stop start NISSAN LATIO 2008 Service Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2008, Model line: LATIO, Model: NISSAN LATIO 2008Pages: 2771, PDF Size: 60.61 MB

Page 784 of 2771

![NISSAN LATIO 2008 Service Owners Manual TROUBLE DIAGNOSIS

BRC-19

< SERVICE INFORMATION >[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

SELF-DIAGNOSIS

Description

If an error is detected in the system, the ABS warning lamp will turn on. In this case NISSAN LATIO 2008 Service Owners Manual TROUBLE DIAGNOSIS

BRC-19

< SERVICE INFORMATION >[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

SELF-DIAGNOSIS

Description

If an error is detected in the system, the ABS warning lamp will turn on. In this case](/img/5/57360/w960_57360-783.png)

TROUBLE DIAGNOSIS

BRC-19

< SERVICE INFORMATION >[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

SELF-DIAGNOSIS

Description

If an error is detected in the system, the ABS warning lamp will turn on. In this case, perform self-diagnosis as

follows:

Operation Procedure

1. Turn ignition switch OFF.

2. Connect CONSULT-III to the data link connector.

3. Turn ignition switch ON.

4. Start engine and drive at approximately 30 km/h (19 MPH) or more for approximately 1 minute.

5. After stopping the vehicle, with the engine running, touch “ABS”, “SELF-DIAG RESULTS” in order on the

CONSULT-III screen.

6. The self-diagnostic results are displayed. (If necessary, the self-diagnostic results can be printed out by

touching “PRINT”.)

• When “NO DTC IS DETECTED” is displayed, check the ABS warning lamp.

7. Conduct the appropriate inspection from the display item list, and repair or replace the malfunctioning

component.

8. Start engine and drive at approximately 30 km/h (19 MPH) or more for approximately 1 minute.

CAUTION:

• When a wheel sensor “short-circuit” is detected, if the vehicle is not driven at 30 km/h (19 MPH)

for at least 1 minute, the ABS warning lamp will not turn off even if the malfunction is repaired.

9. Turn ignition switch OFF to prepare for erasing the memory.

10. Start the engine and touch “ABS”, “SELF-DIAG RESULTS”, “ERASE” in order on the CONSULT-III screen

to erase the error memory.

If “ABS” is not indicated, go to GI-36, "

CONSULT-III Data Link Connector (DLC) Circuit".

CAUTION:

If the error memory is not erased, re-conduct the operation from step 5.

11. For the final inspection, drive at approximately 30 km/h (19 MPH) or more for approximately 1 minute and

confirm that the ABS warning lamp is off.

Display Item List

FUNCTION TEST Conducted by CONSULT-III instead of a technician to determine whether each system is "OK" or "NG".

ECU PART NUMBER ABS actuator and electric unit (control unit) part number can be read. ABS diagnostic mode Description

Page 786 of 2771

![NISSAN LATIO 2008 Service Owners Manual TROUBLE DIAGNOSIS

BRC-21

< SERVICE INFORMATION >[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

Note 1: If wheel sensor 2 for each wheel is indicated, check ABS actuator and electric unit (control unit) power NISSAN LATIO 2008 Service Owners Manual TROUBLE DIAGNOSIS

BRC-21

< SERVICE INFORMATION >[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

Note 1: If wheel sensor 2 for each wheel is indicated, check ABS actuator and electric unit (control unit) power](/img/5/57360/w960_57360-785.png)

TROUBLE DIAGNOSIS

BRC-21

< SERVICE INFORMATION >[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

Note 1: If wheel sensor 2 for each wheel is indicated, check ABS actuator and electric unit (control unit) power supply voltage in addition

to wheel sensor circuit check.

Note 2: If multiple malfunctions are detected including CAN communication line [U1000], perform diagnosis for CAN communication line

first.

DATA MONITOR

Operation Procedure

1. After turning OFF the ignition switch, connect CONSULT-III to the data link connector.

2. Touch “ABS”, “DATA MONITOR” in order on the CONSULT-III screen.

If “ABS” is not indicated, go to GI-36, "

CONSULT-III Data Link Connector (DLC) Circuit".

3. Return to the SELECT MONITOR ITEM screen, and touch “ECU INPUT SIGNALS”, “MAIN SIGNALS” or

“SELECTION FROM MENU”. Refer to the following information.

