NISSAN LATIO 2008 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2008, Model line: LATIO, Model: NISSAN LATIO 2008Pages: 2771, PDF Size: 60.61 MB

Page 2601 of 2771

STARTING SYSTEM

SC-19

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

SC

N

O

P

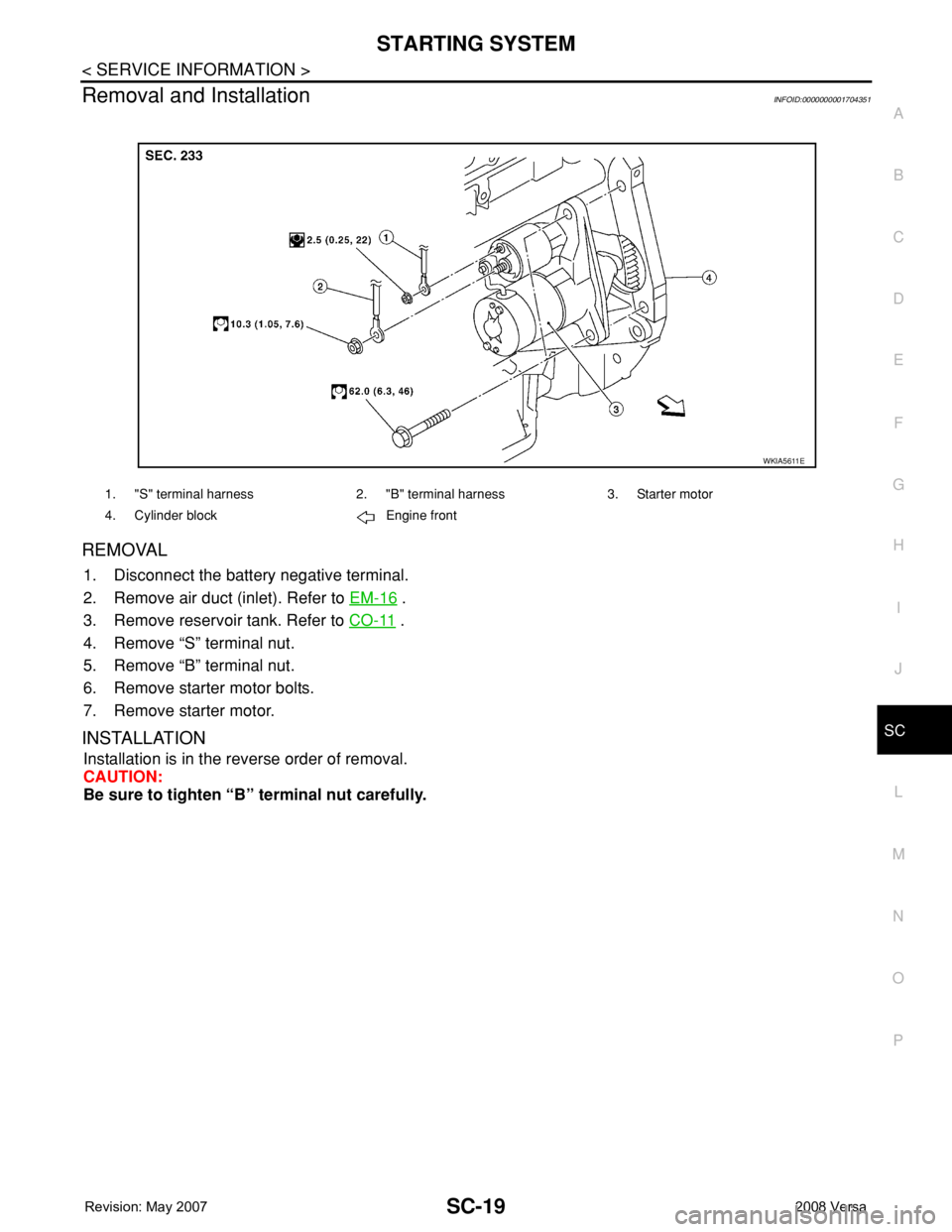

Removal and InstallationINFOID:0000000001704351

REMOVAL

1. Disconnect the battery negative terminal.

2. Remove air duct (inlet). Refer to EM-16

.

3. Remove reservoir tank. Refer to CO-11

.

4. Remove “S” terminal nut.

5. Remove “B” terminal nut.

6. Remove starter motor bolts.

7. Remove starter motor.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

Be sure to tighten “B” terminal nut carefully.

1. "S" terminal harness 2. "B" terminal harness 3. Starter motor

4. Cylinder block Engine front

WKIA5611E

Page 2602 of 2771

SC-20

< SERVICE INFORMATION >

CHARGING SYSTEM

CHARGING SYSTEM

System DescriptionINFOID:0000000001704352

The generator provides DC voltage to operate the vehicle's electrical system and to keep the battery charged.

