engine NISSAN LATIO 2008 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: LATIO, Model: NISSAN LATIO 2008Pages: 2771, PDF Size: 60.61 MB

Page 650 of 2771

BL-216

< SERVICE INFORMATION >

NATS (NISSAN ANTI-THEFT SYSTEM)

1.STARTING ENGINE

Check if the engine could be started by inserting the mechanical key into the ignition key cylinder and operate

ignition switch.

OK >> System is normal.

NG >> GO TO 2.

2.PERFORM SELF DIAGNOSIS

Perform SELF-DIAGNOSIS “NATS V5.0” using CONSULT-III.

NOTE:

NATS program card is necessary to display the “SELF-DIAGNOSIS”.

No malfunction is detected>>Recheck the starting engine section GO TO 1.

Malfunction related to NATS is detected>>GO TO 3.

Malfunctions related to “DON’T ERASE BEFORE CHECKING ENG DIAG” and NATS are detected>>GO

TO 7.

3.IDENTIFYING NATS MALFUNCTION

Self-diagnosis results referring to NATS, but no information about engine self-diagnosis result is displayed on

CONSULT-III. Refer to BL-217, "

Trouble Diagnosis" .

>> GO TO 4.

4.NATS TROUBLE DIAGNOSIS

Repair NATS (if necessary, perform “C/U INITIALIZATION” with CONSULT-III.)

>> GO TO 5.

5.ERASE SELF-DIAGNOSIS

Erase the record of “SELF-DIAGNOSIS” by using CONSULT-III.

>> GO TO 6.

6.STARTING ENGINE

Check if the engine could be started by inserting the mechanical key into the ignition key cylinder and operate

ignition switch.

NG >> GO TO 2.

OK >> End of inspection.

7.IDENTIFYING NATS AND ENGINE CONTROL MALFUNCTION

NATS malfunction and “DON’T ERASE BEFORE CHECKING ENG DIAG” are displayed on the CONSULT-III

screen.

NOTE:

This indication means that malfunction have been detected in NATS and engine control system.

>> GO TO 8.

8.NATS TROUBLE DIAGNOSIS

Repair NATS according to self-diagnosis results refer to NATS (if necessary, perform “C/U INITIALZATIN” with

CONSULT-III.)

NOTE:

Do not erase “SELF-DIAGNOSIS” by using CONSULT-III.

>> GO TO 9.

Page 651 of 2771

NATS (NISSAN ANTI-THEFT SYSTEM)

BL-217

< SERVICE INFORMATION >

C

D

E

F

G

H

J

K

L

MA

B

BL

N

O

P

9.IDENTIFYING ENGINE CONTROL MALFUNCTION

Check engine “SELF-DIAGNOSIS” records with a generalized program card instead of the NATS program

card.

>> GO TO 10.

10.ENGINE CONTROL SYSTEM TROUBLE DIAGNOSIS

Repair engine control system if engine related malfunction is detected.

With engine diagnostic codes present, refer to EC-9

.

Without engine diagnostic codes present, refer to EC-81

.

NOTE:

If only “NATS MALFUNCTION” is displayed, erase the self-diagnosis results.

>> GO TO 11.

11 .STARTING ENGINE

Check if the engine could be started by inserting the mechanical key into the ignition key cylinder and operate

ignition switch.

OK >> GO TO 12.

NG >> GO TO 2.

12.ERASE SELF-DIAGNOSIS

Erase both NATS and ENGINE "SELF-DIAGNOSIS" records by using CONSULT-III NATS program card and

generalized program card.

>> GO TO 13

13.COMFIRMATION

Perform running test with CONSULT-III in engine “SELF-DIAGNOSIS” mode.

“NO DTC” is displayed>> End of inspection.

Malfunction information is displayed>>GO TO 2.

Trouble DiagnosisINFOID:0000000001704111

SYMPTOM MATRIX CHART 1

Page 652 of 2771

BL-218

< SERVICE INFORMATION >

NATS (NISSAN ANTI-THEFT SYSTEM)