4. When “START” is touched, the data monitor screen is displayed.

Display Item List

MAIN RELAY

[ C 111 4 ]ABS actuator relay or circuit malfunction.BRC-26, "Actuator Mo-

tor, Motor Relay, and Cir-

cuit Inspection"

CAN COMM CIRCUIT

[U1000]• CAN communication line is open or shorted.

• ABS actuator and electric unit (control unit) internal malfunction

• Battery voltage for ECM is suddenly interrupted for approxi-

mately 0.5 second or more.BRC-28, "CAN Commu-

nication System Inspec-

tion" (Note 2) Self-diagnostic item Malfunction detecting condition Check system

Item

(Unit)Data monitor item selection

Remarks

ECU INPUT

SIGNALSMAIN

SIGNALSSELECTION

FROM MENU

FR RH SENSOR

(km/h, MPH)×××Wheel speed calculated by front RH

wheel sensor signal is displayed.

FR LH SENSOR

(km/h, MPH)×××Wheel speed calculated by front LH

wheel sensor signal is displayed.

RR RH SENSOR

(km/h, MPH)×××Wheel speed calculated by rear RH

wheel sensor signal is displayed.

RR LH SENSOR

(km/h, MPH)×××Wheel speed calculated by rear LH

wheel sensor signal is displayed.

BATTERY VOLT

(V)×××Voltage supplied to ABS actuator

and electric unit (control unit) is dis-

played.

STOP LAMP SW

(ON/OFF)×××Stop lamp switch (ON/OFF) status is

displayed.

ABS WARN LAMP

(ON/OFF)–××ABS warning lamp (ON/OFF) status

is displayed.

FR LH IN SOL

(ON/OFF)–××Front LH IN ABS solenoid (ON/OFF)

status is displayed.

FR LH OUT SOL

(ON/OFF)–××Front LH OUT ABS solenoid (ON/

OFF) status is displayed.

FR RH IN SOL

(ON/OFF)–××Front RH IN ABS solenoid (ON/

OFF) status is displayed.

FR RH OUT SOL

(ON/OFF)–××Front RH OUT ABS solenoid (ON/

OFF) status is displayed.

RR LH IN SOL

(ON/OFF)–××Rear LH IN ABS solenoid (ON/OFF)

status is displayed.

RR LH OUT SOL

(ON/OFF)–××Rear LH OUT ABS solenoid (ON/

OFF) status is displayed.

Page 787 of 2771

![NISSAN LATIO 2008 Service Owners Manual BRC-22

< SERVICE INFORMATION >[ABS]

TROUBLE DIAGNOSIS

×: Applicable

–: Not applicable

ACTIVE TEST

CAUTION:

• Do not perform active test while driving.

• Make sure to completely bleed air from t NISSAN LATIO 2008 Service Owners Manual BRC-22

< SERVICE INFORMATION >[ABS]

TROUBLE DIAGNOSIS

×: Applicable

–: Not applicable

ACTIVE TEST

CAUTION:

• Do not perform active test while driving.

• Make sure to completely bleed air from t](/img/5/57360/w960_57360-786.png)

BRC-22

< SERVICE INFORMATION >[ABS]

TROUBLE DIAGNOSIS

×: Applicable

–: Not applicable

ACTIVE TEST

CAUTION:

• Do not perform active test while driving.

• Make sure to completely bleed air from the brake system.

• The ABS and brake warning lamps turn on during the active test.

Operation Procedure

1. Connect the CONSULT-III to the data link connector and start the engine.

2. Touch “ABS”.

If “ABS” is not indicated, go to GI-36, "

CONSULT-III Data Link Connector (DLC) Circuit".

3. Touch “ACTIVE TEST”.

4. The SELECT TEST ITEM screen is displayed.

5. Touch necessary test item.

6. With the “MAIN SIGNALS” display selected, touch “START”.

7. The Active Test screen will be displayed, so conduct the following test.

Solenoid Valve Operation Chart

NOTE:

• If active test is performed with brake pedal depressed, pedal stroke may change. This is normal.

• “TEST IS STOPPED” is displayed approximately 10 seconds after operation starts.

