NISSAN LATIO 2008 Service Repair Manual

LATIO 2008

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57360/w960_57360-0.png

NISSAN LATIO 2008 Service Repair Manual

Trending: towing, center console, fuse box location, fold seats, horn, light, engine oil

Page 2591 of 2771

STARTING SYSTEM

SC-9

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

SC

N

O

P

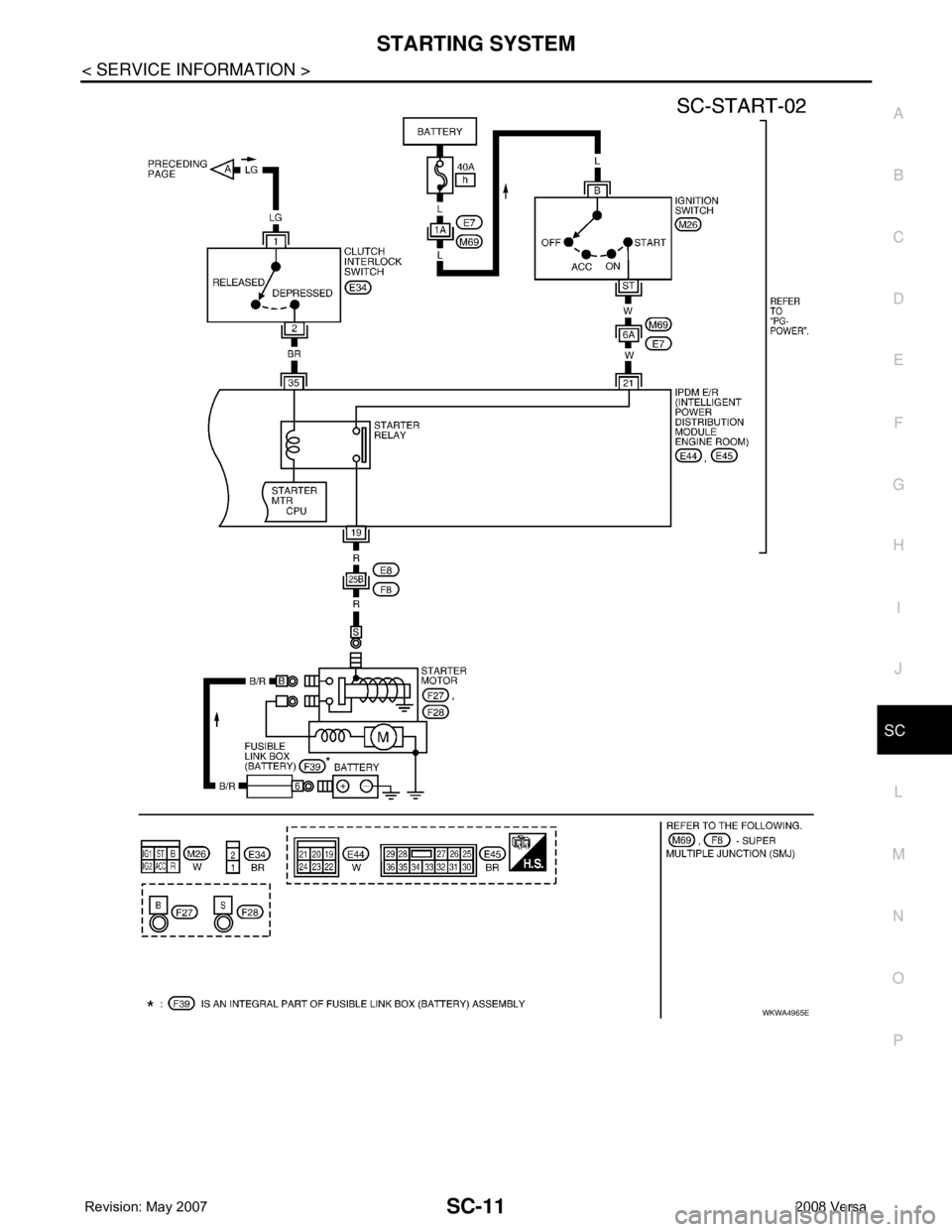

• to IPDM E/R terminal 21.

With the selector lever in the P or N position, power is supplied

• from the transmission control module (TCM) terminal 24

• to IPDM E/R terminal 35.

Ground is supplied at all times

• to IPDM E/R terminals 39 and 59

• through body grounds E15 and E24.

If the IPDM E/R receives a starter relay request ON signal from the BCM over the CAN network, the IPDM E/

R grounds the starter relay and power is supplied

• through terminal 19 of the IPDM E/R

• to terminal S of the starter motor.

The starter motor magnetic switch energizes closing the circuit between the battery and the starter motor. The

starter motor is case ground through the cylinder block. With power and ground supplied, the starter motor

operates.