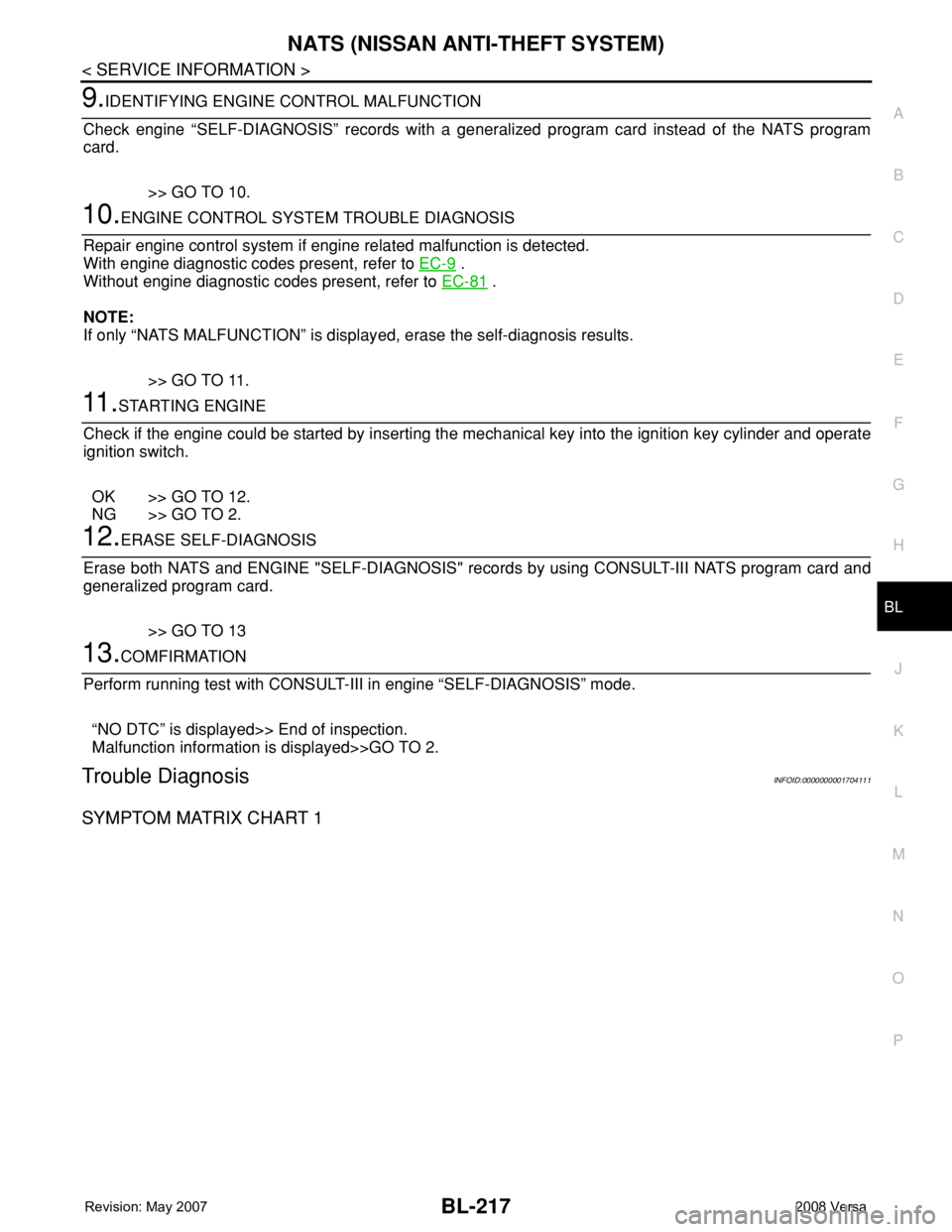

Self-diagnosis related item

• *: When NATS detects trouble, the security indicator lights up while ignition key is in the “ON” position.

SYMPTOM MATRIX CHART 2

Non self-diagnosis related item

*: CONSULT-III self-diagnostic results display screen “no malfunction is detected”.

Diagnosis Procedure 1INFOID:0000000001704112

Self-diagnostic results:

“CHAIN OF ECM-IMMU” displayed on CONSULT-III screen

First perform the “SELF-DIAG RESULTS” in “BCM” with CONSULT-III, then perform the trouble diag-

nosis of malfunction system indicated “SELF-DIAG RESULTS” of “BCM”. Refer to BCS-17, "

CAN Com-

munication Inspection Using CONSULT-III (Self-Diagnosis)" .

1.CONFIRM SELF-DIAGNOSTIC RESULTS

Confirm SELF-DIAGNOSTIC RESULTS “CHAIN OF ECM-IMMU” displayed on CONSULT-III screen.

NOTE:

SYMPTOMDisplayed “SELF-DIAG

RESULTS” on CON-

SULT-III screen.DIAGNOSTIC PROCE-

DURE

(Reference page)SYSTEM

(Malfunctioning part or mode)

• Security indicator

lighting up*

• Engine cannot be

startedCHAIN OF ECM-IMMU

[P1612]PROCEDURE 1

(BL-218

)In rare case, “CHAIN OF ECM-IMMU” might be stored

during key registration procedure, even if the system is

not malfunctioning.

Open circuit in battery voltage line of BCM circuit

Open circuit in ignition line of BCM circuit

Open circuit in ground line of BCM circuit

Open or short circuit between BCM and ECM commu-

nication line

ECM

BCM

CHAIN OF IMMU-KEY

[P1614]PROCEDURE 2

(BL-220

)Malfunction of key ID chip

Communication line between ANT/ AMP and BCM:

Open circuit or short circuit of battery voltage line or

ground line

Open circuit in power source line of ANT/ AMP circuit

Open circuit in ground line of ANT/ AMP circuit

NATS antenna amp.

BCM

ID DISCORD, IMM-

ECM

[P1611]PROCEDURE 3

(BL-221

)System initialization has not yet been completed.

ECM

LOCK MODE

[P1610]PROCEDURE 5

(BL-223

)When the starting operation is carried out five or more

times consecutively under the following conditions,

NATS will shift the mode to one which prevents the en-

gine from being started.

• Unregistered ignition key is used.

• BCM or ECM’s malfunctioning.

Security indicator

lighting up*DON'T ERASE BE-

FORE CHECKING

ENG DIAGWORK FLOW

(BL-215

)Engine trouble data and NATS trouble data have been

detected in ECM

SYMPTOMDIAGNOSTIC PROCEDURE

(Reference page)SYSTEM

(Malfunctioning part or mode)

Security indicator does not light up*.PROCEDURE 4

(BL-222

)Security indictor.

Open circuit between Fuse and BCM

BCM

Page 654 of 2771

BL-220

< SERVICE INFORMATION >

NATS (NISSAN ANTI-THEFT SYSTEM)

For initialization, refer to “CONSULT-III Operation Manual NATS”.

Does the engine start?

Yes >> BCM is malfunctioning.

• Replace BCM. Refer to BCS-18, "

Removal and Installation of BCM" .

• Perform initialization with CONSULT-III

• For initialization, refer to “CONSULT-III Operation Manual NATS”

No >> ECM is malfunctioning.

• Replace ECM.