The voltage output is controlled by the IC regulator.

Power is supplied at all times to generator terminal 3 through

• 10A fuse (No. 29, located in the fuse and fusible link box).

Power is supplied through terminal 1 to charge the battery and operate the vehicle's electrical system. Output

voltage is monitored at terminal 3 by the IC regulator. The charging circuit is protected by the 120A fusible link

[letter a , located in the fusible link box (battery)].

Ground is supplied

• to generator terminal 5

• through body ground F5, and

• through the generator case to the cylinder block

With the ignition switch in the ON or START position, power is supplied

• through 10A fuse [No. 3, located in the fuse block (J/B)]

• to combination meter terminal 28 for the charge warning lamp.

The IC regulator controls ground to terminal 38 of the combination meter through terminal 2 of the generator.

When the ignition is turned on and power becomes available at terminal 2, this "wakes up" the regulator. The

regulator monitors charge output and grounds terminal 2 or leaves it open depending on charge output. With

power and ground supplied, the charge warning lamp will illuminate. When the generator is providing sufficient

voltage, the ground is opened and the charge warning lamp will go off.

If the charge warning lamp illuminates with the engine running, a malfunction is indicated.

Page 2603 of 2771

CHARGING SYSTEM

SC-21

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

SC

N

O

P

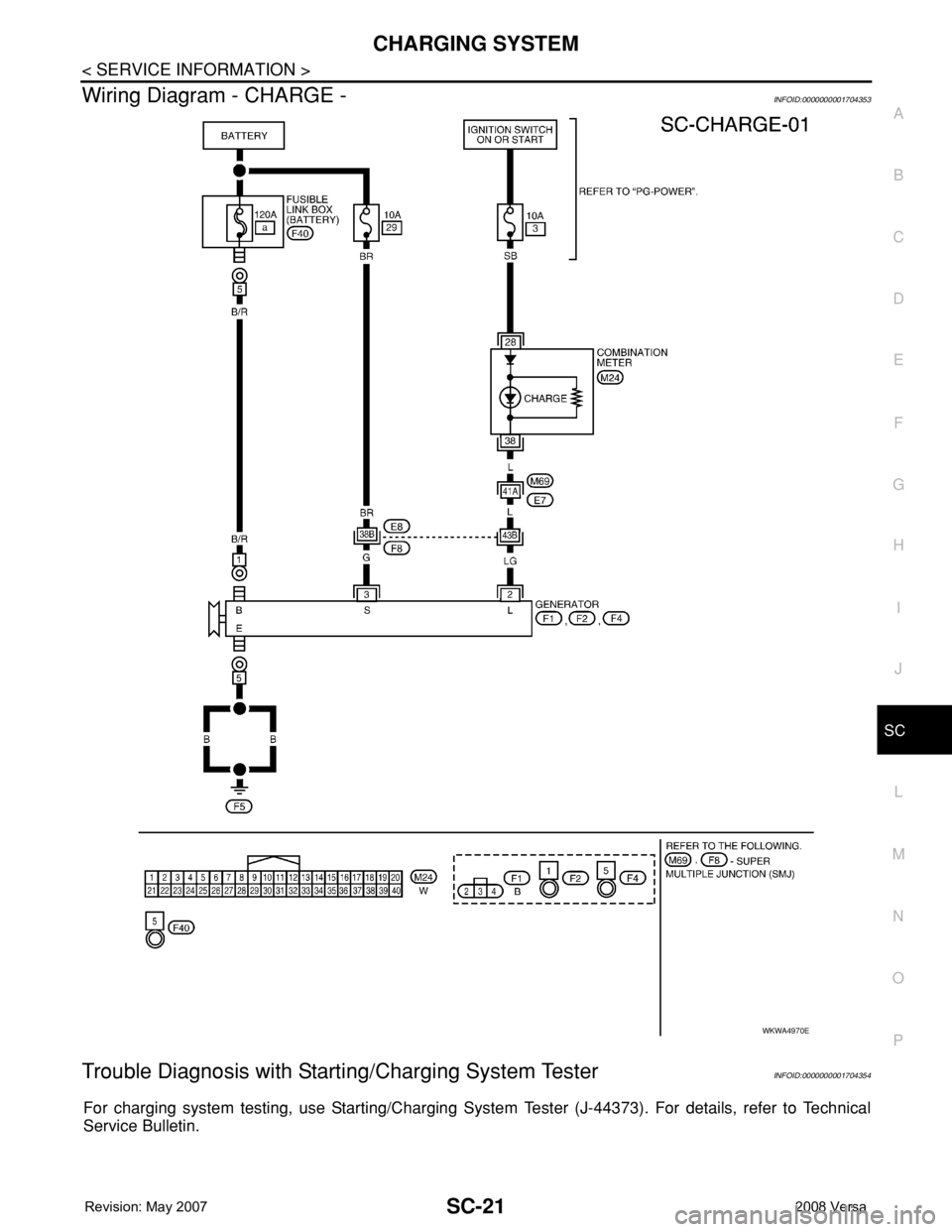

Wiring Diagram - CHARGE -INFOID:0000000001704353

Trouble Diagnosis with Starting/Charging System TesterINFOID:0000000001704354

For charging system testing, use Starting/Charging System Tester (J-44373). For details, refer to Technical

Service Bulletin.