Page 2592 of 2771

SC-10

< SERVICE INFORMATION >

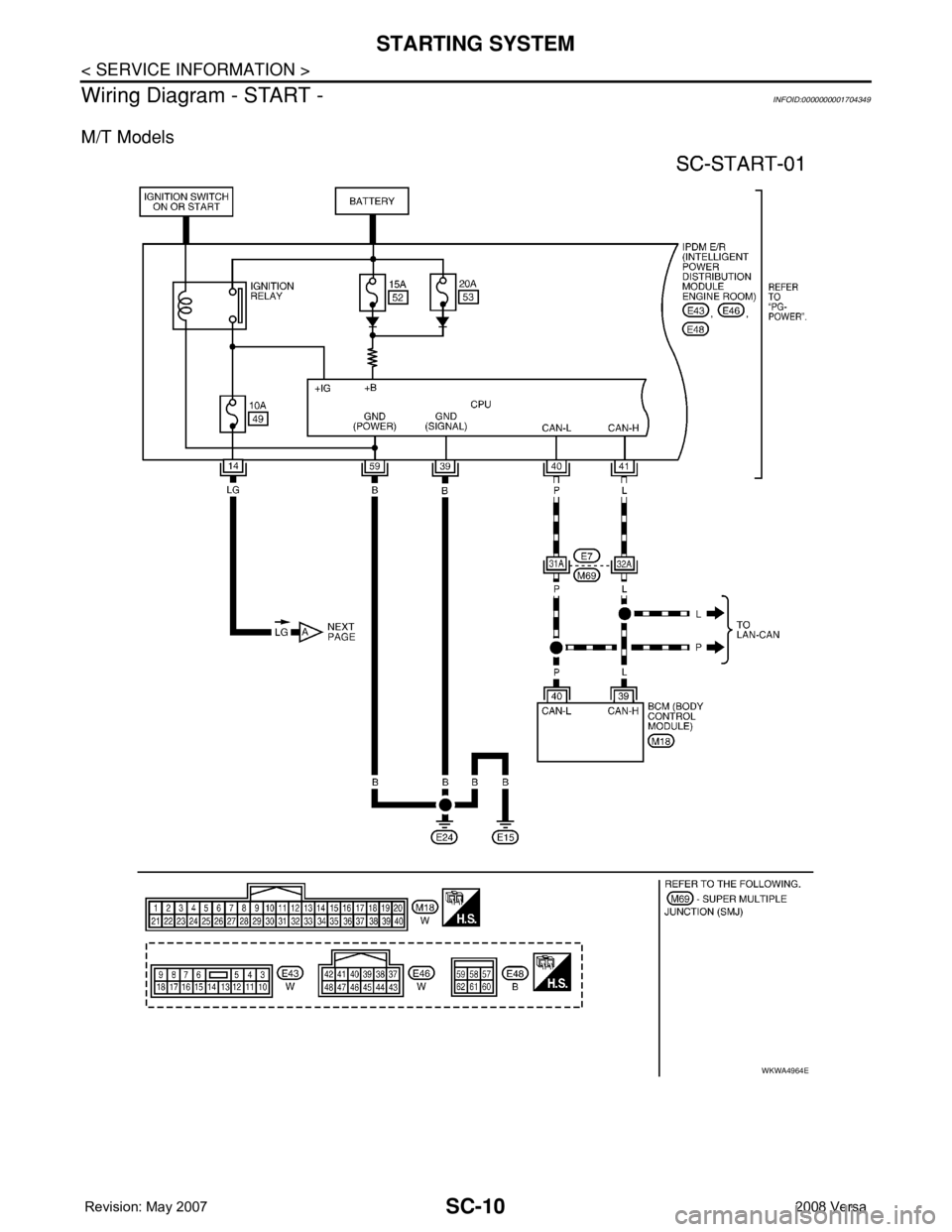

STARTING SYSTEM

Wiring Diagram - START -

INFOID:0000000001704349

M/T Models

WKWA4964E

Page 2593 of 2771

STARTING SYSTEM

SC-11

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

SC

N

O

P

WKWA4965E

Page 2594 of 2771

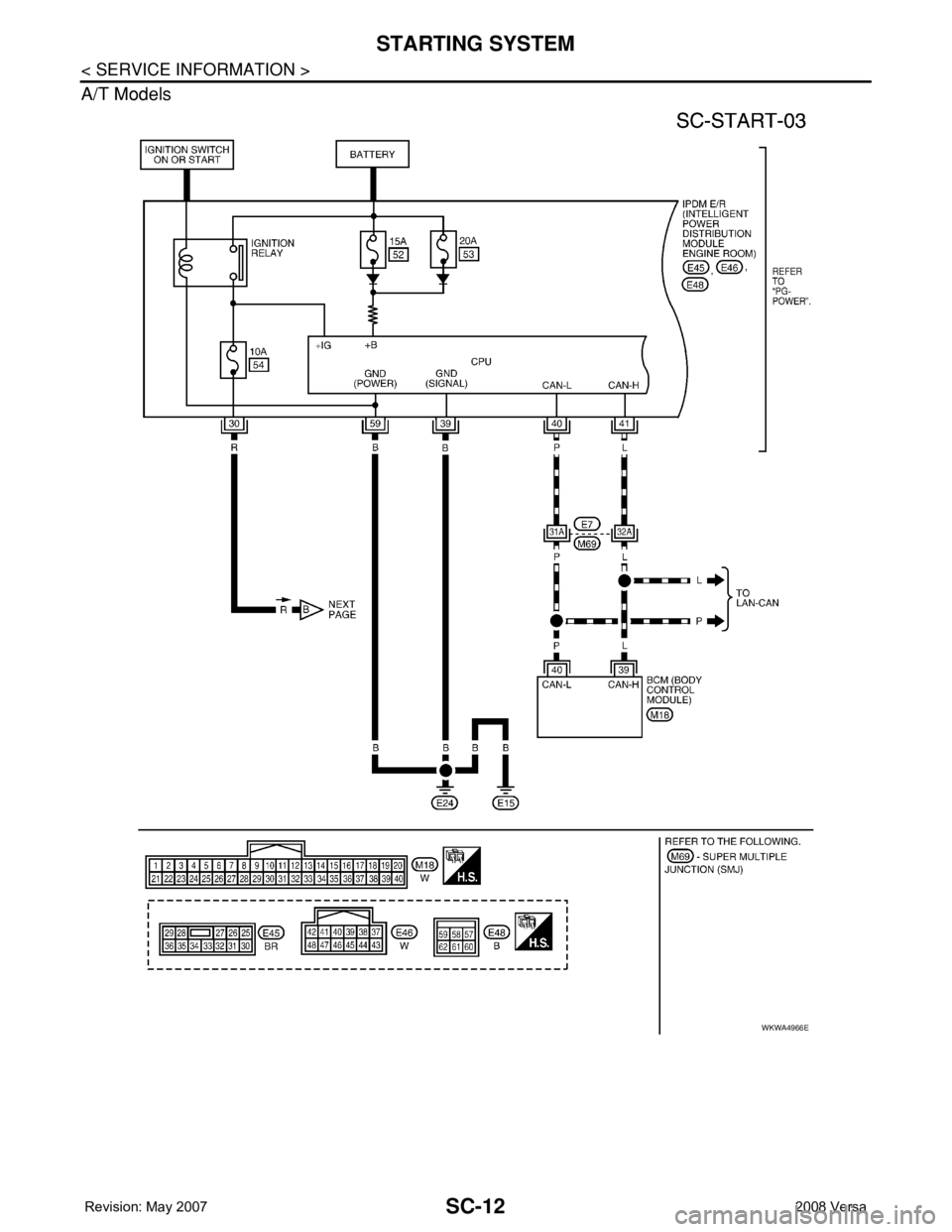

SC-12