• Perform initialization or re-communicating function

• For initialization, refer to “CONSULT-III Operation Manual NATS”

• For re-communicating function, refer to BL-211, "

ECM Re-communicating Function"

Diagnosis Procedure 2INFOID:0000000001704113

Self-diagnostic results:

“CHAIN OF IMMU-KEY” displayed on CONSULT-III screen

1.CONFIRM SELF-DIAGNOSTIC RESULTS

Confirm SELF-DIAGNOSTIC RESULTS “CHAIN OF IMMU-KEY” displayed on CONSULT-III screen.

Is

“CHAIN OF IMMU-KEY” displayed?

Ye s > > G O T O 2 .

No >> GO TO BL-217, "

Trouble Diagnosis" .

2.CHECK NATS ANTENNA AMP. INSTALLATION

Check NATS antenna amp. installation. Refer to BL-224, "

How to Replace NATS Antenna Amp" .

OK or NG

OK >> GO TO 3.

NG >> Reinstall NATS antenna amp. correctly.

3.CHECK NATS IGNITION KEY ID CHIP

Start engine with another registered NATS ignition key.

Does the engine start?

Yes >> Ignition key ID chip is malfunctioning.

• Replace the ignition key

• Perform initialization with CONSULT-III

For initialization, refer to “CONSULT-III Operation Manual NATS”

No >> GO TO 4.

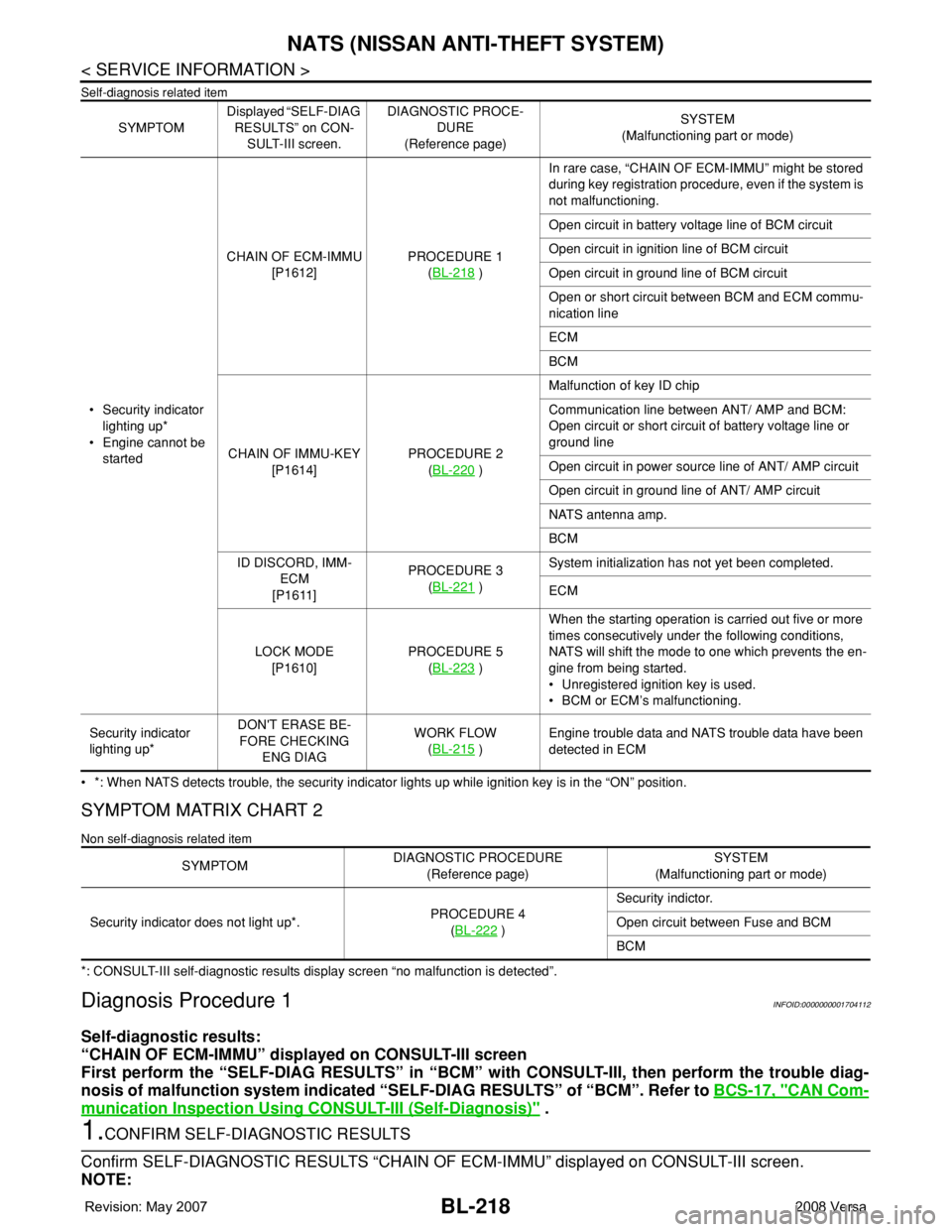

4.CHECK POWER SUPPLY FOR NATS ANTENNA AMP.

1. Turn ignition switch “OFF”.

2. Check voltage between NATS antenna amp. connector and ground.

OK or NG

OK >> GO TO 5.

NG >> Check the following.

• 20A fuse [No. 53, located in IPDM E/R]

• Harness for open or short between fuse and NATS

antenna amp.

5.CHECK NATS ANTENNA AMP. SIGNAL LINE- 1

Check voltage between NATS antenna amp. connector and ground with analog tester.

NATS antenna amp.

connectorTe r m i n a l

Voltage [V]

(Approx.)