WKWA4970E

Page 2604 of 2771

SC-22

< SERVICE INFORMATION >

CHARGING SYSTEM

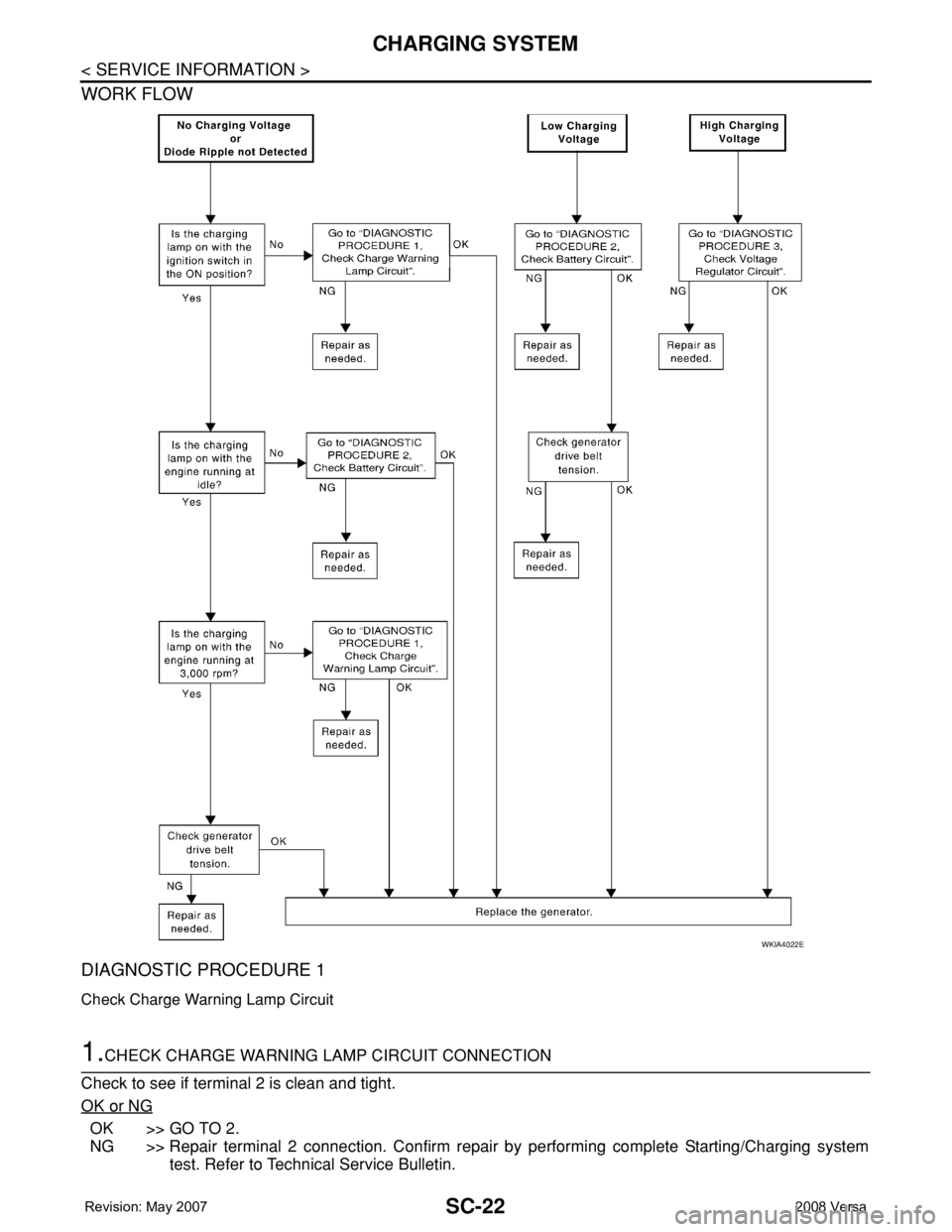

WORK FLOW

DIAGNOSTIC PROCEDURE 1

Check Charge Warning Lamp Circuit

1.CHECK CHARGE WARNING LAMP CIRCUIT CONNECTION

Check to see if terminal 2 is clean and tight.

OK or NG

OK >> GO TO 2.