• After “TEST IS STOPPED” is displayed, to perform test again, repeat Step 6.

ABS Motor

Touch “ON” and “OFF” on the screen. Check that ABS motor relay operates as shown in table below.

RR RH IN SOL

(ON/OFF)–××Rear RH IN ABS solenoid (ON/OFF)

status is displayed.

RR RH OUT SOL

(ON/OFF)–××Rear RH OUT ABS solenoid (ON/

OFF) status is displayed.

MOTOR RELAY

(ON/OFF)–××ABS motor relay signal (ON/OFF)

status is displayed.

ACTUATOR RLY

(ON/OFF)–××ABS actuator relay signal (ON/OFF)

status is displayed.

ABS FAIL SIG

(ON/OFF)––×ABS fail signal (ON/OFF) status is

displayed.

EBD FAIL SIG

(ON/OFF)––×EBD fail signal (ON/OFF) status is

displayed.

EBD SIGNAL

(ON/OFF)––×EBD operation (ON/OFF) status is

displayed.

ABS SIGNAL

(ON/OFF)––×ABS operation (ON/OFF) status is

displayed. Item

(Unit)Data monitor item selection

Remarks

ECU INPUT

SIGNALSMAIN

SIGNALSSELECTION

FROM MENU

TEST ITEM CONDITION JUDGEMENT

FR RH SOL

FR LH SOL

RR RH SOL

RR LH SOLIgnition switch is turned ON.Brake fluid pressure control operation

IN SOL OUT SOL

UP (Increase): OFF OFF

KEEP (Hold): ON OFF

DOWN (Decrease): ON ON

Page 788 of 2771

![NISSAN LATIO 2008 Service Owners Manual TROUBLE DIAGNOSIS

BRC-23

< SERVICE INFORMATION >[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

NOTE:

• If active test is performed with brake pedal depressed, pedal stroke may change. This is normal.

• � NISSAN LATIO 2008 Service Owners Manual TROUBLE DIAGNOSIS

BRC-23

< SERVICE INFORMATION >[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

NOTE:

• If active test is performed with brake pedal depressed, pedal stroke may change. This is normal.

• �](/img/5/57360/w960_57360-787.png)

TROUBLE DIAGNOSIS

BRC-23

< SERVICE INFORMATION >[ABS]

C

D

E

G

H

I

J

K

L

MA

B

BRC

N

O

P

NOTE:

• If active test is performed with brake pedal depressed, pedal stroke may change. This is normal.

• “TEST IS STOPPED” is displayed approximately 10 seconds after operation starts.

Operation ON OFF

ABS actuator relay ON ON

ABS motor relay ON OFF

Page 795 of 2771

![NISSAN LATIO 2008 Service Owners Manual BRC-30

< SERVICE INFORMATION >[ABS]

TROUBLE DIAGNOSES FOR SYMPTOMS

2. Drive vehicle and check brake operation.

NOTE:

• Stopping distance may be longer than vehicles without ABS when road condition i NISSAN LATIO 2008 Service Owners Manual BRC-30

< SERVICE INFORMATION >[ABS]

TROUBLE DIAGNOSES FOR SYMPTOMS

2. Drive vehicle and check brake operation.

NOTE:

• Stopping distance may be longer than vehicles without ABS when road condition i](/img/5/57360/w960_57360-794.png)

BRC-30

< SERVICE INFORMATION >[ABS]

TROUBLE DIAGNOSES FOR SYMPTOMS

2. Drive vehicle and check brake operation.

NOTE:

• Stopping distance may be longer than vehicles without ABS when road condition is slippery.

• Driving the vehicle with the ABS actuator and electric unit (control unit) disconnected may induce DTCs

in electrical control units using CAN communication. After the inspection, clear all DTCs. Refer to LAN-

6, "System Description".

OK or NG

OK >> GO TO 4.

NG >> Perform Basic Inspection. Refer to BRC-16, "

Basic Inspection".

4.CHECK WHEEL SENSORS

Check the following.

• Wheel sensor mounting for looseness

• Wheel sensors for physical damage

• Wheel sensor connectors for terminal damage or loose connections

• Sensor rotor and mount for physical damage

OK or NG

OK >> Check ABS actuator and electric unit (control unit) connector terminals for deformation, discon-

nection, looseness or damage. Reconnect ABS actuator and electric unit (control unit) harness

connector. Then retest.