(+) (–)

M21 1 Ground Battery voltage

PIIB6589E

Page 656 of 2771

BL-222

< SERVICE INFORMATION >

NATS (NISSAN ANTI-THEFT SYSTEM)

“ID DISCORD IMM-ECM”:

Registered ID of BCM is in discord with that of ECM.

Is

“ID DISCORD IMM-ECM” displayed?

Ye s > > G O T O 2 .

No >> GO TO BL-217, "

Trouble Diagnosis" .

2.PERFORM INITIALIZATION WITH CONSULT-III

Perform initialization with CONSULT-III. Re-register all NATS ignition key IDs.

For initialization, refer to “CONSULT-III Operation Manual NATS”.

NOTE:

If the initialization is not completed or malfunctions, CONSULT-III shows message on the screen.

Can the system be initialized?

Yes >> • Start engine. (END)

• (System initialization had not been completed.)

No >> ECM is malfunctioning.

• Replace ECM.

• Perform initialization with CONSULT-III

For initialization, refer to “CONSULT-III Operation Manual NATS”

Diagnosis Procedure 4INFOID:0000000001704115

“COMBINATION METER (SECURITY) DOES NOT LIGHT UP”

1.CHECK FUSE

Check 10A fuse [No.13, located in the fuse block (J/B)]

OK or NG

OK >> GO TO 2.

NG >> Replace fuse.

2.CHECK COMBINATION METER (SECURITY)

1. Install 10A fuse.

2. Start engine and turn ignition switch OFF.

3. Check if the combination meter (security) lights up.

OK or NG

OK >> INSPECTION END.

NG >> GO TO 3.

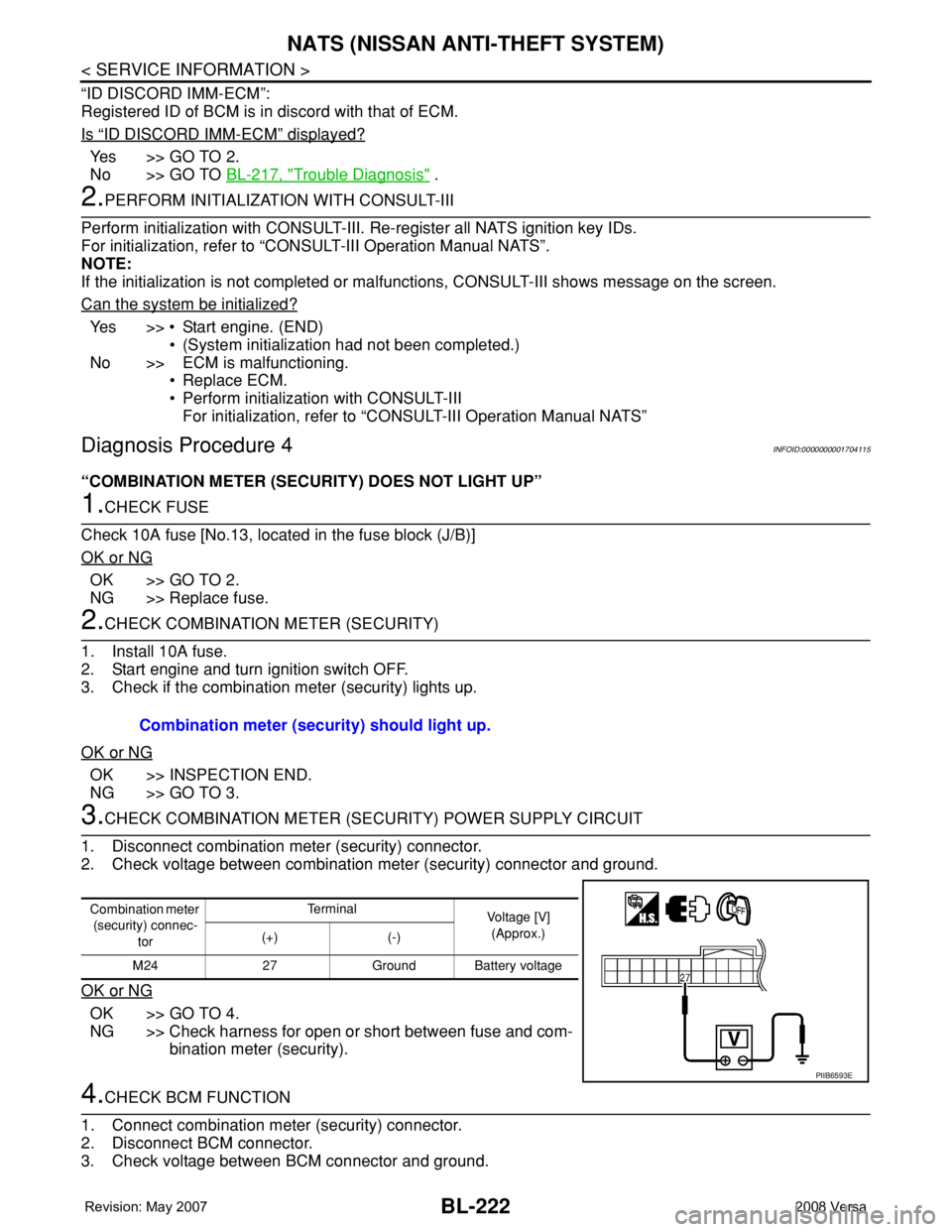

3.CHECK COMBINATION METER (SECURITY) POWER SUPPLY CIRCUIT

1. Disconnect combination meter (security) connector.

2. Check voltage between combination meter (security) connector and ground.

OK or NG

OK >> GO TO 4.

NG >> Check harness for open or short between fuse and com-

bination meter (security).