NG >> Repair terminal 2 connection. Confirm repair by performing complete Starting/Charging system

test. Refer to Technical Service Bulletin.

WKIA4022E

Page 2605 of 2771

CHARGING SYSTEM

SC-23

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

SC

N

O

P

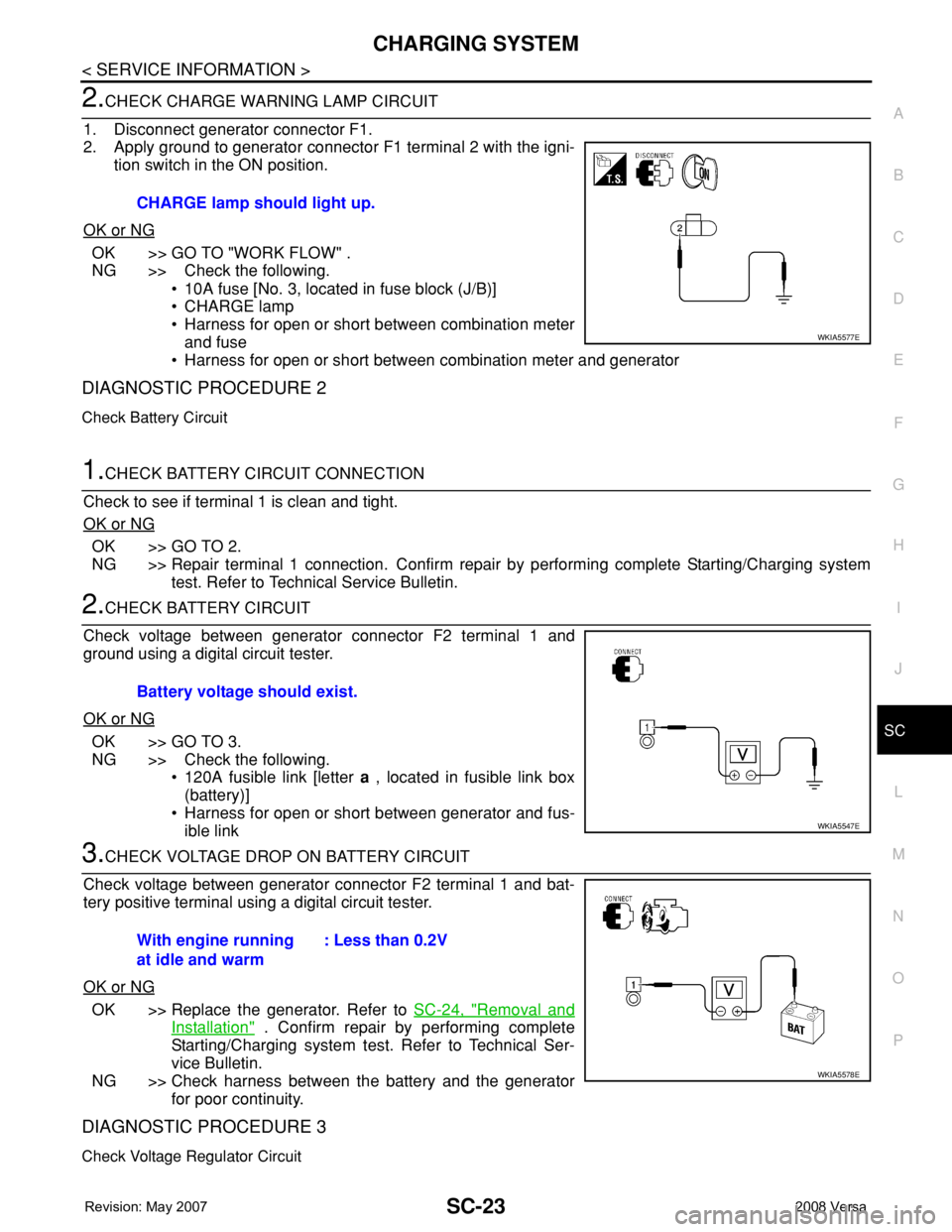

2.CHECK CHARGE WARNING LAMP CIRCUIT

1. Disconnect generator connector F1.

2. Apply ground to generator connector F1 terminal 2 with the igni-

tion switch in the ON position.

OK or NG

OK >> GO TO "WORK FLOW" .

NG >> Check the following.

• 10A fuse [No. 3, located in fuse block (J/B)]

• CHARGE lamp

• Harness for open or short between combination meter

and fuse

• Harness for open or short between combination meter and generator

DIAGNOSTIC PROCEDURE 2

Check Battery Circuit

1.CHECK BATTERY CIRCUIT CONNECTION

Check to see if terminal 1 is clean and tight.

OK or NG

OK >> GO TO 2.

NG >> Repair terminal 1 connection. Confirm repair by performing complete Starting/Charging system

test. Refer to Technical Service Bulletin.