NG >> Repair or replace as necessary.

Long Stopping DistanceINFOID:0000000001703847

1.CHECK BASE BRAKING SYSTEM PERFORMANCE

1. Disable ABS by disconnecting ABS actuator and electric unit (control unit) connector.

2. Drive vehicle and check brake operation.

NOTE:

• Stopping distance may be longer than vehicles without ABS when road condition is slippery.

• Driving the vehicle with the ABS actuator and electric unit (control unit) disconnected may induce DTCs

in electrical control units using CAN communication. After the inspection, clear all DTCs. Refer to LAN-

6, "System Description".

OK or NG

OK >> Go to BRC-29, "ABS Works Frequently".

NG >> Perform Basic Inspection. Refer to BRC-16, "

Basic Inspection".

ABS Does Not WorkINFOID:0000000001703848

CAUTION:

The ABS does not operate when the vehicle speed is 10 km/h (6 MPH) or less.

1.CHECK WARNING LAMP ACTIVATION

Turn ignition switch ON and check for warning lamp activation.

• Warning lamp should activate for approximately 2 seconds after turning the ignition switch ON.

OK or NG

OK >> Carry out self-diagnosis. Refer to BRC-18, "CONSULT-III Function (ABS)".

NG >> Go to BRC-16, "

Basic Inspection".

Pedal Vibration or ABS Operation NoiseINFOID:0000000001703849

NOTE:

During ABS activation, pedal vibration may be felt and a noise may be heard. This is normal and does not indi-

cate a malfunction.

1.CHECK SYMPTOM

1. Apply brake.

2. Start engine.

Does the symptom occur only when engine is started?

YES >> Carry out self-diagnosis. Refer to BRC-18, "CONSULT-III Function (ABS)".