4.CHECK BCM FUNCTION

1. Connect combination meter (security) connector.

2. Disconnect BCM connector.

3. Check voltage between BCM connector and ground. Combination meter (security) should light up.

Combination meter

(security) connec-

torTe r m i n a l

Voltage [V]

(Approx.)

(+) (-)

M24 27 Ground Battery voltage

PIIB6593E

Page 657 of 2771

NATS (NISSAN ANTI-THEFT SYSTEM)

BL-223

< SERVICE INFORMATION >

C

D

E

F

G

H

J

K

L

MA

B

BL

N

O

P

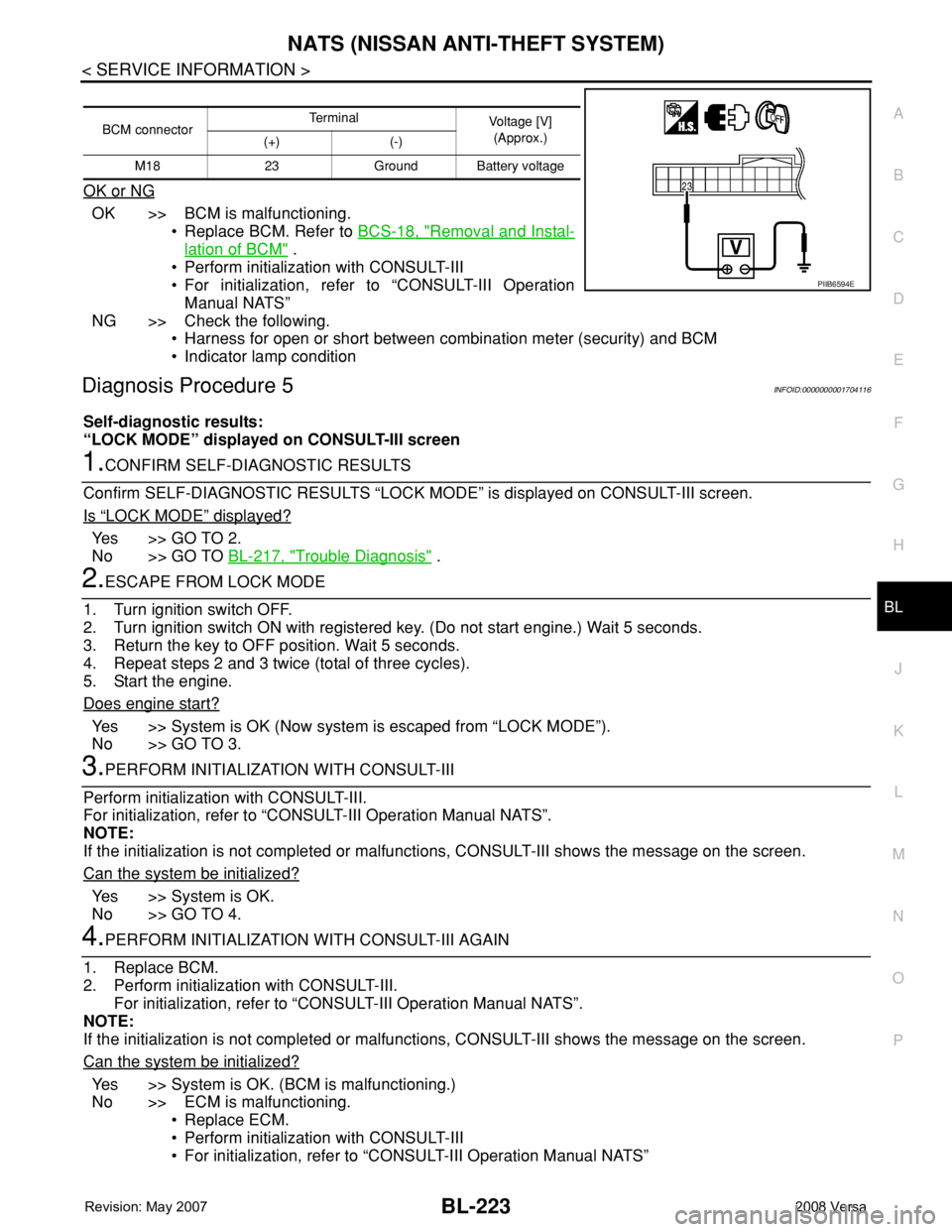

OK or NG

OK >> BCM is malfunctioning.

• Replace BCM. Refer to BCS-18, "

Removal and Instal-

lation of BCM" .

• Perform initialization with CONSULT-III

• For initialization, refer to “CONSULT-III Operation

Manual NATS”

NG >> Check the following.

• Harness for open or short between combination meter (security) and BCM

• Indicator lamp condition

Diagnosis Procedure 5INFOID:0000000001704116

Self-diagnostic results:

“LOCK MODE” displayed on CONSULT-III screen

1.CONFIRM SELF-DIAGNOSTIC RESULTS

Confirm SELF-DIAGNOSTIC RESULTS “LOCK MODE” is displayed on CONSULT-III screen.

Is

“LOCK MODE” displayed?

Yes >> GO TO 2.

No >> GO TO BL-217, "

Trouble Diagnosis" .

2.ESCAPE FROM LOCK MODE

1. Turn ignition switch OFF.

2. Turn ignition switch ON with registered key. (Do not start engine.) Wait 5 seconds.

3. Return the key to OFF position. Wait 5 seconds.

4. Repeat steps 2 and 3 twice (total of three cycles).

5. Start the engine.

Does engine start?

Yes >> System is OK (Now system is escaped from “LOCK MODE”).

No >> GO TO 3.

3.PERFORM INITIALIZATION WITH CONSULT-III

Perform initialization with CONSULT-III.

