transmission NISSAN GT-R 1998 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1998, Model line: GT-R, Model: NISSAN GT-R 1998Pages: 230, PDF Size: 12.66 MB

Page 5 of 230

CONSULT CHECKING SYSTEM

Function and System Application

Diagnostic test mode

Work support

Self-diagnostic results

Trouble diagnostic record Function

This mode enables a technician to adjust some devices faster

and more accurately by following the indications on CONSULT.

ECU discriminated

No.

Data monitor

I I whether each system is "OK" or 'NG". lxH-1-

Conducted by CONSULT instead of a technician to determine

Function test Self-diagnostic

results can be read and erased quickly.

Current self-diagnostic results and all trouble diagnostic records

previously stored can be read.

Active test

ECM part number

L x: Applicable ENGINE

x

Classification

number of a replacement ECU can be read to pre-

vent an incorrect ECU from being installed.

InputIOutput data in the ECM can be read.

Lithium Battery Replacement

x

Diagnostic Test Mode in which CONSULT drives some actuators

apart from the

ECMs and also shifts some parameters

in a

specified range.

ECM part number can be read.

CONSULT contains a lithium battery. When replacing the battery obey the following:

WARNING:

Replace the lithium battery with SANYO Electric Co., Ltd.,

CR2032 only. Use of another battery may

present

a risk of fire or explosion. The battery may present a fire or chemical burn hazard if mistreated.

Do not recharge, disassemble or dispose of in fire.

Keep the battery out of reach of children and discard used battery conforming to the local regulations.

AfT

-

-

x

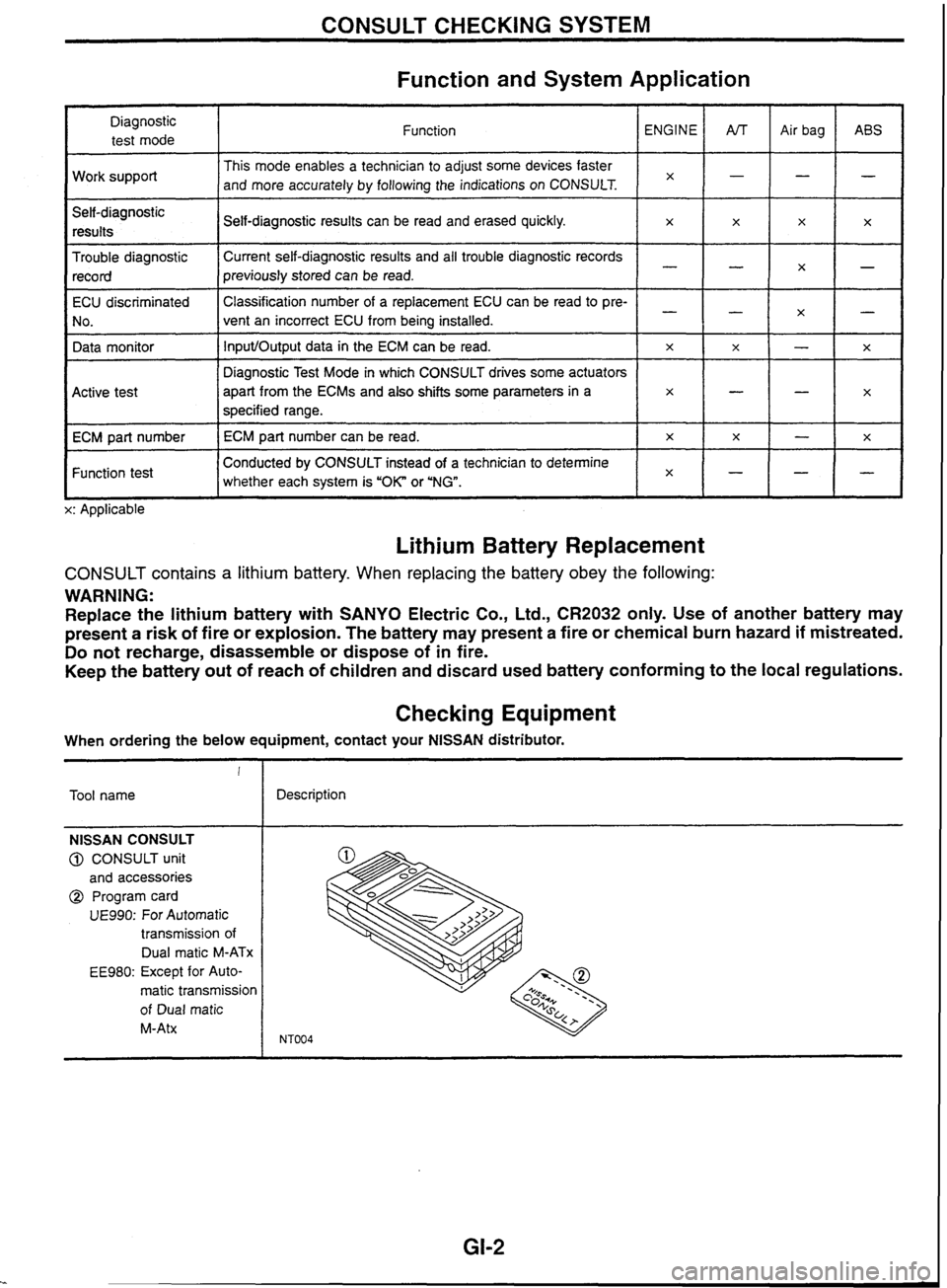

Checking Equipment

x

-

x

x

When ordering the below equipment, contact your NlSSAN distributor. Air

bag

-

-

-

x

!