Page 859 of 2771

CVT-20

< SERVICE INFORMATION >

CVT SYSTEM

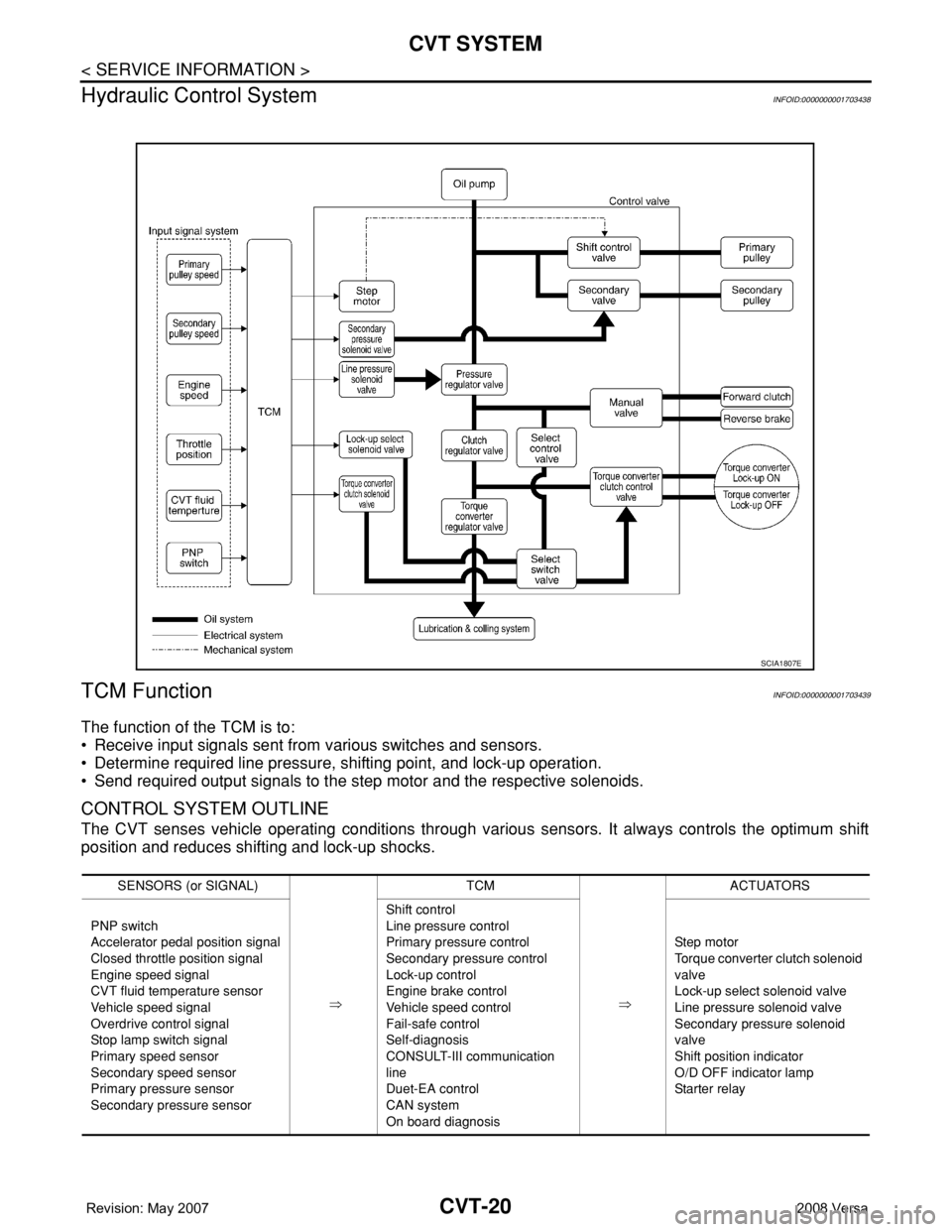

Hydraulic Control System

INFOID:0000000001703438

TCM FunctionINFOID:0000000001703439

The function of the TCM is to:

• Receive input signals sent from various switches and sensors.

• Determine required line pressure, shifting point, and lock-up operation.

• Send required output signals to the step motor and the respective solenoids.

CONTROL SYSTEM OUTLINE

The CVT senses vehicle operating conditions through various sensors. It always controls the optimum shift

position and reduces shifting and lock-up shocks.

SCIA1807E

SENSORS (or SIGNAL)

⇒TCM

⇒ACTUATORS

PNP switch

Accelerator pedal position signal

Closed throttle position signal

Engine speed signal

CVT fluid temperature sensor

Vehicle speed signal

Overdrive control signal

Stop lamp switch signal

Primary speed sensor

Secondary speed sensor

Primary pressure sensor

Secondary pressure sensorShift control

Line pressure control

Primary pressure control

Secondary pressure control

Lock-up control

Engine brake control

Vehicle speed control

Fail-safe control

Self-diagnosis

CONSULT-III communication

line

Duet-EA control

CAN system

On board diagnosisSte p m ot or

Torque converter clutch solenoid

valve

Lock-up select solenoid valve

Line pressure solenoid valve

Secondary pressure solenoid

valve

Shift position indicator

O/D OFF indicator lamp

Starter relay

Page 880 of 2771

TROUBLE DIAGNOSIS

CVT-41

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

CVT

N

O

P

• Before road test, familiarize yourself with all test procedures and

items to check.

• Perform tests on all items until specified symptom is found. Trou-

bleshoot items which check out No Good after road test.

CONSULT-III START PROCEDURE

• Using CONSULT-III, perform a cruise test and record the result.

• Print the result and ensure that shifts and lock-ups take place as per Shift Schedule.

1. Touch “DATA MONITOR” on “SELECT DIAG MODE” screen.

2. Touch “MAIN SIGNALS” to set recording condition.

3. See “Numerical Display”, “Barchart Display” or “Line Graph Display”.

4. Touch “START”.

5. When performing cruise test. Refer to CVT-43, "

Cruise Test" .

6. After finishing cruise test part, touch “RECORD”.

7. Touch “STORE”.

8. Touch “BACK”.

9. Touch “DISPLAY”.

10. Touch “PRINT”.

11. Check the monitor data printed out.

Check before Engine Is StartedINFOID:0000000001703458

1.CHECK O/D OFF INDICATOR LAMP

1. Park vehicle on flat surface.

2. Move selector lever to “P” position.

3. Turn ignition switch OFF. Wait at least 5 seconds.

4. Turn ignition switch ON. (Do not start engine.)

Does O/D OFF indicator lamp come on for about 2 seconds?