< SERVICE INFORMATION >

STARTING SYSTEM

A/T Models

WKWA4966E

Page 2595 of 2771

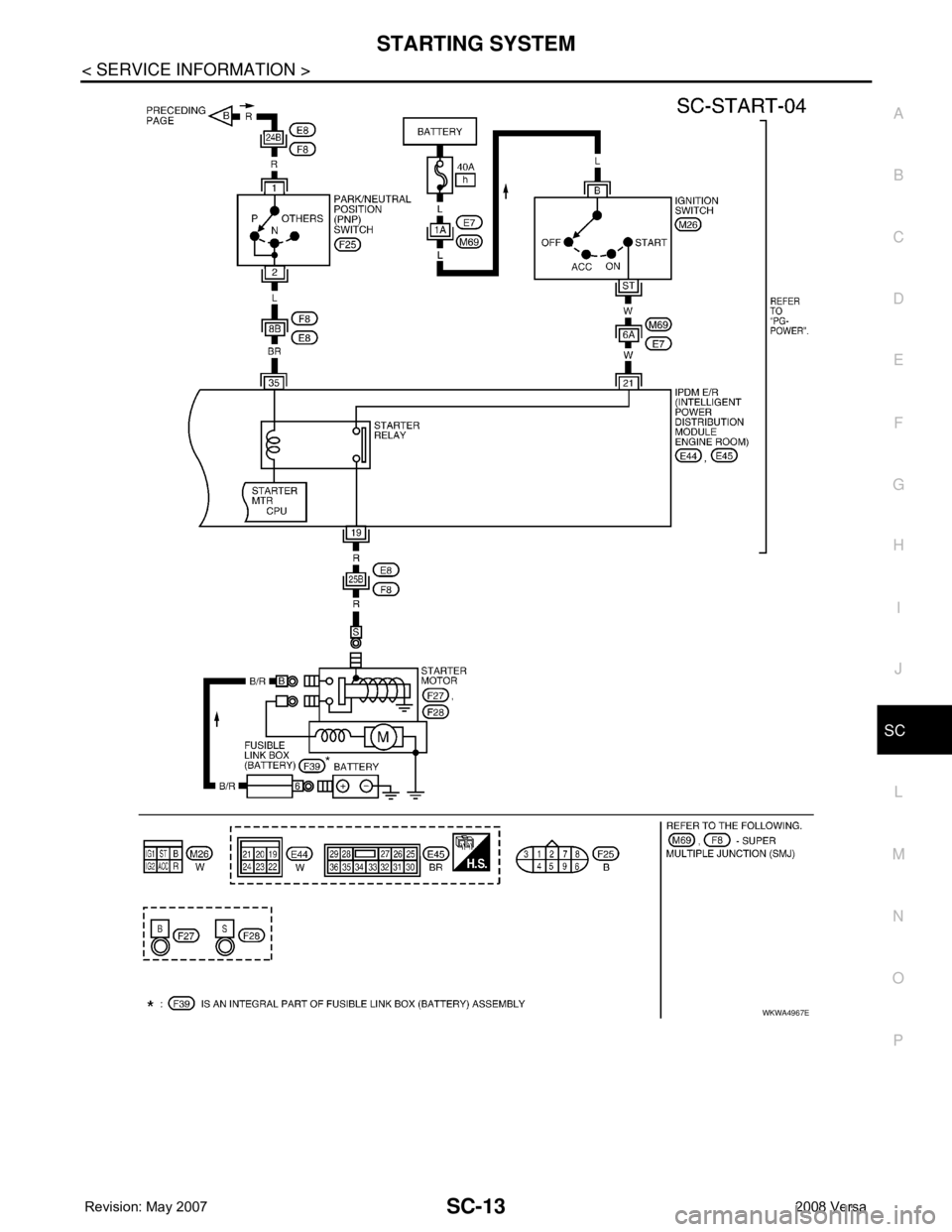

STARTING SYSTEM

SC-13

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

SC

N

O

P

WKWA4967E

Page 2596 of 2771

SC-14

< SERVICE INFORMATION >

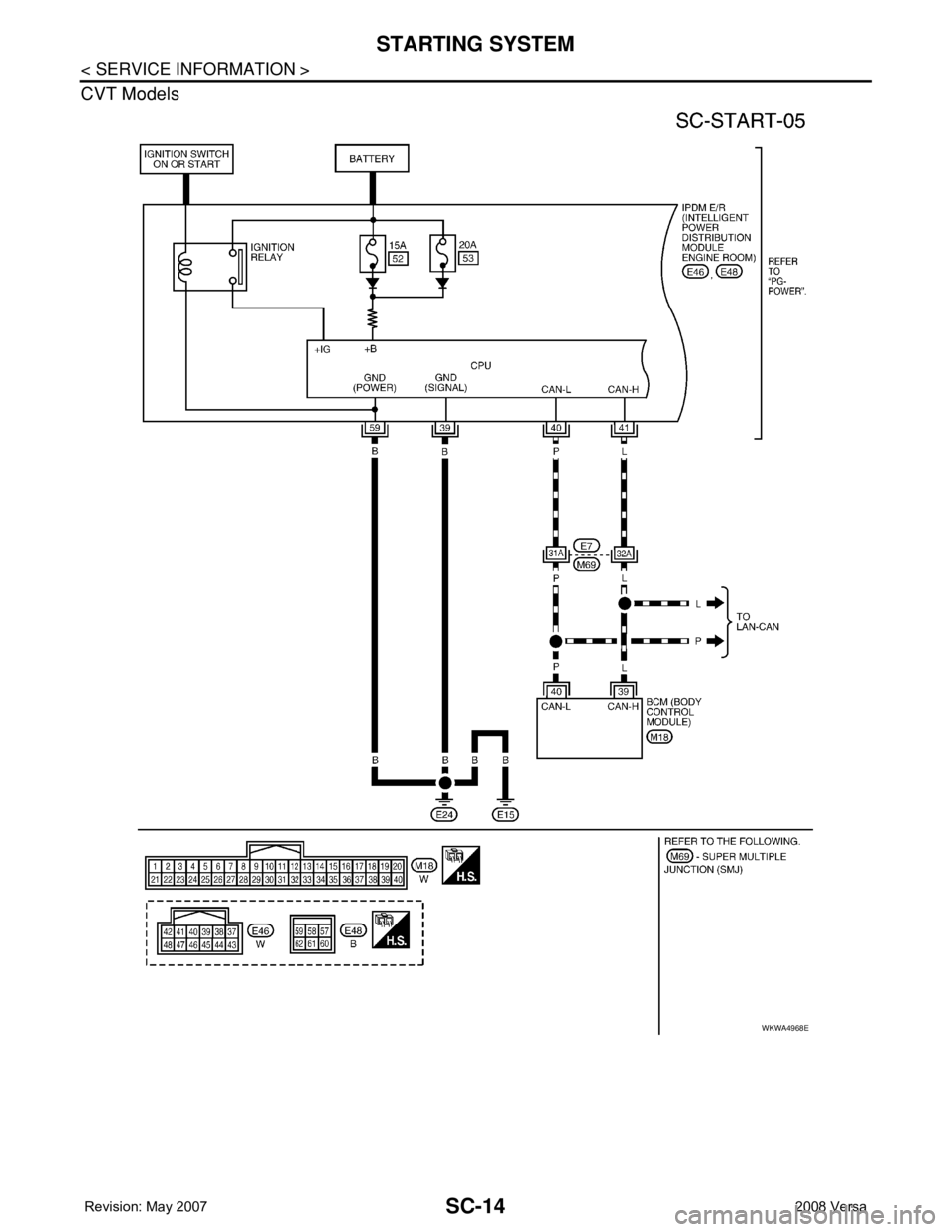

STARTING SYSTEM

CVT Models

WKWA4968E

Page 2597 of 2771