Tool name ABS

-

x

X

-

x

NISSAN CONSULT

@ CONSULT unit

and accessories

@ Program card

UE990: For Automatic

transmission of

Dual

rnatic M-ATx

EE980: Except for Auto-

matic transmission

of Dual

matic

M-Atx

x

-

--

X

-

Description

-

x

-

-

x

x

Page 6 of 230

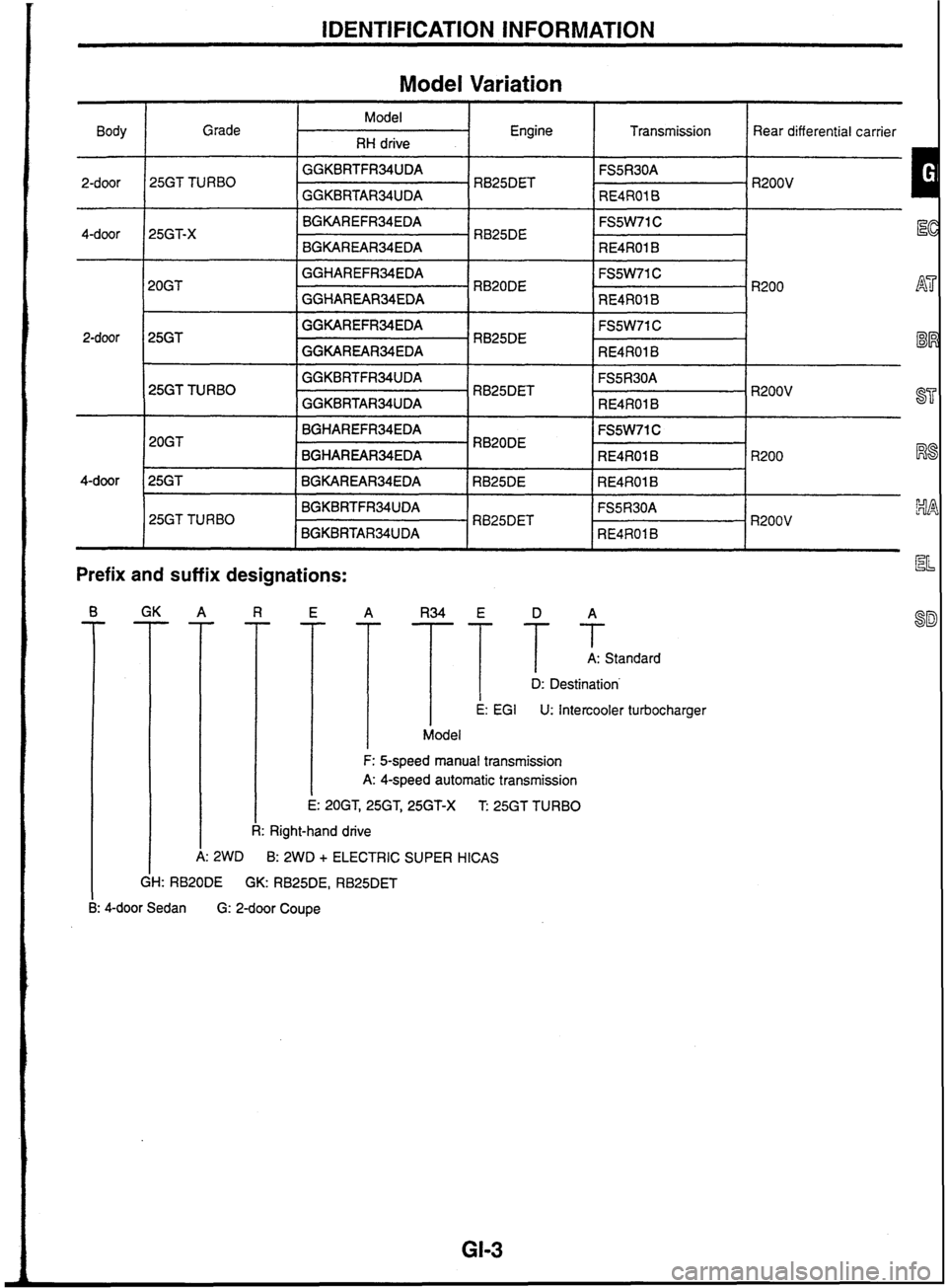

IDENTIFICATION INFORMATION

Model Variation

Model

Body Grade Engine Transmission Rear differential carrier

RH drive

GGKBRTFR34UDA FS5R30A

2-door 25GT TURBO

RB25DET

. R200V

GGKBRTAR34UDA

RE4RO1

B

RB20DE

GGHAREARMEDA

1 GGKAREFRMEDA 1 RB25DE

GGKAREARMEDA

GGKBRTFRMUDA

25GT TURBO

RB25DET R200V

GGKBRTARMUDA

RE4RO1 B

BGHAREFR34EDA FS5W71 C

20GT

RB20DE

BGHAREARMEDA RE4RO1 B R200

i%

I

BGKBRTFR34UDA FS5R30A $#i 25GT TURBO RB25DET

R200V

BGKBRTAR34UDA RE4RO1 B

Prefix and suffix designations:

A: Standard

- 1 TEG, TDestlon' U: intercooler turbocharger

Model

F:

&speed

manual transmission

A: 4-speed automatic transmission

20GT,

25GT,

25GT-X T: 25GT TURBO

k: Right-hand drive

2WD B: 2WD

+ ELECTRIC SUPER HlCAS

GH:

RB20DE

GK:

RB25DE, RB25DET

4-door Sedan G: 2-door Coupe

Page 7 of 230

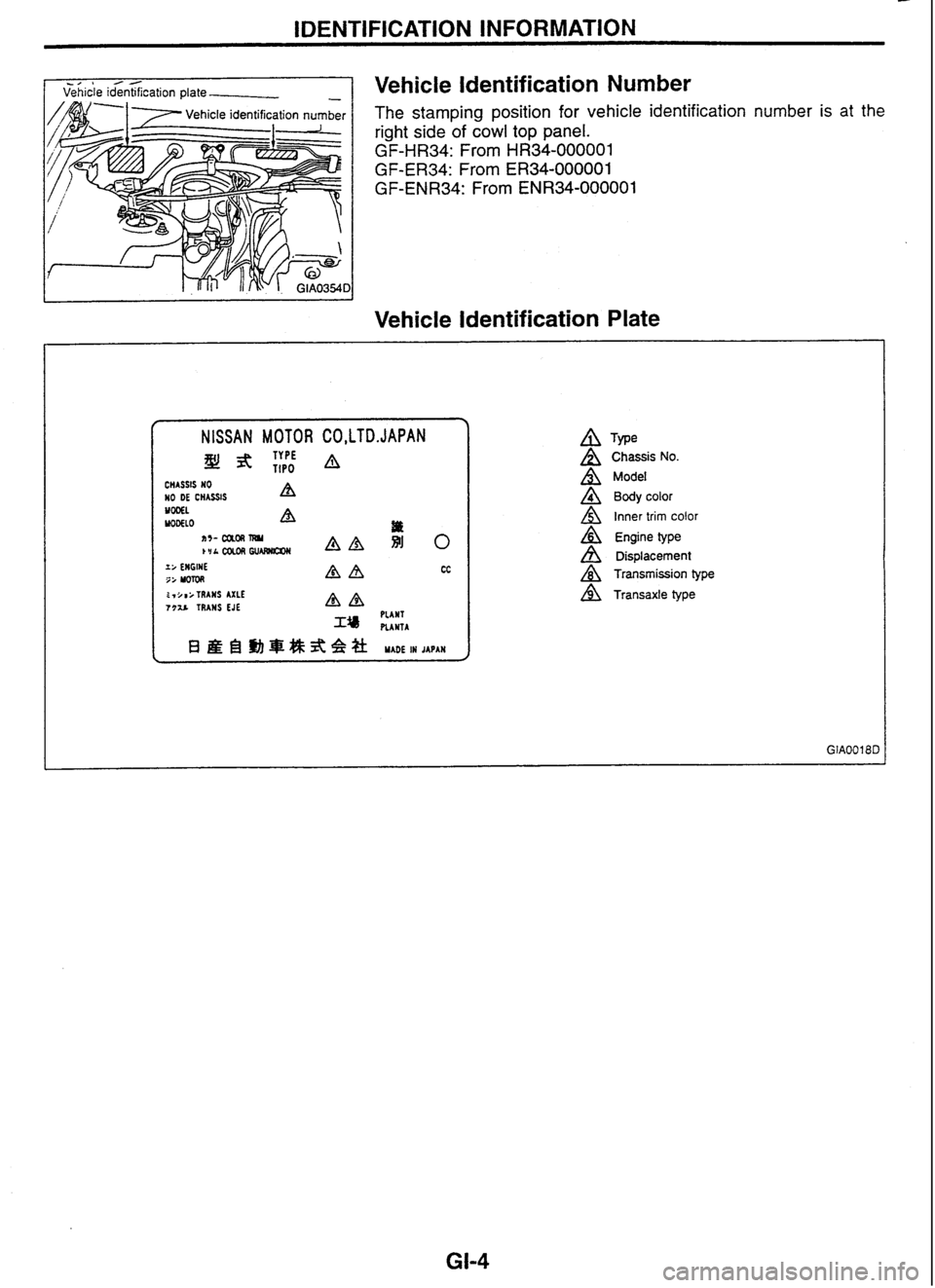

IDENTIFICATION INFORMATION

-2 L .I Vehicle identification plate Vehicle Identification Number

The stamping position for vehicle identification number is at the

right side of cowl top panel.