YES >> 1. Turn ignition switch OFF.

2. Perform self-diagnosis and note NG items.

Refer to CVT-47, "

CONSULT-III Function (TRANSMISSION)" .

3. Go to CVT-41, "

Check at Idle" .

NO >> Stop “Road Test”. Go to CVT-151, "

O/D OFF Indicator Lamp Does Not Come On" .

Check at IdleINFOID:0000000001703459

1.CHECK STARTING THE ENGINE

1. Park vehicle on flat surface.

2. Move selector lever to “P” or “N” position.

3. Turn ignition switch OFF.

4. Turn ignition switch START.

Is engine started?

SAT496G

Page 881 of 2771

CVT-42

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS

YES >> GO TO 2.

NO >> Stop “Road Test”. Mark the box on the CVT-30, "

How to Perform Trouble Diagnosis for Quick and

Accurate Repair" . Go to CVT-153, "Engine Cannot Be Started in "P" and "N" Position" .

2.CHECK STARTING THE ENGINE

1. Turn ignition switch ON.

2. Move selector lever to “D”, “L” or “R” position.

3. Turn ignition switch START.

Is engine started?

YES >> Stop “Road Test”. Mark the box on the CVT-30, "How to Perform Trouble Diagnosis for Quick and

Accurate Repair" . Go to CVT-153, "Engine Cannot Be Started in "P" and "N" Position" .

NO >> GO TO 3.

3.CHECK “P” POSITION FUNCTION

1. Move selector lever to “P” position.

2. Turn ignition switch OFF.

3. Release parking brake.

4. Push vehicle forward or backward.

5. Apply parking brake.

Does vehicle move when it is pushed forward or backward?

YES >> Mark the box CVT-153, "In "P" Position, Vehicle Moves Forward or Backward When Pushed" on

the CVT-30, "

How to Perform Trouble Diagnosis for Quick and Accurate Repair" . Continue “Road

Te s t ” .

NO >> GO TO 4.

4.CHECK “N” POSITION FUNCTION

1. Start engine.

2. Move selector lever to “N” position.

3. Release parking brake.

Does vehicle move forward or backward?

YES >> Mark the box CVT-154, "In "N" Position, Vehicle Moves" on the CVT-30, "How to Perform Trouble

Diagnosis for Quick and Accurate Repair" . Continue “Road Test”.

NO >> GO TO 5.

5.CHECK SHIFT SHOCK

1. Apply foot brake.

2. Move selector lever to “R” position.

Is there large shock when changing from

“N” to “R” position?

YES >> Mark the box CVT-154, "Large Shock "N" → "R" Position" on the CVT-30, "How to Perform Trou-

ble Diagnosis for Quick and Accurate Repair" . Continue “Road Test”.

NO >> GO TO 6.

6.CHECK “R” POSITION FUNCTION

Release foot brake for several seconds.

Does vehicle creep backward when foot brake is released?

YES >> GO TO 7.

NO >> Mark the box CVT-155, "

Vehicle Does Not Creep Backward in "R" Position" on the CVT-30, "How

to Perform Trouble Diagnosis for Quick and Accurate Repair" . Continue “Road Test”.

7.CHECK “D”, “L” POSITIONS FUNCTION

Move selector lever to “D” and “L” positions and check if vehicle creeps forward.

Does vehicle creep forward in all positions?

YES >> Go to CVT-43, "Cruise Test" .

NO >> Stop “Road Test”. Mark the box on the CVT-30, "

How to Perform Trouble Diagnosis for Quick and

Accurate Repair" . Go to CVT-156, "Vehicle Does Not Creep Forward in "D" or "L" Position" .

Page 902 of 2771

DTC P0703 STOP LAMP SWITCH CIRCUIT

CVT-63

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

CVT

N

O

P

DTC P0703 STOP LAMP SWITCH CIRCUIT

DescriptionINFOID:0000000001703483

ON, OFF status of the stop lamp switch is sent via the CAN communication from the combination meter to

TCM using the signal.

CONSULT-III Reference Value in Data Monitor ModeINFOID:0000000001703484

On Board Diagnosis LogicINFOID:0000000001703485

• This is not an OBD-II self-diagnostic item.

