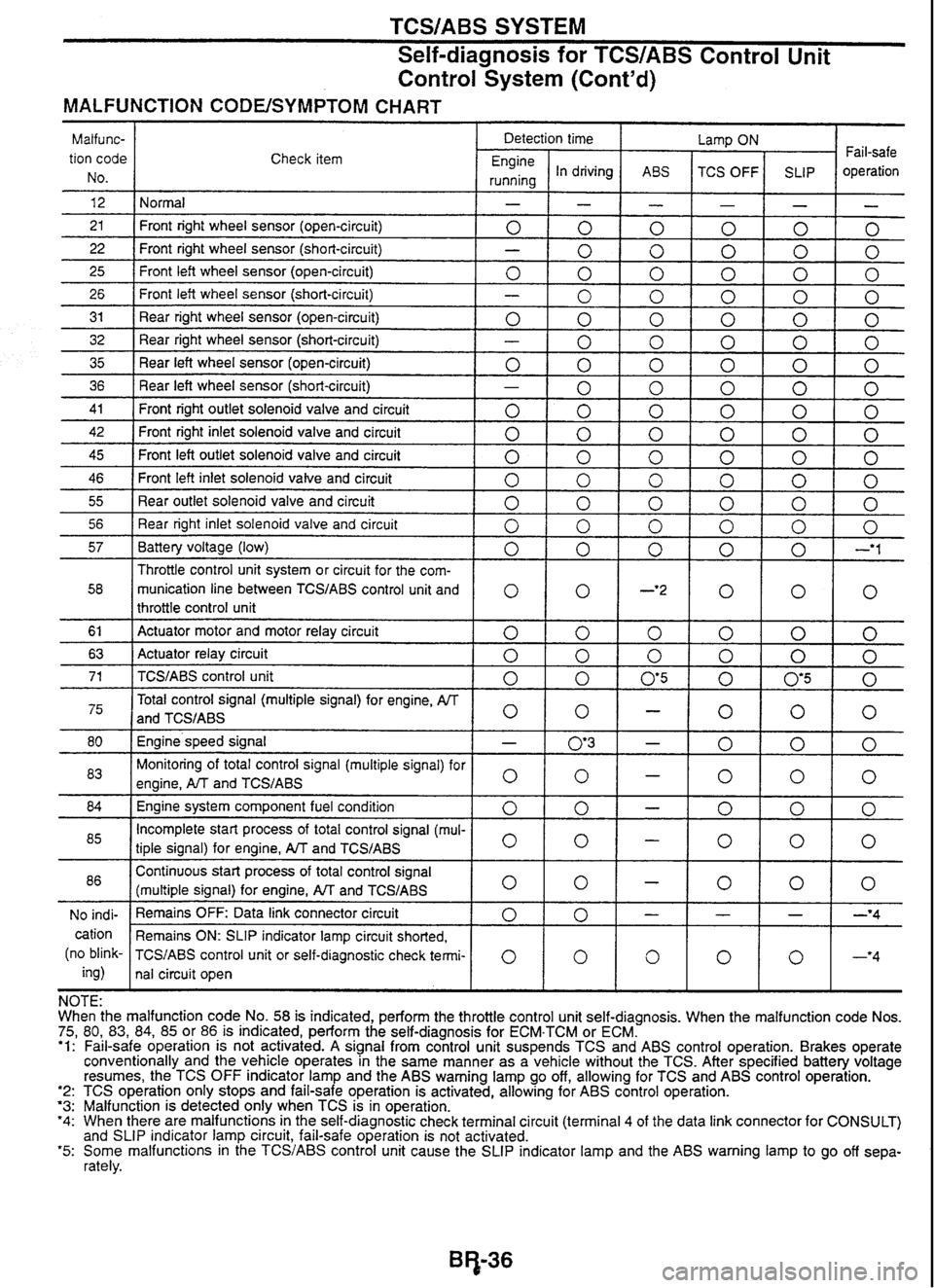

MALFUNCTION CODE/SYMPTOM CHART I I I

75, 'I:

'2: '3: '4:

'5:

Fail-safe operation is not activated. A signal from control unit suspends TCS and ABS control operation. Brakes operate

conventionally and the vehicle operates in the same manner as a vehicle without the TCS. After specified battery voltage

resumes, the TCS

OFF indicator lamp and the ABS warning lamp go off, allowing for TCS and ABS control operation.

TCS operation only stops and fail-safe operation is activated, allowing for ABS control operation.

Malfunction is detected only when TCS is in operation.

When there are malfunctions in the self-diagnostic check terminal circuit (terminal

4 of the data link connector for CONSULT)

and SLlP indicator lamp circuit, fail-safe operation is not activated.

Some malfunctions in the

TCS/ABS

control unit cause the SLlP indicator lamp and the

ABS warning lamp to go off sepa-

rately.

Malfunc-

tion code

No.

12

21 22

25

26

31

32

35

36

41

42

45

46

55

56

57

58

61

63

71

75

80

83

84

85

86

NO indi-

cation

(no blink-

ing)

NOTE:

When the

80, 83,

84, 85 or 86 is indicated, perform the self-diaqnosis for ECM-TCM or ECM.