GF-HR34: From HR34-000001

GF-ER34:

From ER34-000001

GF-ENR34:

From ENR34-000001

--

Vehicle Identification Plate

-- -

NISSAN MOTOR CO,LTD.JAPAN

CHASSlS NO YO DE CHASSIS A MOOEL WDELO A n7- me4 W I

~YLCOLOAWUIWQW( AA 0

z; ENGINE QA cc 2; Mom 2 I ;mi TRANS AXLE T77.b TRANS EJE A& PLANT

nrwrr

A TYP~ A Chassis No.

A Model

A ~ody color

A Inner trim color

A Engine type

Displacement

A Transmission type

A Transaxle type

Page 13 of 230

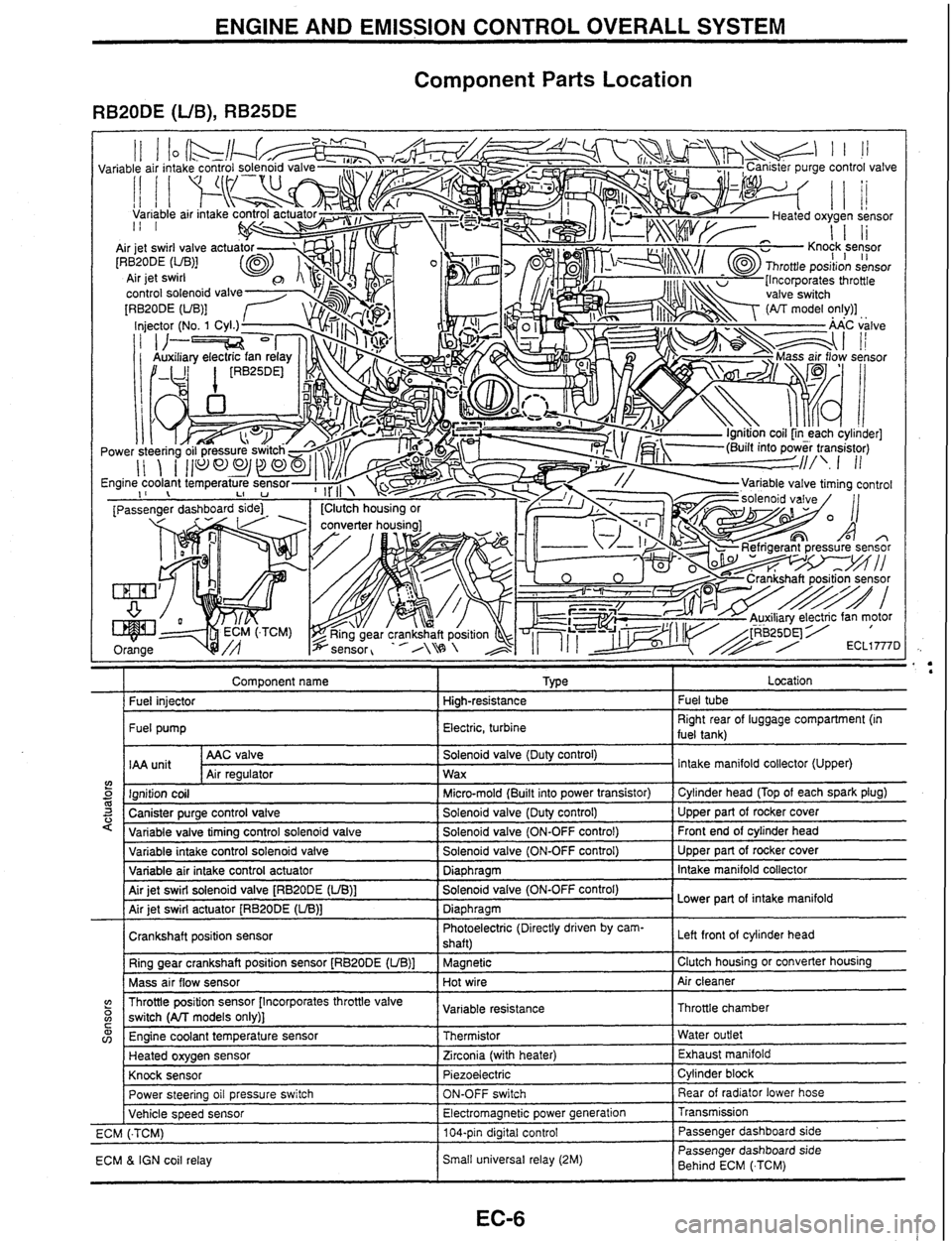

ENGINE AND EMISSION CONTROL OVERALL SYSTEM

Component Parts Location

RB20DE (UB), RB25DE

Component name I Type I Location

I Fuel iniector I Hiah-resistance I Fuel tube

I Fuel pump I Electric, turbine I Right rear of luggage compartment (in

fuel tank)

AAC valve

IAA

unit Air reaulator

5 m 3 '

Solenoid valve (Duty control)

Wax

variable intake control solenoid valve

Variable air intake control actuator

Air jet swirl solenoid valve

[RBPODE (UB)]

Air jet swirl actuator

[RB20DE (LIB)]