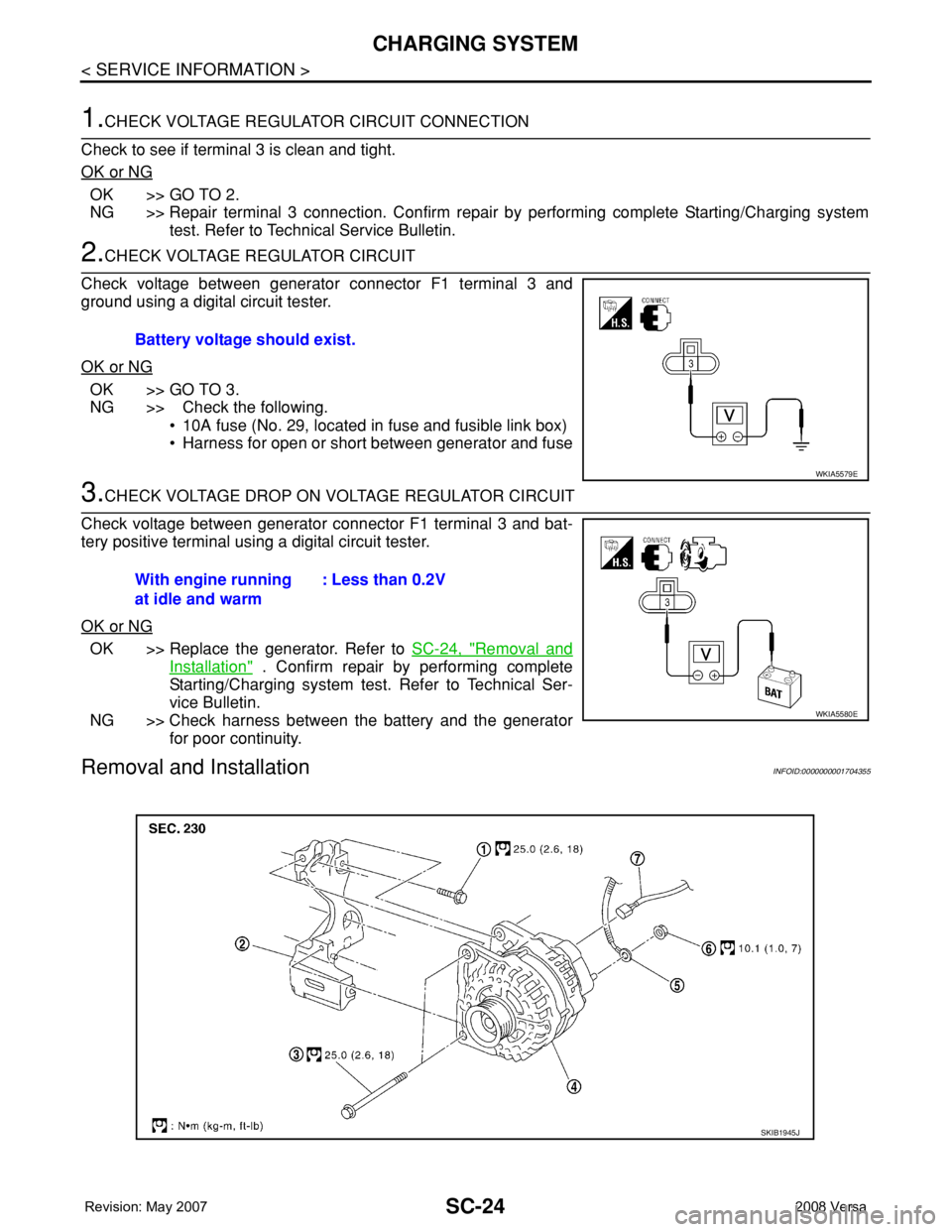

2.CHECK BATTERY CIRCUIT

Check voltage between generator connector F2 terminal 1 and

ground using a digital circuit tester.

OK or NG

OK >> GO TO 3.

NG >> Check the following.

• 120A fusible link [letter a , located in fusible link box

(battery)]