• Diagnostic trouble code “P0703 BRAKE SW/CIRC” with CONSULT-III is detected when the stop lamp switch

does not switch to ON and OFF.

- The stop lamp switch does not switch to ON, OFF.

Possible CauseINFOID:0000000001703486

• Harness or connectors

(Stop lamp switch, and combination meter circuit are open or shorted.)

(CAN communication line is open or shorted.)

• Stop lamp switch

DTC Confirmation ProcedureINFOID:0000000001703487

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If “DTC Confirmation Procedure” has been previously performed, always turn ignition switch OFF and

wait at least 10 seconds before performing the next test.

After the repair, touch “ERASE” on “SELF-DIAG RESULTS” and then perform the following procedure to con-

firm the malfunction is eliminated.

WITH CONSULT-III

1. Turn ignition switch ON. (Do not start engine.)

2. Select “DATA MONITOR” mode for “TRANSMISSION” with CONSULT-III.

3. Start engine.

4. Start vehicle for at least 3 consecutive seconds.

5. If DTC is detected, go to CVT-63, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000001703488

1.CHECK CAN COMMUNICATION LINE

Perform the self-diagnosis check. Refer to CVT-47, "

CONSULT-III Function (TRANSMISSION)".

Is any malfunction of the

“U1000 CAN COMM CIRCUIT” indicated?

YES >> Check CAN communication line. Refer to CVT-56.

NO >> GO TO 2.