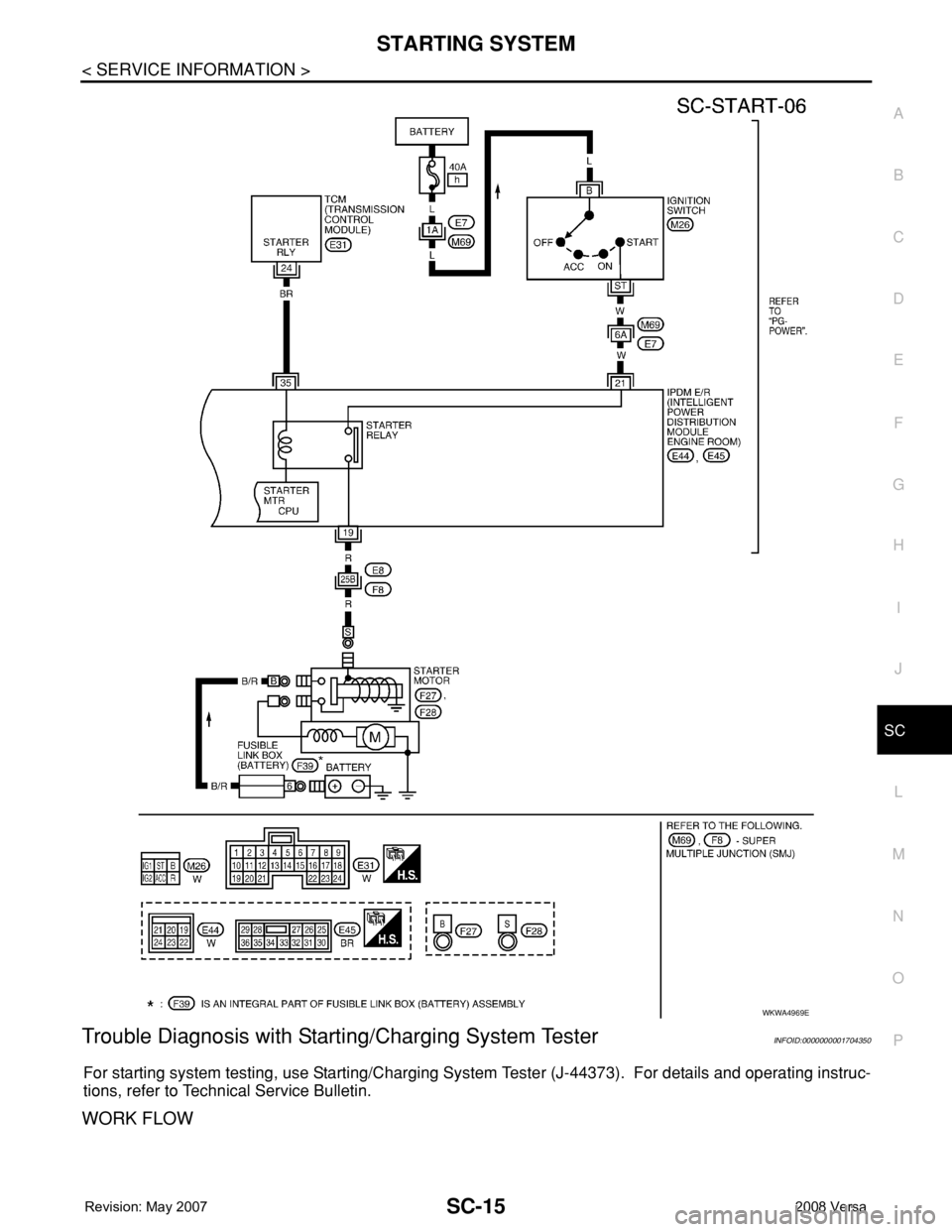

STARTING SYSTEM

SC-15

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

SC

N

O

P

Trouble Diagnosis with Starting/Charging System TesterINFOID:0000000001704350

For starting system testing, use Starting/Charging System Tester (J-44373). For details and operating instruc-

tions, refer to Technical Service Bulletin.