For initialization, refer to “CONSULT-III Operation Manual NATS”.

NOTE:

If the initialization is not completed or malfunctions, CONSULT-III shows the message on the screen.

Can the system be initialized?

Yes >> System is OK.

No >> GO TO 4.

4.PERFORM INITIALIZATION WITH CONSULT-III AGAIN

1. Replace BCM.

2. Perform initialization with CONSULT-III.

For initialization, refer to “CONSULT-III Operation Manual NATS”.

NOTE:

If the initialization is not completed or malfunctions, CONSULT-III shows the message on the screen.

Can the system be initialized?

Yes >> System is OK. (BCM is malfunctioning.)

No >> ECM is malfunctioning.

• Replace ECM.

• Perform initialization with CONSULT-III

• For initialization, refer to “CONSULT-III Operation Manual NATS”

BCM connectorTerminal

Voltage [V]

(Approx.)

(+) (-)

M18 23 Ground Battery voltage

PIIB6594E

Page 662 of 2771

BL-228

< SERVICE INFORMATION >

BODY REPAIR

4. Front pillar inner reinforcement (RH&LH)

5. Lower dash reinforcement

6. 4th crossmember (RH&LH)

7. Front side member rear extension (RH&LH)

8. 3rd crossmember (RH&LH)

9. Front seat outer rear bracket (RH&LH)

10. Front seat inner rear bracket (RH&LH)

11. 2nd crossmember (RH&LH)