• Harness for open or short between generator and fus-

ible link

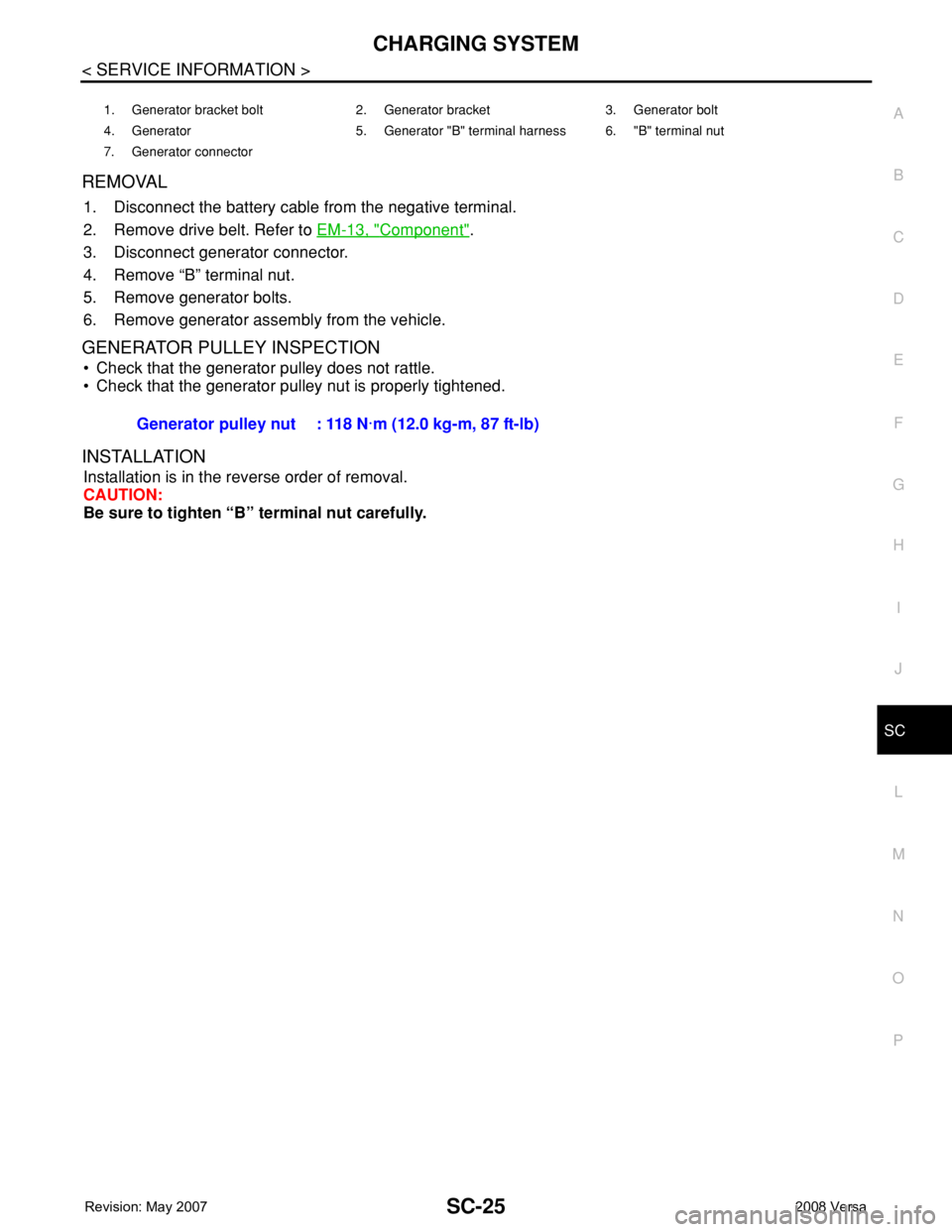

3.CHECK VOLTAGE DROP ON BATTERY CIRCUIT

Check voltage between generator connector F2 terminal 1 and bat-

tery positive terminal using a digital circuit tester.

OK or NG

OK >> Replace the generator. Refer to SC-24, "Removal and

Installation" . Confirm repair by performing complete

Starting/Charging system test. Refer to Technical Ser-

vice Bulletin.

NG >> Check harness between the battery and the generator

for poor continuity.

DIAGNOSTIC PROCEDURE 3

Check Voltage Regulator Circuit

CHARGE lamp should light up.

WKIA5577E

Battery voltage should exist.

WKIA5547E

With engine running

at idle and warm: Less than 0.2V

WKIA5578E

Page 2606 of 2771

SC-24

< SERVICE INFORMATION >

CHARGING SYSTEM

1.CHECK VOLTAGE REGULATOR CIRCUIT CONNECTION

Check to see if terminal 3 is clean and tight.

OK or NG

OK >> GO TO 2.

NG >> Repair terminal 3 connection. Confirm repair by performing complete Starting/Charging system

test. Refer to Technical Service Bulletin.

2.CHECK VOLTAGE REGULATOR CIRCUIT

Check voltage between generator connector F1 terminal 3 and

ground using a digital circuit tester.

OK or NG

OK >> GO TO 3.

NG >> Check the following.

• 10A fuse (No. 29, located in fuse and fusible link box)

• Harness for open or short between generator and fuse

3.CHECK VOLTAGE DROP ON VOLTAGE REGULATOR CIRCUIT

Check voltage between generator connector F1 terminal 3 and bat-

tery positive terminal using a digital circuit tester.