Crankshaft position sensor Ring gear crankshaft position sensor

[RB20DE (UB)]

Mass air flow sensor Intake

manifold collector (Upper)

Ignition coil

Canister purge control valve

Variable valve tirnina control

solenoid valve

(? o C

Solenoid valve (ON-OFF control)

Diaphragm

Solenoid valve (ON-OFF control)

Diaphragm Photoelectric (Directly driven by cam-

shaft)

Magnetic

Hot wire

w v,

Micro-mold (Built into power transistor)

Solenoid valve (Duty control)

Solenoid valve (ON-OFF control) Upper part of rocker cover

Intake manifold collector

Lower part of intake manifold

Left front

of cylinder head

Clutch housing or converter housing

Air cleaner

Throttle position sensor [Incorporates throttle valve

switch

(All models only)]

Power steering oil pressure switch

Vehicle speed sensor

ECM

(.TCM)

ECM

& IGN coil relay Cylinder head

(Top of each spark plug)

Upper part of rocker cover

Front end of cylinder head

Engine coolant temperature sensor

Heated oxygen sensor

Knock sensor Variable

resistance

ON-OFF switch

Electromagnetic power generation

104-pin digital control

Small universal relay (2M) Throttle chamber

Thermistor

Zirconia (with heater)

Piezoelectric Rear of radiator lower hose

Transmission Passenger dashboard side

Passenger dashboard side

Behind ECM

(.TCM) Water

outlet

Exhaust manifold

Cylinder block

Page 14 of 230

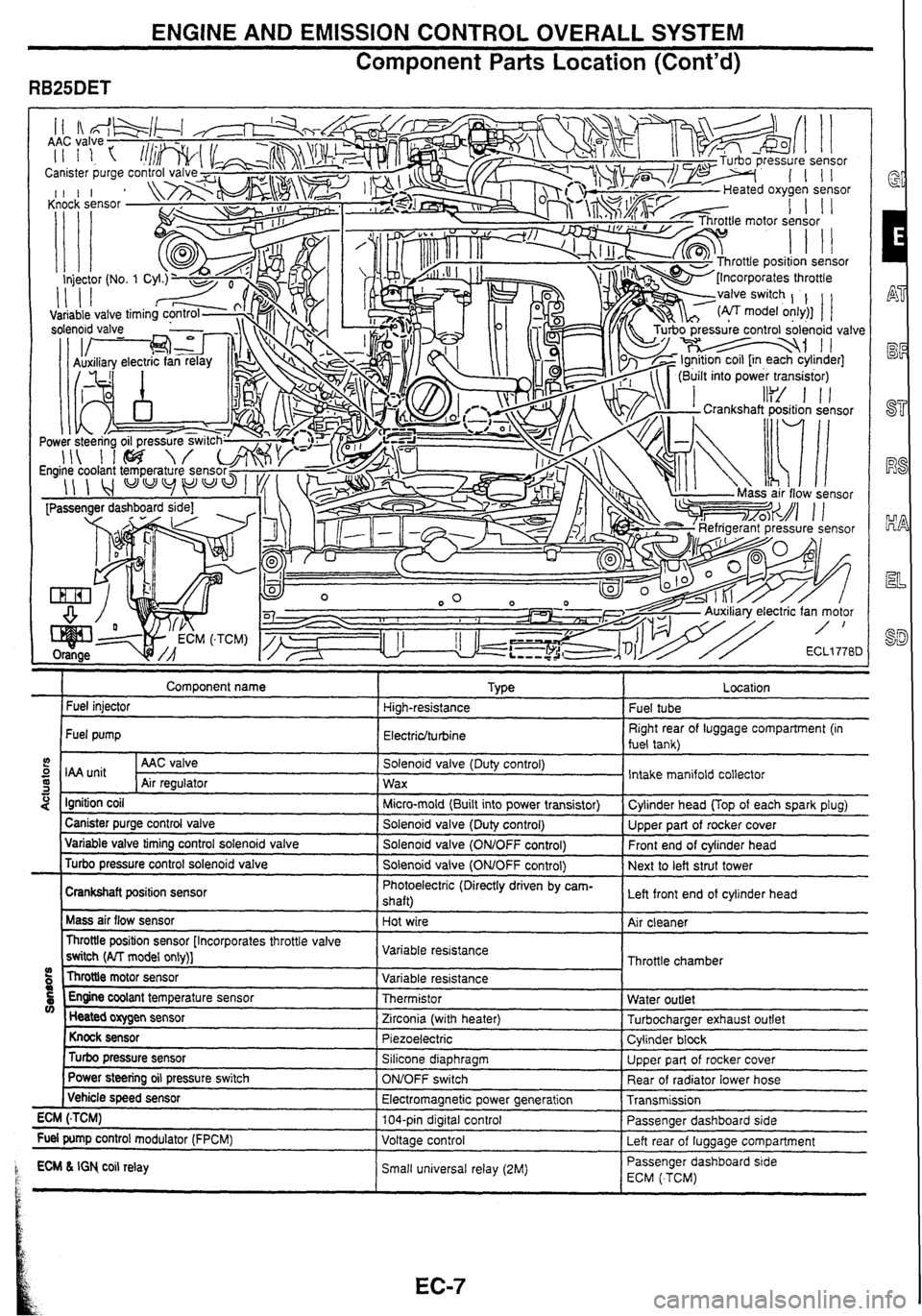

ENGINE AND EMISSION CONTROL OVERALL SYSTEM

Component

Parts Location (Cont'd)

" . . ., . .7

Comoonent name I TVLE a r Fuel injector High-resistance

Fuel pump

Electriclturbine

5 I unit I AAC valve I Solenoid valve (Duty control)

S Air reoulator 1 wax -1 I " - . -.