12. Front seat outer front bracket (RH&LH)

13. Front seat inner front bracket (RH&LH)

14. Fender bracket (RH&LH)

15. Strut housing assembly RH

16. Cowl top side upper (RH&LH)

17. Front strut housing (RH&LH)

18. Upper torque rod reinforcement

19. Closing plate assembly RH

20. Engine mount reinforcement

21. Strut tower front reinforcement RH

22. Front hoodledge lower RH

23. Frame bracket outer (RH&LH)

24. Front bumper support bracket (RH&LH)

25. Closing plate (RH&LH)

26. Front suspension rear bracket (RH&LH)

27. Front side member outrigger (RH&LH)

28. Front side member assembly (RH&LH)

29. Front side member (RH&LH)

30. Frame bracket (RH&LH)

31. Closing plate assembly LH

32. Hoodledge connector (RH&LH)

33. Radiator core side support (RH&LH)

34. Radiator core support upper (RH&LH)

35. Hoodledge upper (RH&LH)

36. Hoodledge reinforcement assembly (RH&LH)

37. Dash side (RH&LH)

38. Dash side assembly (RH& LH)

39. Front floor reinforcement (RH&LH)

40. Front floor front (RH&LH)

41. Front floor center

42. Rear seat crossmember

43. Rear center crossmember

44. Rear seat upper crossmember

45. Rear side member (RH&LH)

46. Sill inner extension (RH&LH)

47. Rear side member extension (RH&LH)

48. Rear side member assembly (RH & LH)

49. Rear floor front

50. Rear floor front assembly

51. Rear floor side (RH&LH)

52. Rear floor rear

Page 683 of 2771

BODY REPAIR

BL-249

< SERVICE INFORMATION >

C

D

E

F

G

H

J

K

L

MA

B

BL

N

O

P

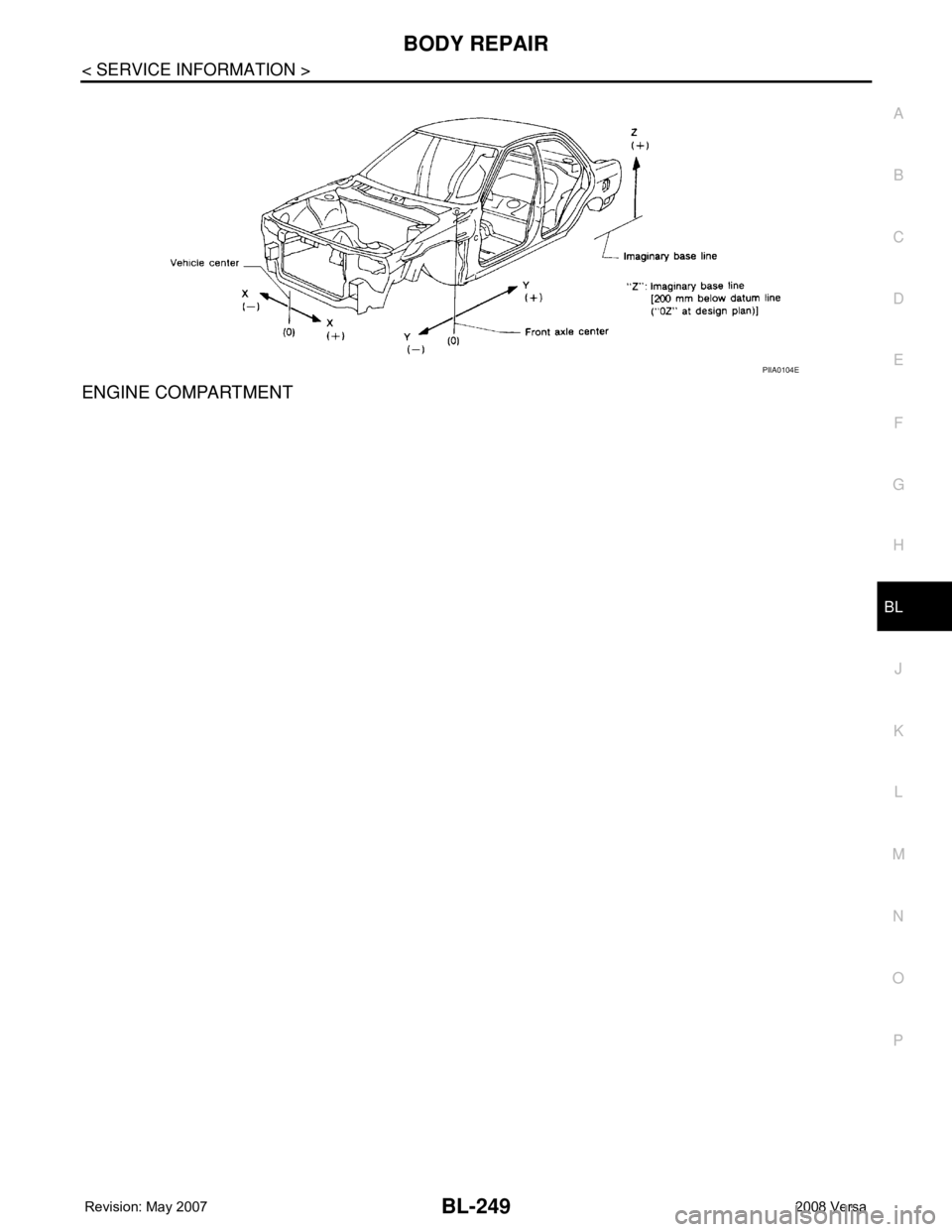

ENGINE COMPARTMENT

PIIA0104E

Page 736 of 2771

BRAKE PEDAL

BR-5

< SERVICE INFORMATION >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

BRAKE PEDAL

Inspection and AdjustmentINFOID:0000000001703779

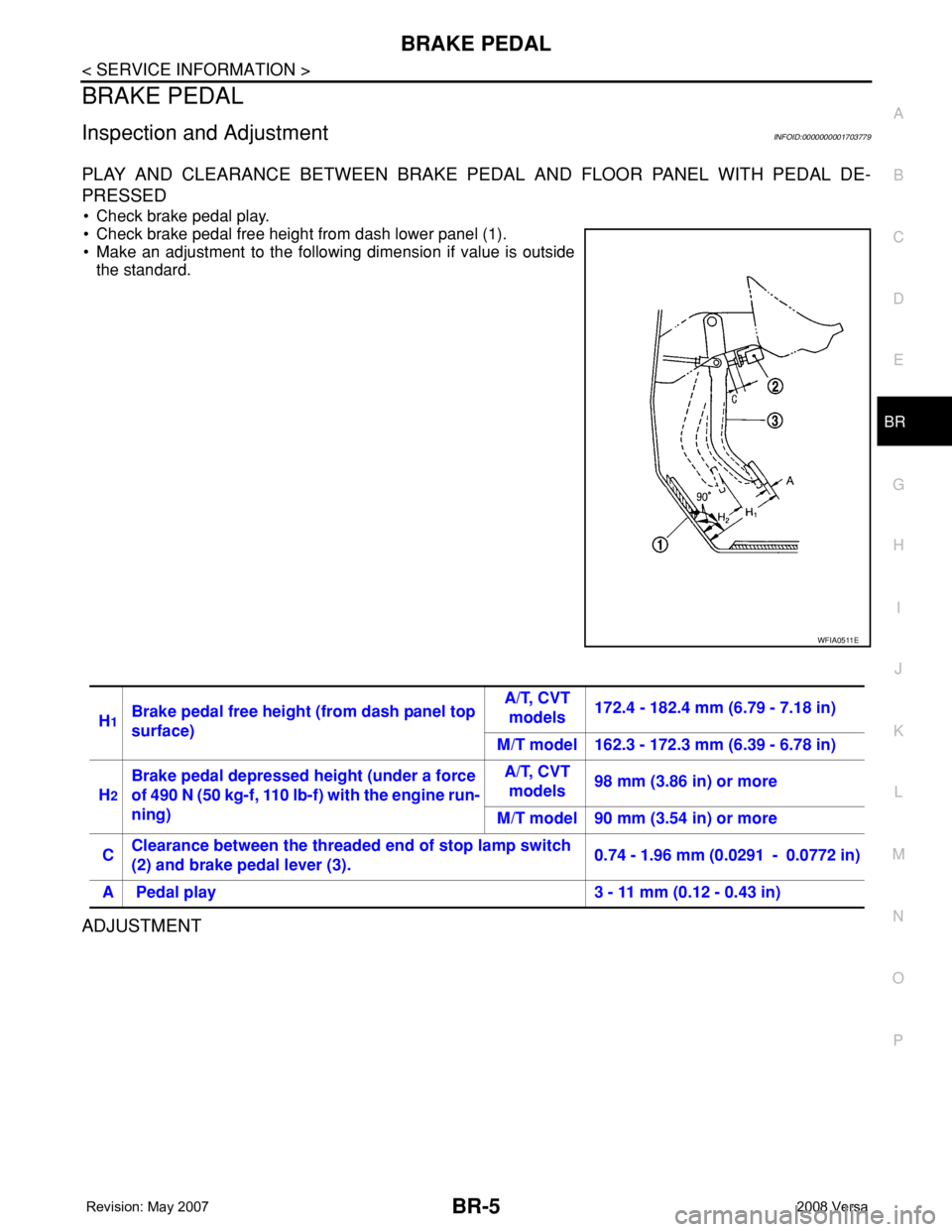

PLAY AND CLEARANCE BETWEEN BRAKE PEDAL AND FLOOR PANEL WITH PEDAL DE-

PRESSED

• Check brake pedal play.

• Check brake pedal free height from dash lower panel (1).

• Make an adjustment to the following dimension if value is outside

the standard.