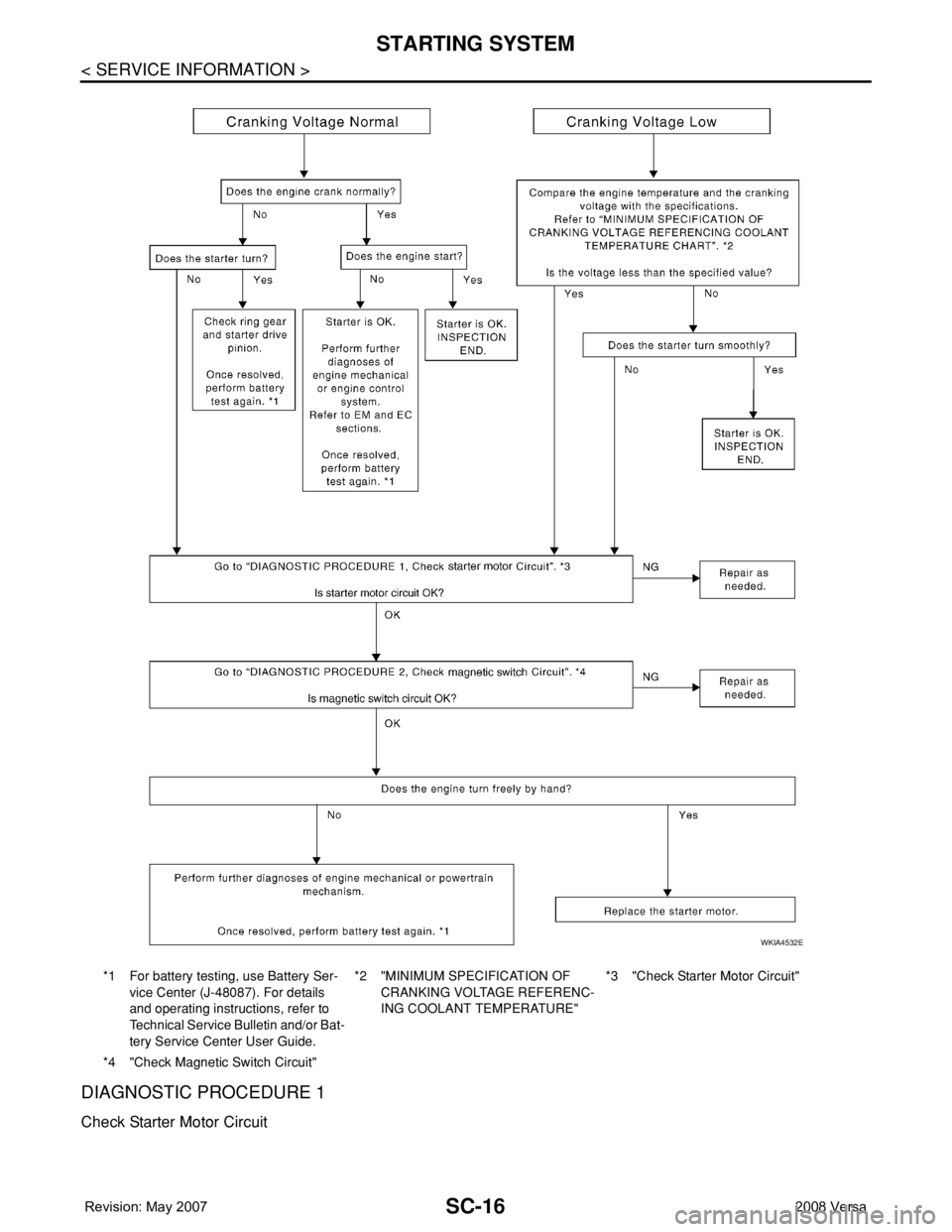

WORK FLOW

WKWA4969E

Page 2598 of 2771

SC-16

< SERVICE INFORMATION >

STARTING SYSTEM

DIAGNOSTIC PROCEDURE 1

Check Starter Motor Circuit

*1 For battery testing, use Battery Ser-

vice Center (J-48087). For details

and operating instructions, refer to

Technical Service Bulletin and/or Bat-

tery Service Center User Guide.*2 "MINIMUM SPECIFICATION OF

CRANKING VOLTAGE REFERENC-

ING COOLANT TEMPERATURE"*3 "Check Starter Motor Circuit"

*4 "Check Magnetic Switch Circuit"