4 Ignition coil I Micro-mold (Built into power transistor)

I Canister purge control valve I Solenoid valve (Dutv control) ---- - Variable valve timing control solenold valve I Solenold valve (ONtOFF control)

Turbo pressure control solenoid valve

I Solenoid valve (OMOFF control)

Crankshaft position sensor Photoelectric

(Directly driven by cam-

shaft)

Mass air flow sensor

Hot wire

Throttle position sensor [Incorporates throttle valve

switch

(AlT model only)] Variable

resistance

Throttle motor sensor

09 Variable resistance

5 Engine coolant temperature sensor Thermistor V) Heated oxygen sensor

Zirconia (with heater)

Knock sensor Piezoelectric

Turbo pressure sensor Silicone diaphragm

Power

steering oil pressure switch

ONJOFF switch

( Vehicle speed sensor

Electromagnetic power generation

ECM

(.TCM) 104-pin digital control

Fuel pump control modulator (FPCM)

Voltage control

1 ECM L IGN co~l relay Small un~versal relay (2M) P t

.

Fuel tube

Right rear of luggage compartment (in

fuel tank)

Intake manifold collector

Cvlinder head

UOD of each soark olua)

Upper part of rocker cover

Front end of cylinder head

Next to left strut tower

Left front end of cylinder head

Air cleaner

Throttle chamber

Water outlet

Turbocharaer exhaust outlet

Cylinder

block

Upper part of rocker cover

Rear of radiator lower hose

Transmission

Passenger dashboard side

Left rear of

luaaaae comoartment

-- Passenger dashboard s~de

ECM ( TCM)