ADJUSTMENT

WFIA0511E

H1Brake pedal free height (from dash panel top

surface)A/T, CVT

models172.4 - 182.4 mm (6.79 - 7.18 in)

M/T model 162.3 - 172.3 mm (6.39 - 6.78 in)

H

2

Brake pedal depressed height (under a force

of 490 N (50 kg-f, 110 lb-f) with the engine run-

ning)A/T, CVT

models98 mm (3.86 in) or more

M/T model 90 mm (3.54 in) or more

CClearance between the threaded end of stop lamp switch

(2) and brake pedal lever (3).0.74 - 1.96 mm (0.0291 - 0.0772 in)

A Pedal play 3 - 11 mm (0.12 - 0.43 in)

Page 737 of 2771

BR-6

< SERVICE INFORMATION >

BRAKE PEDAL

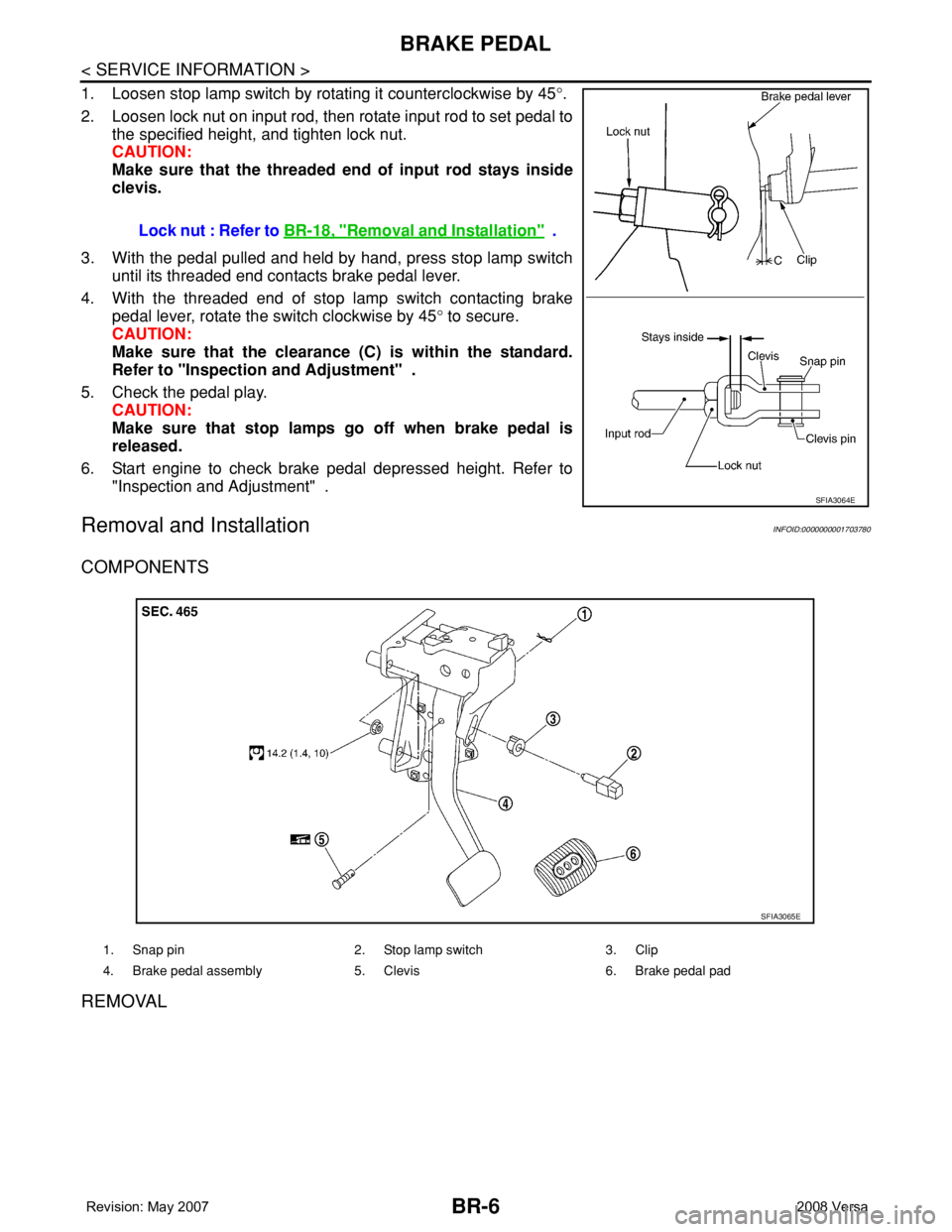

1. Loosen stop lamp switch by rotating it counterclockwise by 45°.

2. Loosen lock nut on input rod, then rotate input rod to set pedal to

the specified height, and tighten lock nut.

CAUTION:

Make sure that the threaded end of input rod stays inside

clevis.

3. With the pedal pulled and held by hand, press stop lamp switch

until its threaded end contacts brake pedal lever.

4. With the threaded end of stop lamp switch contacting brake

pedal lever, rotate the switch clockwise by 45° to secure.

CAUTION:

Make sure that the clearance (C) is within the standard.

Refer to "Inspection and Adjustment" .

5. Check the pedal play.

CAUTION:

Make sure that stop lamps go off when brake pedal is

released.

6. Start engine to check brake pedal depressed height. Refer to

"Inspection and Adjustment" .

Removal and InstallationINFOID:0000000001703780

COMPONENTS

REMOVAL

Lock nut : Refer to BR-18, "Removal and Installation" .

SFIA3064E

1. Snap pin 2. Stop lamp switch 3. Clip

4. Brake pedal assembly 5. Clevis 6. Brake pedal pad

SFIA3065E