OK or NG

OK >> Replace the generator. Refer to SC-24, "Removal and

Installation" . Confirm repair by performing complete

Starting/Charging system test. Refer to Technical Ser-

vice Bulletin.

NG >> Check harness between the battery and the generator

for poor continuity.

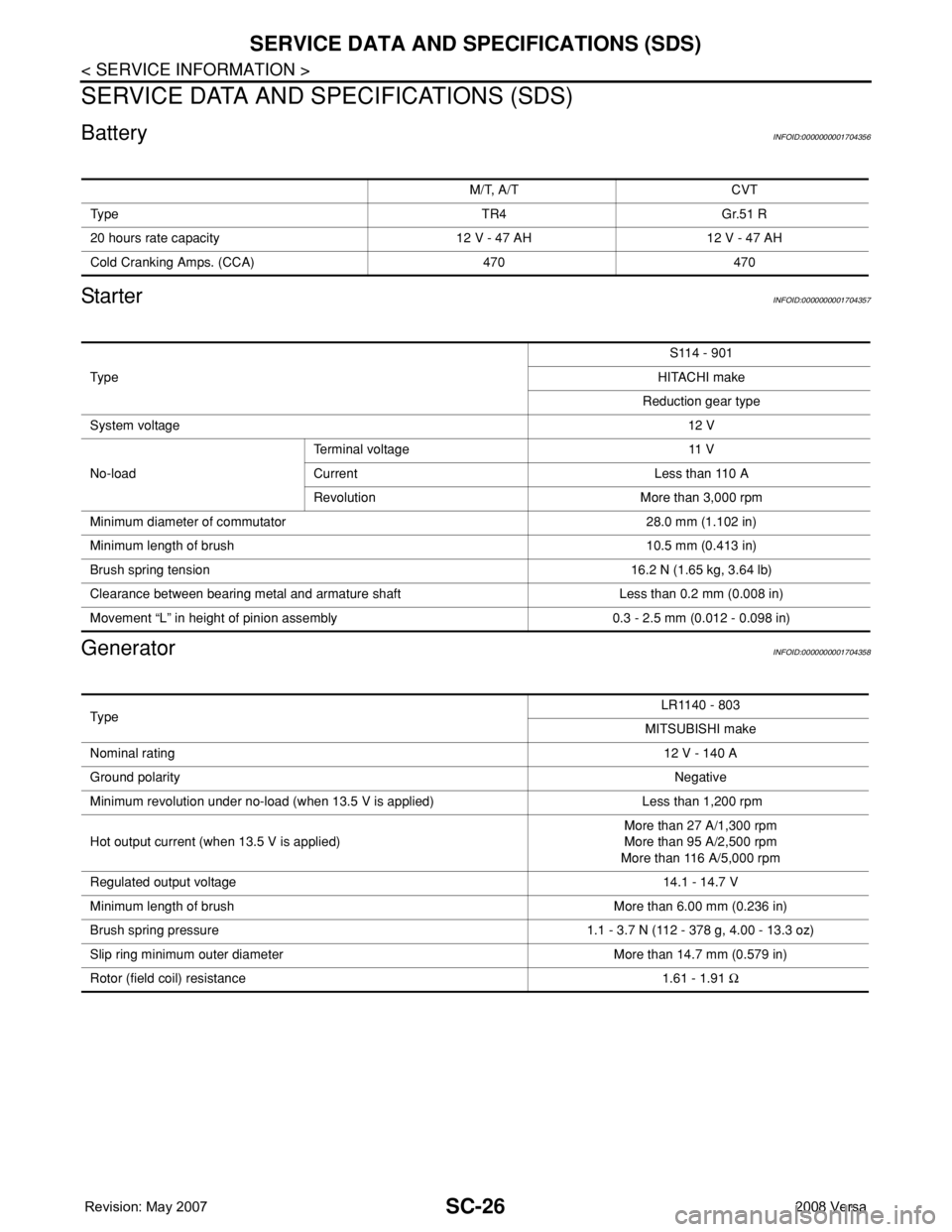

Removal and InstallationINFOID:0000000001704355

Battery voltage should exist.

WKIA5579E

With engine running

at idle and warm: Less than 0.2V

WKIA5580E

SKIB1945J

Page 2607 of 2771

CHARGING SYSTEM

SC-25

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

SC

N

O

P

REMOVAL

1. Disconnect the battery cable from the negative terminal.

2. Remove drive belt. Refer to EM-13, "

Component".

3. Disconnect generator connector.

4. Remove “B” terminal nut.

5. Remove generator bolts.

6. Remove generator assembly from the vehicle.

GENERATOR PULLEY INSPECTION

• Check that the generator pulley does not rattle.

• Check that the generator pulley nut is properly tightened.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

Be sure to tighten “B” terminal nut carefully.