Page 53 of 230

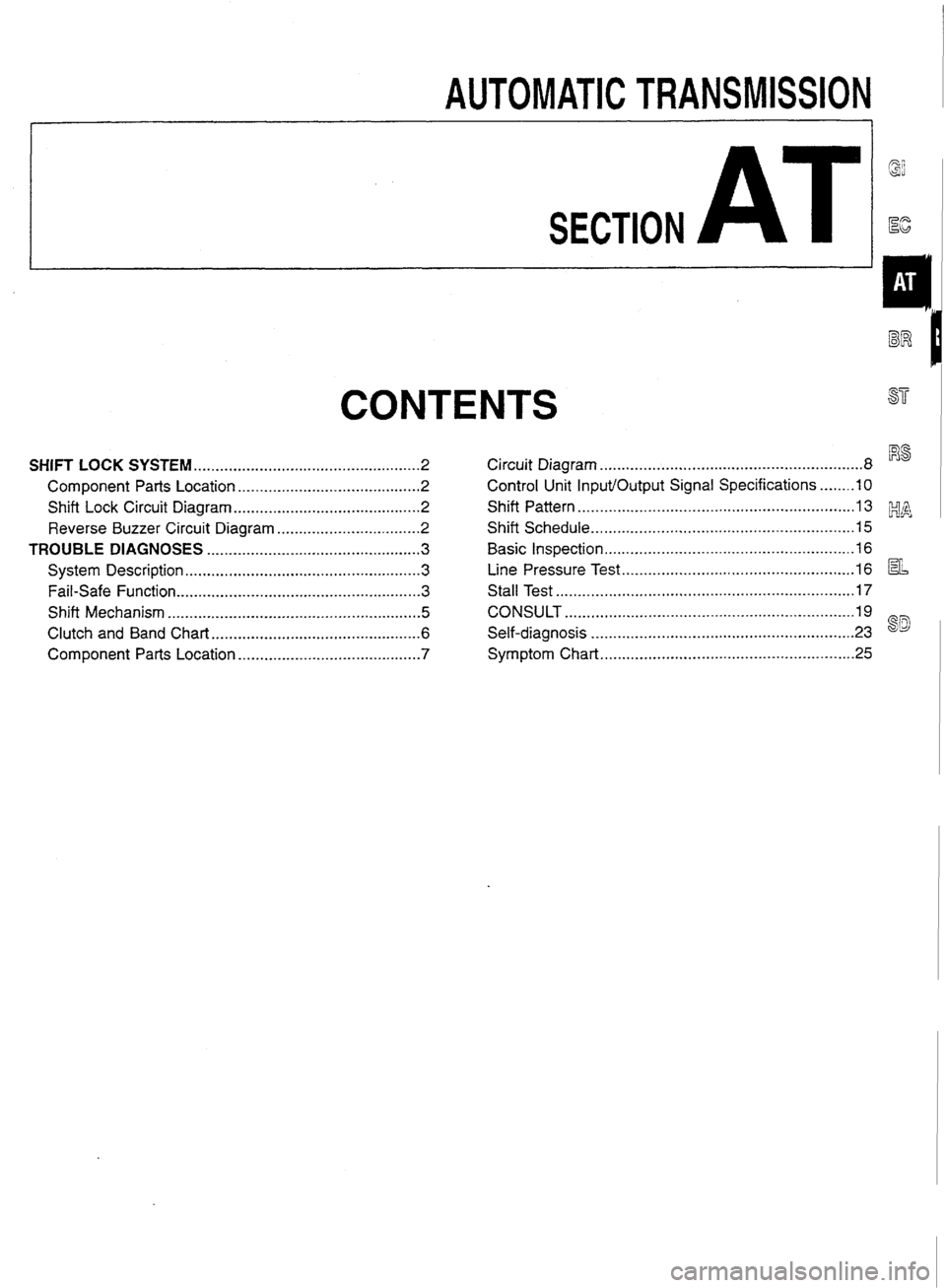

AUTOMATIC TRANSMISSION

SECTION

AT

CONTENTS

SHIFT LOCK SYSTEM .................................................... 2

Component Parts Location .......................................... 2

Shift Lock Circuit Diagram ........................................... 2

Reverse Buzzer Circuit Diagram ................................. 2

TROUBLE DIAGNOSES ................................................. 3

System Description .................................................... ..3

Fail-safe Function ...................................................... ..3

................... Shift Mechanism ............. .........,,.............. .5

Clutch and Band Chart ................................................ 6

Component Parts Location .......................................... 7

........................................................... Circuit Diagram .8

Control Unit Input/Output Signal Specifications ....... .I0

Shift Pattern .............................................................. 1 3

............................................................ Shift Schedule 15

....................................................... Basic Inspection. -16

Line Pressure Test ..................................................... 16

................................................................... Stall Test 17

.................................................................. CONSULT 9

.......................................................... Self-diagnosis ..23

Symptom Chart. ........................................................ -25

Page 58 of 230

TROUBLE DIAGNOSES

Clutch and Band Chart

U0.C

(Low one-

way

clutchl L&R/B

(Low and

reverse

brake)

F/O C

(Forward

clutch)

.

Remarks

PARK POSI-

TION

REVERSE POSITION

O/C

(Overrun

clutch)

*I@

'I@

'18

@

NEUTRAL

POSITION

*"

c'utch)

0

0

WC

clutch)

(Reverse

0

P

R

N

Automatic shift

0

0

FIC

(For-

ward

clutch)

0

0

0

69

0

Band servo

'4

2 Automatic shift

1 st

2nd

-3rd 4th

1 st

1. Locked in 1st

-

4th apply

0

2nd apply

0

'263

*3@

2nd

I st

2nd

0

0

0

DUAL MATIC M-ATx

3rd release

0

8

0

0

0

--

fi In Band servo I FI0.C / UOC I L&WB I

(Reverse clutch) FIC (For- WC (High

ward

clutch) clutch)

PARK POSI-

TION

REVERSE POSITION

NEUTRAL POSITION

@ 0 . . Automatic shift

0 '269 8 - -

-38 8 0

@

G3 0 Automatic shift

10 I I Automatic shift

I I I I I I I

:ch is being set in "OFF position. (D, shift is inhibited.) '2: oil pressure is applied to both 2nd "apply" side and 3rd "releasen side of band servo piston. However, brake band does not contract because oil pressure area on the "releasen side is greater than that on the "apply" side. '3: Oil pressure is applied to 4th "apply" side in condition '2 above, and brake band contracts. '4: A/T will not shift to 4th when overdrive control switch is set in "OFF position.

* 1 : O~erate when control

swil

0: Operates. a: Operates

during "progressive" acceleration.

@: Operates but does not affect power transmission. @: Operates when throttle opening is less than specification, but does not affect engine brake. fi: O~erates when throttle opening is less than specification, activating engine brake.

Page 96 of 230

TCSIABS SYSTEM

System

Description

ABS FUNCTION

During ABS operation, the brake pedal pulsates along with a mechanical noise. This ensures that the ABS

is working properly. mP

When starting up the engine or immediately after the vehicle starts to run, the brake pedal pulsates and G'

a motor noise from the engine compartment can be heard. They are caused by the ABS operation check

and should not be considered abnormal.

A vehicle with the ABS may stop in a longer distance than a vehicle without the ABS when the brake is

EC

applied on a bad road, gravel road, or deep fresh snow.

TCS FUNCTION

TCS/ABS control unit monitors the speed of the driving wheels through 4 wheel speed sensors. If driving

wheel slip is detected, fuel to the engine is cut

ol

and the throttle valve is adjusted so that the engine

a

torque is reduced. On vehicles with automatic transmission, transmission shift schedule is also changed

to control the rear wheel driving torque, which results

in the reduction of wheel slip. This system enables

the throttle valve to be controlled so that optimum engine torque can be achieved in accordance with the

driver's acceleration request.

The driver may not feel satisfied with acceleration on some road surfaces. This poor acceleration occurs

because the operating TCS gives priority to maintaining optimum traction. Therefore, this condition should

R8

be considered normal.