WKIA4532E

Page 2599 of 2771

STARTING SYSTEM

SC-17

< SERVICE INFORMATION >

C

D

E

F

G

H

I

J

L

MA

B

SC

N

O

P

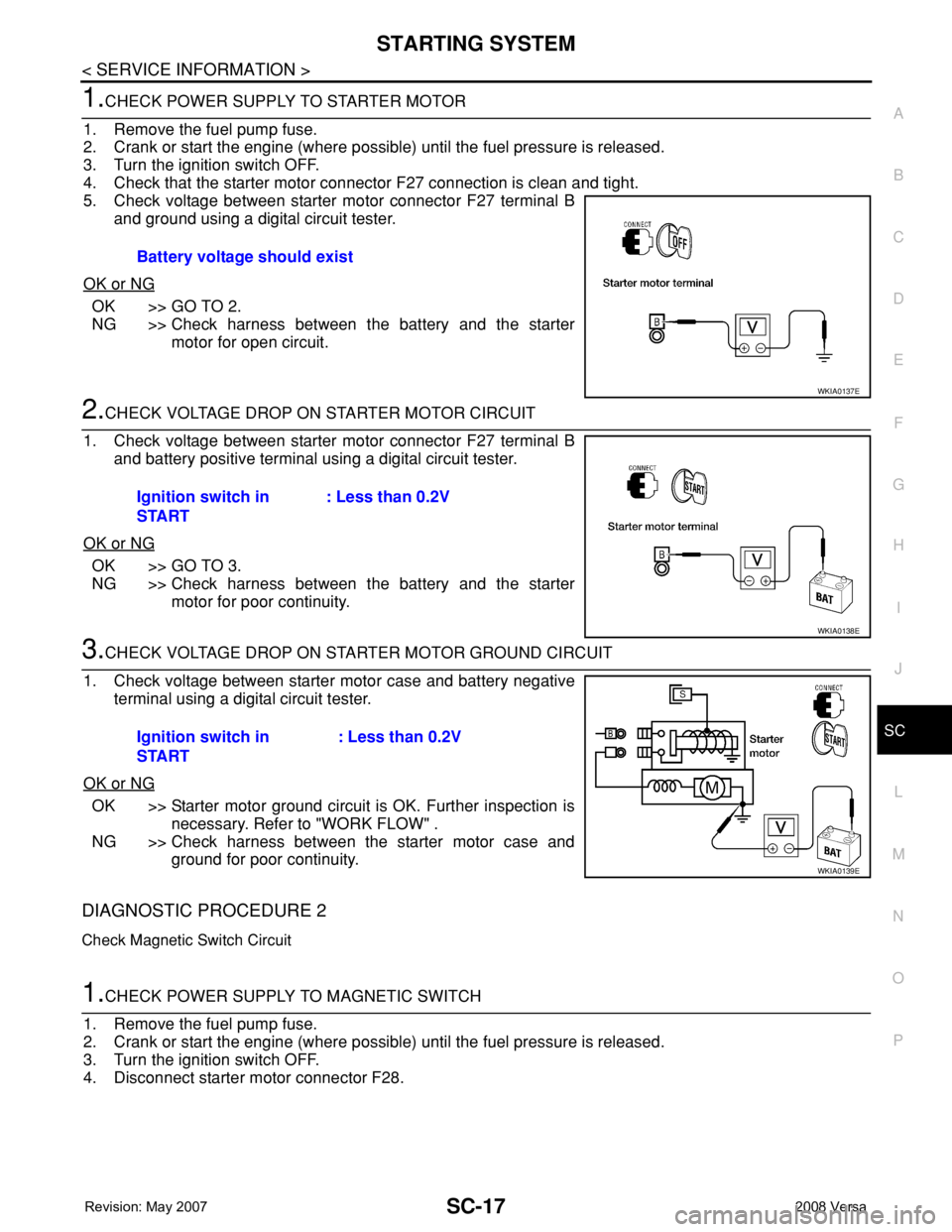

1.CHECK POWER SUPPLY TO STARTER MOTOR

1. Remove the fuel pump fuse.

2. Crank or start the engine (where possible) until the fuel pressure is released.

3. Turn the ignition switch OFF.

4. Check that the starter motor connector F27 connection is clean and tight.

5. Check voltage between starter motor connector F27 terminal B

and ground using a digital circuit tester.

OK or NG

OK >> GO TO 2.

NG >> Check harness between the battery and the starter

motor for open circuit.