1. Generator bracket bolt 2. Generator bracket 3. Generator bolt

4. Generator 5. Generator "B" terminal harness 6. "B" terminal nut

7. Generator connector

Generator pulley nut : 118 N·m (12.0 kg-m, 87 ft-lb)

Page 2608 of 2771

SC-26

< SERVICE INFORMATION >

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

BatteryINFOID:0000000001704356

StarterINFOID:0000000001704357

GeneratorINFOID:0000000001704358

M/T, A/T CVT

Type TR4 Gr.51 R

20 hours rate capacity 12 V - 47 AH 12 V - 47 AH

Cold Cranking Amps. (CCA) 470 470

Typ eS114 - 901

HITACHI make

Reduction gear type

System voltage12 V

No-loadTerminal voltage 11 V

Current Less than 110 A

Revolution More than 3,000 rpm

Minimum diameter of commutator 28.0 mm (1.102 in)

Minimum length of brush 10.5 mm (0.413 in)

Brush spring tension 16.2 N (1.65 kg, 3.64 lb)

Clearance between bearing metal and armature shaft Less than 0.2 mm (0.008 in)

Movement “L” in height of pinion assembly 0.3 - 2.5 mm (0.012 - 0.098 in)

Ty p eLR1140 - 803

MITSUBISHI make

Nominal rating12 V - 140 A

Ground polarityNegative

Minimum revolution under no-load (when 13.5 V is applied) Less than 1,200 rpm

Hot output current (when 13.5 V is applied)More than 27 A/1,300 rpm

More than 95 A/2,500 rpm

More than 116 A/5,000 rpm

Regulated output voltage14.1 - 14.7 V

Minimum length of brush More than 6.00 mm (0.236 in)

Brush spring pressure 1.1 - 3.7 N (112 - 378 g, 4.00 - 13.3 oz)

Slip ring minimum outer diameter More than 14.7 mm (0.579 in)

Rotor (field coil) resistance 1.61 - 1.91 Ω

Page 2609 of 2771

SE-1

BODY

C

D

E

F

G

H

J

K

L

M

SECTION SE

A

B

SE

N

O

P

CONTENTS

SEAT

SERVICE INFORMATION ............................2

PRECAUTIONS ...................................................2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ...................................................................

2

Service Notice ...........................................................2

Precaution .................................................................2

PREPARATION ...................................................3

Special Service Tool .................................................3

Commercial Service Tool ..........................................3

SQUEAK AND RATTLE TROUBLE DIAG-

NOSES ................................................................

4

Work Flow .................................................................4

Generic Squeak and Rattle Troubleshooting ............6

Diagnostic Worksheet ...............................................8

FRONT SEAT ....................................................10

Driver Seat ...............................................................10

Passenger Seat .......................................................11

Removal and Installation .........................................11

Disassembly and Assembly .....................................12

REAR SEAT ......................................................14

Component Parts Drawing ......................................14

Removal and Installation .........................................15

Disassembly and Assembly .....................................17

Component Parts Drawing ......................................20

Removal and Installation .........................................21

Disassembly and Assembly .....................................23

Removal and Installation .........................................25

Disassembly and Assembly .....................................25

Page 2610 of 2771

SE-2

< SERVICE INFORMATION >

PRECAUTIONS

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000001704254

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

Service NoticeINFOID:0000000001704255

• When removing or installing various parts, place a cloth or padding onto the vehicle body to prevent

scratches.

• Handle trim, molding instruments, grille, etc. carefully during removing or installing. Be careful not to oil or

damage them.

• Apply sealing compound where necessary when installing parts.

• When applying sealing compound, be careful that the sealing compound does not protrude from parts.

• When replacing any metal parts (for example body outer panel, member, etc.), be sure to take rust preven-

tion measures.

PrecautionINFOID:0000000001704256

• When removing or disassembling any part, be careful not to damage or deform it. Protect parts which may

get in the way with cloth.

• When removing parts with a screwdriver or other tool, protect parts by wrapping tools with vinyl or tape.

• Keep removed parts protected with cloth.

• If a clip is deformed or damaged, replace it.

• If an unreusable part is removed, replace it with a new one.

• Tighten bolts and nuts firmly to the specified torque.

• After re-assembly has been completed, make sure each part functions correctly.

• Remove stains in the following way.

Water-soluble stains:

Dip a soft cloth in warm water, and then squeeze it tightly. After wiping the stain, wipe with a soft dry cloth.

Oil stain:

Dissolve a synthetic detergent in warm water (density of 2 to 3% or less), dip the cloth, then clean off the stain

with the cloth. Next, dip the cloth in fresh water and squeeze it tightly. Then clean off the detergent completely.

Then wipe the area with a soft dry cloth.

• Do not use any organic solvent, such as thinner or benzine.