2.CHECK STOP LAMP SWITCH CIRCUIT

With CONSULT-III

1. Turn ignition switch ON. (Do not start engine.)

2. Select “ECU INPUT SIGNALS” in “DATA MONITOR” mode for “TRANSMISSION” with CONSULT-III.

3. Read out ON/OFF switching action of the “BRAKE SW”.

Item name Condition Display value

BRAKE SWDepressed brake pedal ON

Released brake pedal OFF

Page 926 of 2771

DTC P0730 BELT DAMAGE

CVT-87

< SERVICE INFORMATION >

D

E

F

G

H

I

J

K

L

MA

B

CVT

N

O

P

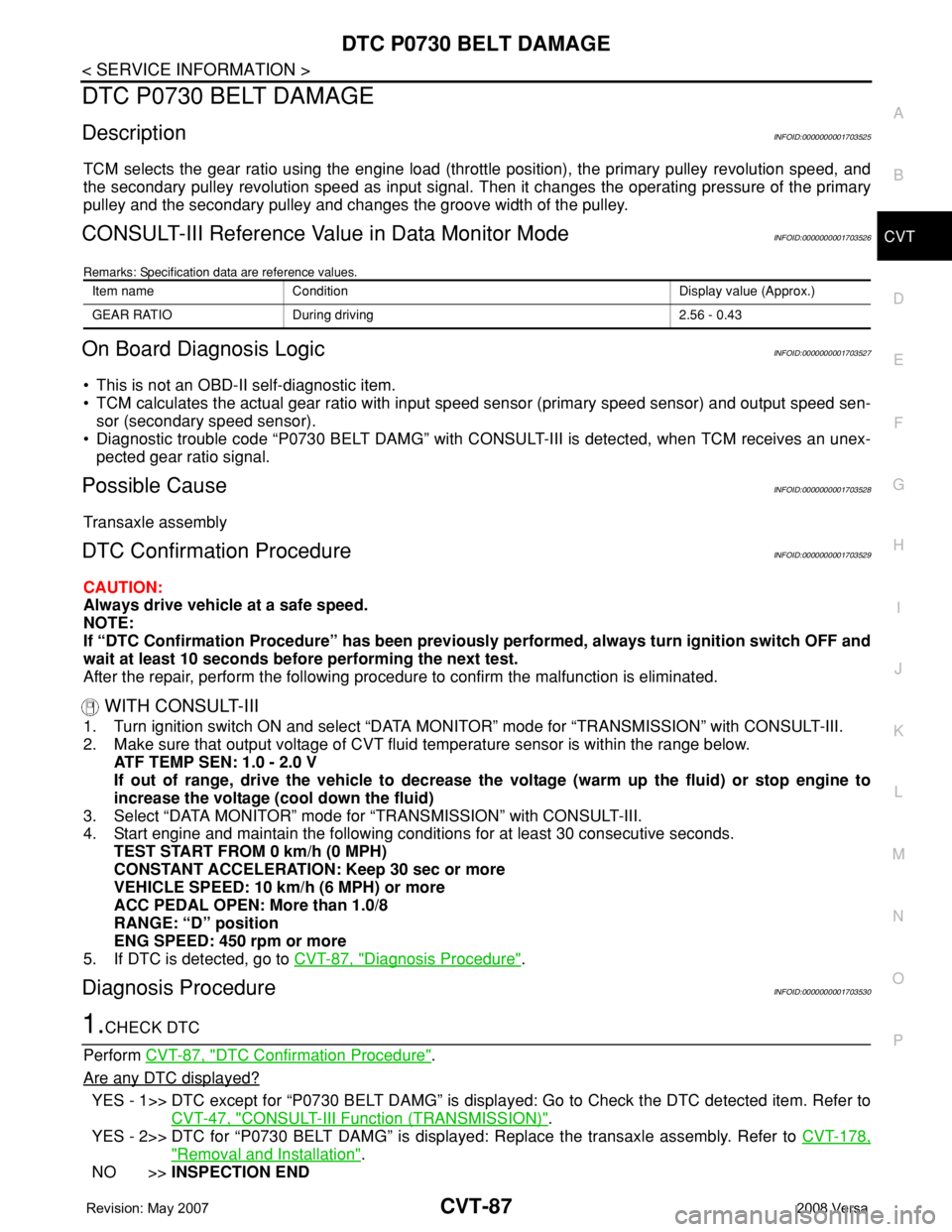

DTC P0730 BELT DAMAGE

DescriptionINFOID:0000000001703525

TCM selects the gear ratio using the engine load (throttle position), the primary pulley revolution speed, and

the secondary pulley revolution speed as input signal. Then it changes the operating pressure of the primary

pulley and the secondary pulley and changes the groove width of the pulley.

CONSULT-III Reference Value in Data Monitor ModeINFOID:0000000001703526

Remarks: Specification data are reference values.

On Board Diagnosis LogicINFOID:0000000001703527

• This is not an OBD-II self-diagnostic item.

• TCM calculates the actual gear ratio with input speed sensor (primary speed sensor) and output speed sen-

sor (secondary speed sensor).

• Diagnostic trouble code “P0730 BELT DAMG” with CONSULT-III is detected, when TCM receives an unex-

pected gear ratio signal.

Possible CauseINFOID:0000000001703528

Transaxle assembly

DTC Confirmation ProcedureINFOID:0000000001703529

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

If “DTC Confirmation Procedure” has been previously performed, always turn ignition switch OFF and

wait at least 10 seconds before performing the next test.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

WITH CONSULT-III

1. Turn ignition switch ON and select “DATA MONITOR” mode for “TRANSMISSION” with CONSULT-III.

2. Make sure that output voltage of CVT fluid temperature sensor is within the range below.

ATF TEMP SEN: 1.0 - 2.0 V

If out of range, drive the vehicle to decrease the voltage (warm up the fluid) or stop engine to

increase the voltage (cool down the fluid)

3. Select “DATA MONITOR” mode for “TRANSMISSION” with CONSULT-III.

4. Start engine and maintain the following conditions for at least 30 consecutive seconds.

TEST START FROM 0 km/h (0 MPH)

CONSTANT ACCELERATION: Keep 30 sec or more

VEHICLE SPEED: 10 km/h (6 MPH) or more

ACC PEDAL OPEN: More than 1.0/8

RANGE: “D” position

ENG SPEED: 450 rpm or more

5. If DTC is detected, go to CVT-87, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000001703530

1.CHECK DTC

Perform CVT-87, "

DTC Confirmation Procedure".

Are any DTC displayed?

YES - 1>> DTC except for “P0730 BELT DAMG” is displayed: Go to Check the DTC detected item. Refer to

CVT-47, "

CONSULT-III Function (TRANSMISSION)".

YES - 2>> DTC for “P0730 BELT DAMG” is displayed: Replace the transaxle assembly. Refer to CVT-178,

"Removal and Installation".

NO >>INSPECTION END

Item name Condition Display value (Approx.)

GEAR RATIO During driving 2.56 - 0.43