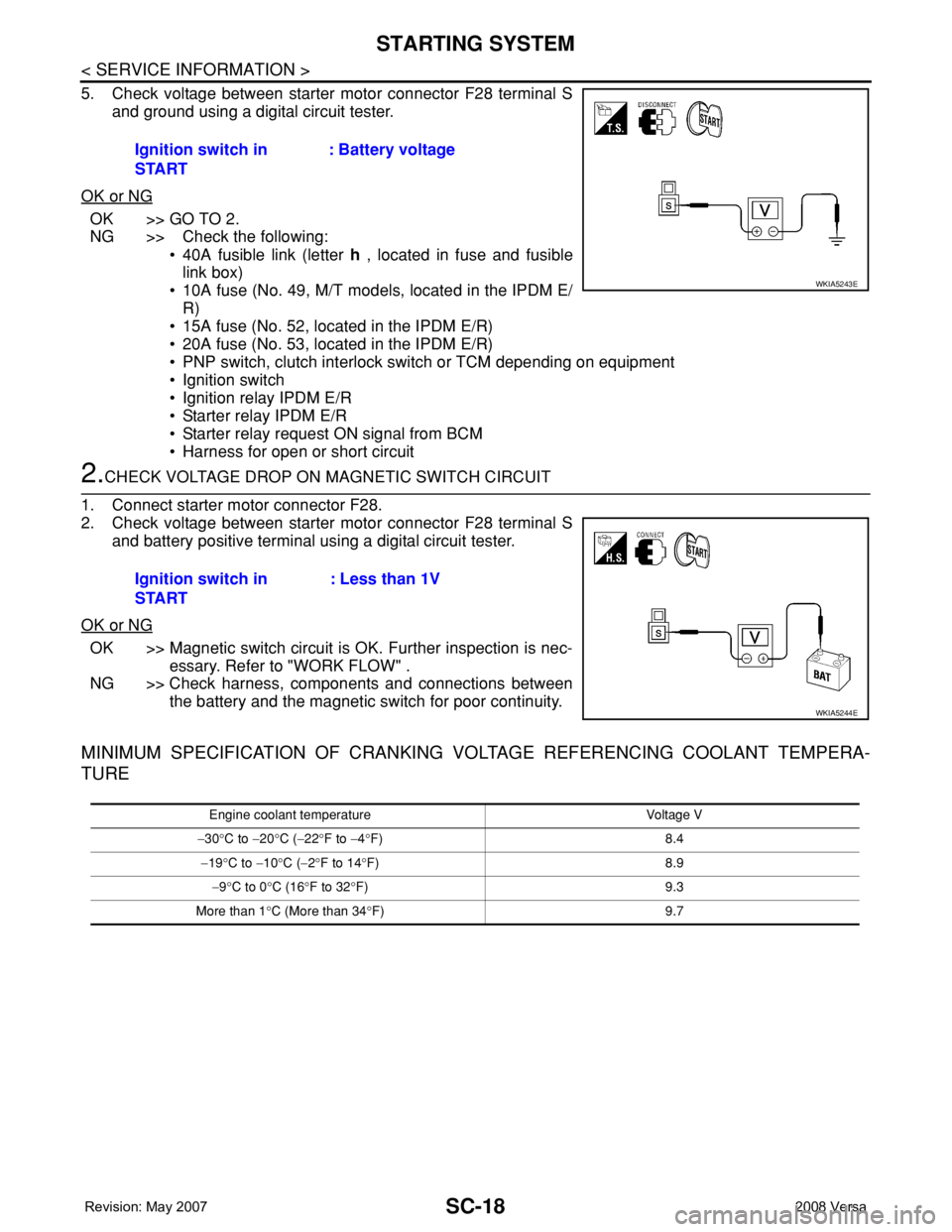

2.CHECK VOLTAGE DROP ON STARTER MOTOR CIRCUIT

1. Check voltage between starter motor connector F27 terminal B

and battery positive terminal using a digital circuit tester.

OK or NG

OK >> GO TO 3.

NG >> Check harness between the battery and the starter

motor for poor continuity.

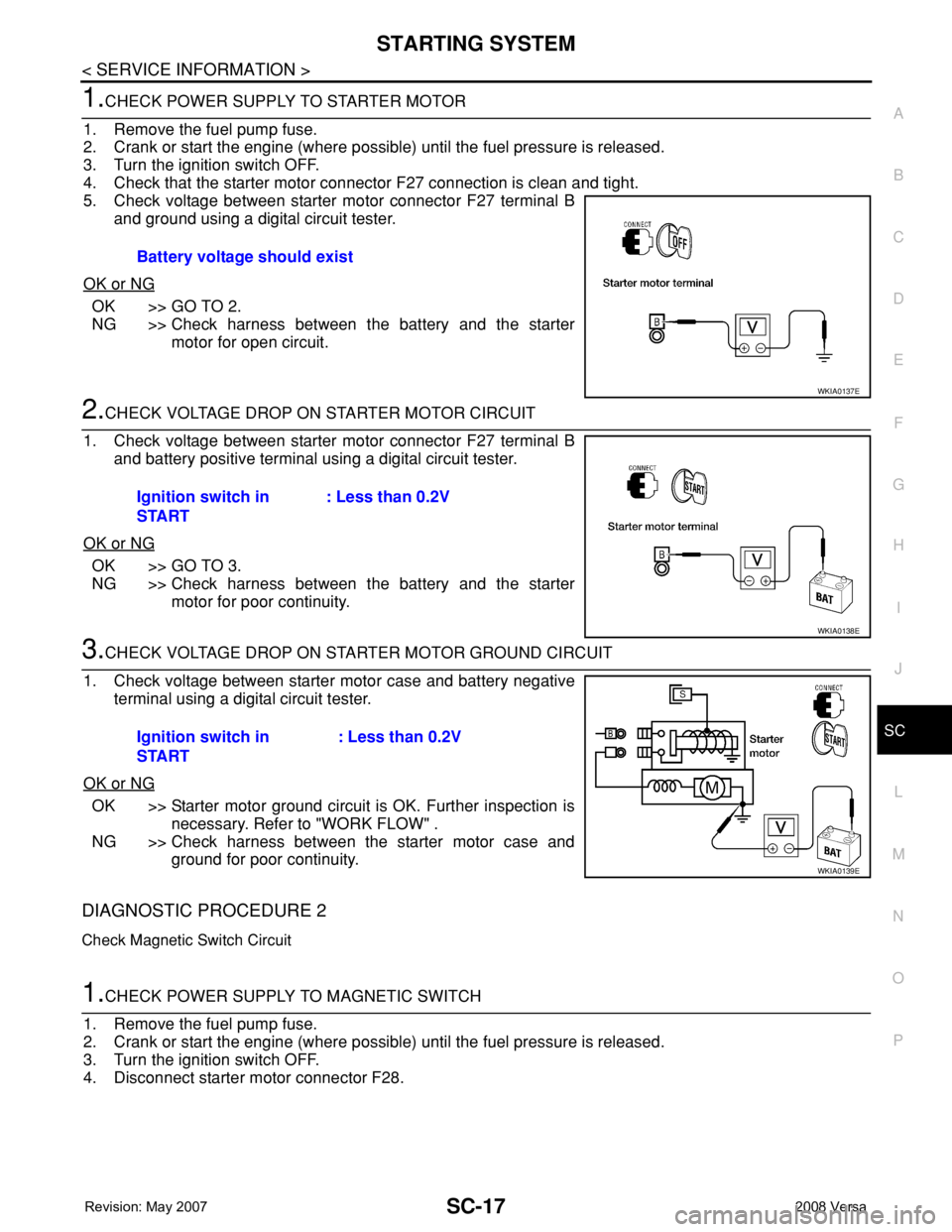

3.CHECK VOLTAGE DROP ON STARTER MOTOR GROUND CIRCUIT

1. Check voltage between starter motor case and battery negative

terminal using a digital circuit tester.

OK or NG

OK >> Starter motor ground circuit is OK. Further inspection is

necessary. Refer to "WORK FLOW" .

NG >> Check harness between the starter motor case and

ground for poor continuity.