Check

item

Normal

Front right wheel sensor (open-circuit)

Front right wheel sensor (short-circuit)

Front left wheel sensor (open-circuit)

Front left wheel sensor (short-circuit)

Rear right wheel sensor (open-circuit)

Rear right wheel sensor (short-circuit)

Rear left wheel sensor (open-circuit)

Rear left wheel sensor (short-circuit)

Front right outlet solenoid valve and circuit

Front right inlet solenoid valve and circuit

Front left outlet solenoid valve and circuit

Front left inlet solenoid valve and circuit

Rear outlet solenoid valve and circuit

Rear right inlet solenoid valve and circuit

Battery voltage (low)

Throttle control unit system or circuit for the corn-

munication

line between TCSIABS control unit

and

throttle control unit

Actuator motor and motor relay circuit

Actuator relay circuit

TCSIABS

control

unit

Total control signal (multiple signal) for engine,

IVT

and TCS/ABS

Engine speed signal

Monitoring of total control signal (multiple signal) for

engine,

AfT and TCS/ABS

Engine system component fuel condition

Incomplete start process of total control signal (mul-

tiple signal) for engine,

AfT and TCSIABS

Continuous start process of total control signal

(multiple signal) for engine, and

TCS/ABS

Remains OFF: Data link connector circuit

Remains ON: SLIP indicator lamp circuit shorted,

TCSIABS

control unit or self-diagnostic check termi-

nal circuit open

malfunction code No. 58 is indicated, perform the Detection

Engine

running

-

0 -

0

-

0 -

0 -

0

0

0

0

0

0

0

0

0

0

0

0

-

0

0

0

0

0

0

throttle control time

In driving

-

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0 -

0'3

0

0

0

0

0

0

unit

a Fail-safe

operation

-

0

0

0

0

0

0

0

0

0

0

0

0

0

0

-'I

0

0

0

0

0

0

0

0

0

0

-'4

-'4

code Nos.

ABS

-

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

-*2

0

0

05

-

-

-

-

-

-

-

0

self-diagnosis. Lamp

ON

TCS OFF

-

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

-

0

When the SLlP

-

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0'5

0

0

0

0

0

0

-

0

malfunction

Page 117 of 230

TCSIABS SYSTEM

CONSULT for Throttle Control Unit Control

System (Cont'd)

SELF-DIAGNOSTIC RESULTS MODE

- - Diagnostic item I Diagnostic item is detected when ... I Check item

THROTTLE

POSl

SEN

THROTTLE MOTOR Throttle

position sensor signal output is abnormally high or

continues to stay low for a certain period of time.

I

Throttle motor sensor signal output is abnormally high or con-

tinues to stay low for

a certain period of time. 1 Throttle motor sensor and circuit

Throttle

position sensor circuit

THRTL OPEN TRGET

THROTTLE ACTUATOR

RLY 1 Throttle motor relay is short-circuited.

[SHORT] Circuit

for throttle motor target angle signal (DKR line) is open

or shorted. TCS/ABS control unit

is abnormal.

Circuit for the communication

line between the throttle control

Throttle motor operation

does not accord with the throttle

motor target angle.

Throttle motor and circuit

I

ENGINE START SIG unit

and the TCSIABS control

unit

1 THROTTLE MOTOR

THROlTLE MOTOR RLY

[OPEN]

I Start signal is not correctiy entered due to short.

Overcurrent

is applied to the throttle motor drive circuit. I

Start signal circuit and

ECM-TCM or

ECM

Throttle motor relay is open.

Throttle motor relay and circuit

connector for

NEUTRAL POSl SW

DATA MONITOR PROCEDURE

Refer to CONSULT Instruction Manual for details on data

monitor function.

Turn ignition switch OFF.

Connect CONSULT connector to data link connector for

CON-

SU LT.

Turn ignition switch ON.

Touch "START' on CONSULT screen.

Touch ''THROTTLE CONTROL" on CONSULT screen.

Touch "DATA MONITOR".

Touch "SETTING" to set recording condition.

Touch one key from

"AUTO TRIG", "MANUAL TRIG" and

"SPECIAL", and then touch "LONG

TIME".

With "AUTO TRIG" selected, the data is automatically recorded

if a malfunction occurs during the data monitor. With "SPE-

CIAL" selected, the data is automatically recorded when TCS

is activated.

Touch "ENTER".

Return to

"SELECT MONITOR ITEM" screen and touch "ALL

SIGNALS". Display data monitor.

If necessary, sequentially touch "REC START', "REC STOP",

"DATA DISPLAY", "NUMBER

PRINT'

and "PRINT' to print

out

the data.

Bb38

Parkheutral position switch signal is not correctly entered due

to open or shorted circuit.

--

Neutral position switch circuit

and PNP switch circuit

Page 123 of 230

ELECTRIC SUPER HICAS

INSPECTION BEFORE DRIVING

Check fluid leakage from power steering components (gear, pump, piping, etc.), and check whether the

fluid level is within the proper range.

Check whether tire size and inflation pressure are within the specified limits. Check also whether the

steering wheel is a genuine part, and whether a non-genuine control unit is attached.

Check whether wheel alignment is within the specified limits.

Check whether suspension system is modified, and whether the modification, if any, has increased the

vehicle weight.

INSPECTION DURING DRIVING

Check facts about trouble (what, when, where, who, why and how).

Check whether the engine is running in good condition.

System Description

This system contains two functions for SUPER HICAS: self-diagnosis function and fail-safe function.

For self-diagnosis function, refer to "SELF-DIAGNOSIS PROCEDURE on pages ST-7 and

ST-12.

FAIL-SAFE FUNCTION

If the system detects some error, it halts the normal control and enters the fail-safe mode.

In this event, the system notifies the driver of a malfunction by turning ON the HICAS warning lamp.

The fail-safe mode is canceled when ignition switch

is turned OFF. If, however, the fail-safe mode is caused

by a vehicle speed signal error, it is automatically canceled when the signal is restored before the ignition

switch is turned OFF.

HICAS WARNING LAMP

When the system is in normal condition, HICAS warning lamp is turned ON by switching the ignition ON, and

is turned OFF after engine has started.