When shiftdown is made or the acceleration pedal is depressed while the vehicle is driven on the road

surface that has different friction coefficients, the TCS may operate temporarily.

r-- 4 Lrd[-i

On vehicles with manual transmission, the SLlP indicator lamp and the TCS OFF indicator lamp may light

up when the engine is about to stall in the conditions shown below.

If the lamps go off when engine speed

increases, there is no problem in the system.

At start, the engine almost stalls and the engine speed is much lower than the idle speed.

The vehicle is driven at an extremely low speed with a high-speed gear engaged.

The clutch has been engaged until the vehicle almost stops. 8D

FAIL-SAFE FUNCTION

ABS system

If any malfunction is detected in the system, the ABS warning lamp, the TCS OFF indicator lamp and the SLlP

indicator lamp in the instrument panel is turned on with the TCSIABS deactivated and the vehicle's brake sys-

tem reverts to normal operation.

TCS system

If any malfunction is detected in the system, both the SLlP indicator lamp and the TCS indicator lamp on the

instrument panel light up and the TCS is shut down. The vehicle operates in the same manner as a vehicle

without the

TCS, while the ABS is operational.

If there is a malfunction in the throttle control system, the TCS becomes inoperative while the ABS

remains functional.

When fail-safe operation is activated, perform the self-diagnosis procedure for the TCSIABS first.

Refer to

BR-27 for details.

Page 201 of 230

![NISSAN GT-R 1998 Service Manual

SERVICE DATA

SECTION SD

CONTENTS

L ] RB20DE (UB) [I 17 FS5R30A 1-

ENGINE MECHANICAL ............................................... 2 MANUAL TRANSMISSION ........................................ NISSAN GT-R 1998 Service Manual

SERVICE DATA

SECTION SD

CONTENTS

L ] RB20DE (UB) [I 17 FS5R30A 1-

ENGINE MECHANICAL ............................................... 2 MANUAL TRANSMISSION ........................................](/img/5/57354/w960_57354-200.png)

SERVICE DATA

SECTION SD

CONTENTS

L ] RB20DE (UB) [I 17 FS5R30A 1-

ENGINE MECHANICAL ............................................... 2 MANUAL TRANSMISSION ........................................... 10

-1 RB25DE /I

ENGINE MECHANICAL .................................................. 4

17 RB25DET I]

ENGINE MECHANICAL .................................................. 6

CLUTCH.. . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. . .. . . . . . . . . . . . . .. . . . .+.. . . . . . . . . . -8

71 FS5W71C

MANUAL TRANSMISSION

.................... ......................... 9

AUTOMATIC TRANSMISSION ........................... .......... 12

TRANSFER .............. ......... ..... .. ... ........ . . ............. 18

PROPELLER SHAFT ................................................. 19

FRONT FINAL DRIVE ................................................. 20

REAR FINAL DRIVE ..................................................... 22

DRIVE SHAFT ............................................................... 24

AXLE & SUSPENSION ................................................. 25

ROAD WHEEL AND TIRE ............................................. 27

BRAKE. ... ...... . .. ... . .... . . . . . .... . .. .. . . .. . . .. . . . .. . . .. ... .. .. . . . . . . . . .. .... . -28

STEERING ........... ............. ..... ... ............... ...... ................ 29

SUPER HICAS ............................................................ 30

Page 209 of 230

MANUAL TRANSMISSION

BACKLASH ADJUSTING SHIMS

Measurement height

mm

--

Items

Main drive gear

1st gear

2nd gear

3rd gear Thickness

mm Standard mm

0.05 - 0.10

0.05

- 0.20

0.05

- 0.20

0.05

- 0.20

Selective parts Parts number

Counter shaft

front bearing

4th gear I -

5th gear 1 0.05 - 0.20 Ail

BAULK RlNG CLEARANCE Reverse idler gear 1 0.05 - 0.20

END PLAY Measurement

position

2nd and 3rd

Inner baulk ring clearance 'an

1 st gear 1 0.31 - 0.41

Items

2nd gear

1 0.11-0.21

Standard

mm

3rd gear 1 0.11 - 0.21

Outer

baulk ring

lnn'er baulk ring

7 4th gear 5th gear

Reverse idler gear

Counter gear Main drive gear end play

Mainshaft high-synchro side

Rear end of mainshaft end bearing

SNAP RlNG

- -

0.24 - 0.41

0.05

- 0.50

0

- 0.16

0

- 0.13

0 - 0.18

0

- 0.14

4th and 5th ( 1.20 - 1.60 1 Less than 0.8

Selective parts

Thickness

mm I Parts number - -- Reverse gear 1 1.10 - 1.55 1 Less than 0.7

Main drive gear

TIGHTENING TORQUE

Unit: N.m (kg-rn)

Counter drive gear

I

TIM side to 40 - 49

Transmission to engine mounting bolt Engine side to 30

- 39

TIM side (3.0 - 4.0) I High-synchro side 32263 V5200 1 32263

"5201

Rear end of shaft I I

Mainshaft 1.1

32228 20 1 00