DIAGNOSTIC PROCEDURE 2

Check Magnetic Switch Circuit

1.CHECK POWER SUPPLY TO MAGNETIC SWITCH

1. Remove the fuel pump fuse.

2. Crank or start the engine (where possible) until the fuel pressure is released.

3. Turn the ignition switch OFF.

4. Disconnect starter motor connector F28.Battery voltage should exist

WKIA0137E

Ignition switch in

START: Less than 0.2V

WKIA0138E

Ignition switch in

START: Less than 0.2V

WKIA0139E

Page 2600 of 2771

SC-18

< SERVICE INFORMATION >

STARTING SYSTEM

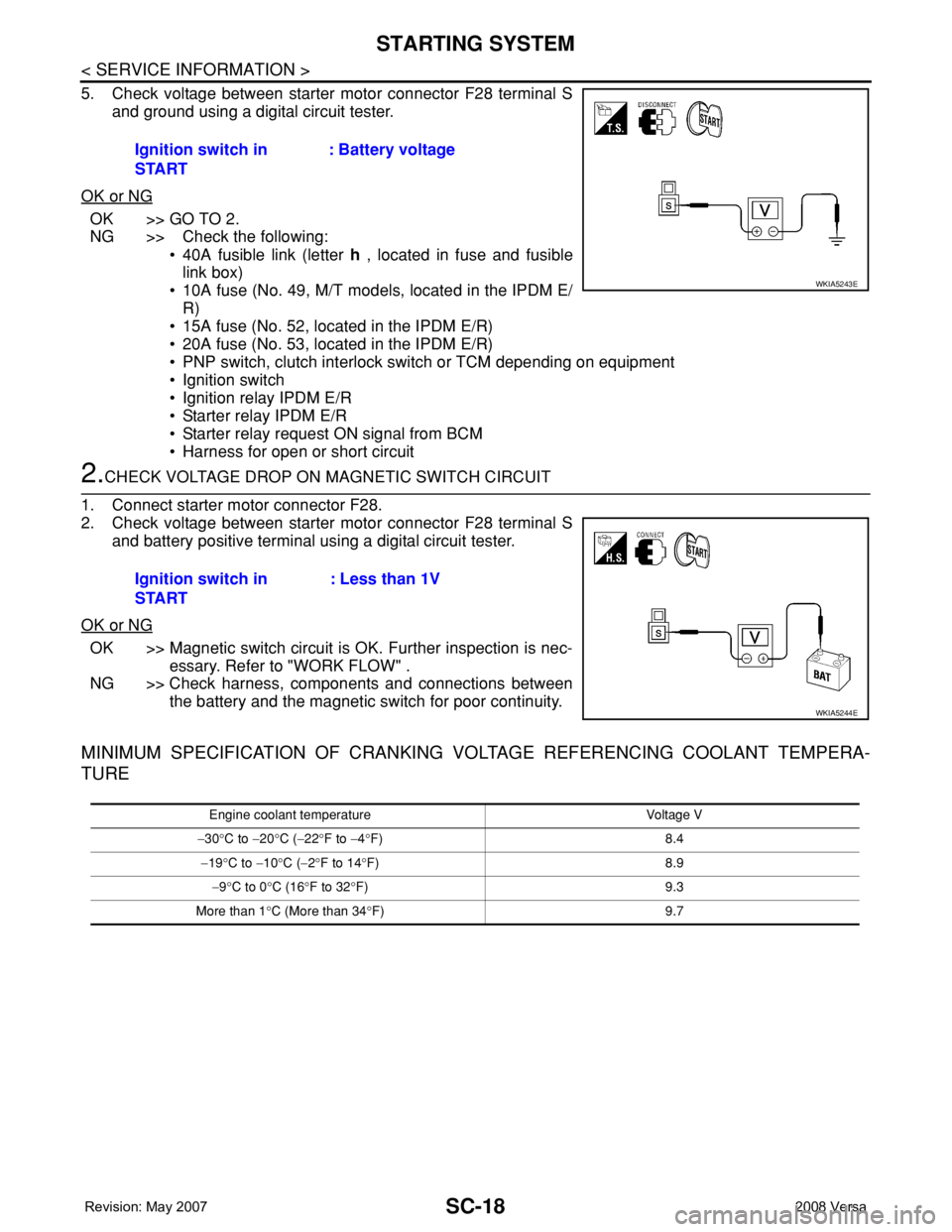

5. Check voltage between starter motor connector F28 terminal S

and ground using a digital circuit tester.

OK or NG

OK >> GO TO 2.

NG >> Check the following:

• 40A fusible link (letter h , located in fuse and fusible

link box)

• 10A fuse (No. 49, M/T models, located in the IPDM E/

R)

• 15A fuse (No. 52, located in the IPDM E/R)

• 20A fuse (No. 53, located in the IPDM E/R)

• PNP switch, clutch interlock switch or TCM depending on equipment

• Ignition switch

• Ignition relay IPDM E/R

• Starter relay IPDM E/R

• Starter relay request ON signal from BCM

• Harness for open or short circuit

2.CHECK VOLTAGE DROP ON MAGNETIC SWITCH CIRCUIT

1. Connect starter motor connector F28.

2. Check voltage between starter motor connector F28 terminal S

and battery positive terminal using a digital circuit tester.

OK or NG

OK >> Magnetic switch circuit is OK. Further inspection is nec-

essary. Refer to "WORK FLOW" .

NG >> Check harness, components and connections between

the battery and the magnetic switch for poor continuity.

MINIMUM SPECIFICATION OF CRANKING VOLTAGE REFERENCING COOLANT TEMPERA-

TURE

Ignition switch in

START: Battery voltage

WKIA5243E

Ignition switch in

START: Less than 1V

WKIA5244E

Engine coolant temperature Voltage V

−30°C to −20°C (−22°F to −4°F) 8.4

−19°C to −10°C (−2°F to 14°F) 8.9

−9°C to 0°C (16°F to 32°F) 9.3

More than 1°C (More than 34°F) 9.7

Trending: key battery, horn, ad blue, center console, spare wheel, length, tires